Patents

Literature

42results about How to "Feel solid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

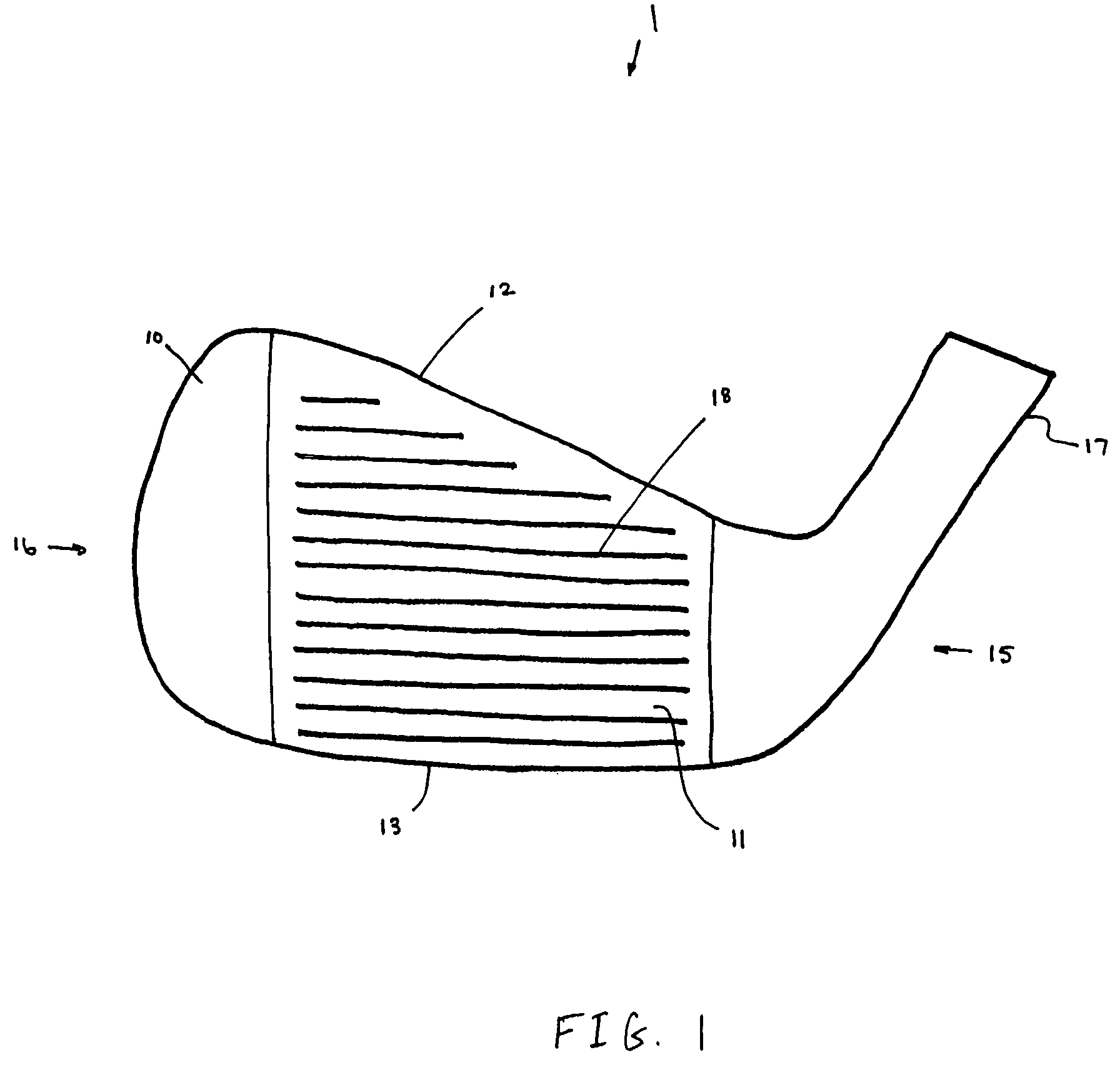

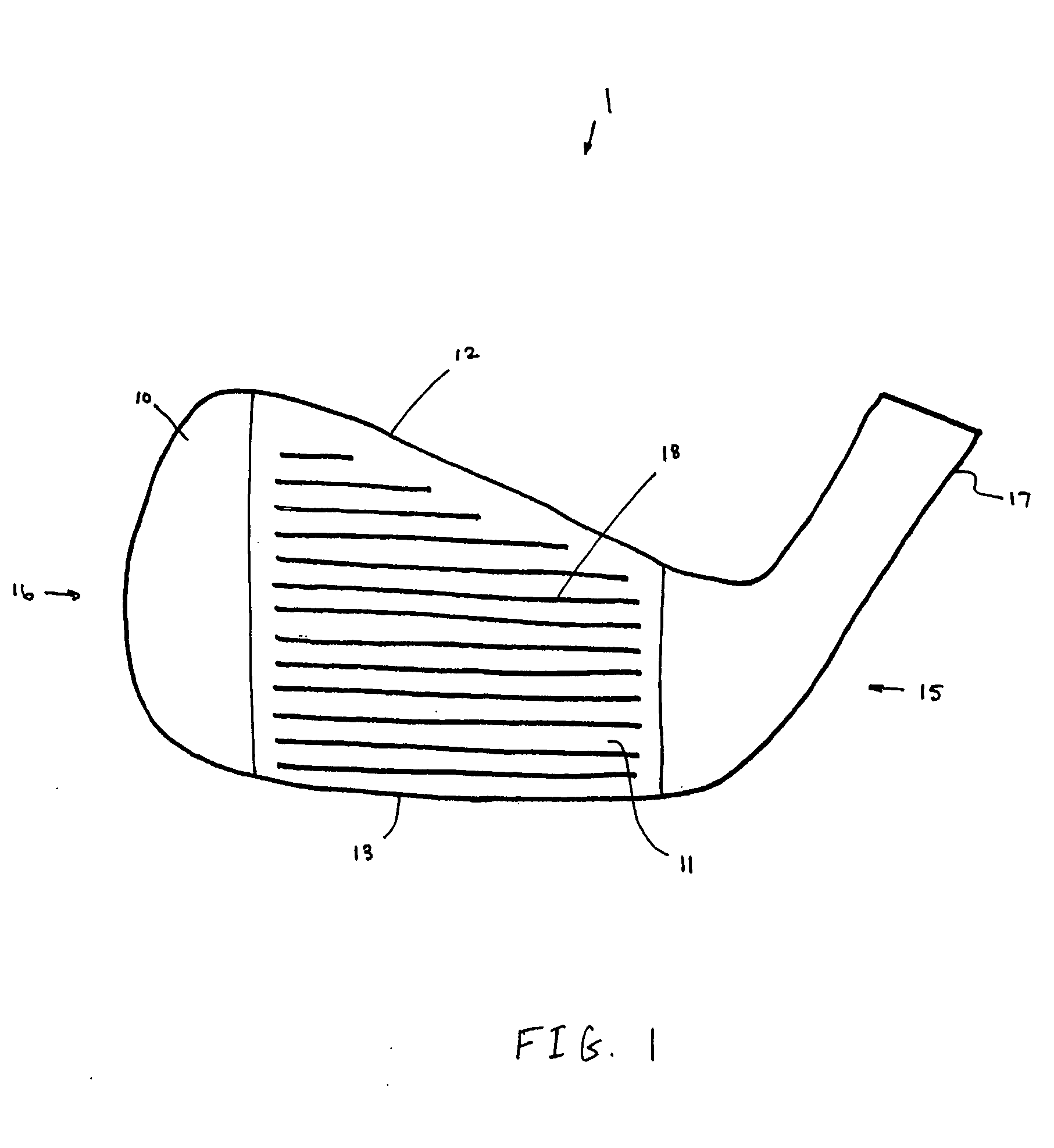

Iron golf club

InactiveUS7338387B2Lower center of gravityHigh moment of inertiaGolf clubsRacket sportsHigh densityMetallic materials

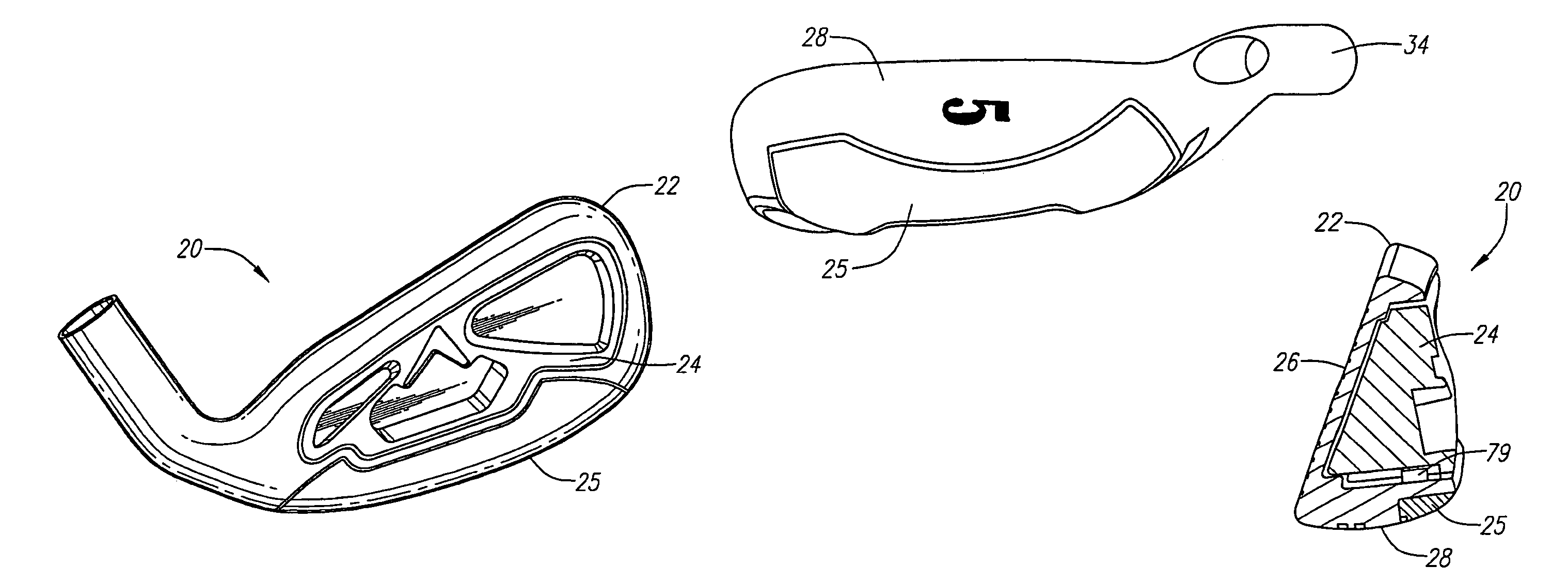

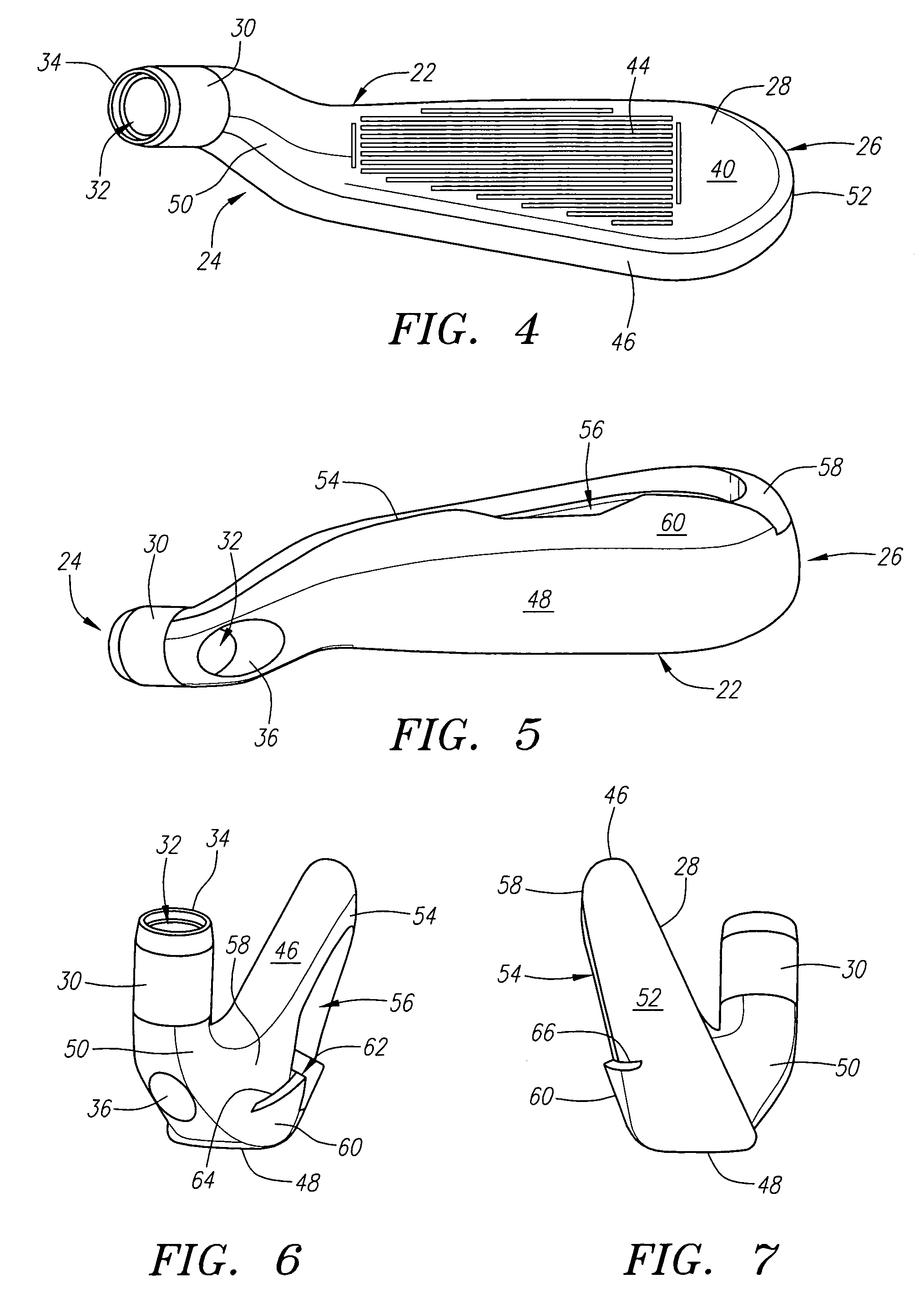

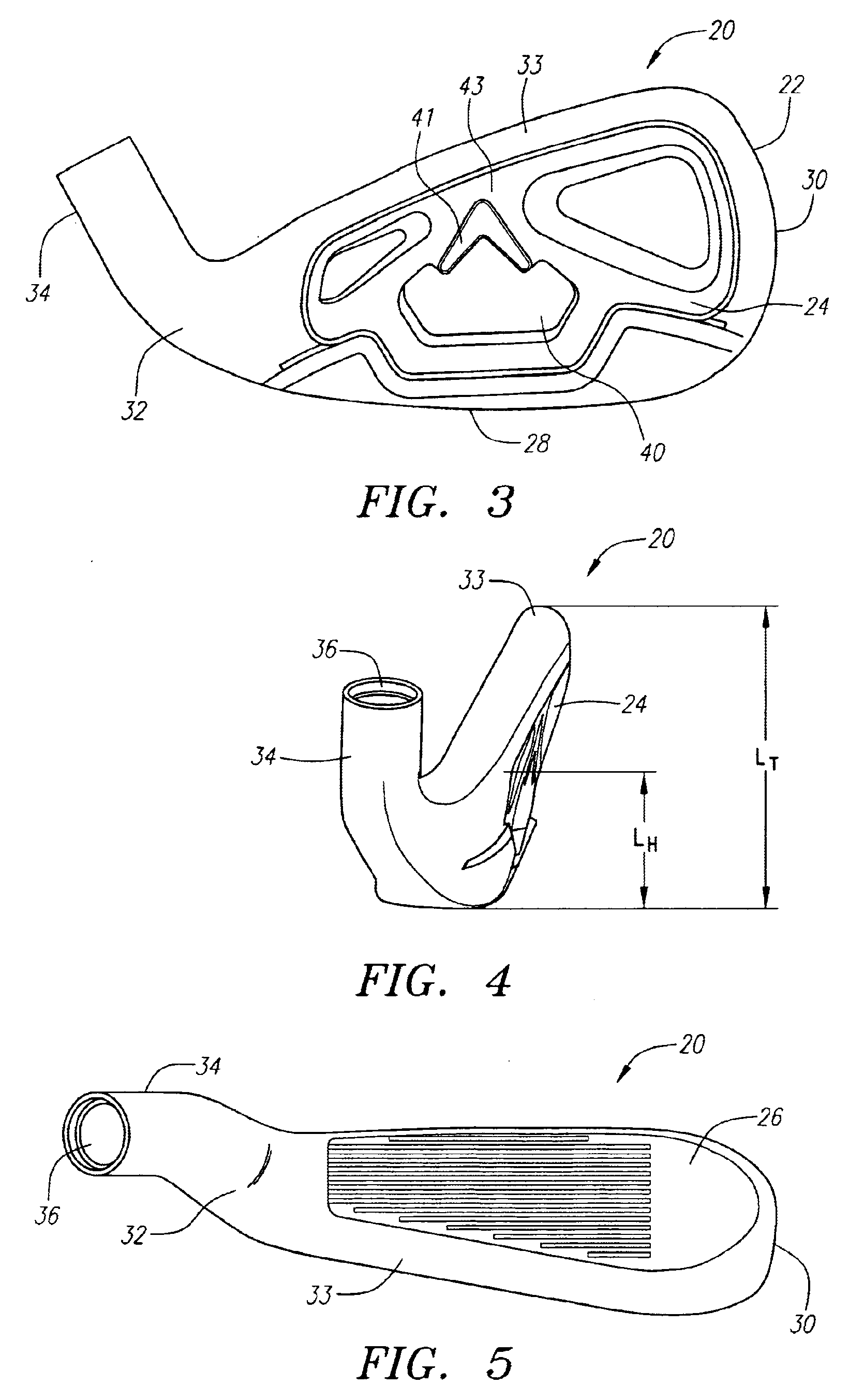

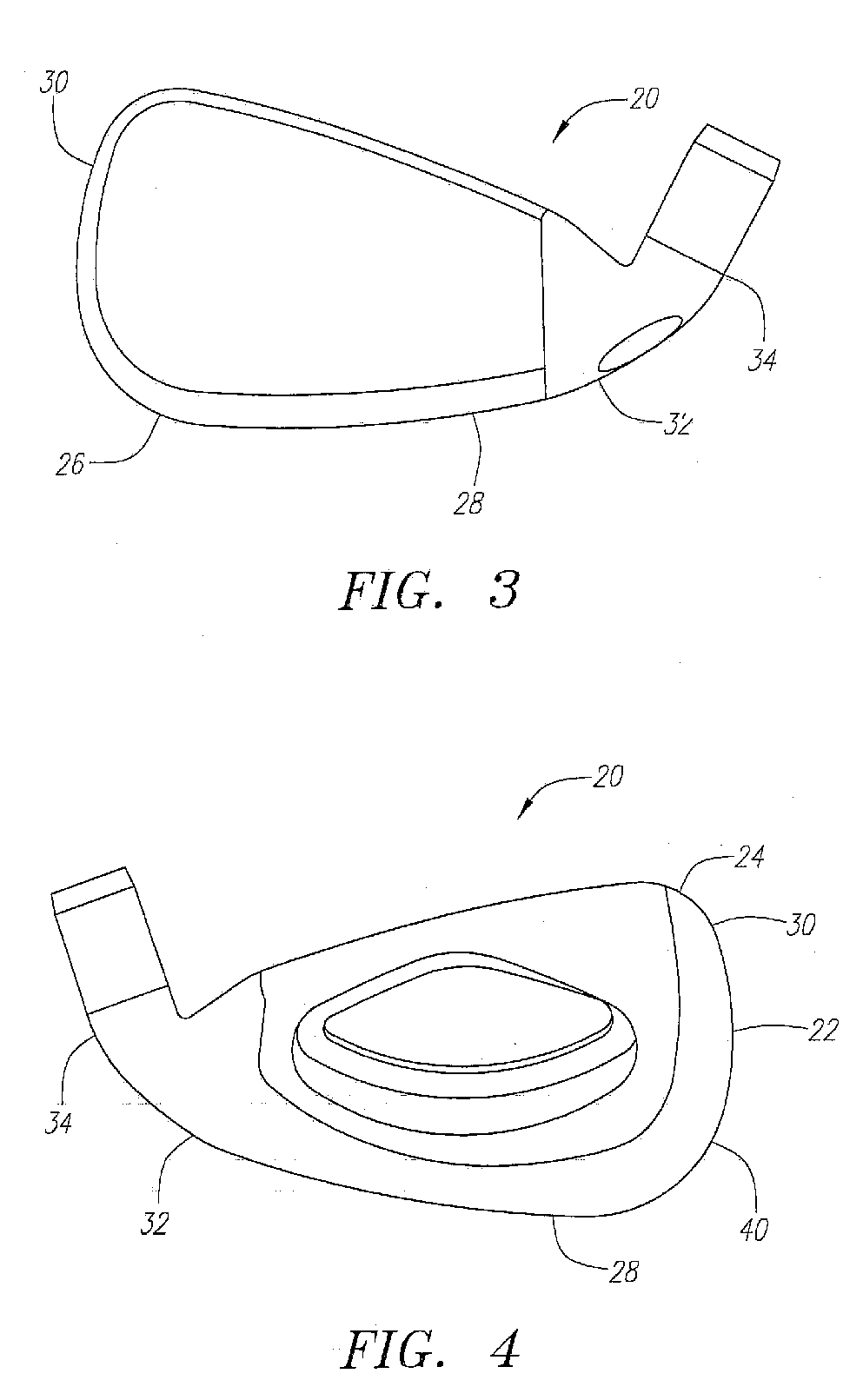

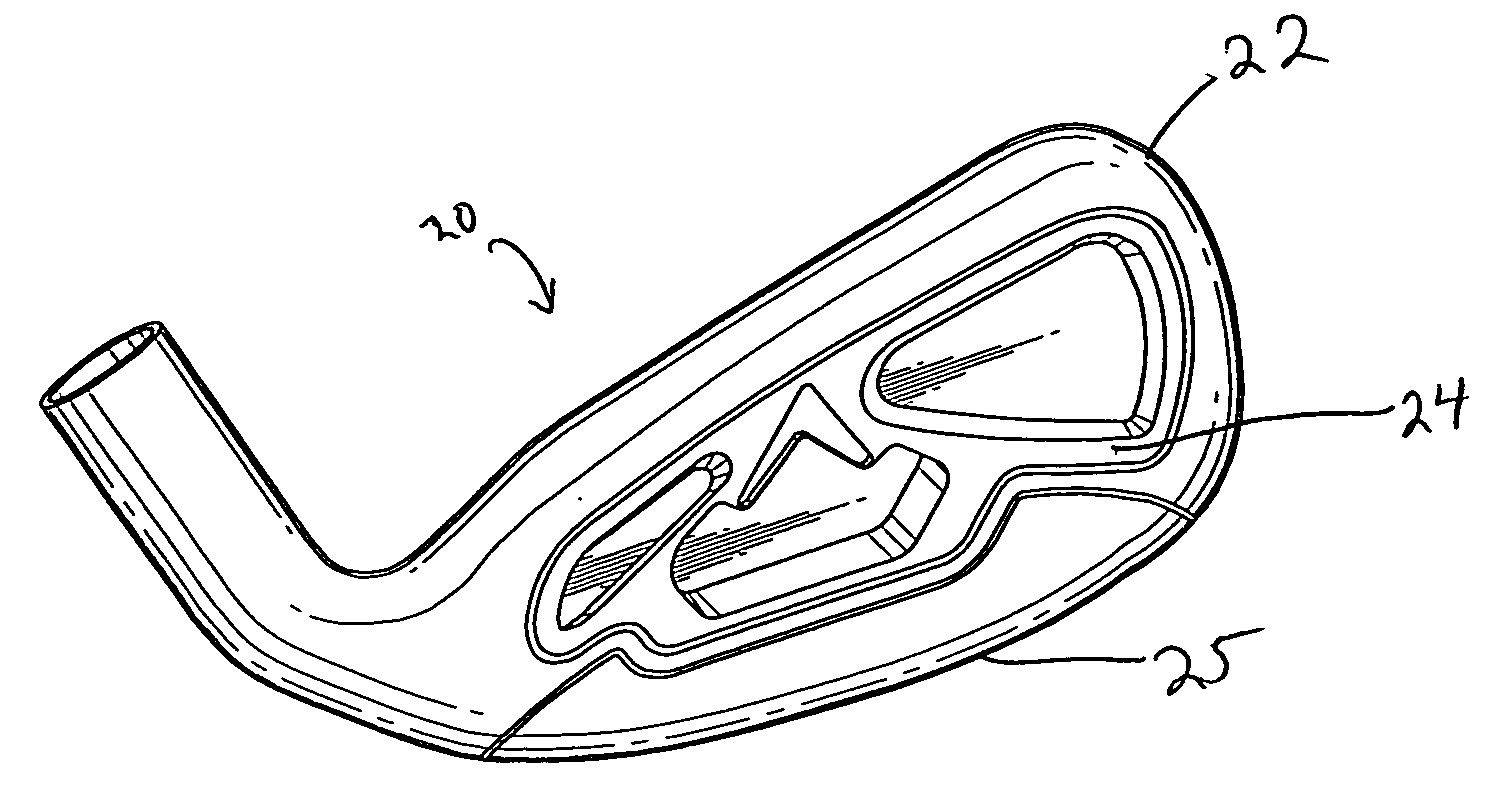

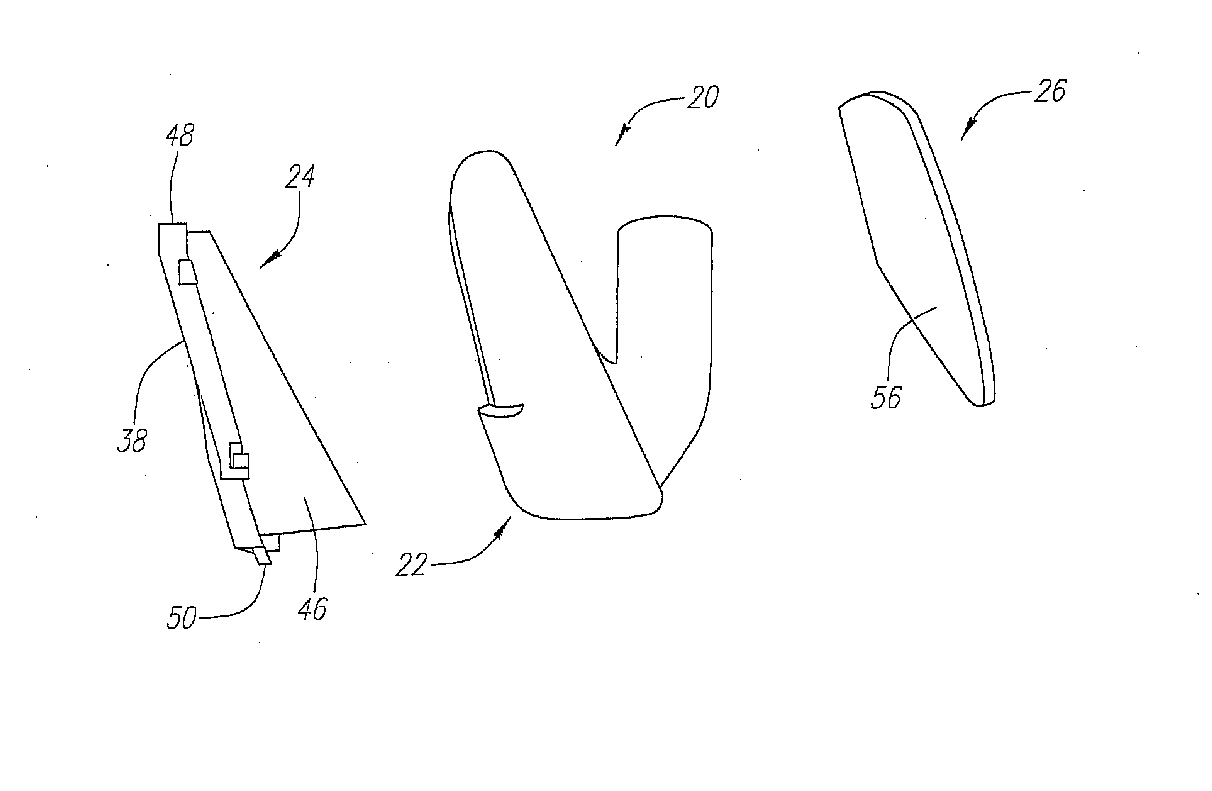

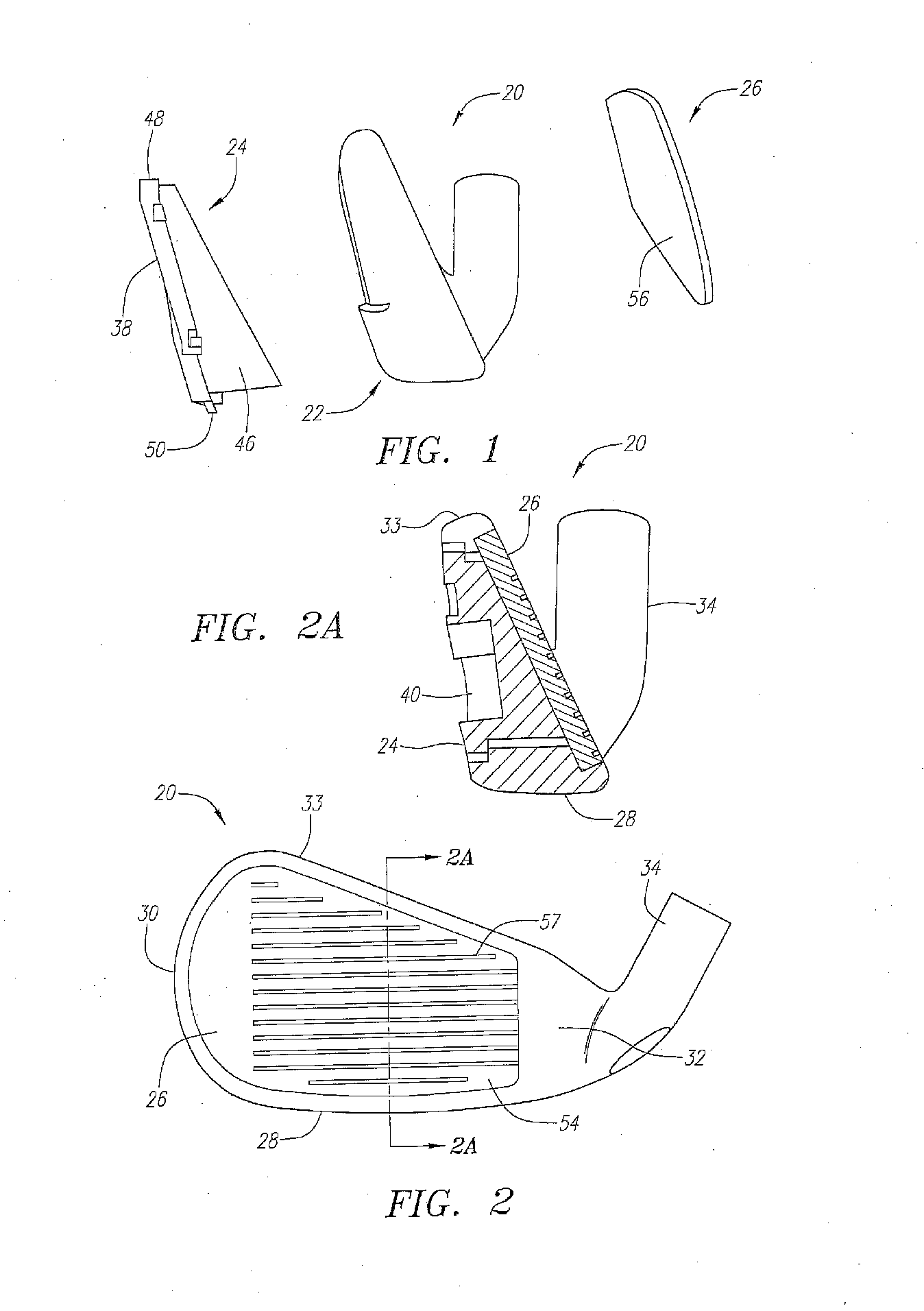

The iron golf club head (20) of the present invention is preferably composed of three main components: a main body (22), a central member (24) and a mass member (25). The Mass member (25) is preferably composed of a high density material such as a nickel-tungsten alloy. The central member (24) is preferably composed of a lightweight, non-metal material. The main body (22) is preferably composed of a titanium alloy material. The iron golf club head (20) preferably has high moments of inertia Izz and Ixx, and a low center of gravity.

Owner:TOPGOLF CALLAWAY BRANDS CORP

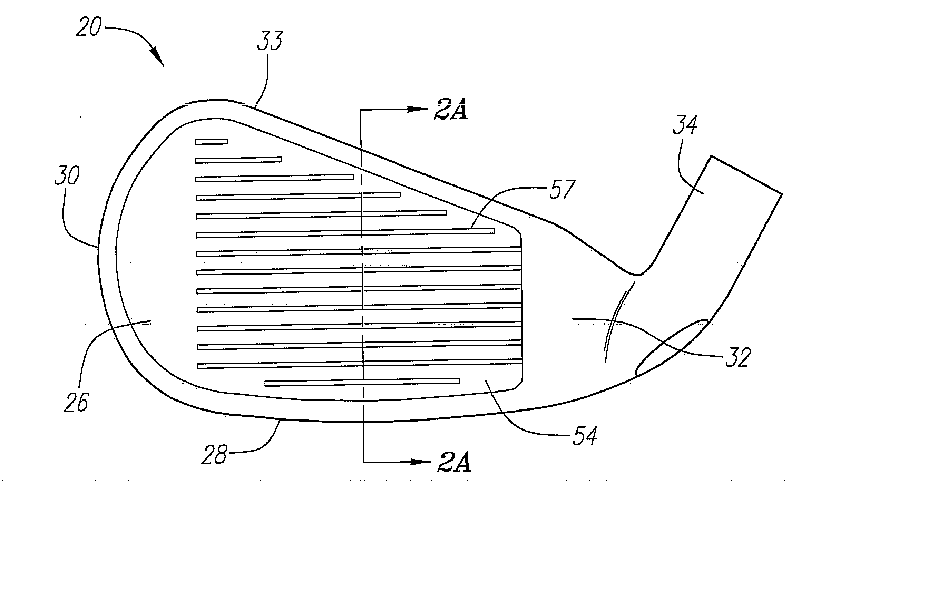

Iron-type golf club

InactiveUS7083531B2Lower center of gravityHigh moment of inertiaGolf clubsRacket sportsEngineeringMoment of inertia

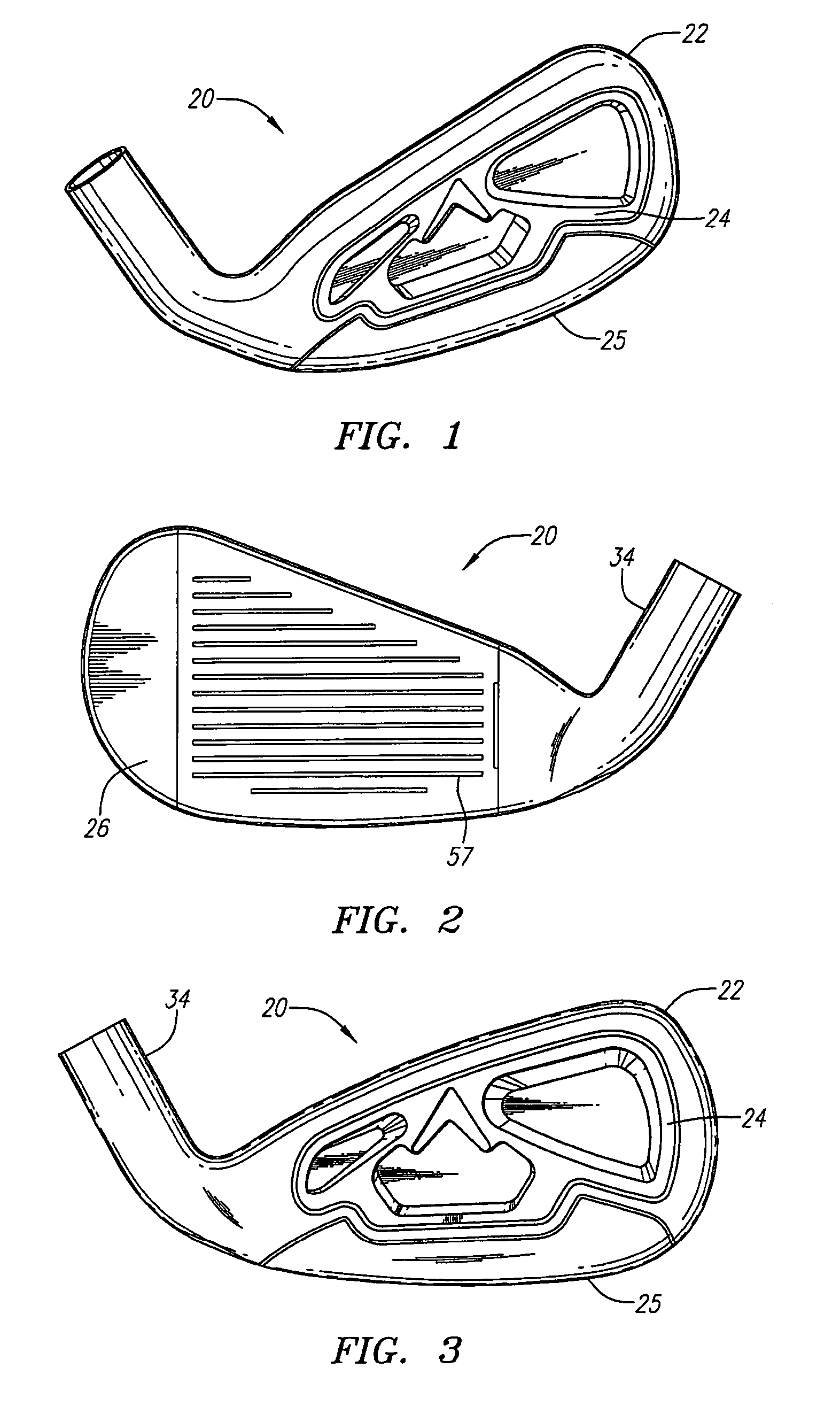

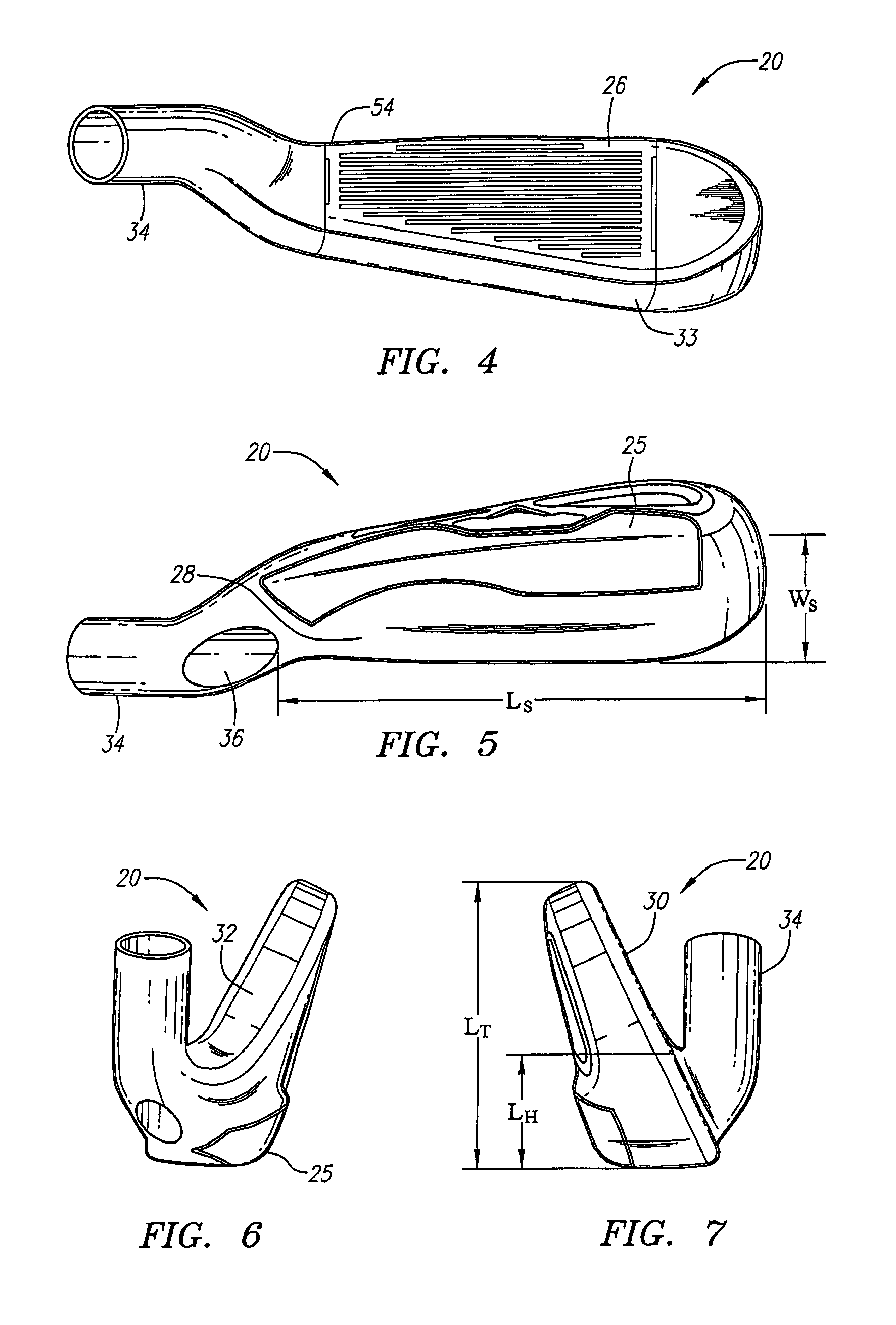

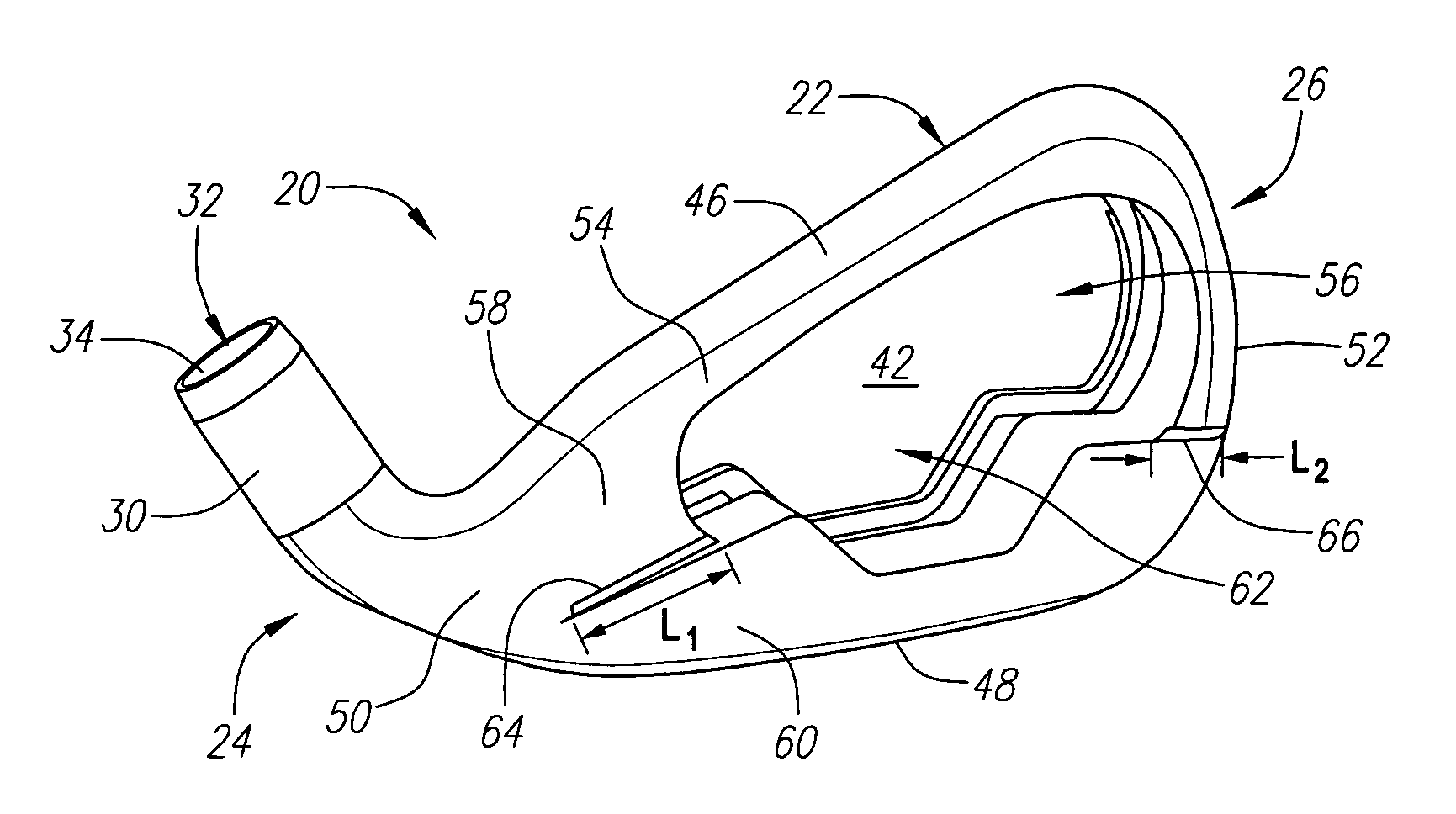

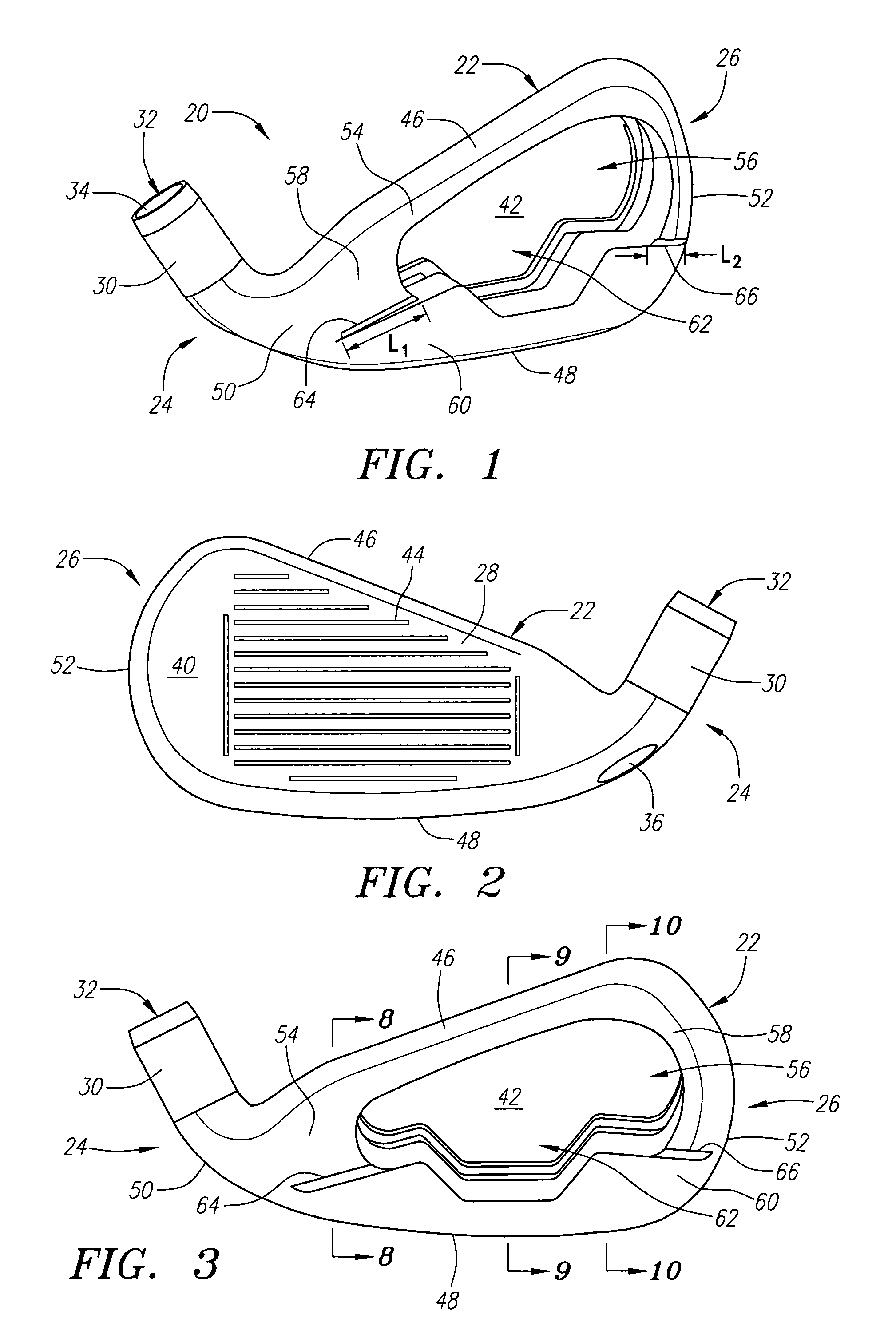

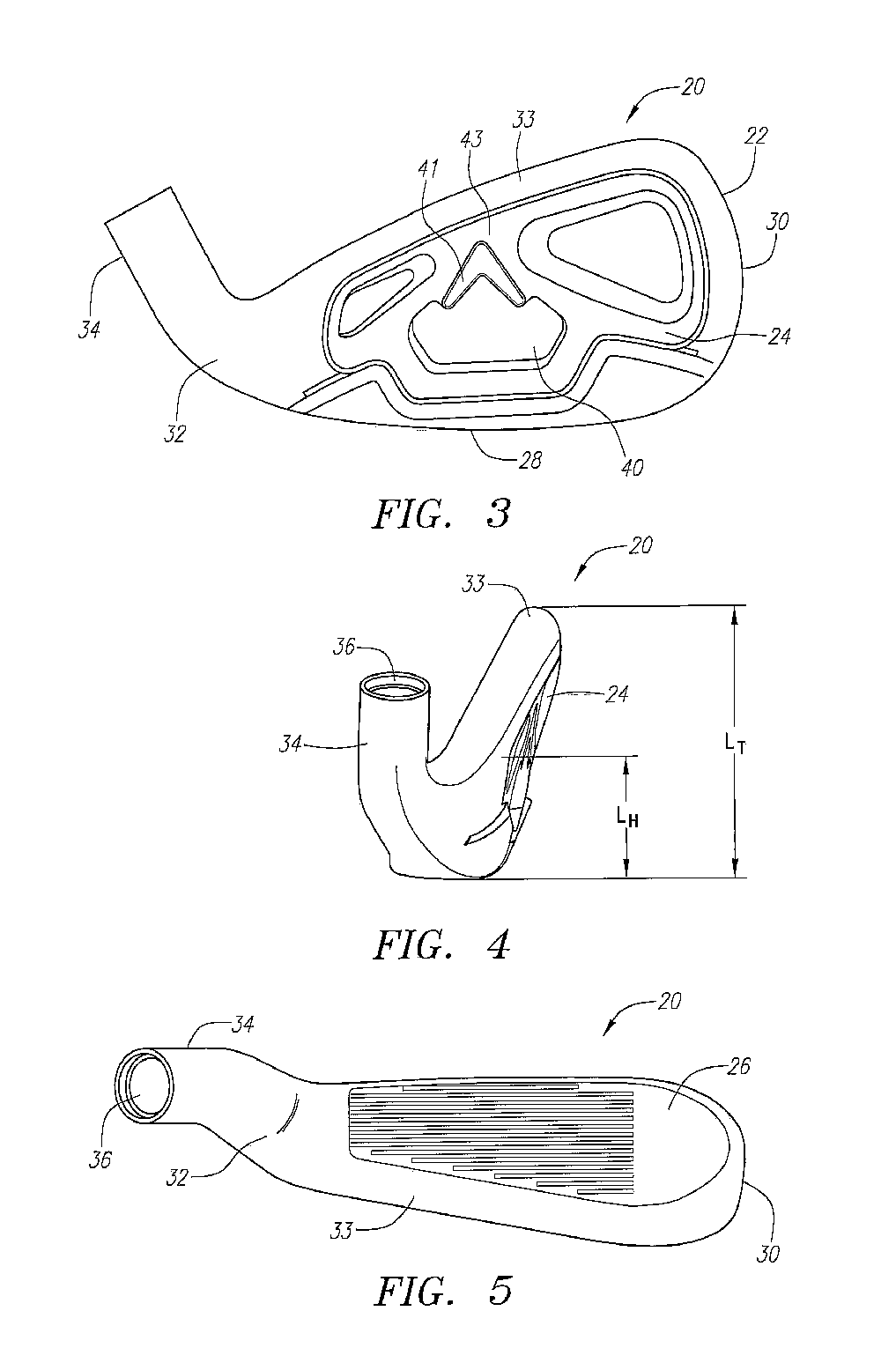

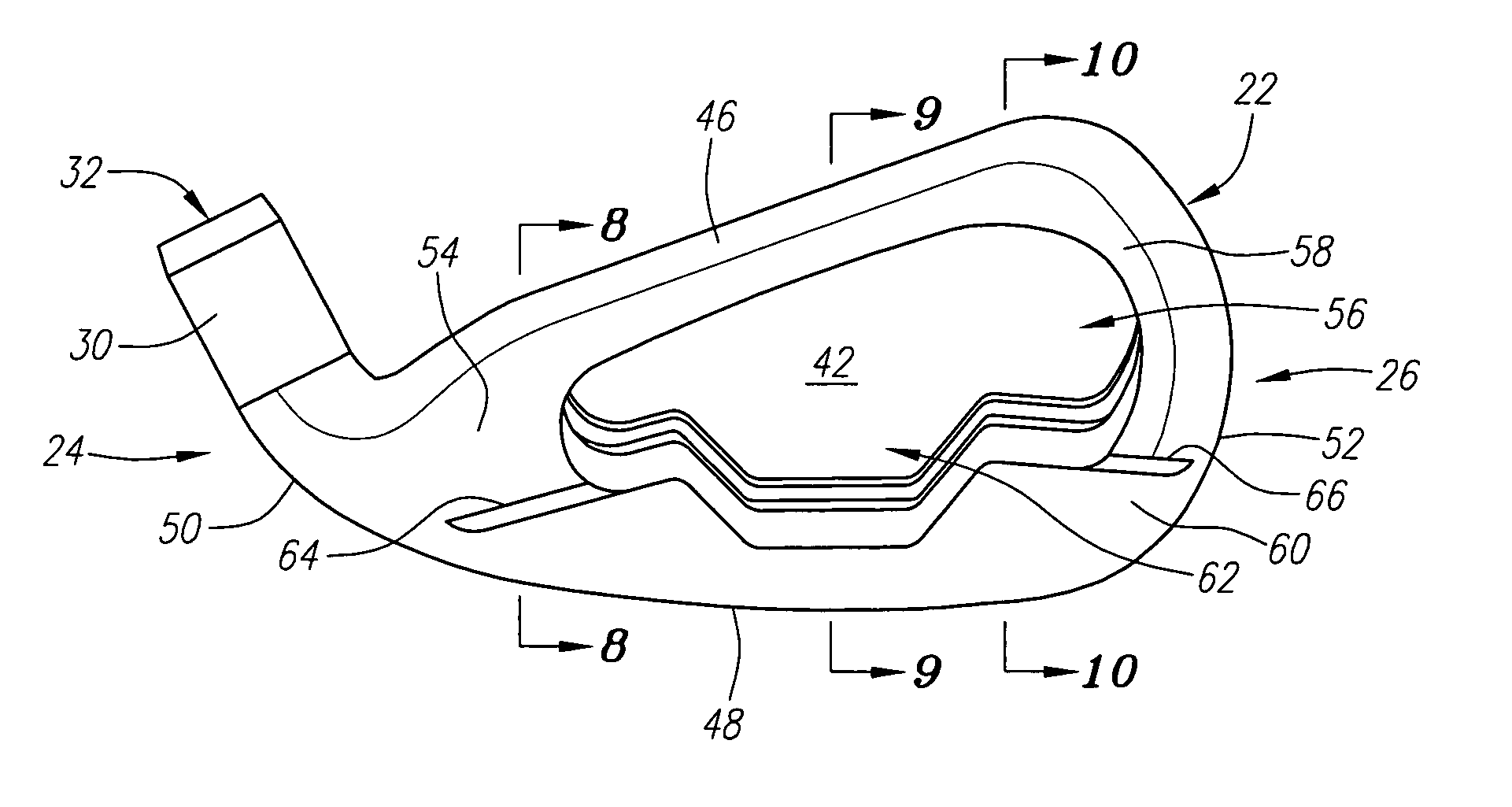

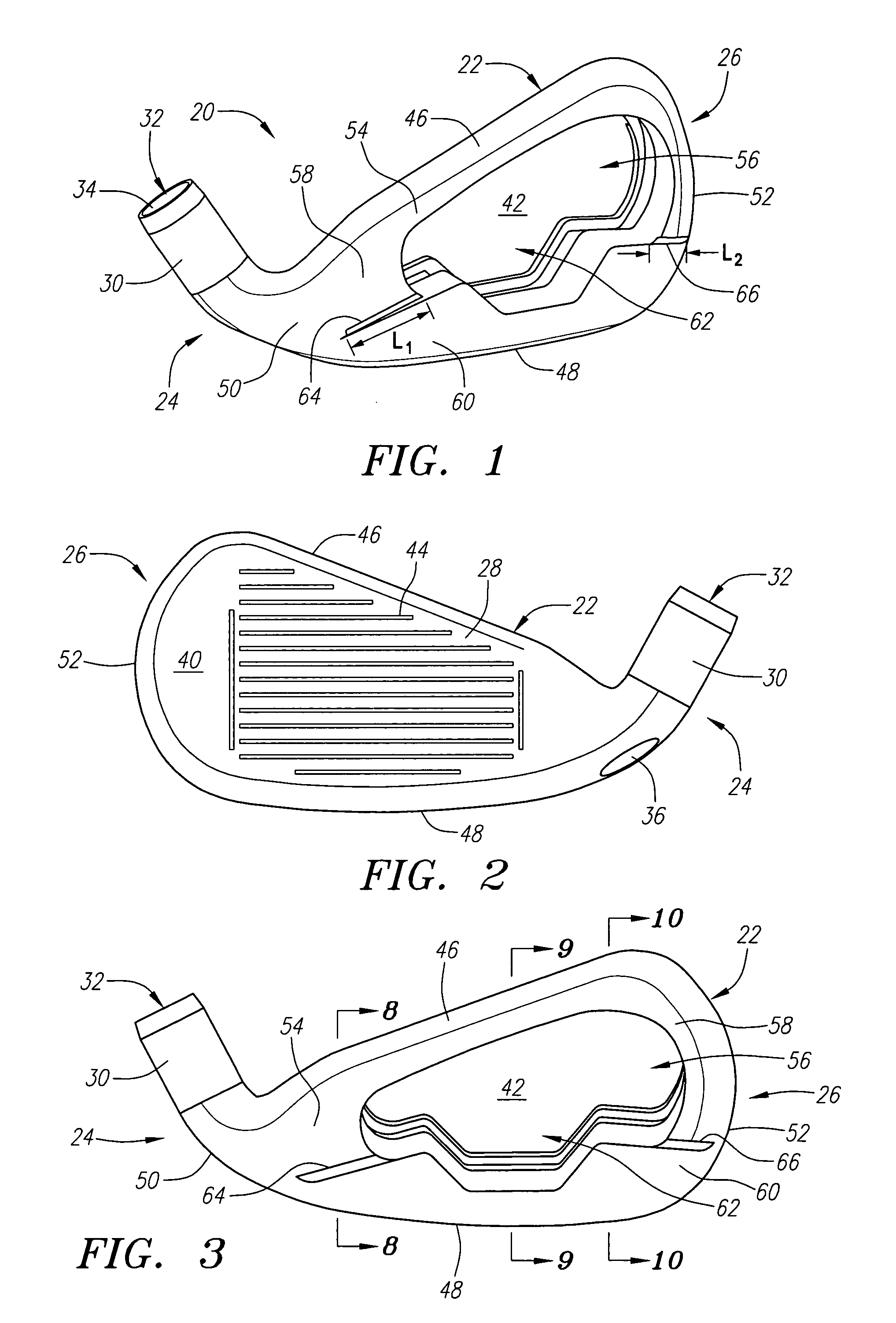

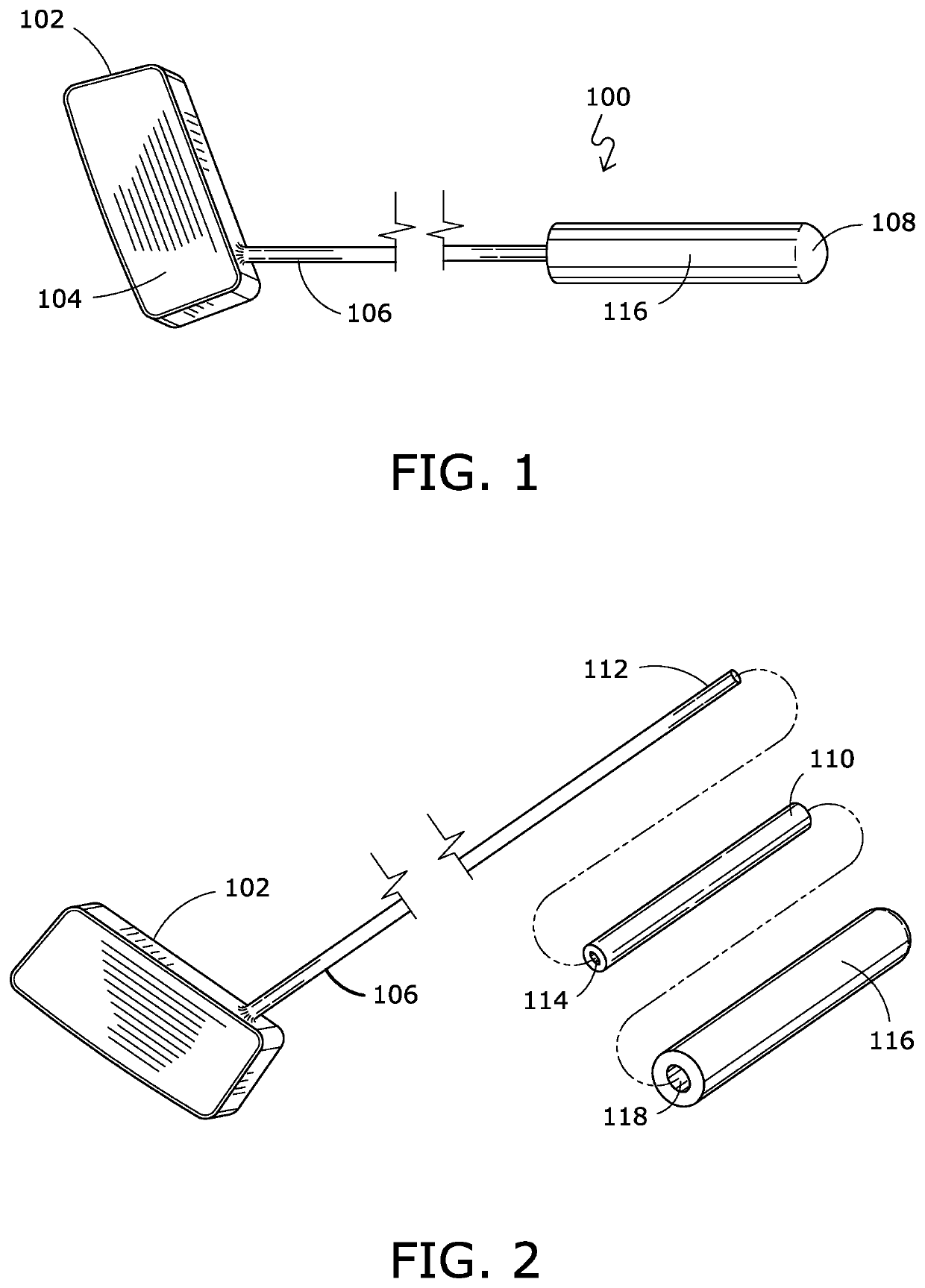

An iron-type golf club head (20) includes a body (22) having a front wall (28) with a ball-striking surface (40). The body (22) further includes a rear surface (54) that has external rear cavity (56) formed therein. The rear surface (54) includes an upper portion (58) and a lower portion (60). The upper portion (60) is separated from the lower portion (59) by the external rear cavity (56) and at least one groove (64, 66). The lower portion (60) of the rear surface (54) has a notch (62) formed therein, which communicates with the external rear cavity (56). The golf club head (20) preferably has high moments of inertia Izz and Ixx.

Owner:TOPGOLF CALLAWAY BRANDS CORP

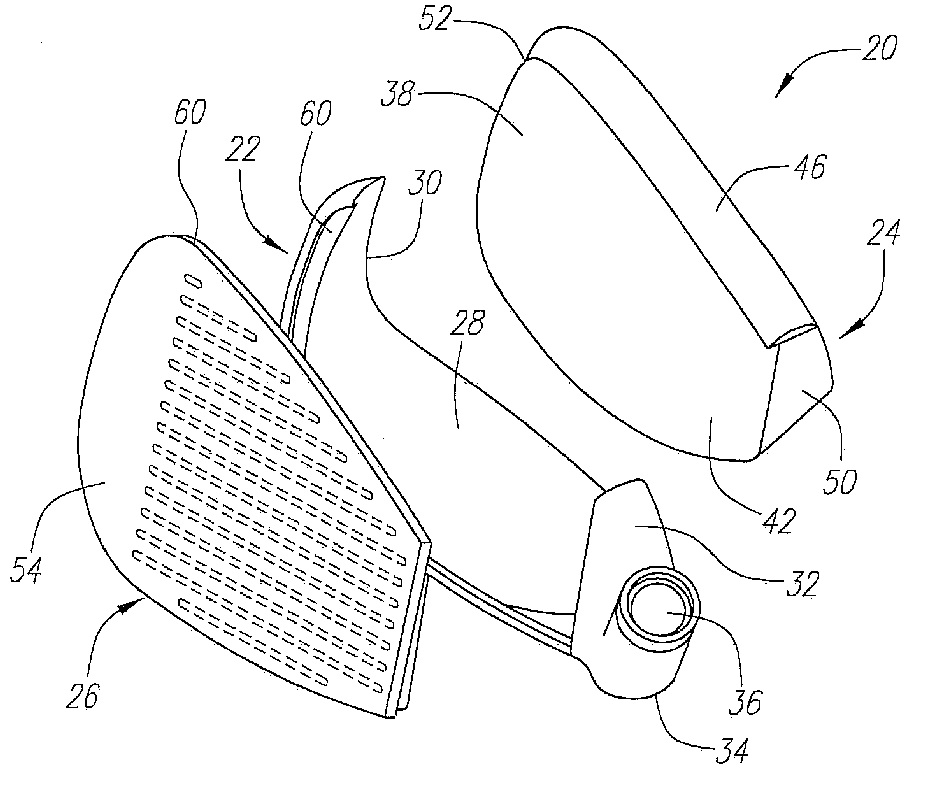

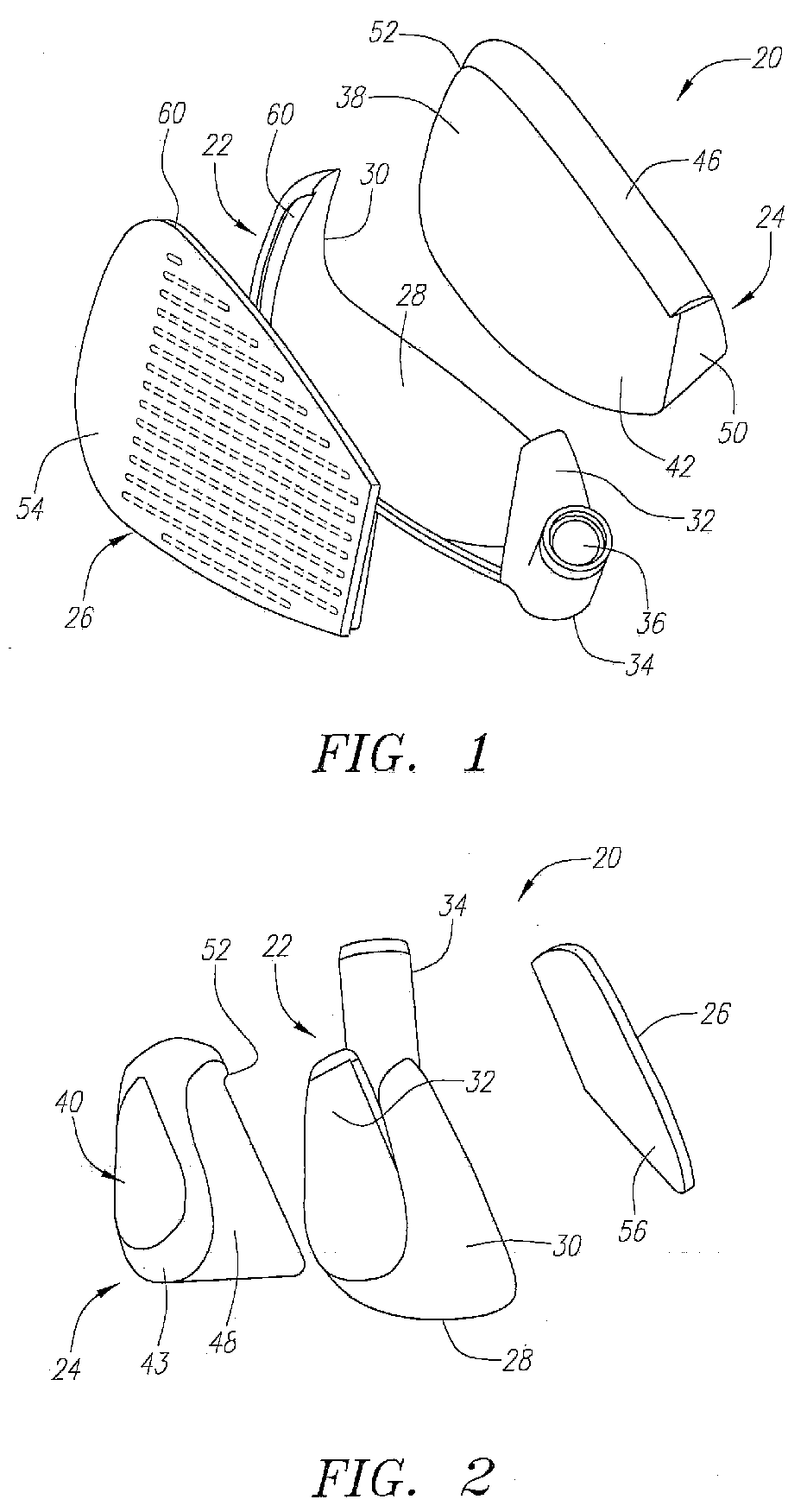

Iron golf club

InactiveUS6857973B2Lower center of gravityHigh moment of inertiaGolf clubsHigh densityMetallic materials

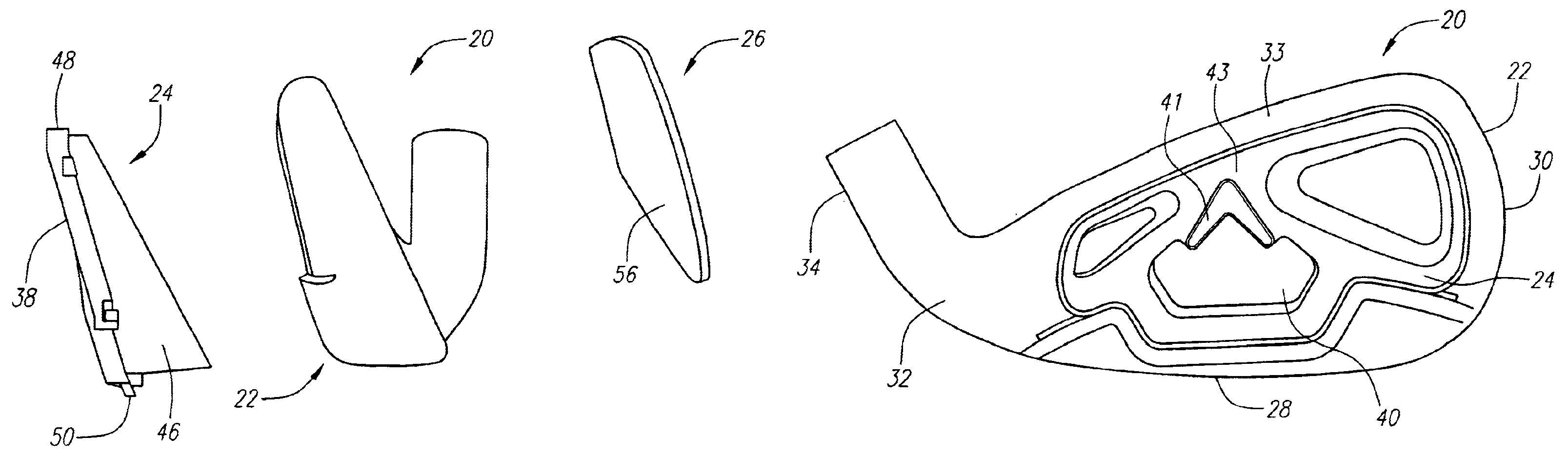

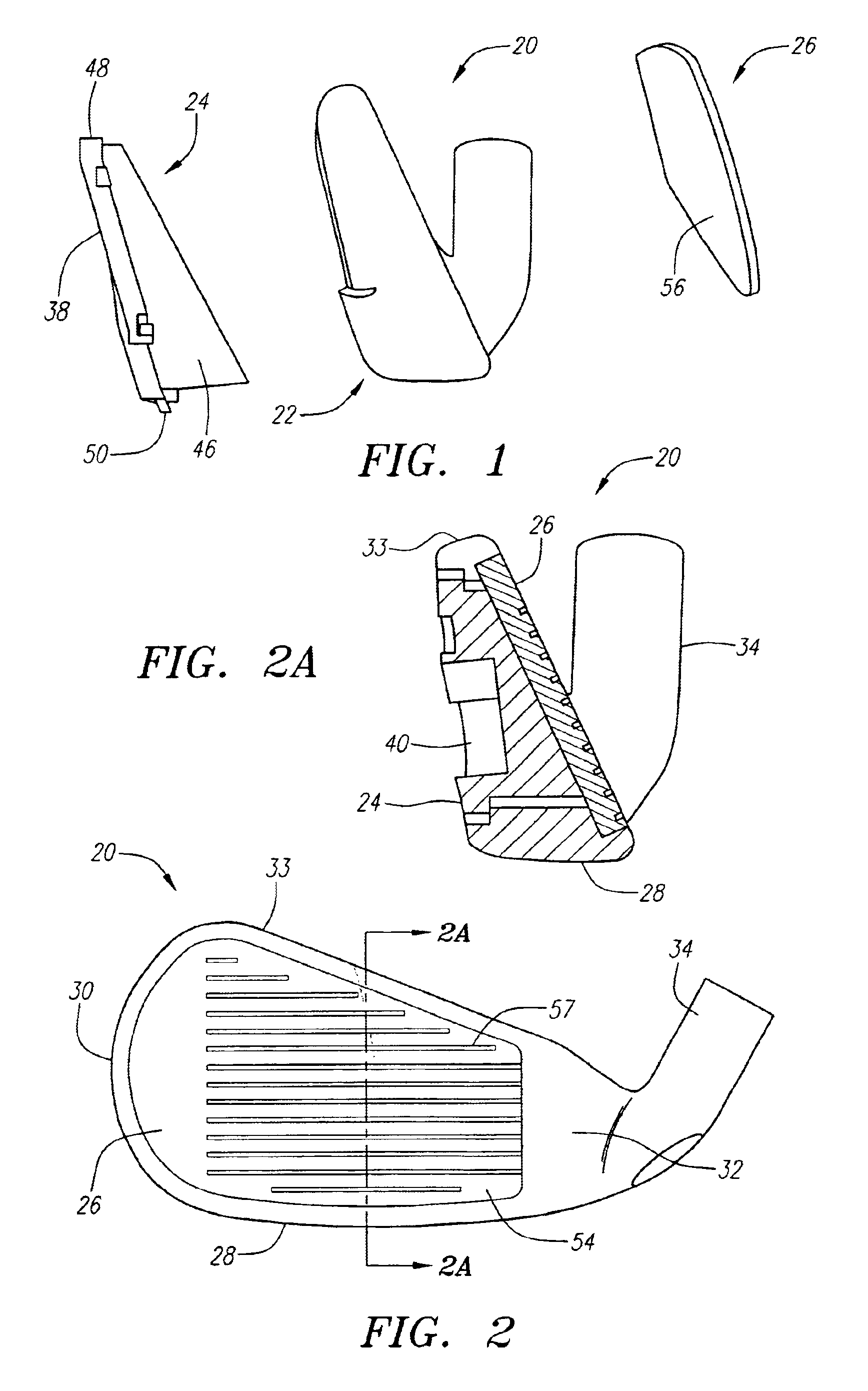

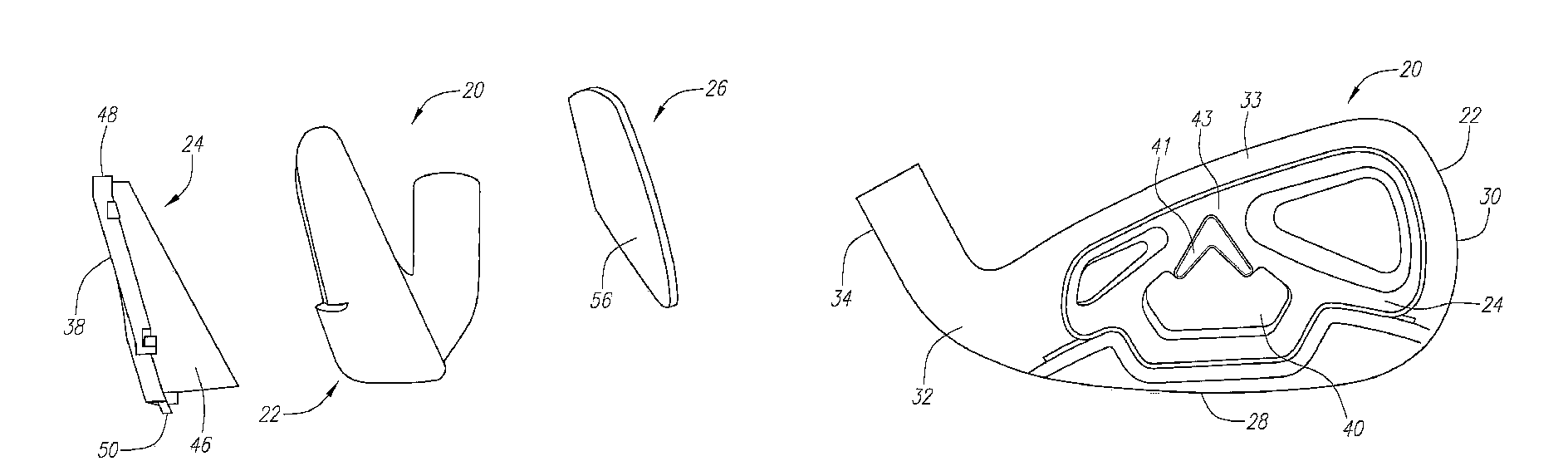

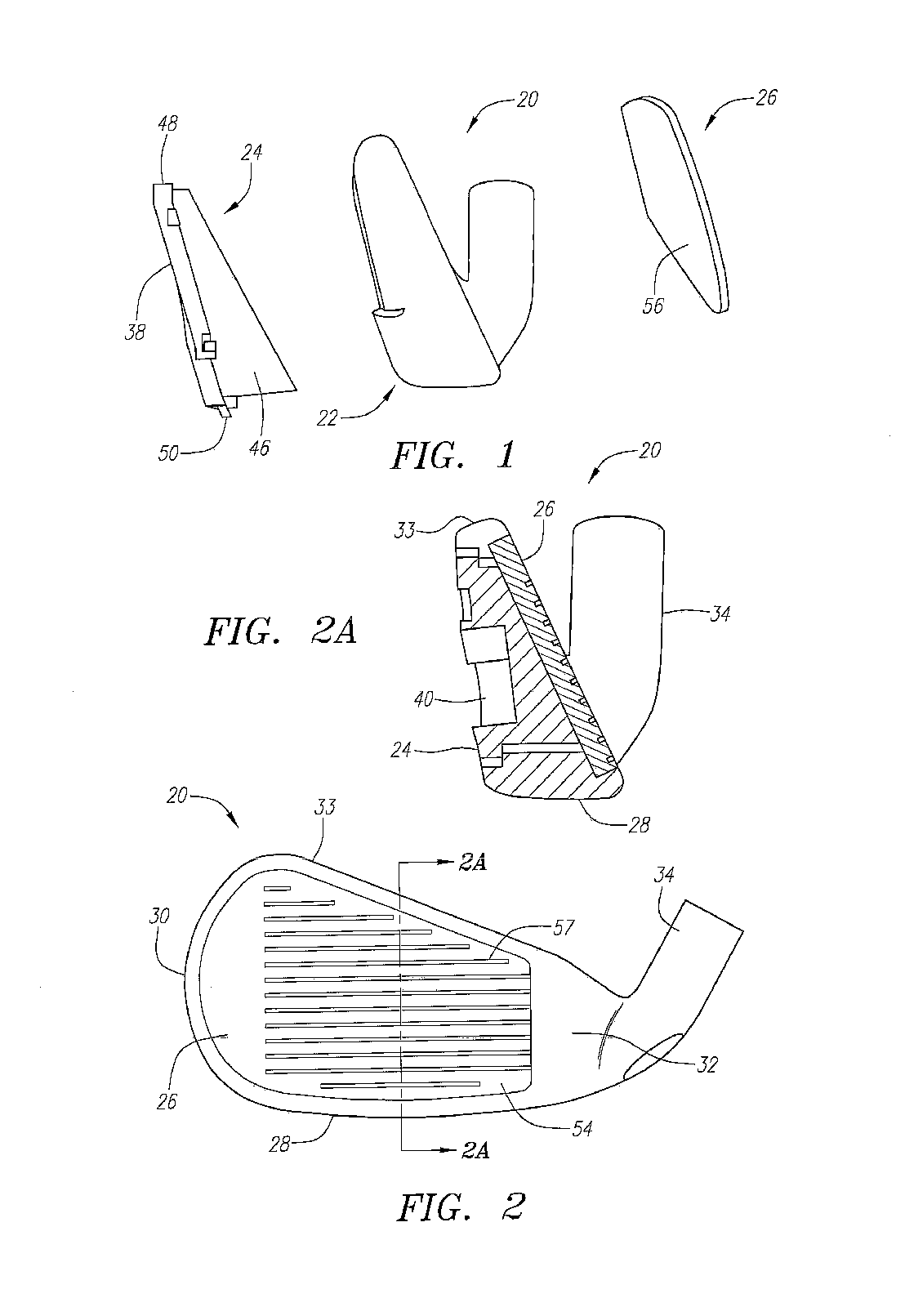

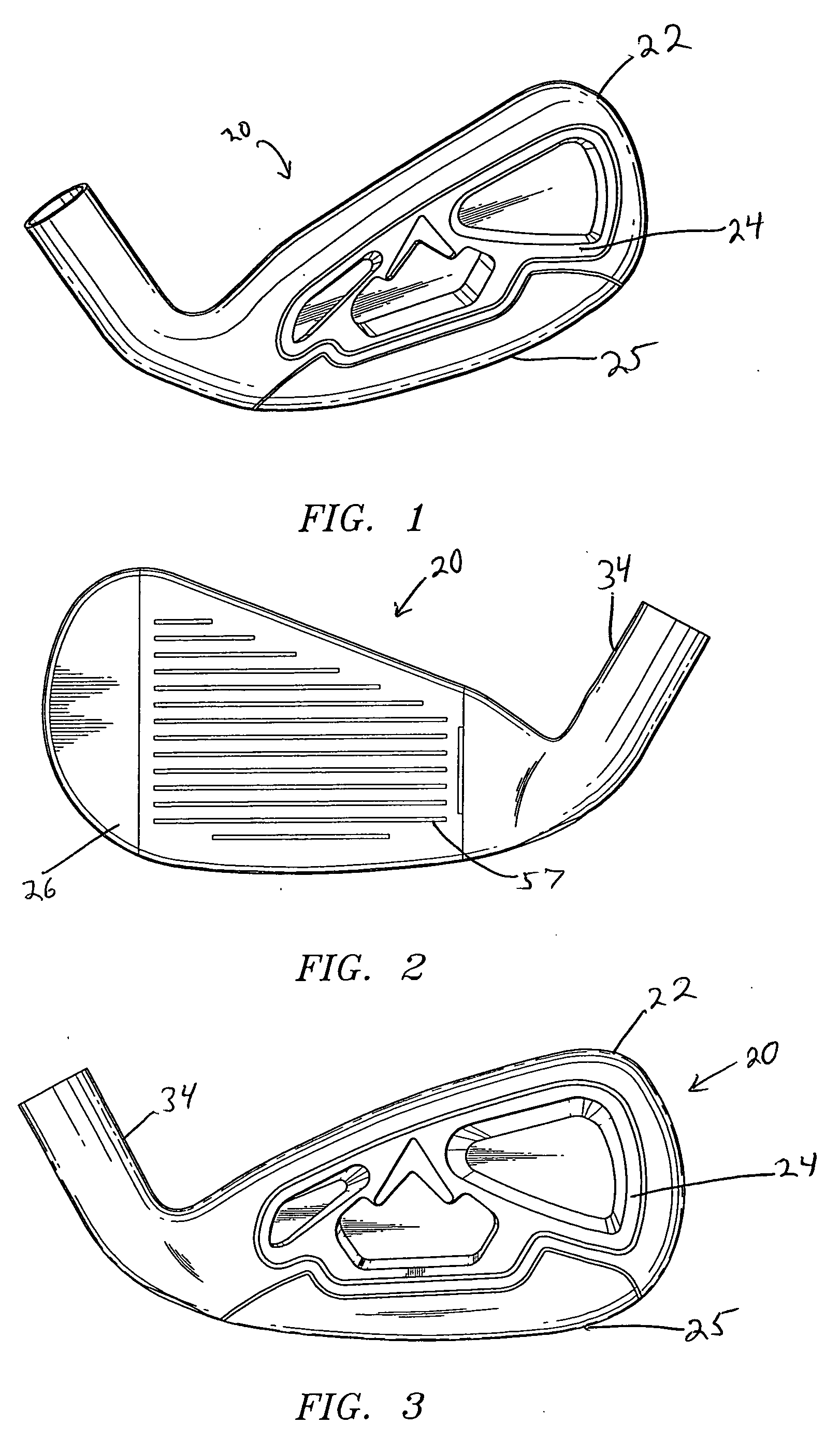

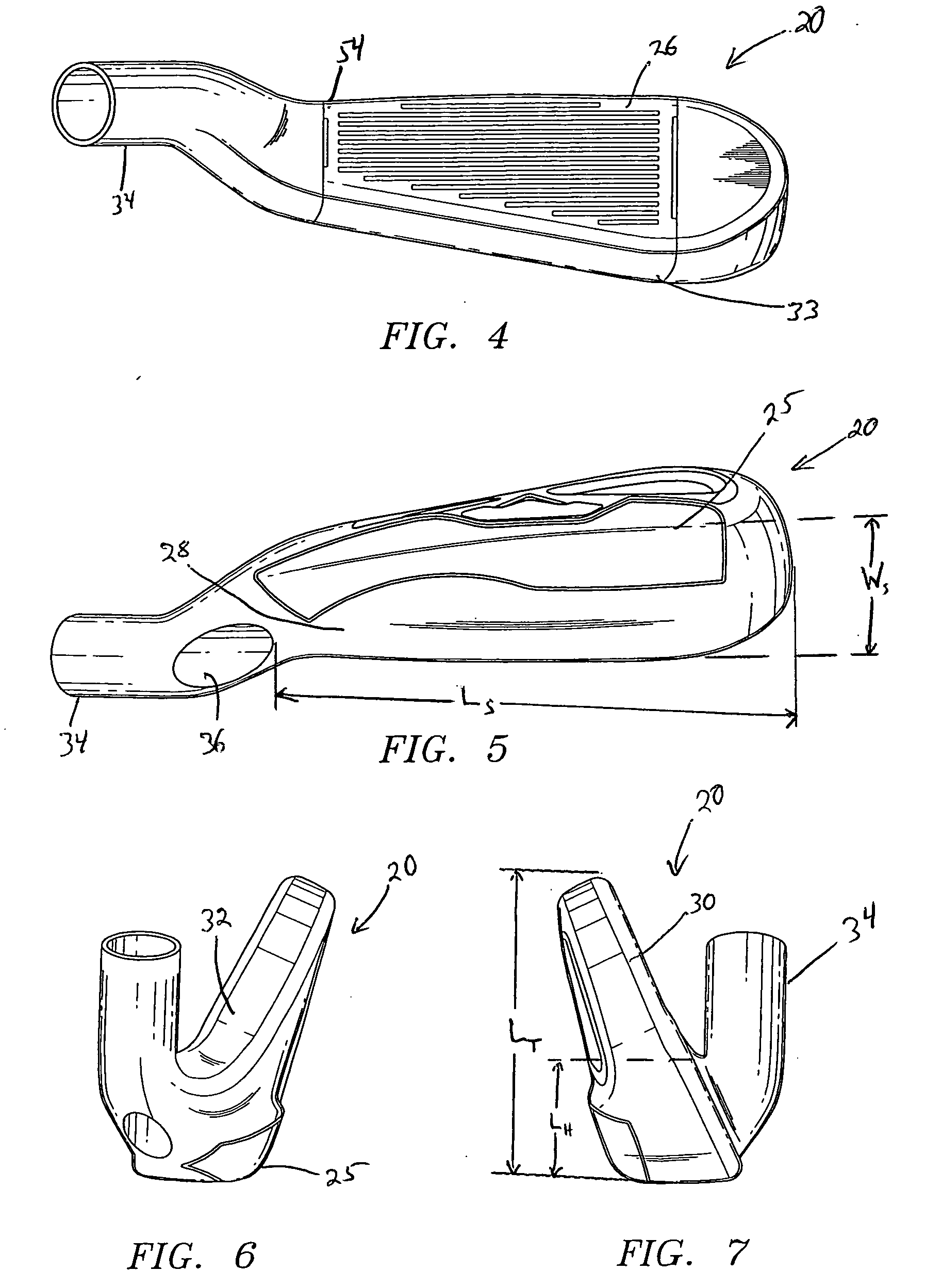

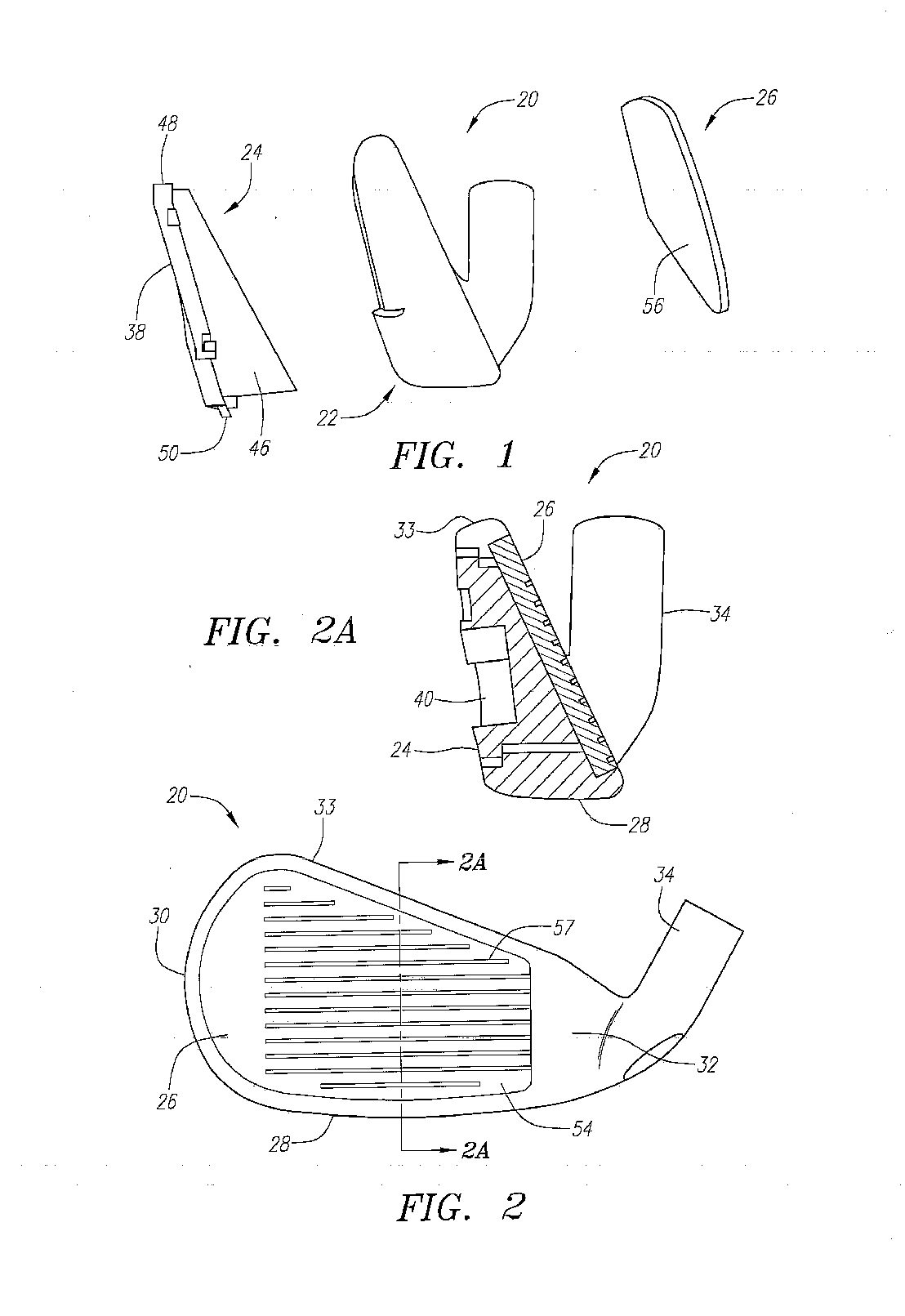

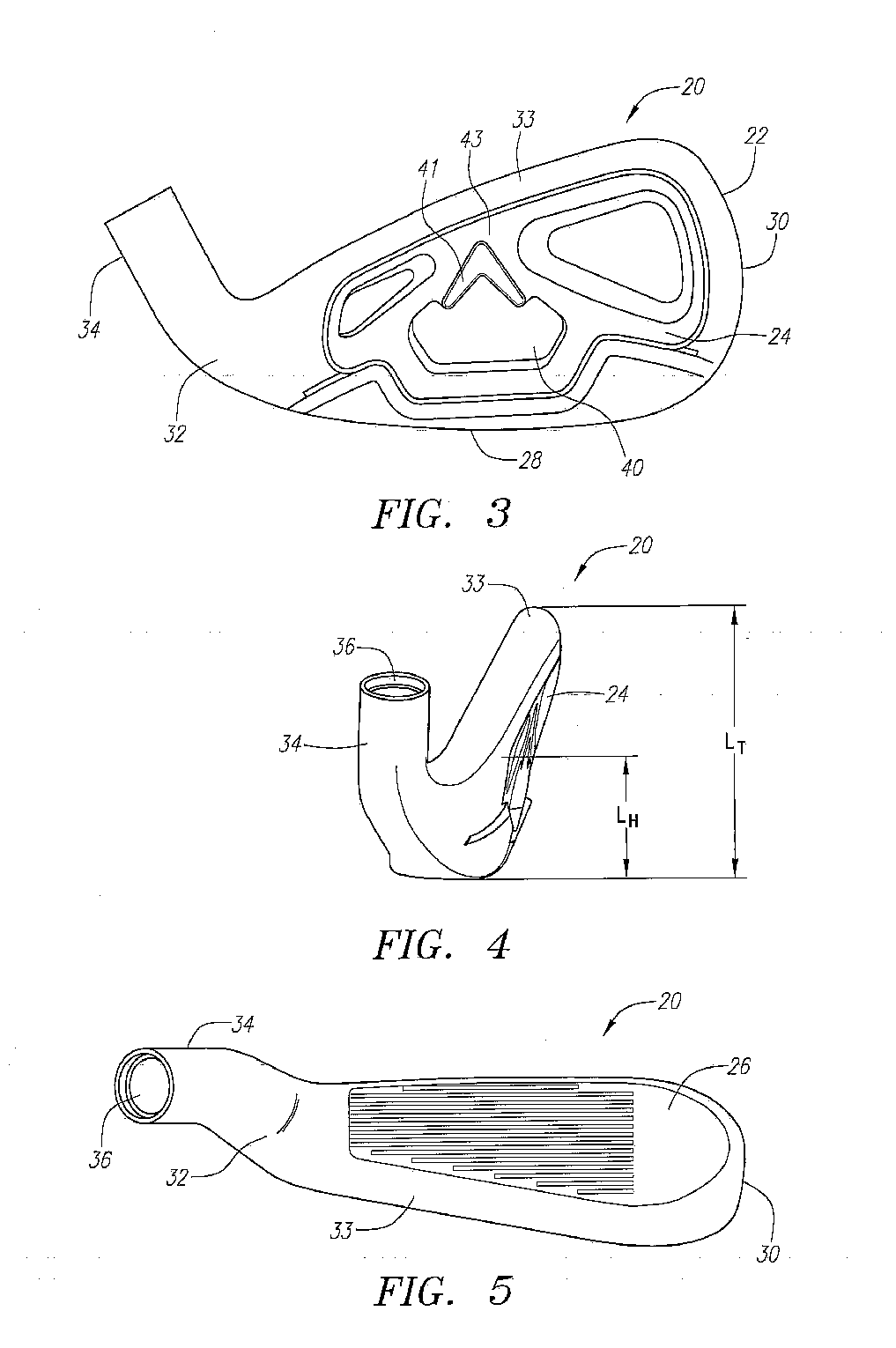

The iron golf club head (20) of the present invention is preferably composed of three main components: a periphery member 22, a central member 24 and a face plate 26. The periphery member (22) is preferably composed of a high density material such as a nickel-tungsten alloy. The central member (24) is preferably composed of a lightweight, non-metal material. The face plate (26) is preferably composed of a titanium alloy material. The iron golf club head (20) preferably has high moments of inertia Izz and Ixx.

Owner:TOPGOLF CALLAWAY BRANDS CORP

Variable density golf club

InactiveUS7815523B2Improving the club head moment of inertiaEnlarging the sweet spotGolf clubsRacket sportsHeel-and-toeMoment of inertia

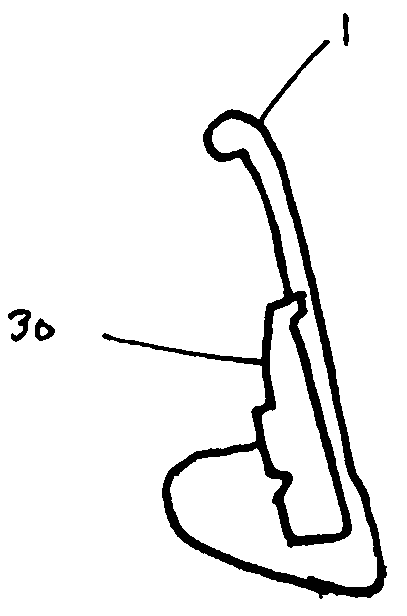

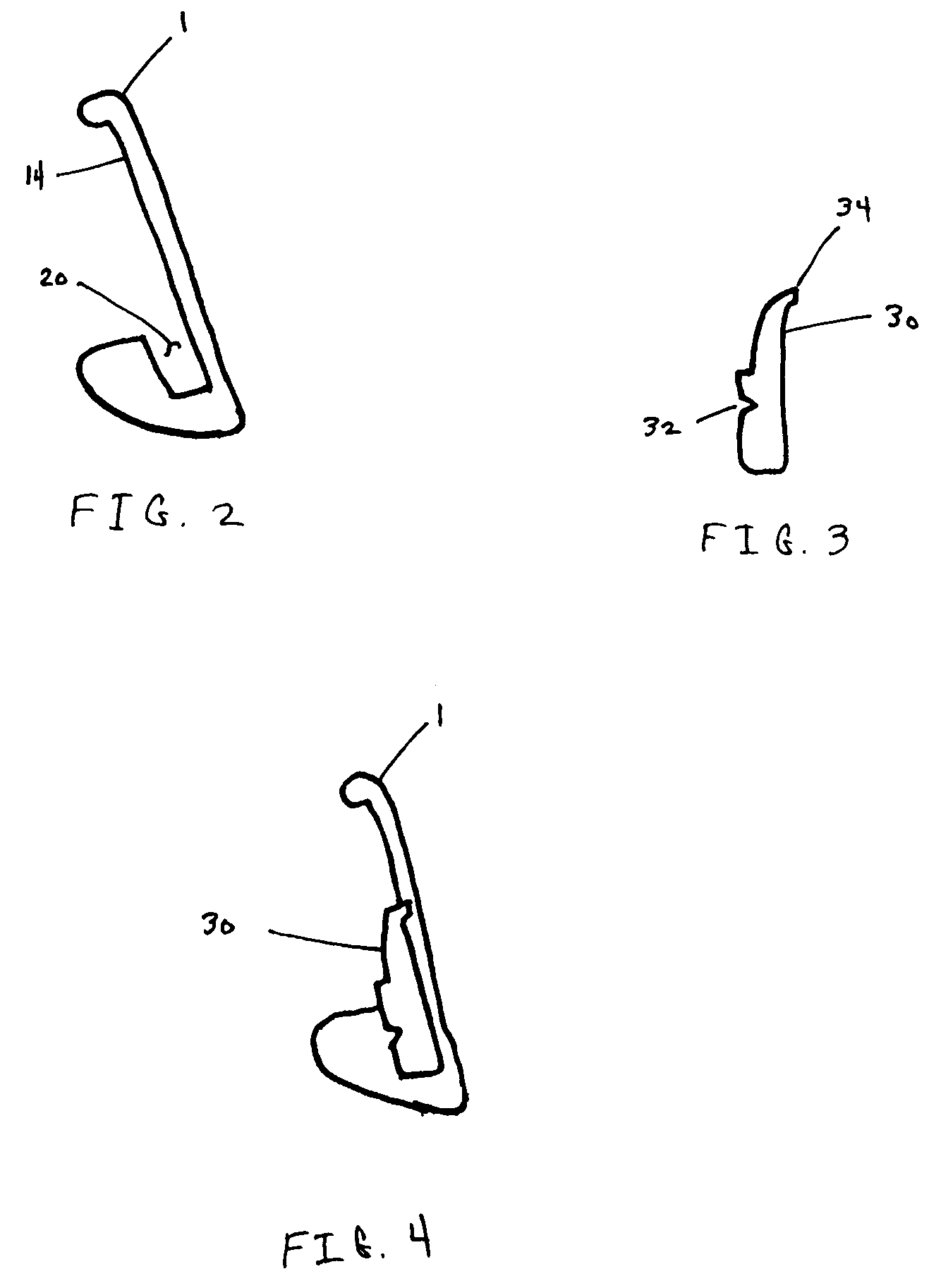

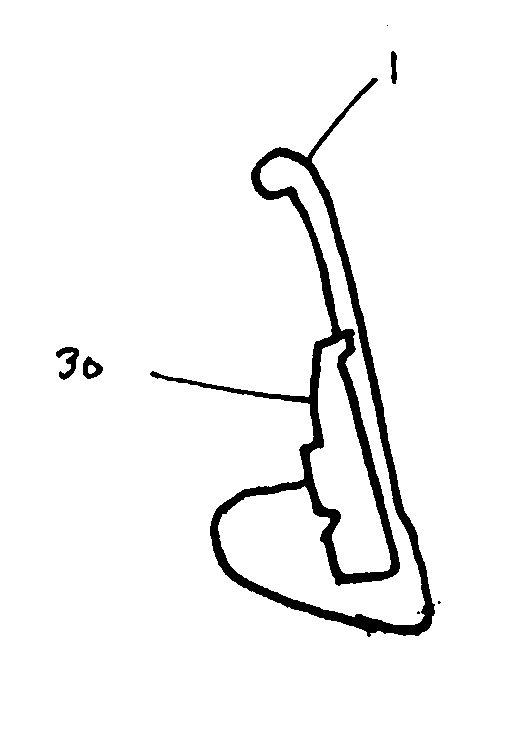

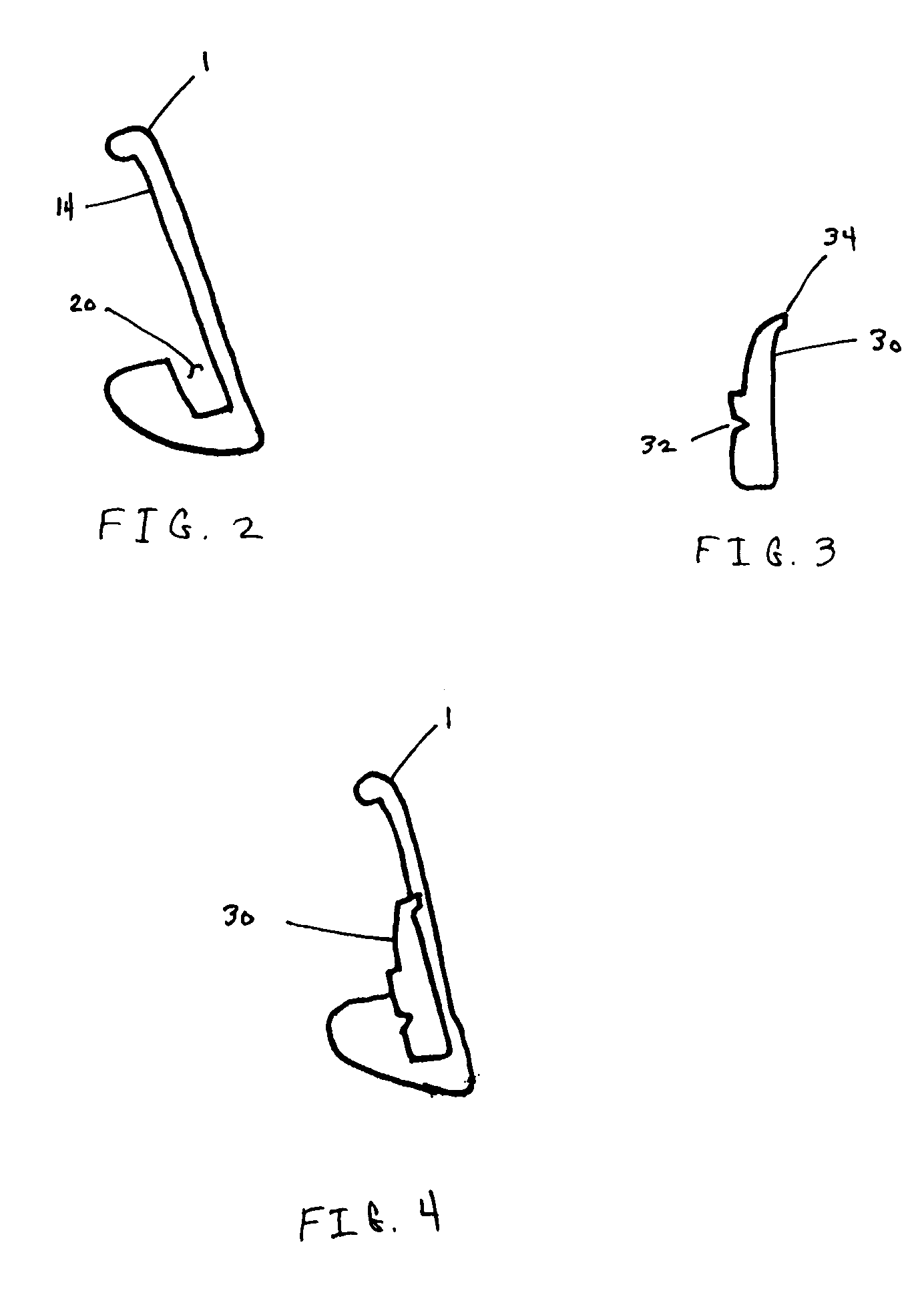

A golf club head having portions of varying density is disclosed and claimed. The club head includes a body with a recess in the back between the heel and toe and extending toward the sole. An insert that is configured to matingly correspond to the recess is positioned within the recess. The insert has a lower specific gravity than the club head body, biasing the club head mass toward the club head perimeter. The insert can form a muscle of the club head. The club head is forged, and the recess is formed by machining. After the insert is positioned within the recess, the club head-insert combination is subjected to additional forging and finishing steps. The present invention increases the club head moment of inertia and / or enlarges the club head sweet spot while retaining the golfer's ability to work the golf ball and shape the golf shot. The present invention can be used with forged, blade, and muscle back clubs, which have not heretofore been enhanced in these manners.

Owner:ACUSHNET CO

Iron golf club

InactiveUS7220189B2Lower center of gravityHigh moment of inertiaGolf clubsRacket sportsHigh densityMetallic materials

The iron golf club head (20) of the present invention is preferably composed of three main components: a periphery member 22, a central member 24 and a face plate 26. The periphery member (22) is preferably composed of a high density material such as a nickel-tungsten alloy. The central member (24) is preferably composed of a lightweight, non-metal material. The face plate (26) is preferably composed of a titanium alloy material. The iron golf club head (20) preferably has high moments of inertia Izz and Ixx.

Owner:TOPGOLF CALLAWAY BRANDS CORP

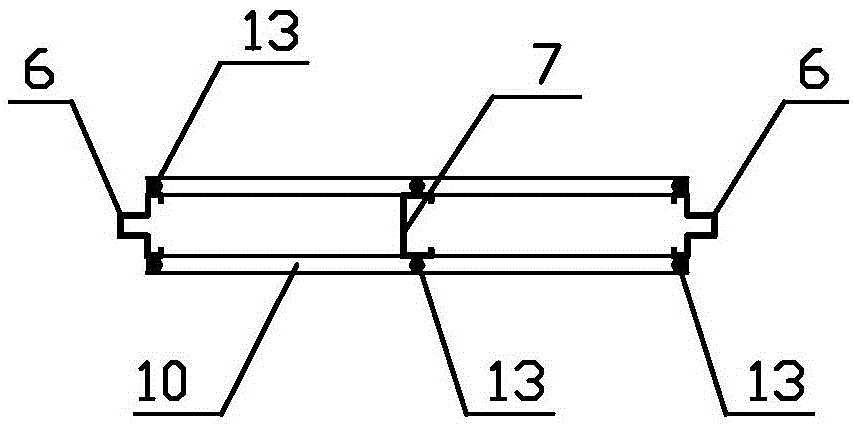

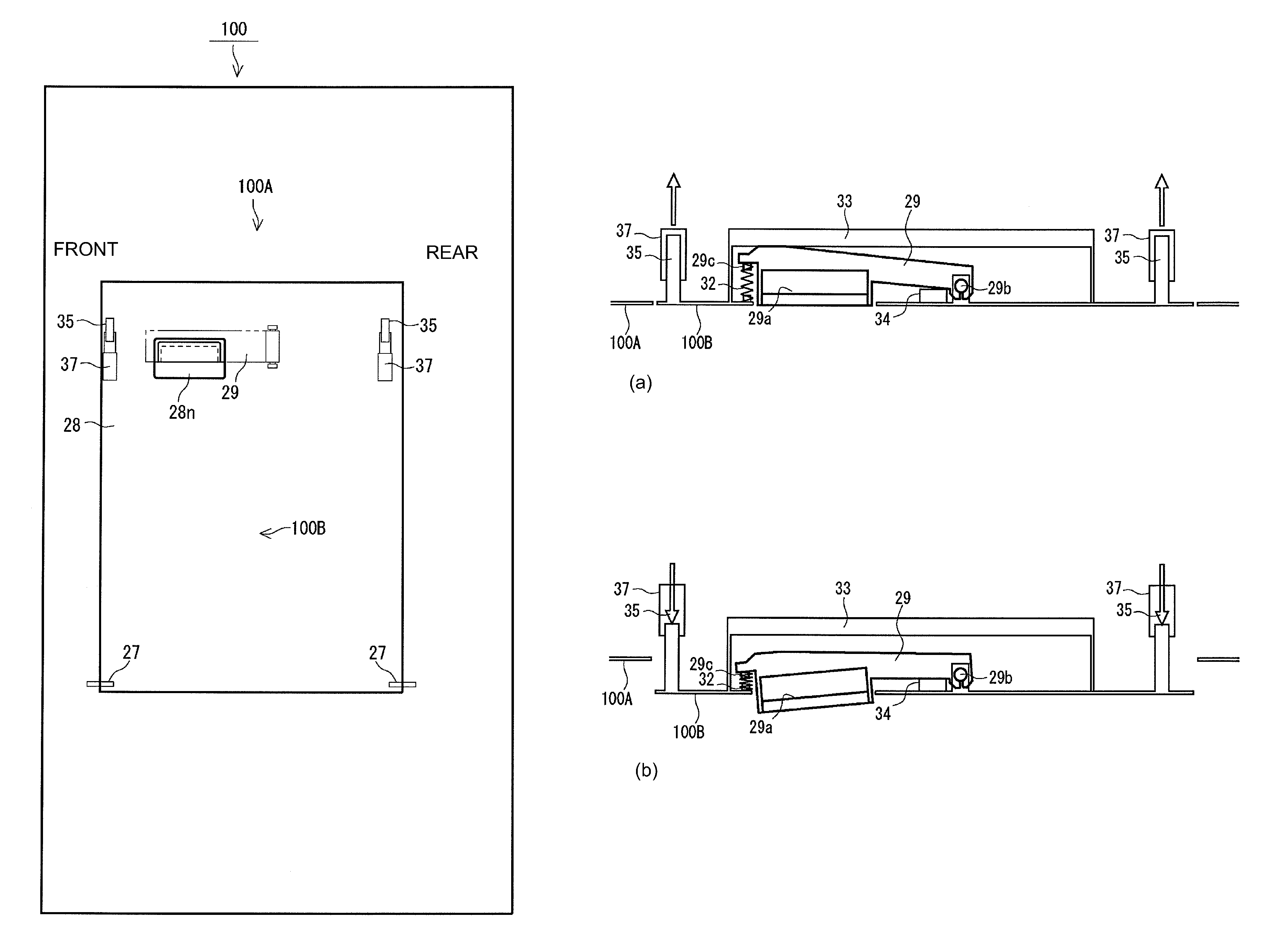

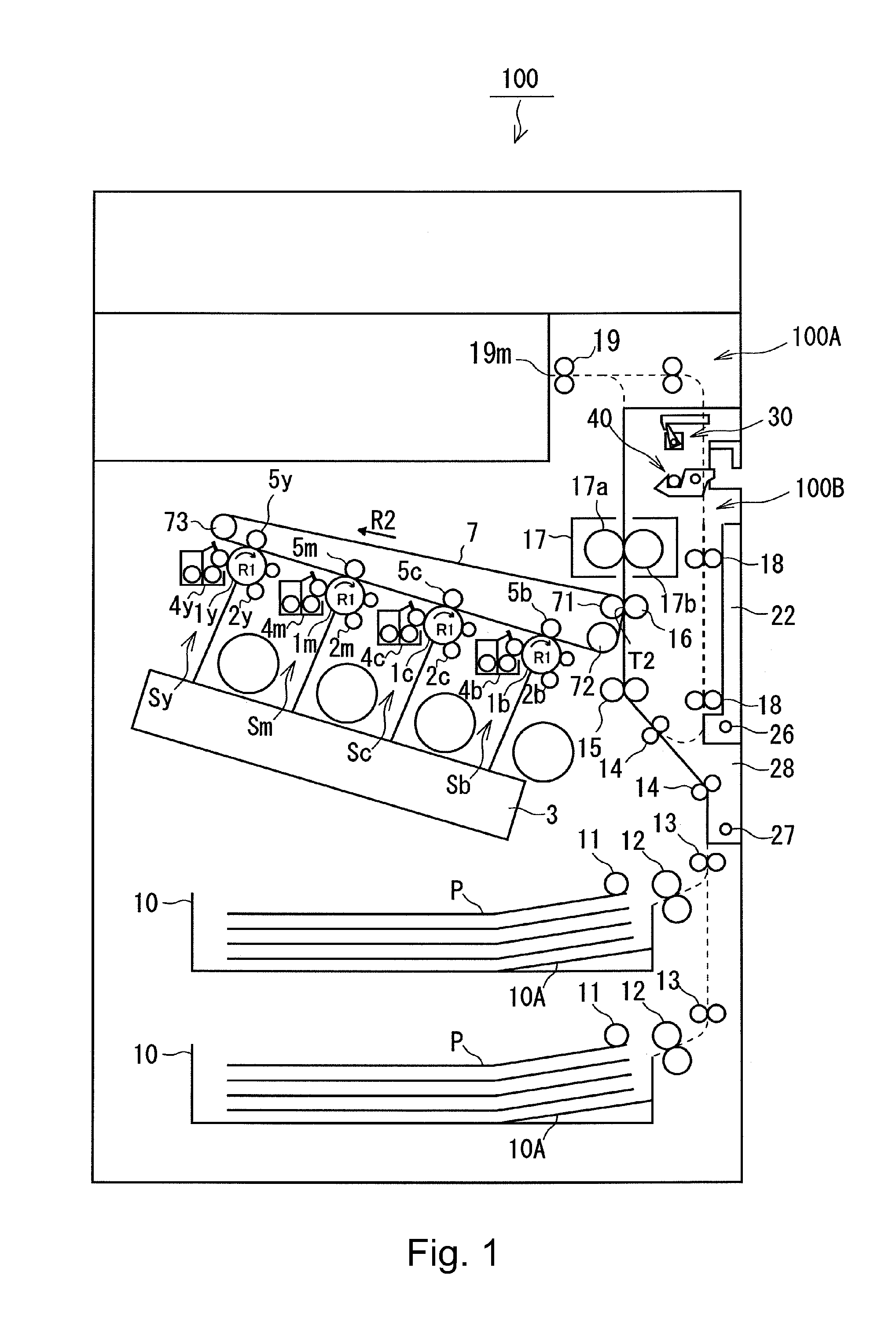

Image forming apparatus

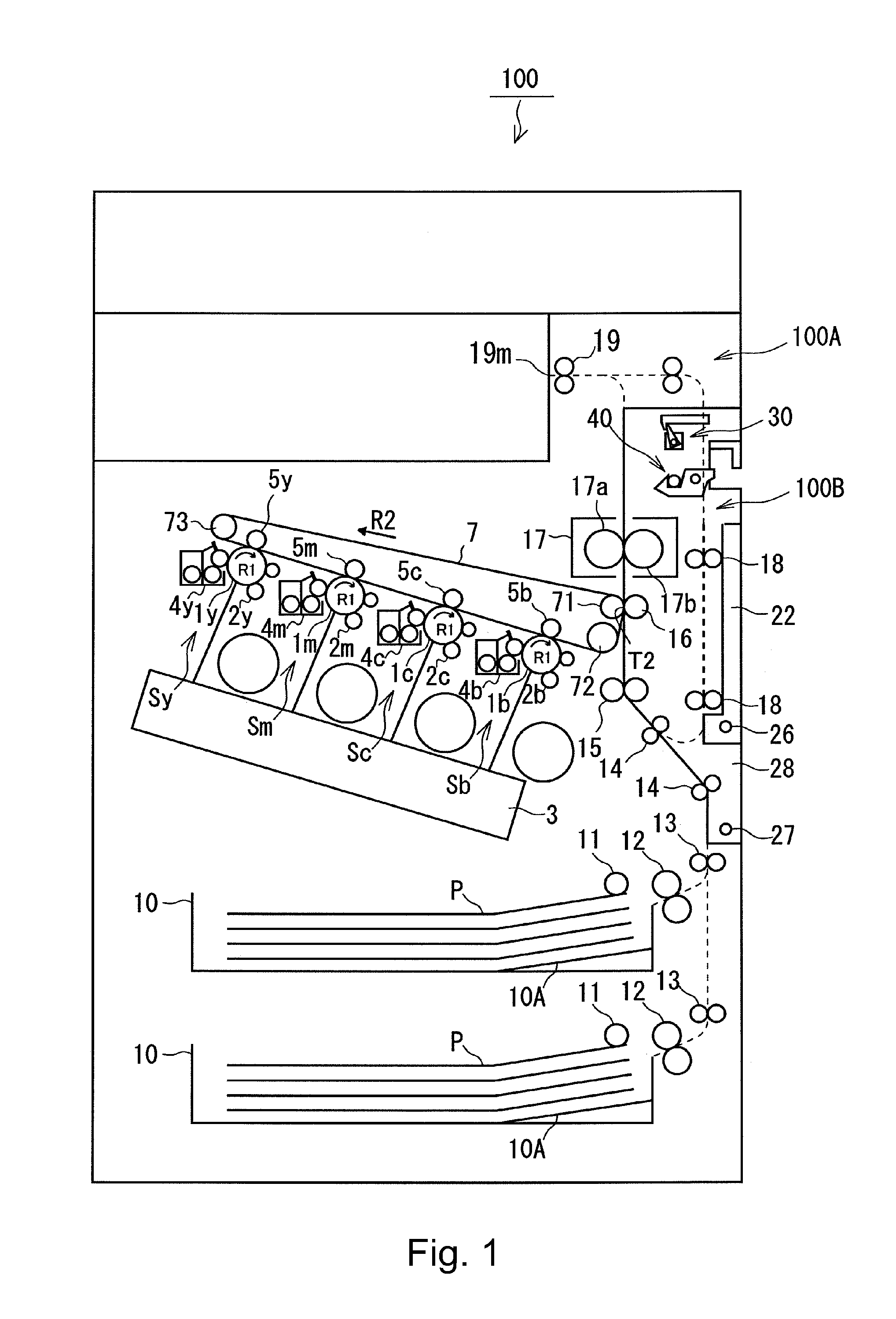

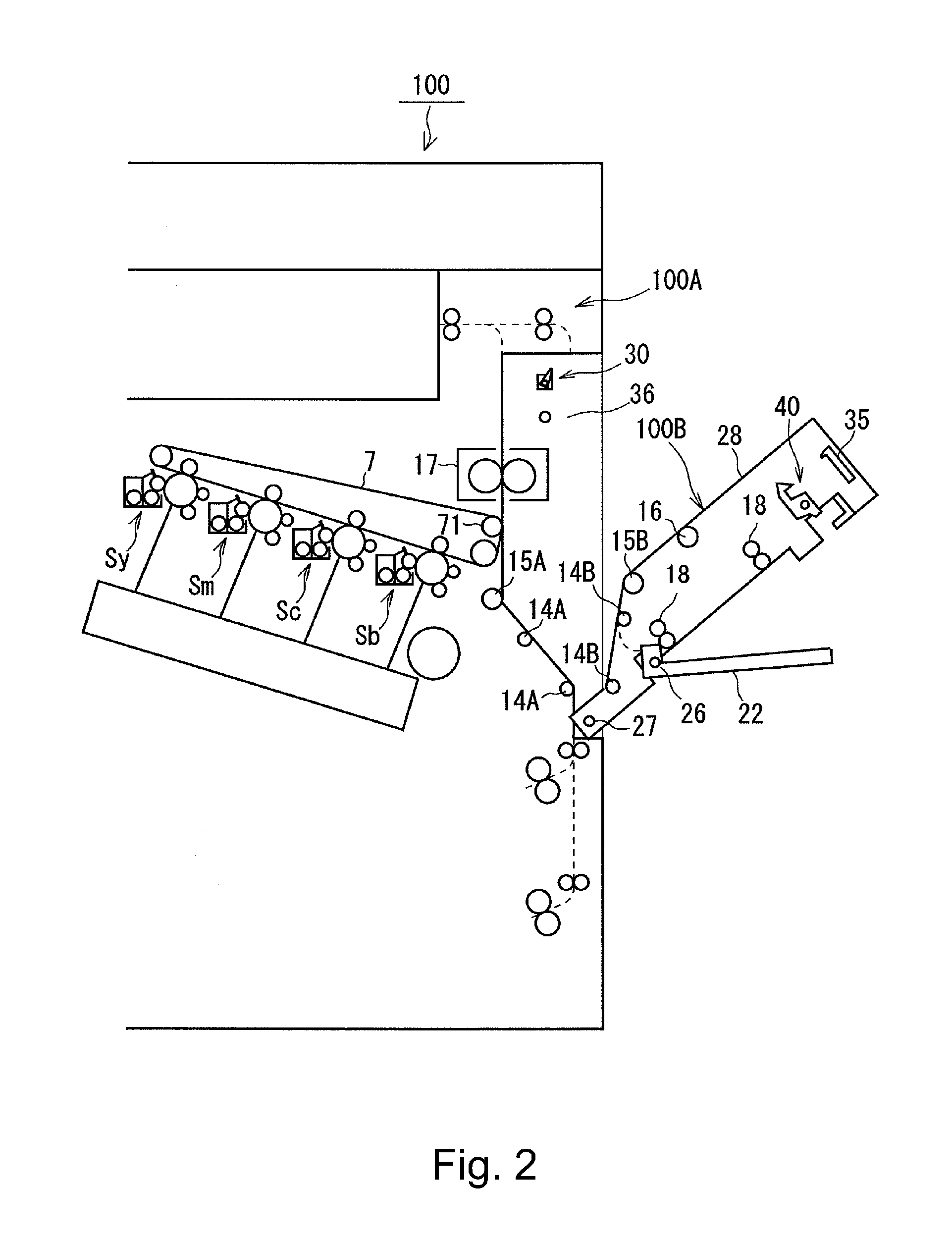

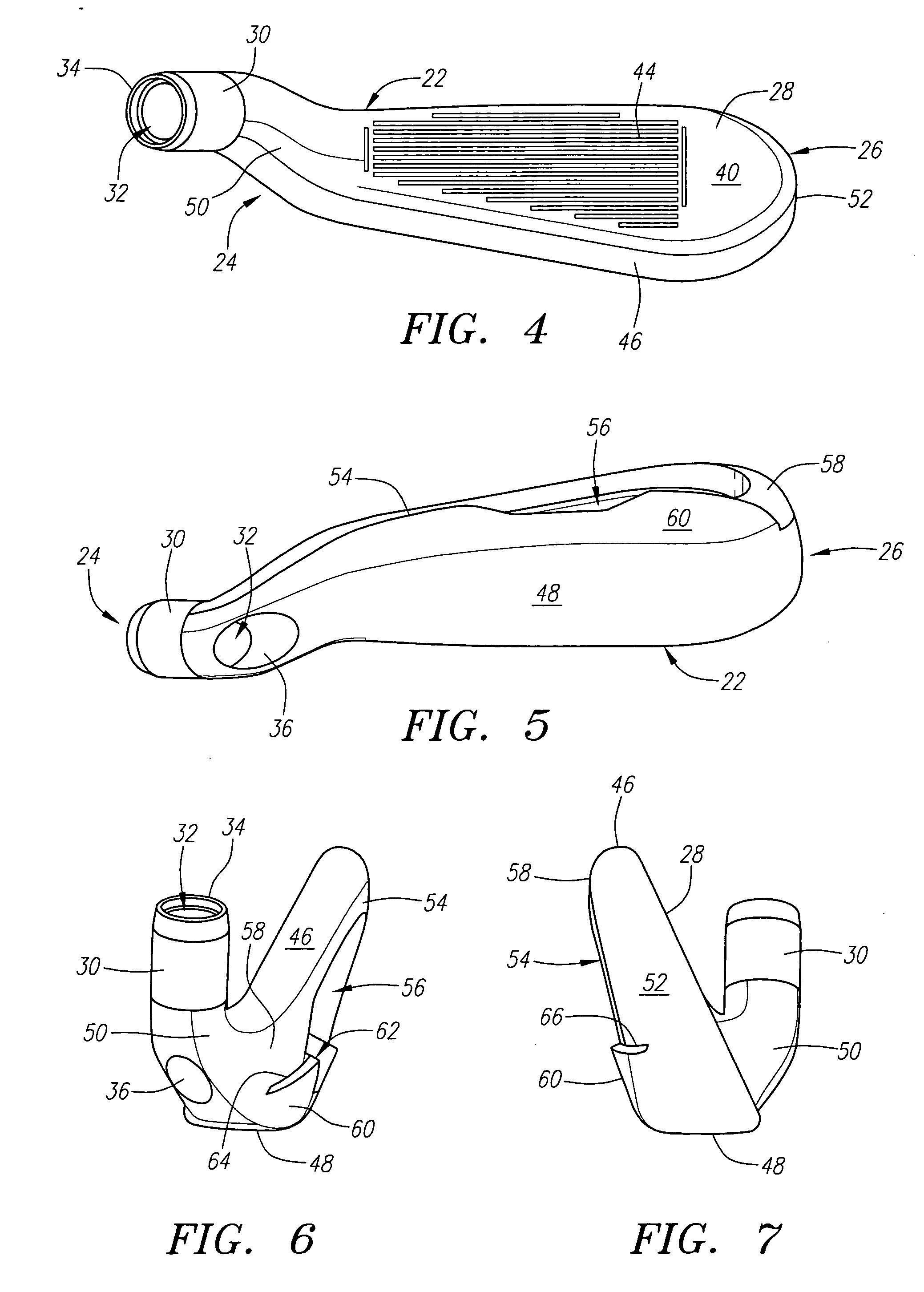

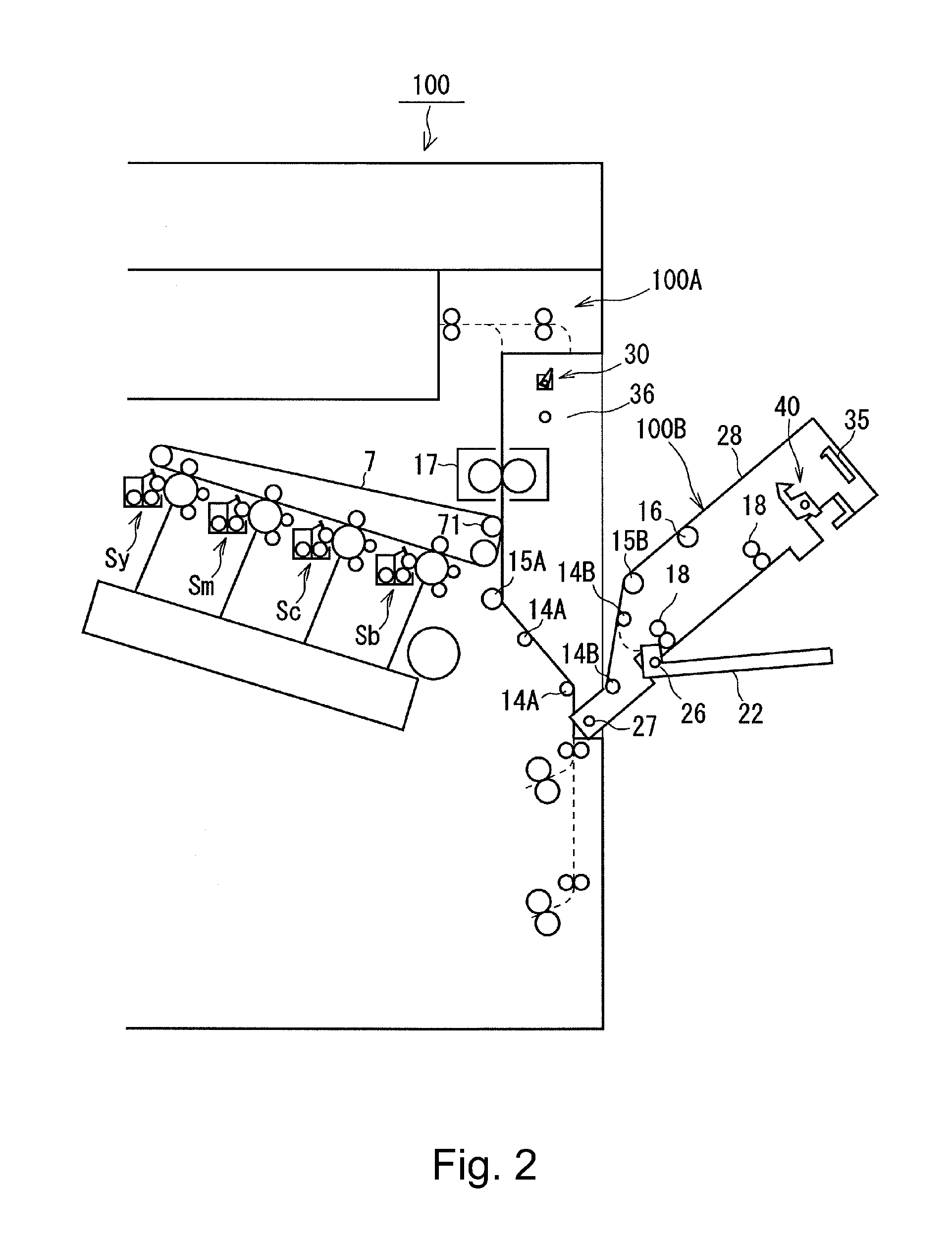

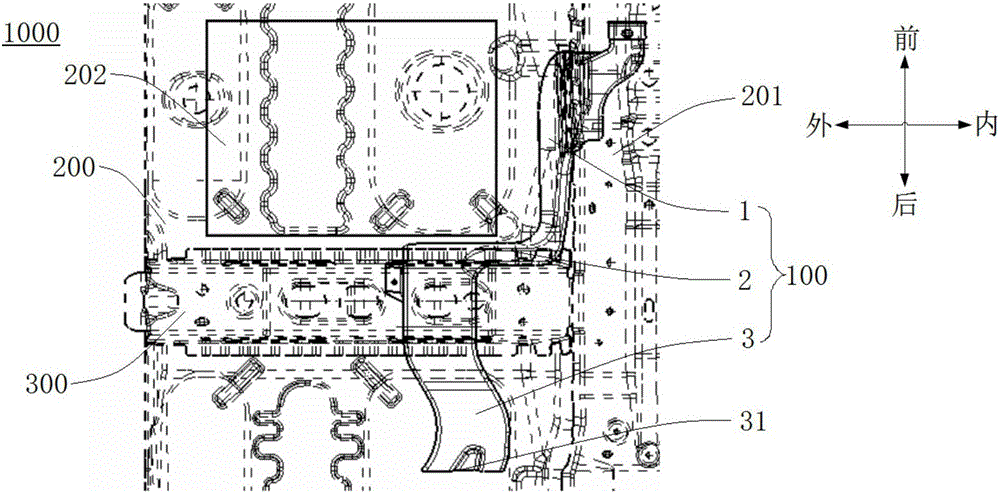

InactiveUS20110293326A1Easy to openFeel solidElectrographic process apparatusImage formationEngineering

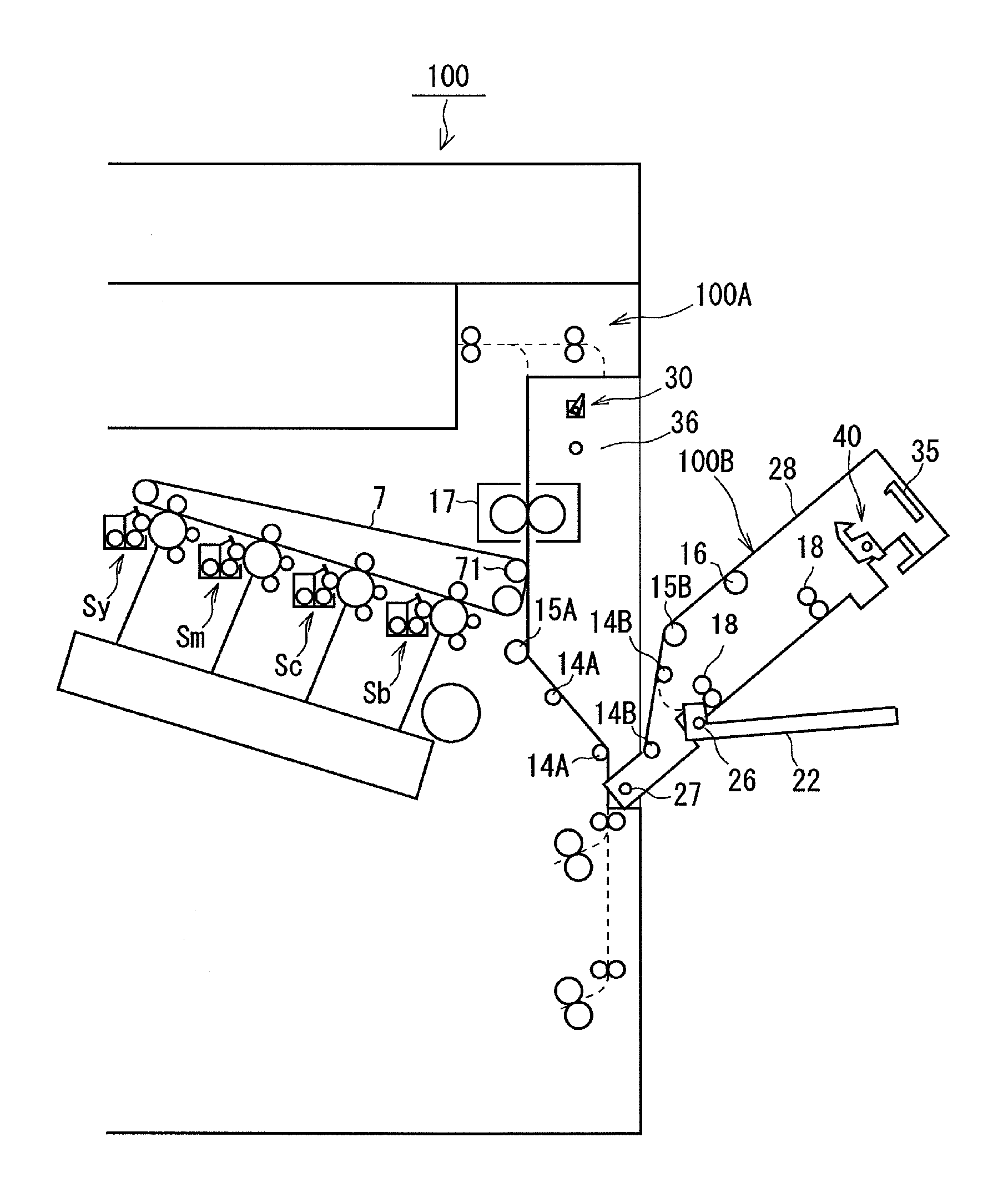

An image forming apparatus includes a main assembly; a door member which supports one of roller members constituting a feeding nip for a recording material and which is rotatable about an axis parallel with said roller members in a sidewise direction of said main assembly to open said feeding nip; a pair of urging mechanisms which are provided at opposite end portions of said door member with respect to a front-rear direction of said main assembly and which fix said door member to said main assembly so as to be capable of opening and closing said door member, said urging mechanism urging said door member toward said main assembly in a state that said door member is closed; and an operating member provided with a grip for manual opening of said door member, said grip being disposed in a position nearer to a front side than a center portion position of said door member with respect to the front-rear direction, and said operating member being rotatably supported in a position nearer to a rear side than a center position between urging mechanisms.

Owner:CANON KK

Iron golf club

InactiveUS20050170908A1Lower center of gravityHigh moment of inertiaGolf clubsRacket sportsHigh densityEngineering

The iron golf club head (20) of the present invention is preferably composed of three main components: a periphery member 22, a central member 24 and a face plate 26. The periphery member (22) is preferably composed of a high density material such as a nickel-tungsten alloy. The central member (24) is preferably composed of a lightweight, non-metal material. The face plate (26) is preferably composed of a titanium alloy material. The iron golf club head (20) preferably has high moments of inertia Izz and Ixx.

Owner:TOPGOLF CALLAWAY BRANDS CORP

Variable density golf club

InactiveUS20060035721A1Increase club head moment of inertiaEnlarge club head sweet spotGolf clubsRacket sportsHeel-and-toeMoment of inertia

A golf club head having portions of varying density is disclosed and claimed. The club head includes a body with a recess in the back between the heel and toe and extending toward the sole. An insert that is configured to matingly correspond to the recess is positioned within the recess. The insert has a lower specific gravity than the club head body, biasing the club head mass toward the club head perimeter. The insert can form a muscle of the club head. The club head is forged, and the recess is formed by machining. After the insert is positioned within the recess, the club head-insert combination is subjected to additional forging and finishing steps. The present invention increases the club head moment of inertia and / or enlarges the club head sweet spot while retaining the golfer's ability to work the golf ball and shape the golf shot. The present invention can be used with forged, blade, and muscle back clubs, which have not heretofore been enhanced in these manners.

Owner:ACUSHNET CO

Iron golf club

InactiveUS20060084527A1Lower center of gravityHigh moment of inertiaGolf clubsRacket sportsHigh densityMoment of inertia

The iron golf club head (20) of the present invention is preferably composed of three main components: a main body (22), a central member (24) and a mass member (25). The Mass member (25) is preferably composed of a high density material such as a nickel-tungsten alloy. The central member (24) is preferably composed of a lightweight, non-metal material. The main body (22) is preferably composed of a titanium alloy material. The iron golf club head (20) preferably has high moments of inertia Izz and Ixx, and a low center of gravity.

Owner:TOPGOLF CALLAWAY BRANDS CORP

Iron-Type Golf Club

InactiveUS20060025237A1Lower center of gravityHigh moment of inertiaGolf clubsRacket sportsEngineeringMoment of inertia

An iron-type golf club head (20) includes a body (22) having a front wall (28) with a ball-striking surface (40). The body (22) further includes a rear surface (54) that has external rear cavity (56) formed therein. The rear surface (54) includes an upper portion (58) and a lower portion (60). The upper portion (60) is separated from the lower portion (59) by the external rear cavity (56) and at least one groove (64, 66). The lower portion (60) of the rear surface (54) has a notch (62) formed therein, which communicates with the external rear cavity (56). The golf club head (20) preferably has high moments of inertia Izz and Ixx.

Owner:TOPGOLF CALLAWAY BRANDS CORP

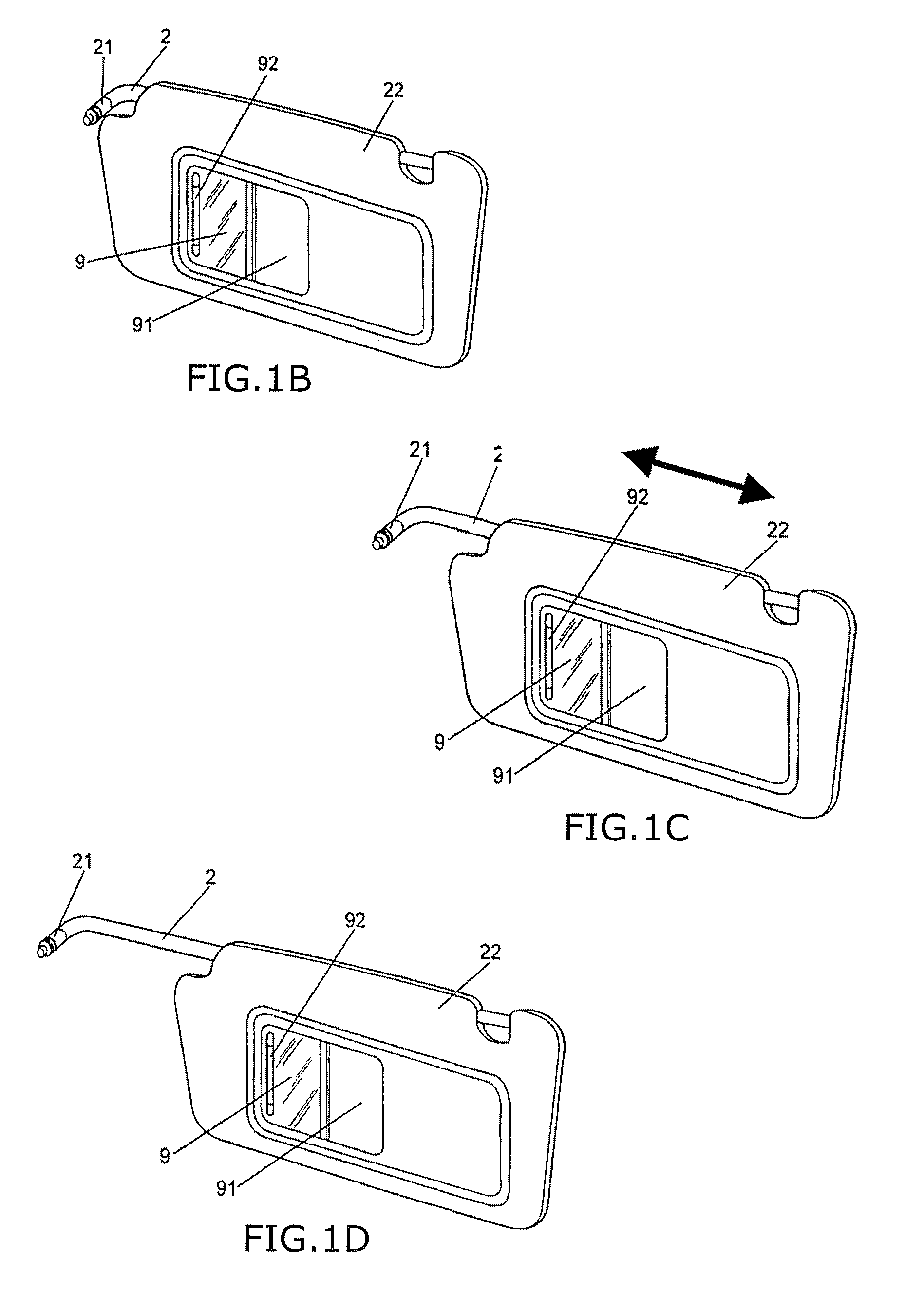

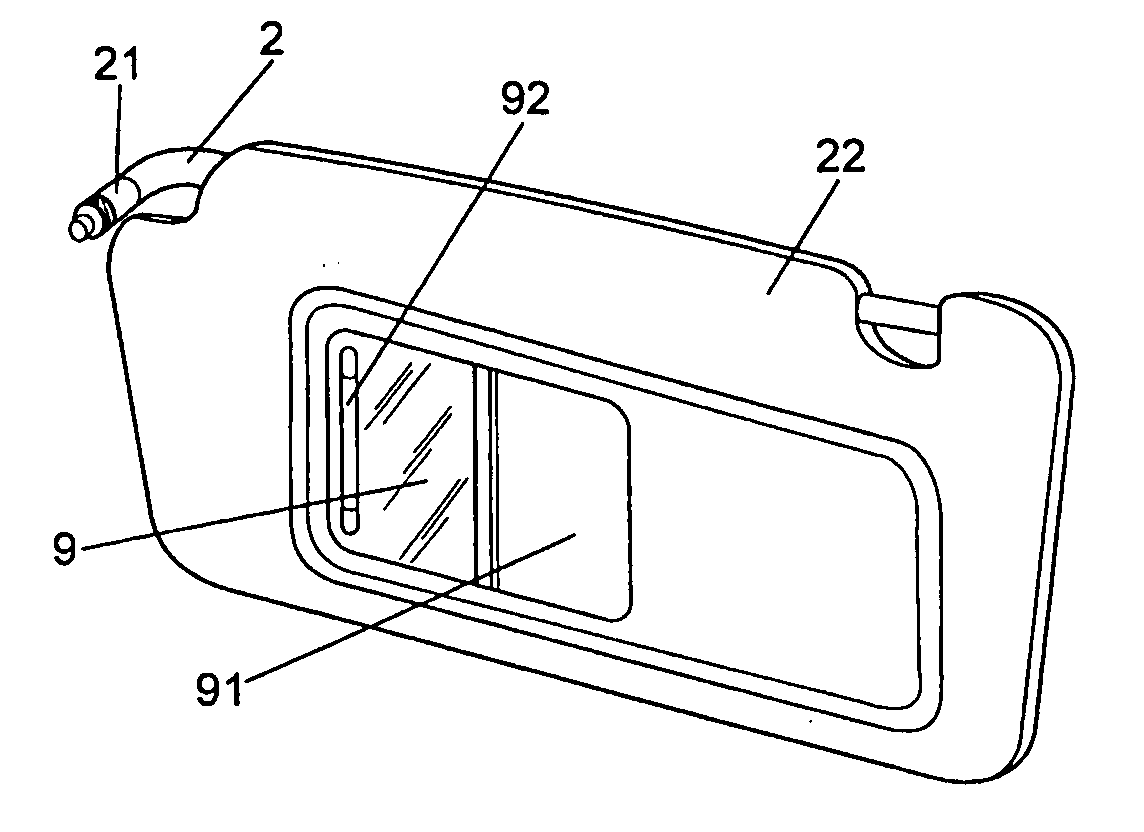

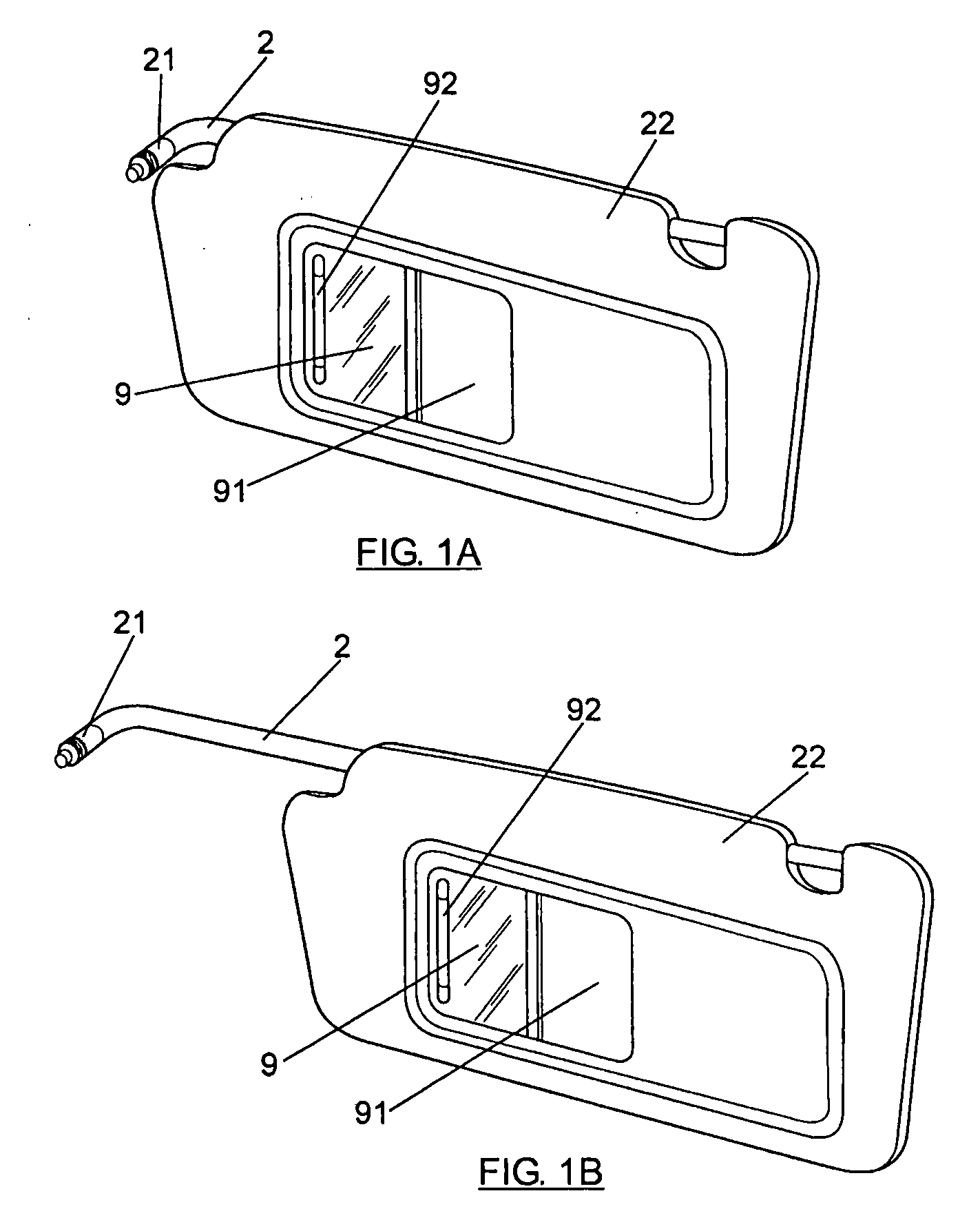

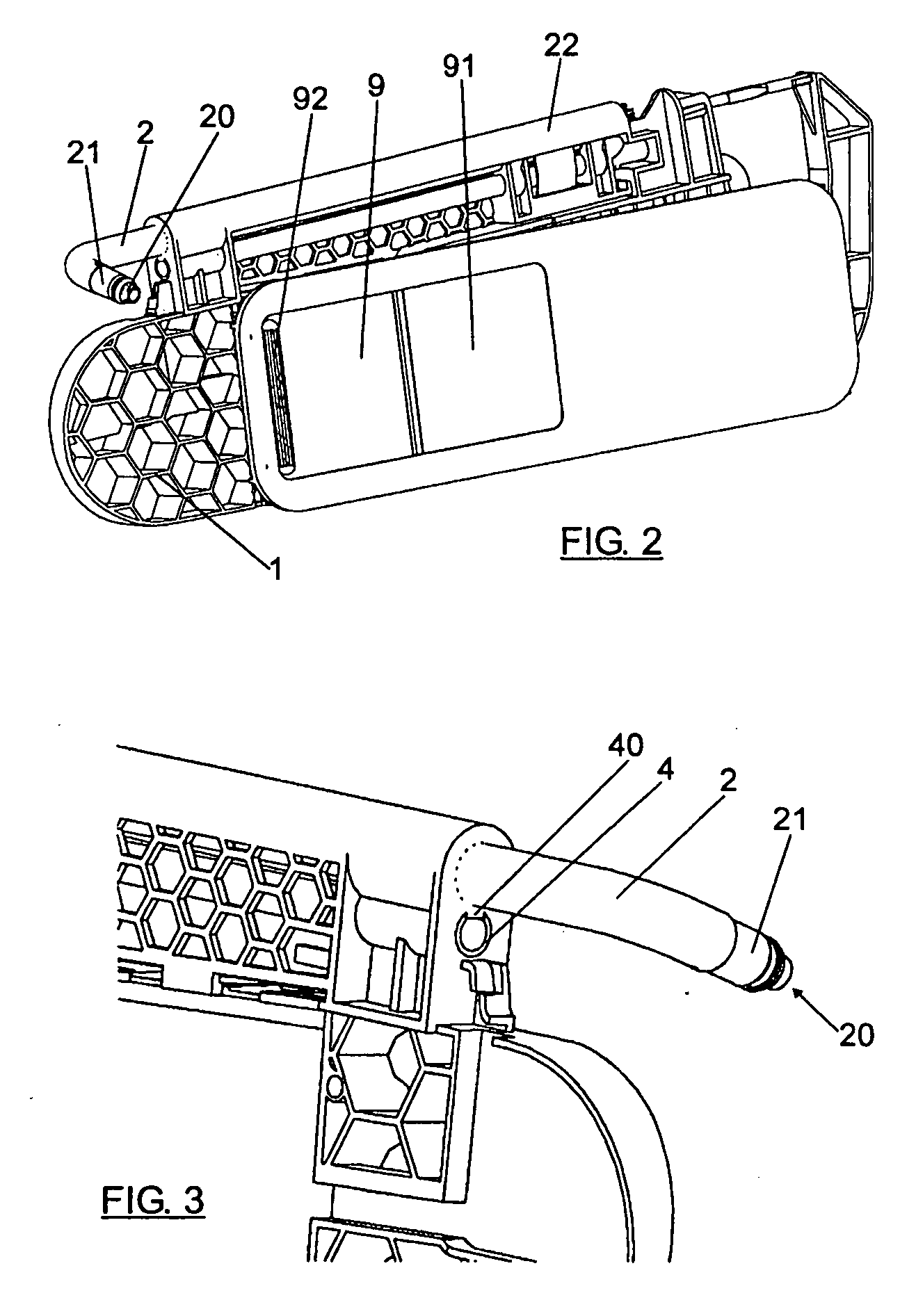

Sliding sun visor

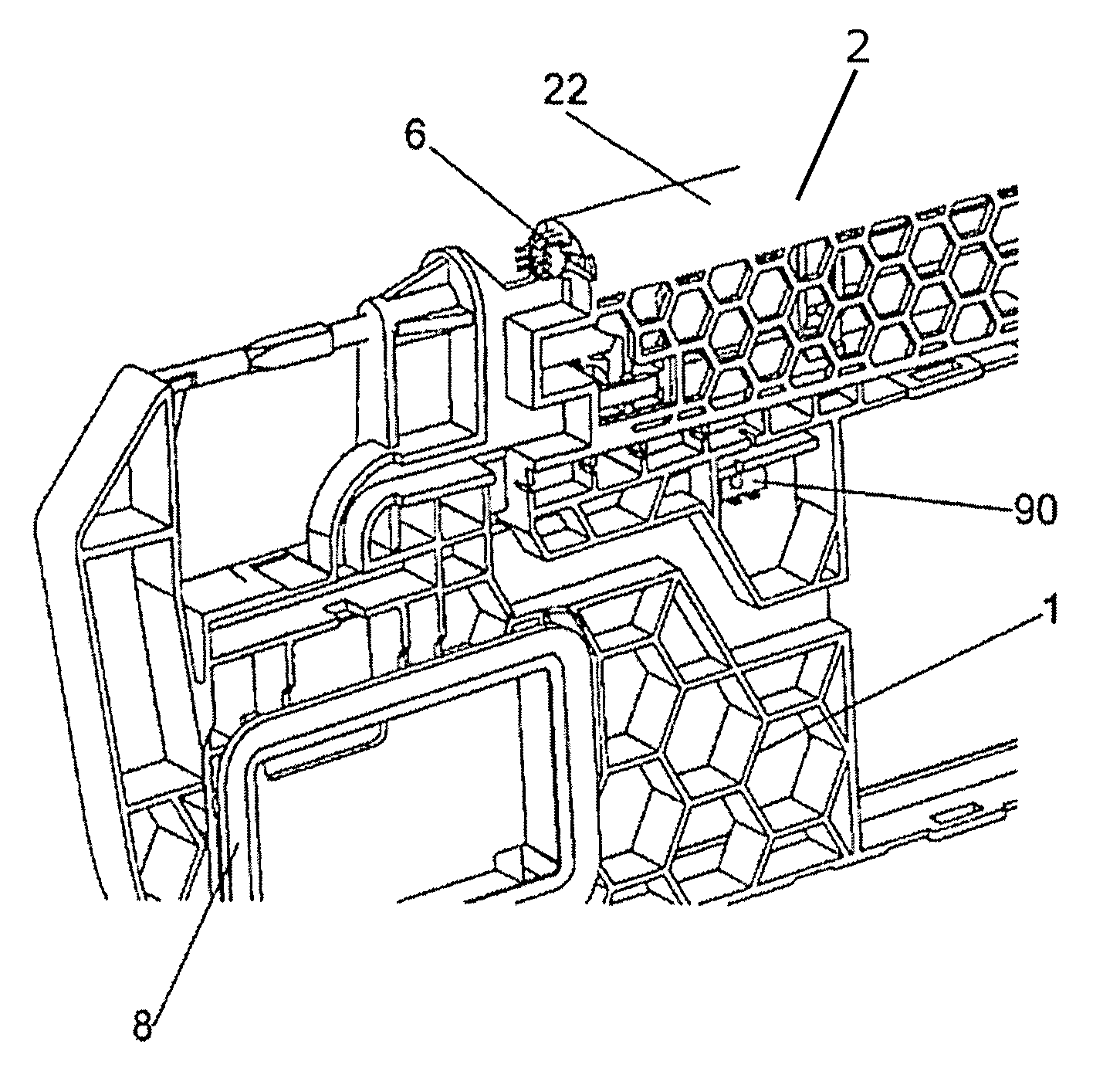

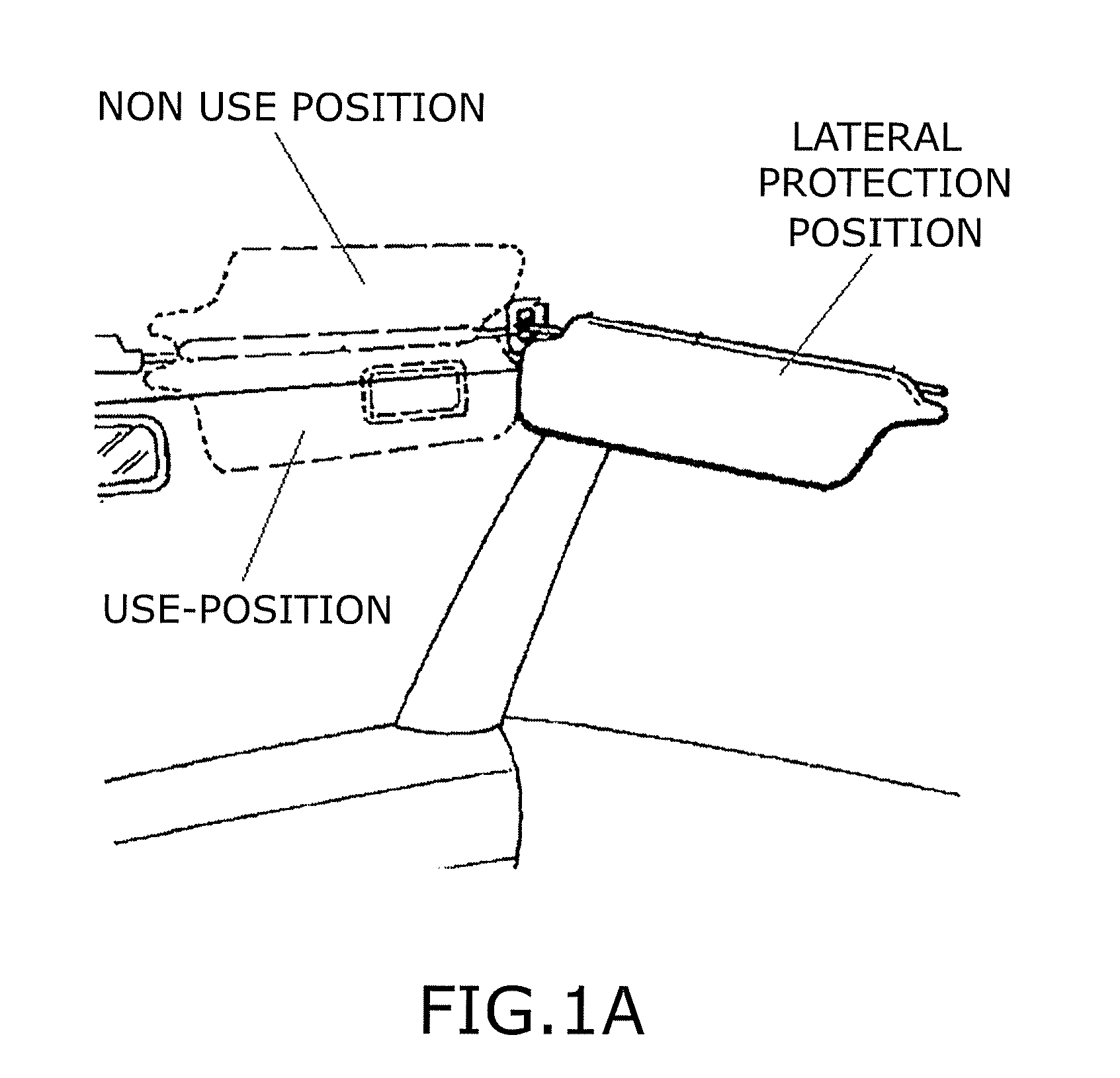

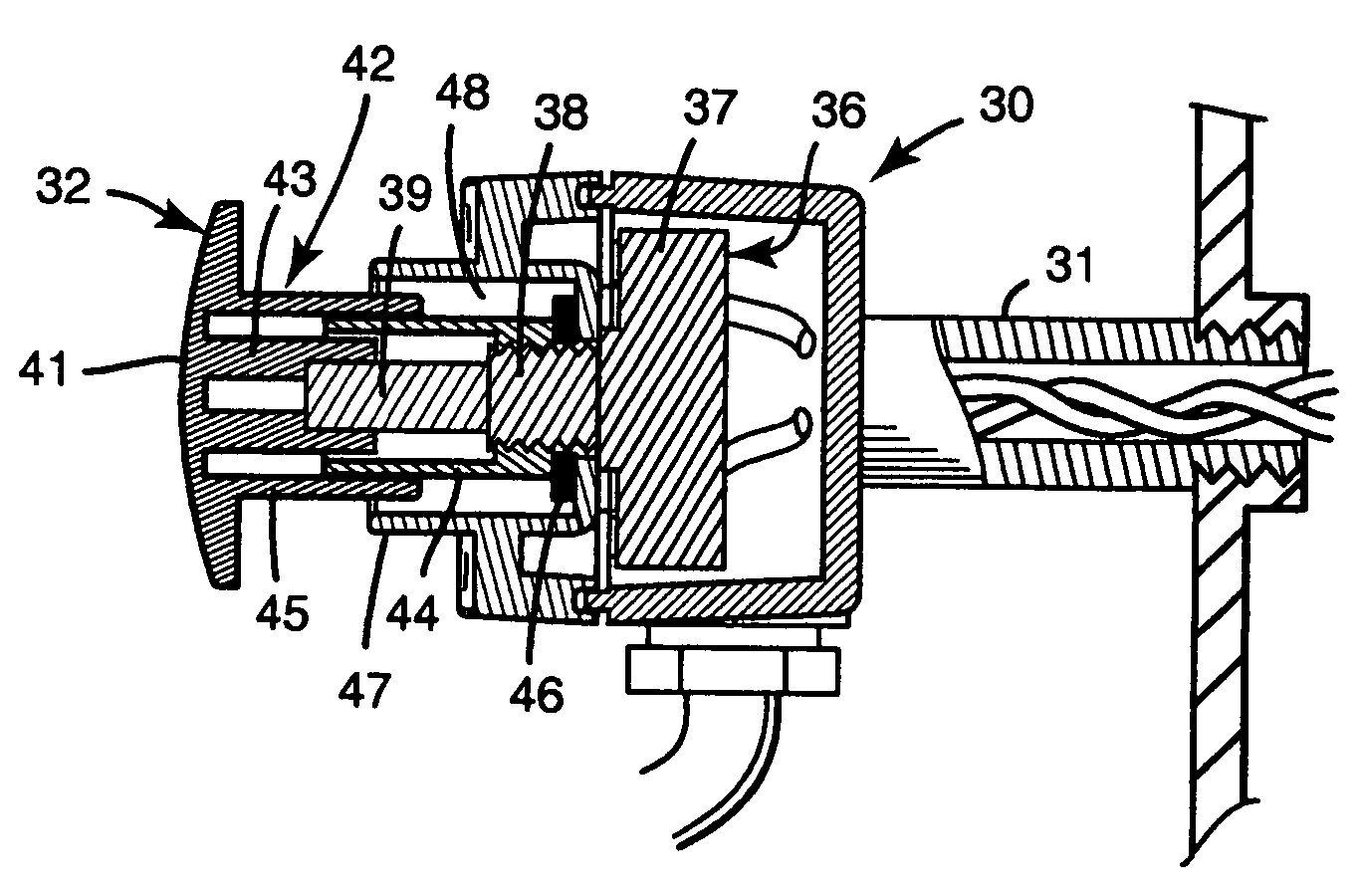

InactiveUS7384088B2Precise positioningFeel solidAntiglare equipmentMonocoque constructionsElectrical conductorVisor

A sliding sun visor having: a pivot rod (2); a conductor (3) for supplying power to at least one electrical device included in the sun visor structure (1). The conductor (3) has a second portion having at least a length to enable the sun visor structure (1) be positioned in the most extended use-position. The sun visor structure (1) has conductor housing elements (4) for housing the second portion of the conductor. The conductor housing elements (4) are parallel to the pivot rod (2). The conductor housing elements (4) are provided with a longitudinal groove (40), the conductor (3) has continuous conductor cables from the first end to the at least one electrical device and the conductor (3) is transversally folded.

Owner:GRP ANTOLIN ING SA

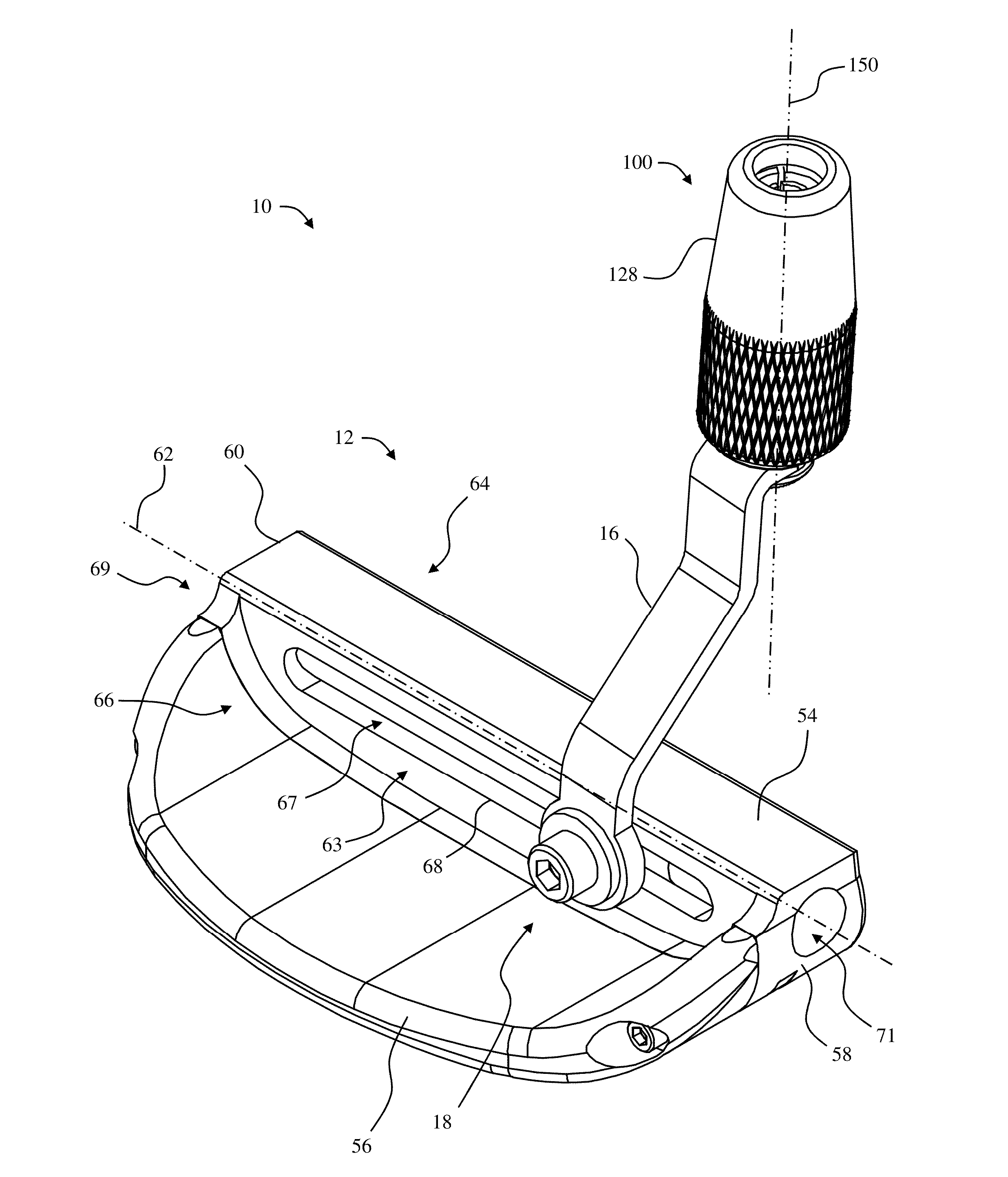

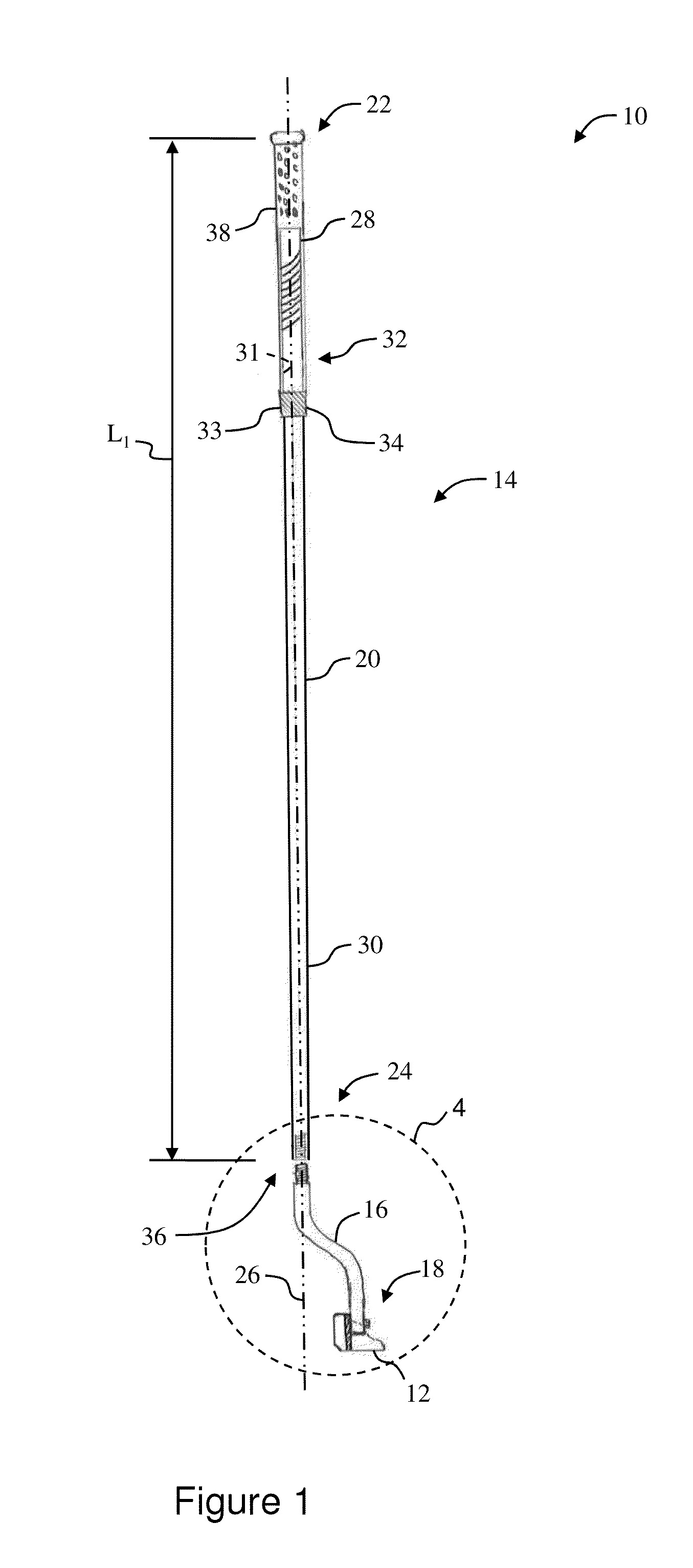

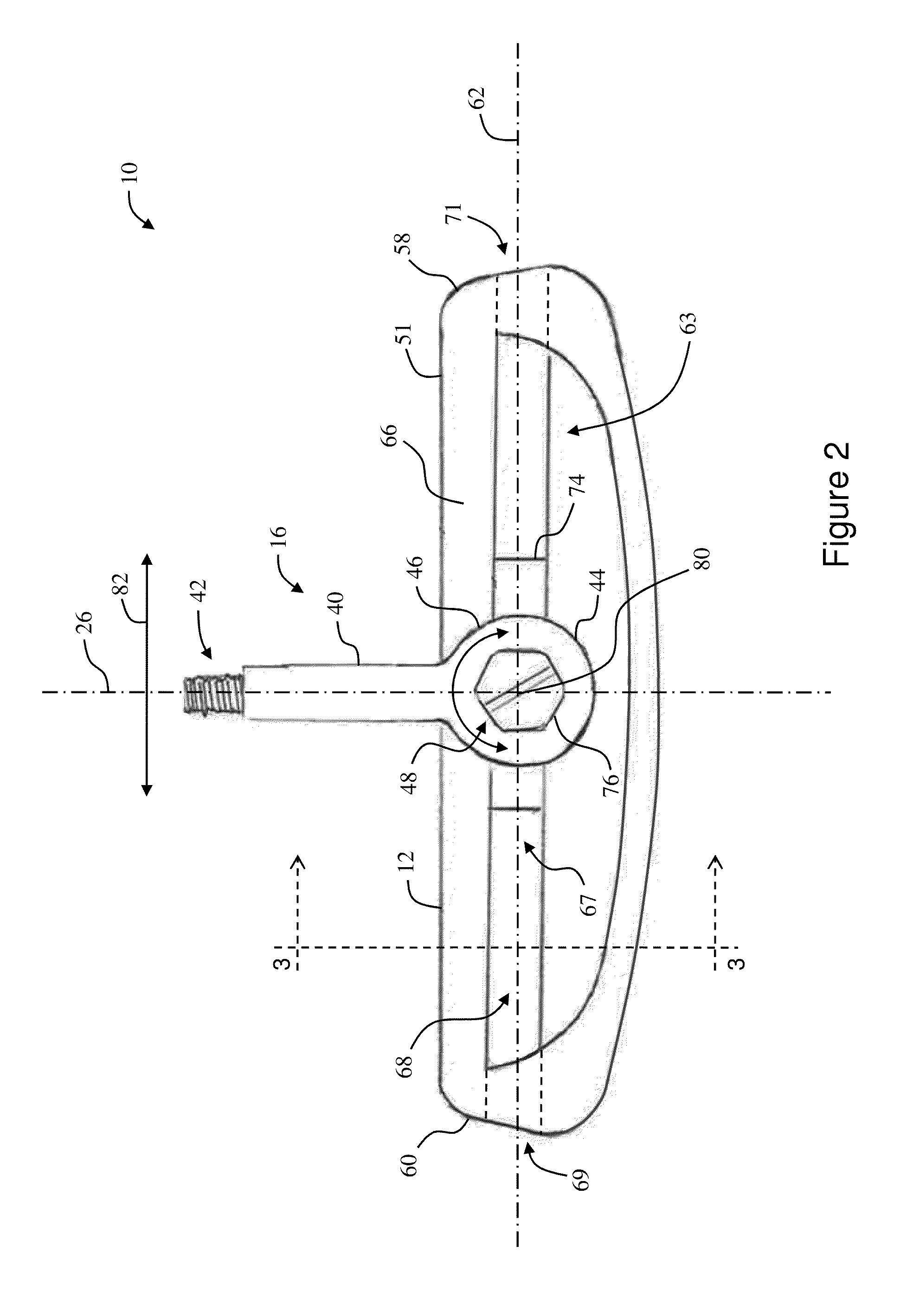

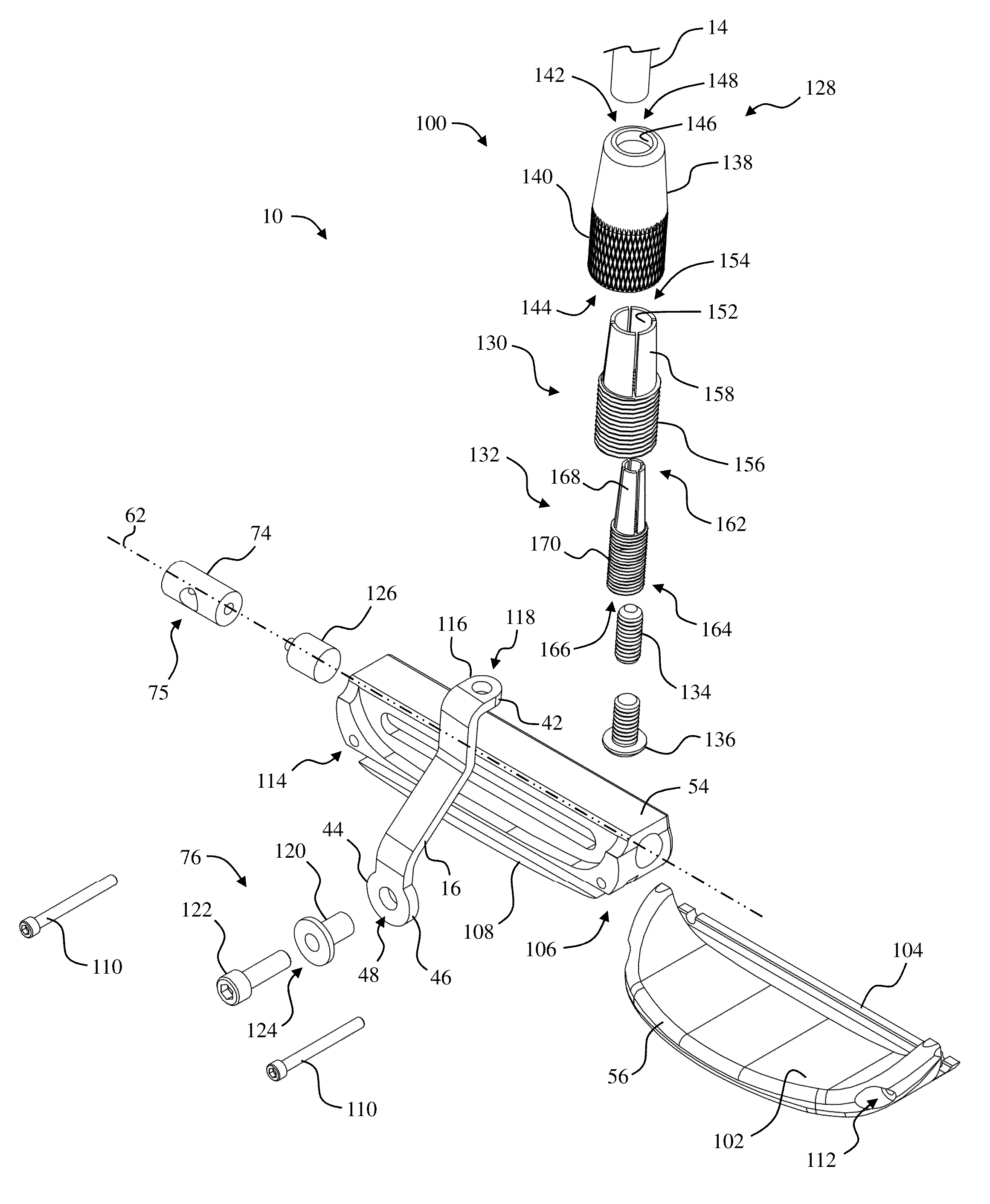

Adjustable Golf Club System

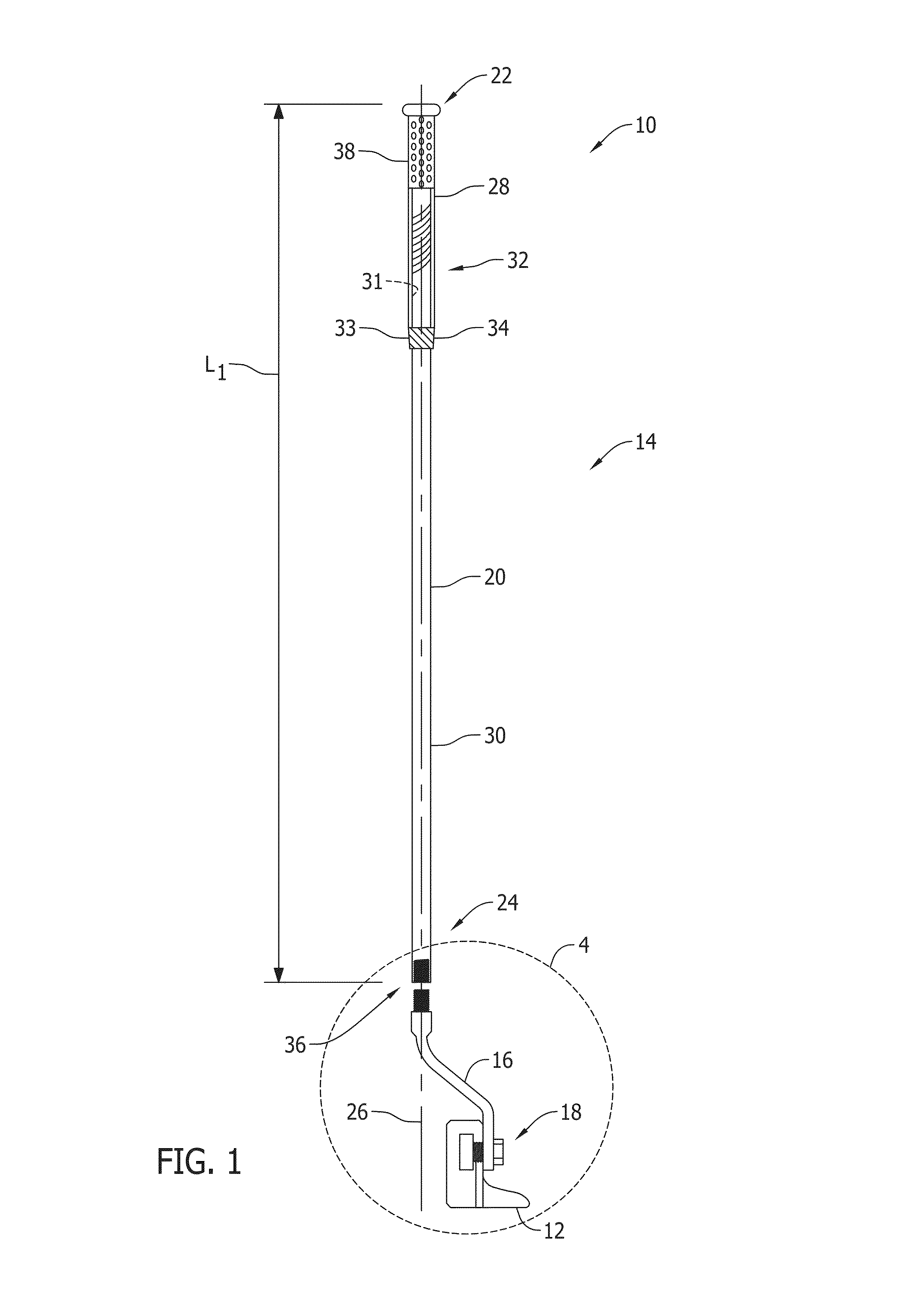

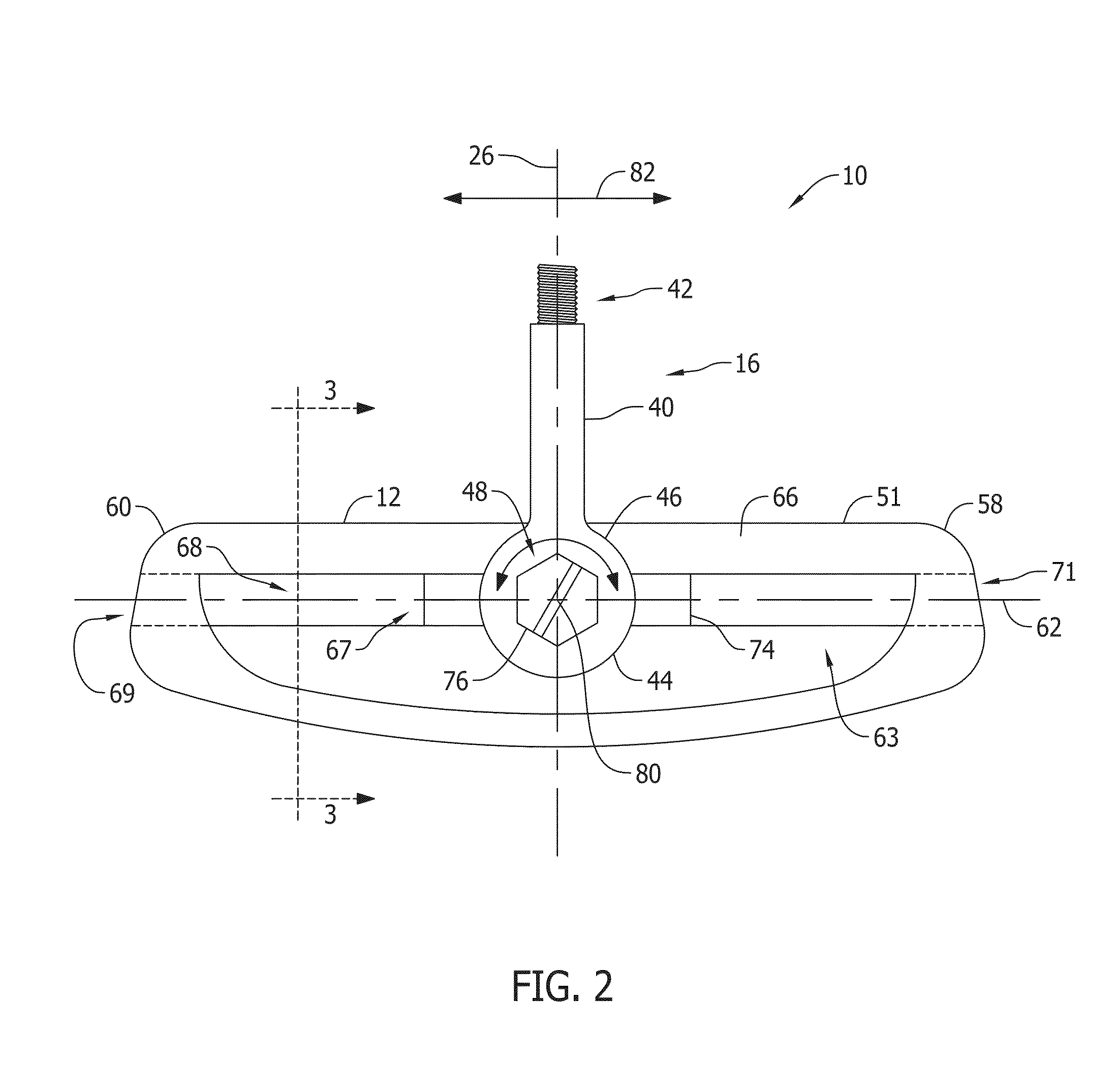

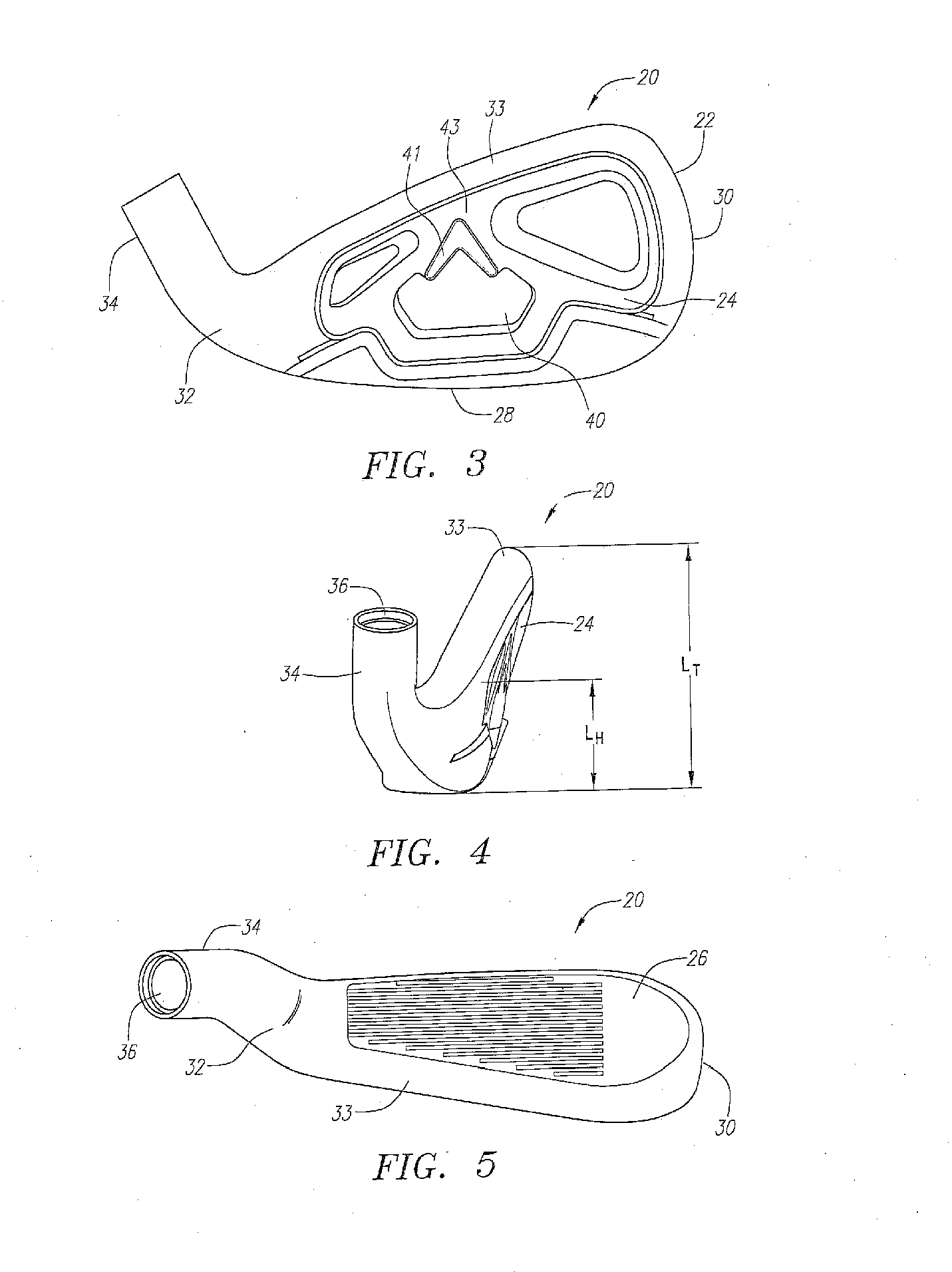

ActiveUS20150045137A1Facilitate removably couplingFacilitate friction fitGolf clubsGolf BallGolf club

An adjustable golf club system is described herein. The adjustable golf club system includes a club shaft, a club head, a hosel, and an adjustment assembly that is removably coupled to the club head and the hosel to facilitate adjusting an orientation of the hosel with respect to the club head. The club head includes a club head cavity that extends between a toe portion and a heal portion. The hosel includes a first end that is coupled to the club shaft and a second end that includes a fastener head. The adjustment assembly includes a sliding member and a hosel fastener that is coupled to the sliding member. The sliding member is positioned within the club head cavity and movable between the toe portion and the heal portion. The hosel fastener extends through the fastener head to the sliding member to couple the hosel to the club head.

Owner:ESPOSITO BRIAN

Sliding sun visor

InactiveUS20060113819A1Precise positioningFeel solidAntiglare equipmentMonocoque constructionsElectrical conductorEngineering

A sliding sun visor having: a pivot rod (2); a conductor (3) for supplying power to at least one electrical device included in the sun visor structure (1). The conductor (3) has a second portion having at least a length to enable the sun visor structure (1) be positioned in the most extended use-position. The sun visor structure (1) has conductor housing elements (4) for housing the second portion of the conductor. The conductor housing elements (4) are parallel to the pivot rod (2). The conductor housing elements (4) are provided with a longitudinal groove (40), the conductor (3) has continuous conductor cables from the first end to the at least one electrical device and the conductor (3) is transversally folded.

Owner:GRP ANTOLIN ING SA

Iron Golf Club

InactiveUS20050130765A1Lower center of gravityHigh moment of inertiaGolf clubsRacket sportsHigh densityMoment of inertia

The iron golf club head (20) of the present invention is preferably composed of three main components: a periphery member 22, a central member 24 and a face plate 26. The periphery member (22) is preferably composed of a high density material such as a nickel-tungsten alloy. The central member (24) is preferably composed of a lightweight, non-metal material. The face plate (26) is preferably composed of a titanium alloy material. The iron golf club head (20) preferably has high moments of inertia Izz and Ixx.

Owner:TOPGOLF CALLAWAY BRANDS CORP

Hard hydrolysis-resistant, low-pitting performance and strong-peel strength polyurethane resin and preparation method thereof

InactiveCN104356348AImprove and increase peel strengthImprove and increase water resistanceCoatingsTextiles and paperAlcoholOrganic solvent

The invention discloses hard hydrolysis-resistant, low-pitting performance and strong-peel strength polyurethane resin and a preparation method thereof. The preparation method is characterized by comprising the following steps of adding an organic solvent, macromolecular dihydric alcohol, a chain extender, an antioxidant and a part of isocyanate into a reaction kettle according to a proportion, performing reaction for 1 to 2 hours under 60 to 80 DEG C and normal pressure, adding an organic tin or bismuth catalyst, preserving heat, feeding the residual isocyanate in batches into the reaction kettle, supplementing the organic solvent in batches according to the viscosity condition of a reaction system until the viscosity of a product is 80 to 120Pa.s / 25 DEG C, and finally adding a reaction termination agent to obtain a hard hydrolysis-resistant, low-pitting performance and strong-peel strength polyurethane resin product with solid content of 35 to 40 percent. The prepared resin is applied to the production of synthetic leather, and a produced leather product has a solid hand-feel, high hydrolysis resistance and low pitting performance.

Owner:HEFEI ANLI POLYURETHANE NEW MATERIAL

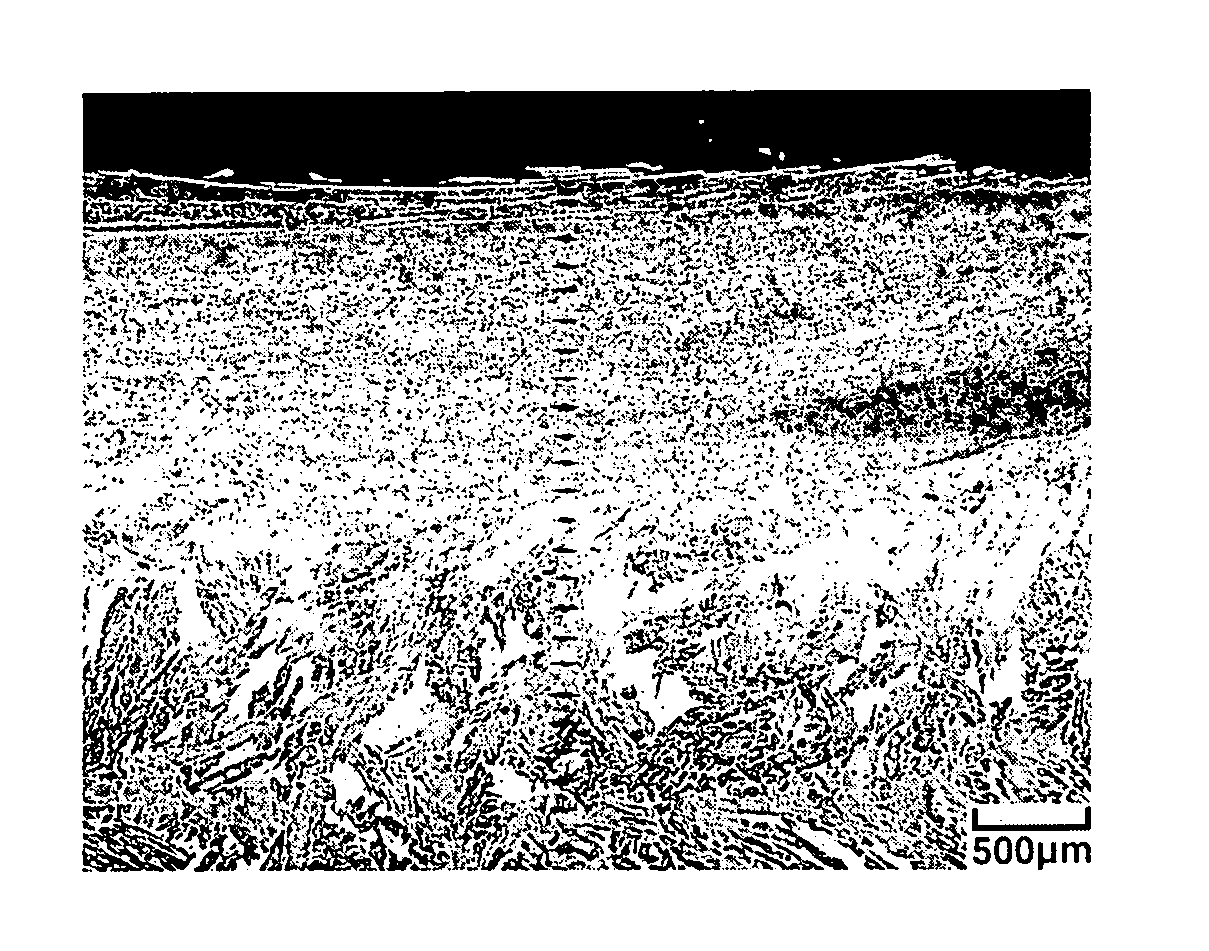

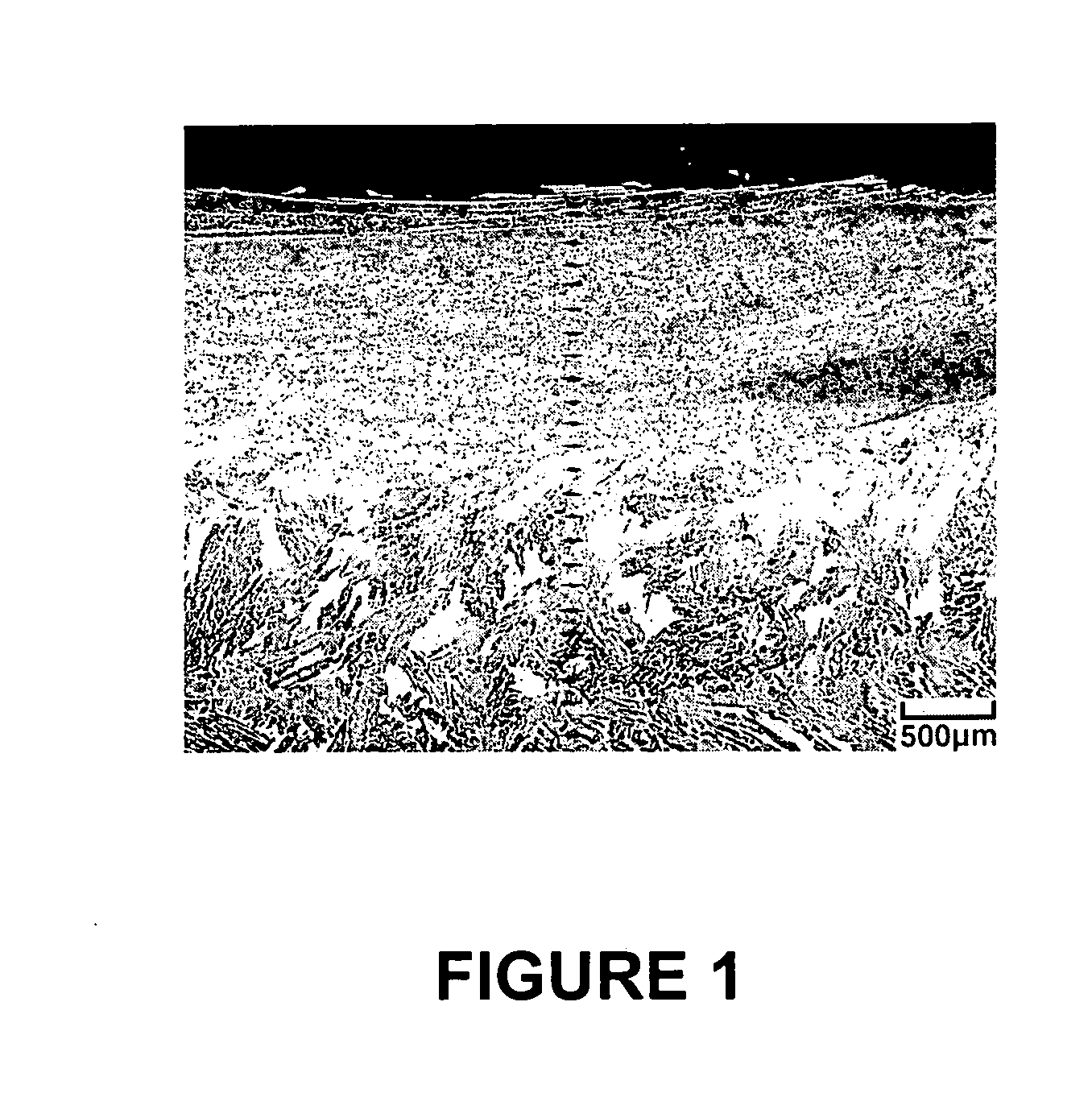

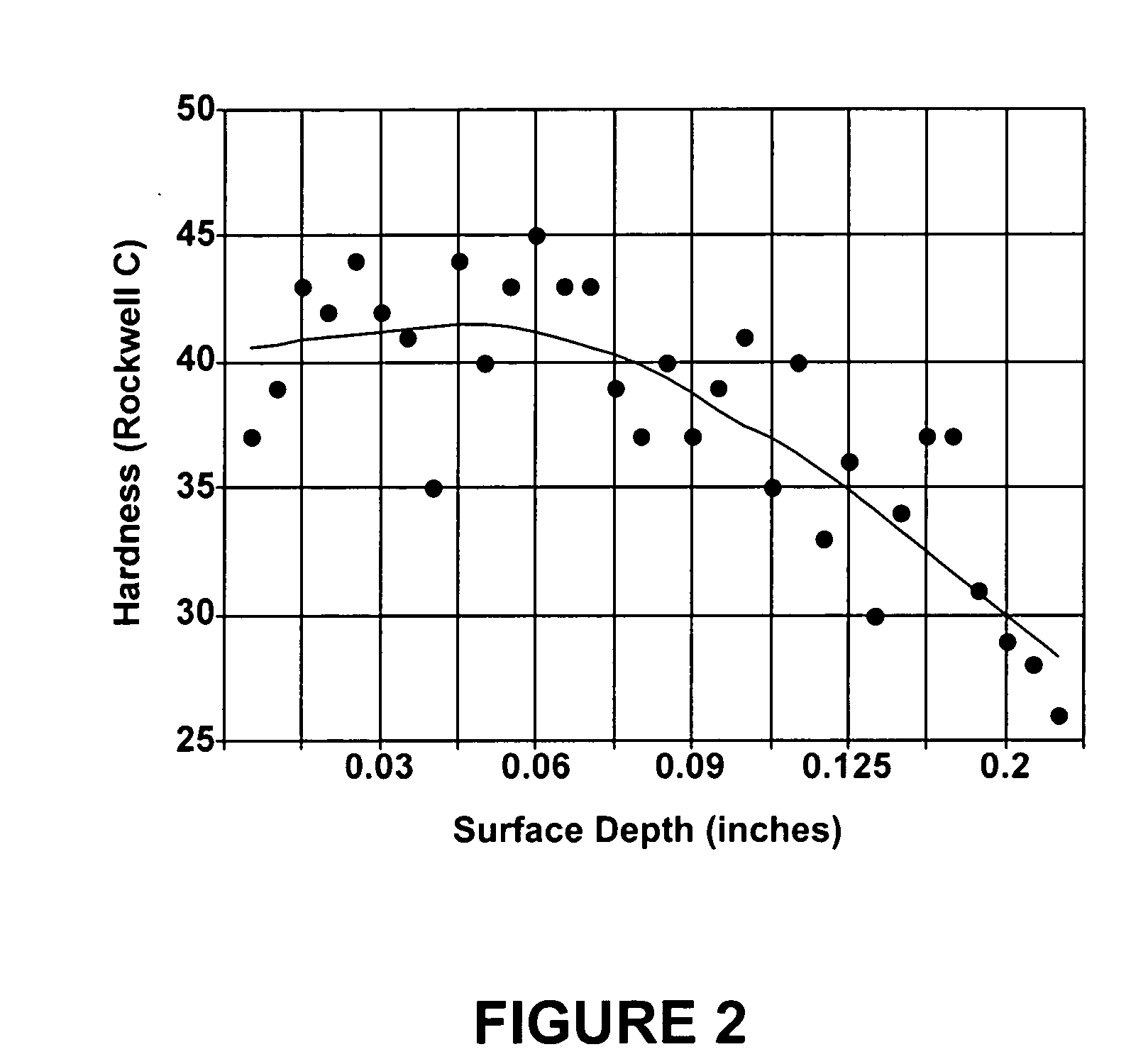

Enhanced golf club performance via friction stir processing

Friction stir processing (FSP) provides a hardened golf club face that more efficiently transfers momentum between the golf club and the ball, increasing the launch velocity so as to provide increased loft (for a given distance traveled by the ball). The FSP hardened face is also more resistant to wear so that the golf club provides more consistent performance and lasts longer. A practice club having a friction stir processed sweet spot on the face may enable the golfer to feel whether the ball has been hit by the sweet spot.

Owner:TELEDYNE LICENSING

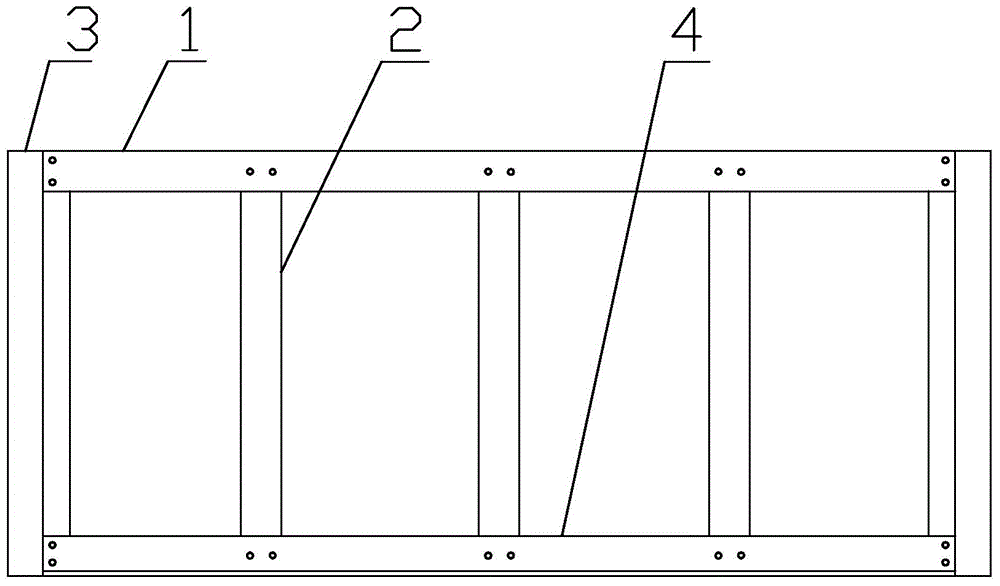

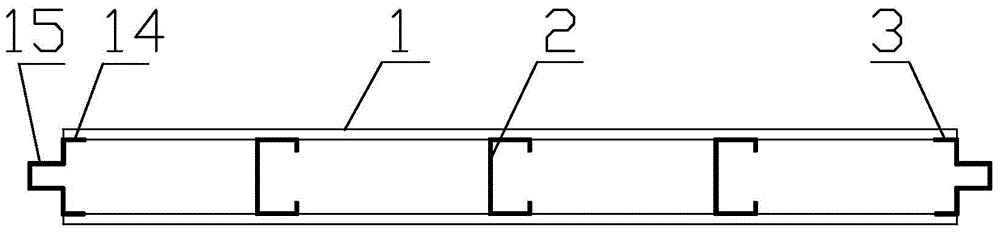

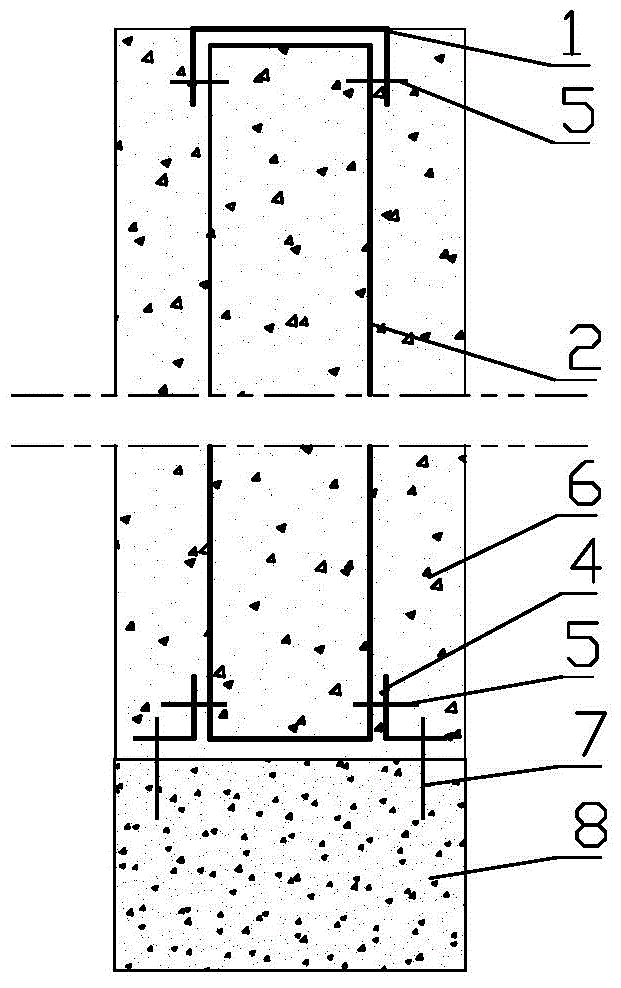

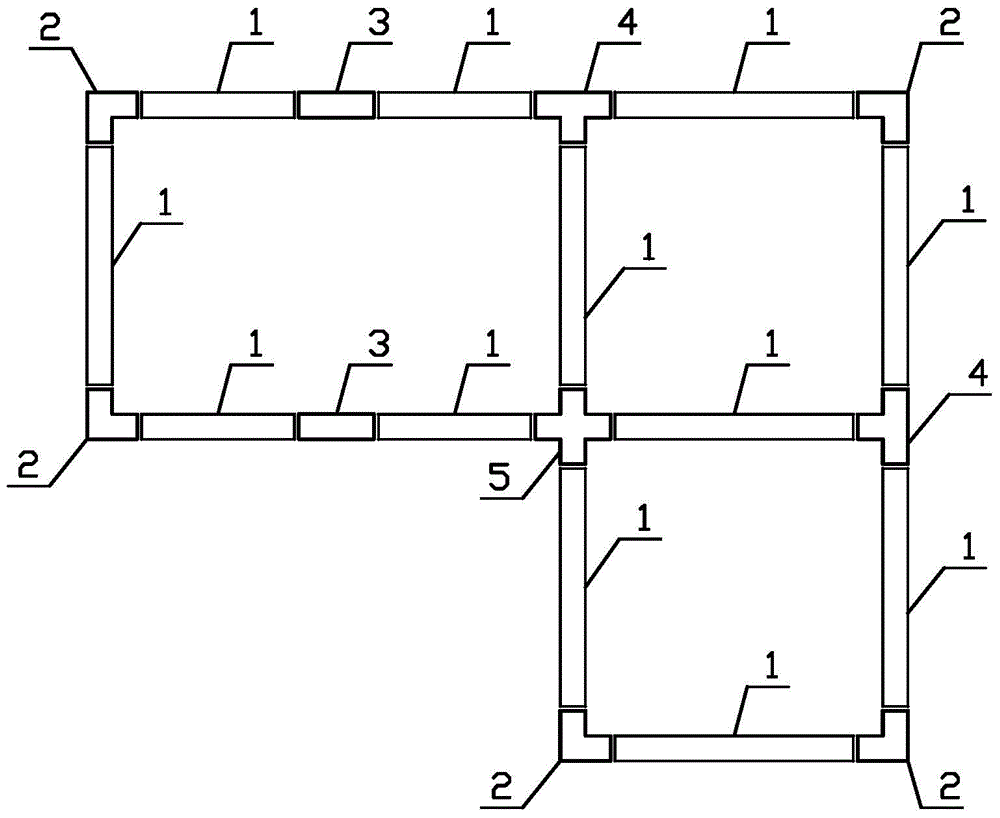

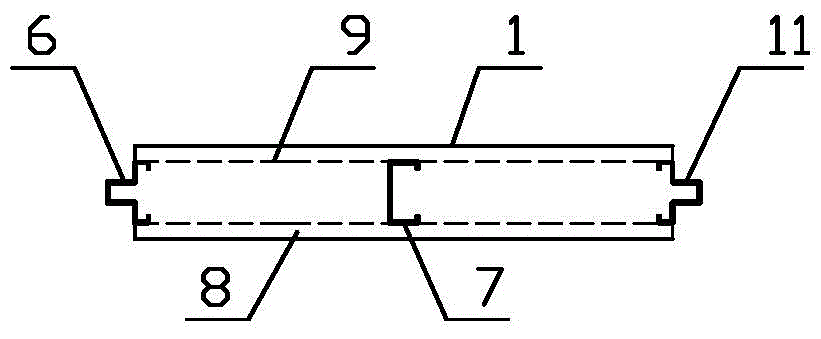

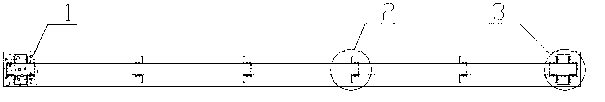

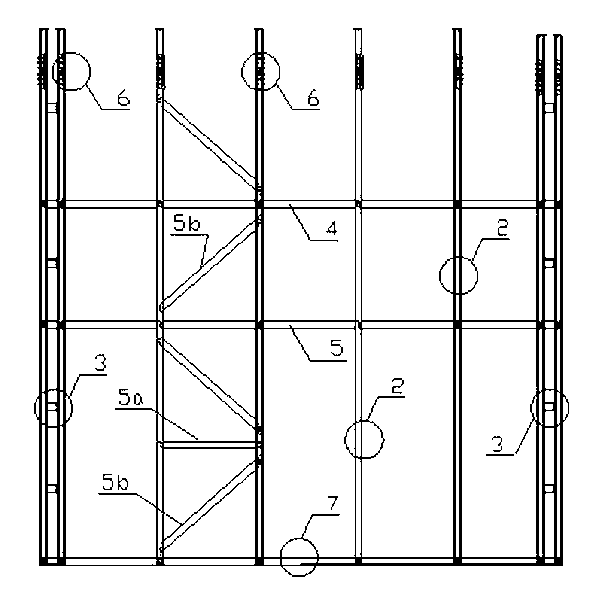

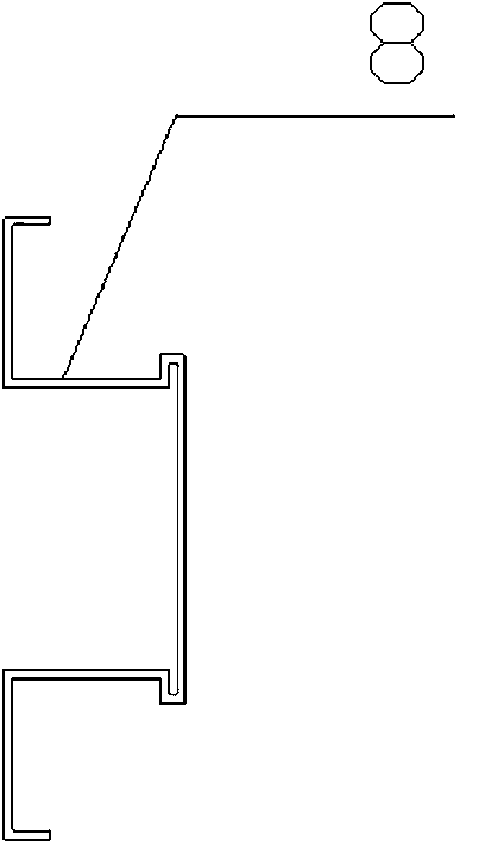

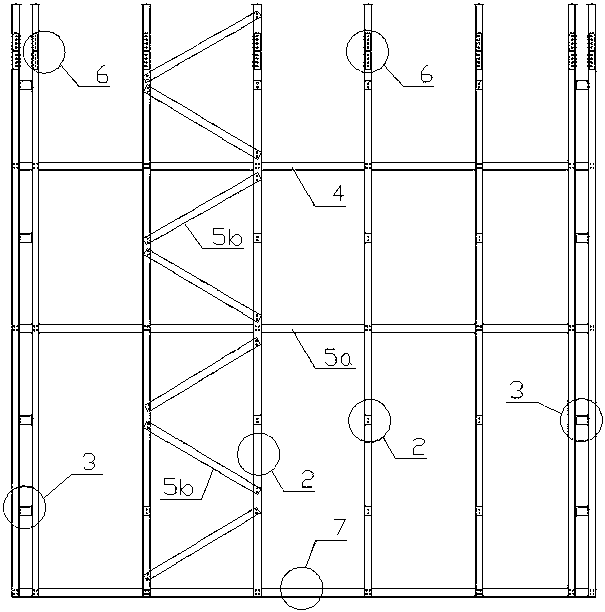

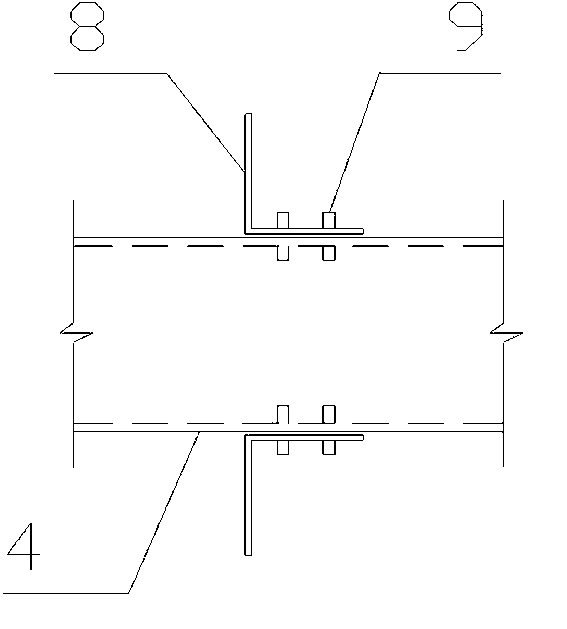

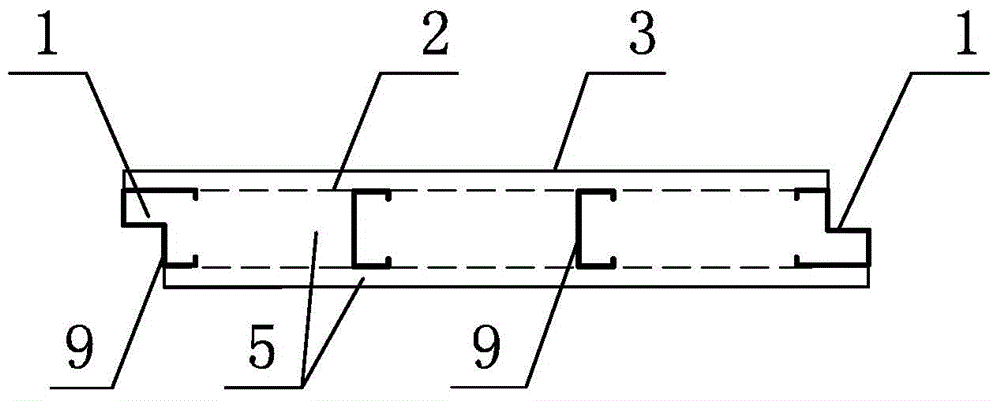

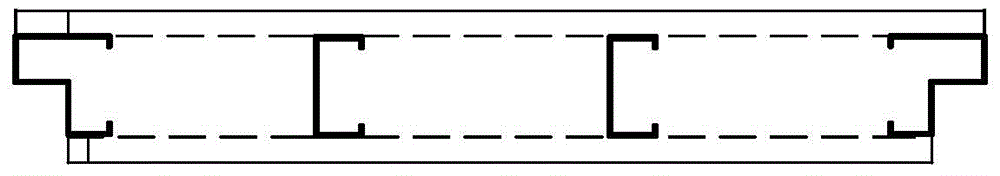

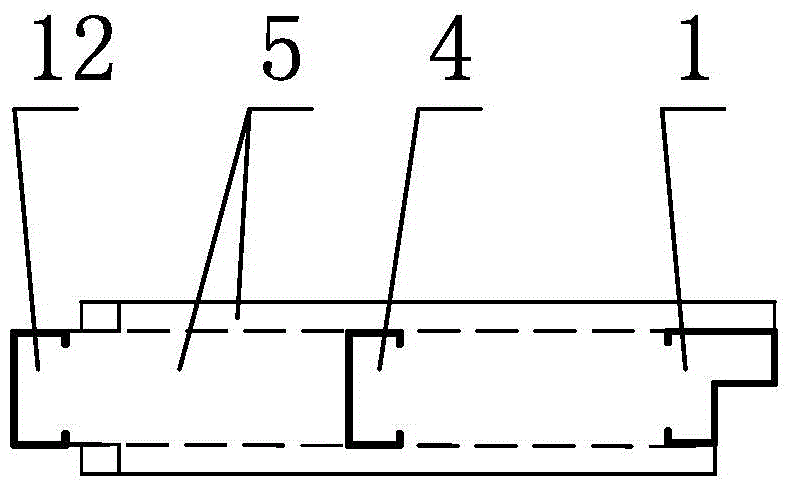

Combined wall formed by single prefabricated wall sections and construction method

Provided are a combined wall formed by single prefabricated wall sections and a construction method thereof. The combined wall is a building wall formed by splicing prefabricated wall sections with set structures through square adapter steel with U-shaped connecting pieces, the prefabricated wall sections are straight wall sections filled with fillers, thin-walled cold-formed steel columns vertically penetrating through the wall is arranged at two ends or two ends and the middle, and outwards-protruding convex cap steel columns are arranged at two ends. The combined wall with the convex cap steel columns is inserted into the U-shaped connecting pieces fixed to the square adapter steel, and screws are fixed and spliced with the square adapter steel and basic embedded bolts to form the wall. Modular installation parts are few, anti-drawing connecting pieces are convenient and quick to install, construction cost is low, and the combined wall is suitable for large-scale production of light steel joist and filler combined houses. Only one type of prefabricated combined walls is adopted, so that the prefabricated combined walls are simple in installation in fields and are light in weight and good anti-seismic property, and errors are not easily made.

Owner:WUHAN SKYSTEEL BUILDING SYST ENG CO LTD

Light steel keel and lightweight concrete prefabricated combining wall and construction method thereof

ActiveCN104790555AReduce calculation lengthNot easy to rustWallsBuilding material handlingKeelSteel columns

The invention discloses a light steel keel and lightweight concrete prefabricated combining wall and construction method thereof. The wall comprises a prefabricated combining straight wall and an L-shaped or a straight or a T-shaped or a cross-shaped prefabricated combining column. The prefabricated combining straight wall and the combining column are fabricated through light steel keels and lightweight concrete. Wall columns at the two ends of a prefabricated combining straight wall keel are protruding steel column sections, and the upper end and the lower end of each wall column are provided with guide rails. The keel of the prefabricated combining column is composed of a concave steel column, an upper end guide rail and a column bottom plate, the concave steel column is connected with a foundation through a base plate and foundation preburied bolts, and protruding steel columns and the concave steel column between the prefabricated combining straight wall and the prefabricated combining column are directly connected through bolts. The wall avoids wet operation of pouring concrete, anti-drawing pieces are convenient to install, wall installation accuracy is easy to control, the manufacturing cost is low, and therefore the wall is suitable for installation of massive light steel keel and lightweight concrete combined houses.

Owner:WUHAN SKYSTEEL BUILDING SYST ENG CO LTD

Image forming apparatus

An image forming apparatus includes a main assembly; a door member which supports one of roller members constituting a feeding nip for a recording material and which is rotatable about an axis parallel with said roller members in a sidewise direction of said main assembly to open said feeding nip; a pair of urging mechanisms which are provided at opposite end portions of said door member with respect to a front-rear direction of said main assembly and which fix said door member to said main assembly so as to be capable of opening and closing said door member, said urging mechanism urging said door member toward said main assembly in a state that said door member is closed; and an operating member provided with a grip for manual opening of said door member, said grip being disposed in a position nearer to a front side than a center portion position of said door member with respect to the front-rear direction, and said operating member being rotatably supported in a position nearer to a rear side than a center position between urging mechanisms.

Owner:CANON KK

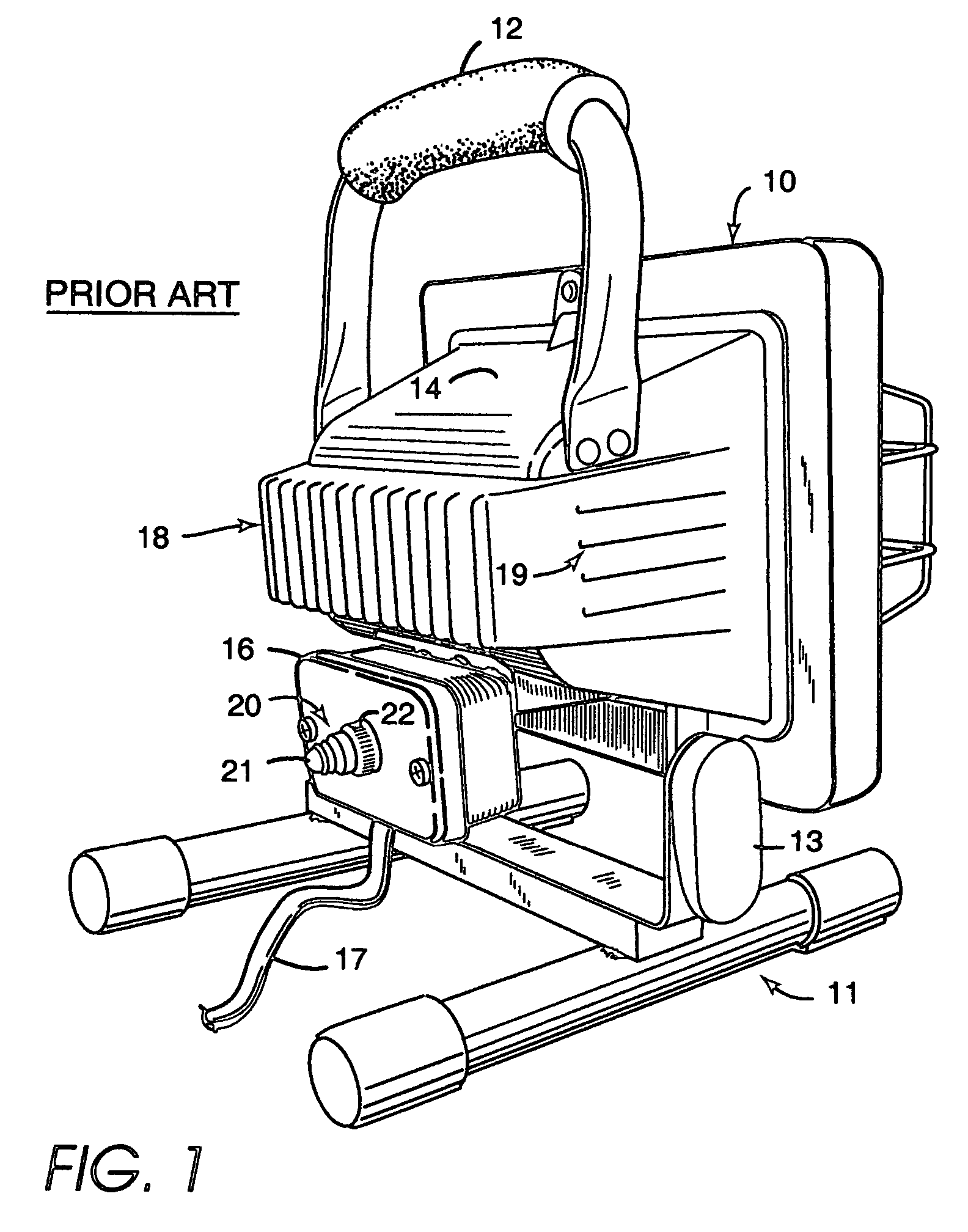

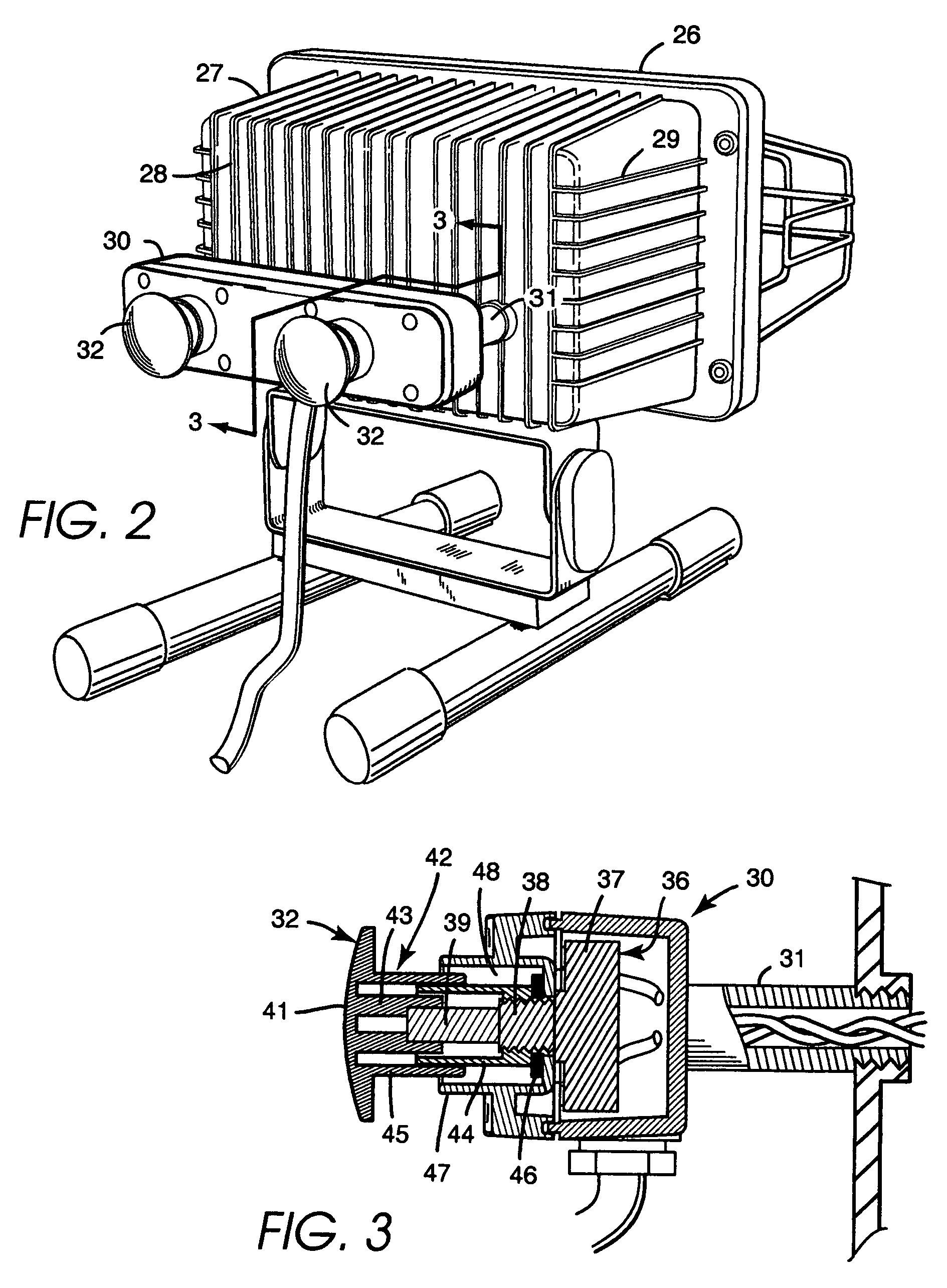

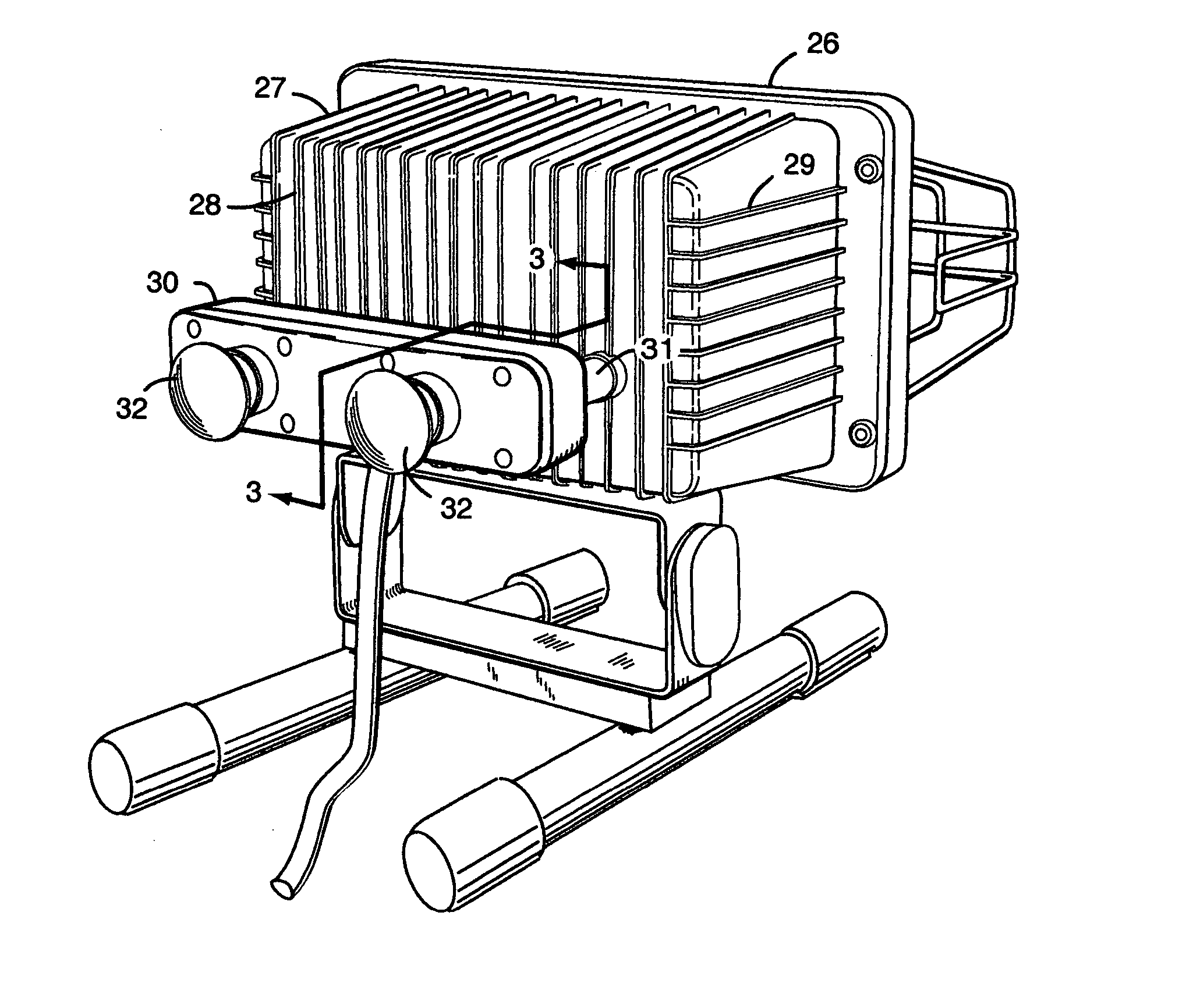

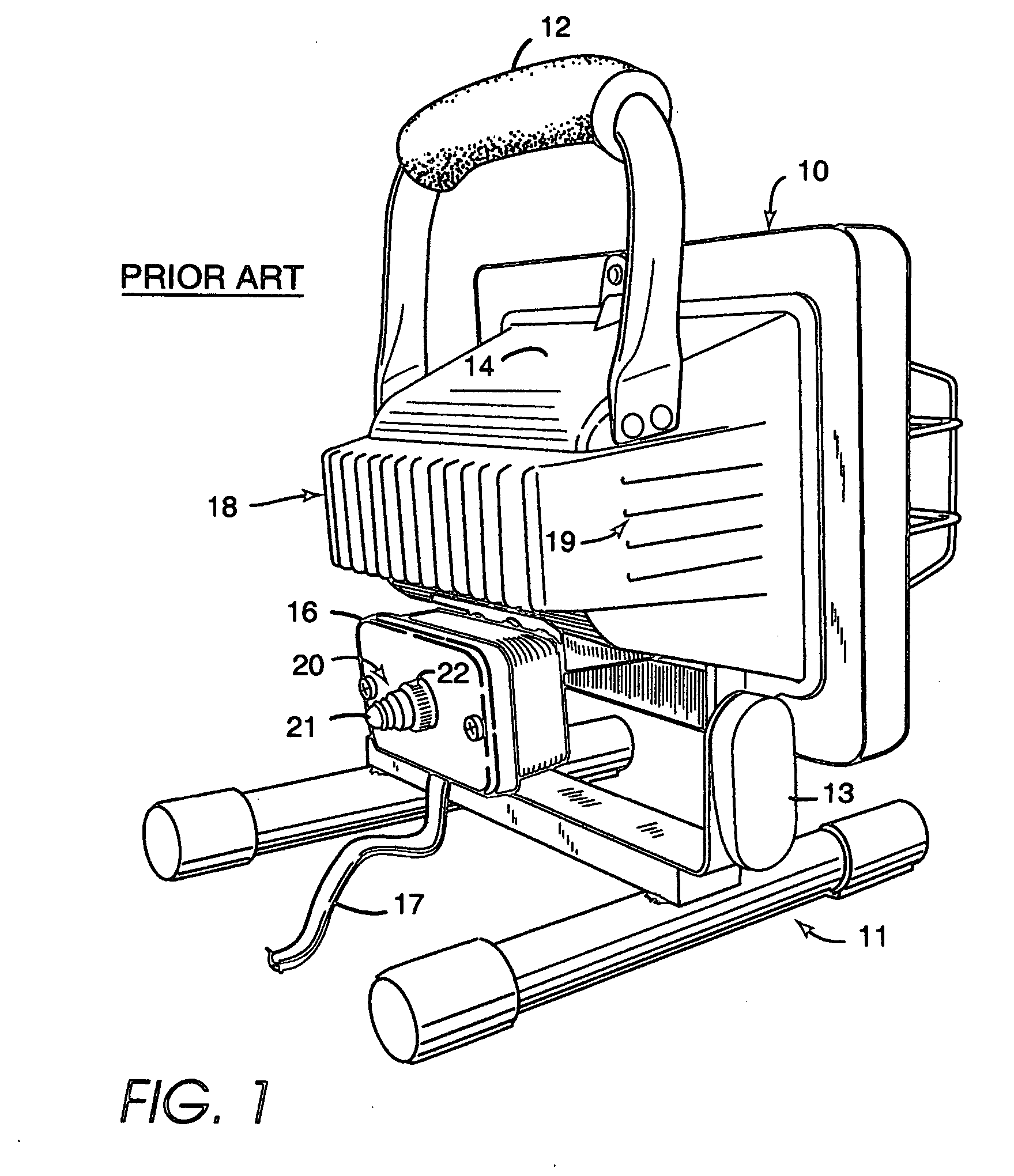

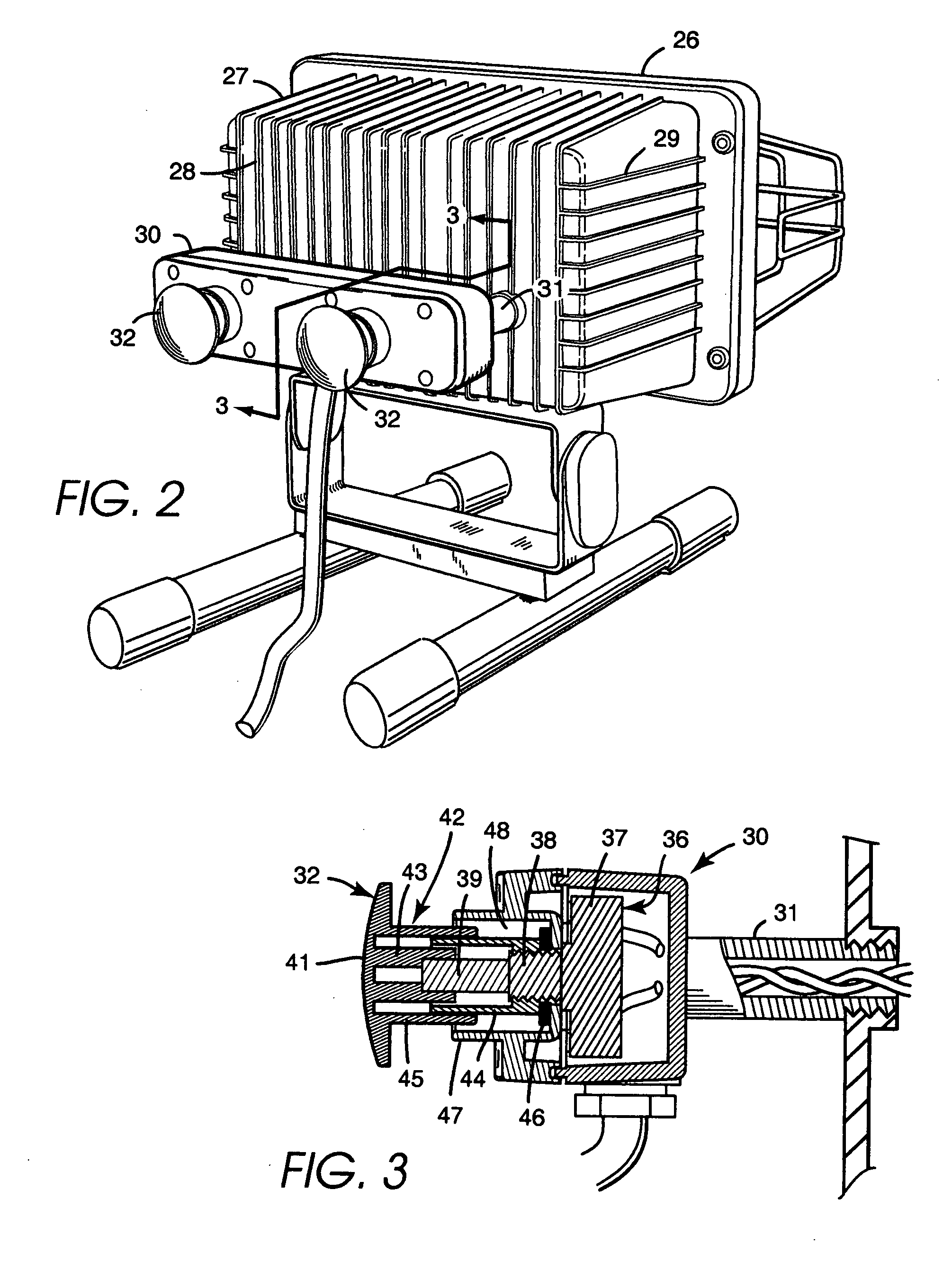

Worklight with ergonomic switch

InactiveUS7579567B2Feel solidGuaranteed ease of operationEmergency actuatorsContact operating partsEngineeringPush-button

An ergonomically designed switch for a halogen worklight. The worklight includes a switch housing attached to the worklight head and a push-action switch mounted in the switch housing for energizing one or more halogen lamps mounted in the worklight head. An ergonomic switch is operated by pressing on a switch button, which is formed to present an ergonomically sized engagement surface to the user. The size of the engagement surface is related to the typical size of a finger pad of the human hand. Through the simple expedient of providing a substantial switch button on the actuating shaft of the switch and sizing the engagement surface of the button to correlate with the size of the human hand, the ease and comfort of operation of the worklight is dramatically improved over worklights having awkward switch mechanisms long thought in the prior art to be unavoidable. The switch button is structured and arranged with a guide assembly to provide stabile travel and a solid feel to the user when activating the switch.

Owner:POLLUX LIGHTING

Capped steel keel and light concrete combined wall

ActiveCN102995790AFacilitate mechanized productionEasy to installWallsEngineeringStructural engineering

The invention discloses a capped steel keel and light concrete combined wall, wherein a capped steel keel is composed of a plurality of sheet columns (2), a plurality of square columns (3), floor ring beams (4), one or more wall waist ring beams (5), wall bracing cross bars and wall bracing diagonal bars; the combined wall is internally provided with the plurality of longitudinally-arranged square columns (3) and the plurality of sheet columns (2); and the floor ring beams (4) and the wall waist ring beams (5) are connected with the sheet columns (2) and the square columns (3) by using screws or bolts after horizontally passing through holes (21) of the sheet columns (2) and the square columns (3) so that a frame structure is formed. Compared with the prior art, the capped steel keel and light concrete combined wall has the advantages of fewer connecting parts, high production mechanization level, simplicity in field assembly, low cost and the like so as to have favorable application prospect.

Owner:WUHAN UNIV OF TECH

Adjustable golf club system

An adjustable golf club system is described herein. The adjustable golf club system includes a club shaft, a club head, a hosel, and an adjustment assembly that is removably coupled to the club head and the hosel to facilitate adjusting an orientation of the hosel with respect to the club head. The club head includes a club head cavity that extends between a toe portion and a heal portion. The hosel includes a first end that is coupled to the club shaft and a second end that includes a fastener head. The adjustment assembly includes a sliding member and a hosel fastener that is coupled to the sliding member. The sliding member is positioned within the club head cavity and movable between the toe portion and the heal portion. The hosel fastener extends through the fastener head to the sliding member to couple the hosel to the club head.

Owner:ESPOSITO BRIAN

Combined wall with angle steel keel combined with light concrete

The invention discloses a combined wall with an angle steel keel combined with light concrete. The light concrete is foam concrete, ceramsite concrete, perlite concrete, polyphenyl granule concrete, coal ash concrete and the like. The angle steel keel is formed by connecting densely arranged angle steel sheet columns and square columns through a floor ring beam, a wall waist ring beam, a wall bracing truss and a screw or a bolt. The sheet column or the square column is formed from an angle steel chord member with a turned edge or not, a square (rectangular) pipe, an angle steel, a channel steel connecting piece or a stamped part through connection by means of a screw or a bolt or through bonding spot welding. The floor ring beam, the wall waist ring beam and the wall bracing truss are fabricated from square (rectangular) pipes and channel steels. The break of the angle steel chord member is formed from an angle steel jointing connecting piece through connection by using a screw or a bolt or through bonding spot welding. An angle steel guide rail is connected with a foundation ring beam chemically or through an embedded bolt. The sheet columns and the square columns are connected with the guide rail directly through a screw and a bolt or through bonding spot welding. The combined wall provided by the invention has the advantages of high bearing capability, simplicity in production and assembly, good fireproof and corrosive resisting performance, low manufacturing cost and the like.

Owner:WUHAN UNIV OF TECH

Worklight with ergonomic switch

InactiveUS20070227871A1Feel solidGuaranteed ease of operationEmergency actuatorsContact operating partsPush-buttonHalogen lamp

An ergonomically designed switch for a halogen worklight. The worklight includes a switch housing attached to the worklight head and a push-action switch mounted in the switch housing for energizing one or more halogen lamps mounted in the worklight head. An ergonomic switch is operated by pressing on a switch button, which is formed to present an ergonomically sized engagement surface to the user. The size of the engagement surface is related to the typical size of a finger pad of the human hand. Through the simple expedient of providing a substantial switch button on the actuating shaft of the switch and sizing the engagement surface of the button to correlate with the size of the human hand, the ease and comfort of operation of the worklight is dramatically improved over worklights having awkward switch mechanisms long thought in the prior art to be unavoidable. The switch button is structured and arranged with a guide assembly to provide stabile travel and a solid feel to the user when activating the switch.

Owner:POLLUX LIGHTING

Light prefabricated combined wall

The invention discloses a light prefabricated combined wall. Three kinds of light prefabricated wall sections with identical composition are spliced through adapting steel columns or directly through bolts / self-tapping screws to from a straight combined wall, an L-shaped wall, a T-shaped wall or a cross-shaped wall; the light prefabricated wall sections are straight wall sections as a whole, a plurality of vertical steel wall columns, upper guide rails transversely connected with tops of the steel wall columns and upper guide rails transversely connected with two sides of bottoms of the steel wall columns respectively form a framework, and the wall sections are filled with light concrete; L-shaped steel wall columns or C-shaped steel wall columns are arranged at two ends of each light prefabricated wall section. With the adoption of the prefabricated combined wall, the wet operation of in-place concrete pouring is avoided, anti-pull connecting pieces are convenient to mount, the wall mounting accuracy is easy to control, the construction cost is low, and the prefabricated combined wall is suitable for mass production of light steel keel and light concrete combined houses.

Owner:WUHAN SKYSTEEL BUILDING TECH

Iron golf club

InactiveUS20050187032A1Lower center of gravityHigh moment of inertiaGolf clubsRacket sportsHigh densityEngineering

The iron golf club head (20) of the present invention is preferably composed of three main components: a periphery member 22, a central member 24 and a face plate 26. The periphery member (22) is preferably composed of a high density material such as a nickel-tungsten alloy. The central member (24) is preferably composed of a lightweight, non-metal material. The face plate (26) is preferably composed of a titanium alloy material. The iron golf club head (20) preferably has high moments of inertia Izz and Ixx.

Owner:TOPGOLF CALLAWAY BRANDS CORP

Putter Type Golf Club

InactiveUS20200139205A1Improve stabilityReduce vibrationGolf clubsRacket sportsControl theoryGolf club

A putter type golf club having a putter head and elongated, solid metal shaft attached thereto. A grip fixture is attached to an upper section of the elongated shaft and a golf grip is attached to and overlies the grip fixture forming a solid connection between the shaft, the grip fixture and the grip.

Owner:DIEPENBROCK JR WILLIAM R

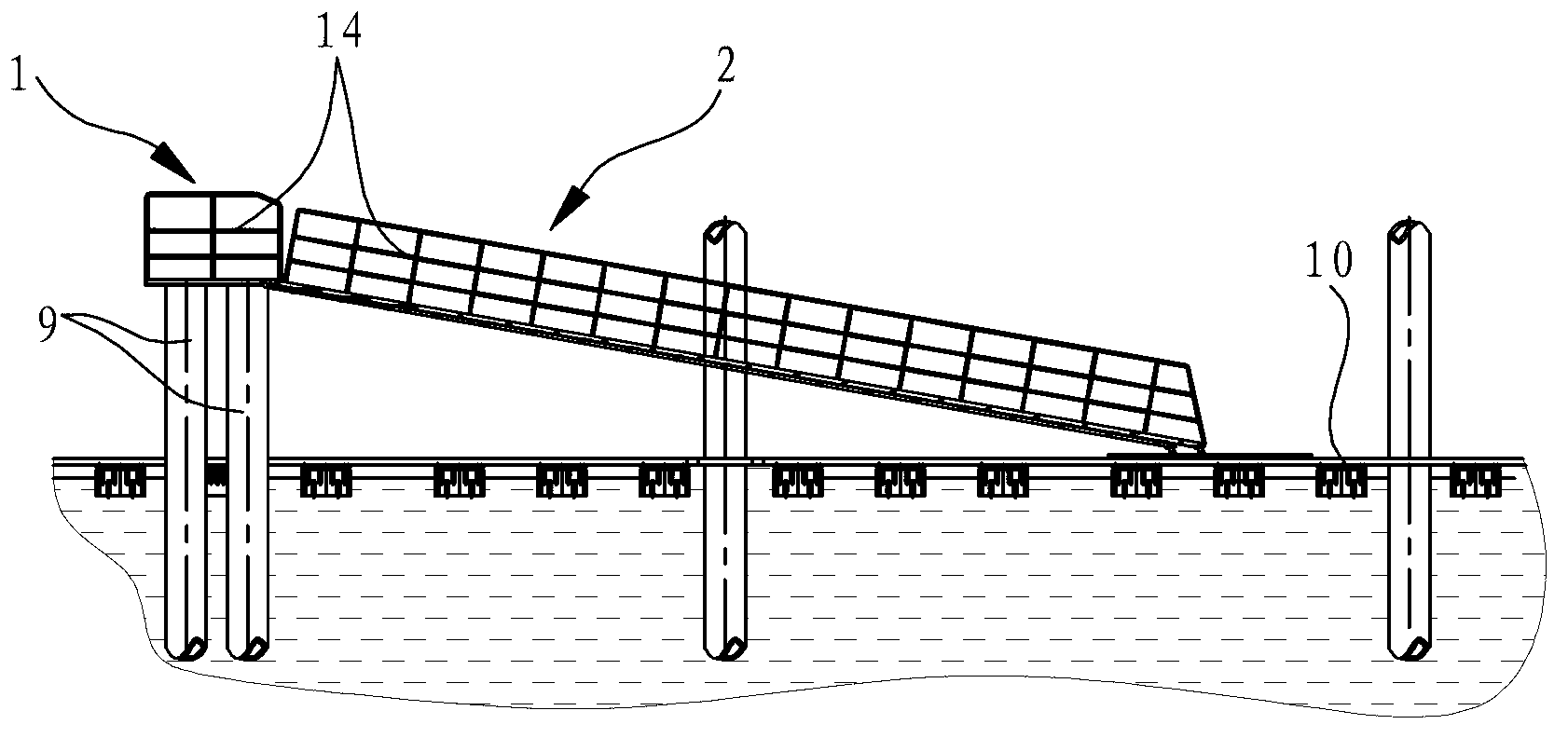

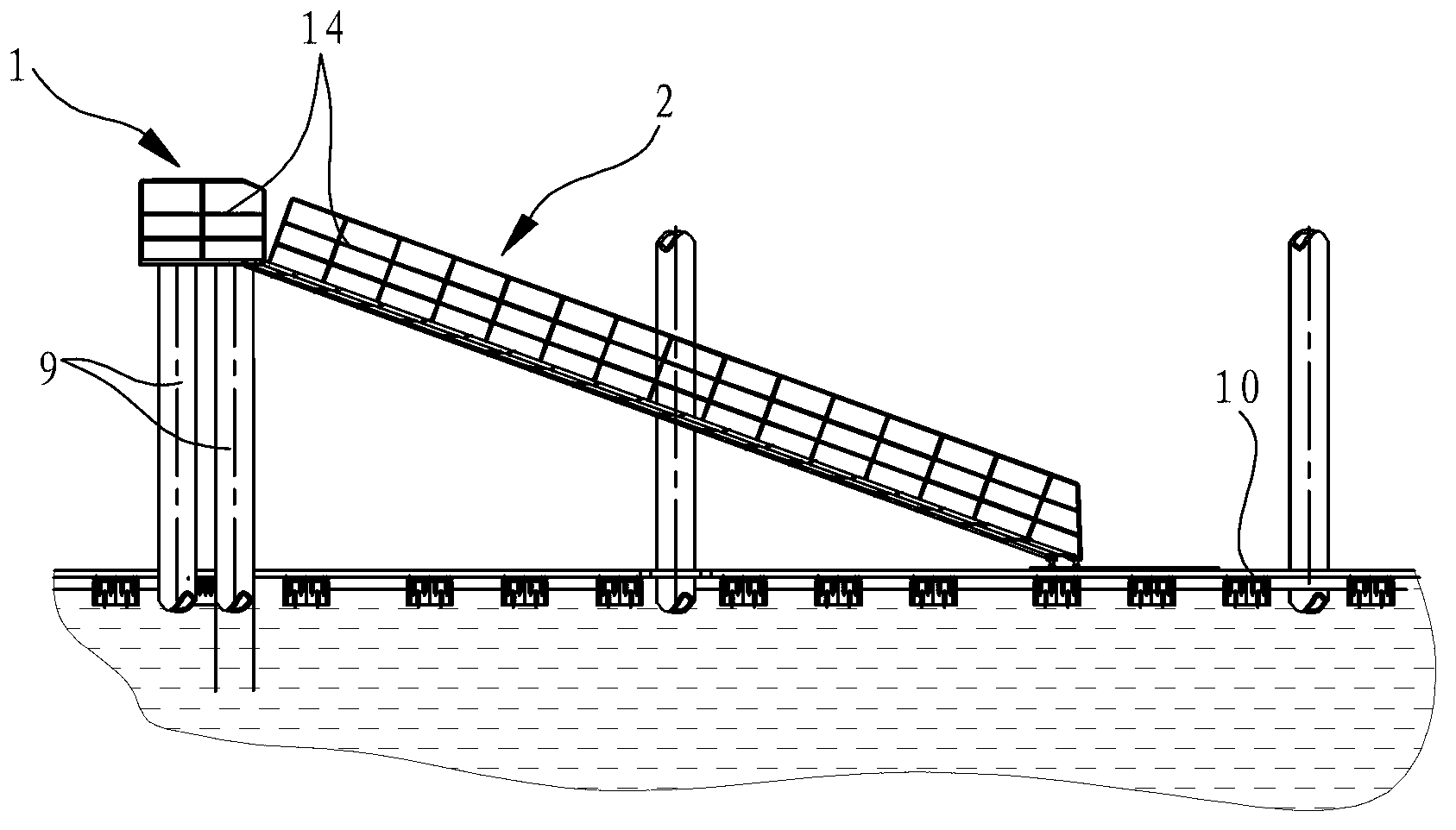

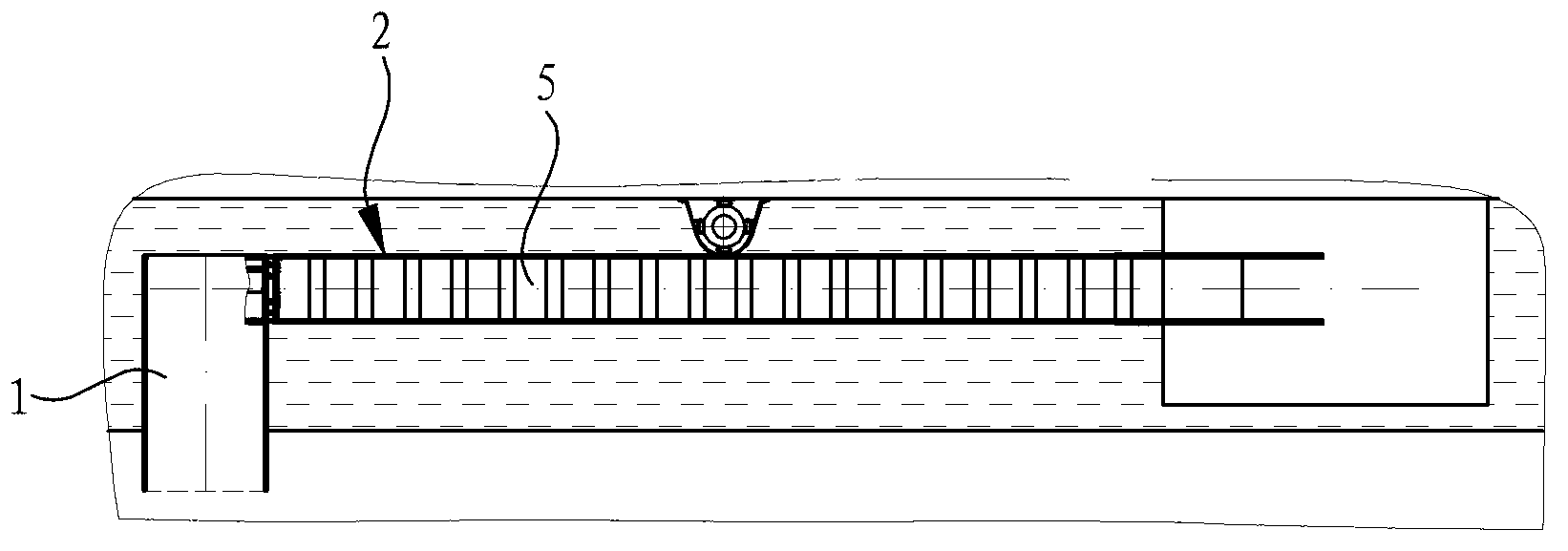

Movable ladder for floating wharf

The invention relates to a movable ladder for a floating wharf. The movable ladder comprises a fixed section and a movable section. The movable ladder is characterized in that the movable section comprises two upper beam frames, two lower beam frames, step pedals, first pulleys and second pulleys, wherein the two upper beam frames are in parallel and obliquely arranged at both sides of the movable ladder, and the top ends of the two upper beam frames are articulated with the fixed section through hinge shafts; the two lower beam frames are in parallel and obliquely arranged at both sides of the movable ladder; the step pedals are sequentially and horizontally arranged between the upper beam frames and the lower beam frames at intervals from top to bottom, and both sides of the step pedals are respectively articulated with the upper beam frames and the lower beam frames; the first pulleys are arranged on the bottom ends of the upper and lower beam frames and positioned in pulley sliding grooves in a floating bridge; the second pulleys are arranged on the top ends of the lower beam frames and positioned in a guide sliding groove in the fixed section; and pulley shafts of the second pulleys and the hinge shafts are positioned at a same horizontal height. According to the invention, a light movable ladder shape is adopted, a parallelogram principle is applied, and a step surface is kept almost parallel with a horizontal plane all the time during tide rising and ebbing, so that the potential safety hazards of wharfmen on the wharf floating up or down are greatly reduced.

Owner:ZHEJIANG OCEAN UNIV

Watercolor ink composition for writing utensils and method for producing it

A watercolor ink composition for writing utensils comprising at least an alkali-soluble acrylic copolymer, a lower alcohol solvent, water, and a coloring material wherein the alkali-soluble acrylic copolymer has a molecular weight of from 7000 to 15,000, an acid value of from 30 to 100, and a glass transition point of from −10 to 60° C. The watercolor ink composition for writing utensils that has colored or colorless transparency in appearance and has both transparent feeling and solid feeling in handwriting can be provided.

Owner:TOMBOW PENCIL CO LTD

Back row foot air blowing pipe for vehicle and vehicle having same

InactiveCN106808974AFeel solidImprove the ride experienceAir-treating devicesVehicle heating/cooling devicesEngineering

The invention discloses a back row foot air blowing pipe for a vehicle and a vehicle having the same. The back row foot air blowing pipe is arranged on a floor of the vehicle; the back row foot air blowing pipe avoids an underfoot zone of passengers on a front row seat; the back row foot air blowing pipe includes a front section, a connection section and a back section; the connection section is connected between the front section and the back section; the front section is arranged near a floor central channel of a floor; the connection section is arranged near a seat cross beam of a front row seat; and the back section extends backward and blows air to passengers on the back row seat. The back row foot air blowing pipe can ensure a stable feeling of the passengers on the front row seat, can protect the back row foot air blowing pipe from being broken by stepping of the passengers on the front row seat, can ensure the air outlet capacity of the back row foot air blowing pipe, and can improve the riding experience of the passengers.

Owner:BAIC MOTOR CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com