Capped steel keel and light concrete combined wall

A lightweight concrete, combined technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of affecting the integrity and bearing capacity of the wall, many connecting parts and screws, affecting the efficiency of structural production and installation, etc. The effect of high force, few connecting parts and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Below in conjunction with example the present invention will be further described, but not limited to the content described below.

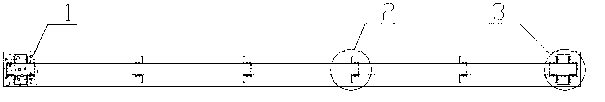

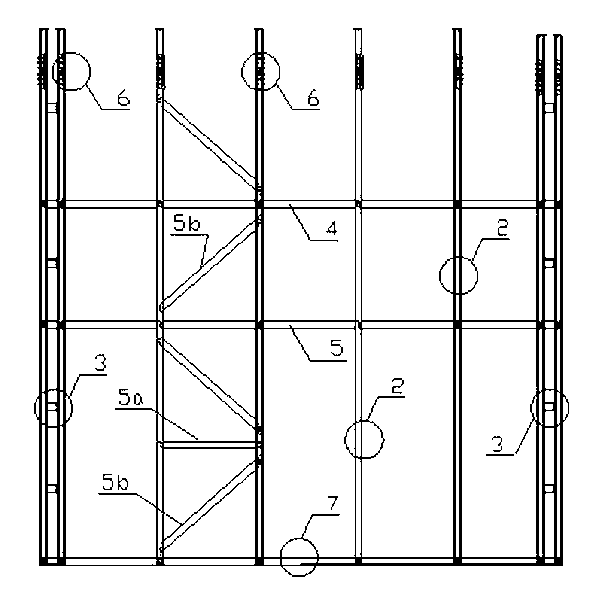

[0059] The composite wall combined with hat steel keel and lightweight concrete provided by the invention can be used for low-rise and multi-storey houses, and its structure is as follows: figure 1 and figure 2 As shown, it is composed of lightweight concrete 1 and hat steel keel.

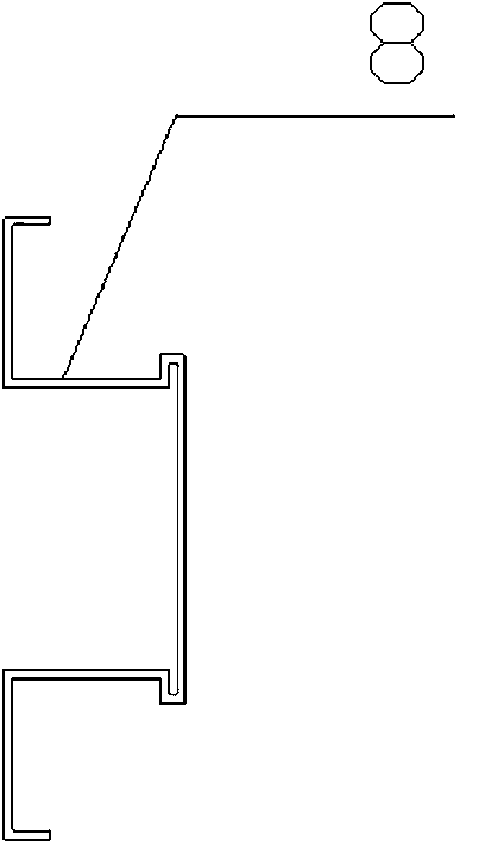

[0060] The structure of the hat steel keel is as follows figure 2 As shown, it is composed of sheet columns 2, square columns 3, floor ring beams 4, wall waist ring beams 5, wall support cross bars 5a and wall support diagonal bars 5b, wherein: inside the wall, a number of longitudinally arranged Square column 3 and a plurality of sheet columns 2. The floor ring beam 4 and the wall waist ring beam 5 cross the hole 21 on the upper flange of the sheet column 2 and the square column 3 and are connected by connectors 20 to form a frame structure. The connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com