Stable-typed fusible safe resistor and production method thereof

A safety resistor and stable technology, which is applied in the manufacture of fuses, wound resistance elements, spiral coil/screw disk resistance elements, etc., can solve the problem that the winding distance and length of the alloy wire are not specified, and the resistor cannot be quickly melted and burned. Problems such as fire associated with bad equipment, to achieve the effect of reasonable structural design, easy mechanized production, and prevention of collision connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

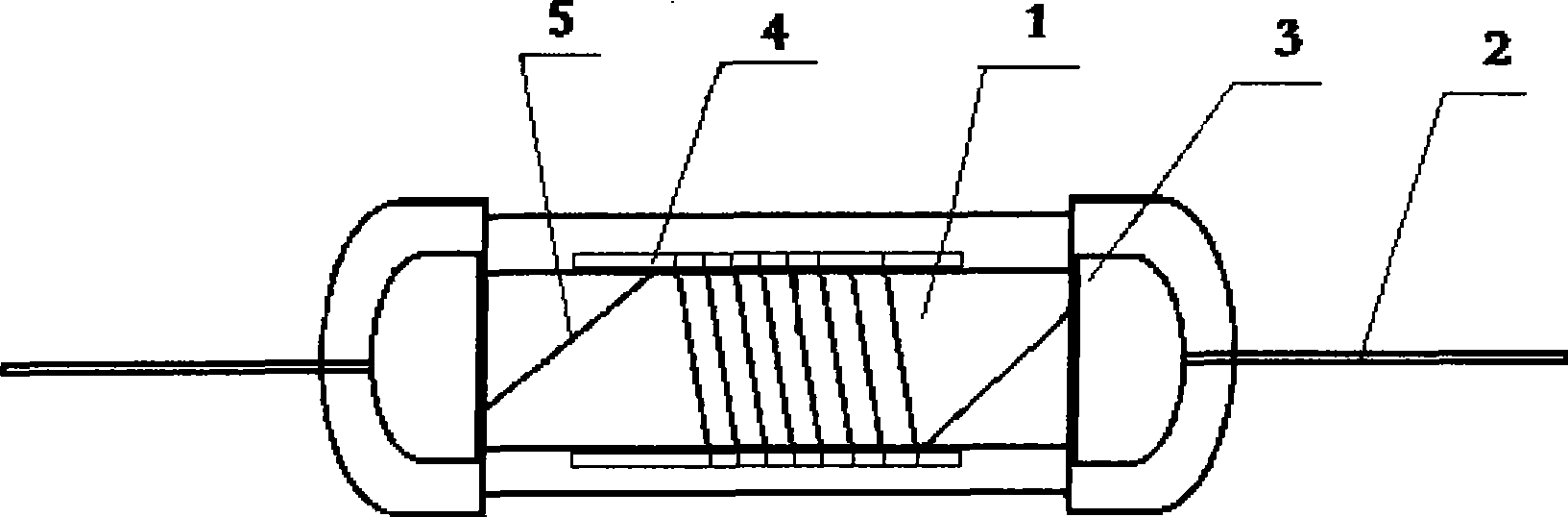

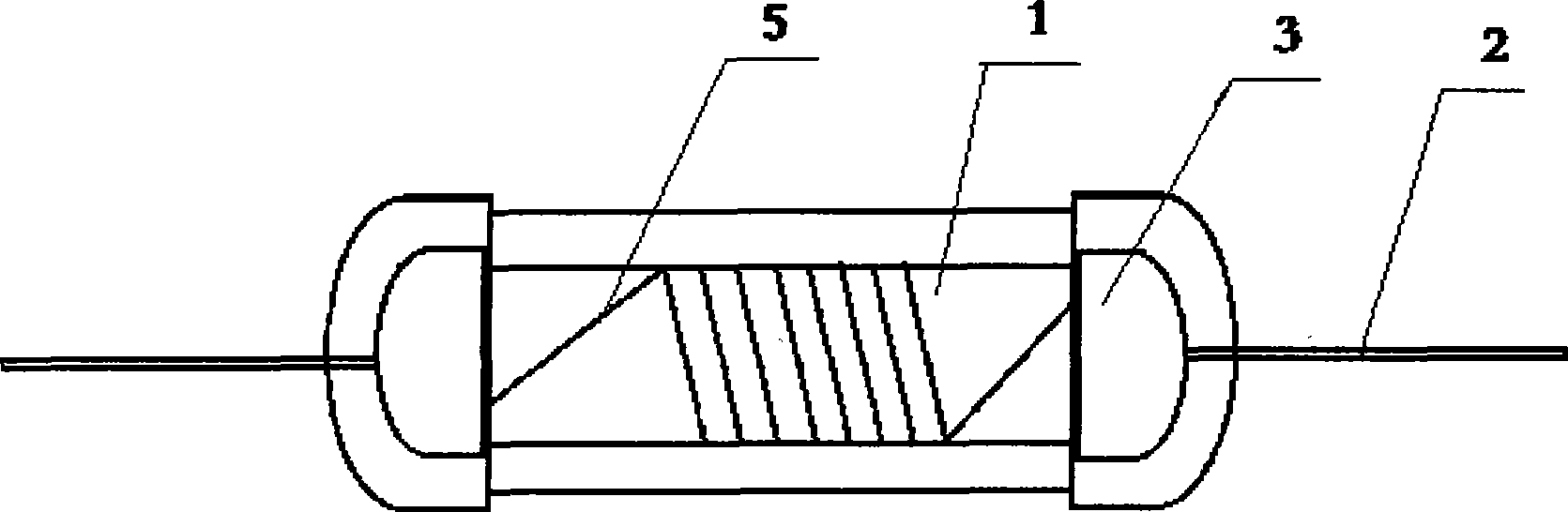

[0035] Below in conjunction with accompanying drawing, the present invention will be further described:

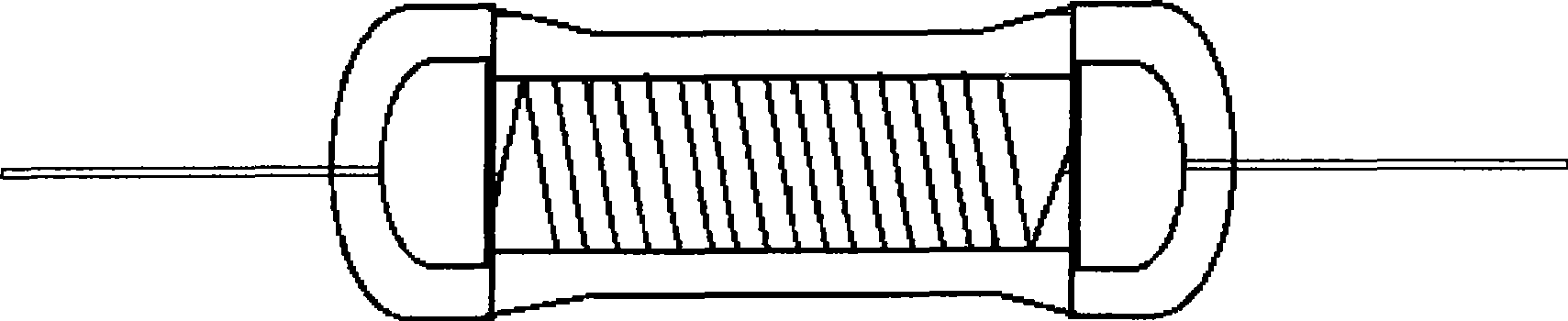

[0036] Such as figure 2 As shown, a stable fusible safety resistor of the present invention is composed of an electric porcelain rod body 1 and a cap body 3 arranged at both ends of the electric porcelain rod body 1 and connected with a wire 2. Among the components of the electric porcelain rod 1, oxidation The aluminum content is below 75%, and its main specifications are 2*7, 2*8, 2.5*8, 3.0*8, 3.0*10, 3.5*10, etc. In the present invention, a paint layer 4 is spray-coated on the middle part of the electric porcelain rod body 1, and the paint layer 4 is made of silicone resin paint, for example, the silicone resin non-flammable paint produced by Qingdao Dazhou Electronics and its Korean headquarters. The spraying length of the paint layer 4 accounts for 10% to 90% of the length of the insulator rod, and the outer surface of the paint layer 4 is wound with alloy wires 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com