Patents

Literature

42results about How to "Installation accuracy is easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

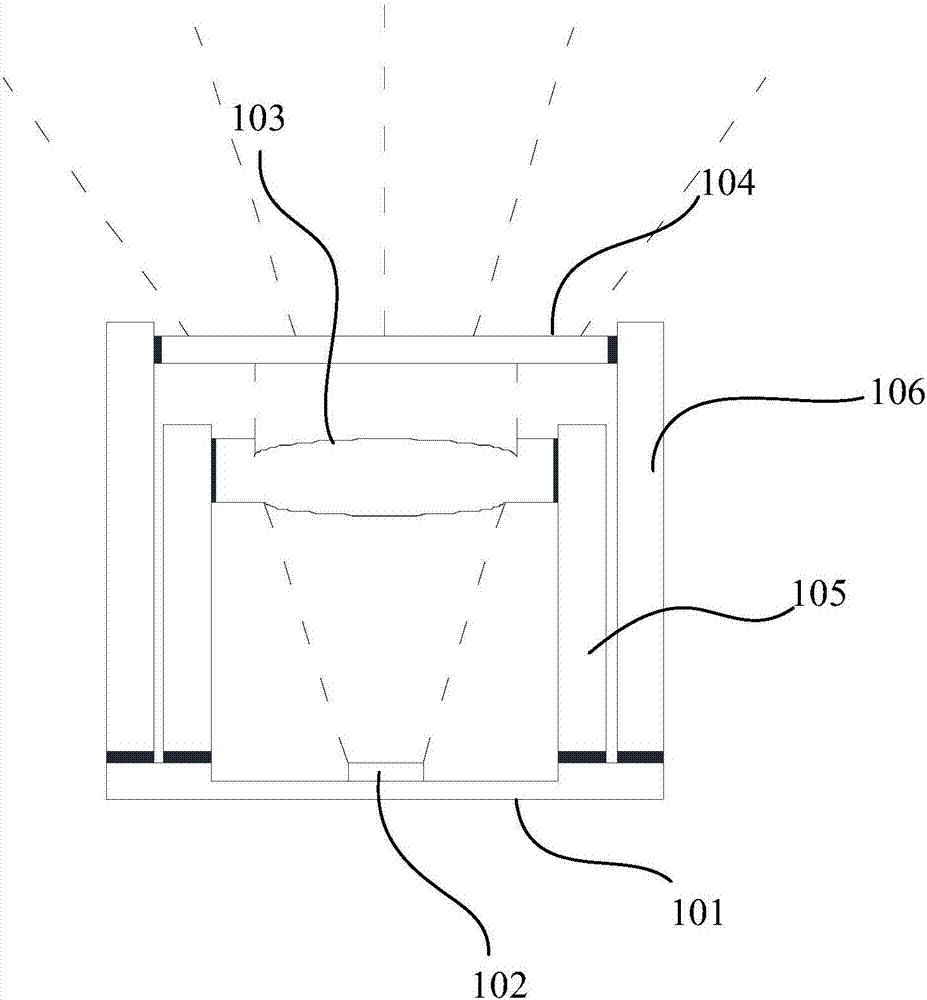

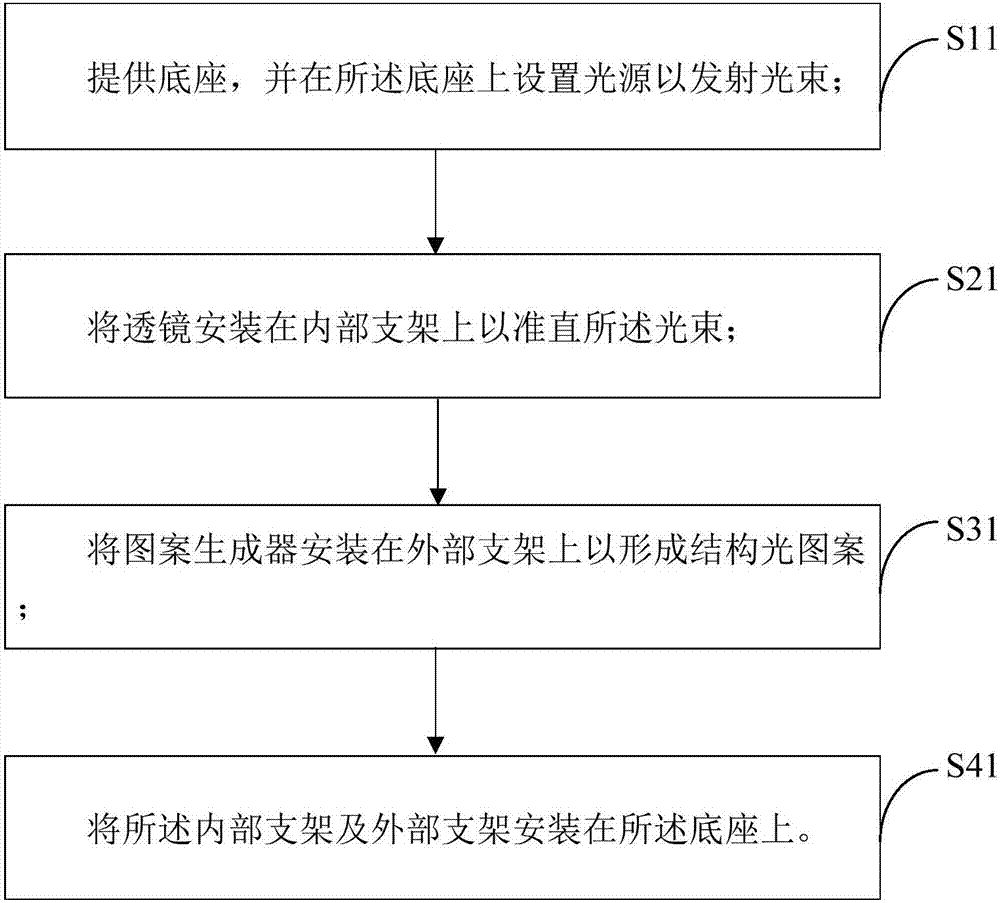

Projection module and manufacturing method therefor and depth camera

PendingCN107229173AMiniaturizationGuaranteed performanceProjectorsCamera body detailsForeign matterMiniaturization

Embodiments of the invention relate to the photoelectric technical field, and provide a projection module and a depth camera. The projection module comprises a base, a light source, a lens supported by an internal bracket, and a pattern generator supported by an external bracket for generating structural optical patterns, wherein the internal bracket and the external bracket are independent non-integrated structures; the internal bracket and the external bracket are mounted on the base; the projection module adopts the internal bracket to support the lens, and adopts the external bracket to bear the pattern generator; the internal bracket and the external bracket are independent structures, so that installation of the lens and the pattern generator can be performed separately without causing mutual constraint; when the internal bracket equipped with the lens and the external bracket equipped with the pattern generator are mounted on the base, the relative positions of the light source, the lens and the pattern generator can be adjusted in a relative easy manner, the installation precision can be controlled easily, the installation efficiency is high and the miniaturization of the depth camera can be facilitated; and in addition, falling off of foreign matters, such as dust and chippings and the like, in the installation process can be avoided, and the lens performance can be ensured.

Owner:SHENZHEN ORBBEC CO LTD

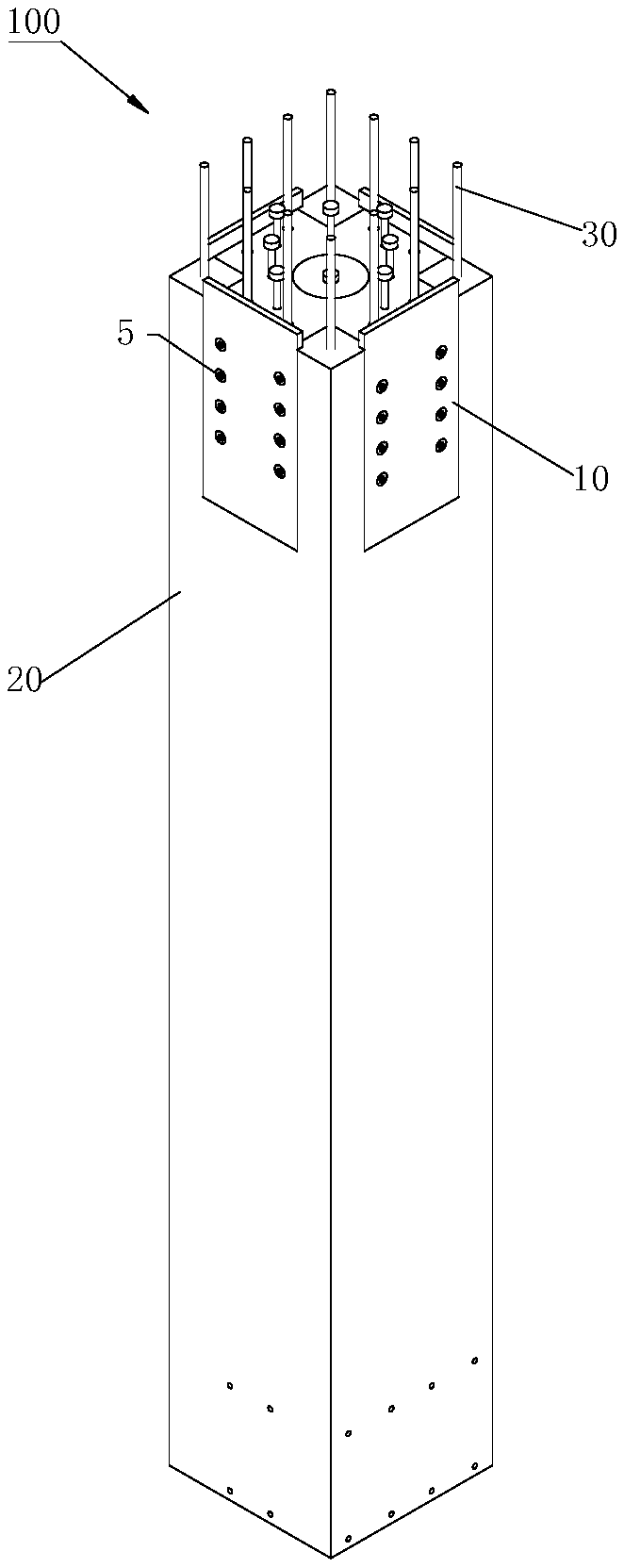

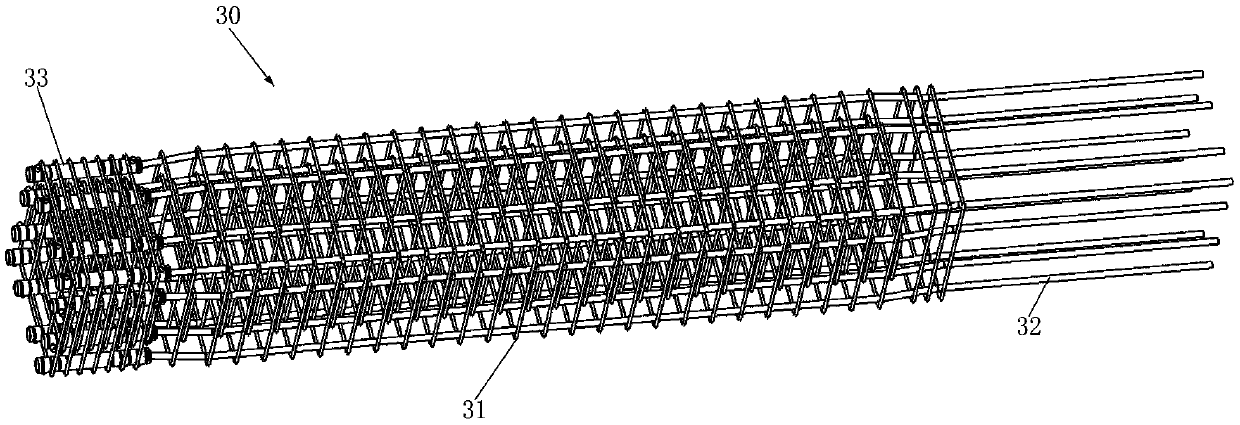

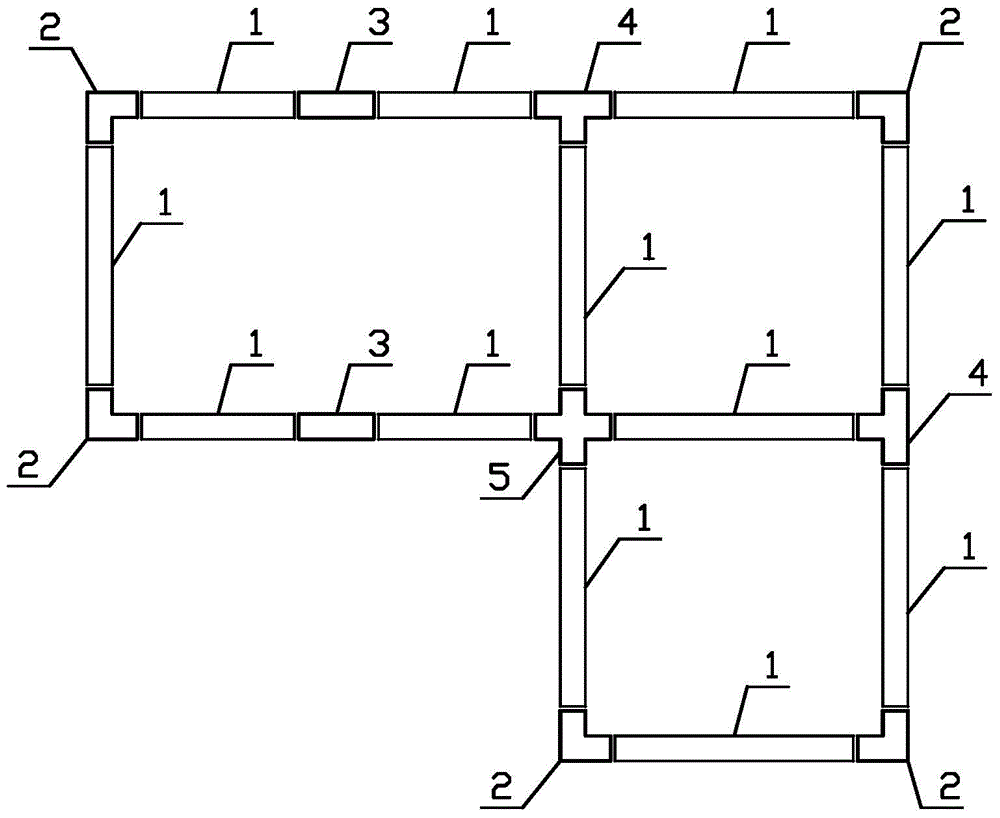

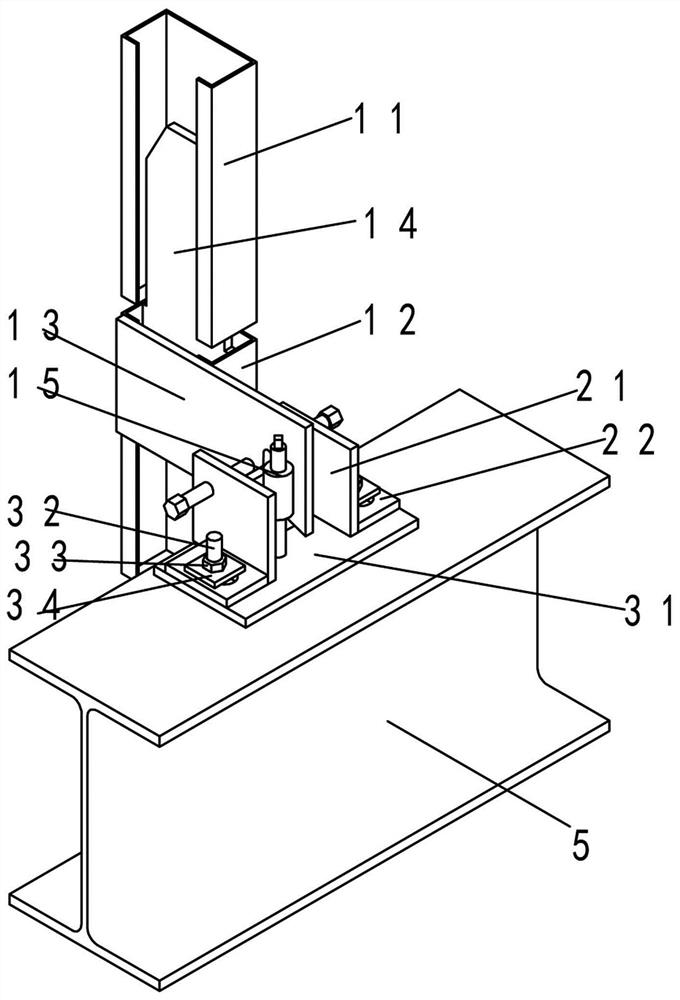

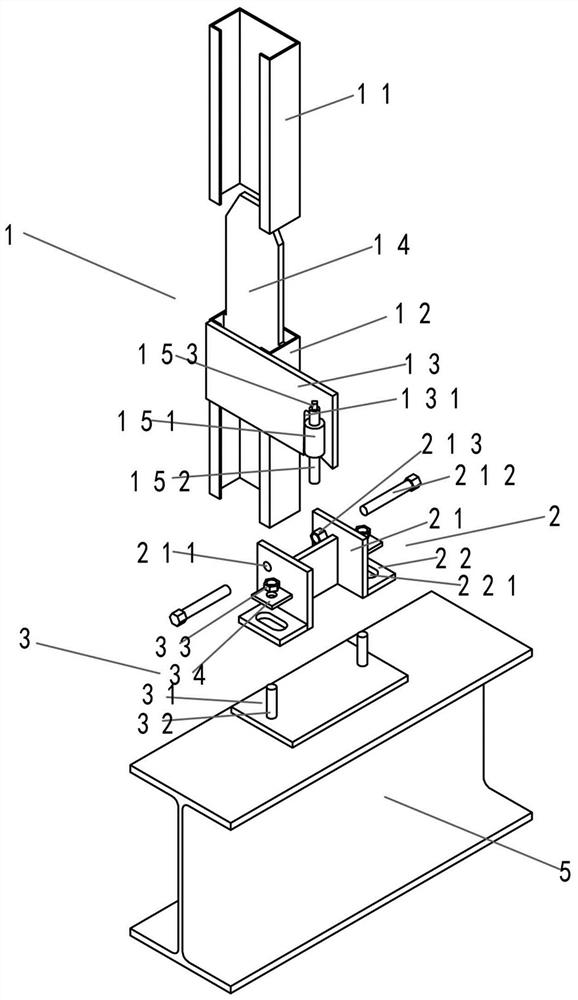

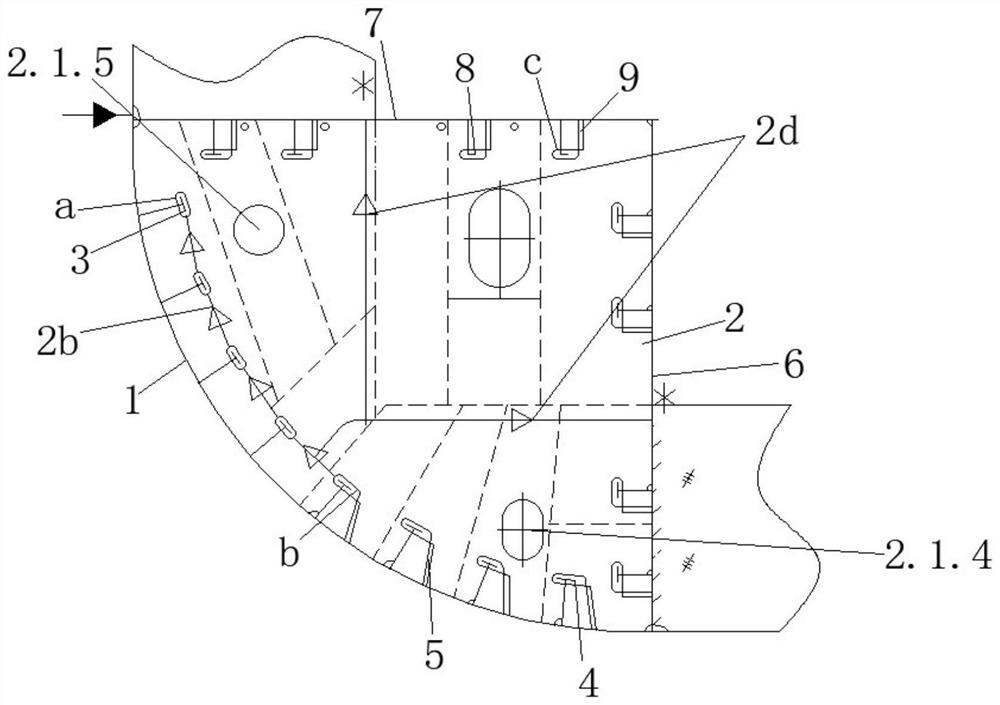

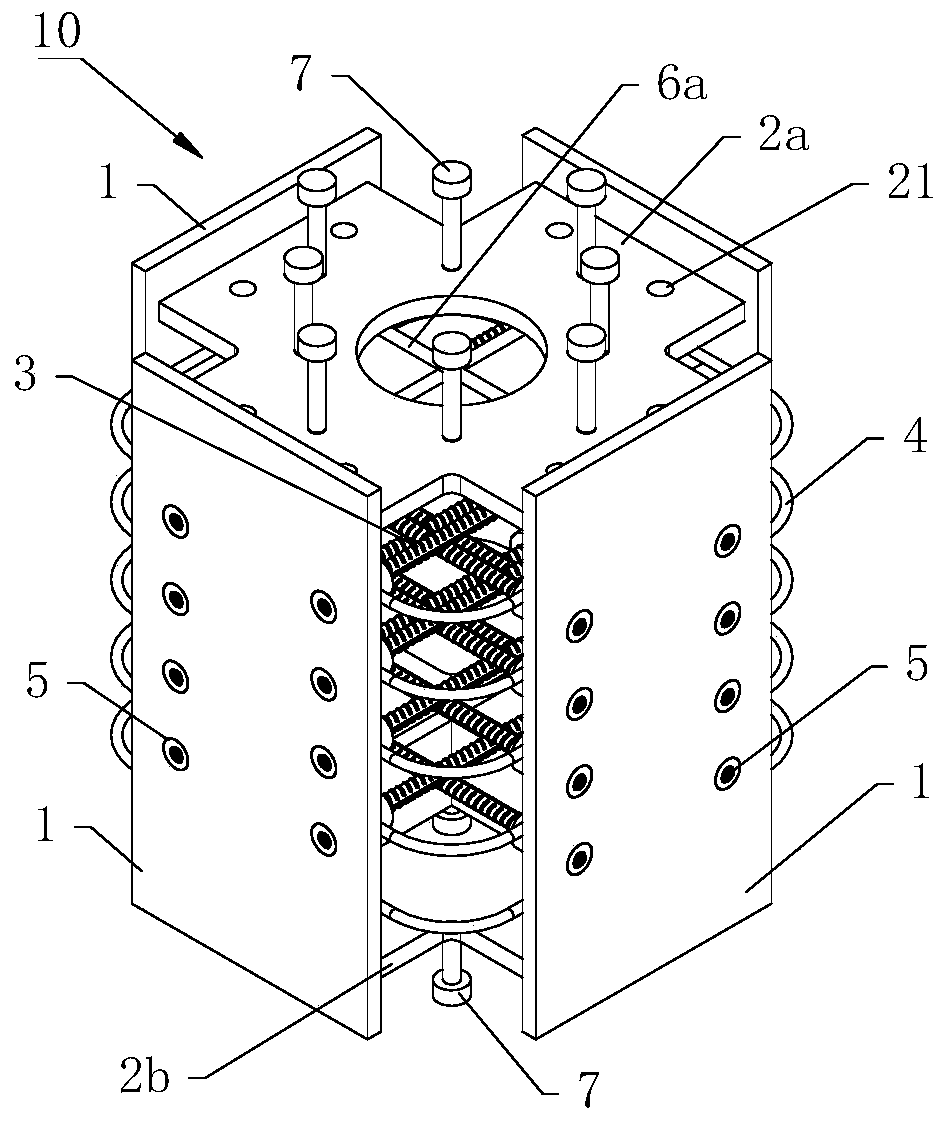

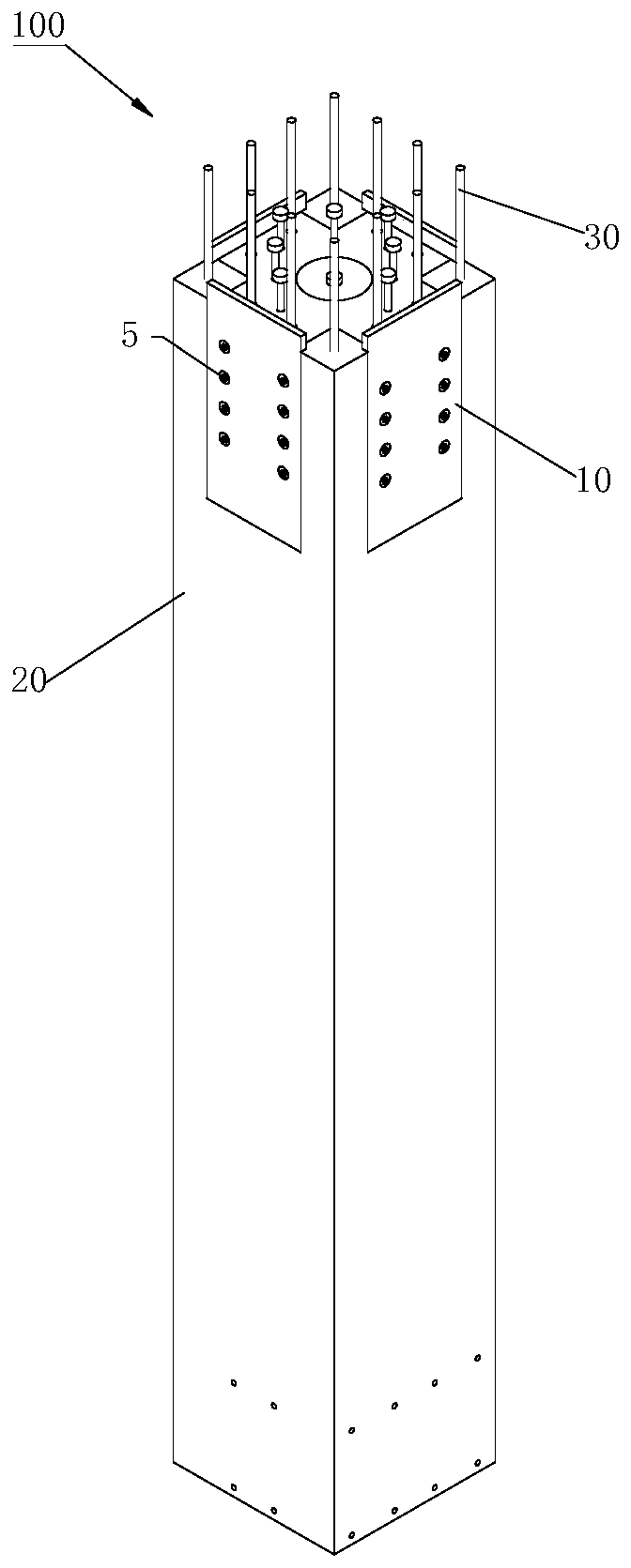

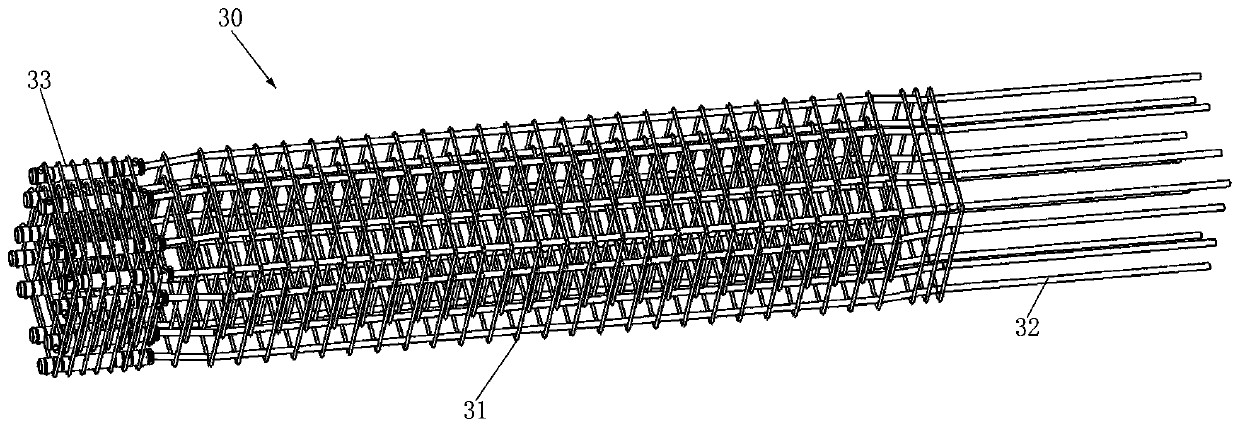

Steel structure joint, prefabricated column, manufacturing method thereof and assembling method of column beam

ActiveCN109537811AReliable forceEasy to produceStrutsCeramic shaping apparatusFull life cycleEngineering

The invention belongs to the technical field of building construction, and provides a steel structure joint, a prefabricated column, a manufacturing method thereof and an assembling method of a columnbeam. The steel structure joint is reliable in stress and convenient to produce and manufacture; the prefabricated column with the steel structure joint is easy to transport and store, the installingprocess of a steel beam and the prefabricated column on site is easy and convenient, operation is convenient, no formwork erection is needed on site, supporting is easy, no operation space limit is caused, dry type construction is performed, the installing precision is easy to control, the later corrosion resistance and fireproof treating area is small, the full-life-cycle maintenance cost is low, the advantages of a fabricated building is sufficiently reflected, the construction efficiency and the construction quality are improved, and waste and building waste are reduced.

Owner:CHINA CONSTR SCI & TECH CO LTD

Precise installation method for expansion joint of concrete roadway type steel

InactiveCN102852066AEasy to operateSimple preparation processPaving detailsBridge structural detailsSurface layerEngineering

The invention relates to concrete roadway construction method, and specially a precise installation method for expansion joint of concrete roadway type steel. The method includes pre-burying expansion joint distribution steel in advance; clearing provided groove bottom, fully laying plastic cloth, filling yellow sand to bottom part of asphalt surface layer to elevation, spreading asphalt, and rolling; putting lines according to design requirement, cutting the provided expansion joint position, and clearing; welding shaped steel regulating device by adopting nuts and bolts; burying and fixing the shaped steel regulating device in reinforced concrete; installing shaped steel, preliminarily fixing steel expansion joint, and interval-fixing bolts after meeting requirement; assembling steel bars, and arranging molds; performing flatness precise detection, and adopting shaped steel regulating device to regulate flatness precise regulation; pouring steel fiber reinforced concrete; and demolding, and installing rubber water-stop belt. The invention reduces construction cost, and improves installation quality.

Owner:CHINA MCC20 GRP CORP

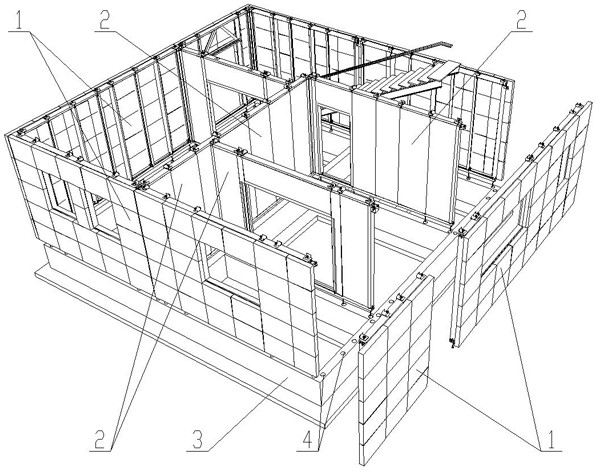

Light steel keel and lightweight concrete prefabricated combining wall and construction method thereof

ActiveCN104790555AReduce calculation lengthNot easy to rustWallsBuilding material handlingKeelSteel columns

The invention discloses a light steel keel and lightweight concrete prefabricated combining wall and construction method thereof. The wall comprises a prefabricated combining straight wall and an L-shaped or a straight or a T-shaped or a cross-shaped prefabricated combining column. The prefabricated combining straight wall and the combining column are fabricated through light steel keels and lightweight concrete. Wall columns at the two ends of a prefabricated combining straight wall keel are protruding steel column sections, and the upper end and the lower end of each wall column are provided with guide rails. The keel of the prefabricated combining column is composed of a concave steel column, an upper end guide rail and a column bottom plate, the concave steel column is connected with a foundation through a base plate and foundation preburied bolts, and protruding steel columns and the concave steel column between the prefabricated combining straight wall and the prefabricated combining column are directly connected through bolts. The wall avoids wet operation of pouring concrete, anti-drawing pieces are convenient to install, wall installation accuracy is easy to control, the manufacturing cost is low, and therefore the wall is suitable for installation of massive light steel keel and lightweight concrete combined houses.

Owner:WUHAN SKYSTEEL BUILDING SYST ENG CO LTD

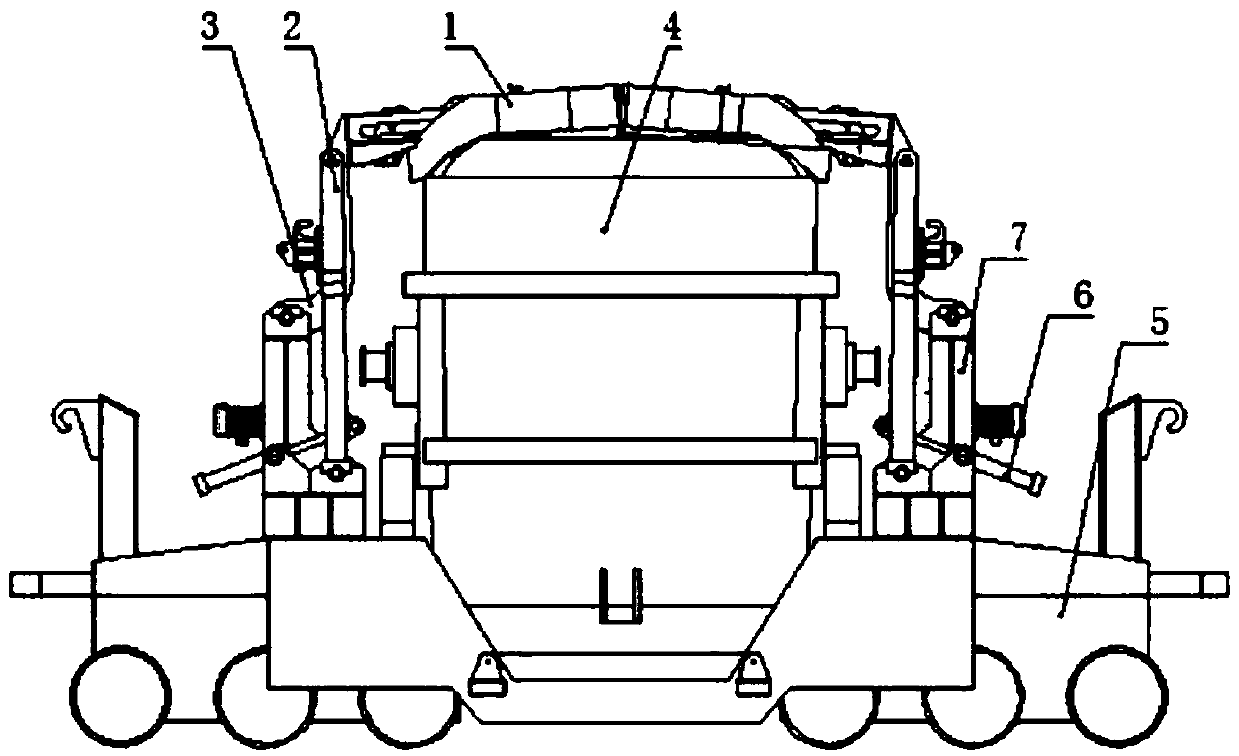

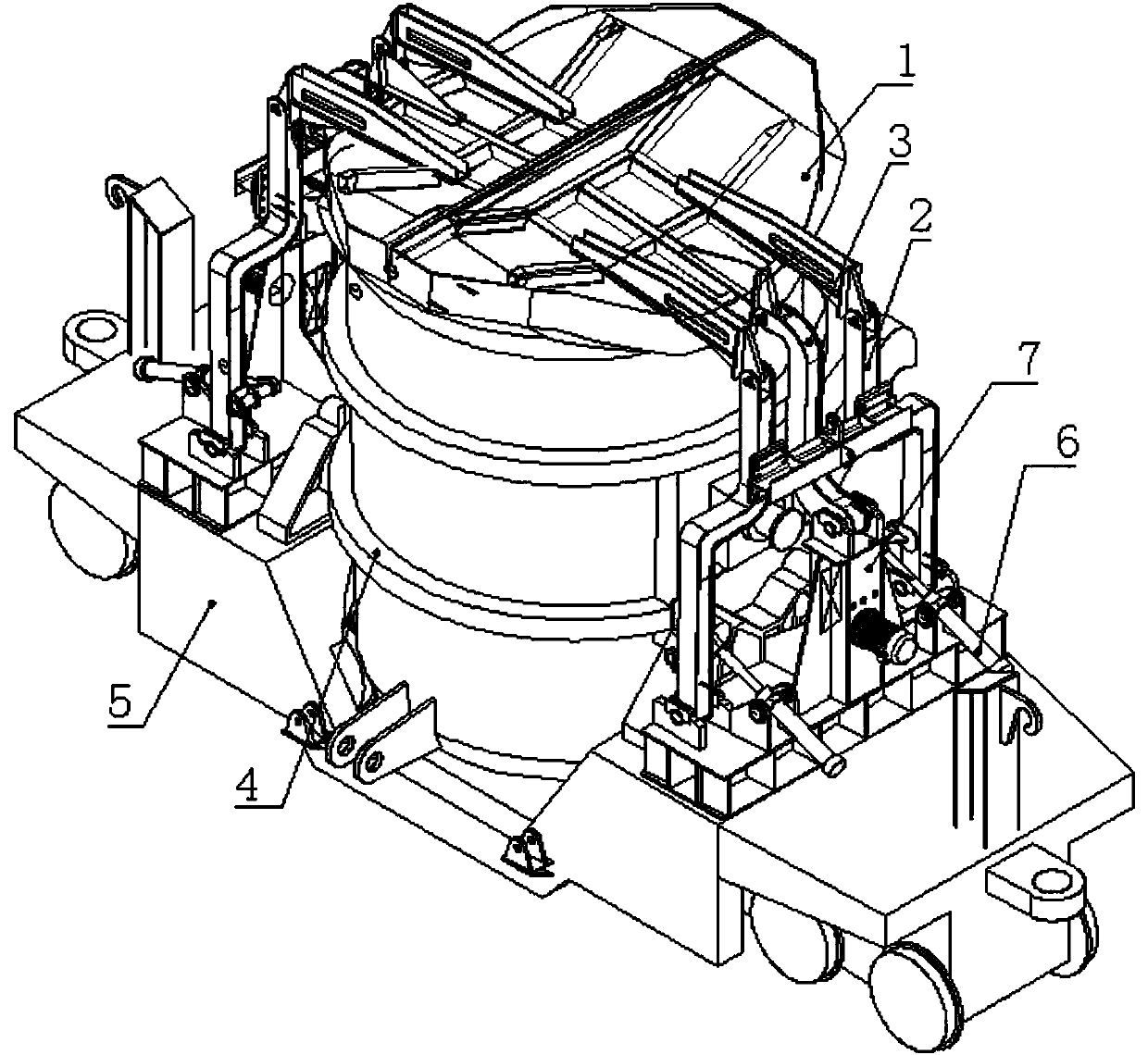

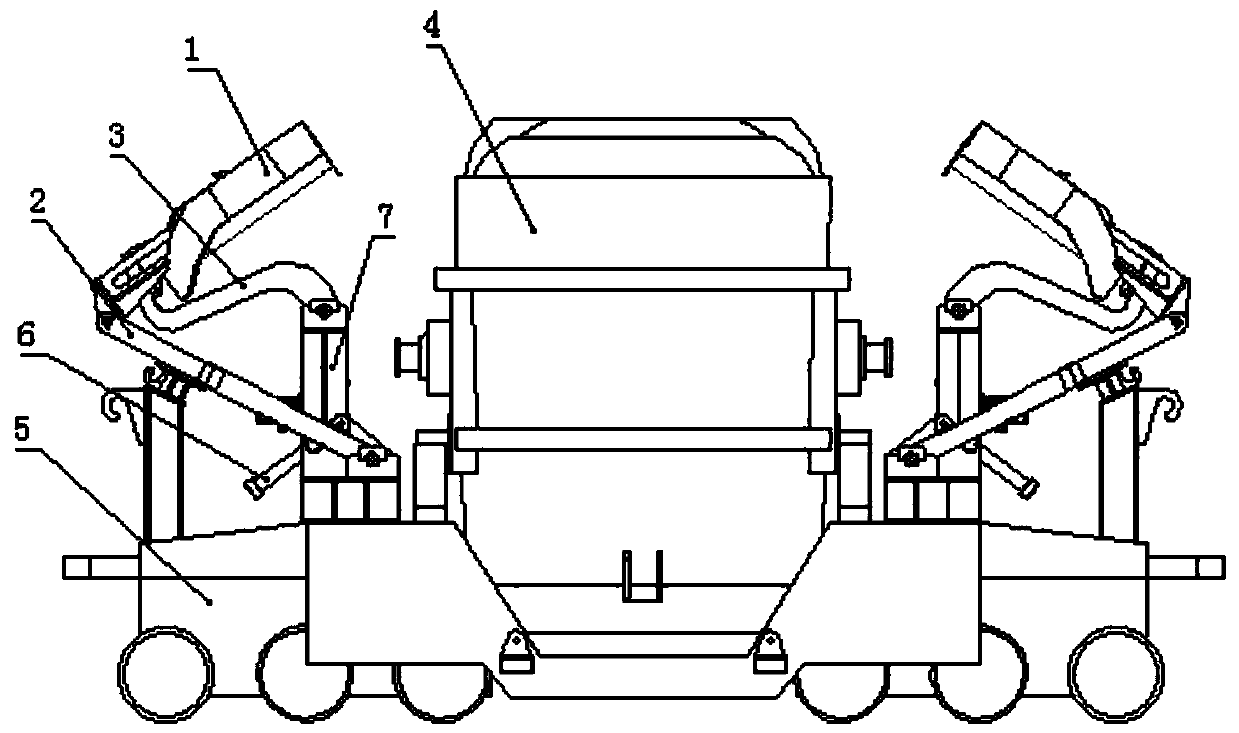

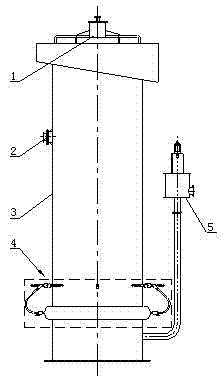

Ladle capping and uncapping device

PendingCN107803494AAdapt to slagging heightReduce the frequency of slaggingMelt-holding vesselsJoystickEngineering

The invention discloses a ladle capping and uncapping device. Capping and uncapping mechanisms are arranged on the two sides of a ladle on a ladle vehicle. Each capping and uncapping mechanism comprises a semicircular ladle cap, driving rocking bars, a connecting rod, oil cylinders and a base, wherein two support rods at the upper ends of the driving rocking bars are hinged to the semicircular ladle cap, and two legs at the lower ends of the driving rocking bars are hinged to the base; one oil cylinder is hinged to the inner side of each leg, and the other ends of the oil cylinders are hingedto the base; the two ends of the connecting rod are hinged to the base and the semicircular ladle cap correspondingly. The ladle capping and uncapping device is convenient to install, high in practicality, free of weather influence and higher in safety.

Owner:MAANSHAN SHUANGYI MACHINERY MFG

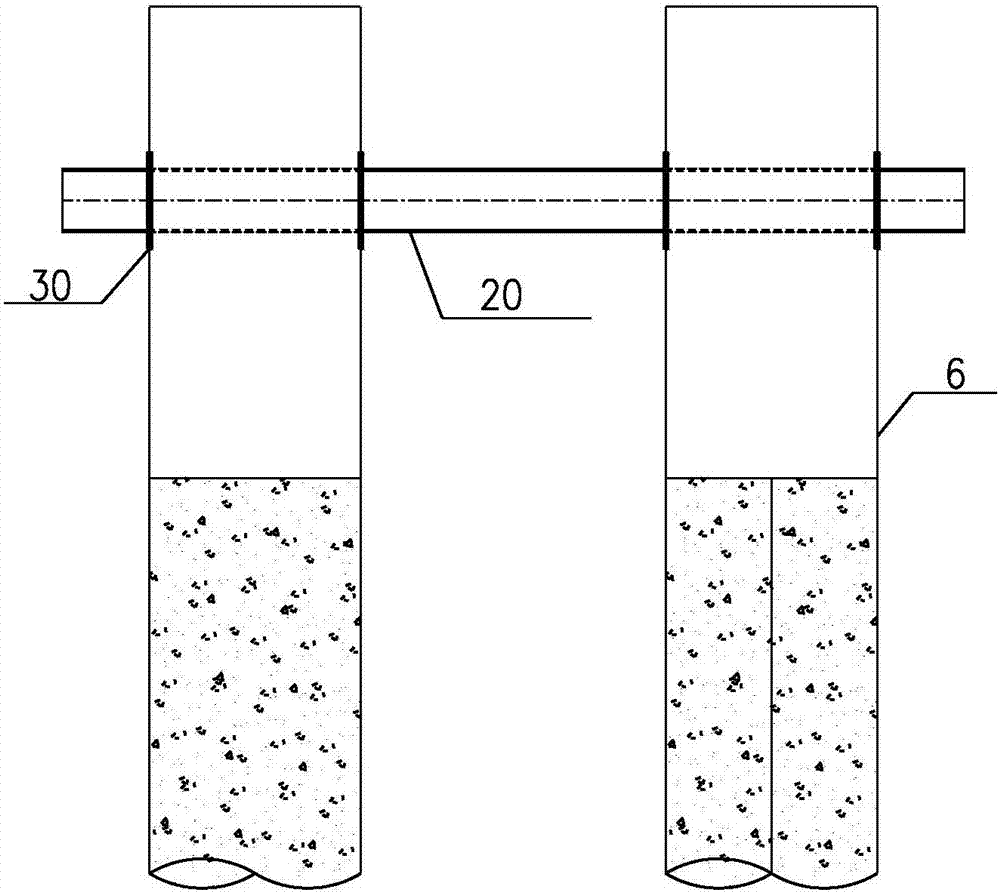

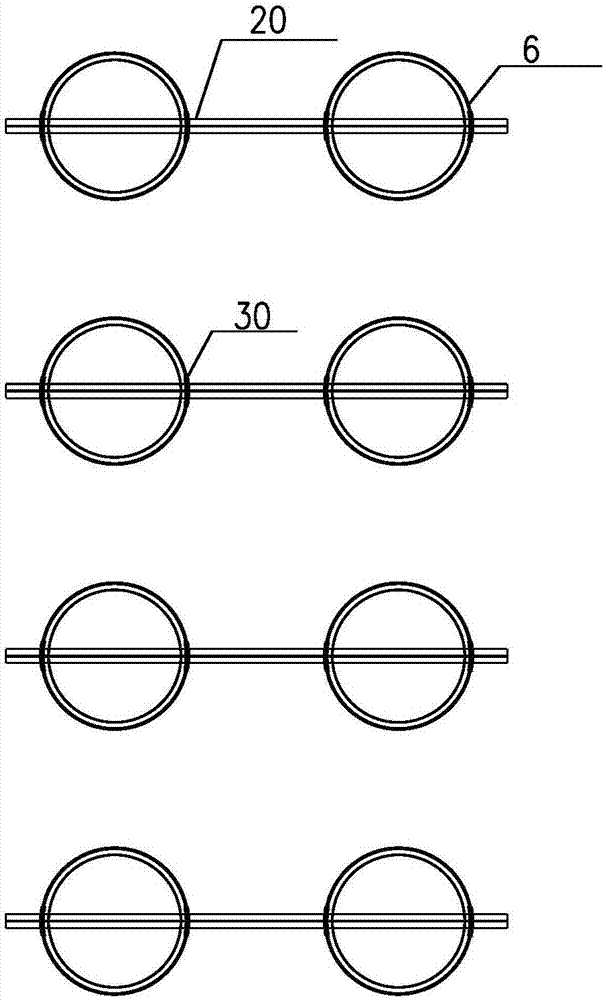

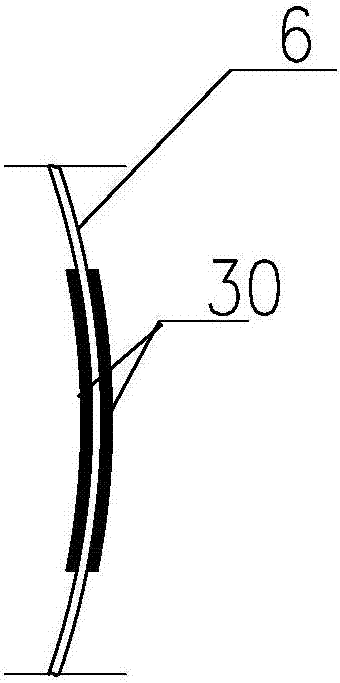

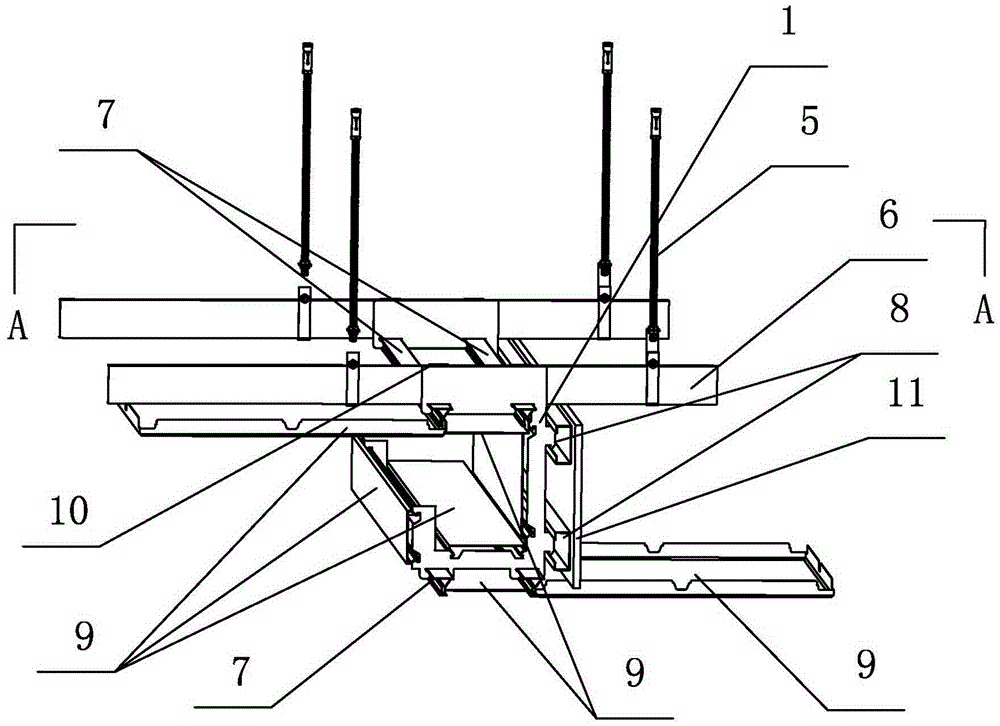

Steel suspension box hoisting system with integral hoisting function and hoisting method of steel suspension box hoisting system

ActiveCN107142954AReduce security risksReduce serious safety hazardsArtificial islandsUnderwater structuresCantileverMechanical engineering

The invention discloses a steel suspension box hoisting system with an integral hoisting function and a hoisting method of the steel suspension box hoisting system, and belongs to the field of sub-beam structure construction. The steel suspension box hoisting system comprises a steel suspension box and an assembly platform of the steel suspension box, wherein the assembly platform comprises a plurality of steel protective cylinders and a plurality of platform beams; penetrating open pores are prefabricated on the protective cylinder walls of all the steel protective cylinders; positioning-guiding mechanisms are arranged at the open pores of all the steel protective cylinders; a whole row of steel protective cylinders movably penetrate through each platform beam through the open pores of the steel protective cylinders; the two ends of each platform beam are exposed from the steel protective cylinders arranged at the two ends of the row; and the steel suspension box comprises the following four parts: a baseplate structure, a wall body structure, cantilever beams, as well as laterally stable supports and section steel suspension rods. By adoption of the steel suspension box hoisting system disclosed by the invention, the safety risk of detaching the assembly platform can be reduced; the time to establish and detach the assembly platform can be shortened to the greatest extent, the work efficiency can be improved, and the engineering progress can be accelerated; materials adopted for the assembly platform can be recycled to the greatest extent; and meanwhile, the difficulty in hoisting construction of the steel suspension box and the labor consumption can be reduced, the construction period can be shortened, and the mounting precision can be easier to control.

Owner:CCCC SHEC FOURTH ENG +1

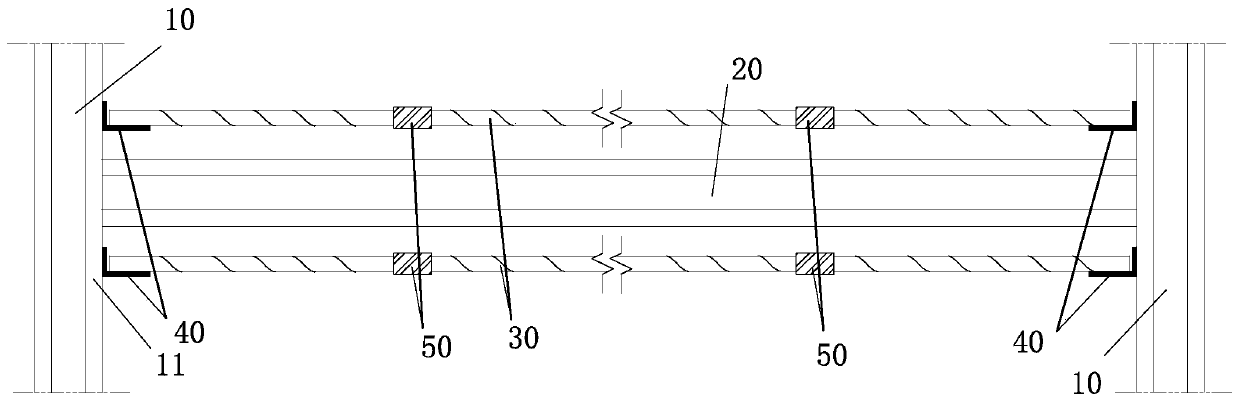

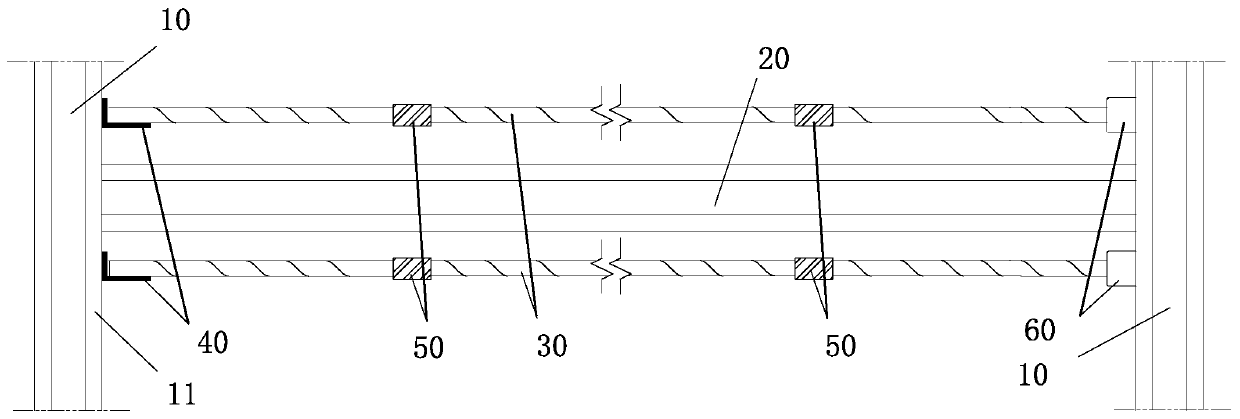

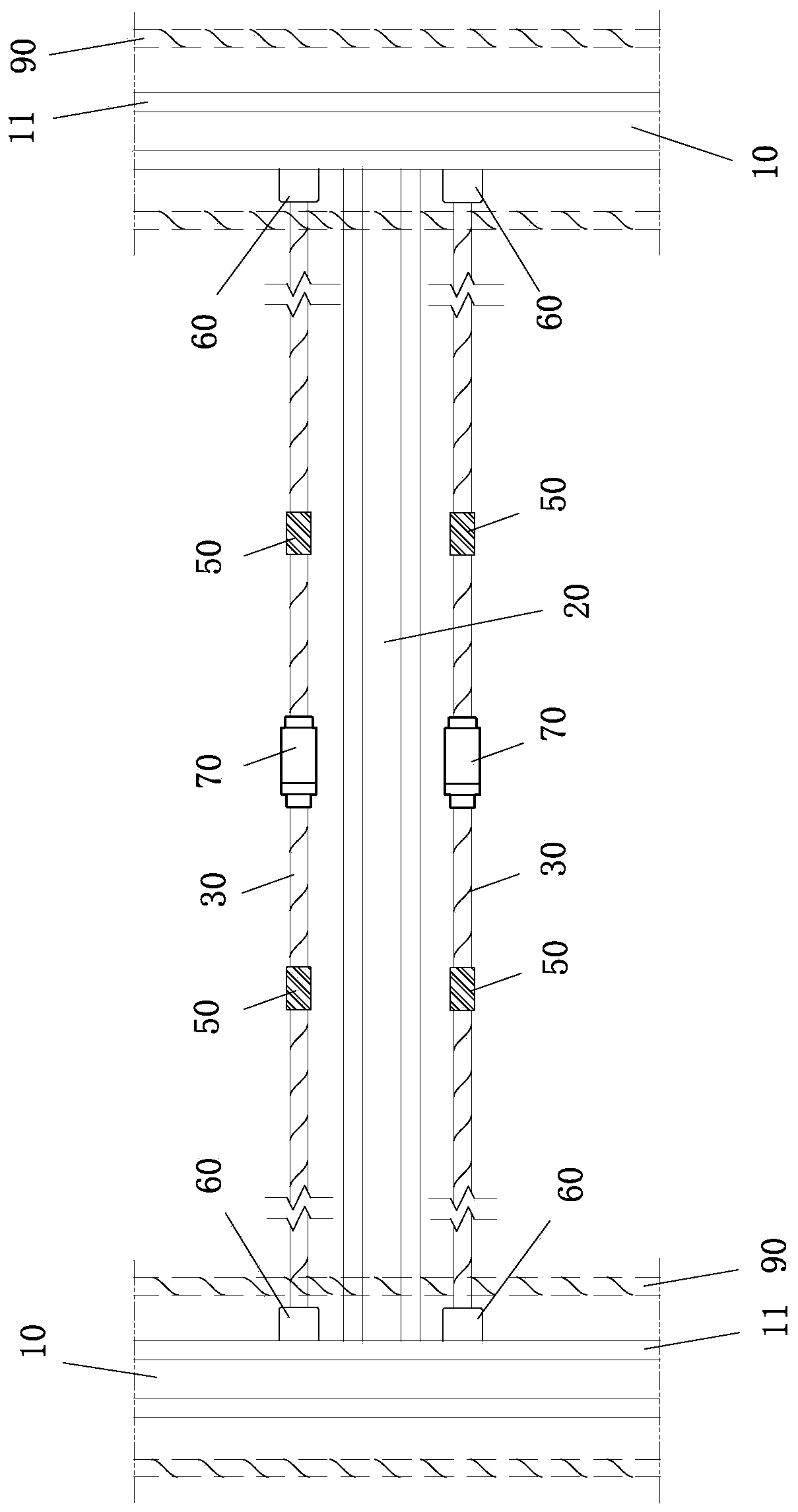

Steel-reinforced beam load-bearing bar structure, construction method thereof and steel-reinforced concrete structure

PendingCN110821045AGuarantee the construction qualitySimple and fast constructionStrutsBuilding reinforcementsReinforced concreteRebar

The invention discloses a steel-reinforced beam load-bearing bar structure, a construction method thereof and a steel-reinforced concrete structure. The steel-reinforced beam load-bearing bar structure comprises two steel bar sections which are installed between flange plates of vertical steel reinforcements of two steel-reinforced columns; one ends of the two steel bar sections are in screw jointwith connectors which are pre-welded on the flange plates of the corresponding vertical steel reinforcements correspondingly, and the other ends of the two steel bar sections are mutually connected through double screw sleeves; and each steel bar section is one transverse steel bar, or each steel bar section is formed by connection with a plurality of transverse steel bars through straight threadsleeves. The steel-reinforced beam load-bearing bar structure is reasonable in design, and the problems that in the prior art, material waste is severe, tying of vertical steel bars through hoops isinterfered, the installation accuracy cannot be controlled, and the construction efficiency is low are effectively solved.

Owner:CHINA RAILWAY CONSTR ENG GROUP

Super sized iron piece high precision mounting construction method

ActiveCN101280629ASmall lifting weightReduce construction costsBuilding material handlingSheet steelBuilding construction

The invention discloses a highly precise construction method for ultra-large steel pieces, which is characterized in that the construction method comprises the steps as follows: partitioning steel piece and opening hole ---> fixing and installing anchor ---> hoisting steel piece plate in position ---> welding anchor pieces and each blocked steel piece plate ---> casting concrete; the construction method lowers construction cost, ensures the precision of installation and has good use effect.

Owner:YANJIAN GRP CO LTD

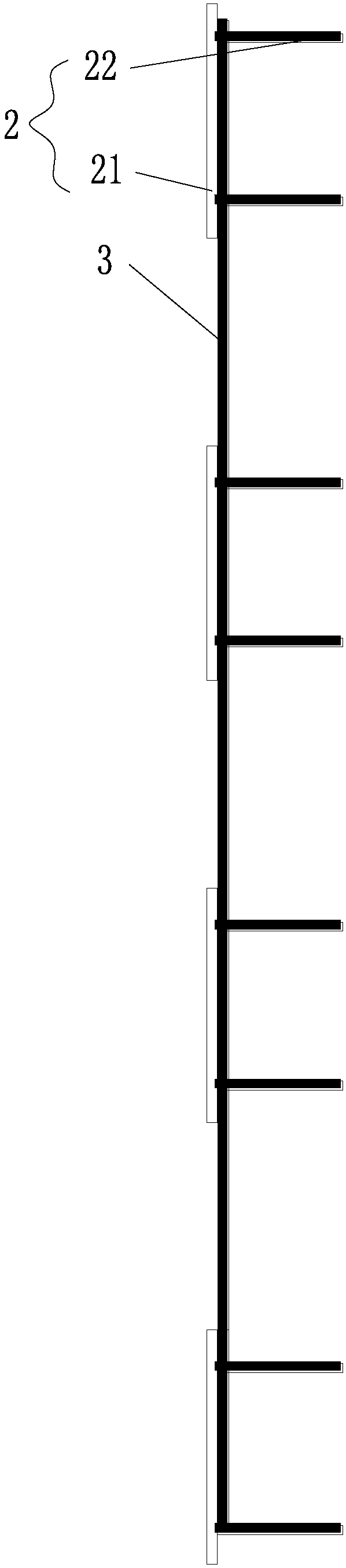

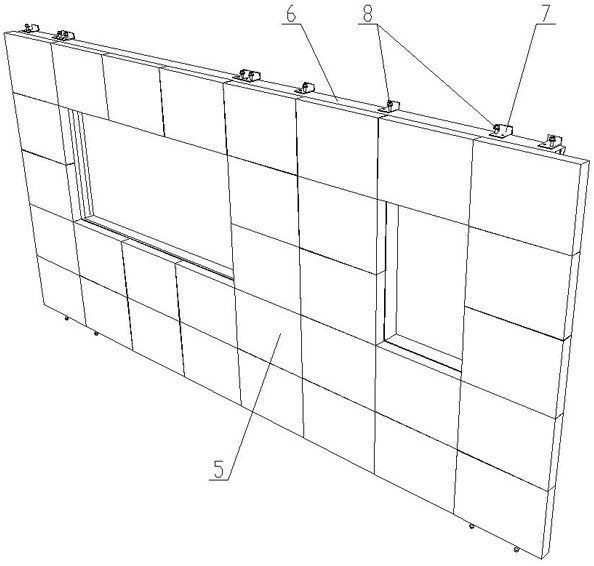

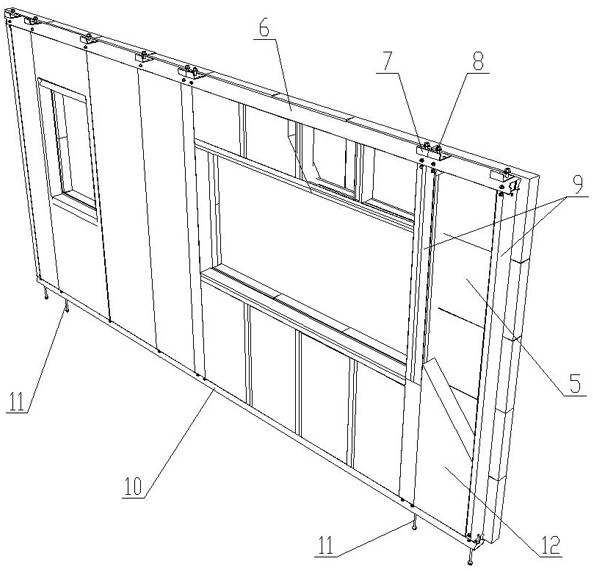

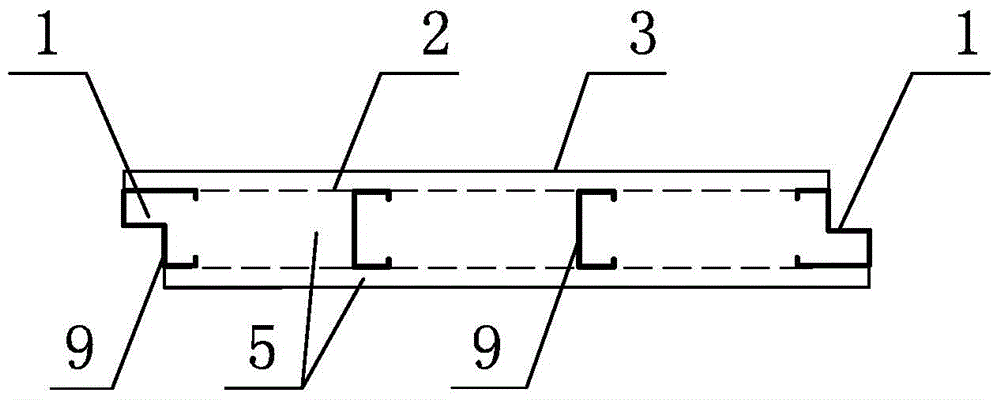

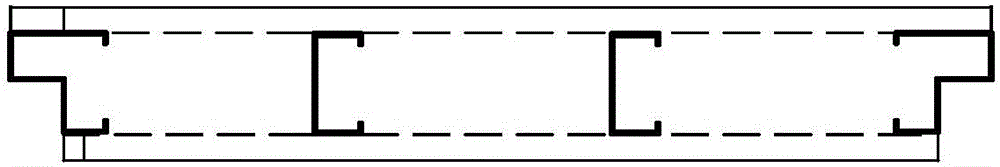

Plug-in light steel exterior wall panel connection node

PendingCN111997245AImprove bearing capacityInstallation accuracy is easy to controlWallsStructural deformationEngineering

The invention provides a plug-in light steel exterior wall panel connection node, and relates to the technical field of building construction. The plug-in light steel exterior wall panel connection node comprises a plug-in connecting piece, a node steel support and a positioning bottom late, wherein the plug-in connecting piece comprises a first vertical keel, a second vertical keel, a vertical plate and a plug plate; a vertical groove is formed in the vertical plate; a load-bearing piece is arranged on the side face of the vertical plate, and comprises a load-bearing cylinder and a load-bearing screw rod; the node steel support comprises an H-shaped seat and an ear plate; the H-shaped seat extends into the vertical groove; horizontal holes and limiting bolts are formed in two sides of theH-shaped seat; a horizontal groove is formed in the ear plate; the positioning bottom plate comprises a positioning steel plate, a positioning screw rod and a positioning nut; and the positioning screw rod extends into the horizontal groove. The plug-in light steel exterior wall panel connection node provided by the invention can realize adjustment in three direction in the wall panel installation process, and is controllable in installation accuracy and high in installation efficiency. In the design use stage, the light steel exterior wall panel flexible connection node has high load-bearingstrength, and can adapt to the deformation of a main body structure.

Owner:ZHEJIANG DADONGWU CONSTR TECH CO LTD

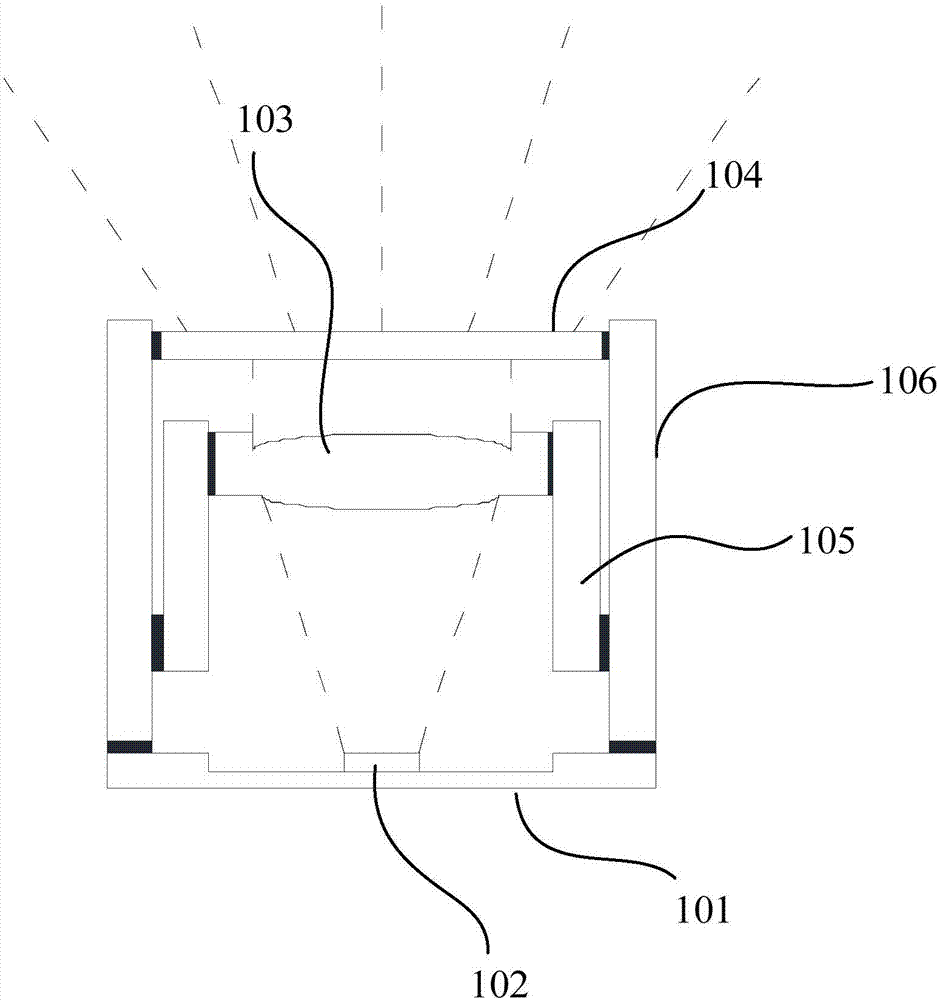

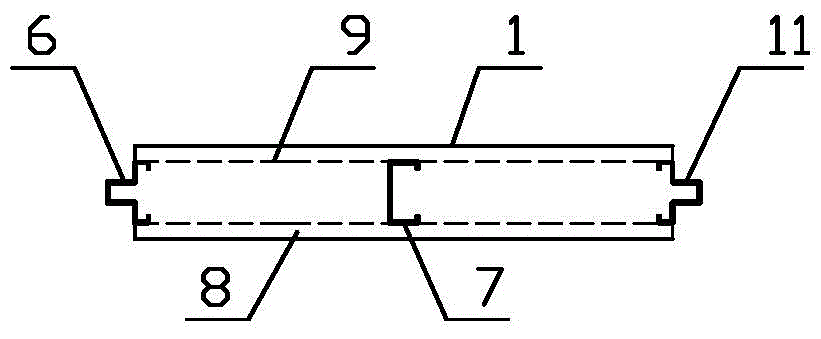

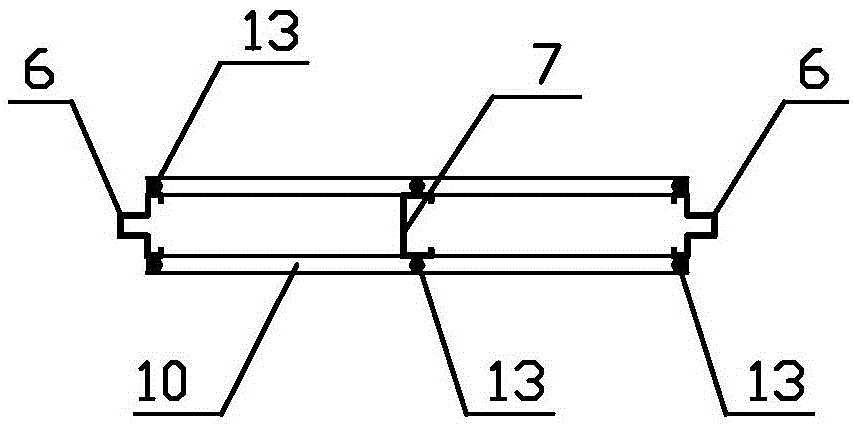

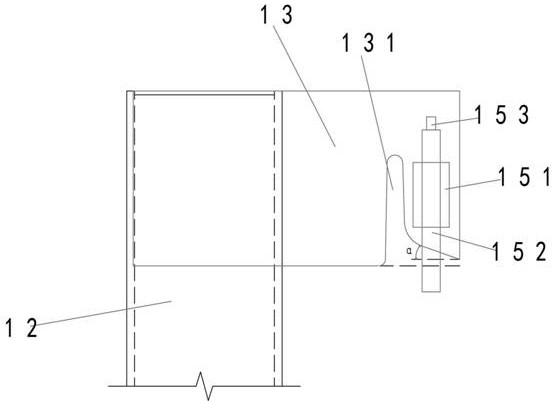

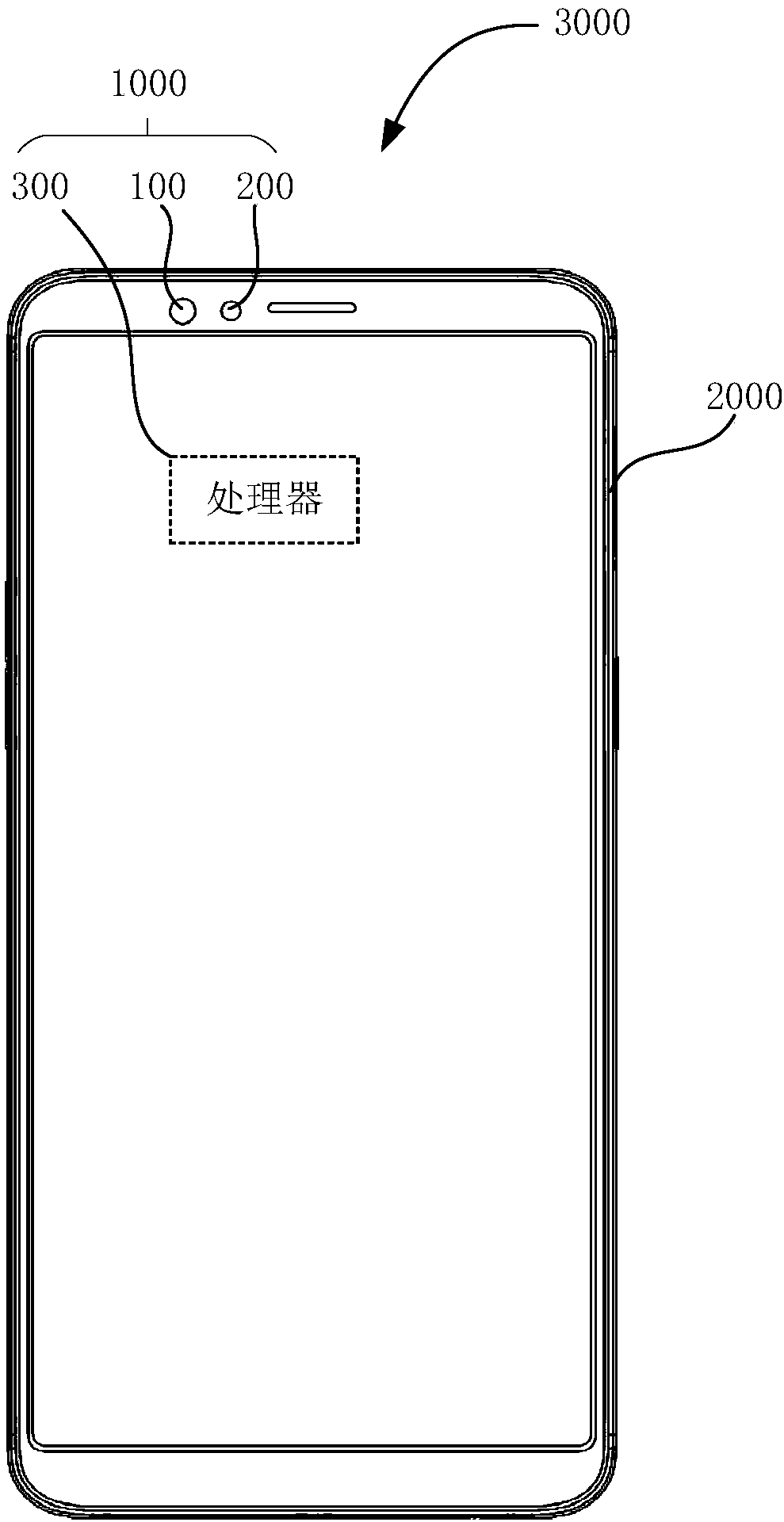

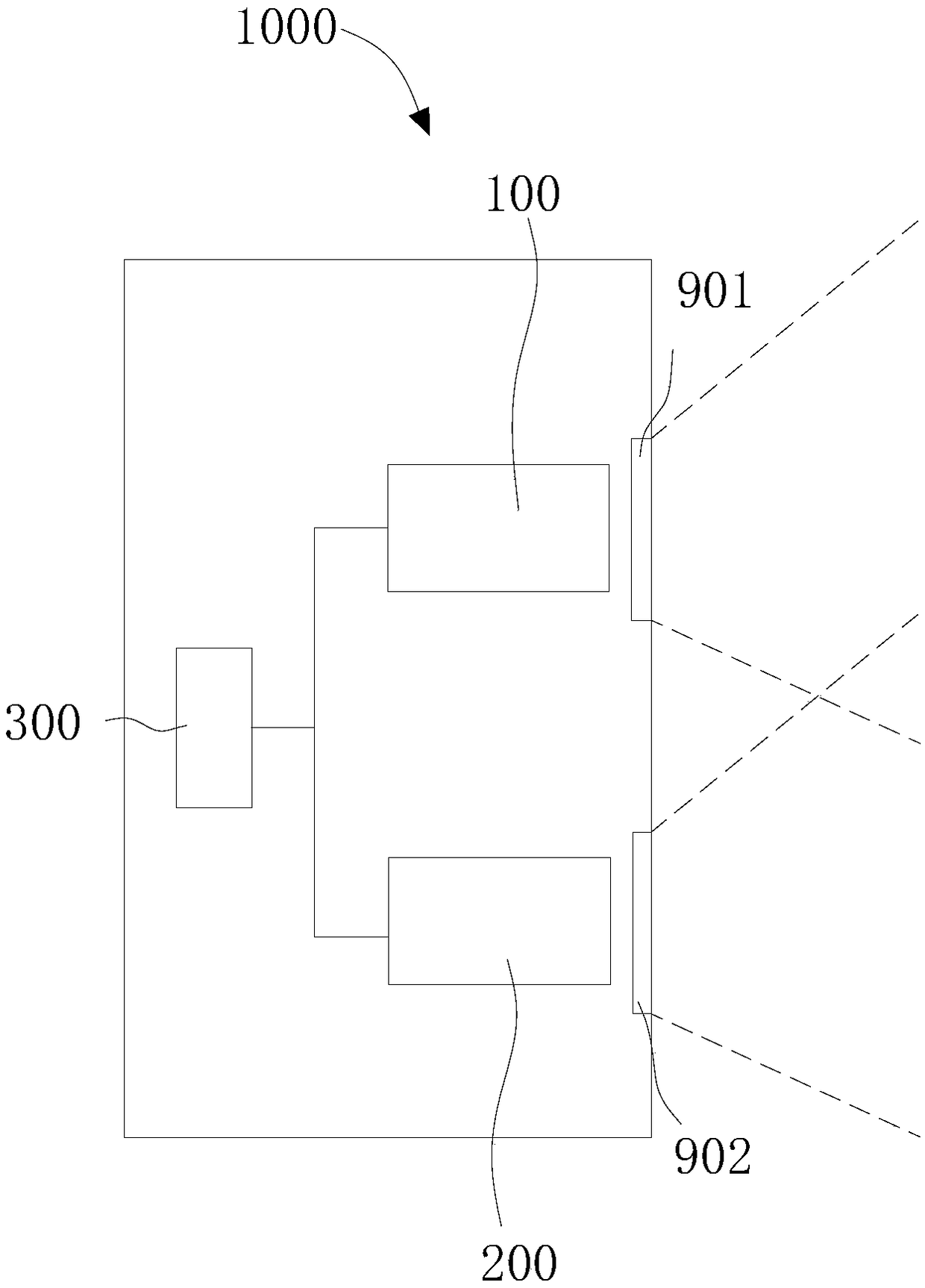

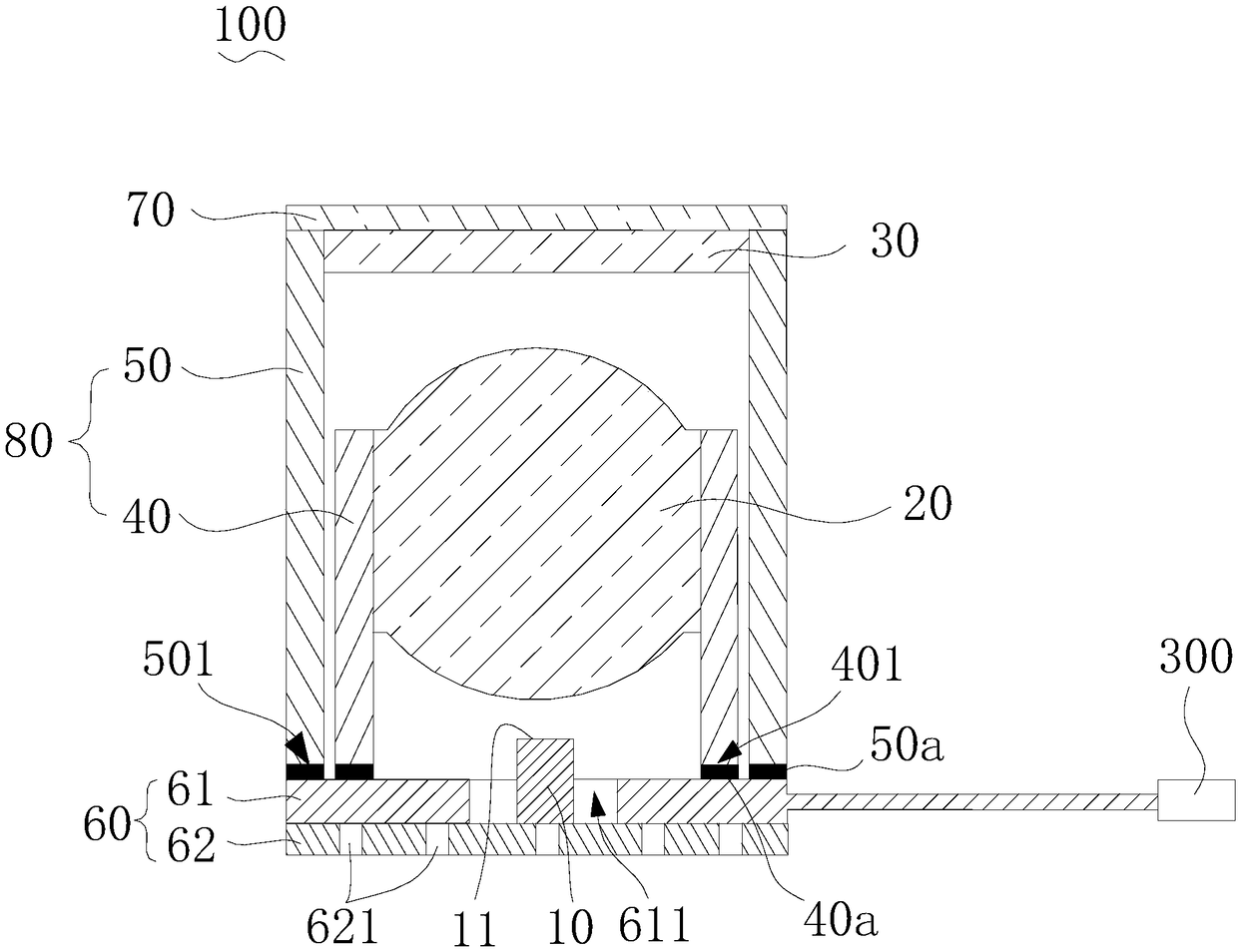

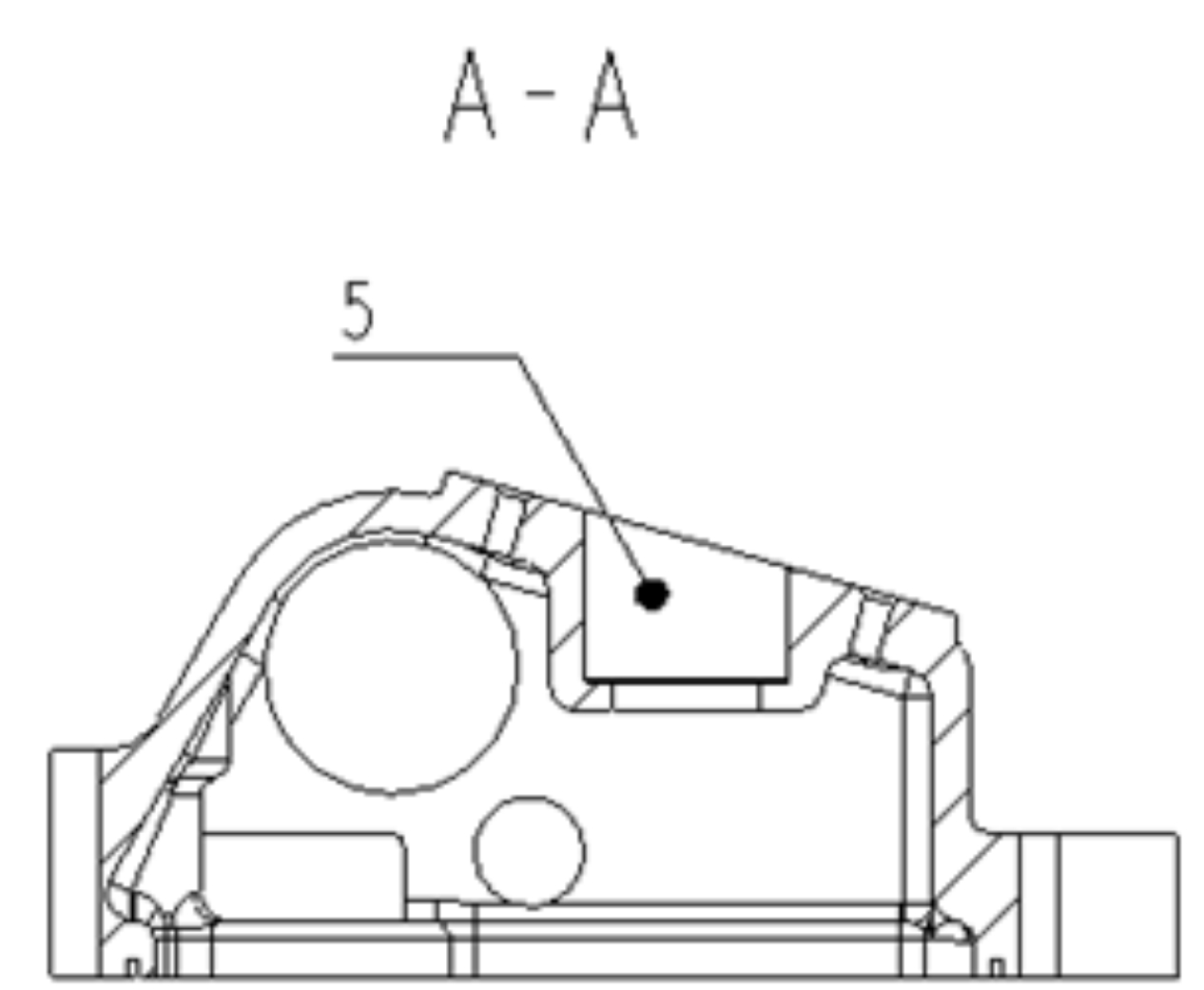

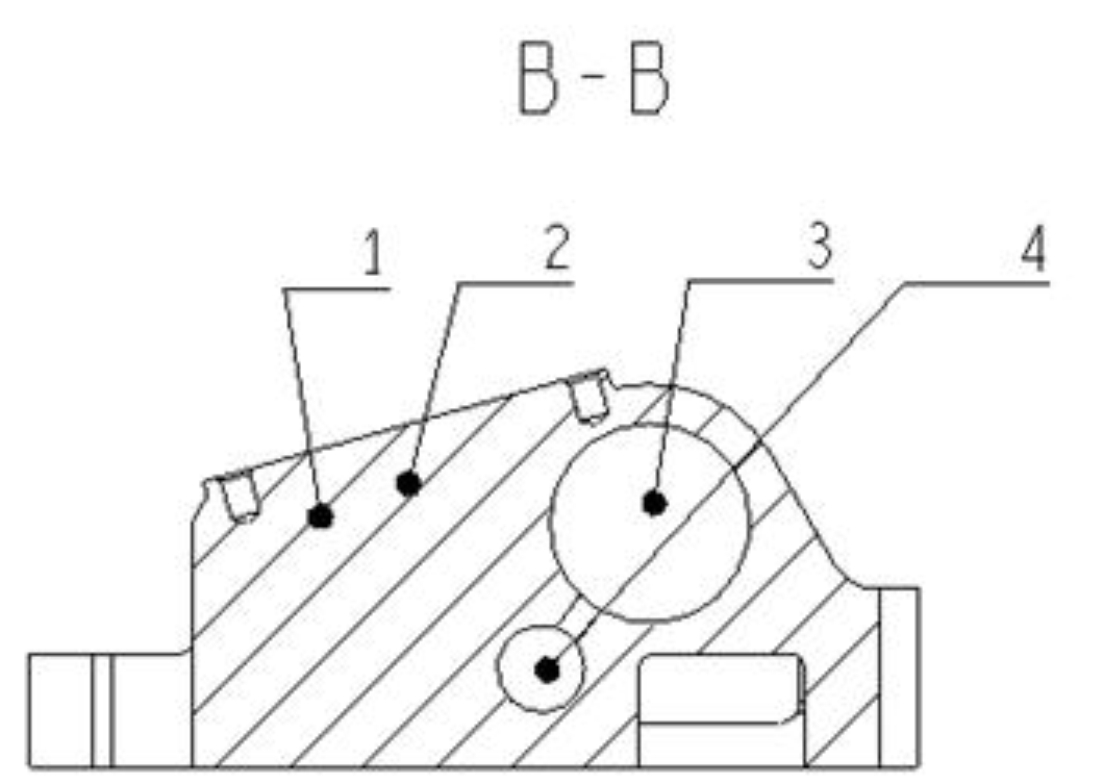

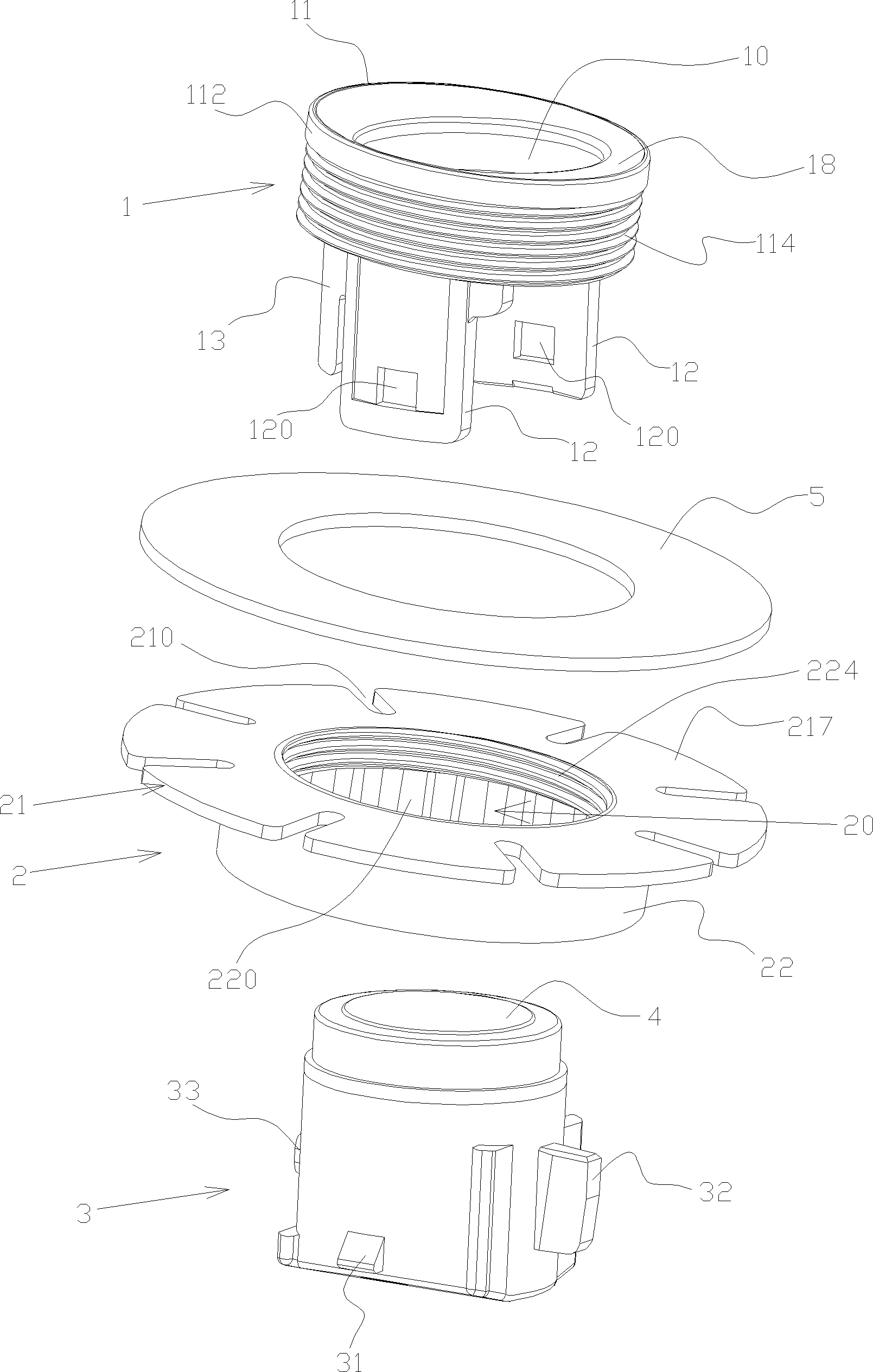

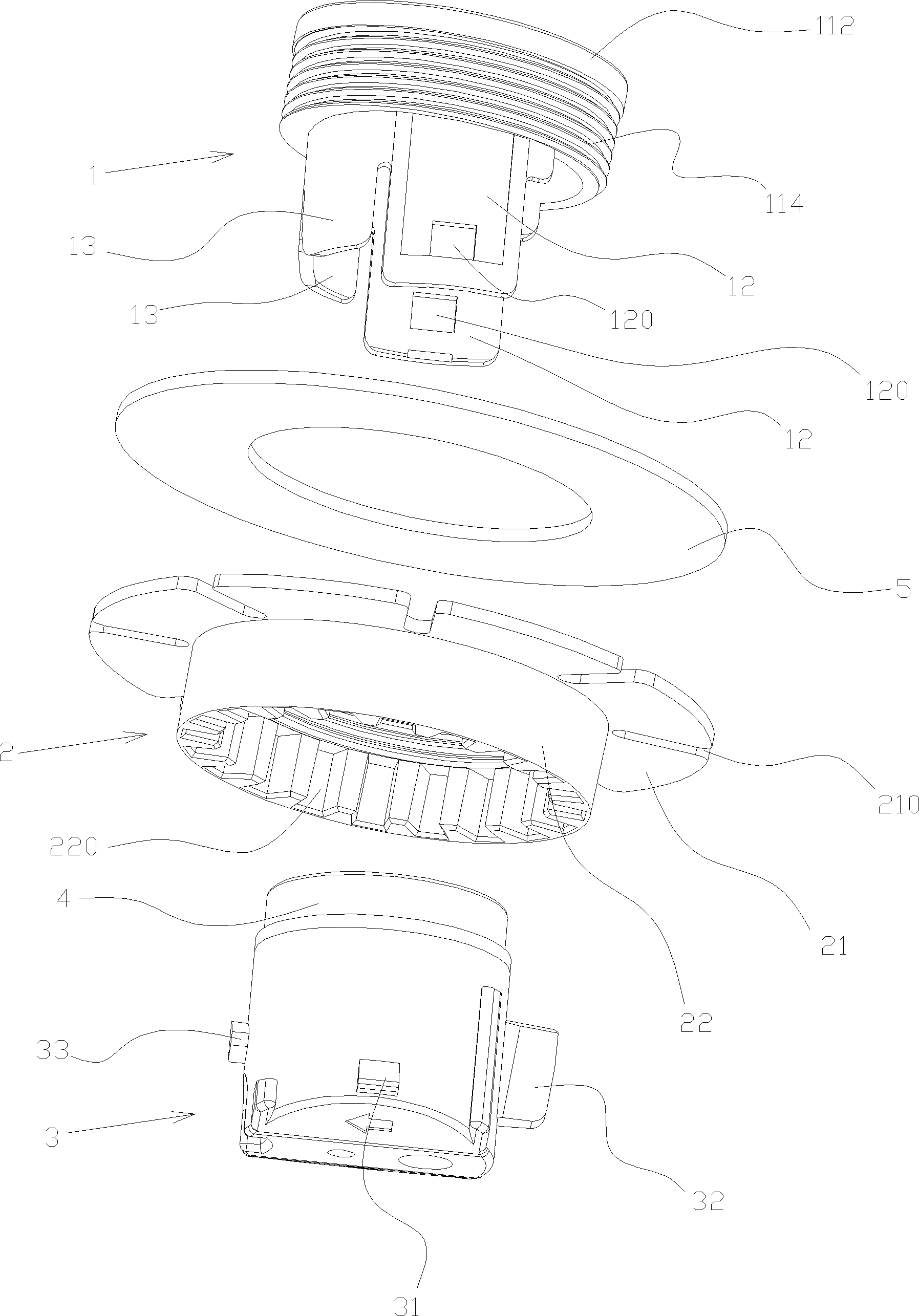

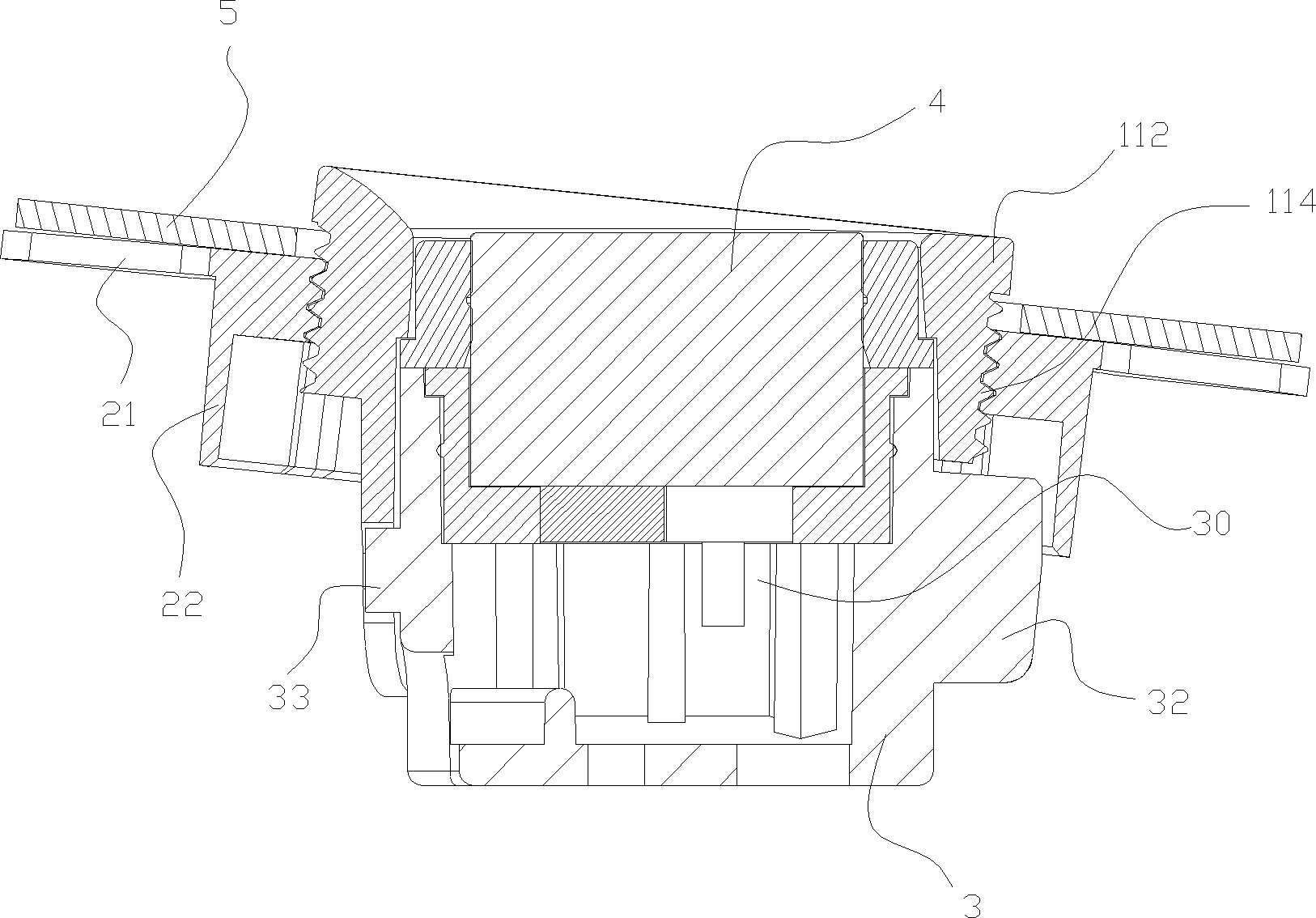

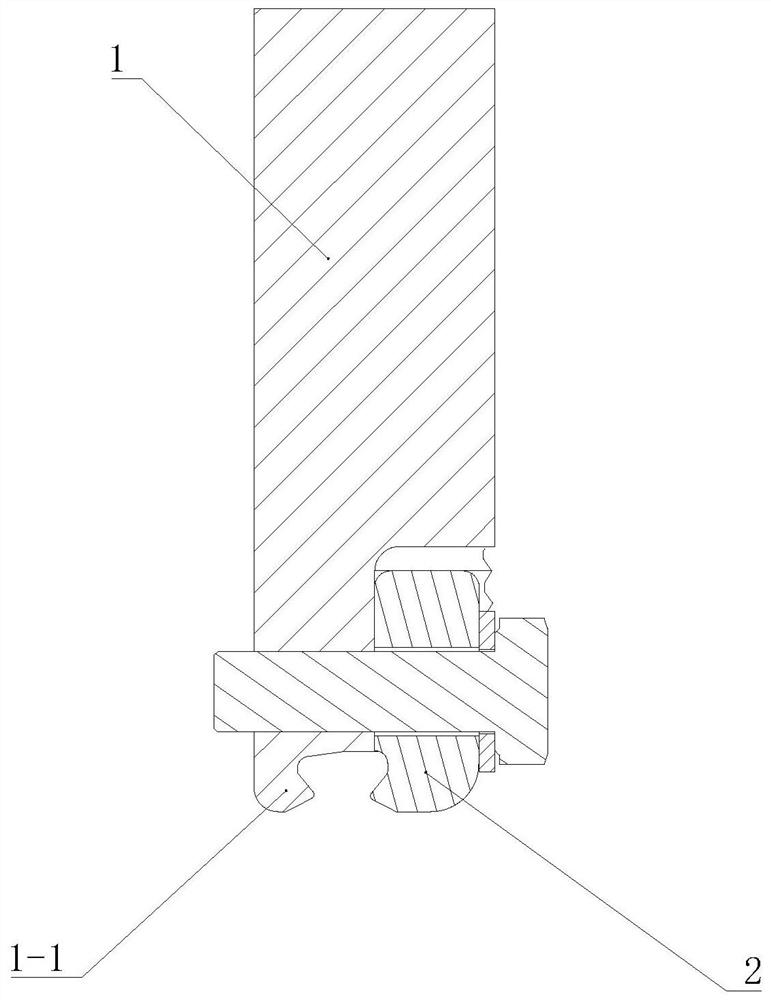

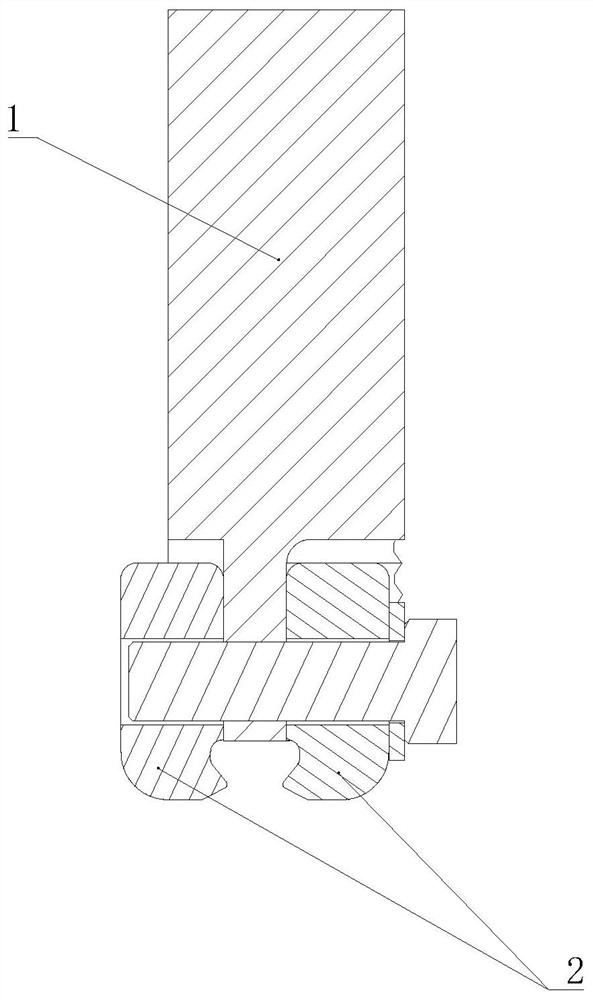

Laser projector, camera module and electronic device

InactiveCN108594458AEasy to adjustInstallation accuracy is easy to controlMountingsPhysicsLaser light

The invention discloses a laser projector, a camera module and an electronic device. The laser projector includes a substrate assembly, a barrel assembly, a light source, a collimating element, and adiffraction element. The barrel assembly is disposed on the substrate assembly. The lens barrel assembly includes a collimating bracket and a diffraction bracket, and the collimating bracket and the diffraction bracket are in a split structure. The light source is disposed on the substrate assembly for emitting laser light. The collimating element is supported by the collimating bracket for collimating the laser light emitted by the light source, the light source is an edge emitting laser, and the edge emitting laser includes a light emitting surface, and the light emitting surface faces the collimating element. The diffraction element is supported by the diffraction bracket for diffracting the laser light collimated by the collimating element to form a laser pattern. The laser projector,the camera module and the electronic device according to the embodiments of the present invention respectively support the collimating element and the diffraction element by using the split collimating bracket and the diffraction bracket, respectively, facilitating the installation and position adjustment of the collimating element and the diffraction element, and the mounting efficiency is high.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

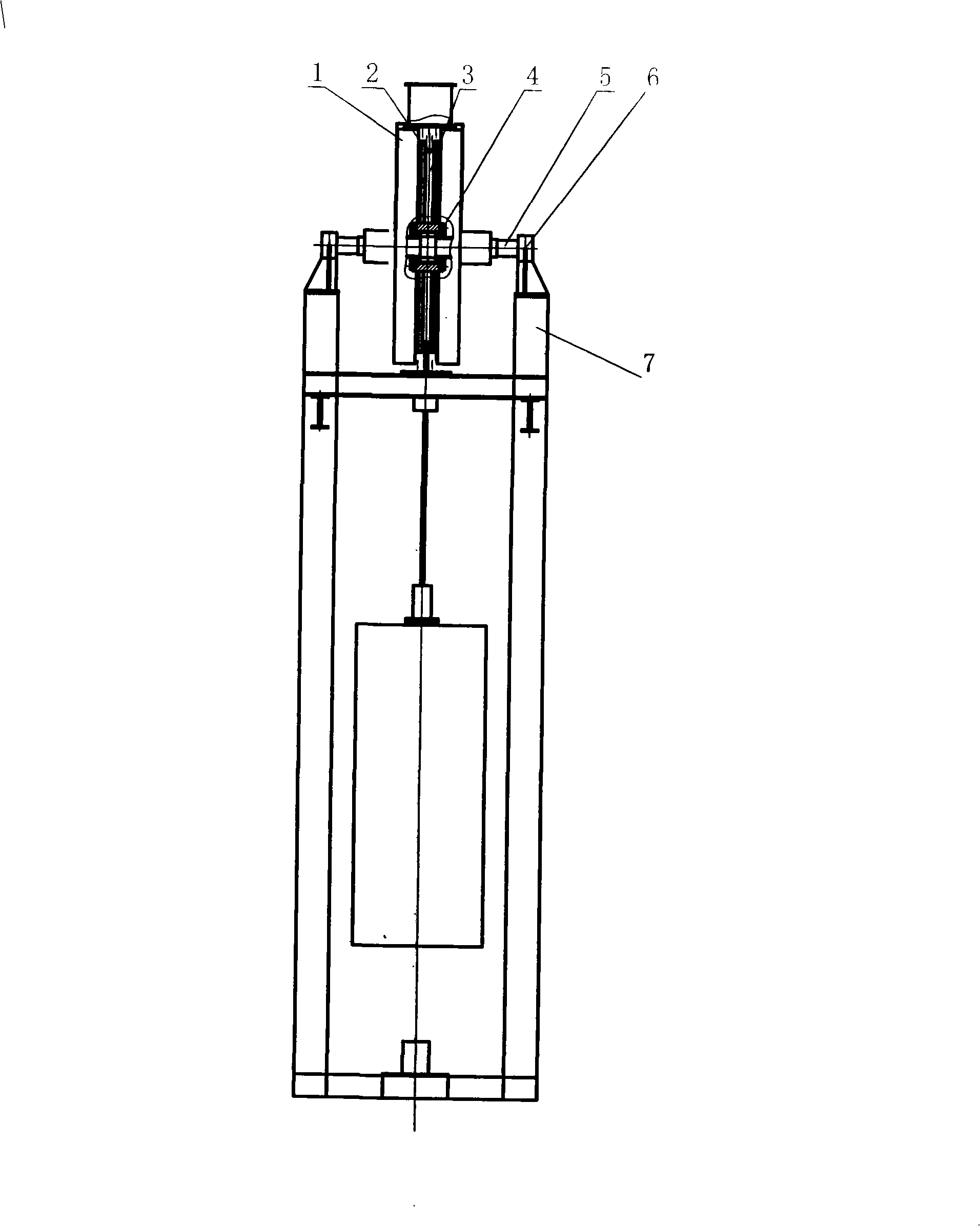

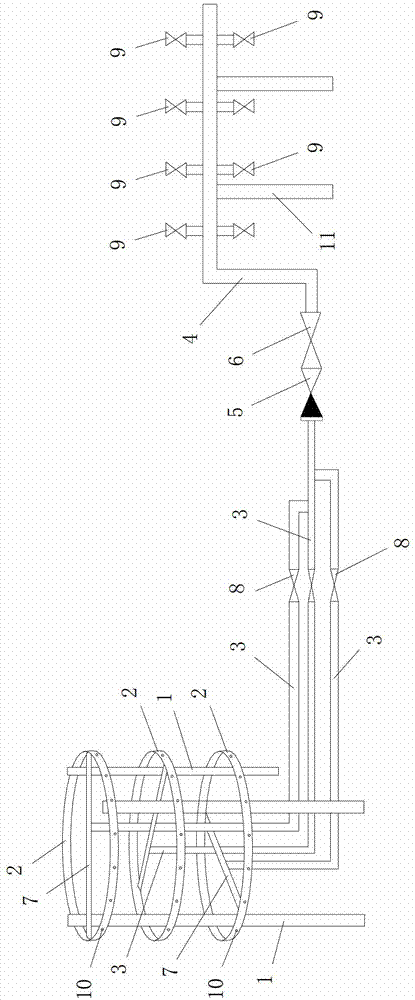

Circular disc permanent magnetism wind water double cold linear motor oil pumping machine

ActiveCN101289930AStroke can be adjusted freelyReasonable forceFluid removalPropulsion systemsCircular discRolling-element bearing

The invention relates to a pumping unit with a disk permanent magnet water-cooled and air-cooled linear motor. Two sides of a rope pulley are respectively provided with a set of disk permanent magnetic water-cooled and air-cooled synchronous three-phase linear motor drive set the primary of which is a stator, the secondary of which is a motor and the secondary is a permanent magnet; the motor adopts water-cooled and air-cooled motor. The secondary is respectively fixed on the two sides of the rope pulley to form a whole; the primary is fixed on the same shaft outside the secondary; a gap is arranged between the primary and the secondary; the primary drives the secondary which drives the rope pulley to rotate; an inner hole of the rope pulley is provided with a rolling bearing; an outer sleeve of the bearing is rotated along with the rope pulley; and an inner sleeve of the bearing is fixed with the shaft. The pumping unit has the advantages of simple structure, multi-pole, low rotating speed, big torque, no environmental pollution, no lubricant, long service life, convenient maintenance, few replaceable parts and easy matching.

Owner:HENGDA ELECTRIC MACHINE GROUP WEIHAI

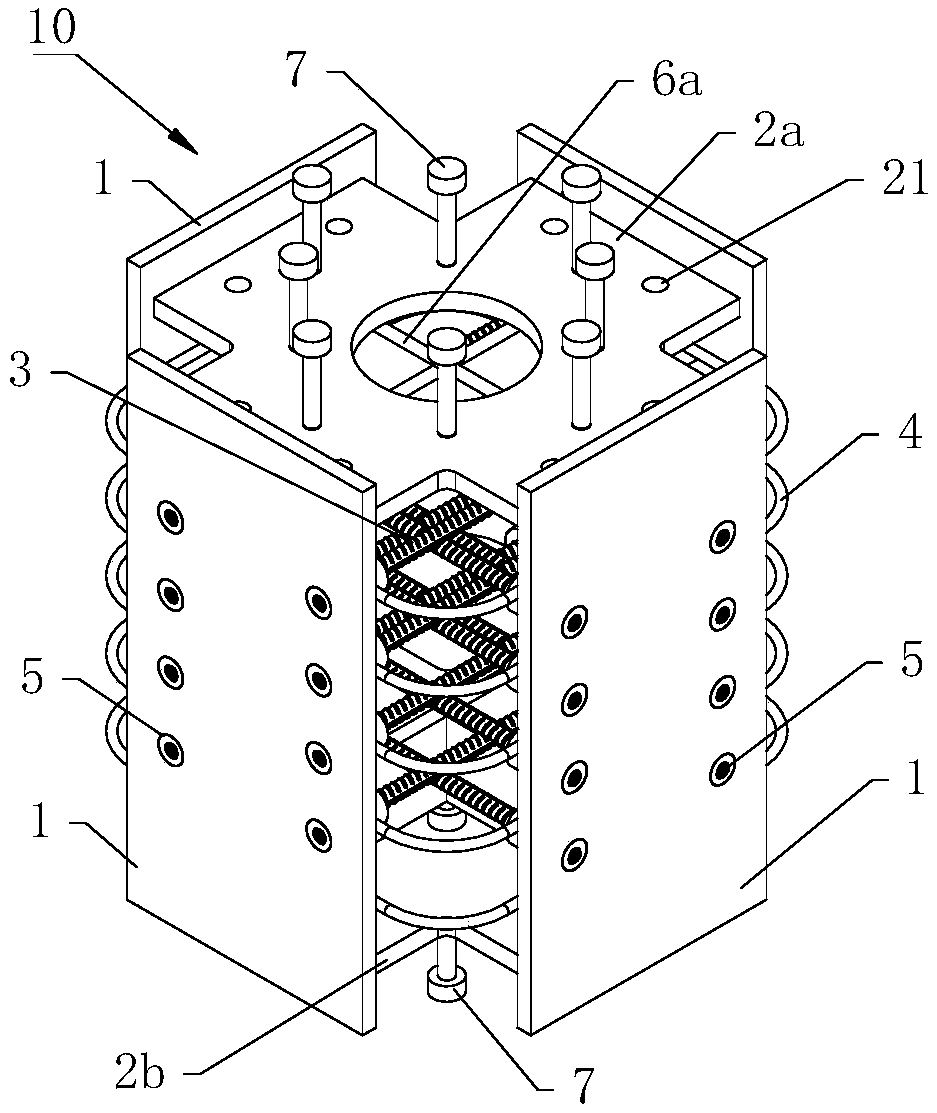

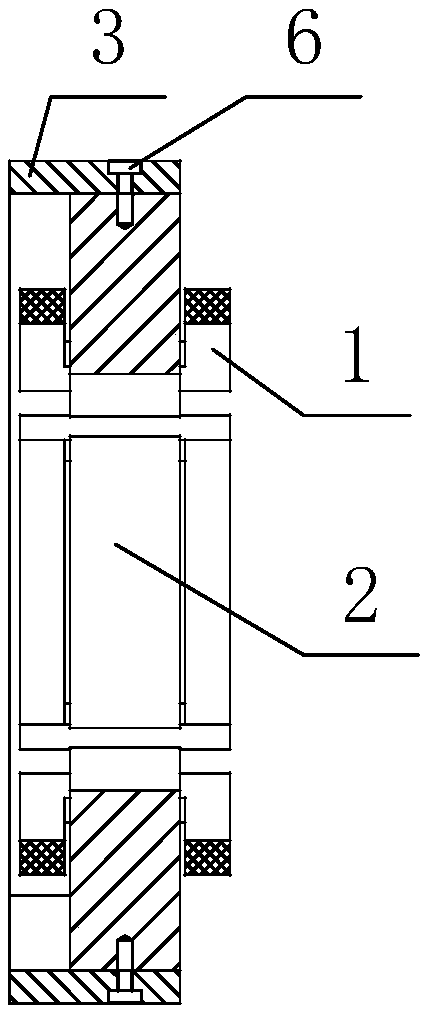

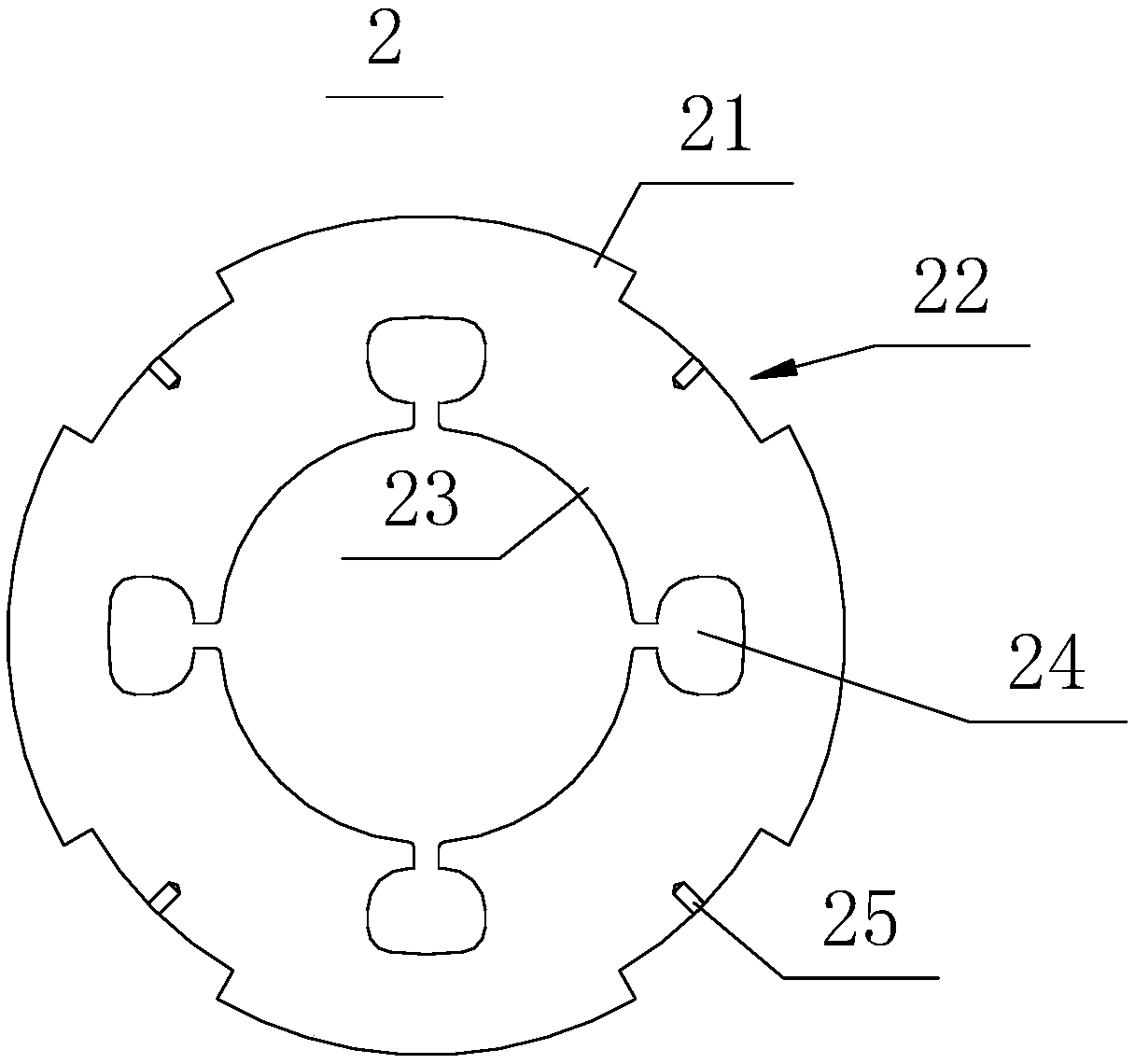

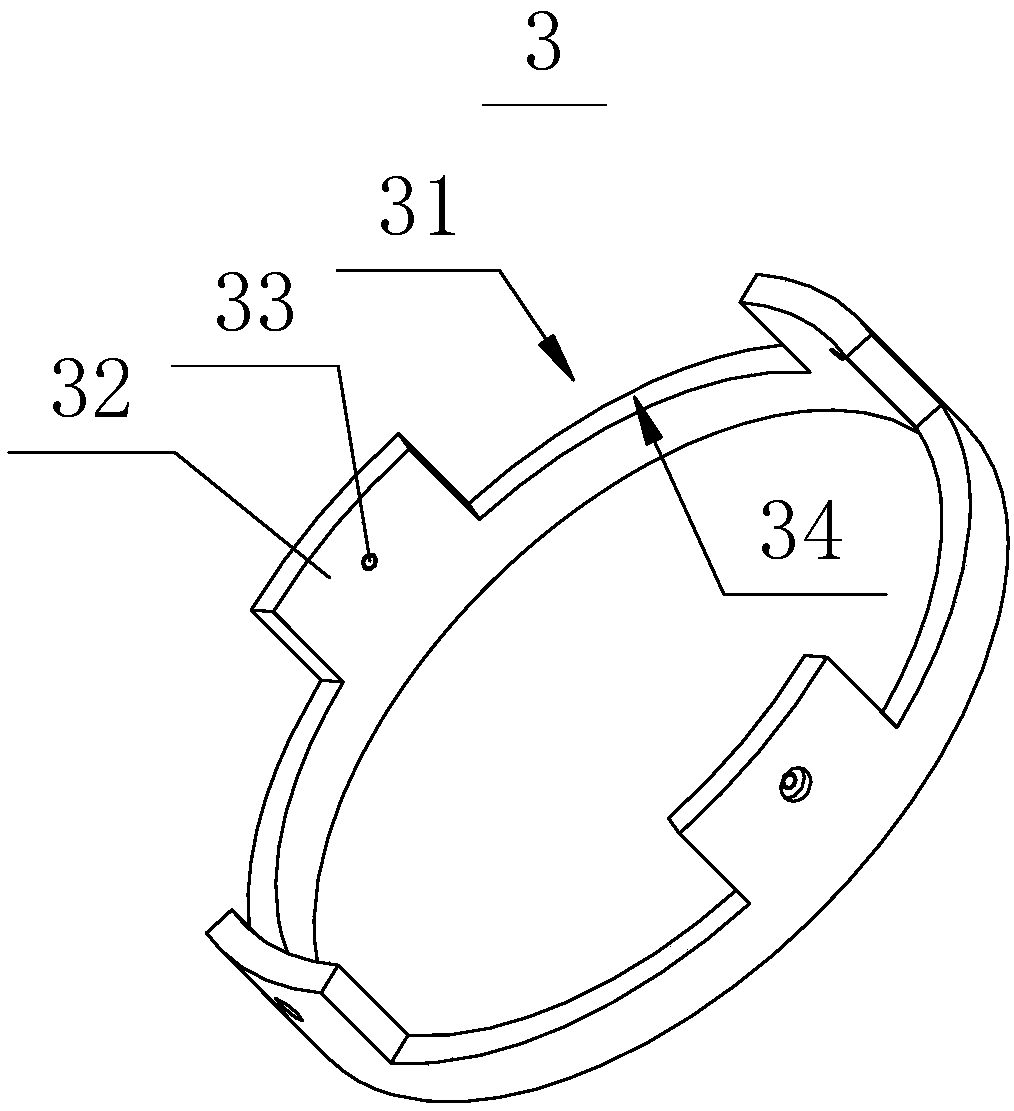

Radial stator core structure, bearing stator and hybrid radial magnetic bearing

The invention provides a radial stator core structure which comprises a radial stator core and a radial ring connected together, wherein the inner ring of the radial stator core is provided with a wire winding groove; a protruding part corresponding to the wire winding groove is arranged on the outer circumferential wall of the radial stator core; and a groove part in transition fit with the protruding part is arranged on the radial ring. The invention further provides a hybrid radial magnetic bearing which comprises a rotor and a bearing stator, wherein the rotor is coaxially arranged in thebearing stator. Compared with the prior art, the magnetic conductive area of the radial stator core is increased on the condition that the boundary dimension is not increased, and the problem in the prior art that magnetic saturation can be reached easily at the wire winding groove of the radial stator core is solved, so that the electromagnetism utilization ratio and the bearing capacity of the bearing are increased and improved. The radial stator core structure can further optimize the assembling technology to increase the assembling success rate and product percent of pass.

Owner:GREE ELECTRIC APPLIANCES INC

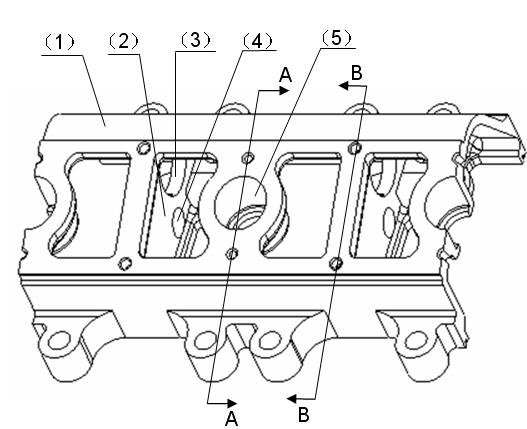

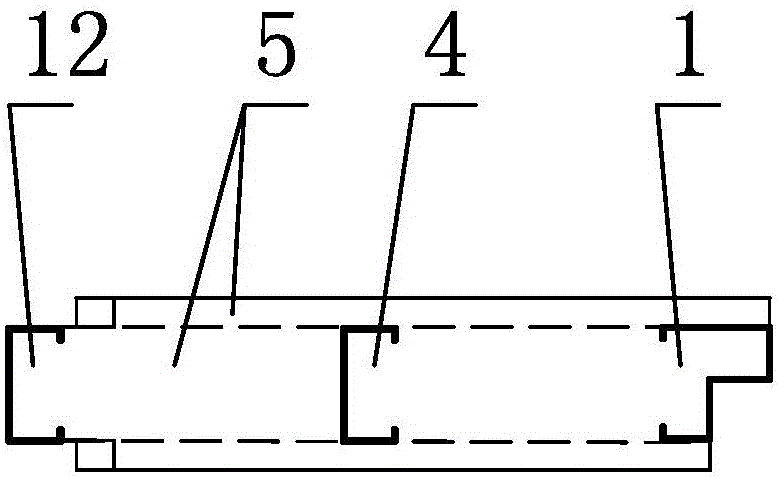

Novel integrated valve chamber cover

The invention relates to a novel integrated valve chamber cover. The novel valve chamber cover comprises a cover body (1), wherein at least one camshaft installing hole (3), an air intake rockshaft installing hole (4) and an oil sprayer installing hole (5) are formed in the cover body (1); a baffle plate (2) is arranged inside the cover body (1); the camshaft installing hole (3) and the air intake rockshaft installing hole (4) are formed in the baffle plate (2); the camshaft installing hole (3) is formed on the upper part of the air intake rockshaft installing hole (4); and the oil sprayer installing hole (5) is formed on the top of the cover body (1). The novel integrated valve chamber cover has the advantages that the novel integrated valve chamber cover has a compact structure; a few parts are required to be assembled, so that an assembling process can be simplified; a dimensional chain is shortened, so that installation precision is easy to control compared with that of the conventional structure; and a camshaft and an oil sprayer are convenient to disassemble and can be removed without the removal of related parts such as the valve chamber cover.

Owner:NO 70 INST OF CHINA NORTH IND GRP

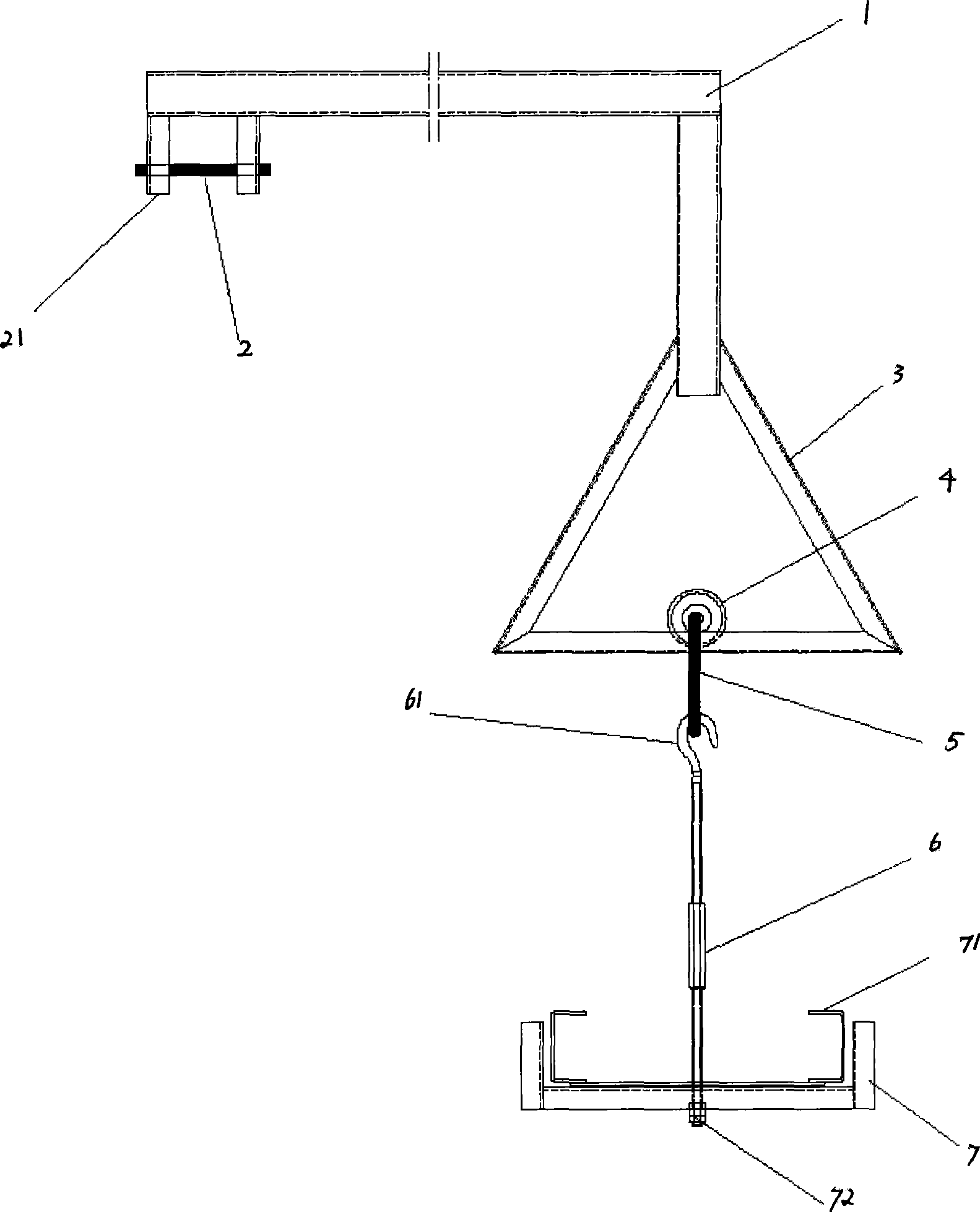

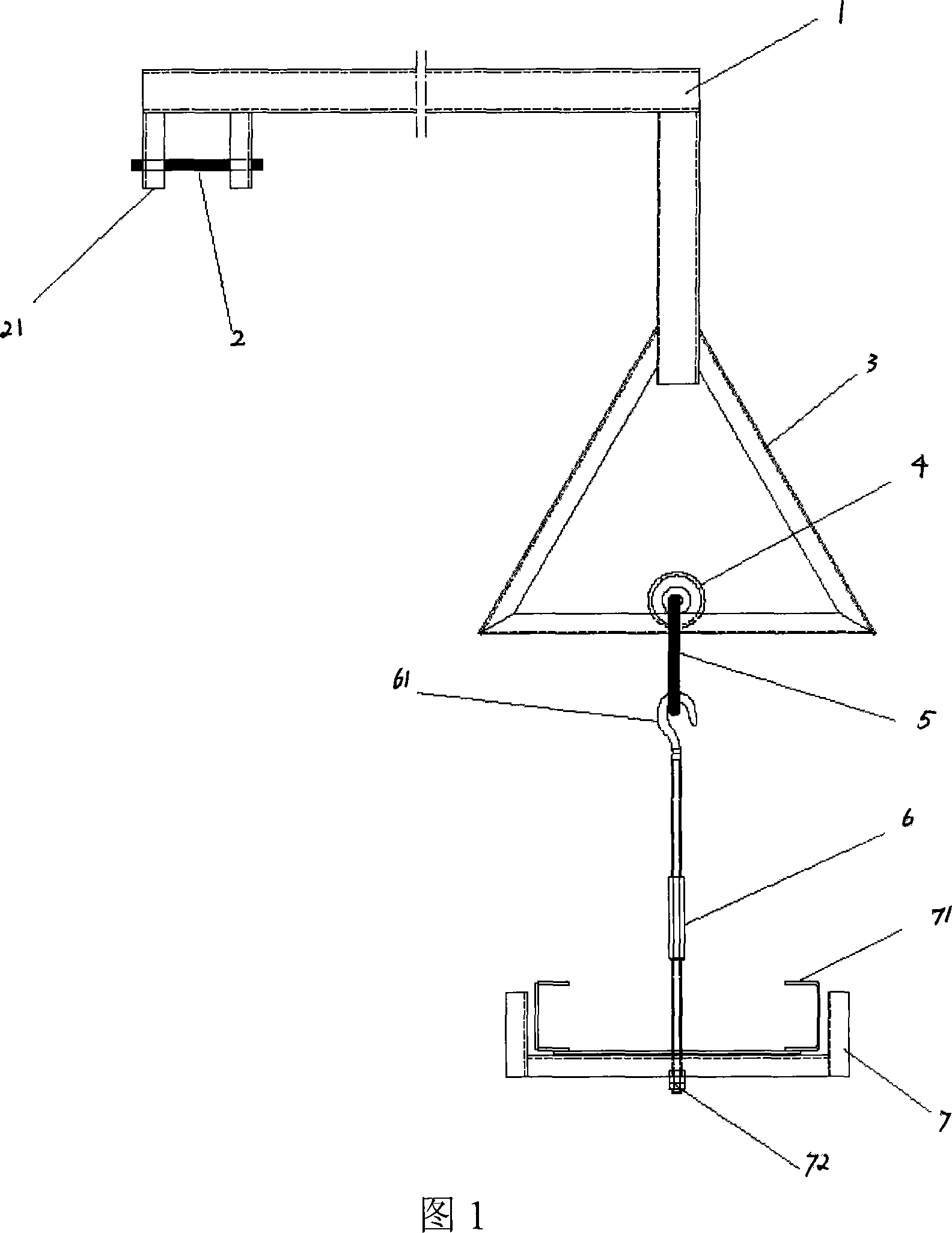

Large span cable bridge rack installation mold and installation method thereof

ActiveCN101459320ASolve efficiency problemsFix security issuesCable installation apparatusLoad-engaging elementsCable trayVertical edge

The invention relates to mounting of large span bridges, in particular to a mounting mould for a large span cable bridge, which comprises a right angle cantilever, a bolt, a hanger sliding support, a bearing, a ring, a rigging turnbuckle and a hanger bracket, wherein the bolt is horizontally connected to the end portion of a horizontal edge of the right angle cantilever, the top end of the hangersliding support is fixedly connected to a vertical edge of the right angle cantilever, the bearing is arranged in a groove of a bottom side of the hanger sliding support and can roll right and left, the ring penetrates through the bearing center and surrounds the bottom side of the hanger, and the top end of the rigging turnbuckle is hooked to the ring via a hook. The invention further provides amethod utilizing the mounting mould for large span cable bridges to mount cable bridges, which comprises steps of measuring and manufacturing the mounting mould for large span cable bridges on the site, fixing a bridge with the mounting mould, hoisting, adjusting the cable bridge and then fixing in position. The invention solves difficulties of low construction efficiency and high safety hazards during construction of high-altitude large span cable bridges, and further increases construction efficiency.

Owner:CHINA MCC20 GRP CORP

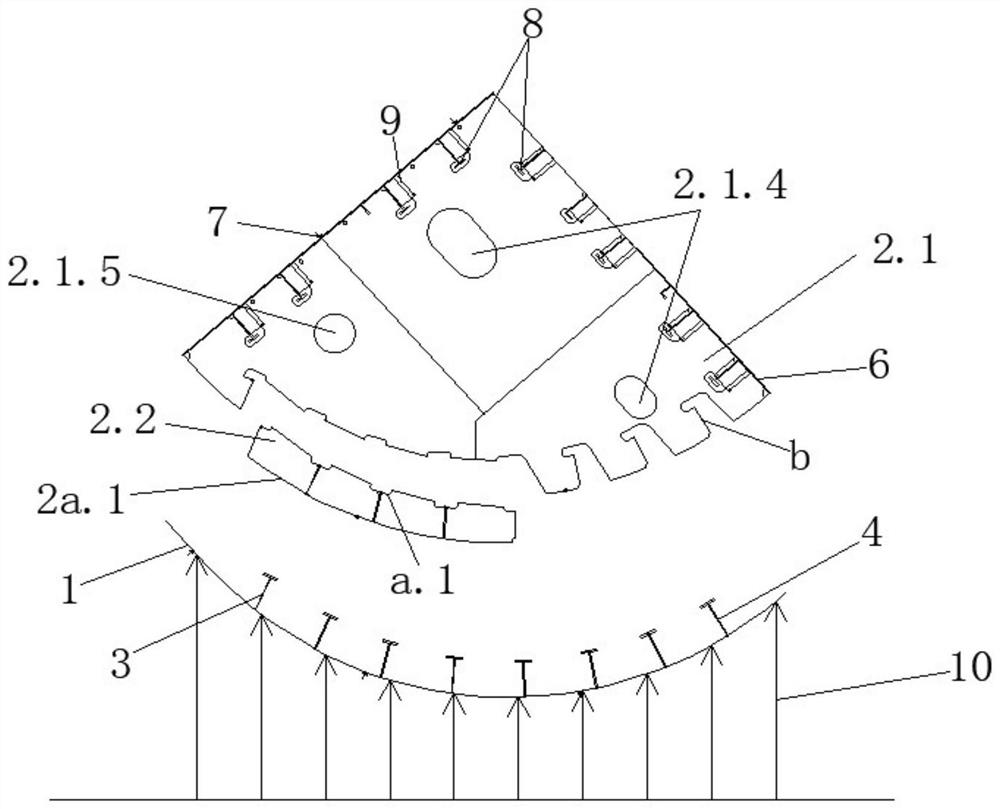

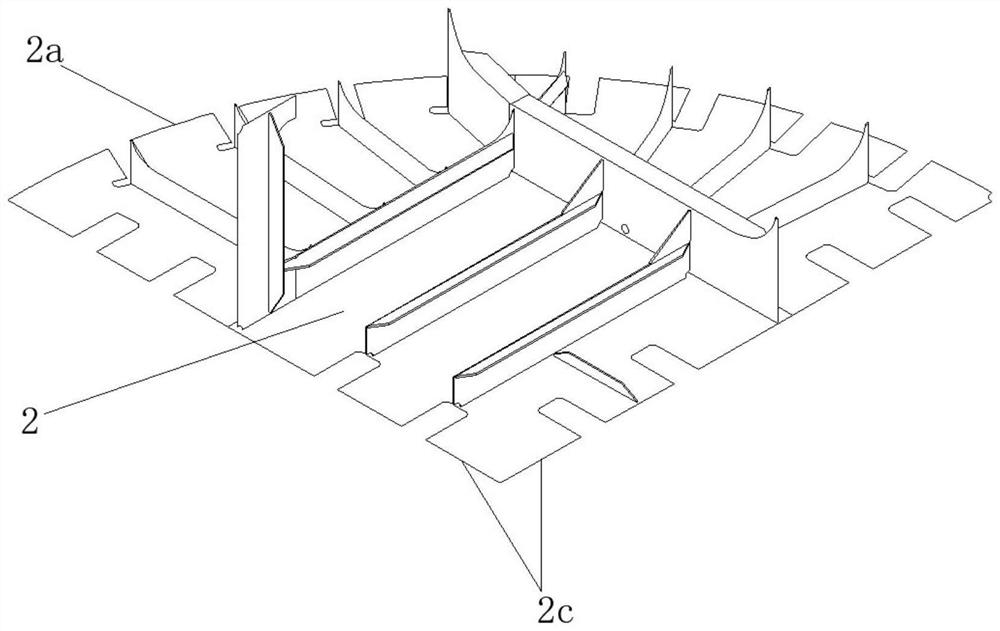

Container ship bilge-to-circle segmented structure and segmented construction method thereof

ActiveCN113815807AShorten fetal cycleImprove construction efficiencyWaterborne vesselsWatercraft hull designBilgeStructural engineering

The invention relates to the technical field of ship bilge-to-circle structures, in particular to a container ship bilge-to-circle segmented structure which comprises an outer plate and a rib plate, the outer plate is arc-shaped and is provided with a first T-shaped profile, and the rib plate is provided with an arc-shaped edge matched and butted with the outer plate. The edge of the arc-shaped edge is provided with a first through hole matched with the first T-shaped profile in an inserted mode and a first plate seam dividing the first through hole, the first plate seam divides the rib plate into a rib plate body and a rib plate splicing plate which are mutually independent and spliced, and the rib plate splicing plate comprises a part of the arc-shaped edge and a part of the first through hole. The invention further relates to a segmented construction method of the segmented structure, the segmented structure is constructed in a normal state by taking the outer plate as a jig frame surface, firstly, the outer plate splicing plate is used for splicing the arc-shaped outer plate on the jig frame, the first T-shaped profile and the rib plate splicing plate are installed on the outer plate, then the rib plate main body is installed on the outer plate, and the rib plate body and the rib plate splicing plate are spliced to form the rib plate. The tire position period can be shortened, the construction efficiency is improved, and the installation precision is easy to control.

Owner:JIANGNAN SHIPYARD GRP CO LTD

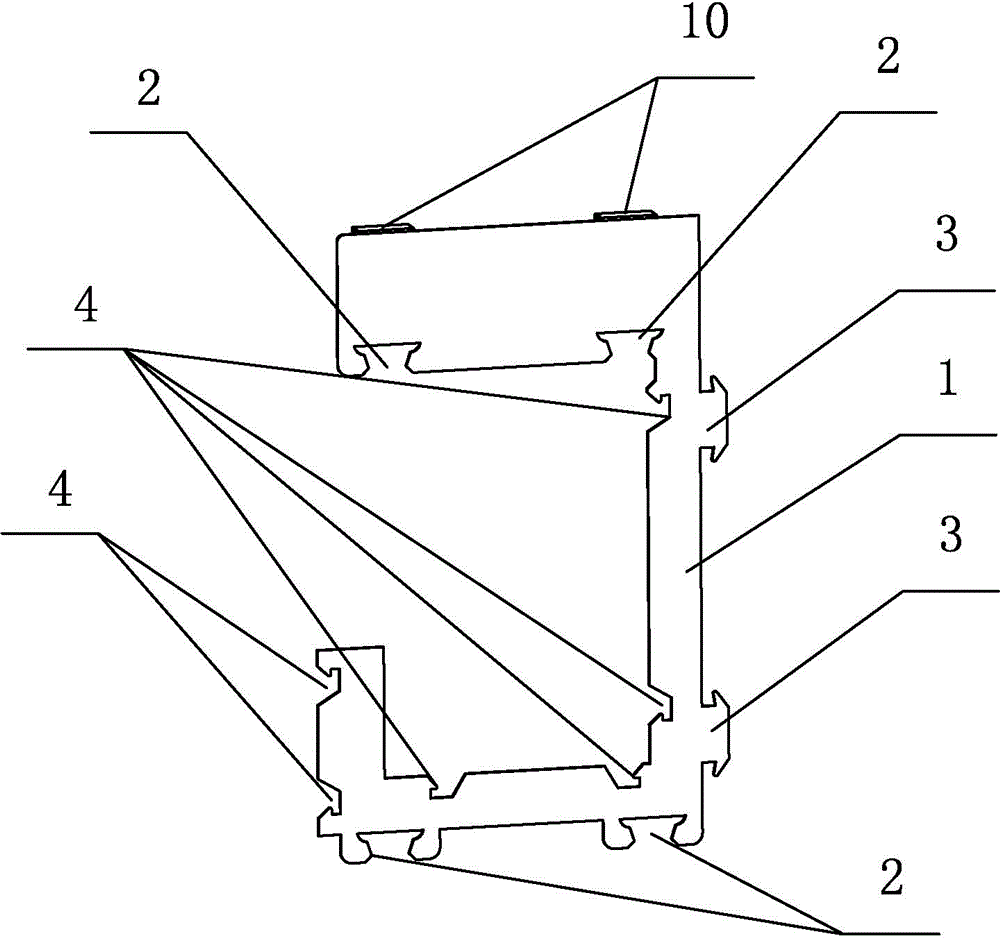

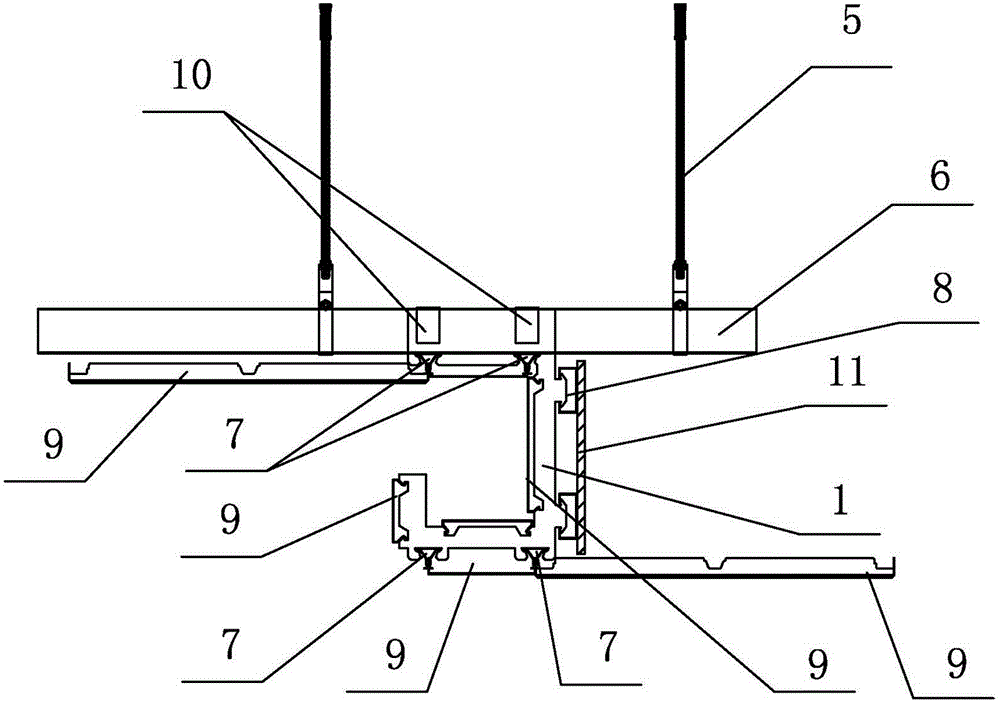

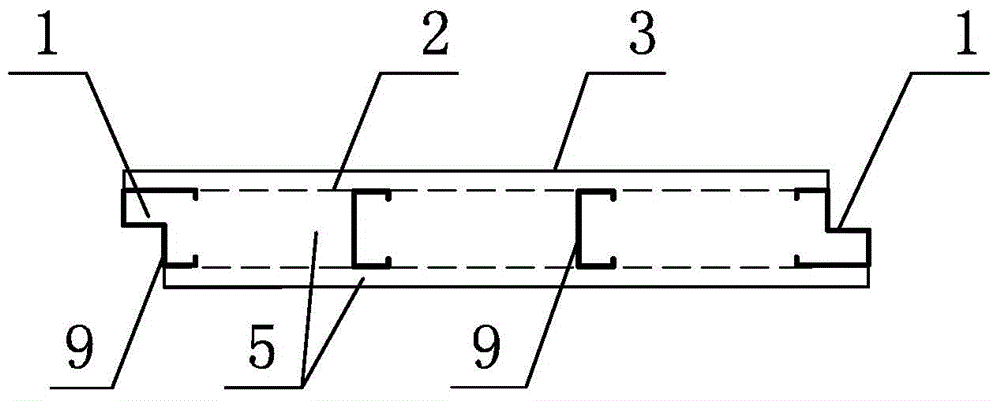

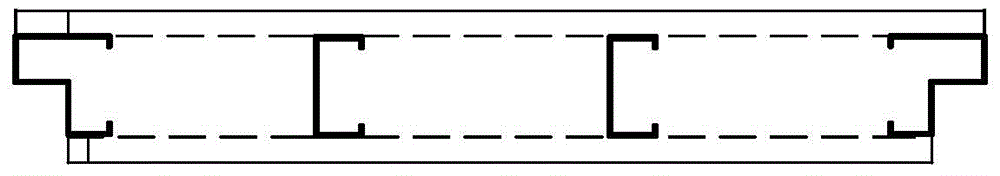

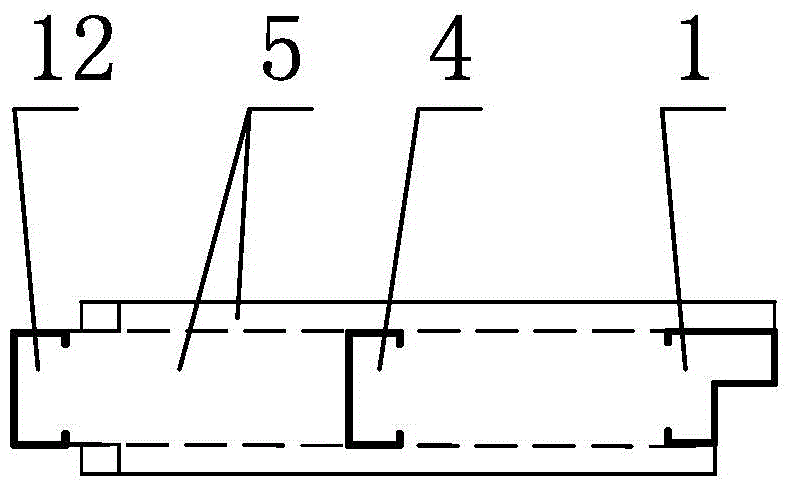

Ceiling connecting piece and ceiling with ceiling connecting pieces

The invention discloses a ceiling connecting piece which comprises a connecting piece body. A plurality of buckling openings and / or protrusions used for fixing keels are arranged on the connecting piece body, the multiple keels penetrate through the buckling openings or connected to the protrusions in a clamping mode, the keels and the connecting piece body are crossed, at least two ceiling connecting pieces hang the multiple keels which are arranged in the same direction, the keels can be provided with buckling boards or gypsum boards, and various three-dimensional shapes are formed by the multiple keels, the connecting pieces, the buckling boards and / or the gypsum boards. A ceiling connected through the ceiling connecting pieces comprises a plurality of lifting rods which are fixed to a roof at certain intervals, the lifting rods are fixedly connected with the main keel, the ceiling connecting pieces are hung on the main keel, at least two ceiling connecting pieces are arranged side by side and hang the keels which are arranged in the same direction, the buckling boards or the gypsum boards are installed on the keels, and various three-dimensional shapes are formed by the keels, the connecting pieces, the buckling boards or the gypsum boards.

Owner:奉涛

Light prefabricated combined wall

The invention discloses a light prefabricated combined wall. Three kinds of light prefabricated wall sections with identical composition are spliced through adapting steel columns or directly through bolts / self-tapping screws to from a straight combined wall, an L-shaped wall, a T-shaped wall or a cross-shaped wall; the light prefabricated wall sections are straight wall sections as a whole, a plurality of vertical steel wall columns, upper guide rails transversely connected with tops of the steel wall columns and upper guide rails transversely connected with two sides of bottoms of the steel wall columns respectively form a framework, and the wall sections are filled with light concrete; L-shaped steel wall columns or C-shaped steel wall columns are arranged at two ends of each light prefabricated wall section. With the adoption of the prefabricated combined wall, the wet operation of in-place concrete pouring is avoided, anti-pull connecting pieces are convenient to mount, the wall mounting accuracy is easy to control, the construction cost is low, and the prefabricated combined wall is suitable for mass production of light steel keel and light concrete combined houses.

Owner:WUHAN SKYSTEEL BUILDING TECH

Built-in stand type cast-in-place reinforced concrete pillar and construction method

ActiveCN104947853AEase of workConducive to installation streamlined operationStrutsBuilding material handlingReinforced concrete columnArchitectural engineering

The invention provides a built-in stand type cast-in-place reinforced concrete pillar which comprises a concrete pillar body and main ribs arranged in the concrete pillar body. The periphery of the concrete pillar body is provided with built-in stands at intervals in the height direction. The built-in stands comprise supporting rods connected with the main ribs and four stand rods connected with the other ends of the supporting rods. The stand rods are parallel to the corresponding concrete pillar body side faces. The adjacent stand rods are connected through corner connectors at the ends. The exterior of the stand rods of the built-in stand is provided with a formwork. The built-in stand type cast-in-place reinforced concrete pillar is reasonable in structure and simple in step. When the built-in stand type cast-in-place reinforced concrete pillar is mounted, as long as the situation that the outer side faces of the stand rods and the corner connectors flush with the exterior and the corner of the pillar is guaranteed, additional alignment of the formwork and adjustment and correction of the perpendicularity of the formwork are not needed in the mounting process, the requirement for the technological level of personnel who mount the formwork on site is low, construction efficiency can be greatly improved, mounting accuracy is easy to control, construction quality can be improved, and the working difficulty of formwork mounting is lowered.

Owner:CHINA ELEVENTH CHEM CONSTR

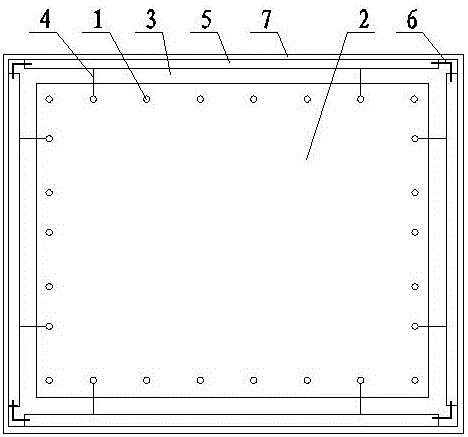

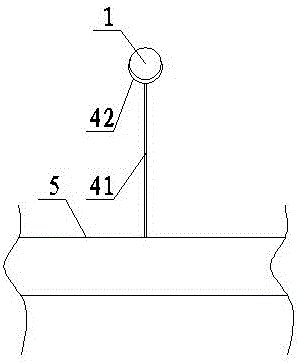

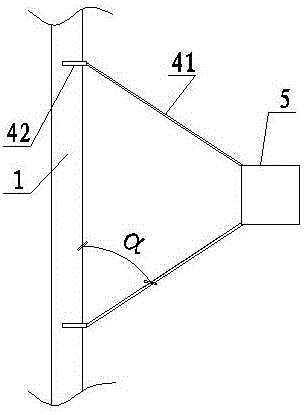

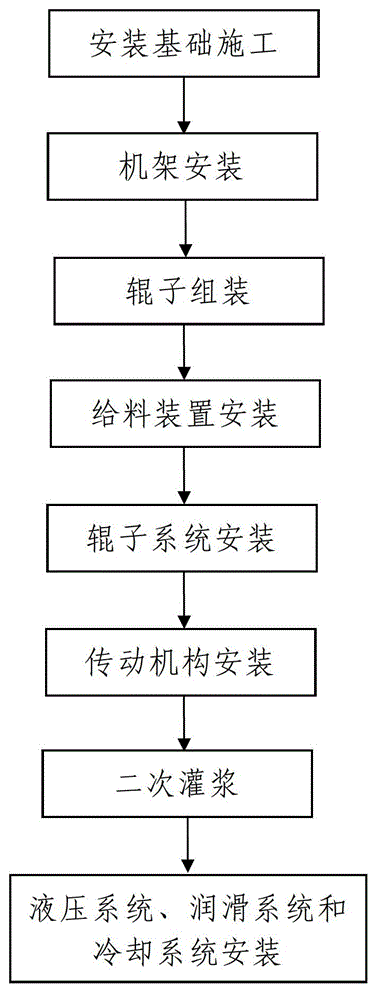

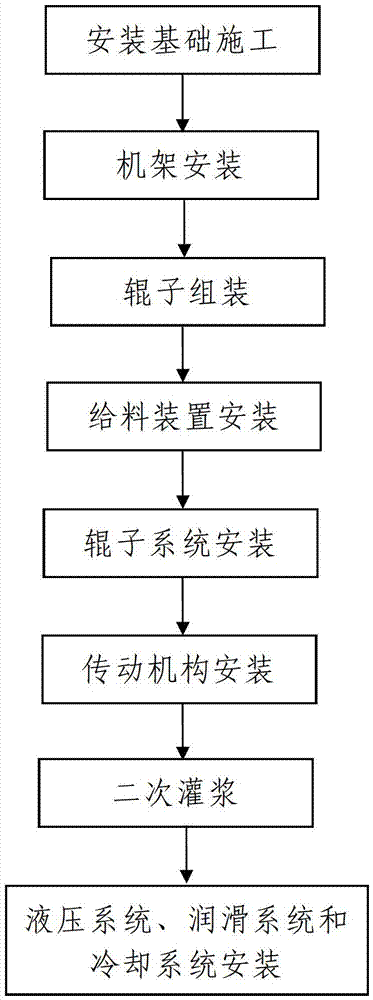

High-pressure grinding roller installation construction technology

ActiveCN103143931AThe method steps are simpleReasonable designAssembly machinesArchitectural engineeringHigh pressure

The invention discloses a high-pressure grinding roller installation construction technology. A to-be-installed high-pressure grinding roller comprises a rack, as well as a feeding device, a roller system, a lubrication system and a cooling system that are all mounted on the rack, wherein the roller system comprises a fixed roller, and a movable roller driven by a hydraulic system; the movable roller and the fixed roller are connected with a motor drive mechanism respectively through a transmission mechanism; and moreover, both the movable roller and the fixed roller comprise a roller tire, and a roller core coaxially arranged in the roller tire in a sleeving manner. The installation construction technology comprises the following steps: 1 installation foundation construction; 2 rack installation; 3 roller assembly; 4 feeding device installation; 5 roller system installation; 6 transmission mechanism installation; and 7 installation of a hydraulic system, a lubrication system and a cooling system. According to the high-pressure grinding roller installation construction technology, the steps are simple, the design is reasonable, the realization is convenient, the installation construction progress is fast, the installation construction quality is easy to control, and the problems that the construction technology is complicated, the installation progress is slower, and the installation quality is difficult to ensure during the installation construction process of the present high-pressure roller grinding machine are effectively solved.

Owner:SCEGC EQUIP INSTALLATION GRP COMPANY

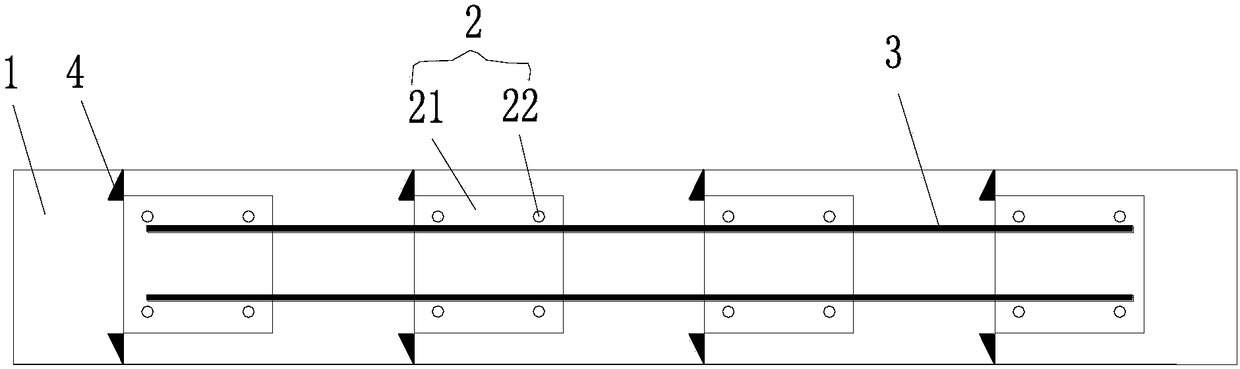

Installation method for pre-embedded iron parts

InactiveCN109306740AInstallation accuracy is easy to controlQuick and precise positioning installationBuilding constructionsRebarPre embedding

The invention discloses an installation method for pre-embedded iron parts. The method comprises the steps that the arrangement spacing of multiple pre-embedded iron parts is determined according to the construction demand at first; each pre-embedded iron part comprises a pre-embedded plate and multiple anchor bars, the anchor bars are fixed to the front face of each pre-embedded plate, and the anchor bars on each pre-embedded plate are at least arranged in two rows; then, the arrangement spacing of the pre-embedded iron parts is marked on a basic platform; the back faces of the pre-embedded plates are placed on the corresponding marks of the basic platform respectively; connection steel bars and the pre-embedded iron parts are fixed so that the pre-embedded iron parts can be integrally connected, and the integrally-connected pre-embedded iron parts are located on the same plane; the integrally-connected pre-embedded iron parts are positioned on a steel bar framework of a wallboard. According to the installation method, the pre-embedded iron parts are integrally connected for use, the overall mounting precision of the pre-embedded iron parts in group is easily controlled, the control effect is good, convenience is provided for quickly and precisely installing the pre-embedded iron parts, the installation efficiency is improved, and the construction demand is met.

Owner:MCC5 GROUP CORP SHANGHAI

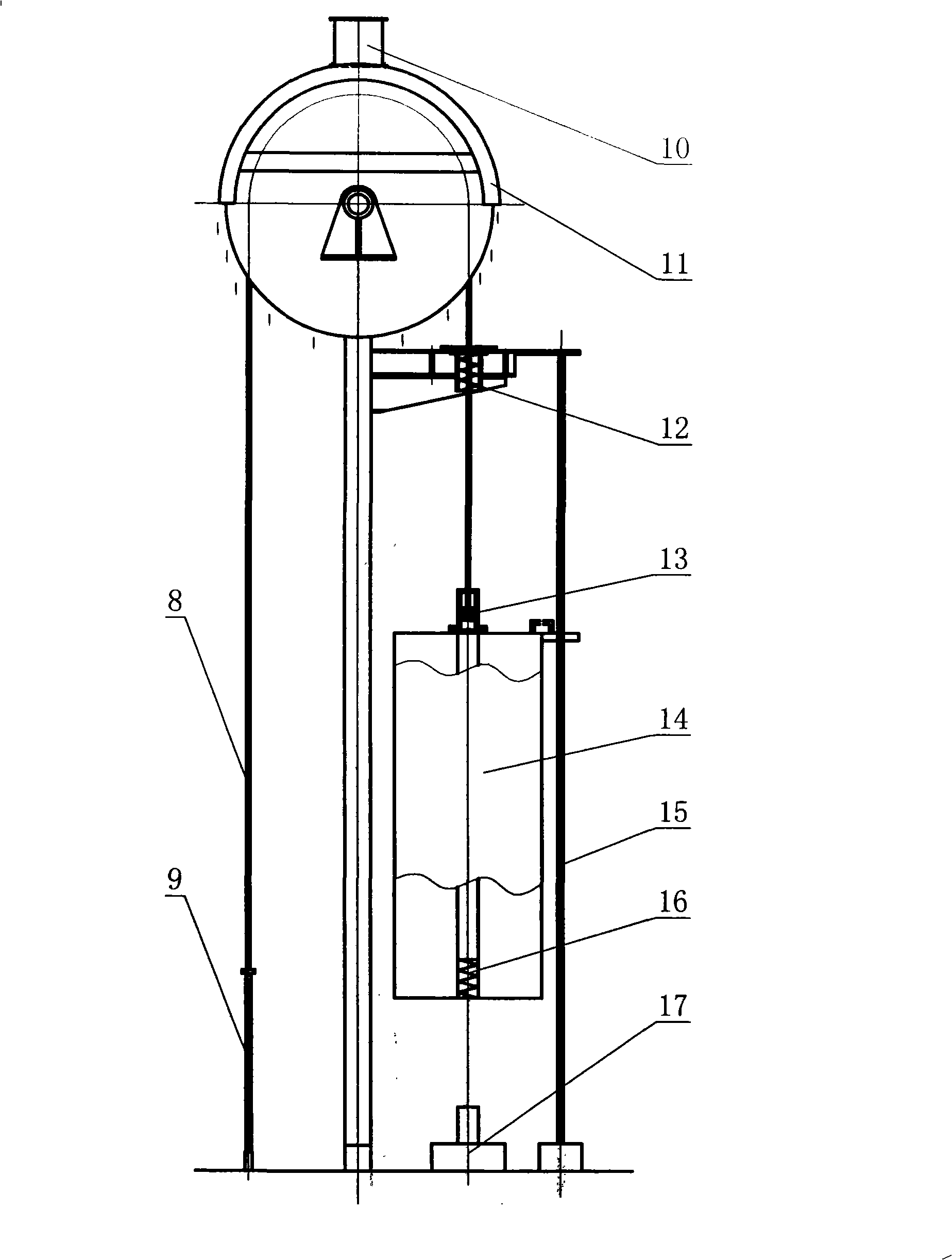

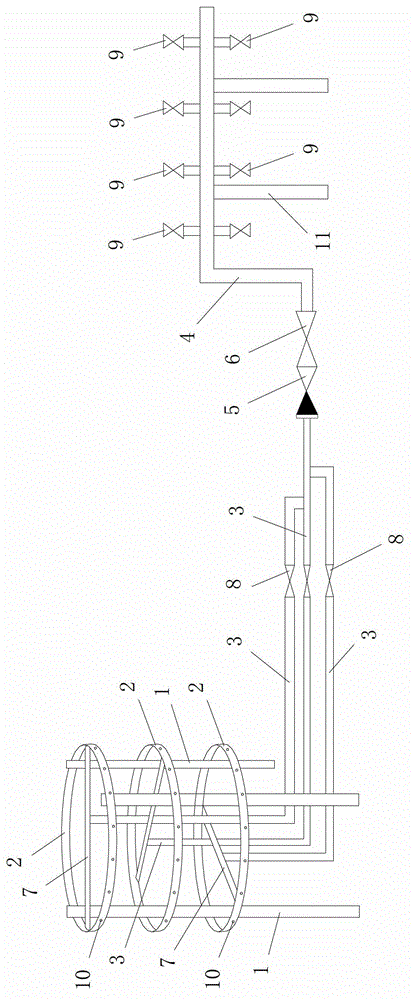

Flotation column feeding system

The invention discloses a flotation column feeding system, which comprises a feeding pipe, a plurality of pulp outflow pipes, a feeding pipe fixed support and a feeding pipe casing pipe; the feeding pipe is transversely inserted in a column body of a flotation column and is fixed with the column through a flange; a plurality of pulp outflow pipes are arranged on the pipe wall of the feeding pipe; the feeding pipe fixed support is fixedly installed in the column body and is positioned below the feeding pipe; and the feeding pipe casing pipe and a casing pipe flange are welded into a whole and are then welded on the wall of the flotation column. According to the feeding system provided by the invention, without passing through a feeding branch pipe, pulp is distributed to the flotation column through a pulp outlet directly connected with the feeding pipe, so that the probability that the pulp blocks the feeding system can be greatly reduced; and the feeding pipe is connected with the column body of the flotation column through the casing pipe, so that the installing precision can be easily controlled, the feeding pipe can be conveniently maintained and changed, a rubber liner can be simply installed in the feeding pipe, and the feeding pipe can have longer service life.

Owner:BGRIMM MACHINERY & AUTOMATION TECH CO LTD +1

Reversing radar sensing assembly

ActiveCN102632844BFirmly connectedImprove performanceWave based measurement systemsVehicle componentsRadarEngineering

The invention discloses a reversing radar sensing assembly, comprising a sensor. The reversing radar sensing assembly further comprises a cover cap, an adjusting piece and a base, wherein the cover cap is placed into a pre-set through hole of an automobile retaining bar as a front end and comprises a cylindrical cover provided with an axial through hole and an extending piece arranged at one side of the cylindrical cover; the adjusting piece comprises a cylindrical part provided with the axial through hole and a sheet-shaped part which radially expands from one end of the cylindrical part and is fixedly connected with the automobile retaining bar; the base is provided with a containing space for assembling a sensor; the cylindrical cover of the cover cap is sleeved by the adjusting piece through the cylindrical part; the base is arranged in the cylindrical cover of the cover cap by using the sensor as the front end and the base and the extending part of the cover cap and the base and the cylindrical part of the adjusting piece are respectively fixed. The reversing radar sensing assembly provided by the invention can be suitable for the automobile retaining bars with different thicknesses so as to realize hidden type installation. Furthermore, the reversing radar sensing assembly is simple in structure, stable in connection and easy to install.

Owner:STEELMATE CO LTD

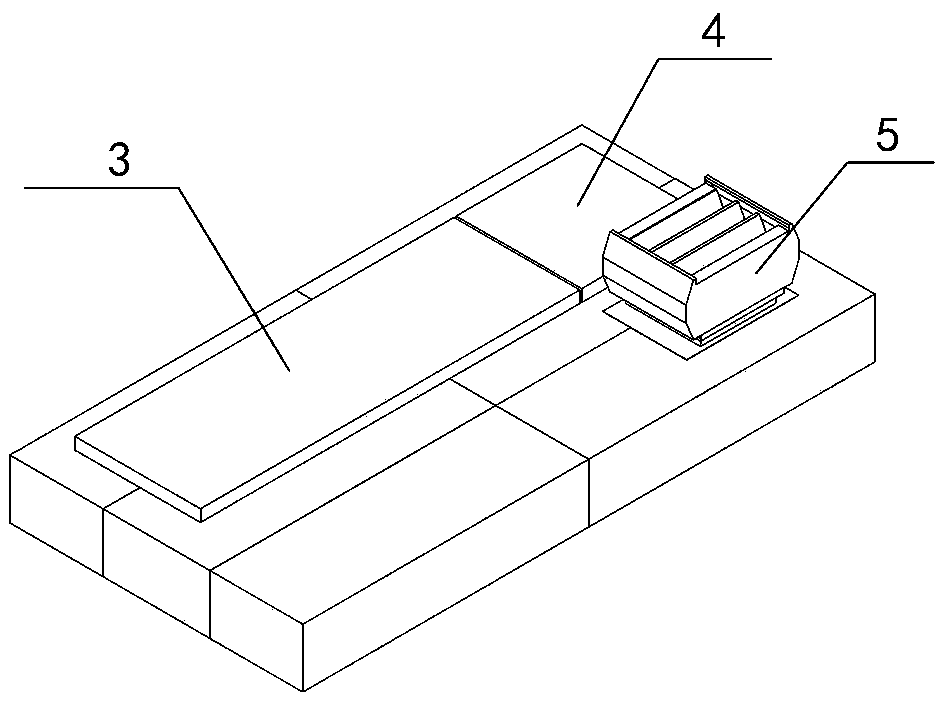

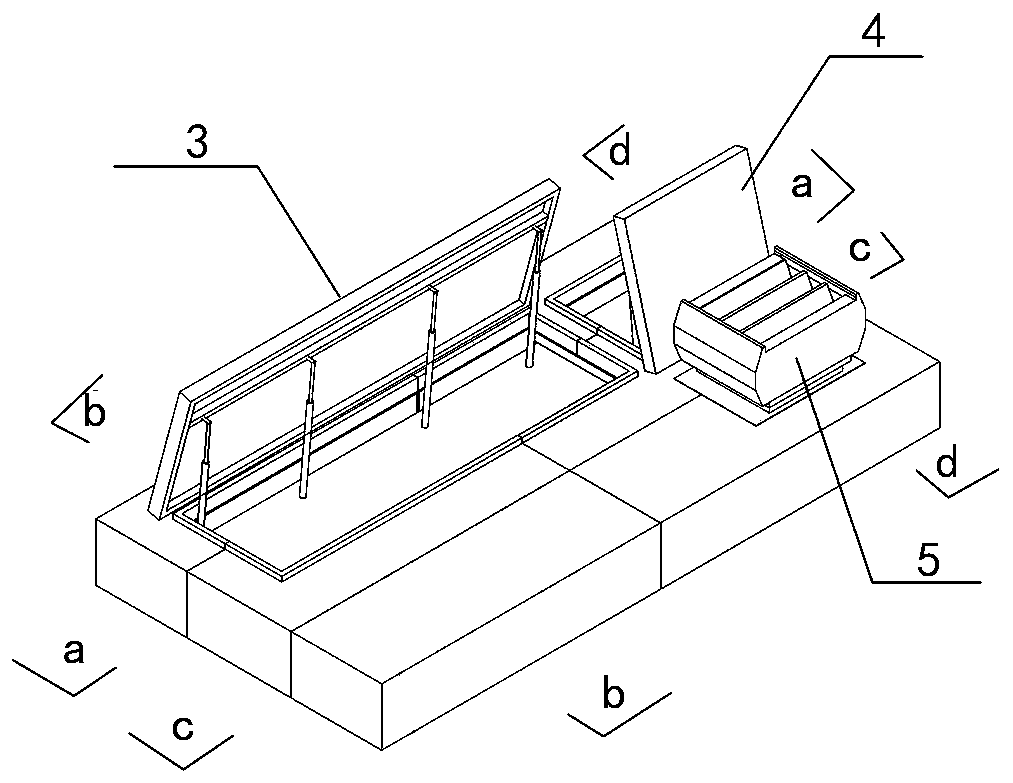

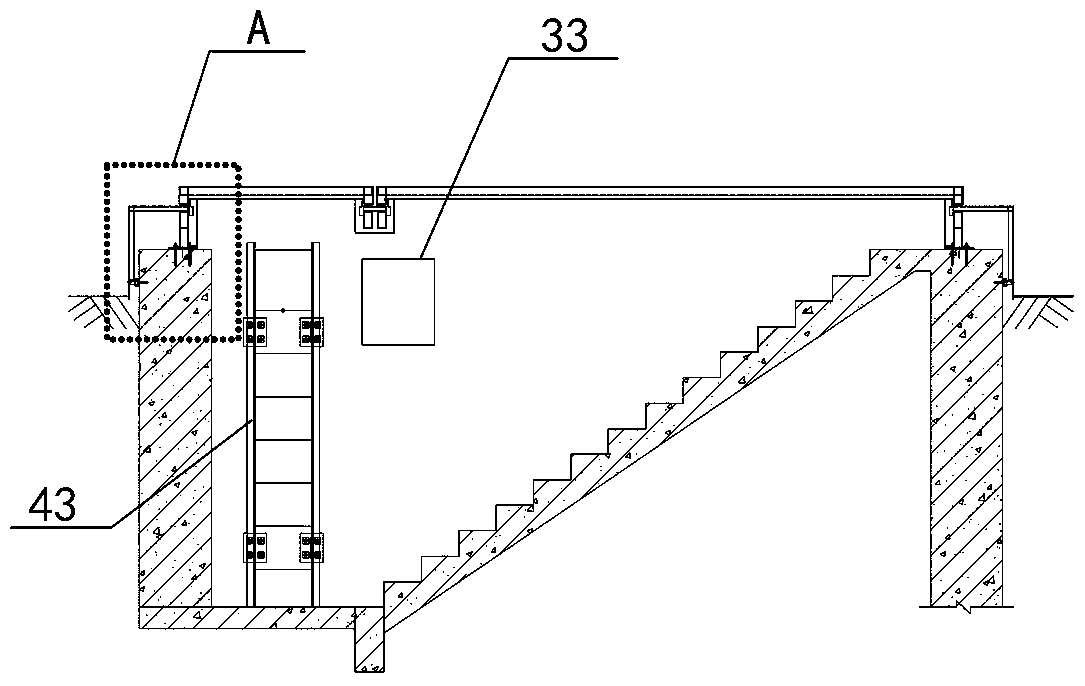

Urban pipe gallery entrance and exit system and installation method thereof

PendingCN109056805AEnsure safetyReduce distortionArtificial islandsUnderwater structuresKeelElectro hydraulic

The invention discloses an urban pipe gallery entrance and exit system, which is arranged at an entrance and an exit of an urban pipe gallery and comprises a panel supporting keel, a frame, a steel panel, an electric opening system, a manual opening system and a horizontal louver system. The electric opening system comprises an electric opening fan, an electric hydraulic rod and a control electricbox, wherein the electric opening fan is connected to the panel supporting keel through a hinge, and one end of the electric hydraulic rod is connected to a building structure while the other end ofthe electric hydraulic rod is connected to the electric opening fan. The manual opening system comprises a manual opening fan, a manual pneumatic push rod and an escalator, wherein the manual openingfan is connected to the panel supporting keel through the hinge, one end of the manual pneumatic pushing rod is connected to the panel supporting keel while the other end of the manual pneumatic pushing rod is connected to the manual opening fan, and the escalator is arranged below the manual opening fan. The exit height of the urban pipe gallery entrance and exit system is lower, the road administration appearance is more attractive, the structure is safe, the installation accuracy is easier to control, and the engineering quality is guaranteed. An outer panel is tightly spliced and connected, the deformation is very small, and the surface material is easier to replace.

Owner:BEIJING GENERAL MUNICIPAL ENG DESIGN & RES INST +1

Manufacturing and mounting method for combined wall of fabricated house

A manufacturing and mounting method of a combined wall for a fabricated house comprises the steps that firstly, a plurality of outer walls and inner walls are prefabricated, each outer wall is provided with a light microcrystalline plate and a concrete wall layer, each inner wall is provided with a concrete wall layer, and a plurality of floor connecting pieces are arranged on the top sides of ceiling keels of the outer walls and the inner walls in a penetrating mode through a plurality of connecting bolts; a plurality of foundation bolts are arranged on the bottom sides of the ground keels of the outer wall body and the inner wall body in a penetrating mode; a concrete foundation is manufactured, a plurality of wall body mounting holes are machined in the concrete foundation, then the wall body mounting holes are filled with grouting materials, the outer wall body and the inner wall body are hoisted to the concrete foundation, and the foundation bolts are inserted into the wall body mounting holes respectively; and the floor slab is hoisted to the top side of the bottommost layer of combined wall body, and the outer wall body and the inner wall body are hoisted to the lower layer of combined wall body layer by layer. The combined wall can be prefabricated in a factory or on site, wet operation of concrete pouring on site is avoided, and the installation precision is easy to control.

Owner:洛阳北玻轻晶石新材料有限公司

High-pressure grinding roller installation construction technology

ActiveCN103143931BThe method steps are simpleReasonable designAssembly machinesMotor driveArchitectural engineering

The invention discloses a high-pressure grinding roller installation construction technology. A to-be-installed high-pressure grinding roller comprises a rack, as well as a feeding device, a roller system, a lubrication system and a cooling system that are all mounted on the rack, wherein the roller system comprises a fixed roller, and a movable roller driven by a hydraulic system; the movable roller and the fixed roller are connected with a motor drive mechanism respectively through a transmission mechanism; and moreover, both the movable roller and the fixed roller comprise a roller tire, and a roller core coaxially arranged in the roller tire in a sleeving manner. The installation construction technology comprises the following steps: 1 installation foundation construction; 2 rack installation; 3 roller assembly; 4 feeding device installation; 5 roller system installation; 6 transmission mechanism installation; and 7 installation of a hydraulic system, a lubrication system and a cooling system. According to the high-pressure grinding roller installation construction technology, the steps are simple, the design is reasonable, the realization is convenient, the installation construction progress is fast, the installation construction quality is easy to control, and the problems that the construction technology is complicated, the installation progress is slower, and the installation quality is difficult to ensure during the installation construction process of the present high-pressure roller grinding machine are effectively solved.

Owner:SCEGC EQUIP INSTALLATION GRP COMPANY

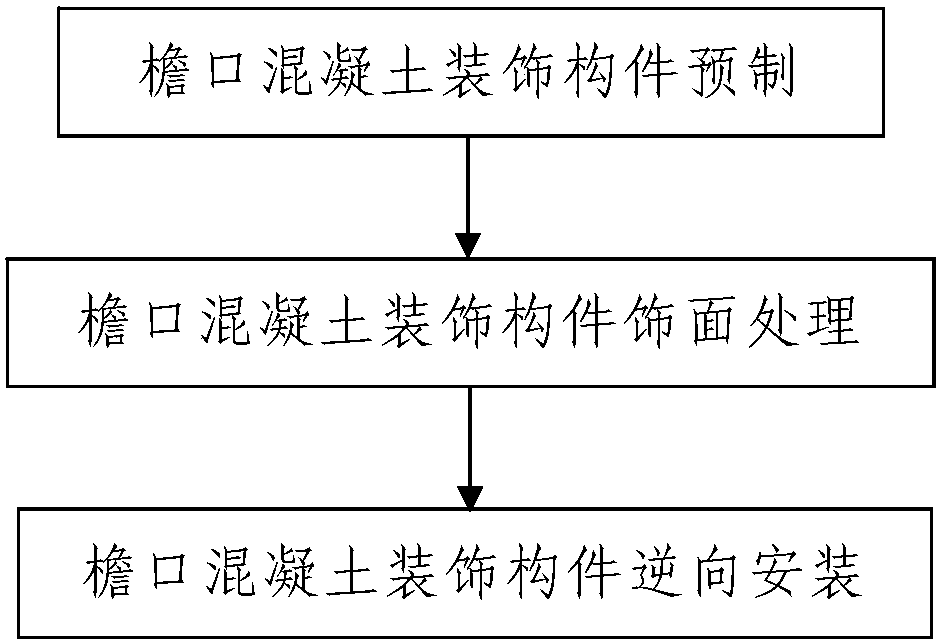

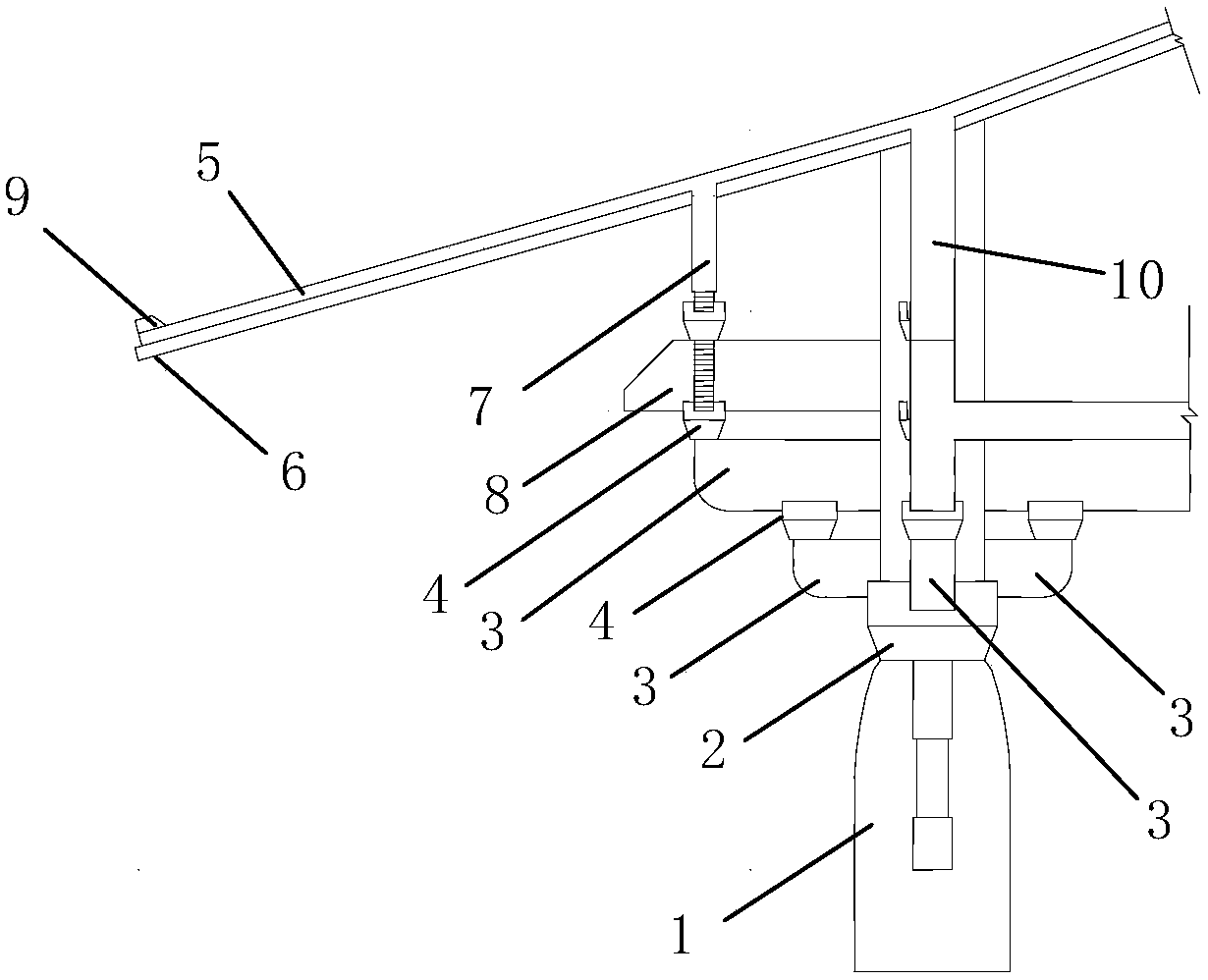

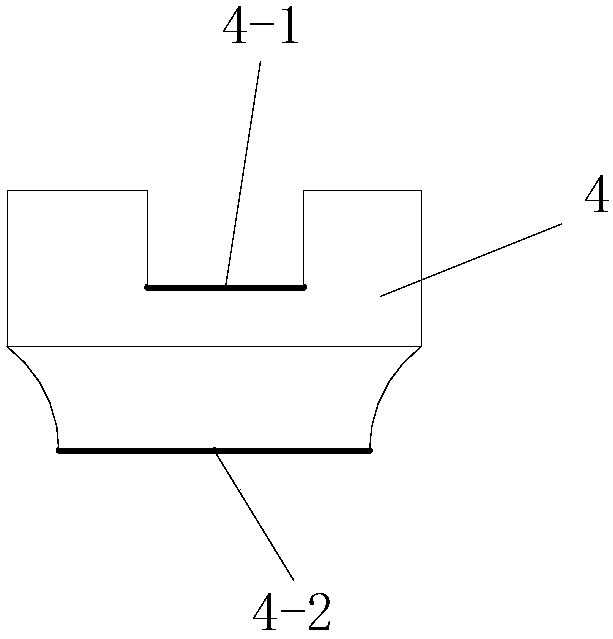

Construction method of prefabrication and reverse installation of concrete decorative components for cornices of antique buildings

Owner:SHAANXI CONSTR ENG GRP NO 7 BUILDING ENG

Manufacturing method of prefabricated column, assembly method of column and beam

ActiveCN109537811BReliable forceEasy to produceStrutsCeramic shaping apparatusConstruction engineeringMechanical engineering

Owner:CHINA CONSTR SCI & TECH CO LTD

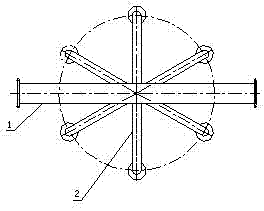

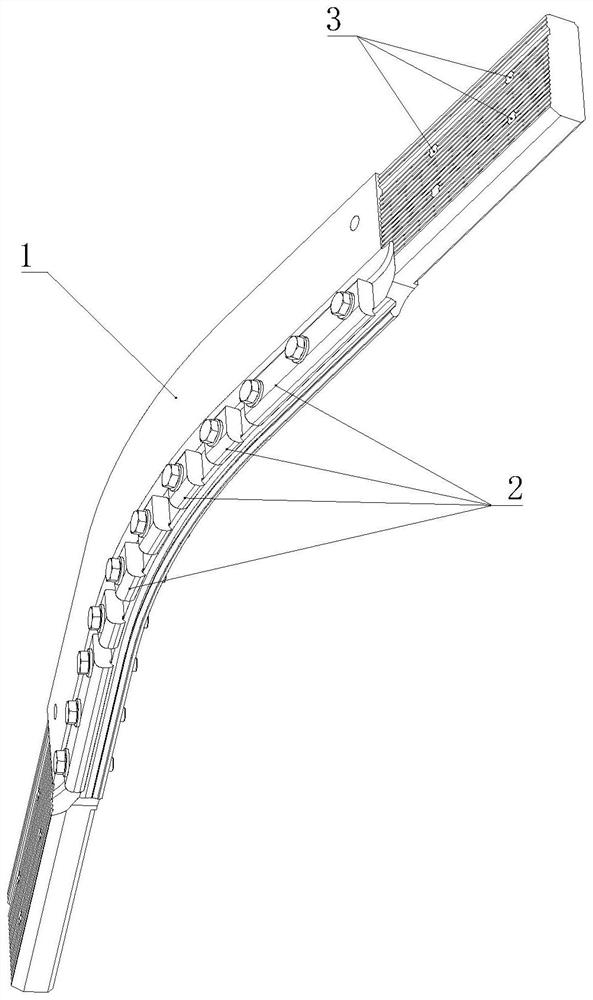

Rail transit turnout busbar transition piece and contact line clamping device

PendingCN111731160AAvoid the problem that the bending angle is too large and difficult to processReduce dosageCoupling device connectionsPower railsBusbarEngineering

The invention discloses a rail transit turnout busbar transition piece and a contact line clamping device. The transition piece comprises a transition piece body, the transition piece body is bent inthe length direction, and a clamping plate capable of clamping a contact line is arranged on the lower edge of the transition piece body. The structure for applying the transition piece to the contactline clamping device comprises a pair of transition piece bodies, wherein each transition piece body is bent along the length direction, the transition piece further comprises an anchoring plate connected with a positioning device, the pair of transition piece bodies are fixed on the anchoring plate to form an X shape, bus bars are arranged at the two ends of each transition piece body, and the clamping plate capable of clamping the contact line is arranged at the lower edge of each transition piece body; the transition piece is used for replacing a busbar so that the problem that the busbaris difficult to process due to an overlarge bending angle is avoided; the device is of an integrated hyperbolic structure, and the number of positioning and hanging parts and the number of center anchoring devices are reduced. The device is of an integrated structure, and the two contact lines can be consistent in height.

Owner:CHINA RAILWAY HIGH SPEED ELECTRIFICATION EQUIP CORP LTD

A lightweight prefabricated composite wall

The invention discloses a light prefabricated combined wall. Three kinds of light prefabricated wall sections with identical composition are spliced through adapting steel columns or directly through bolts / self-tapping screws to from a straight combined wall, an L-shaped wall, a T-shaped wall or a cross-shaped wall; the light prefabricated wall sections are straight wall sections as a whole, a plurality of vertical steel wall columns, upper guide rails transversely connected with tops of the steel wall columns and upper guide rails transversely connected with two sides of bottoms of the steel wall columns respectively form a framework, and the wall sections are filled with light concrete; L-shaped steel wall columns or C-shaped steel wall columns are arranged at two ends of each light prefabricated wall section. With the adoption of the prefabricated combined wall, the wet operation of in-place concrete pouring is avoided, anti-pull connecting pieces are convenient to mount, the wall mounting accuracy is easy to control, the construction cost is low, and the prefabricated combined wall is suitable for mass production of light steel keel and light concrete combined houses.

Owner:WUHAN SKYSTEEL BUILDING TECH

Large span cable bridge rack installation mold and installation method thereof

ActiveCN101459320BImprove construction efficiencyEasy constructionCable installation apparatusLoad-engaging elementsVertical edgeEngineering

The invention relates to mounting of large span bridges, in particular to a mounting mould for a large span cable bridge, which comprises a right angle cantilever, a bolt, a hanger sliding support, a bearing, a ring, a rigging turnbuckle and a hanger bracket, wherein the bolt is horizontally connected to the end portion of a horizontal edge of the right angle cantilever, the top end of the hangersliding support is fixedly connected to a vertical edge of the right angle cantilever, the bearing is arranged in a groove of a bottom side of the hanger sliding support and can roll right and left, the ring penetrates through the bearing center and surrounds the bottom side of the hanger, and the top end of the rigging turnbuckle is hooked to the ring via a hook. The invention further provides amethod utilizing the mounting mould for large span cable bridges to mount cable bridges, which comprises steps of measuring and manufacturing the mounting mould for large span cable bridges on the site, fixing a bridge with the mounting mould, hoisting, adjusting the cable bridge and then fixing in position. The invention solves difficulties of low construction efficiency and high safety hazards during construction of high-altitude large span cable bridges, and further increases construction efficiency.

Owner:CHINA MCC20 GRP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com