Reversing radar sensing assembly

A sensor component, reversing radar technology, applied in vehicle parts, instruments, radio wave measurement systems, etc., can solve the problems of affecting detection accuracy, damage, and the sensor assembly structure cannot be installed on the bumper, to ensure accuracy and performance. Stable and controllable installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

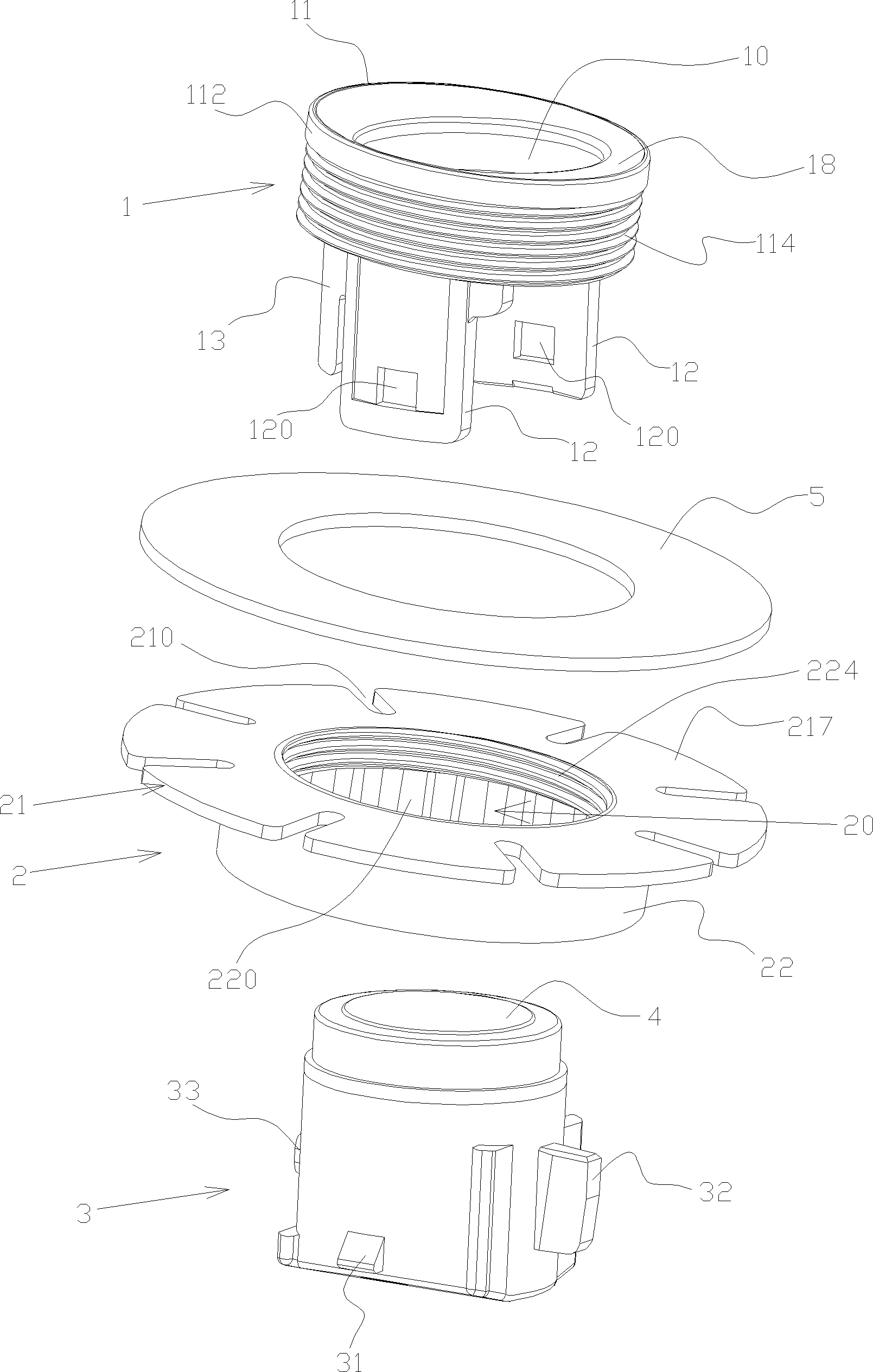

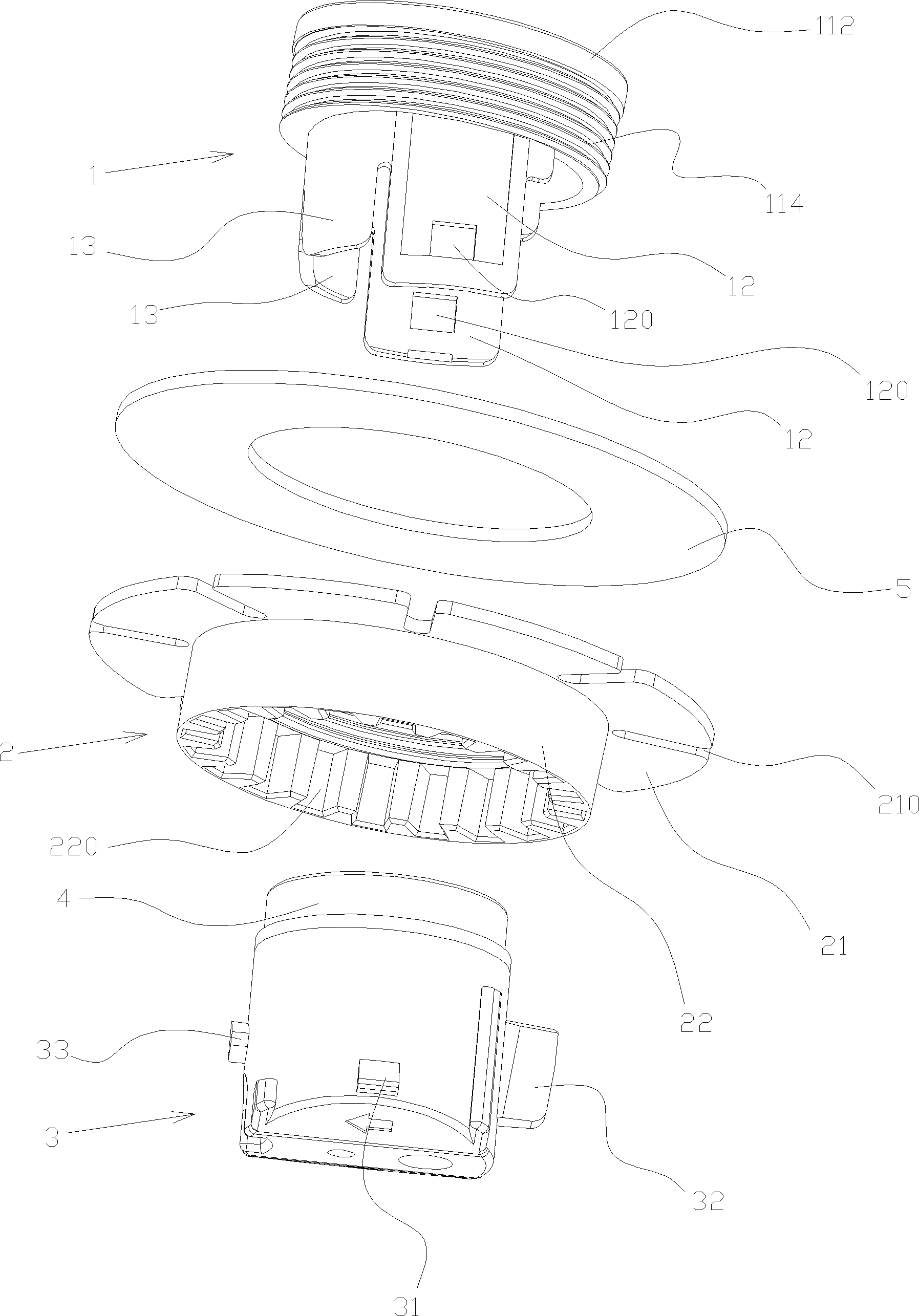

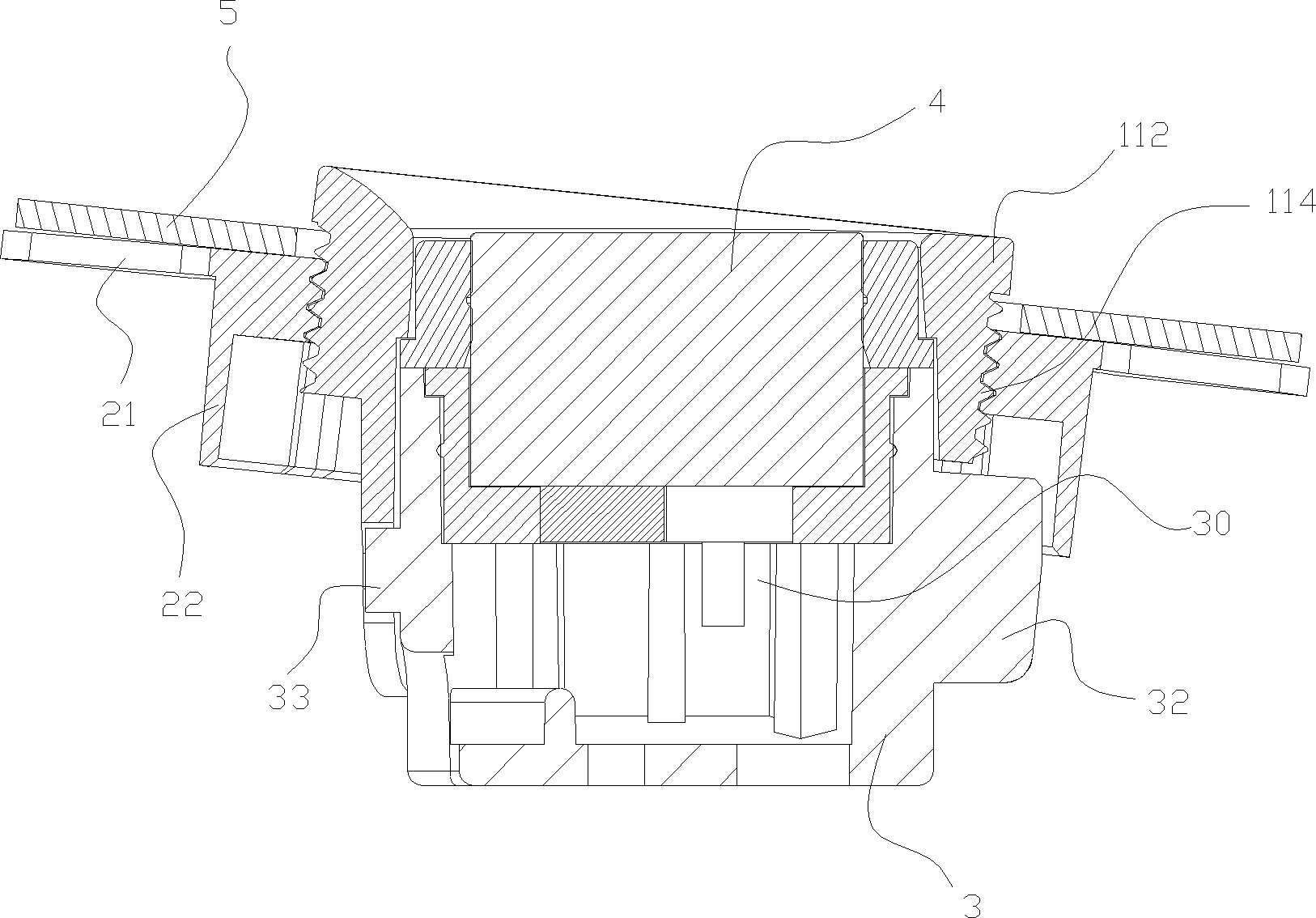

[0029] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0030] The reversing radar sensing assembly of the present invention, as a necessary component of the car reversing radar system, is often installed in the preset through hole on the rear bumper or similar front-end parts of the car, and can also be installed in other directions of the car. For example, in the through-holes preset on the side or forward guard bars or similar front parts, so that the distance between these cars and the roadblocks in this direction is initially sensed. A plurality of through holes are usually provided on the bumper or similar front-end parts on the same side of the car, so that a plurality of reversing radar sensor assemblies of the present invention are installed correspondingly, and a central control unit is arranged inside the car, and the central control unit collects various Set the signal detected by the sensing component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com