Steel structure joint, prefabricated column, manufacturing method thereof and assembling method of column beam

A technology for steel structures and prefabricated columns, applied in the directions of columns, piers, pillars, etc., can solve the problems of difficult on-site operation of column and beam installation, high maintenance cost in the whole life cycle, inconvenient production and production of prefabricated columns, etc., and achieves easy control of installation accuracy. , Improve construction efficiency and construction quality, without the effect of operating space restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

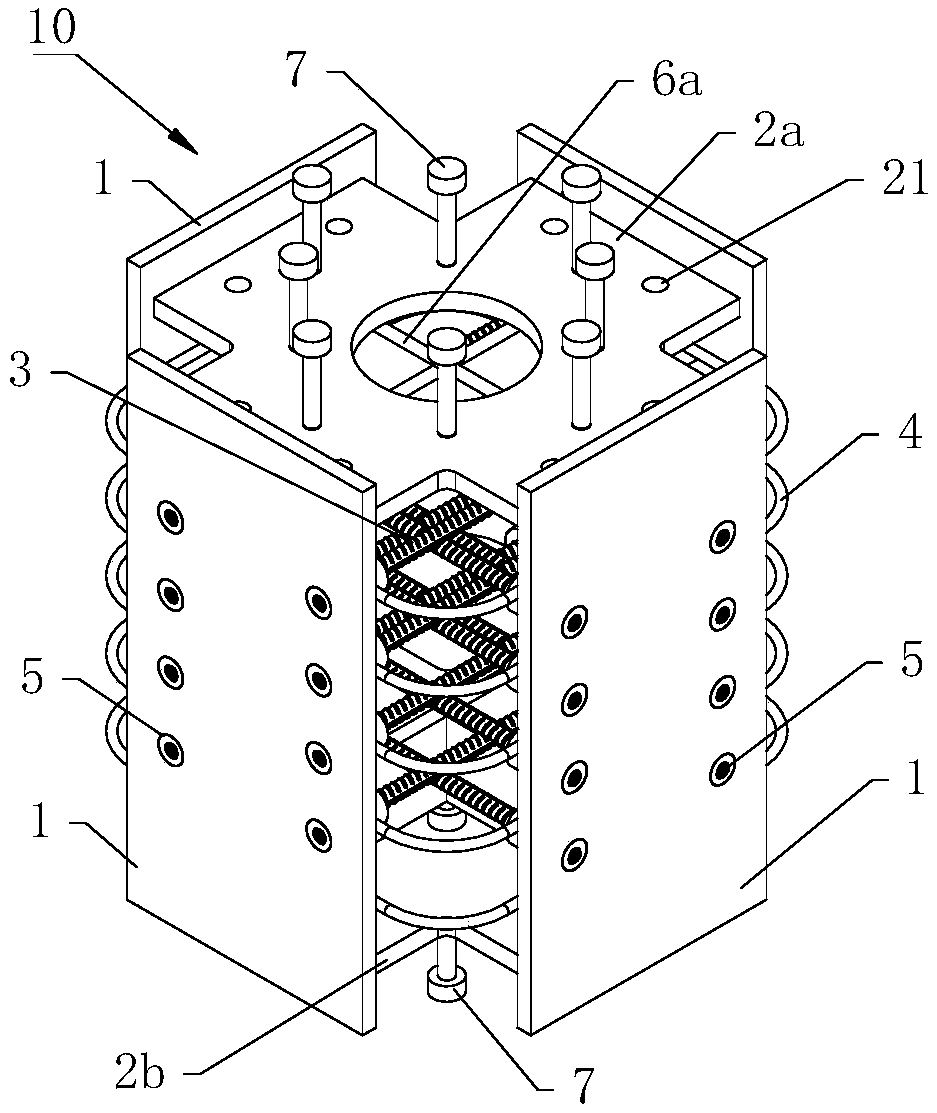

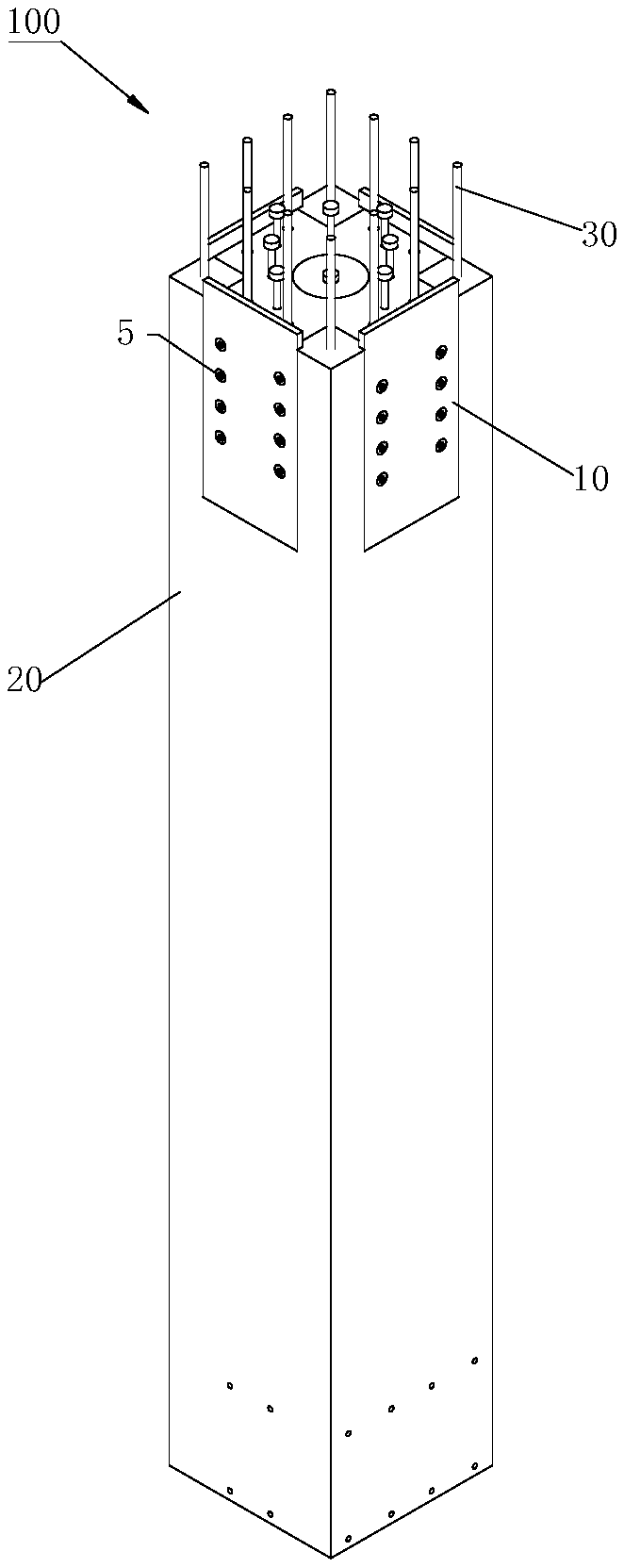

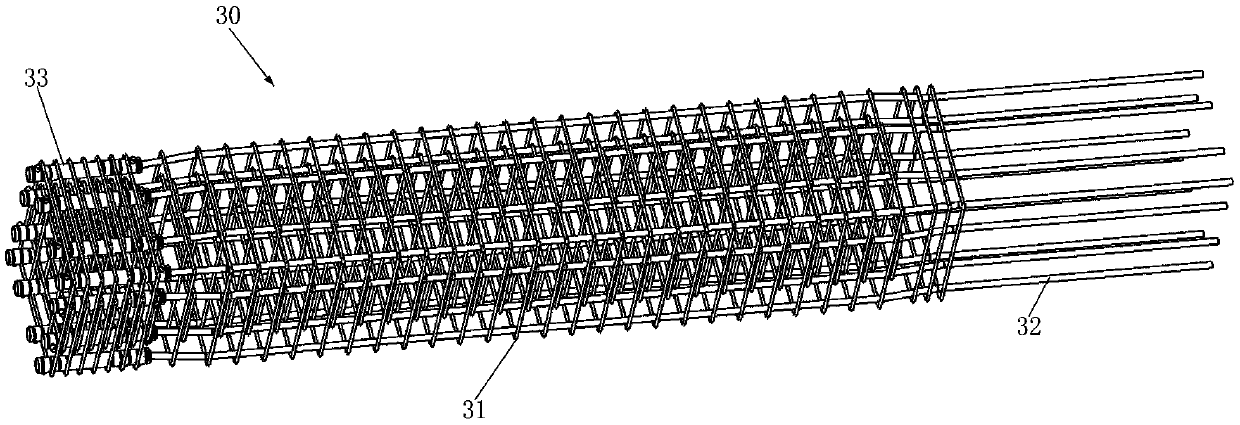

[0080] See figure 1 , shows a steel structure node 10 provided by this embodiment, including a side plate 1 on the side, a top plate 2a on the top, several pairs of tie rods 3, several stirrups 4, high-strength bolt sleeves 5, and a middle cross plate 6a and the base plate 2b at the bottom.

[0081] In this embodiment, the side surfaces of the top plate 2a and the bottom plate 2b both extend out from the connecting portion, and both the top plate 2a and the bottom plate 2b are in the shape of a cross. Both the connecting portion of the top plate 2a and the connecting portion of the bottom plate 2b are provided with a plurality of perforations 21 along their respective thickness directions, and the reserved holes 21 are used for the steel bars of the reinforcement cage to pass through.

[0082] The connecting portion of the top plate 2a is fixedly connected to the top inner surface of the side plate 1, and the connecting portion of the bottom plate 2b is fixedly connected to t...

Embodiment 2

[0143] See Figure 18 , the present embodiment provides another steel structure node 10, including a side plate 1 on the side, a top plate 2a on the top, several pairs of tie rods 3, several stirrups 4 and a bottom plate 2b.

[0144] Except for the content mentioned below, the steel structure node 10 of this embodiment is the same as that of Embodiment 1:

[0145] In this embodiment, high-strength bolt sleeves 8 are embedded in the perforations on the top plate 2a and the bottom plate 2b, and the high-strength bolt sleeves 8 protrude from the plane of the top plate 2a. The high-strength bolt sleeve 8 is installed on both ends of the vertical tension bolt 9, and the high-strength bolt sleeve 8 on the top plate 2a is connected with the high-strength bolt sleeve 8 on the bottom plate 2b through the vertical tension bolt 9.

[0146] The connecting portion of the top plate 2 a is fixedly connected to the top surface of the side plate 1 , and the connecting portion of the bottom pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com