Rigidity-heterosexual type combined shear connector

A technology for connecting parts and elastic parts, which is applied in the field of steel and concrete composite structures, can solve the problems of weak shear strength of the joint surface, large stress on welding studs, and excessively dense welding studs, and achieves good economic benefits and scientific research value. High accuracy and versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

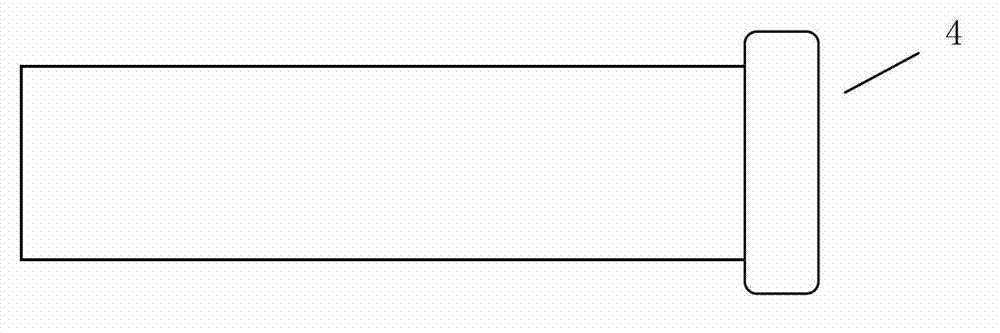

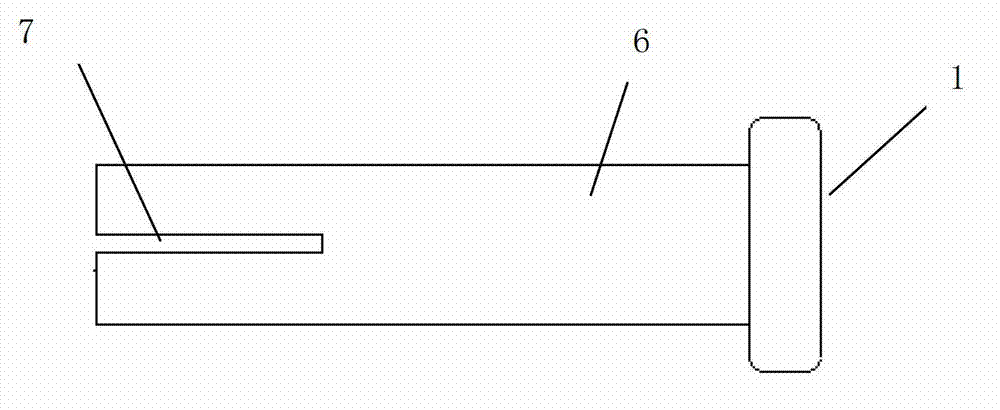

[0036] Please also see Figure 2a , 2b . A slit 7 is cut out along the direction of the nail rod 6 at the root of the welding stud 4 by using a slitting machine, and then the slit welding stud 1 is obtained. The gap 7 is located at the diameter position of the nail rod 6 . The diameter and height of the welding stud 4 are determined by the design requirements of the shear bearing capacity of the steel-concrete joint surface. The width of the gap 7 should be between 0.5mm-1.0mm, and the height is determined by the design requirements of the shear stiffness of the steel-concrete joint surface, but should not exceed 3 / 4 of the height of the selected nail rod 6 . In order to avoid excessive reduction of the shear bearing capacity of the connector, the width of the gap 7 should not be too wide, and when the width of the gap 7 is greater than 0.2mm, it can greatly reduce the shear stiffness.

[0037] Compared with the same shear performance in all directions of welding stud 4, t...

Embodiment 2

[0044] Such as Figure 4a , 4b As shown, a slit 13 is cut on the kerf welding stud 12, and the slit 13 deviates from the position of the diameter. In this way, the reduction degree of the shear stiffness of the seam welding stud 12 is slightly smaller than that of the seam welding stud 1 in the first embodiment.

Embodiment 3

[0046] Figure 5a , 5bAs a modification of Embodiment 2, on the kerf welding stud 10, the slit 11 deviates from the diameter and has a smaller arc relative to the nail shank, that is, the arc height H of the slit 11 and the horizontal projection length L of the arc The ratio is less than or equal to 1 / 10. By changing the width and length of the gaps 11 and 13, seam welding studs with different shear rigidities can be obtained. The shape of the gap curve is designed to be consistent with the shear deformation of the welding stud, so that the welding stud is more prone to shear deformation and the shear stiffness is smaller.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com