Rigid connection joint of steel tube concrete pile and steel beam

A technology of steel pipe concrete columns and rigid connections, which is applied in the direction of construction and building construction, can solve problems such as poor economic performance, affecting the quality of concrete pouring in steel pipe columns, and large steel consumption in node areas, so as to achieve economic performance improvement, The effect of convenient construction and reasonable joint stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

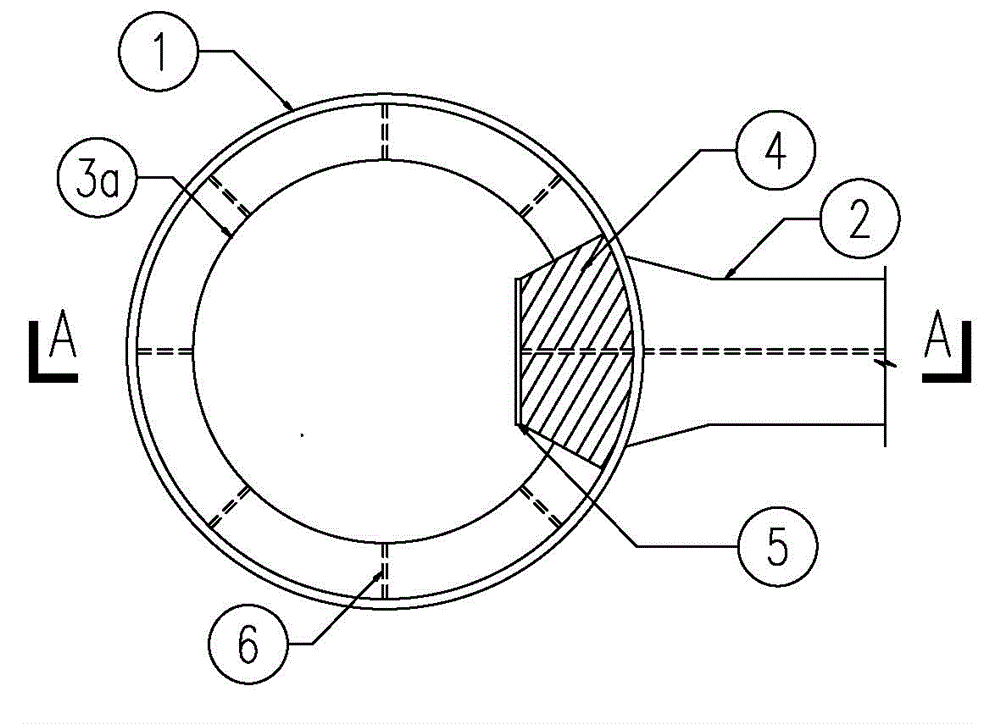

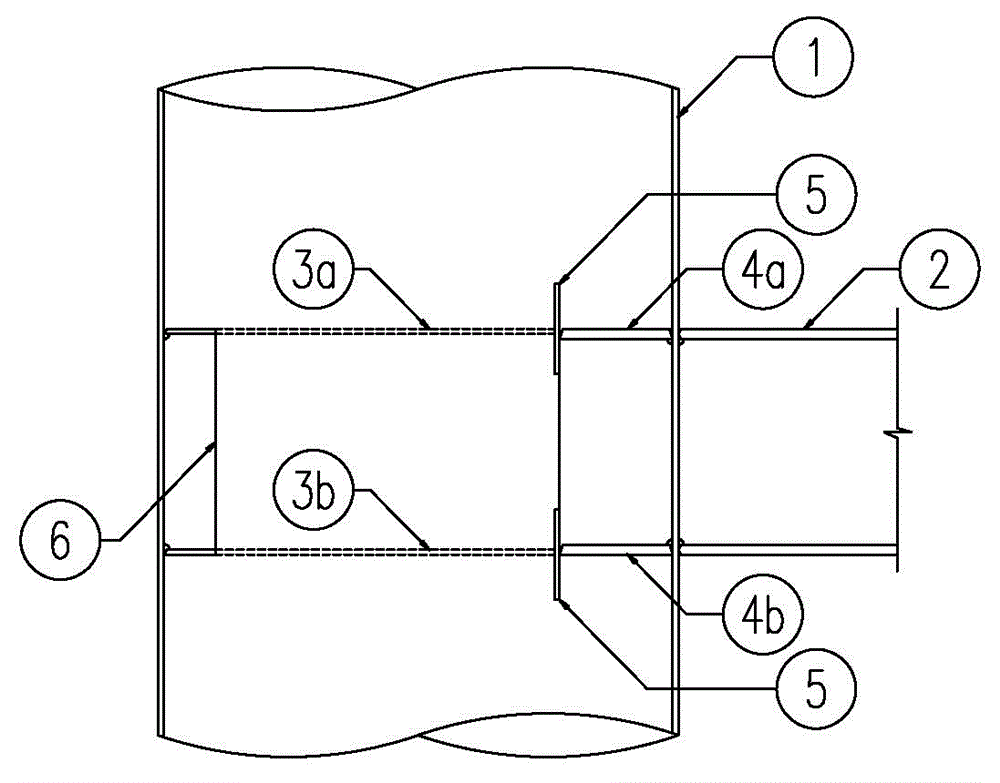

[0016] like figure 1 and figure 2 As shown, the manufacturing and assembling steps of the embodiment of the present invention are as follows:

[0017] 1. The steel tube concrete column 1 that meets the design requirements is formed by coiling the plate and performing splicing and welding.

[0018] 2. In the steel tube concrete column 1, weld the positioned upper reinforcement ring 3a and lower reinforcement ring 3b, the upper flange plate extension 4a and the lower flange plate extension 4b and the stiffener 6 between the upper and lower reinforcement rings; At the same time, the splicing section corresponding to the steel beam 2 is welded outside the steel pipe concrete column 1 according to design requirements.

[0019] 3. In the joint of the present invention, the end plates 5 are welded. As shown in the figure, the end plates 5 are respectively located at the ends of the upper flange plate extension 4a and the lower flange plate extension 4b.

[0020] 4. After completi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com