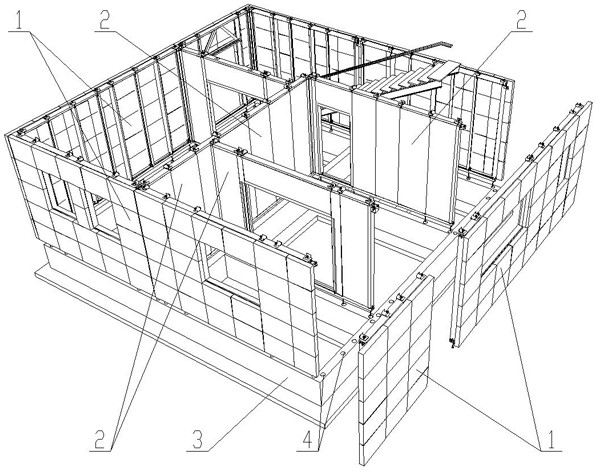

Manufacturing and mounting method for combined wall of fabricated house

An installation method and a combined technology are applied in the field of production and installation of combined walls, which can solve the problems of restricting the production of light steel keel and lightweight concrete combined houses, poor thermal insulation, fire prevention and sound insulation performance, and difficult to control installation accuracy, and achieve It is not easy to overall and local instability, good fire and sound insulation performance, and easy to control the installation accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0018] Referring to the accompanying drawings, the specific implementation is as follows:

[0019] A method for manufacturing and installing a combined wall for a prefabricated house, comprising the following steps:

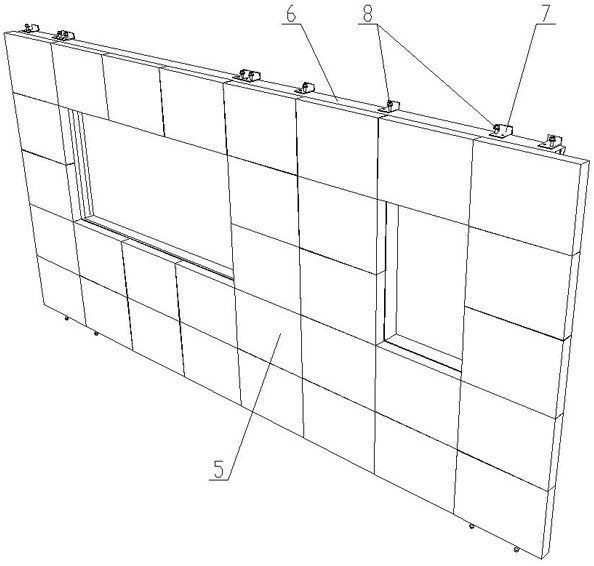

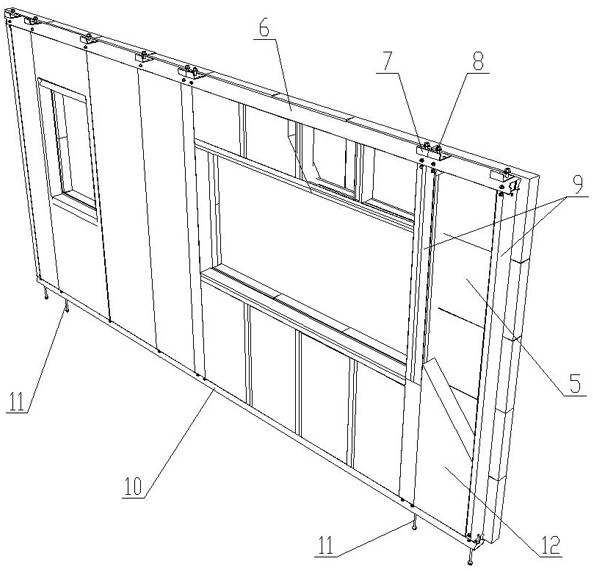

[0020] Install a plurality of vertical keels 9 between the sky keel 6 and the ground keel 10 respectively, process connection grooves on the surface of the light microcrystalline stone plate 5, and then install the light microcrystalline stone plate 5 on the multiple vertical keels 9 One side of the connecting groove is aligned with multiple vertical keels 9 respectively, and then filled with lightweight concrete 12 between the multiple vertical keels 9, and the lightweight concrete 12 is bonded with the lightweight microcrystalline stone slab 5 , forming a concrete wall layer located inside the outer wall 1 .

[0021] A plurality of vertical keels 9 are respectively installed between the sky keel 6 and the ground keel 10, then a plurality of keel braces 13 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com