Patents

Literature

86results about How to "Avoid wet work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

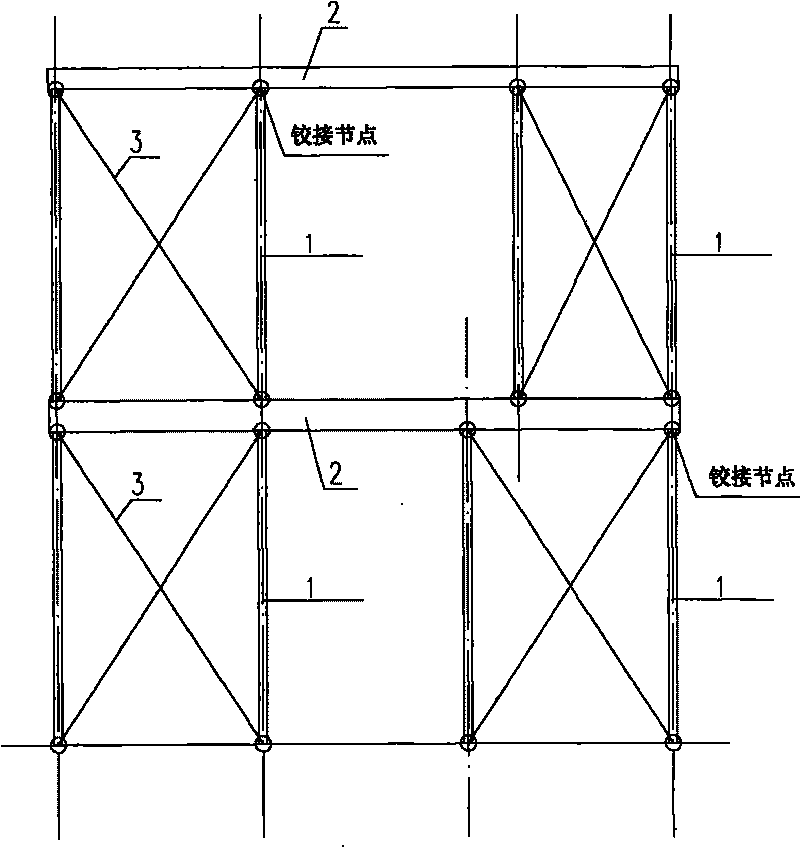

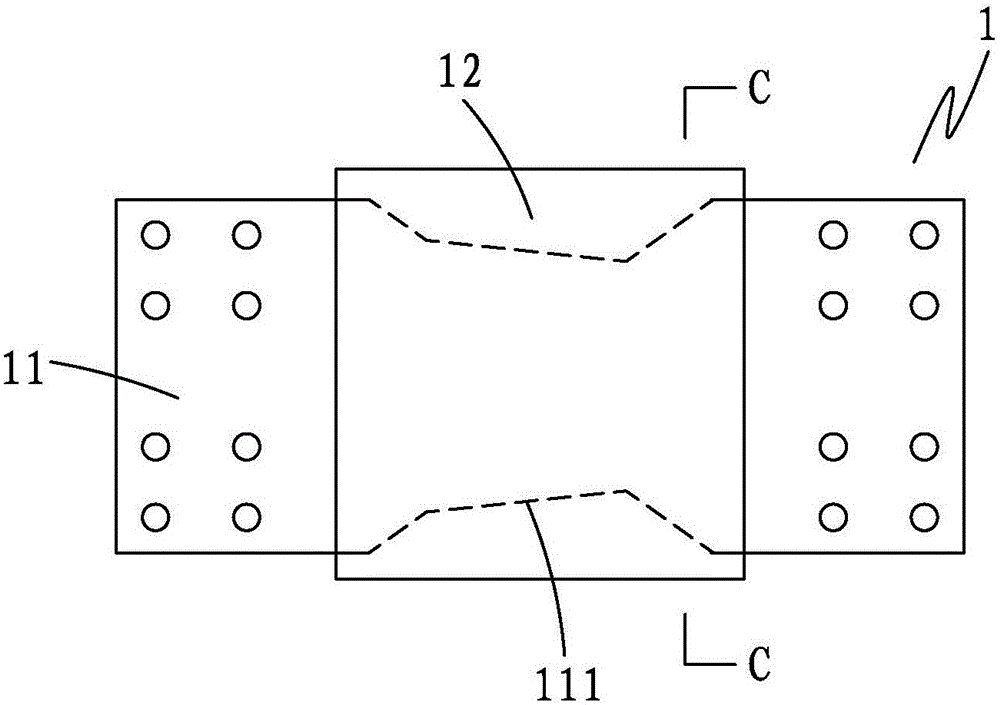

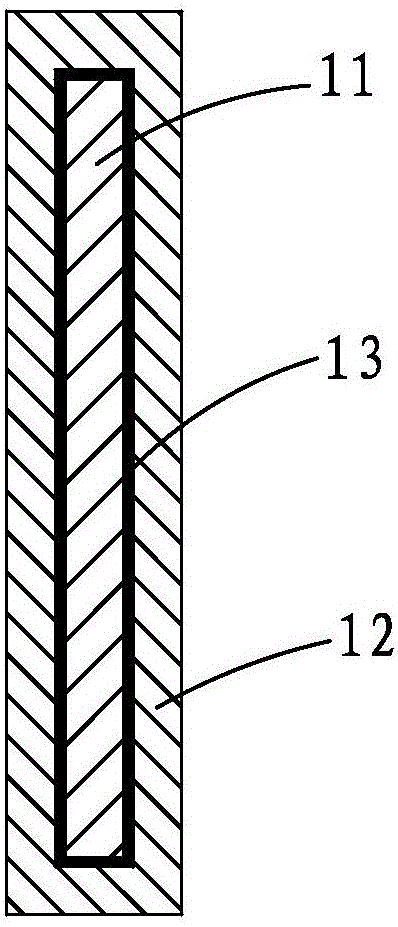

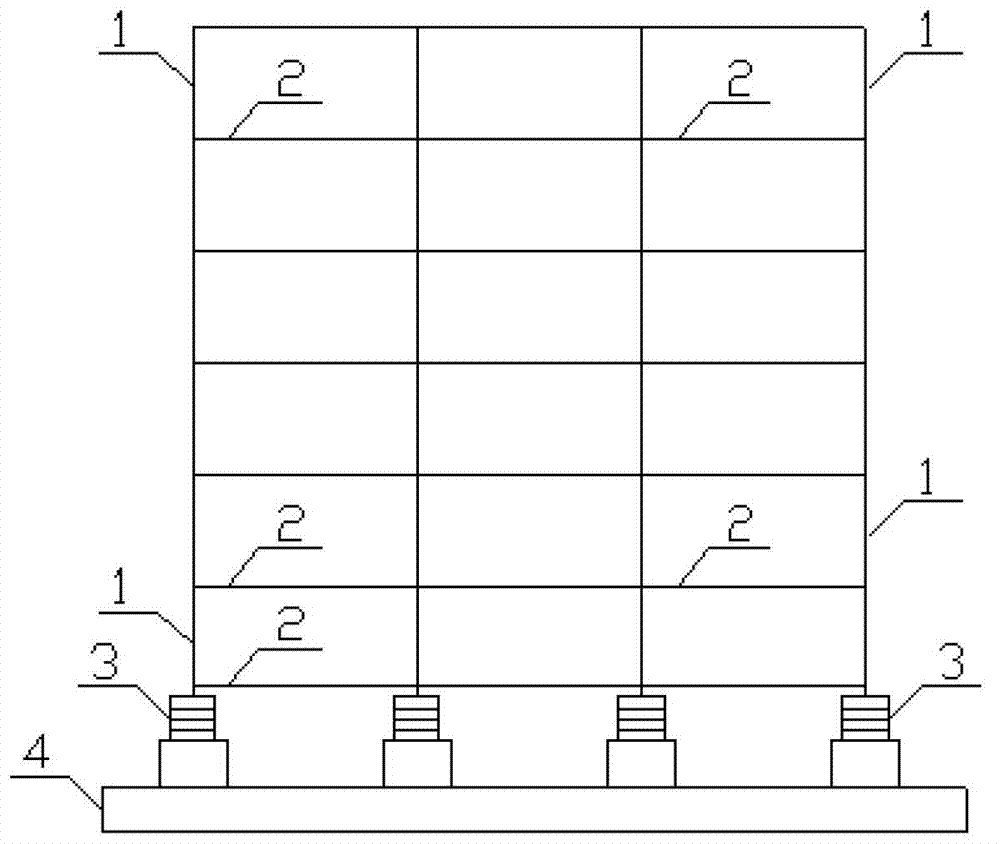

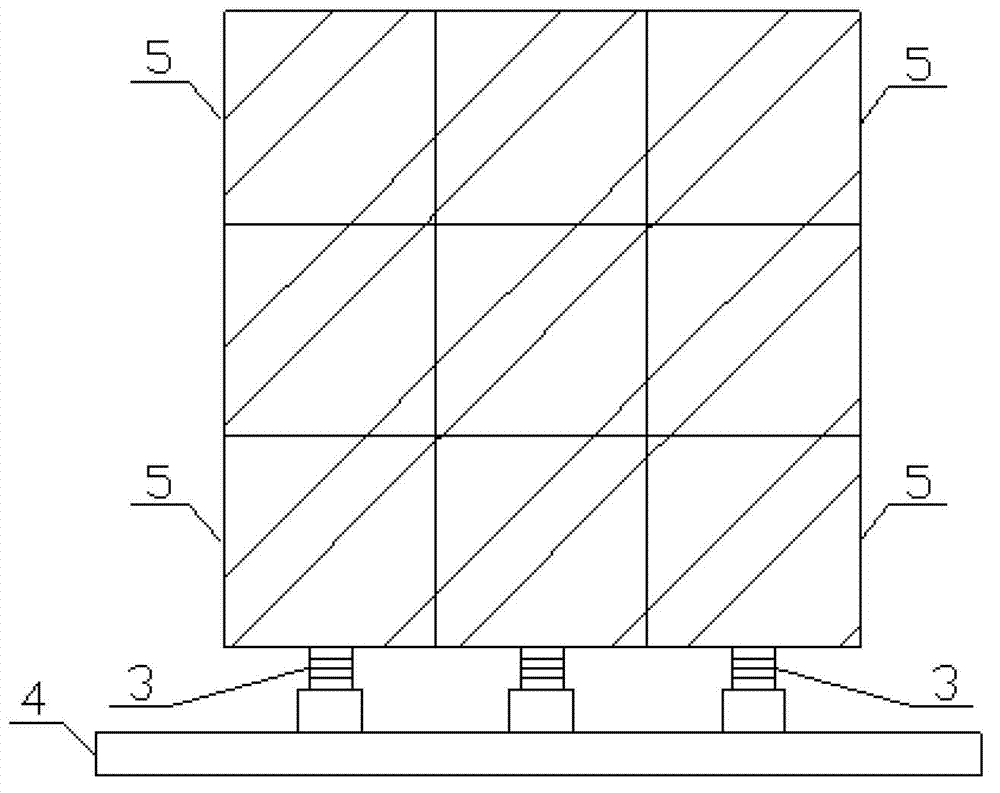

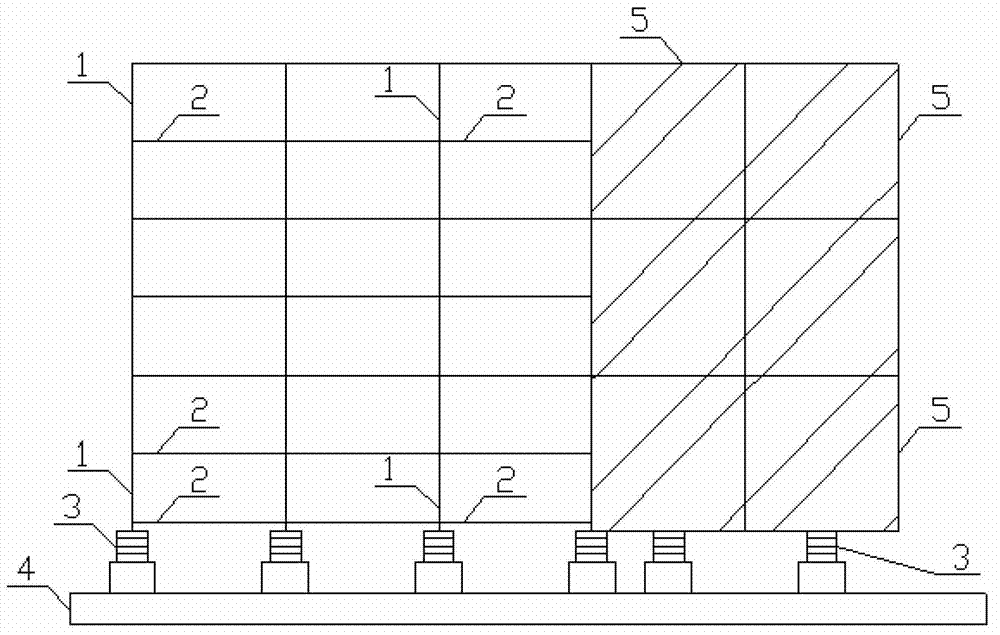

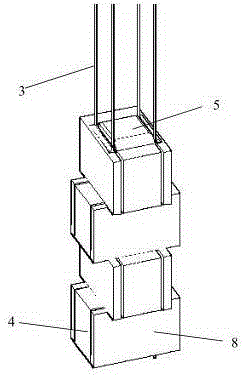

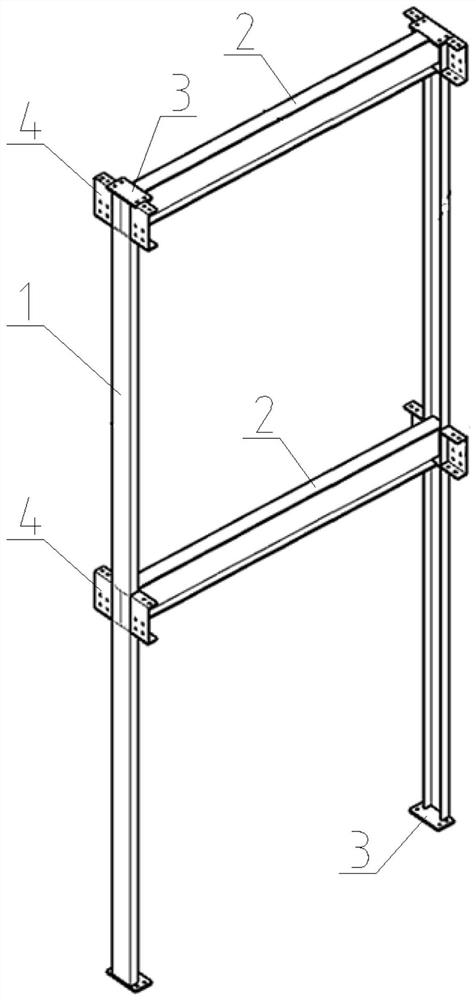

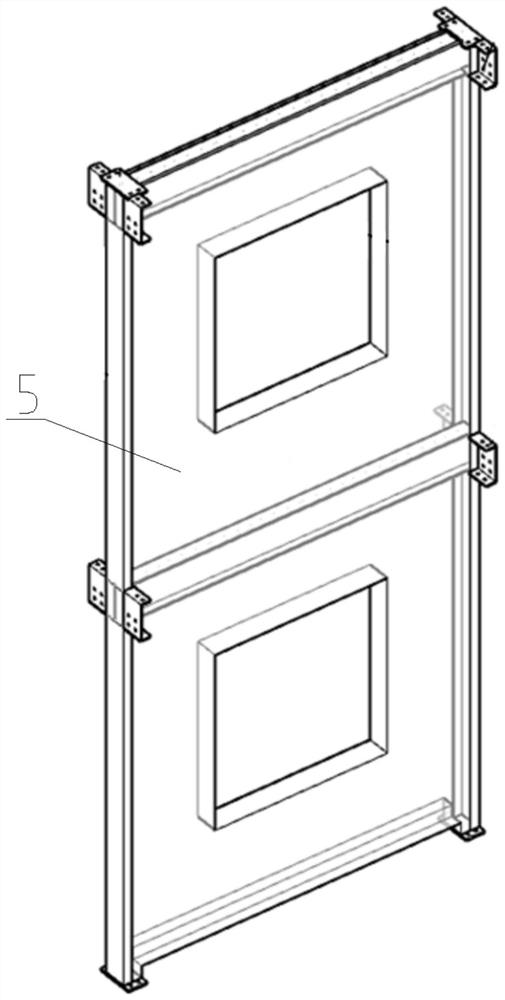

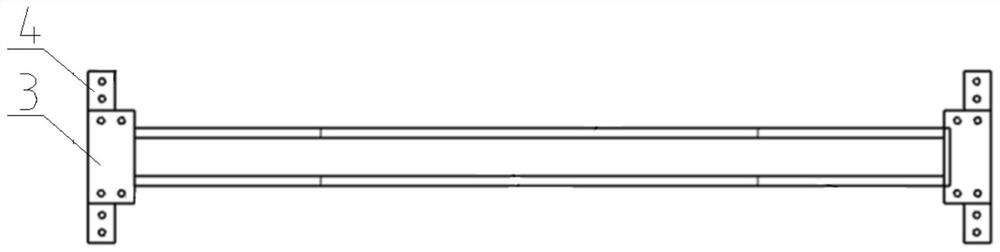

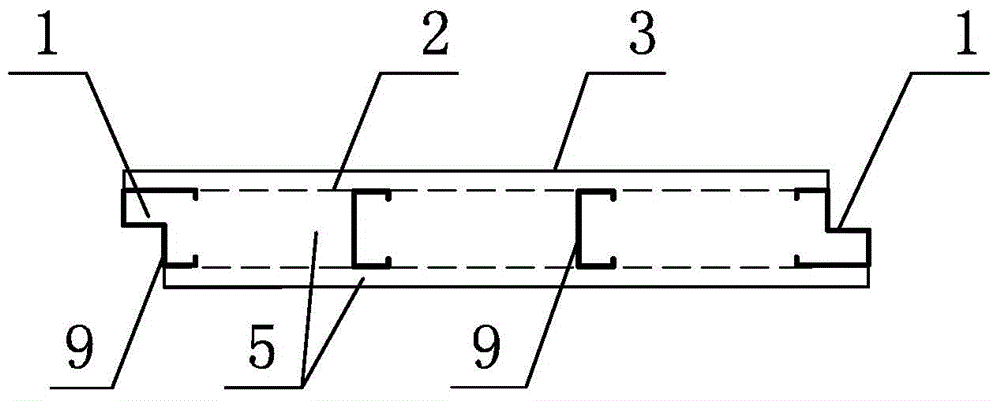

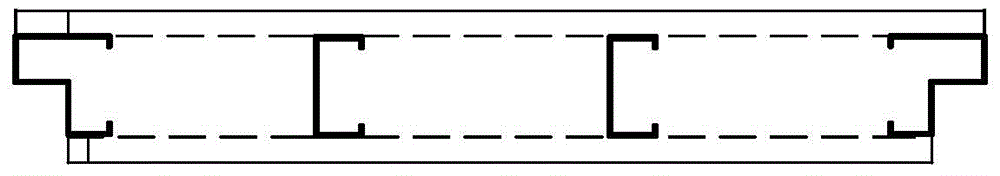

Structural system of industrial low storied dwelling

ActiveCN101748903AReasonable forceAvoid wastingBuilding constructionsDwelling buildingFloor slabSimple component

The invention belongs to the field of building structures, and in particular relates to a structural system of an industrial low storied dwelling adopting modularized design, factory production and field mounting. The structural system of the industrial low storied dwelling comprises steel columns, steel girders, inter-column supports, steel girder horizontal supports, floor slabs, connecting nodes between the steel columns and a foundation, the connecting nodes between the steel columns and the steel girders, the connecting nodes between the steel columns and the inter-column supports, the connecting nodes between the steel girders and the steel girder horizontal supports, rigid connection nodes between the steel girders, the connecting nodes between the steel girders and the floor slabs, roofing surrounding systems and wall surface surrounding systems, wherein the steel columns are connected with the foundation through pre-embedded bolts; the steel columns are connected with the steel girders through bearing type high-strength bolts; the steel columns are connected with the inter-column supports through ordinary bolts; the steel girders are connected with the steel girder horizontal supports through the ordinary bolts; the steel girders are in fully rigid connection through continuous girders; the slabs are connected with the steel girders through male pins or special fasteners; and each of the roofing surrounding systems and the wall surface surrounding systems is of a block type. The structural system of the invention has the characteristics of clear stress of the structure, simple component connection, convenient and quick mounting, attractive appearance, good rationality and economical efficiency of unit steel amount, and is favorable for industrial production.

Owner:宝业集团浙江建设产业研究院有限公司

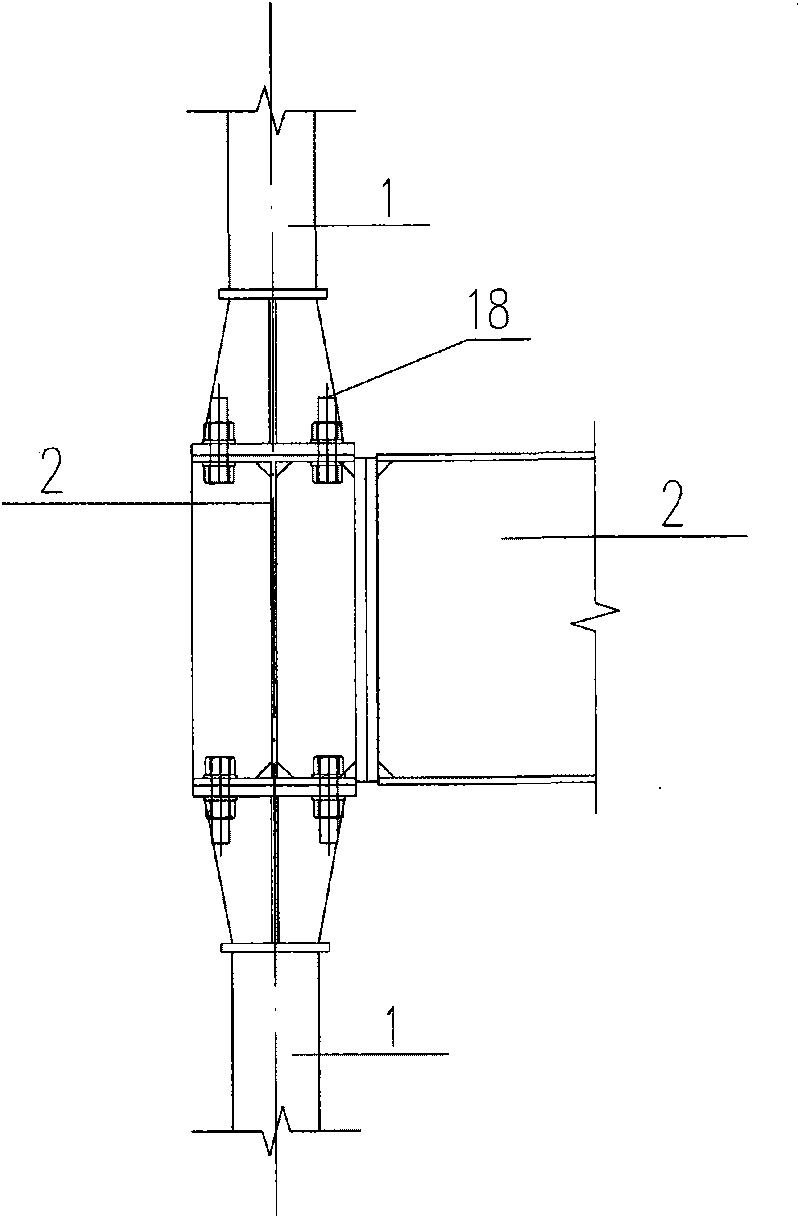

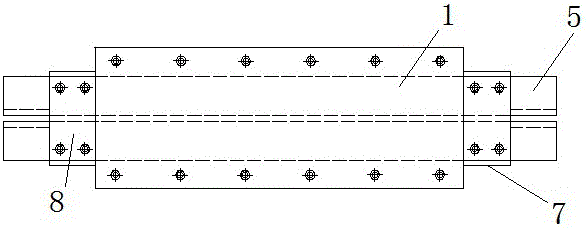

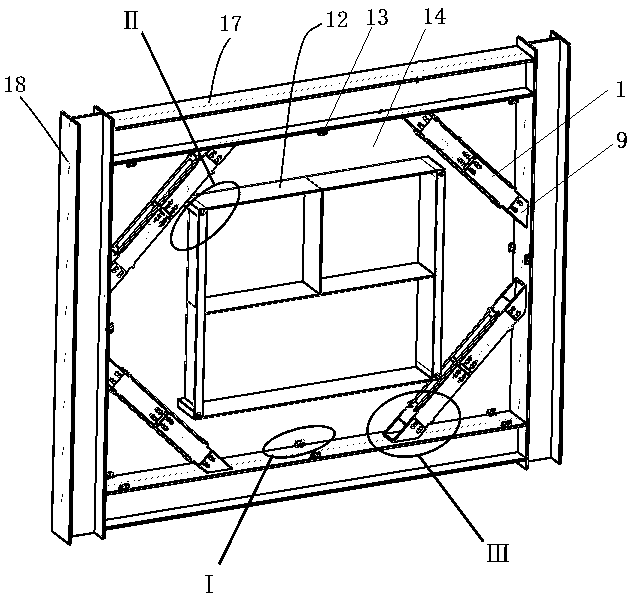

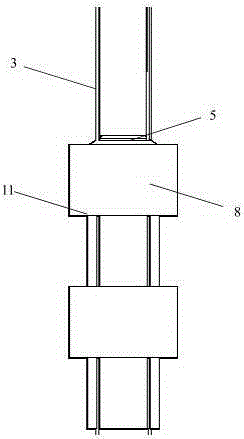

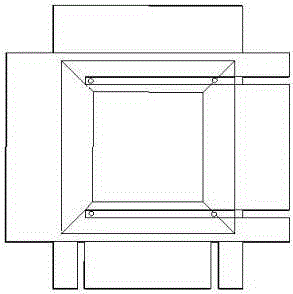

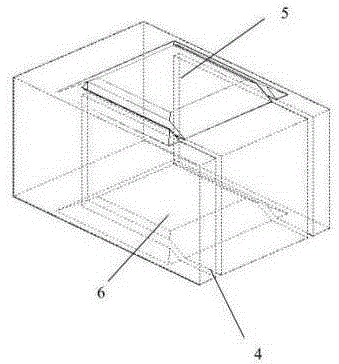

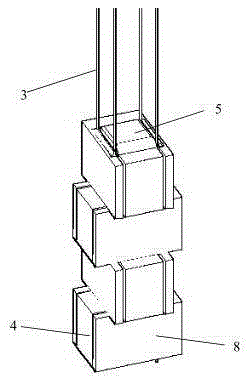

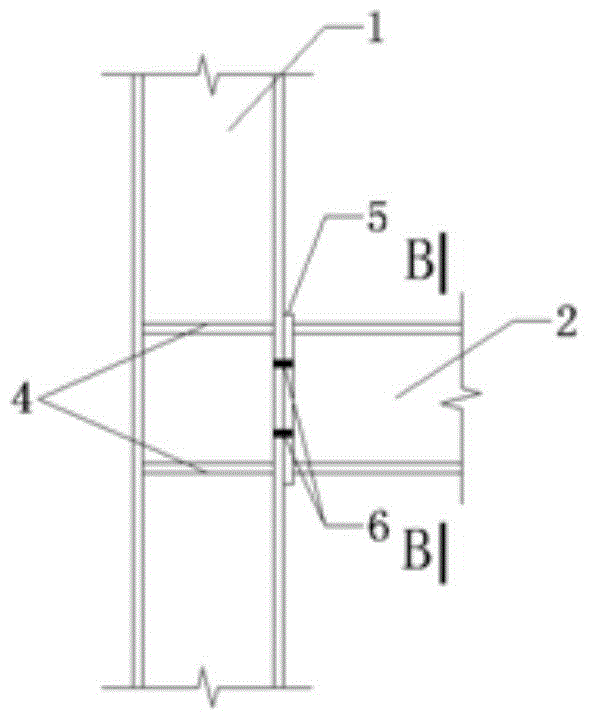

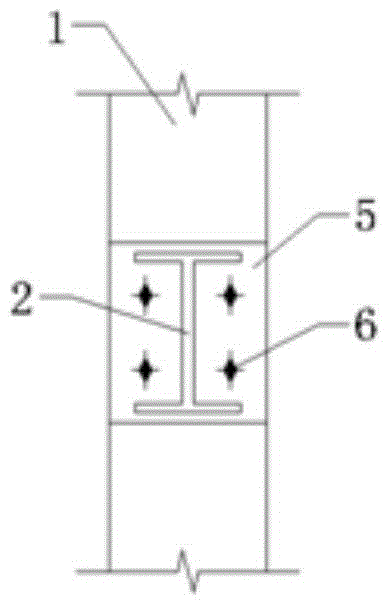

Fully-prefabricated assembled concrete column-concrete beam buckling-restrained energy-consuming joint

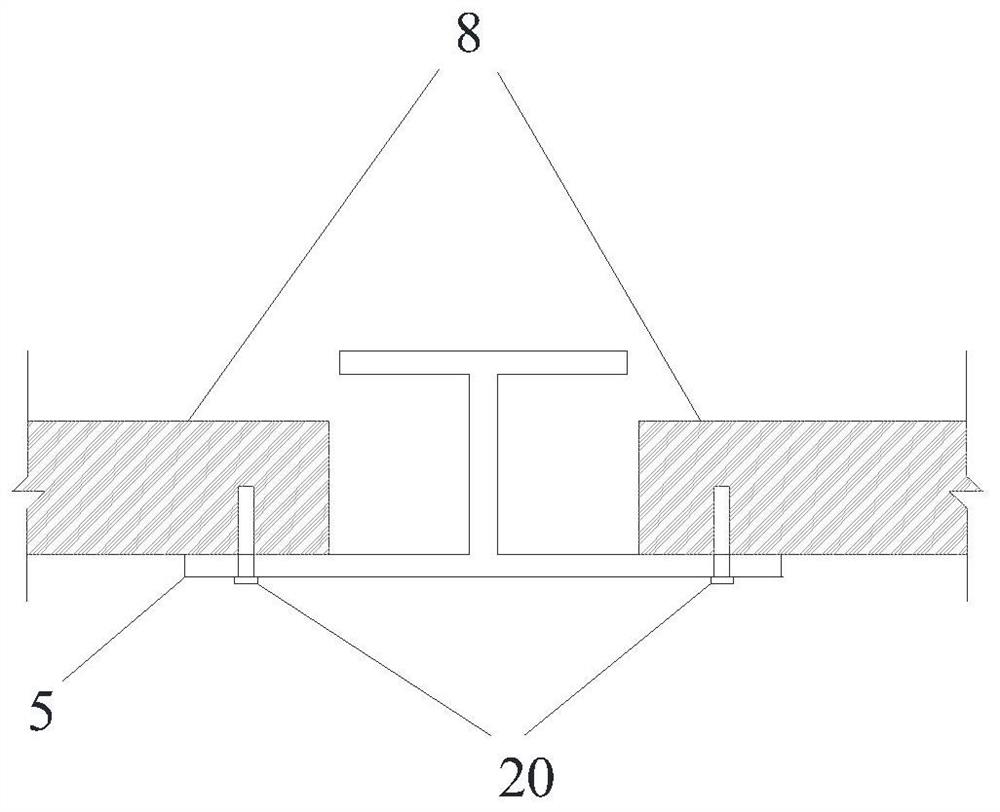

InactiveCN105780960AAvoid wet workSpeed up the construction progressShock proofingPlastic propertyFlange

The invention provides a fully-prefabricated assembled concrete column-concrete beam buckling-restrained energy-consuming joint which comprises two buckling-restrained flange metal plate energy-consuming dampers, two high-strength web connecting plates, a first pre-buried steel beam and a second pre-buried steel beam. One end of the first pre-buried steel beam is buried in a concrete column while the other end of the same outwards extends out of a column face, one end of the second pre-buried steel beam is buried in a concrete beam while the other end of the same outwards extends out of a beam end face, upper and lower flanges of the first pre-buried steel beam and the second pre-buried steel beam are connected through the buckling-restrained flange metal plate energy-consuming dampers, and two sides of the middles of the first pre-buried steel beam and the second pre-buried steel beam are connected through the high-strength web connecting plates. The fully-prefabricated assembled concrete column-concrete beam buckling-restrained energy-consuming joint has the advantages that outward moving of a plastic hinge from the column beam can be realized through the buckling-restrained energy-consuming joint, so that damage to a core area of the buckling-restrained energy-consuming joint is reduced, and anti-seismic performance requirements on 'strong column and weak beam' and 'strong shearing and weak bending' are met.

Owner:FUJIAN UNIV OF TECH

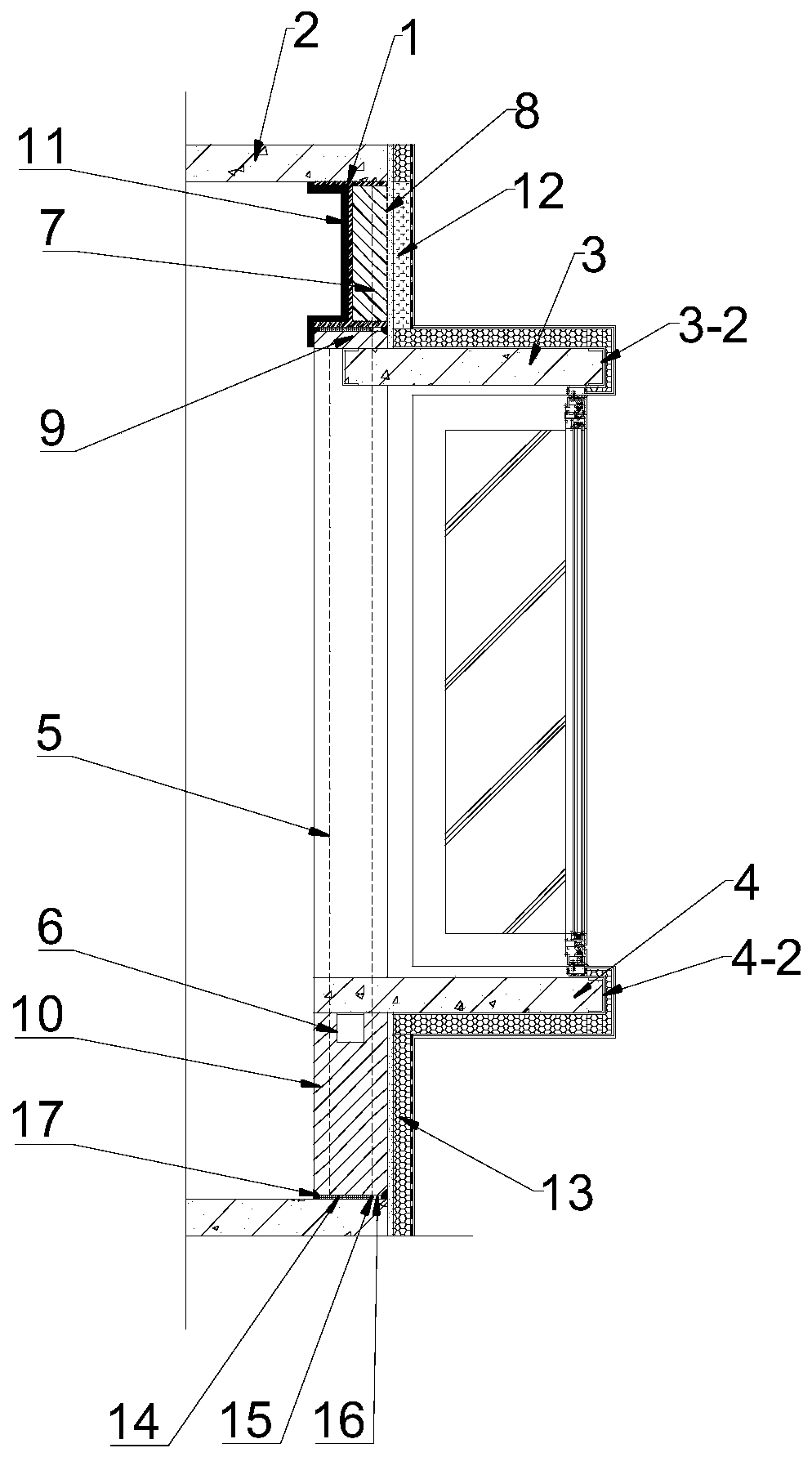

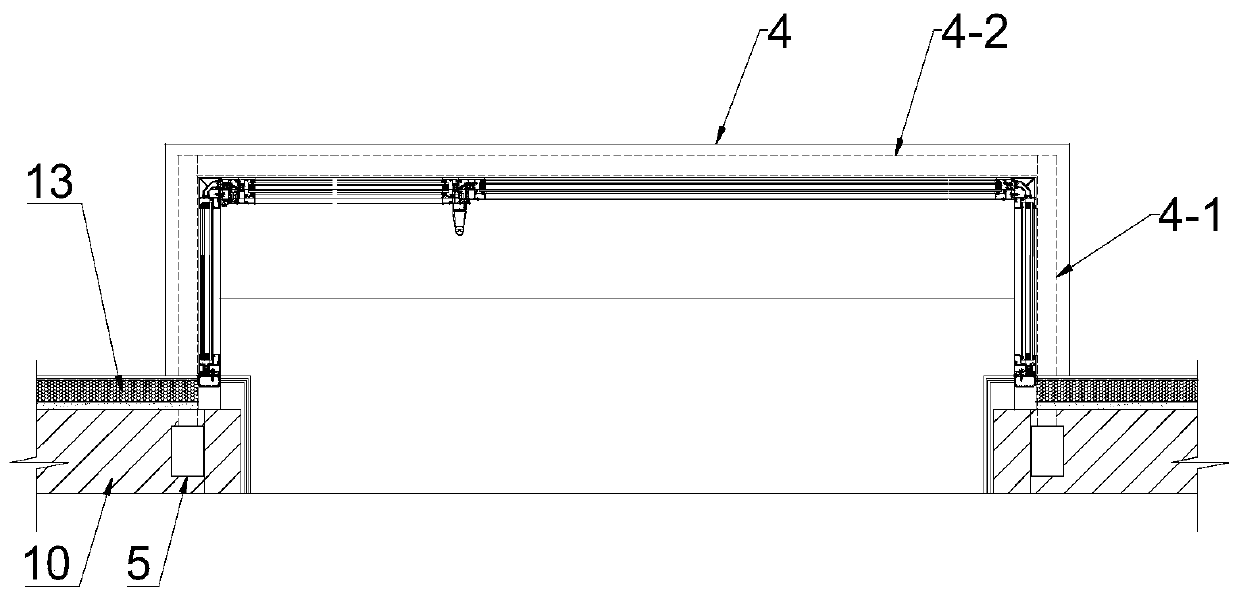

Dry-hanging keel decorative board heat insulation composite wall and its construction method

The invention relates to a thermal insulation compound wall body of a dry hanging keel decoration plate and a construction method, wherein a prefabricated thermal insulation keel is mounted on a basal layer wall body through a mechanical anchor firmware, and then a negative angle column and a positive angle column are mounted, heat-insulating material is filled between the positive angle column and the negative angle column, both lateral sides of the invention are respectively equipped with two thermal insulation keels, and J-shaped slotted plates are respectively mounted on the two thermal insulation keels, and a prefabricated door-window insulating sleeve hole is mounted on a door-window opening, the periphery of a sash is filled and infused with foaming polyurethanes, a heat-insulating board is filled between the thermal insulation keels, and the thermal insulation keels are fixed by an anchor firmware with a round plate, and the foaming polyurethanes are infused in gaps, at last a cladding decoration panel is fixedly mounted on the outer side of the thermal insulation keels by self-threading screws. The thermal insulation property of the thermal insulation compound wall body is excellent, and the thermal insulation compound wall body achieves an integral dry construction, the architectural exterior facing is rich and colorful, the cubic effect is strong, the invention is not easy to be polluted, which can be widely applied to civilian constructions which are newly constructed, enlarged, and rebuilt and needs thermal insulation and heat insulation, in particular to villas whose heights of eaves are less than 20m and floors are less than 3 to 4, and outer-eaves decoration of middle grade and high grade constructions.

Owner:北京住总集团有限责任公司 +1

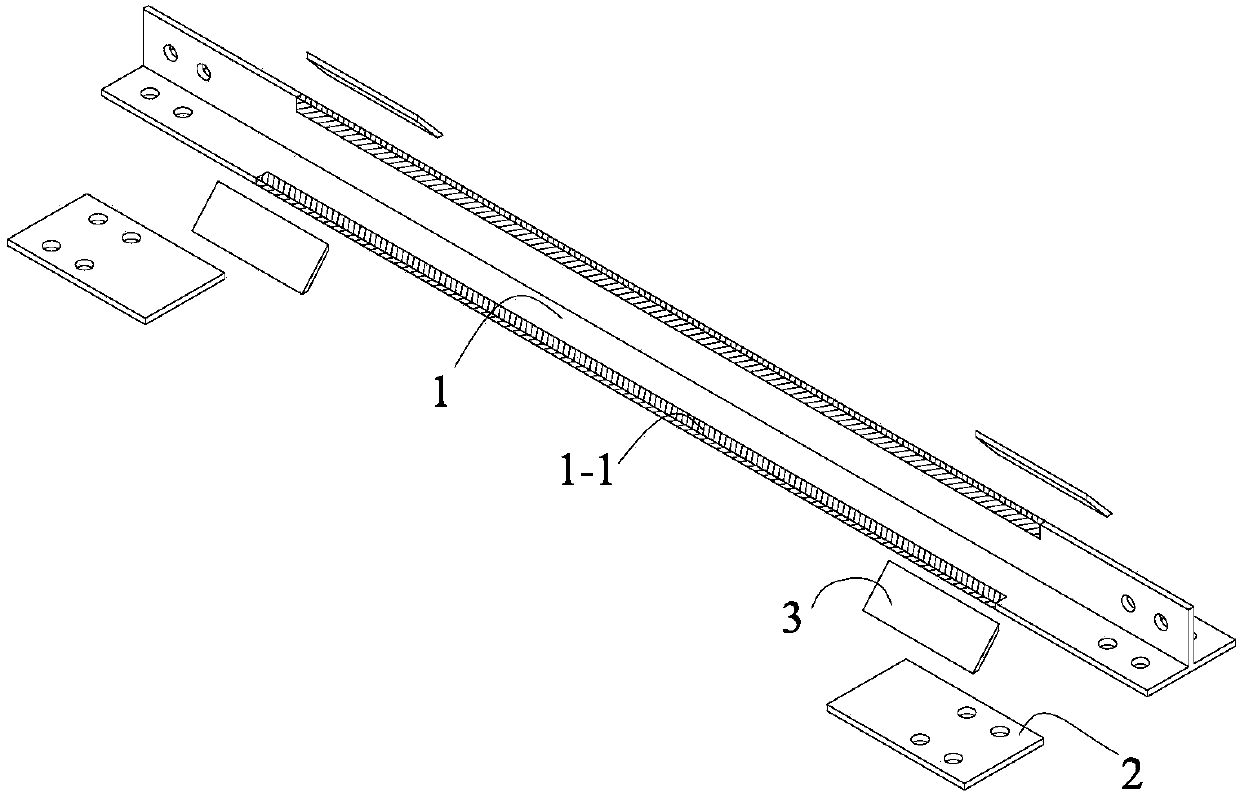

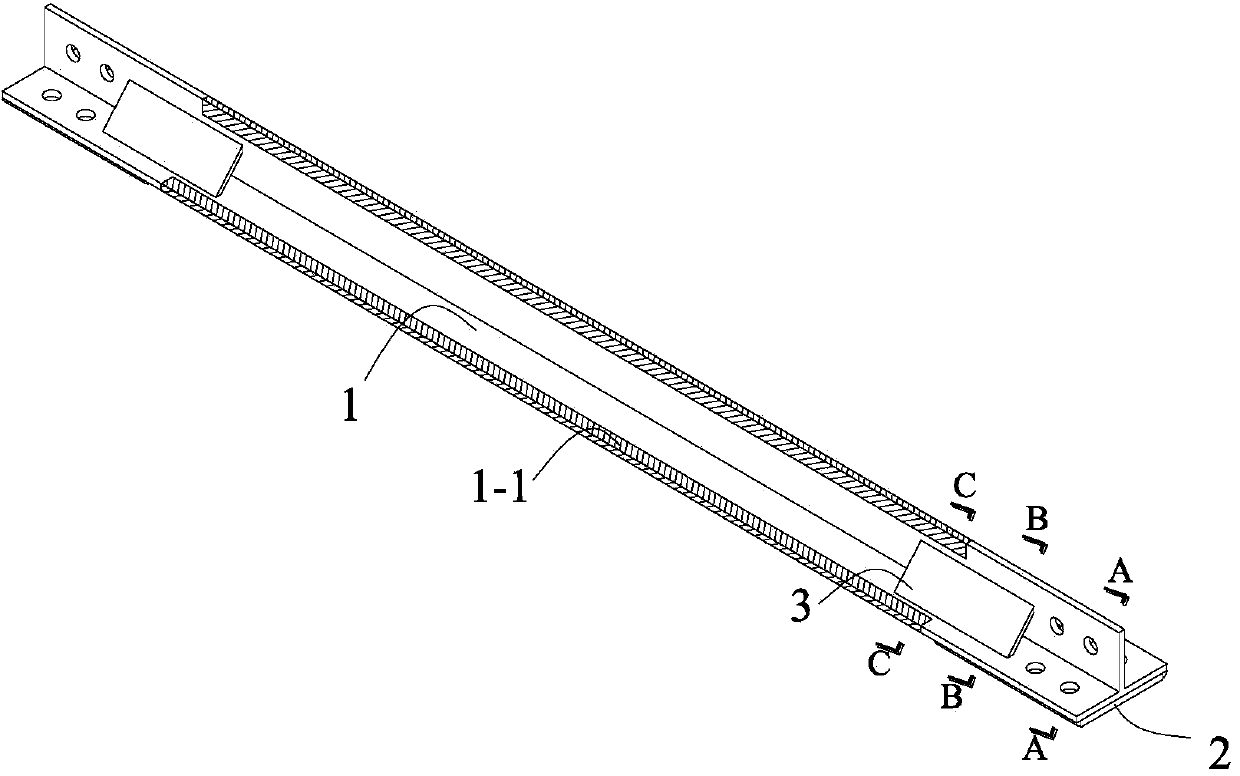

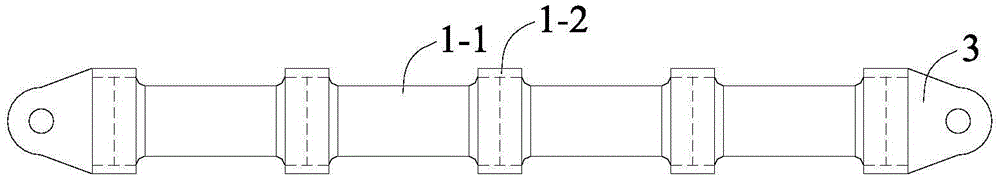

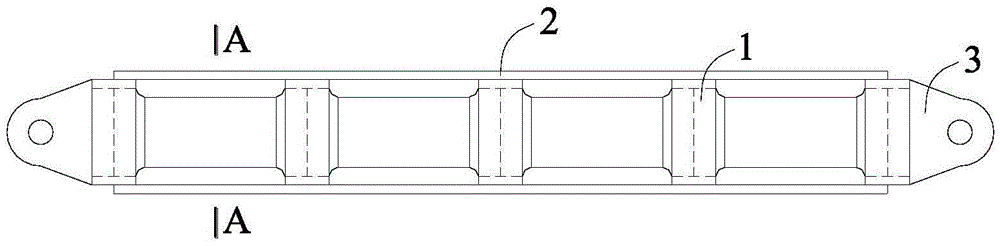

Bamboo-shaped buckling-restrained brace

ActiveCN105714952AShorten the lengthDestabilization will not happenShock proofingBuckling-restrained braceCoaxial line

The invention discloses a bamboo-shaped buckling-restrained brace, comprising a core component, an external restrained component and reinforced connecting components, wherein the core component is formed by alternately arranging a plurality of circular energy dissipation sections and a plurality of circular elastic sections along a longitudinal coaxial line; each circular elastic section comprises a plurality of middle elastic sections and two end elastic sections; the cross sectional area of each circular energy dissipation section is smaller than that of the corresponding circular elastic section; the core component is positioned in the external restrained component; each reinforced connecting component is composed of a node section, a connecting section and a reinforcing barrel. The bamboo-shaped buckling-restrained brace disclosed by the invention has the advantages that all the circular energy dissipation sections are shorter, and only yield without buckling under the action of an axial force, so that mortar is unnecessarily added or additional parts are unnecessarily arranged for restraining the circular energy dissipation sections, the cross sectional area of each circular energy dissipation section is smaller than that of each circular elastic section, the yielding force is less, and the rigidity requirement on the external restrained component is lower, therefore the external restrained component can be a simple circular casing, and the effects of simple structure, convenience in processing and lighter dead-weight are achieved.

Owner:SOUTHEAST UNIV

Buckling restrained brace with staggered intersecting plates

ActiveCN103741830AAvoid damageIncrease the force sectionShock proofingBuckling-restrained braceCore component

The invention discloses a buckling restrained brace with staggered intersecting plates. The buckling restrained brace comprises a dissipating core component, a first reinforcing plate group, a second reinforcing plate group, and a uniform-section buckling restraint part. The first reinforcing plate group is fixedly connected to outer surfaces of two flanges of two tail ends of the dissipating core component. The uniform-section buckling restraint part is disposed outside the middle of the dissipating core component. The second reinforcing plate group is fixedly connected between the flanges and webs of the dissipating core component. The buckling restrained brace with staggered intersecting plates has the advantages that the middle of the dissipating core component can yield first and the ends of the dissipating core component can be in the elastic phase under the action of high external force, with no need of cutting a dissipating core plate, and accordingly damage of the dissipating core component caused by cutting is avoided; only the flanges or web edges of the dissipating core component are restrained, overall and local buckling of the dissipating core component is effectively guaranteed, conflict between the buckling restraint part and the two reinforcing plate groups is avoided, the section of the buckling restraint part in the length-wise direction is equal, and manufacturing difficulty is significantly reduced.

Owner:SOUTHEAST UNIV

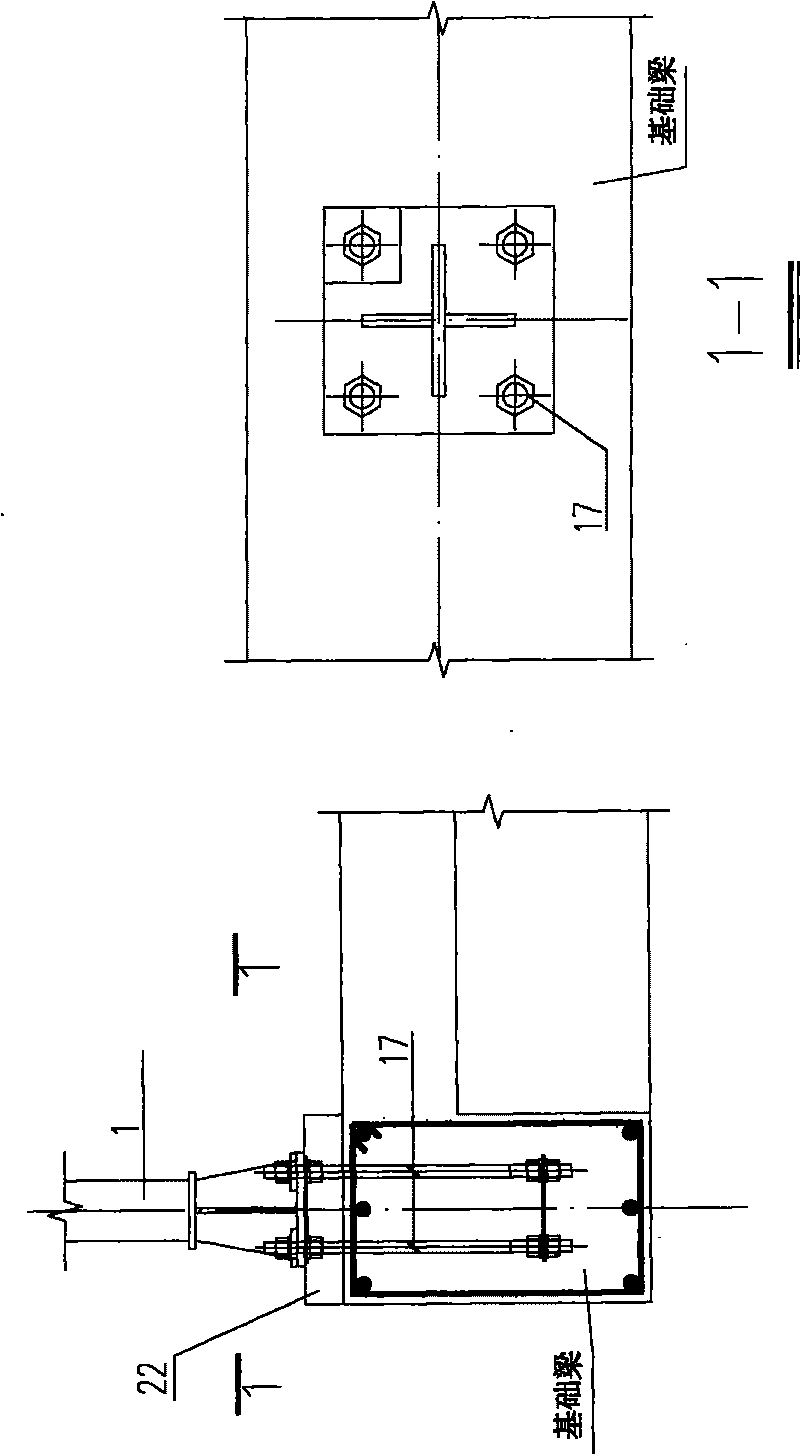

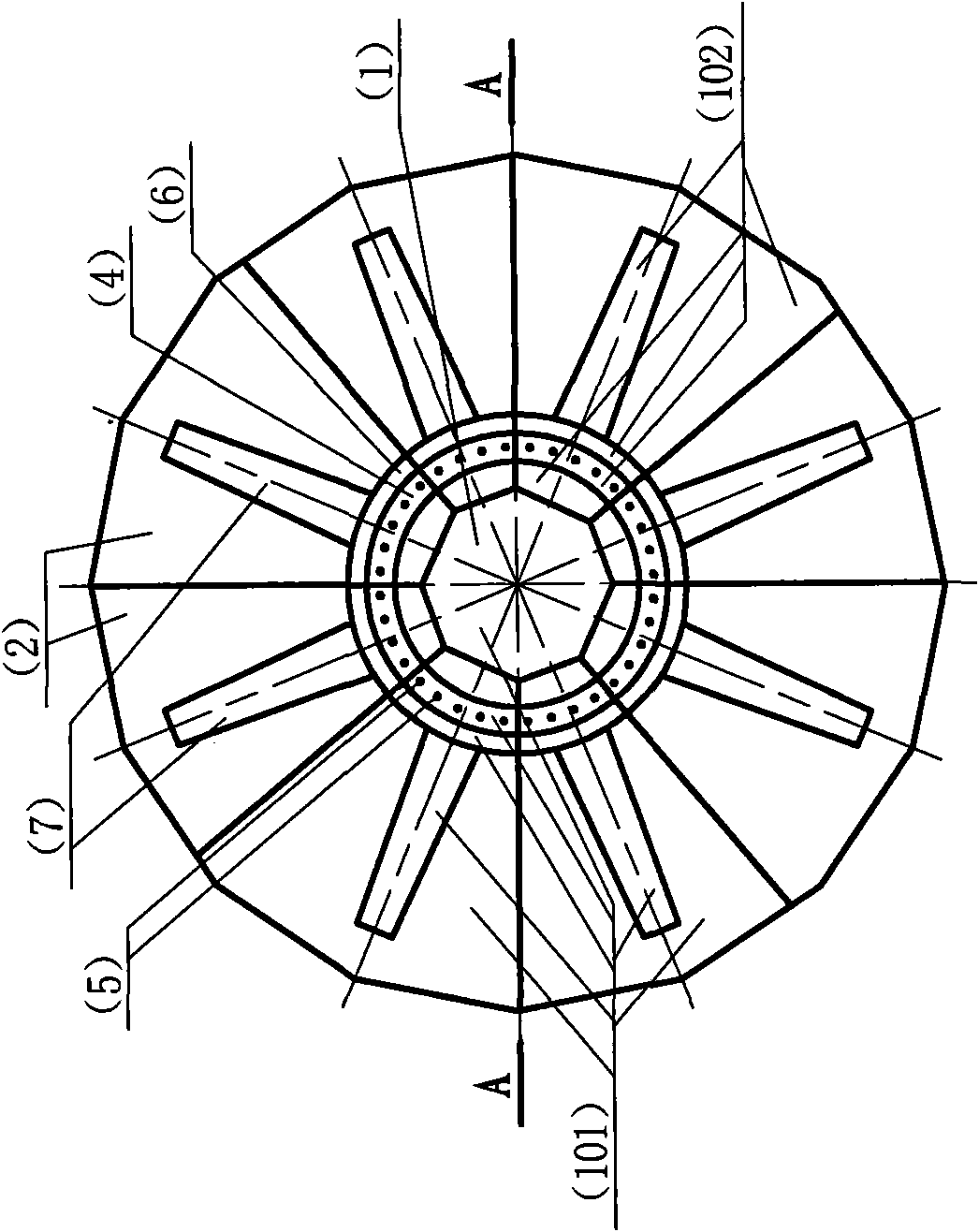

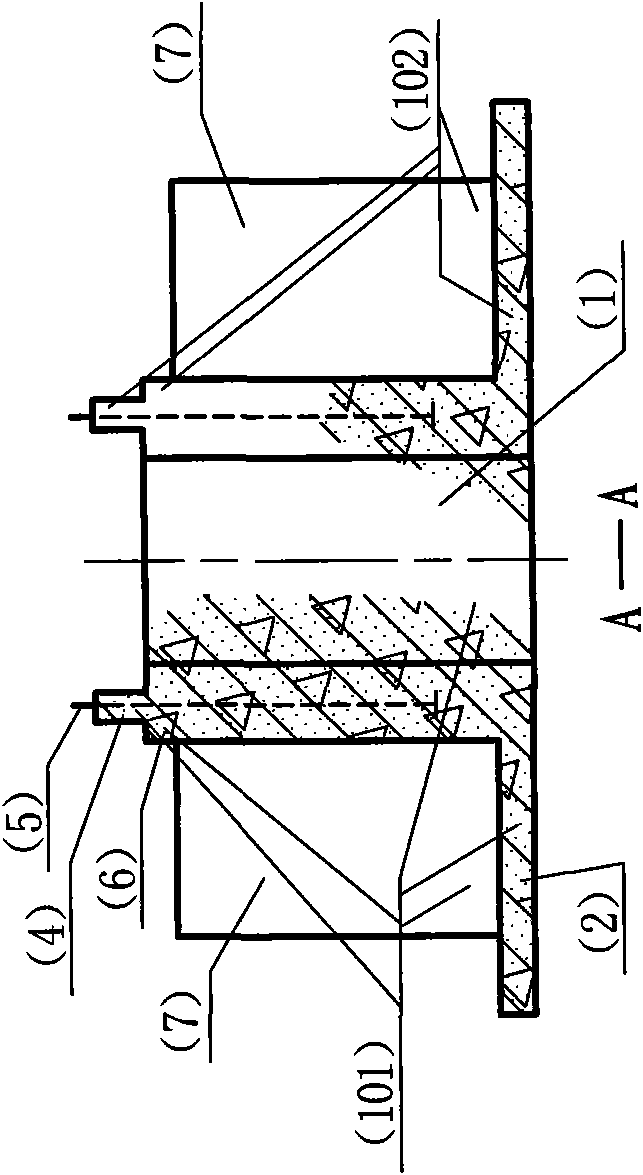

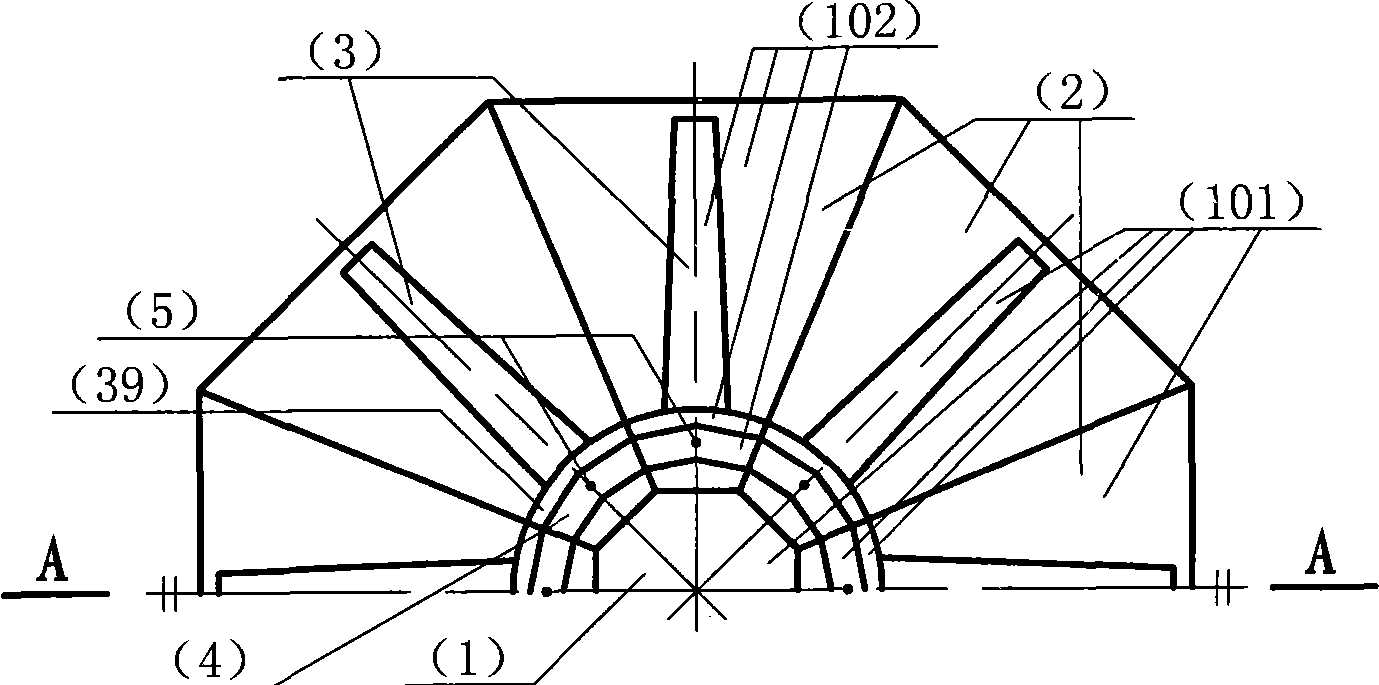

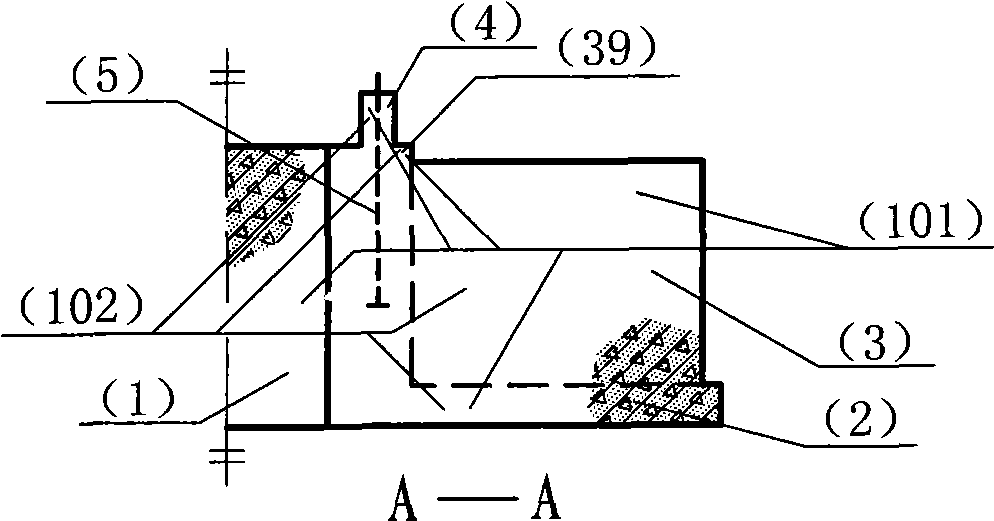

Combination foundation of large-scale tower mast type mechanical equipment

InactiveCN101560774AReduce investmentReduce manufacturing costFoundation engineeringElectricityPre stress

The invention discloses a combination foundation configured on large-scale tower mast type mechanical equipment, such as wind power generating sets and the like. The combination foundation consists of a regular polygon or circular shape independent foundation beam slab structure formed by horizontal combination or vertical and horizontal combination of prefabricated concrete components and balk cargoes such as sand, stone or earth or the like. A prestressing force combination and connection system with overlapped upper-lower double-channel radial type horizontal spaces and closed horizontal circumference, a concave convex key positioning system and an anti-shearing seamless concrete connection surface constitution system jointly realize all functions of the original entire cast-in-place concrete foundation. The combination foundation is obviously characterized by saving capital, protecting environment, reducing cost and being capable of being used in a displacement and repetition manner.

Owner:赵正义

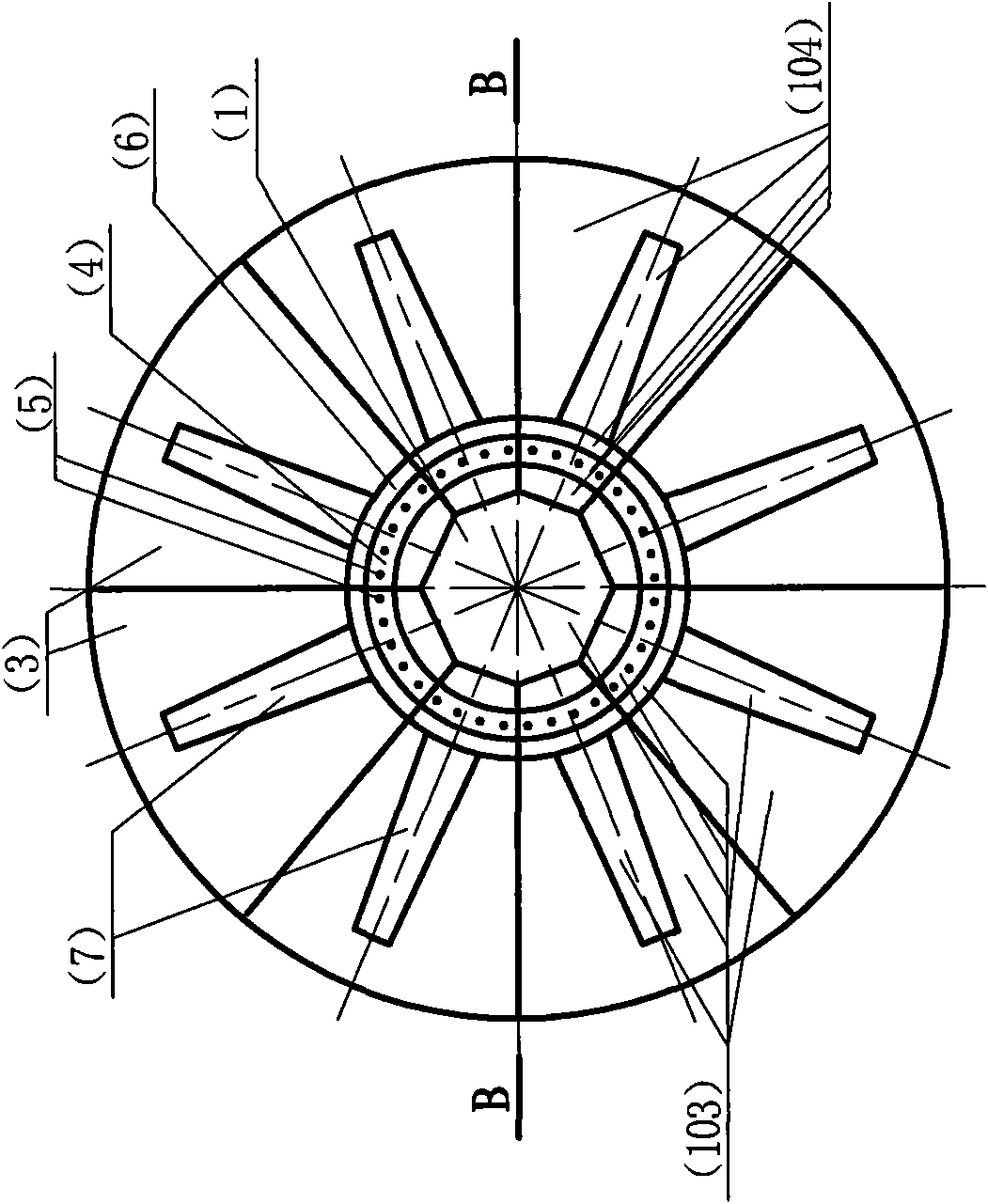

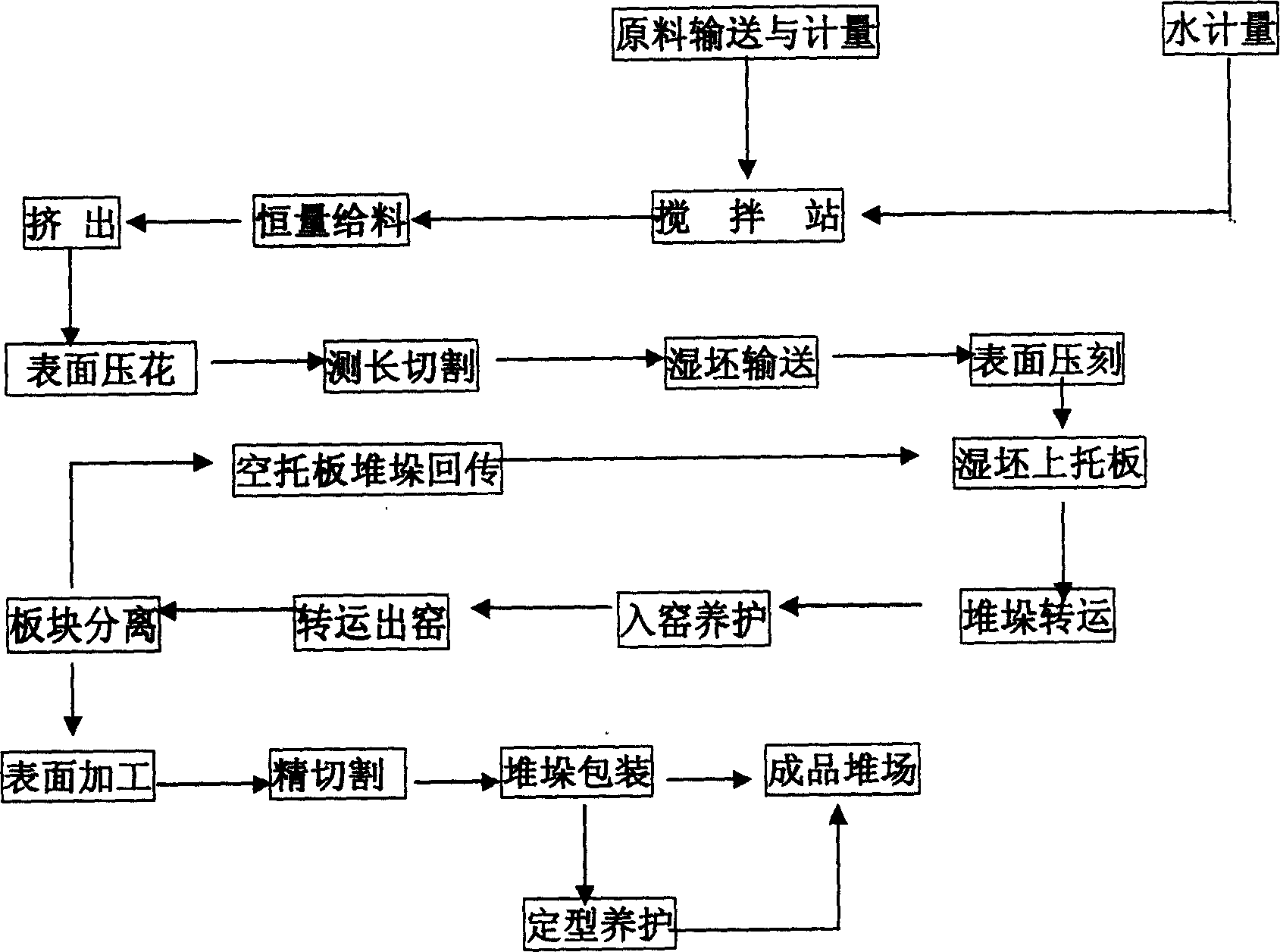

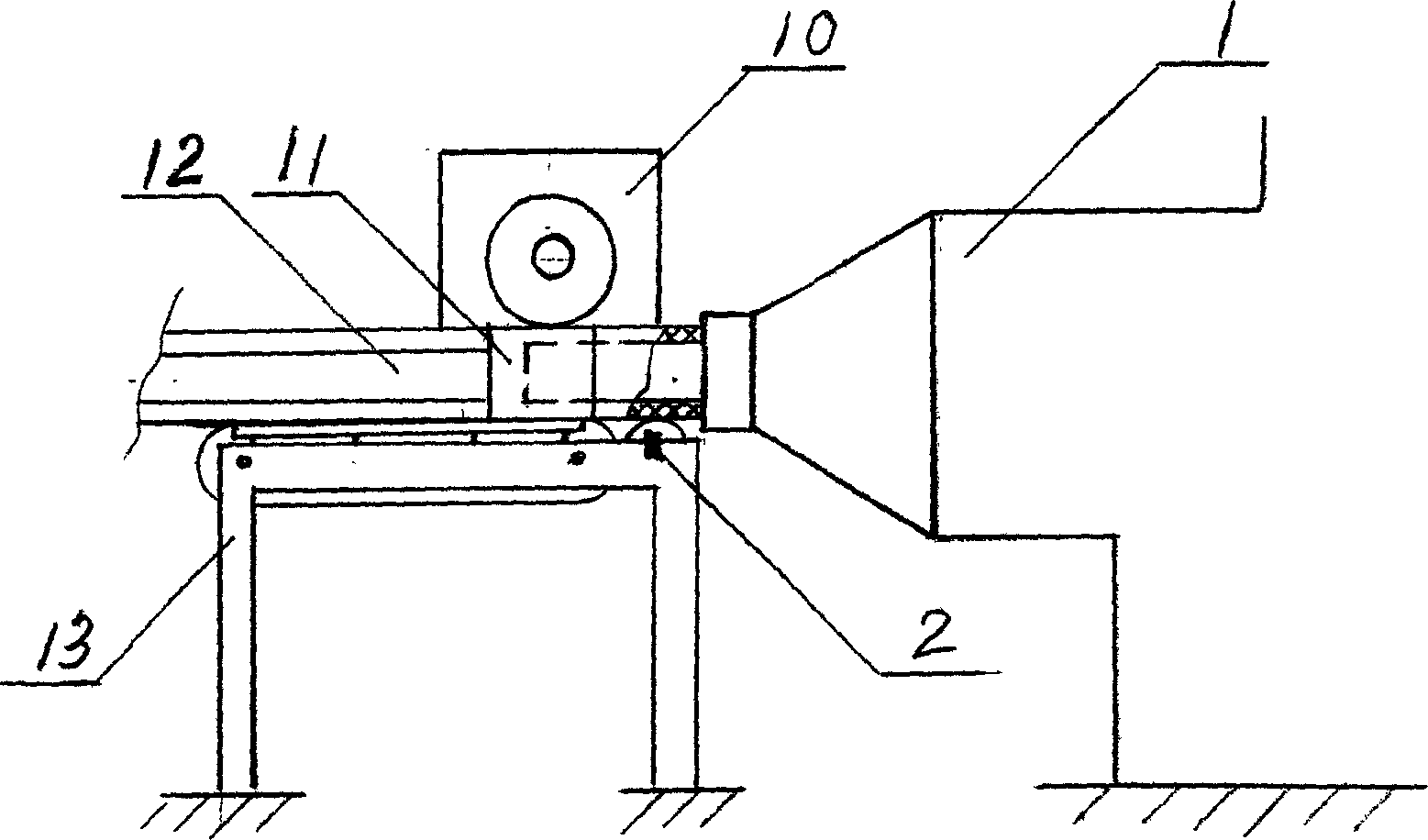

Light-duty high-strength fabric cement fly ash construction wallboard and complete set equipment for making same

ActiveCN1632258ASimple and fast constructionReduce the use of areaConstruction materialCeramic shaping apparatusThermal insulationNoise barrier

A light high-strength fiber cement fly ash building wallboard and its complete set of equipment, which use cement, silica powder, fly ash, plant fiber, methylcellulose (MC) and water as raw materials, and the wallboard can not only be used in construction Inner partition walls, and can be used for building exterior walls, exterior decorative walls, and public facilities such as sound insulation walls, firewalls, retaining walls, enclosures, etc., and can also produce such as L-shaped, baseboards, mirror lines, etc. The special-shaped board avoids the low technical index and the singleness of product types in the traditional wallboard production. It has high strength, exquisite and beautiful appearance, not easy to deform, and has outstanding performances such as bending resistance, anti-corrosion, anti-ultraviolet radiation, anti-freezing and thawing, machinability, heat preservation, sound insulation, and fire prevention.

Owner:项宏疆 +1

Assembly type seismic insulation house structure

InactiveCN102733506AImprove seismic performanceReduced seismic responseShock proofingEngineeringBuilding construction

The invention discloses an assembly type seismic insulation house structure. The assembly type seismic insulation house structure comprises prefabrication columns, prefabrication beams, seismic insulation supports and a foundation; the seismic insulation supports are arranged between the prefabrication columns on the bottom layer and the foundation; the upper ends of the seismic insulation supports are connected with the prefabrication columns on the bottom layer; and the lower ends of the seismic insulation supports are connected with the foundation. By the assembly type seismic insulation house structure, the seismic performance of an assembly house can be effectively improved; and the assembly type seismic insulation house structure is definite and reasonable in stress, and high in quality and construction speed.

Owner:SOUTHEAST UNIV

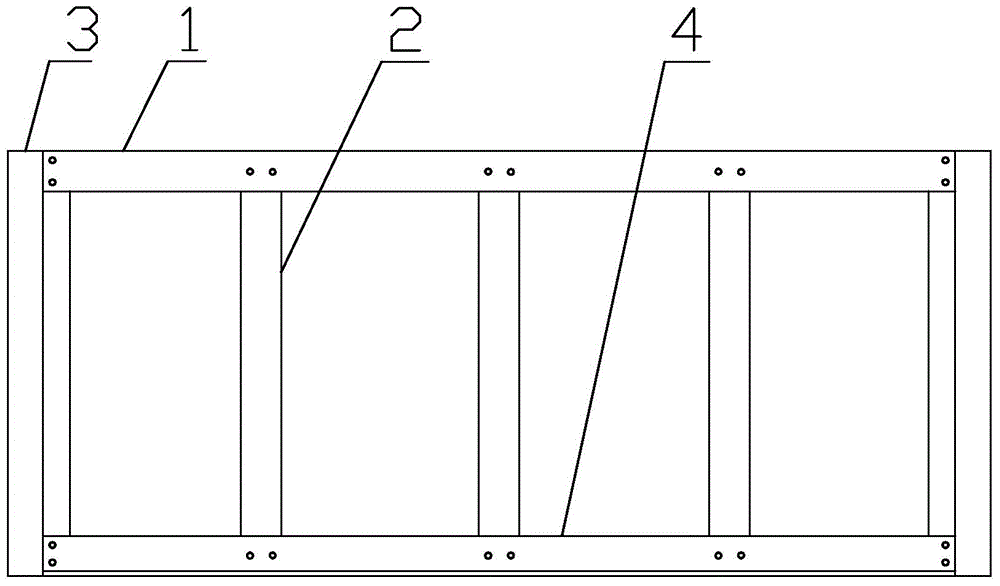

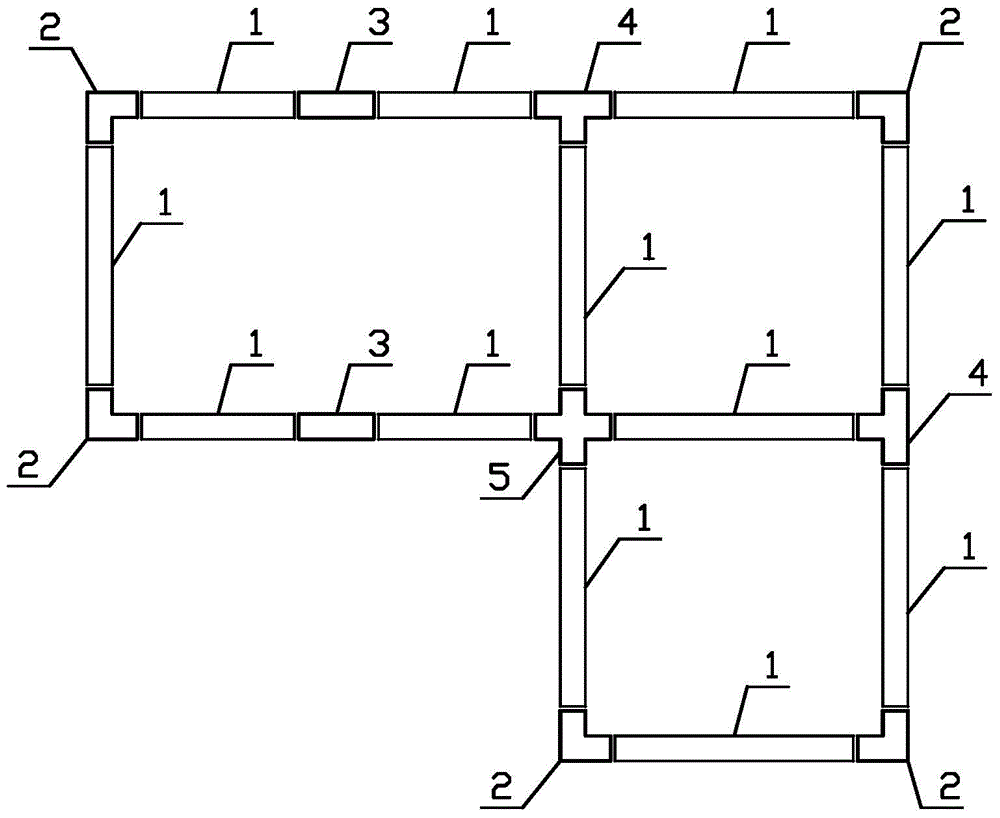

Combined wall formed by single prefabricated wall sections and construction method

Provided are a combined wall formed by single prefabricated wall sections and a construction method thereof. The combined wall is a building wall formed by splicing prefabricated wall sections with set structures through square adapter steel with U-shaped connecting pieces, the prefabricated wall sections are straight wall sections filled with fillers, thin-walled cold-formed steel columns vertically penetrating through the wall is arranged at two ends or two ends and the middle, and outwards-protruding convex cap steel columns are arranged at two ends. The combined wall with the convex cap steel columns is inserted into the U-shaped connecting pieces fixed to the square adapter steel, and screws are fixed and spliced with the square adapter steel and basic embedded bolts to form the wall. Modular installation parts are few, anti-drawing connecting pieces are convenient and quick to install, construction cost is low, and the combined wall is suitable for large-scale production of light steel joist and filler combined houses. Only one type of prefabricated combined walls is adopted, so that the prefabricated combined walls are simple in installation in fields and are light in weight and good anti-seismic property, and errors are not easily made.

Owner:WUHAN SKYSTEEL BUILDING SYST ENG CO LTD

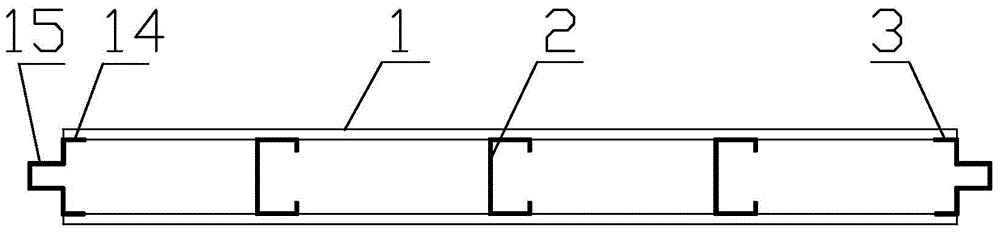

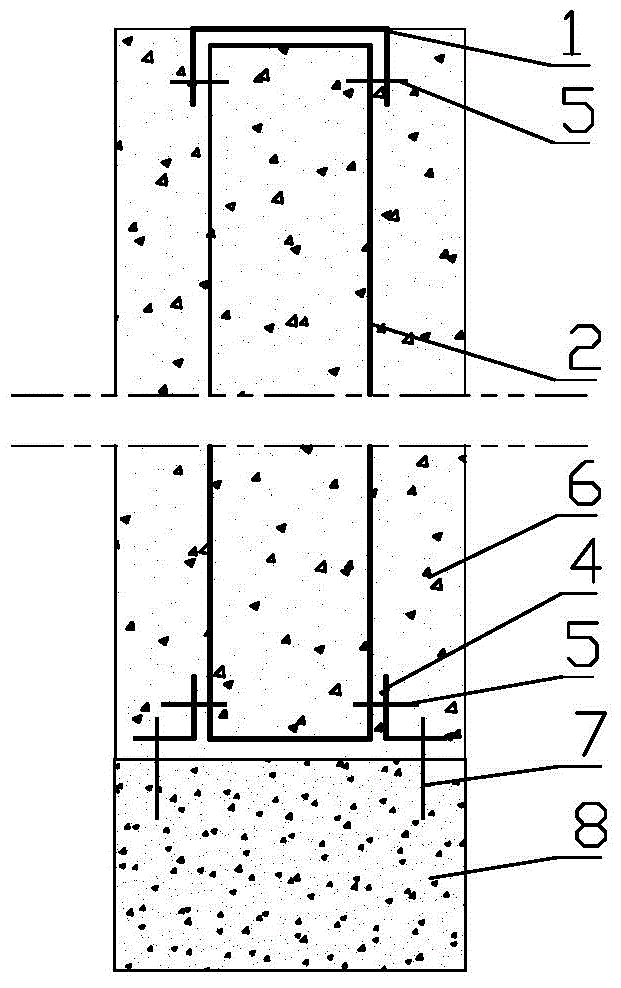

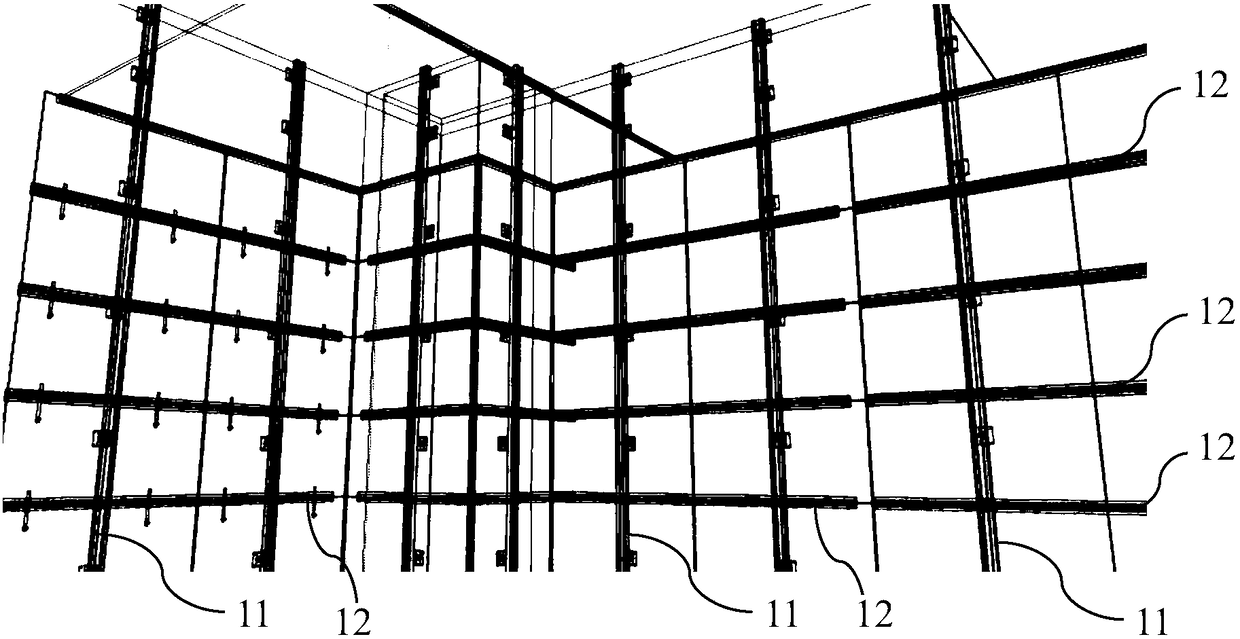

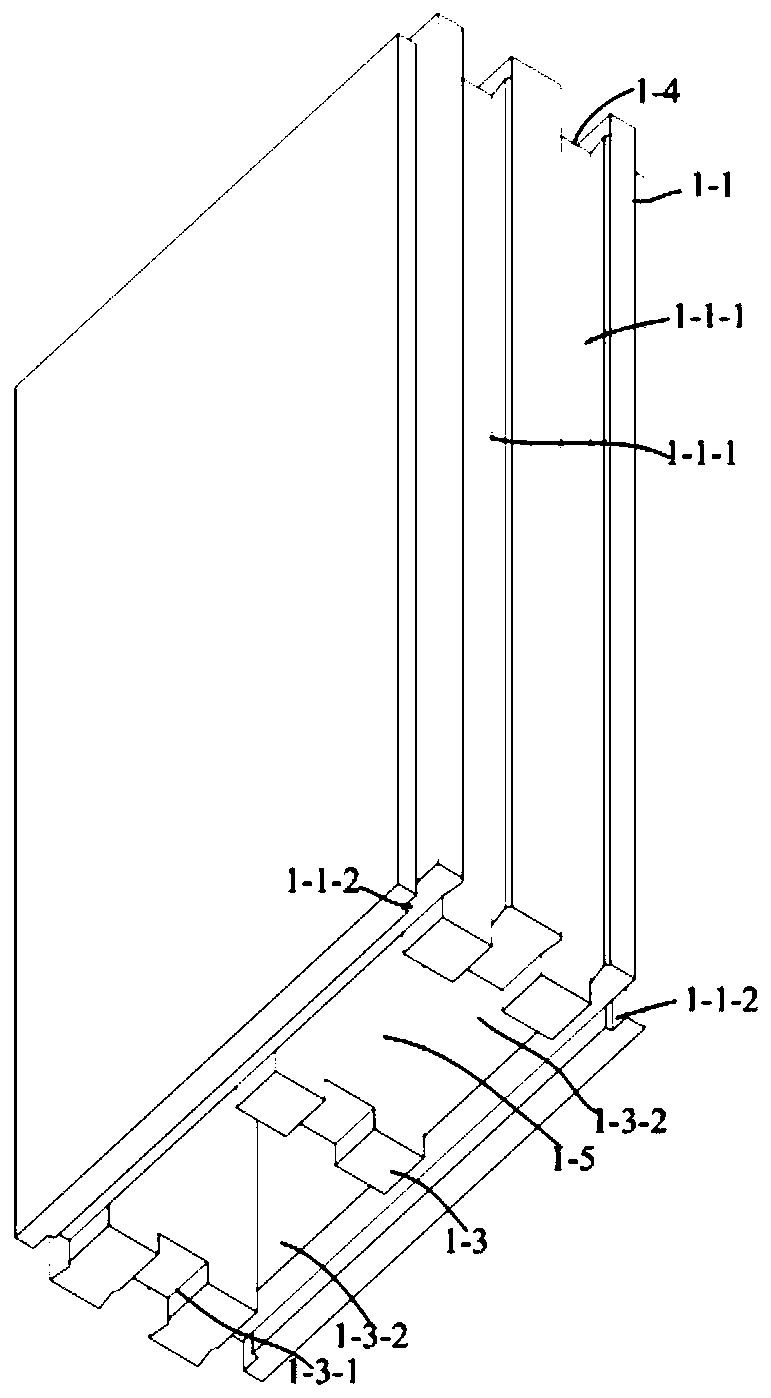

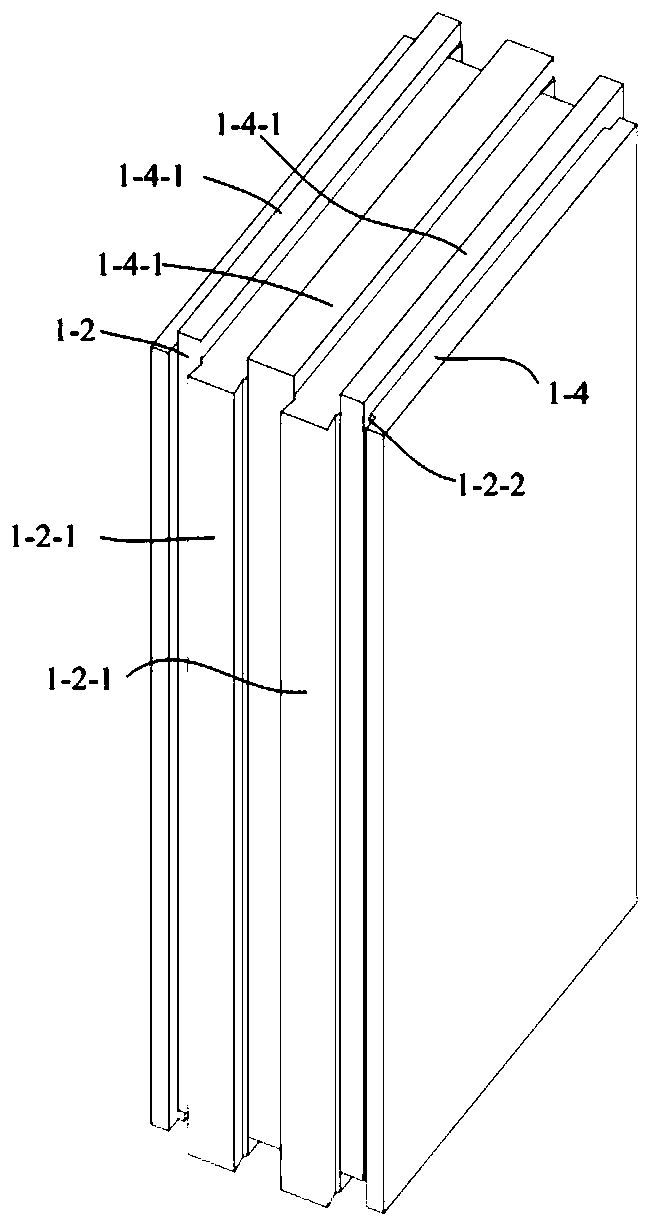

Light steel keel and lightweight concrete prefabricated combining wall and construction method thereof

ActiveCN104790555AReduce calculation lengthNot easy to rustWallsBuilding material handlingKeelSteel columns

The invention discloses a light steel keel and lightweight concrete prefabricated combining wall and construction method thereof. The wall comprises a prefabricated combining straight wall and an L-shaped or a straight or a T-shaped or a cross-shaped prefabricated combining column. The prefabricated combining straight wall and the combining column are fabricated through light steel keels and lightweight concrete. Wall columns at the two ends of a prefabricated combining straight wall keel are protruding steel column sections, and the upper end and the lower end of each wall column are provided with guide rails. The keel of the prefabricated combining column is composed of a concave steel column, an upper end guide rail and a column bottom plate, the concave steel column is connected with a foundation through a base plate and foundation preburied bolts, and protruding steel columns and the concave steel column between the prefabricated combining straight wall and the prefabricated combining column are directly connected through bolts. The wall avoids wet operation of pouring concrete, anti-drawing pieces are convenient to install, wall installation accuracy is easy to control, the manufacturing cost is low, and therefore the wall is suitable for installation of massive light steel keel and lightweight concrete combined houses.

Owner:WUHAN SKYSTEEL BUILDING SYST ENG CO LTD

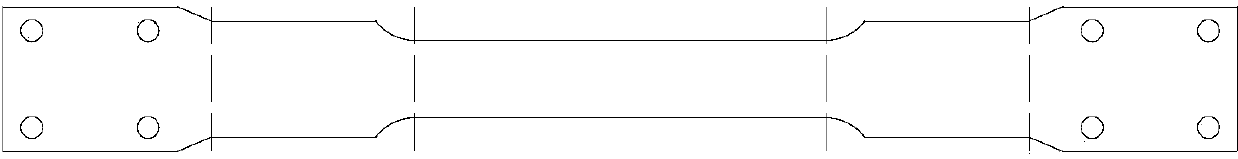

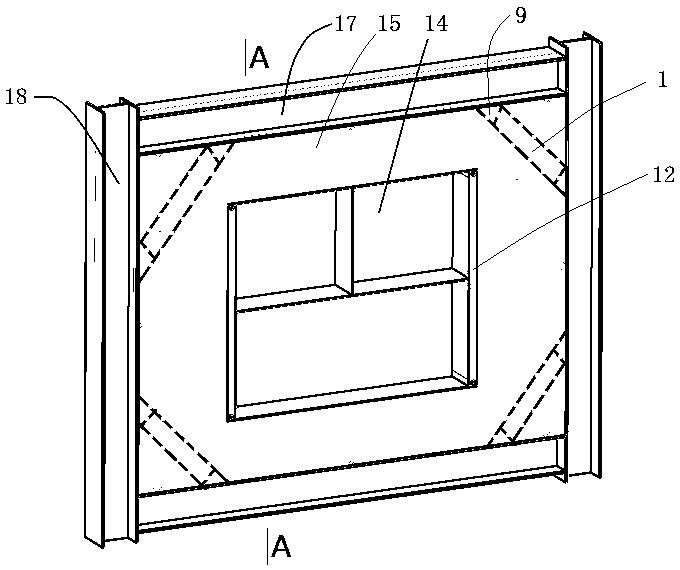

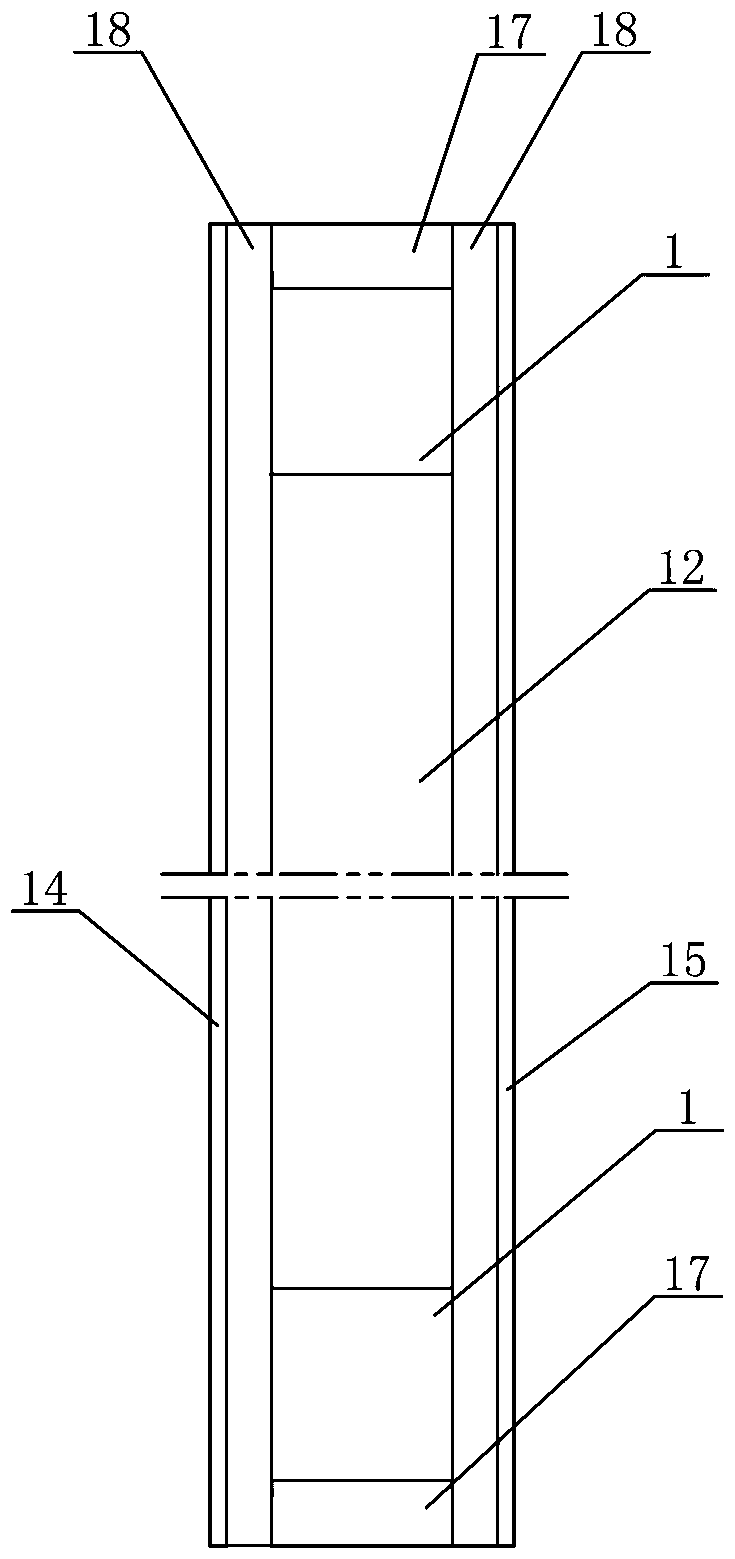

T-shaped assembly type buckling-restrained brace member

InactiveCN105888092AAvoid wet workEasy to transportProtective buildings/sheltersShock proofingBuckling-restrained braceFlange

The invention provides a T-shaped assembly type buckling-restrained brace member, which is suitable for axis pressure members of buildings and structures. The T-shaped assembly type buckling-restrained brace member is characterized by comprising a T-shaped assembly type buckling-restrained brace inner core and a buckling-restrained outer coating restraint member, wherein the T-shaped assembly type buckling-restrained brace inner core is arranged in the buckling-restrained outer coating restraint member by inner core double angle steels clamping a straight steel plate. The restraint of a core area is characterized in that a core area top restraint cover plate, core area flange restraint cushion strips and the leg backs of core area restraint angle steels are connected by bolts; the leg tips of the two core area restraint angle steels, and core area web restraint cushion strips between the two core area restraint angle steels are connected by bolts; the leg tips of two transition area restraint angle steels, the straight steel plate and the inner core double angle steels are connected by bolts; the leg backs of the two transition area restraint angle steels, the straight steel plate, the inner core double angle steels and a transition area top restraint cover plate are connected by bolts. The T-shaped assembly type buckling-restrained brace member has the advantages that the production and the construction are simple and convenient, the production cost is low, the production cycle is short, the property is stable, and the like.

Owner:NORTHEAST DIANLI UNIVERSITY

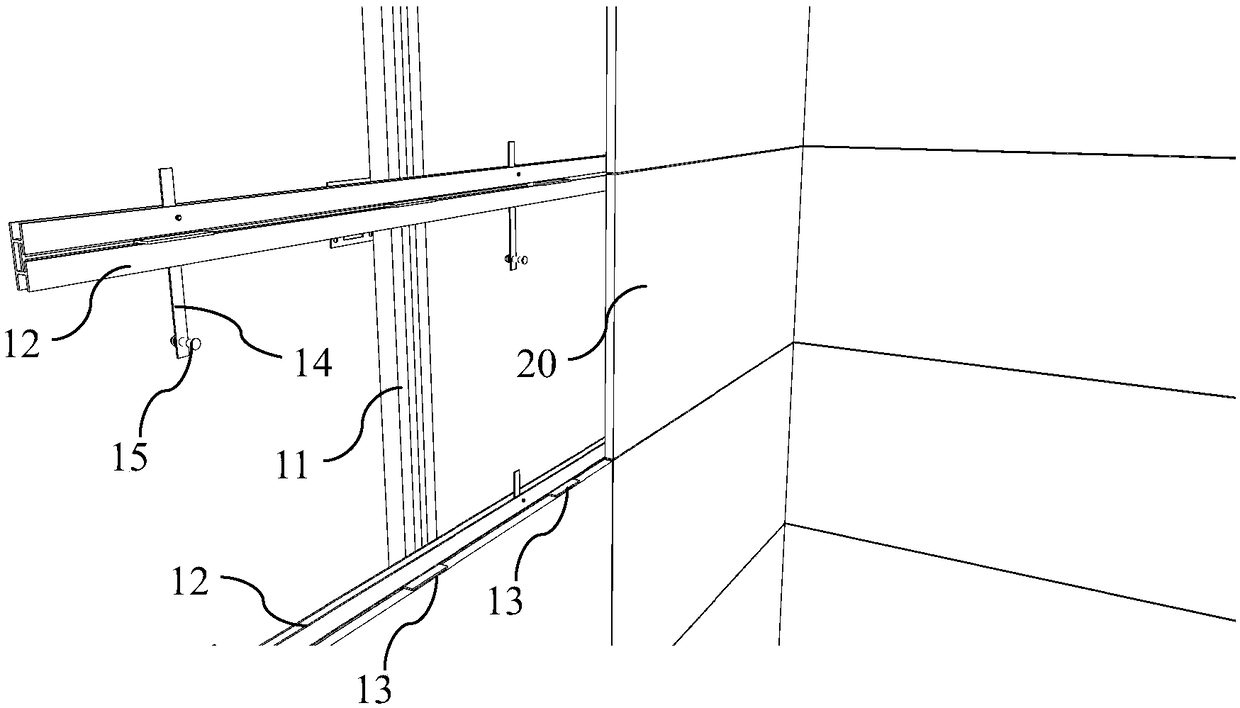

Wall tile drying and hanging system and construction method

The invention provides a wall tile drying and hanging system and a construction method. The wall tile drying and hanging system comprises multiple strips of vertical keels fixed to a wall surface separately, multiple strips of horizontal reels fixed to the corresponding vertical keels respectively and a plurality of tile supporting and hanging assemblies assembled to the horizontal keels; each tile supporting and hanging assembly includes transverse supporting components, hanging rods and back bolts, wherein the transverse supporting components are located on corresponding horizontal keels andprovided with horizontal supporting parts for supporting tiles, and the size of the horizontal supporting parts stretching out of the horizontal keels is smaller than the thickness of the tiles; theupper portions of the hanging rods are fixed to the horizontal keels, and free ends of the back bolts are provided with fixing heads for being inserted into fixing holes in the back faces of the tiles. Through the tile supporting and hanging assemblies, the tiles are fixed to a framework of the wall surface so that not only can wet operation be avoided, the construction progress is accelerated, but also the construction quality can be improved, and reuse of the tiles and framework is achieved.

Owner:丰屋蔀家科技(深圳)有限公司

T-shaped light-weight steel frame, T-shaped light-weight steel assembling type compound wall plate and installation method thereof

InactiveCN105804324AImprove insulation effectAvoid pressure instabilityBuilding reinforcementsInsulation layerWhole body

The invention provides a T-shaped light-weight steel frame, a T-shaped light-weight steel assembling type compound wall plate and an installation method thereof. The T-shaped light-weight steel frame is used as a connection part of a wall body corner of an assembling type room in a connecting process, and connection construction and structure problems are solved very well. The T-shaped light-weight steel frame comprises a first framework and a second framework, which are vertical to each other; an outer edge frame is made of M-shaped steel and the interior is made of C-shaped steel; the outer edge frame is connected by a C-shaped connection part through a self-tapping screw; the wall plate is filled into the light-weight steel frame through a sandwiched heat insulation layer and is used for keeping heat and limiting the deformation of the light-weight steel frame; horizontal anti-shearing, anti-cracking and anti-impact performances of the wall body are improved through the light-weight steel frame and an external maintenance plate; vertical connection between the wall body and a main plate is realized through a turn buckle of the outer edge frame of the light-weight steel frame and a sleeve, so that the wall bodies of the upper and lower layers are connected to form a whole body, and the connection reliability of the wall body and the main plate is enhanced. The T-shaped light-weight steel frame is high in assembling degree, is suitable for industrial production, and integrates heat insulation and structure; the connection structure is safe and reliable, is easy to construct, mount and replace and is relatively low in cost.

Owner:江苏保力自动化科技有限公司

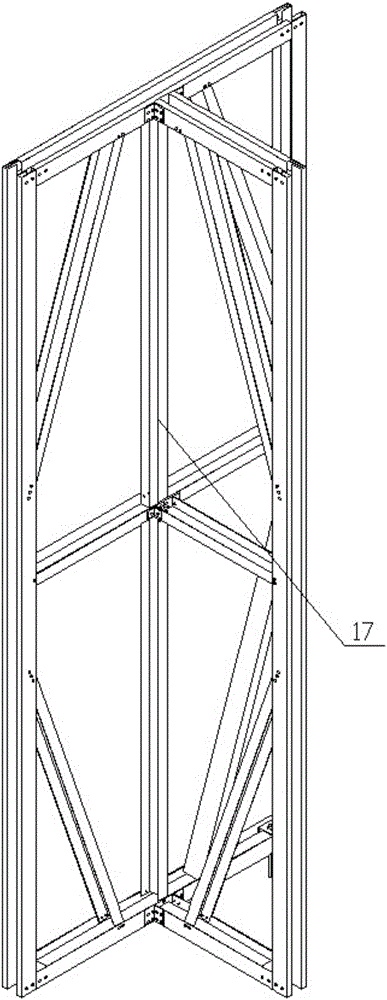

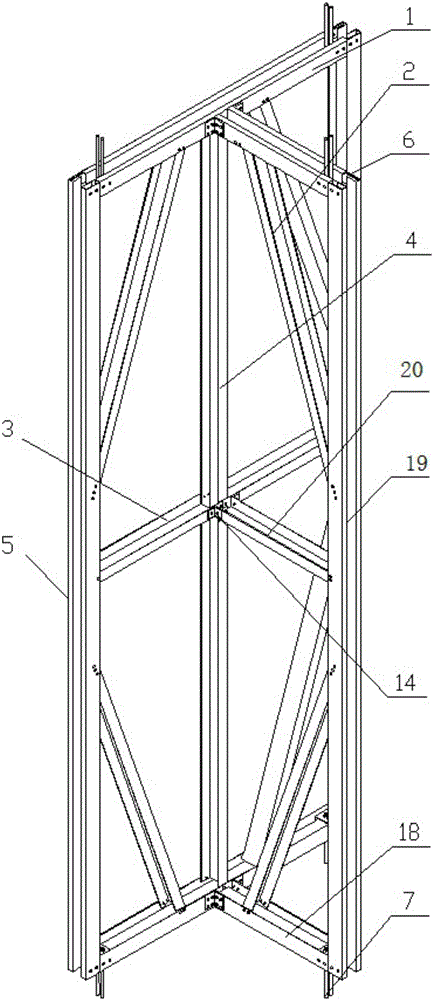

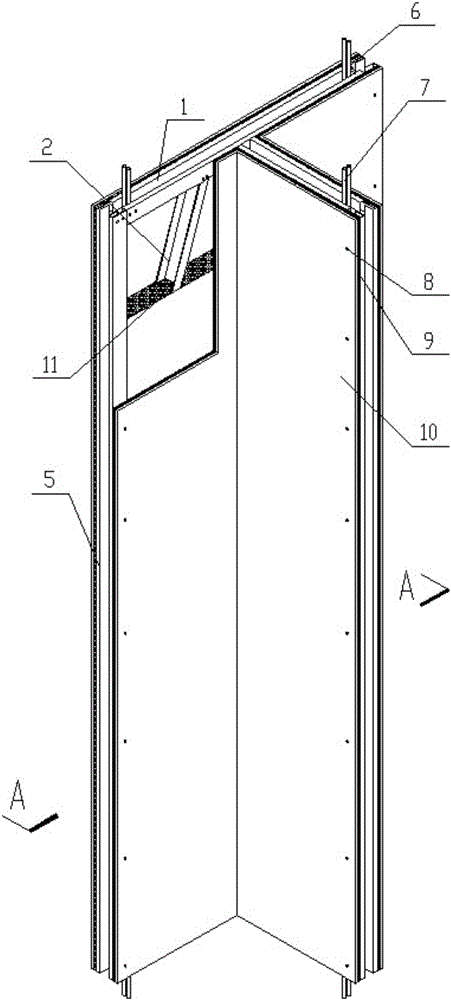

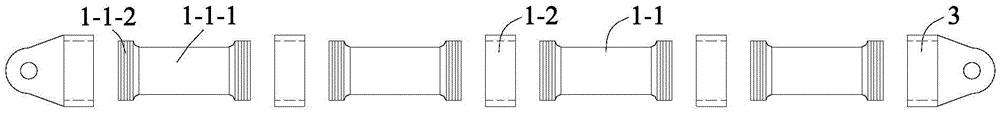

Modularized bamboo-shaped buckling restrained brace

ActiveCN105604205AIncrease production capacityRealize the designShock proofingBuckling-restrained braceEngineering

The invention discloses a modularized bamboo-shaped buckling restrained brace which comprises a core part, an outer restraining part and a structure connecting part. The core part comprises a plurality of circular energy dissipation sections and a plurality of elastic sleeves. Each circular energy dissipation section comprises a middle section and connecting sections at two ends. The core part is located inside the outer restraining part. The inner surface of the outer restraining part closely attaches to or is tangent to the outer surfaces of the elastic sleeves of the core part. One end of the structure connecting part extends into the outer restraining part, and the other end thereof extends out of the outer restraining part to be connected with a structure. The modularized bamboo-shaped buckling restrained brace has the advantages that the circular energy dissipation sections and elastic sleeves of the modularized bamboo-shaped buckling restrained brace can be produced in batch in factories, the circular energy dissipation sections and elastic sleeves can be selected and combined according to the length requirement of the buckling restrained brace, and accordingly the modularized production and design of the core part can be achieved.

Owner:CHINA JINGYE ENG TECH CO LTD +2

Self-resetting energy consumption wall structure with storage function

InactiveCN107747364ASimple wall structureEasy to assembleWallsProtective buildings/sheltersWall plateSelf repair

The invention discloses a self-resetting energy consumption wall structure with a storage function. The self-resetting energy consumption wall structure comprises resetting energy consumption supportsarranged in a wall body frame and is characterized in that a wall cabinet is arranged in the wall body frame and is closed into a wall body structure through a front wall plate and a rear wall plate,and the front wall plate and the rear wall plate are fixed to angle steel welded to the wall body frame through bolts; an opening in embedding fit with the wall cabinet is formed in the front wall plate; and the wall cabinet is arranged in the space of the wall body frame after being fixed to the rear wall plate through bolts and is closed into the wall body structure through the rear wall plateand the front wall plate. Compared with the prior art, the self-resetting energy consumption wall structure has the advantages that the wall body structure is simple, assembly is convenient, conciseness and attractiveness are achieved, energy consumption capacity is high, and the storage space is large; the self-resetting energy consumption wall structure can be self-repaired, the residual interlayer displacement angle of the structure is reduced effectively, the repairing cost is lowered, and standardization, industrialization and integration are easy to achieve; and wet operation is avoidedthrough assembly type construction, and the self-resetting energy consumption wall structure is especially suitable for large space buildings.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

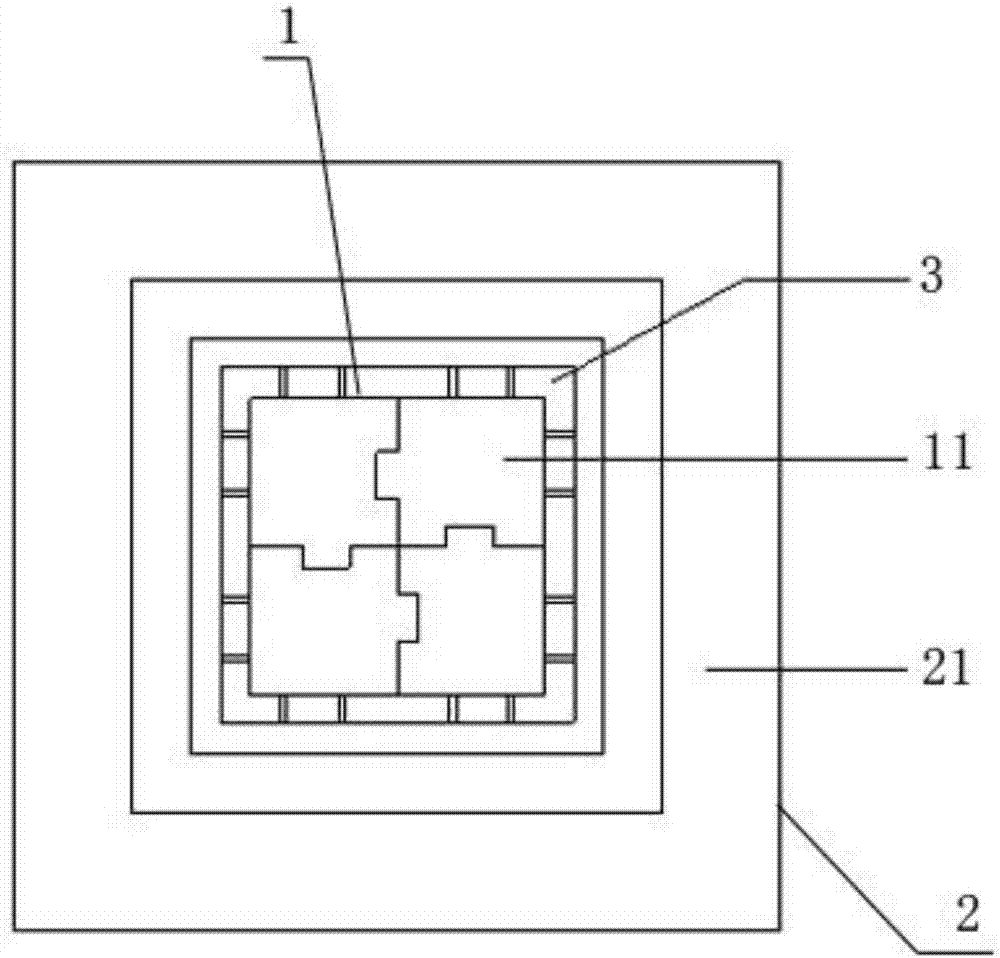

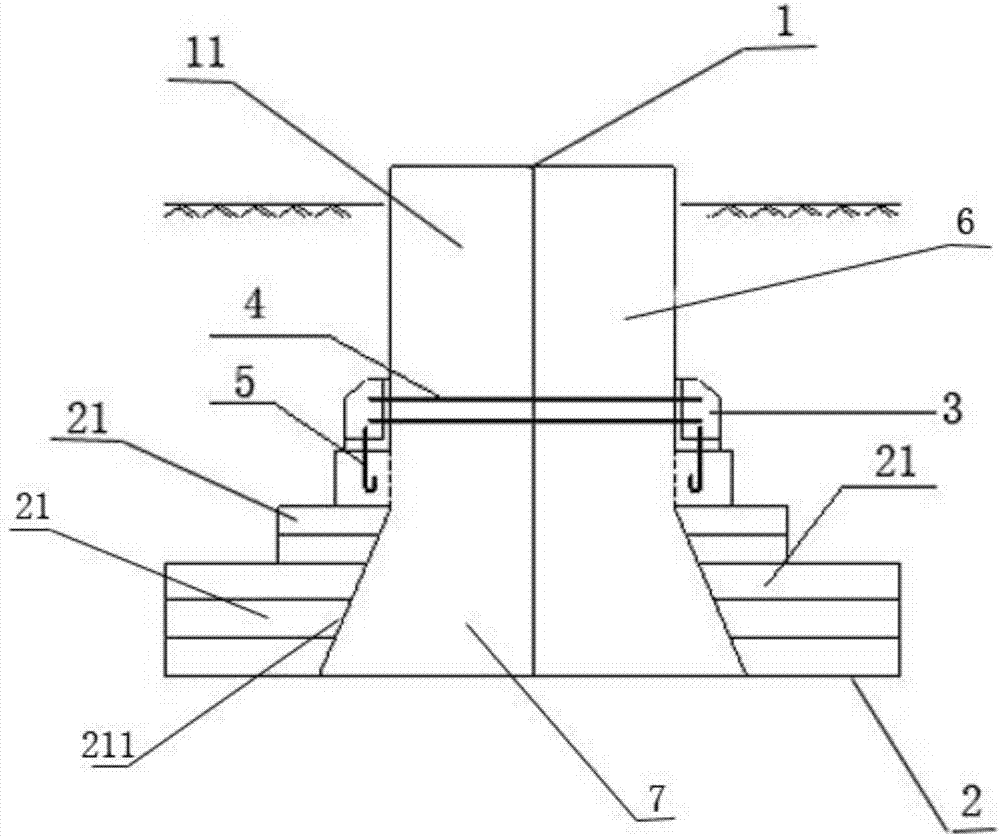

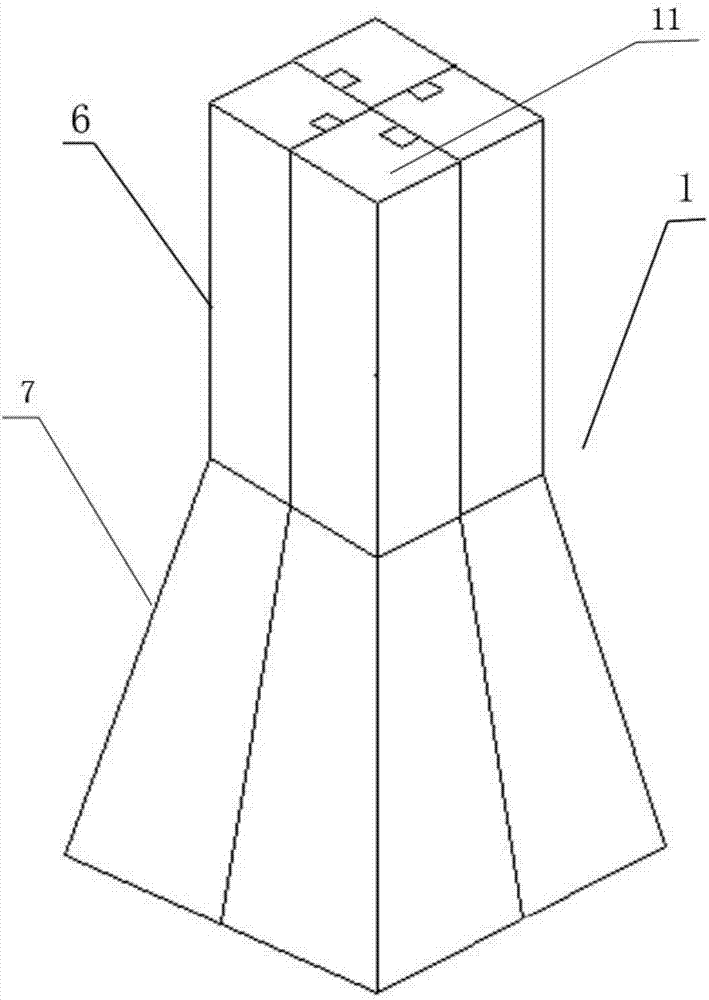

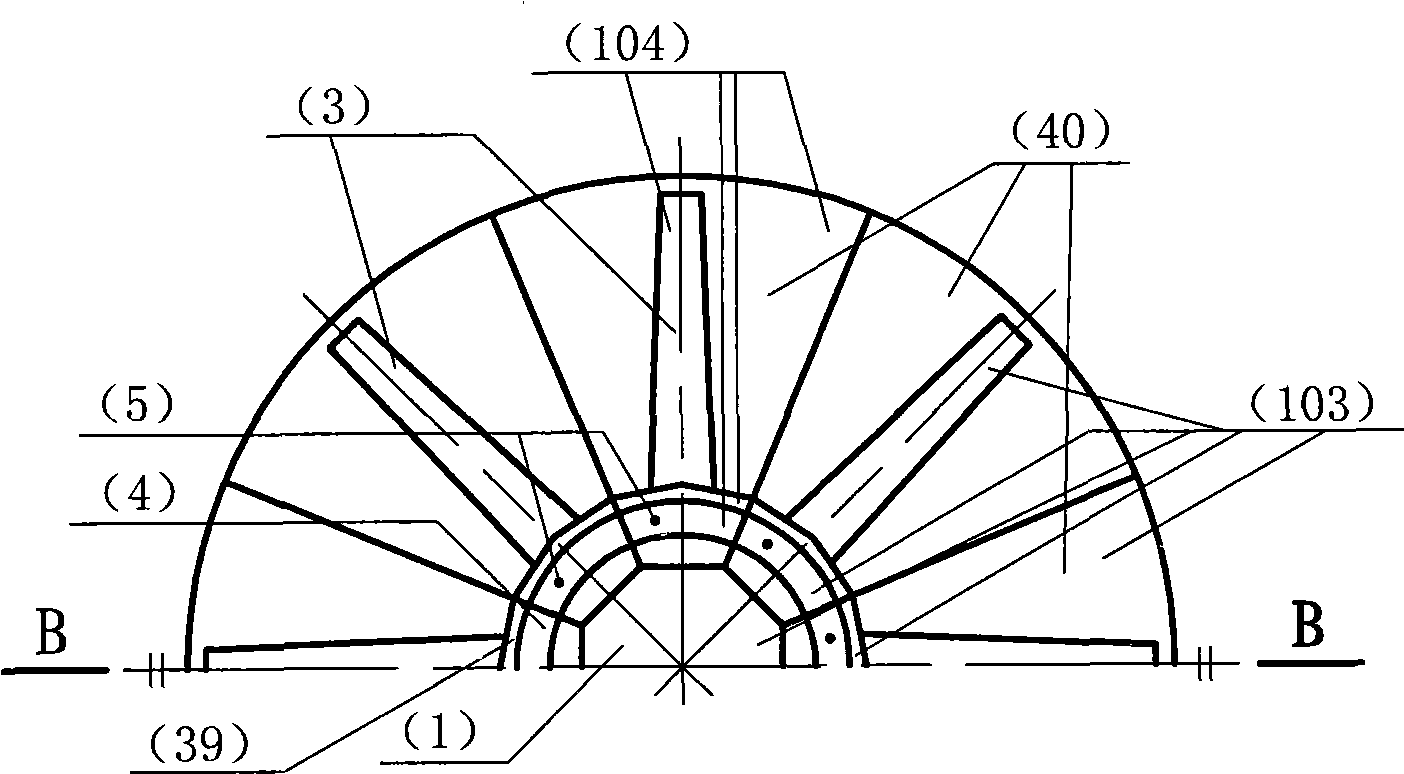

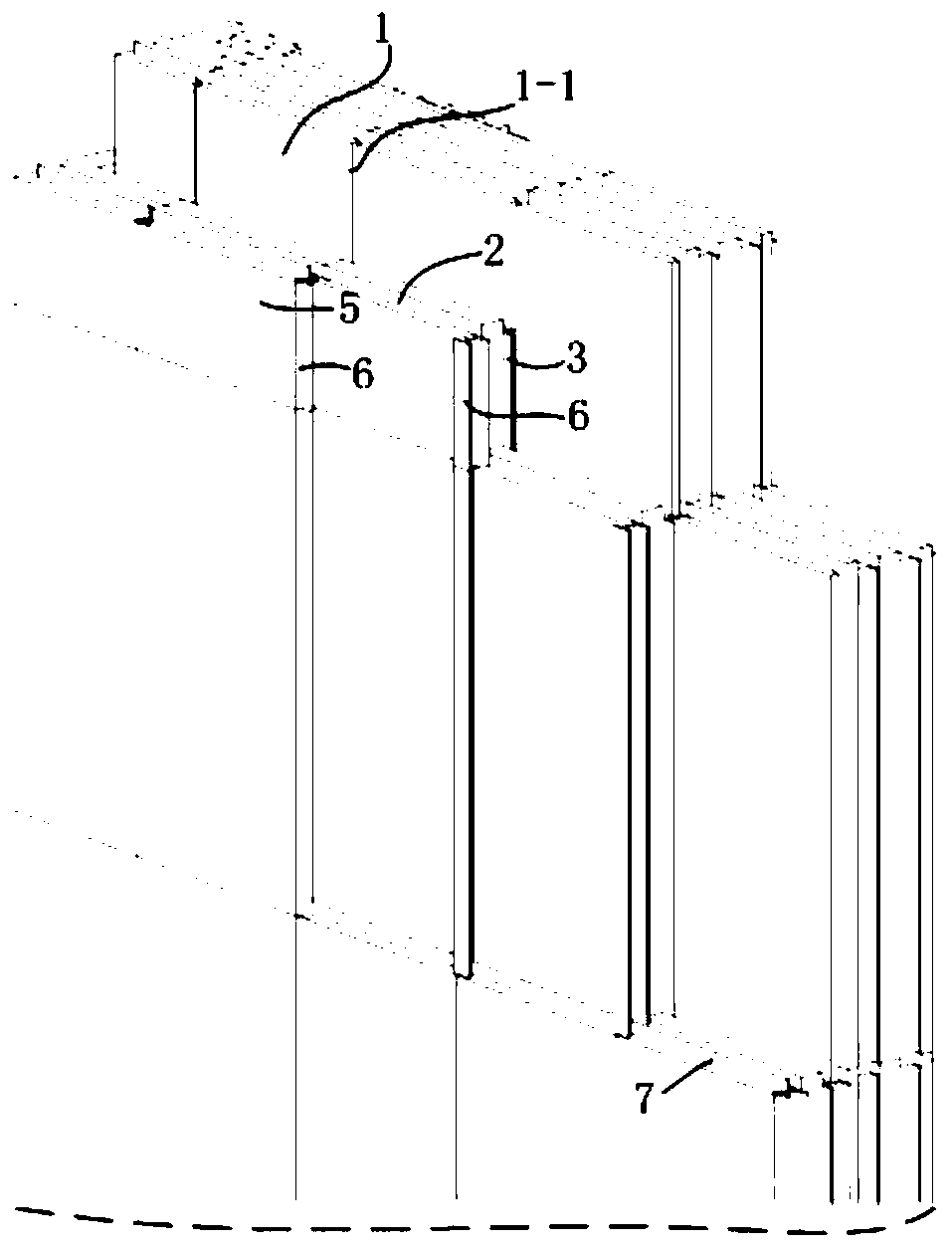

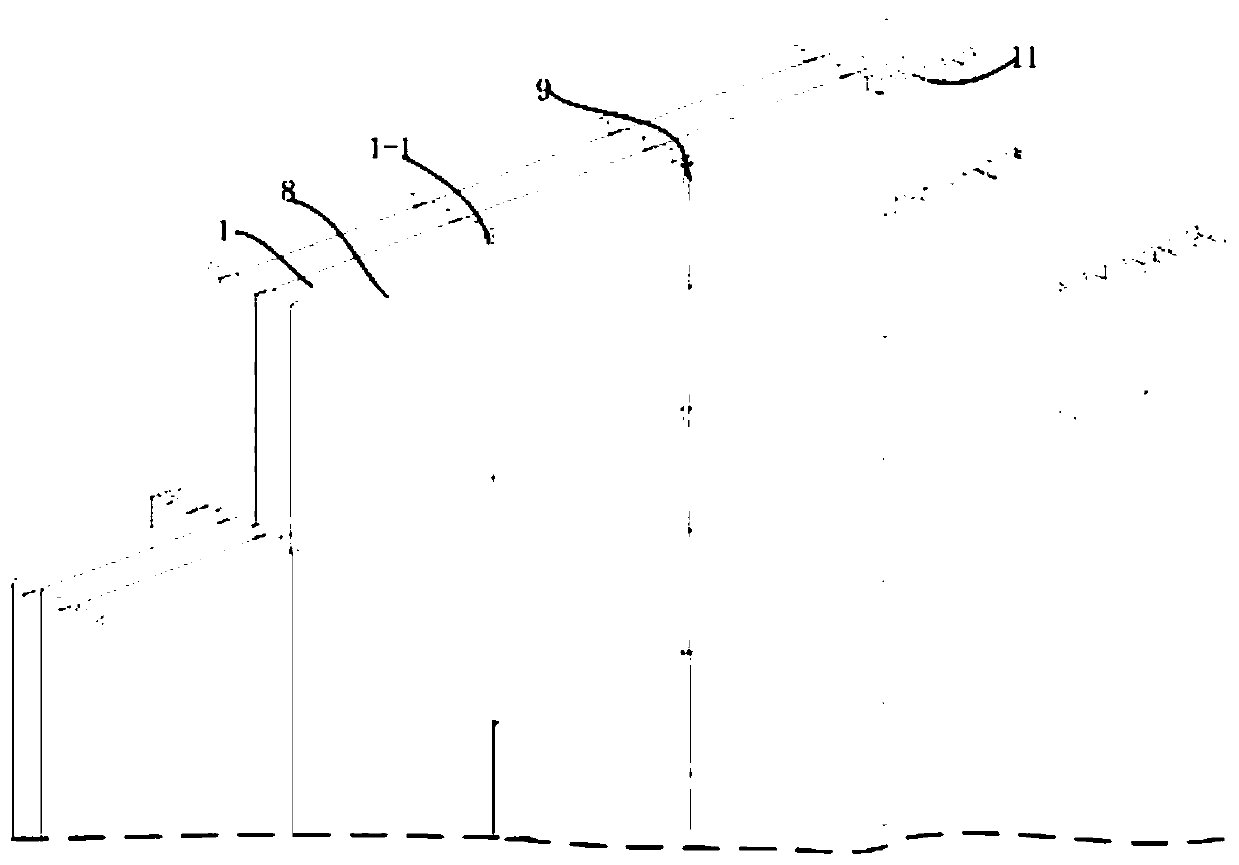

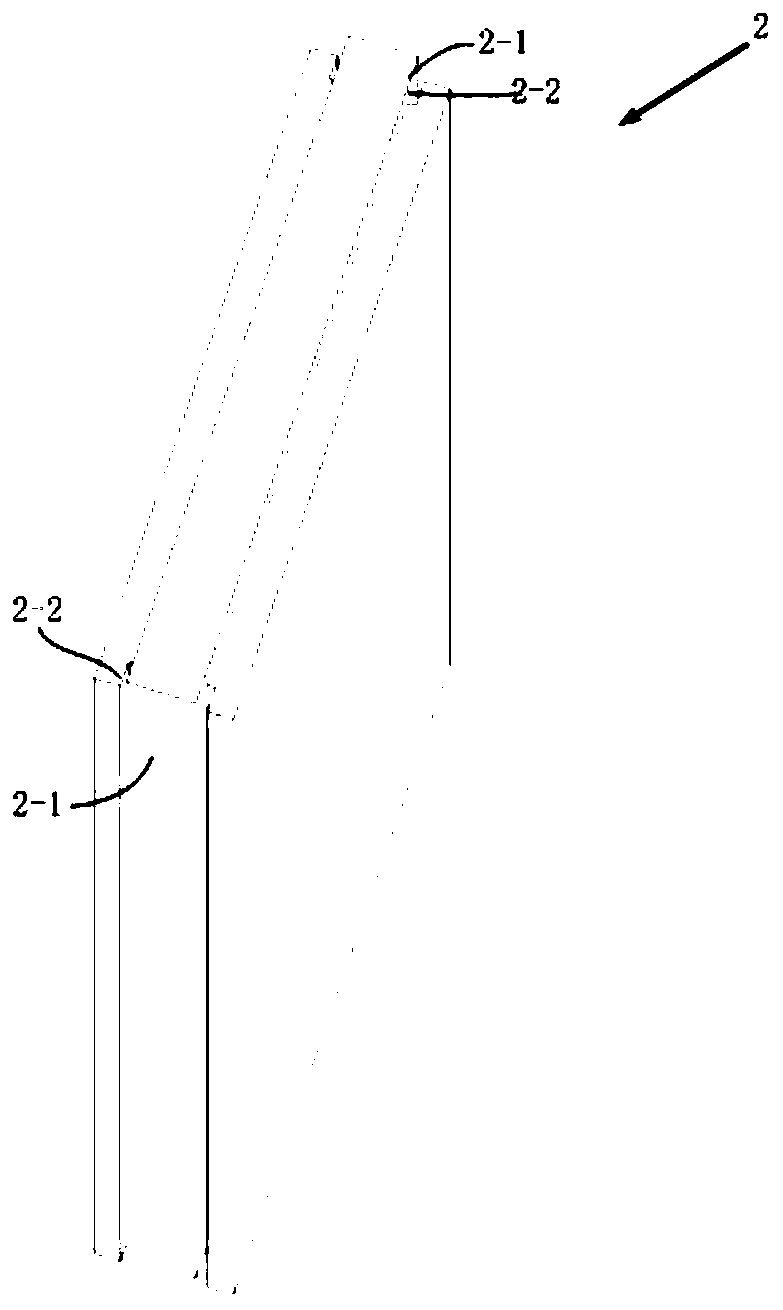

Pole tower prefabricated assembly type concrete stepped foundation and assembling method thereof

ActiveCN108005099AIngenious structural designImprove work efficiencyFoundation engineeringWind energy generationTowerTransmission equipment

The invention relates to a pole tower prefabricated assembly type concrete stepped foundation and belongs to the technical field of power communication transmission equipment. The pole tower prefabricated assembly type concrete stepped foundation comprises a core column, a stepped hoop and steel plate connecting keys. The core column comprises a plurality of splicing columns. The splicing columnsare of the same structure and are sequentially spliced into the core column through splicing grooves and splicing strips. The core column comprises an upper column body and a lower prismoid body fixedto the lower end of the upper column body. The stepped hoop comprises a plurality of annular sleeves with different outer diameters and inner diameters. The multiple steel plate connecting keys are mounted on the outer side of the core column and the periphery of the upper end of the stepped hoop. The steel plate connecting keys are fixed to the upper end of the stepped hoop through embedded anchors. The steel plate connecting keys are fixed to the core column through through anchor bars. The pole tower prefabricated assembly type concrete stepped foundation is ingenious in structure design,all construction projects are changed into all prefabricated modules, by splicing all the modules, the operation efficiency is improved, the construction period is shortened, and an assembling methodof the pole tower prefabricated assembly type concrete stepped foundation is simple and convenient to operate.

Owner:JIANGSU ELECTRIC POWER CO +2

Large combined base with mast type structure

InactiveCN101503880AReduce investmentReduce manufacturing costFoundation engineeringElectricityPre stress

The invention relates to a combined foundation arranged on a large-scale mast type structure such as a wind power generating unit and the like, which is formed by a regular polygonal or circular independent foundation beam slab structure combined by concrete precast components, and solid loose materials such as sand, stone, soil and the like. A prestressed combined connecting system of which upper and lower double-way radiation horizontal spaces are crossed and the horizontal periphery is closed, a concave-convex key positioning system, a concrete shear-resisting zero clearance connecting face forming system and a dispersion material silo system achieve the function of the prior integral cast-in-place concrete foundation. The combined foundation has the remarkable characteristics of resource conservation and environmental protection, lowers the cost, and can be shifted and used repeatedly.

Owner:赵正义

Construction method of novel structural column for frame-structured cross filled walls

ActiveCN105155728AReduce construction proceduresShorten the construction periodWallsBuilding material handlingVertical barEngineering

A construction method of a novel structural column for frame-structured cross filled walls is characterized in that vertical bars are fixed in embedding holes of embedded parts by means of welding; by centering on building of the structural column along with the building of filled walls corresponding to four sides of the structural column, building is carried out one block by one block in the building manner of a traditional filled wall; the thickness of each prefabricated segment block plus a mortar joint is equal to the thickness of two common bricks plus a mortar joint.

Owner:朱占元

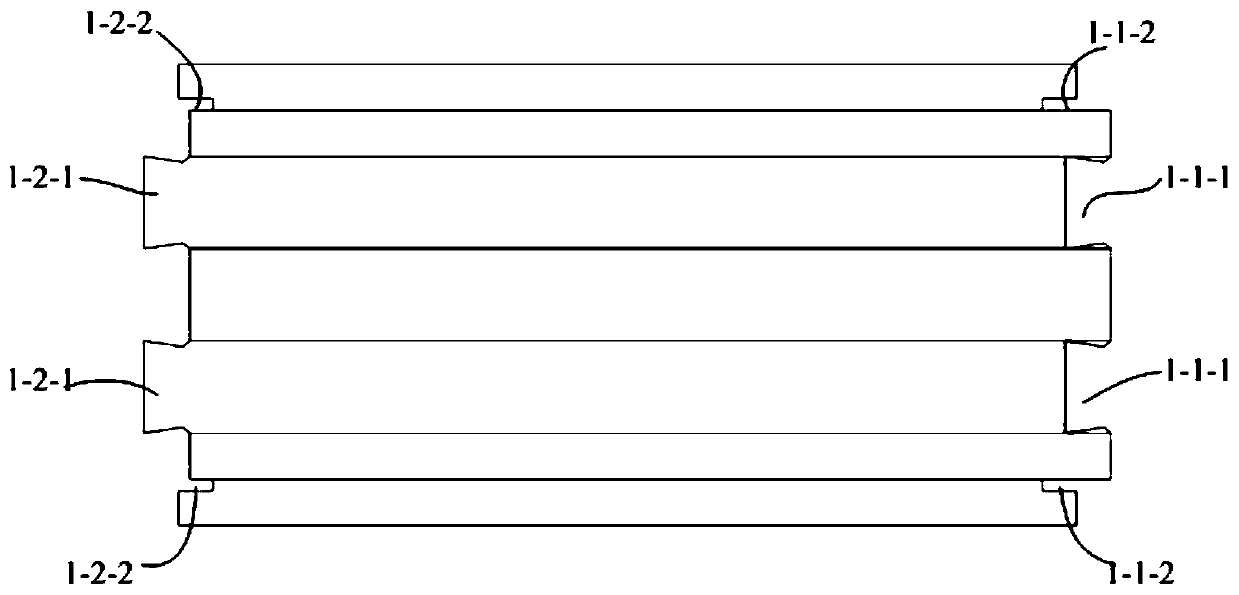

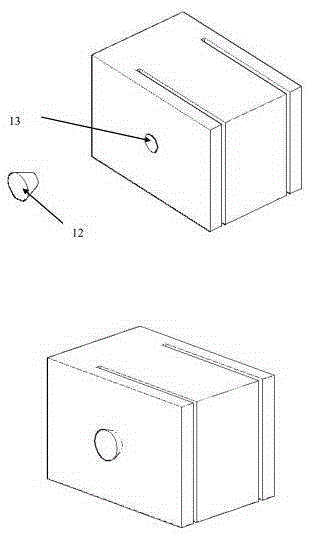

Brick bodies, wall body and building body

The embodiments of the invention disclose brick bodies, a wall body and a building body. The brick bodies comprise square block bodies, wherein first tenon grooves are formed in the first side surfaces, and first tenon heads are arranged at the positions, corresponding to the first tenon grooves, of the second side surfaces; second tenon grooves are formed in the third side surfaces, and second tenon heads are arranged at the positions, corresponding to the second tenon grooves, of the fourth side surfaces; the first tenon grooves and the first tenon heads are in the shape of dovetail, so that the two brick bodies adjacent to each other left and right are fixed to the first tenon heads through the first tenon grooves in a fit mode, and the two brick bodies adjacent to each other up and down are fixed to the second tenon heads through the second tenon grooves in a fit mode, the walling process of the wall body is like inserting Lego blocks so as to avoid the use of mortar, on-site wet work and building construction waste are reduced, construction is convenient, therefore, the flexibility and construction efficiency of masonry buildings are improved, the standardized full-size system of the brick bodies can meet the requirements of various sizes of various buildings, and the cost is greatly reduced when the quality of brick body products is improved through the industrialized production,

Owner:金点石(北京)建筑设计咨询服务有限责任公司

Socket, wall body and building body

ActiveCN110957604AImprove AssemblabilityIncrease flexibilityWallsCoupling contact membersArchitectural engineeringMechanical engineering

The invention relates to the field of building construction, in particular to a socket, a wall body and a building body. The socket comprises a first body and a socket; a T-shaped first mounting groove is formed in the first body; the cross section of the socket is T-shaped, the socket is inserted into the first mounting groove, the socket comprises a T-shaped hollow I-shaped shell and a hollow II-shaped shell, a plurality of jacks are formed in the side surface of the I-shaped shell, and the II-shaped shell is mounted on the lower surface of the I-shaped shell; a plurality of conducting strips corresponding to the jacks in position are installed in the I-type shell, a wiring assembly is arranged in the II-type shell, one end of the wiring assembly is arranged on the II-type shell in a protruding mode and connected with the conducting strips, and the other end of the wiring assembly is used for being connected with a cable. By providing the novel socket, the socket can be installed ina wall body in a splicing and inserting mode, and the assembling performance of the socket is improved.

Owner:金点石(北京)建筑设计咨询服务有限责任公司

Construction method of novel constructional column of framework structure crisscross filler wall

InactiveCN105256920AReduce construction proceduresShorten the construction periodWallsBuilding material handlingBuilding construction

Owner:清远市远宏建筑工程有限公司

Non-shear wall system of fully-fabricated building and wallboard module prefabricating method of non-shear wall system

The invention discloses a non-shear wall system of a fully fabricated building and a wallboard module prefabricating method thereof, the system comprises a plurality of steel frame wallboard modules integrally prefabricated by steel frame-heat preservation and sound insulation wallboards, and steel frame columns of the adjacent steel frame wallboard modules on the same layer are spliced and then are connected and fixed through column-beam connecting components and fasteners. The assembly units are steel frame wallboard modules, adjacent modules are connected and fixed through fasteners, and connection is convenient and reliable. Joints of adjacent modules are changed into dry connection from traditional wet connection, so that on-site wet operation is reduced, on-site construction efficiency is improved, and the construction period is effectively shortened; the factory prefabrication of the module is realized, and the processing progress is not influenced by weather and seasons. The plate type structure of the module is convenient to transport, wet operation basically does not exist on site, wall column systems, beam columns and wallboards can be bolted and combined on site, and construction is simple and convenient.

Owner:中建五局第三建设有限公司 +1

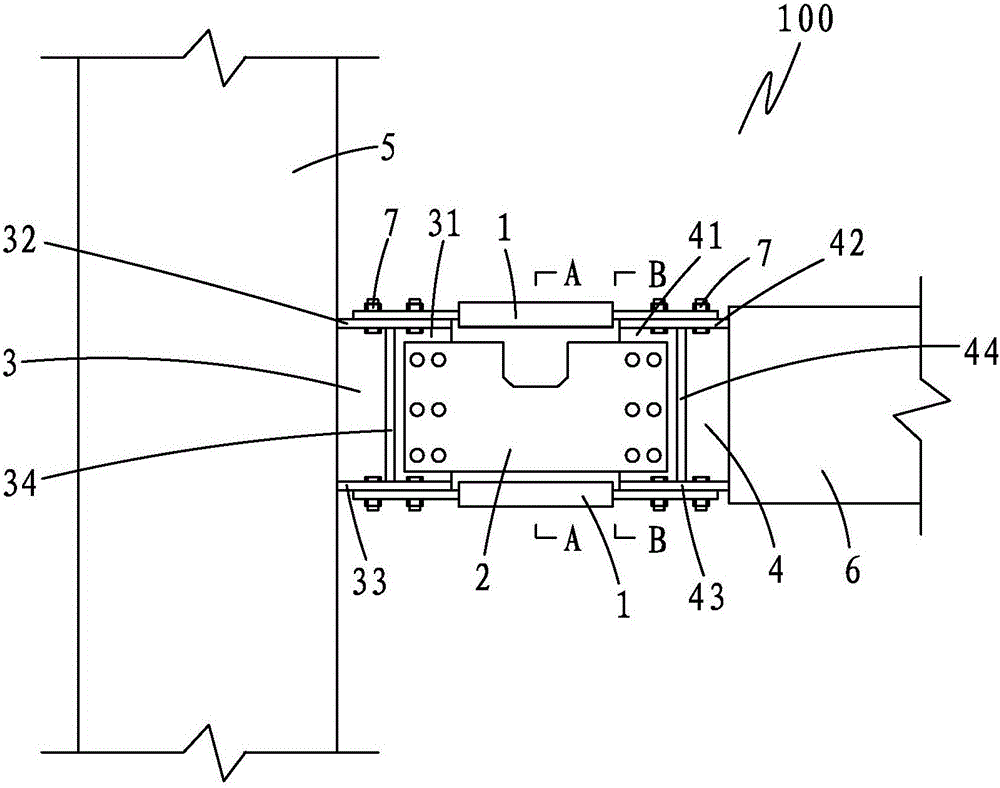

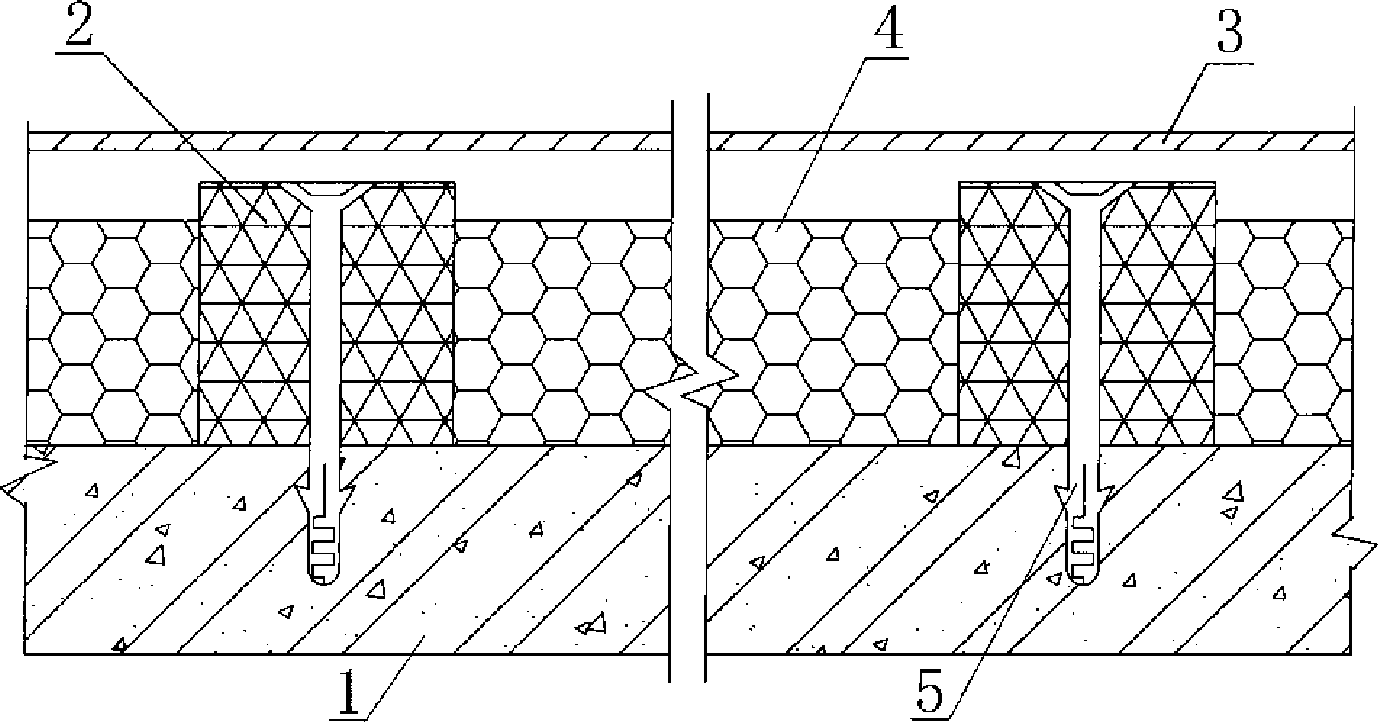

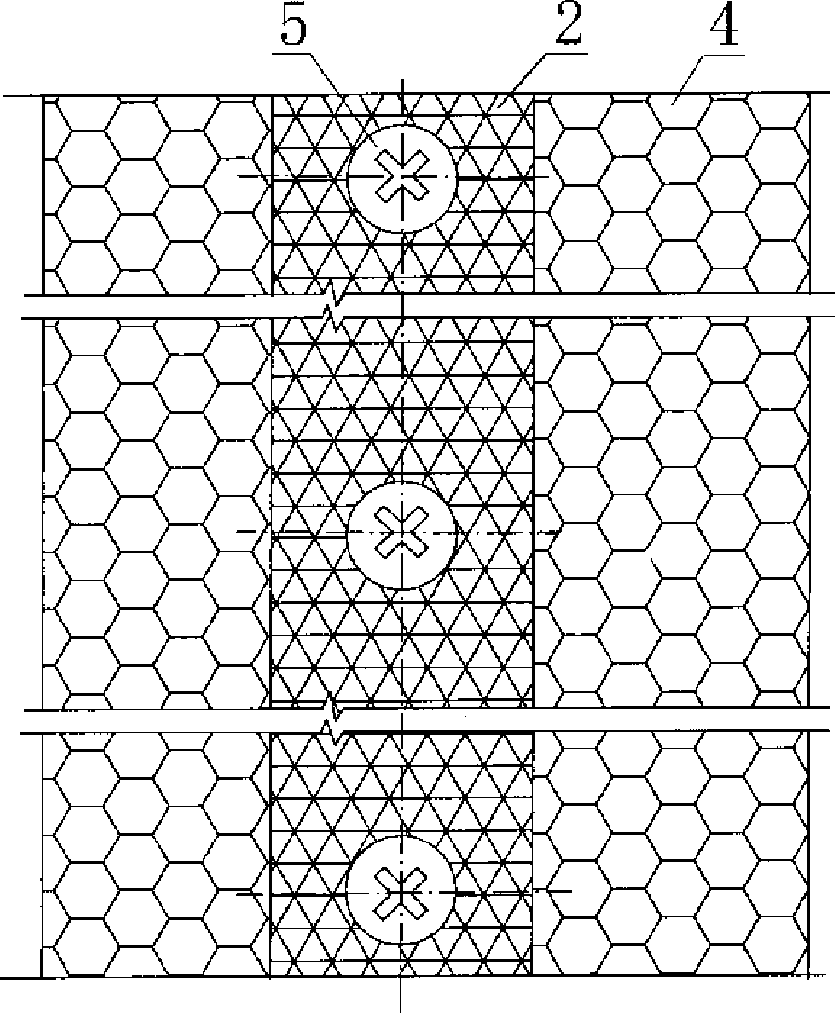

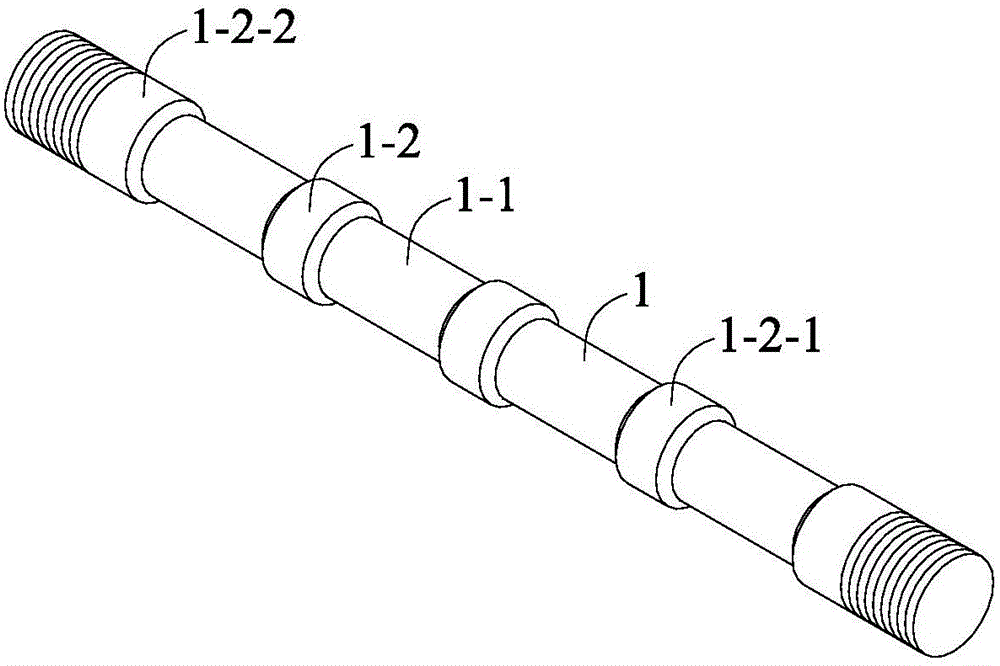

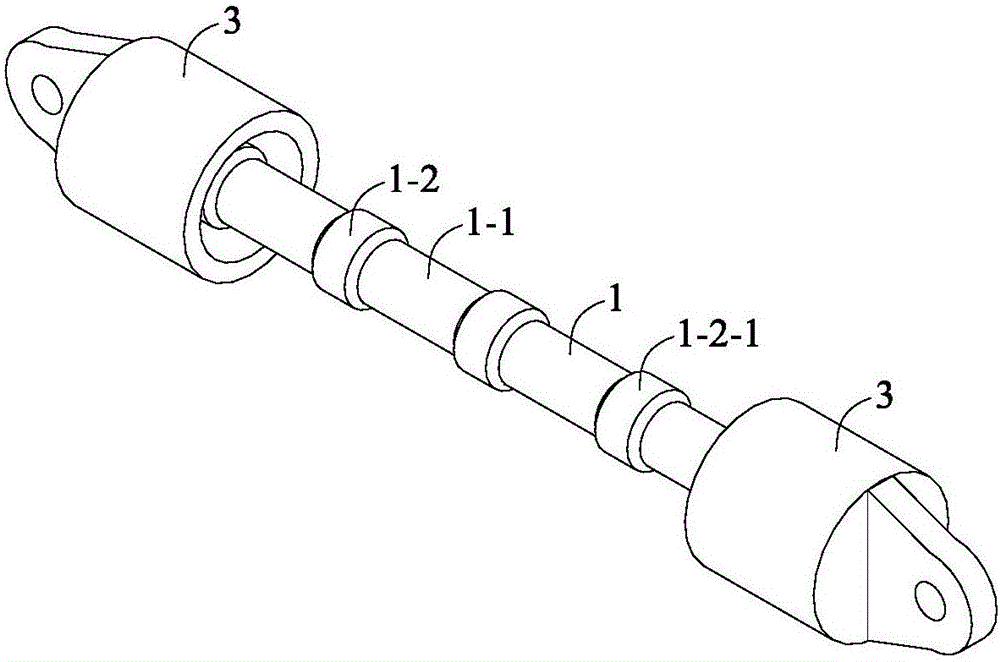

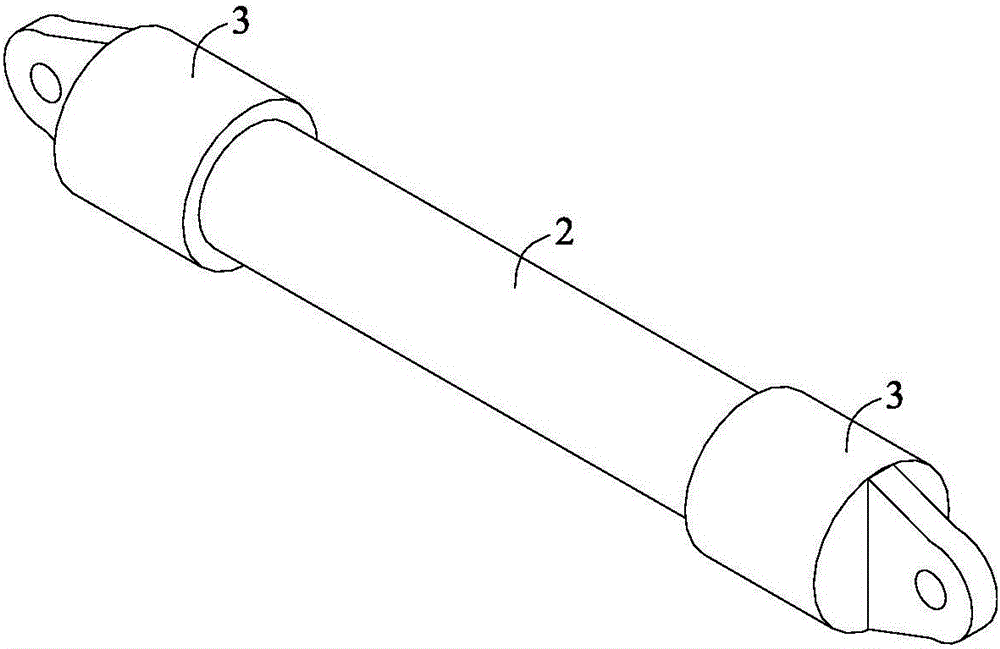

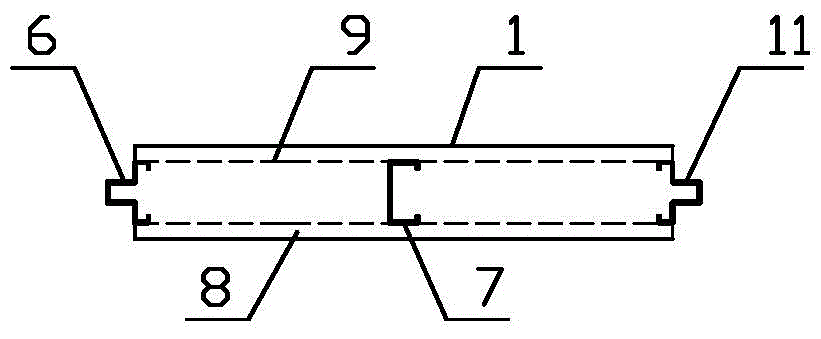

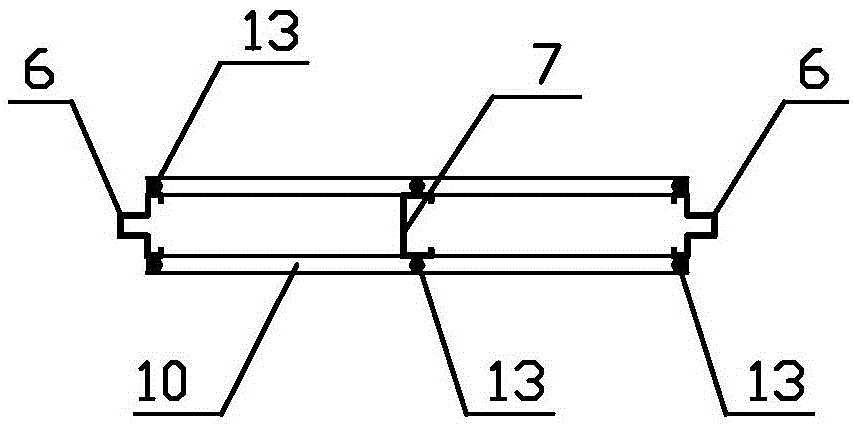

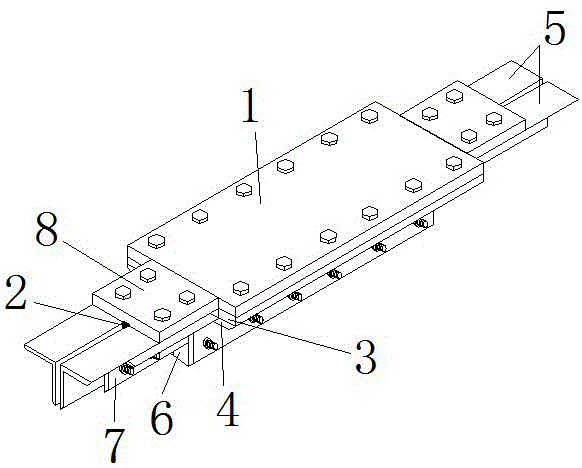

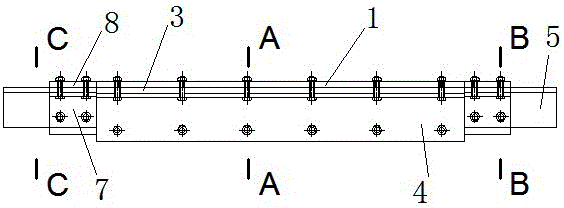

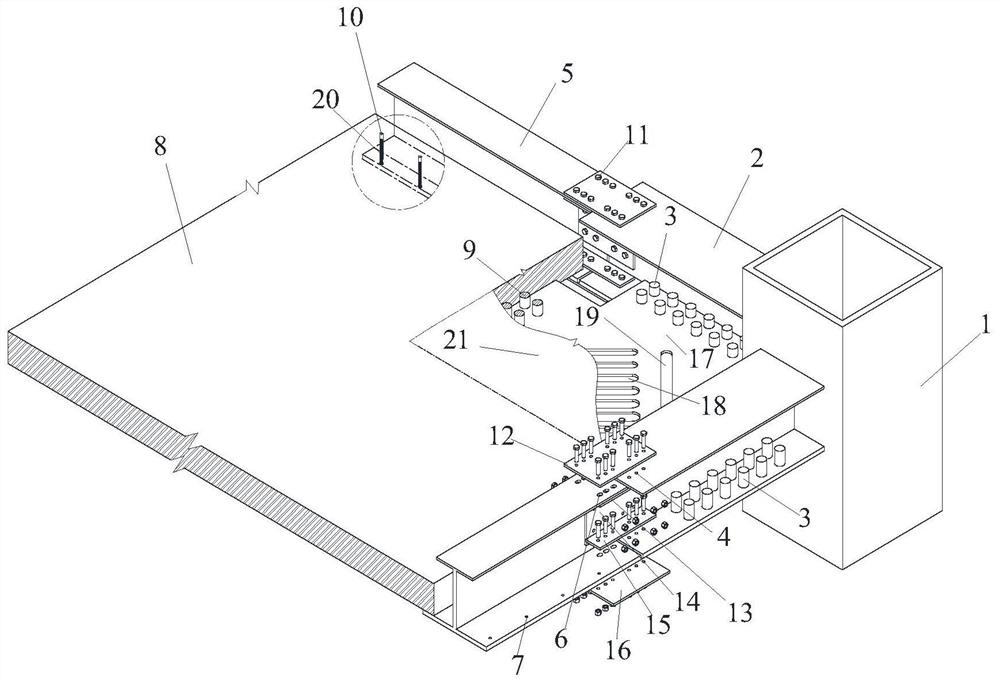

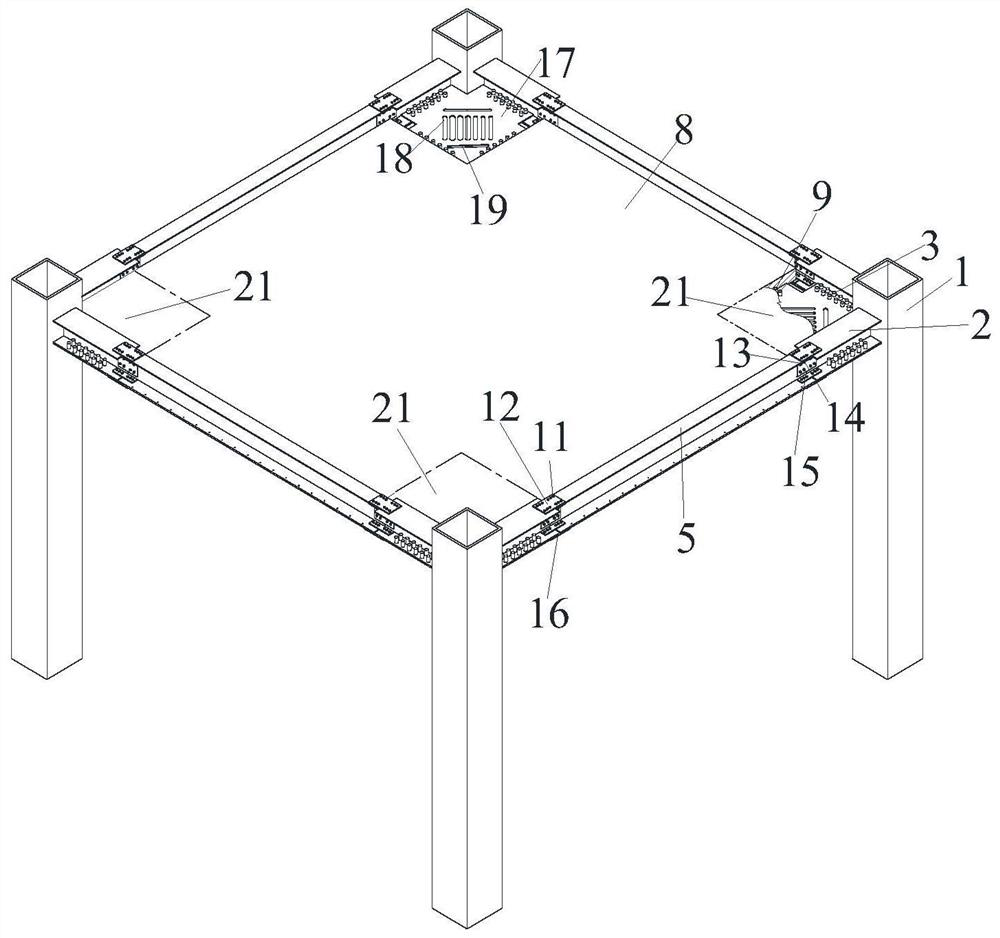

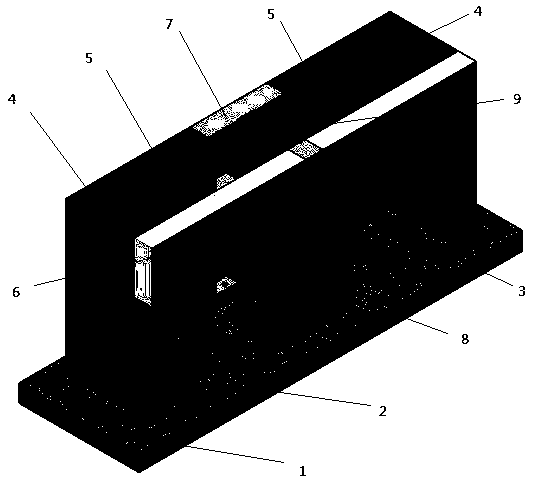

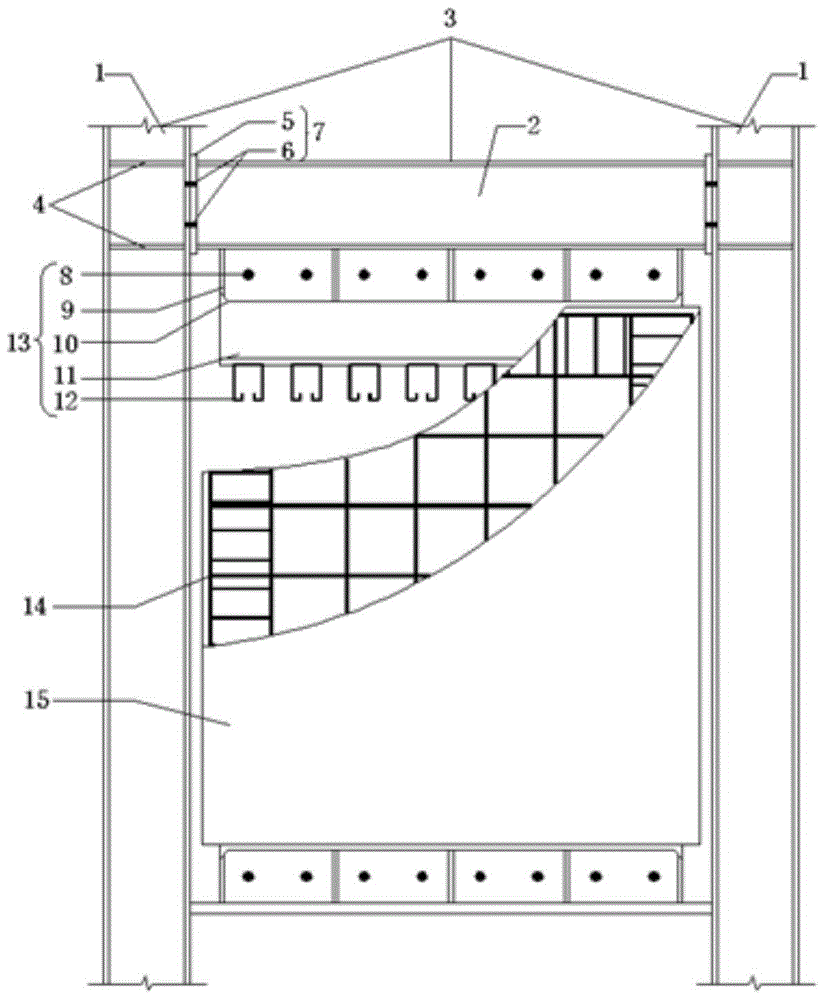

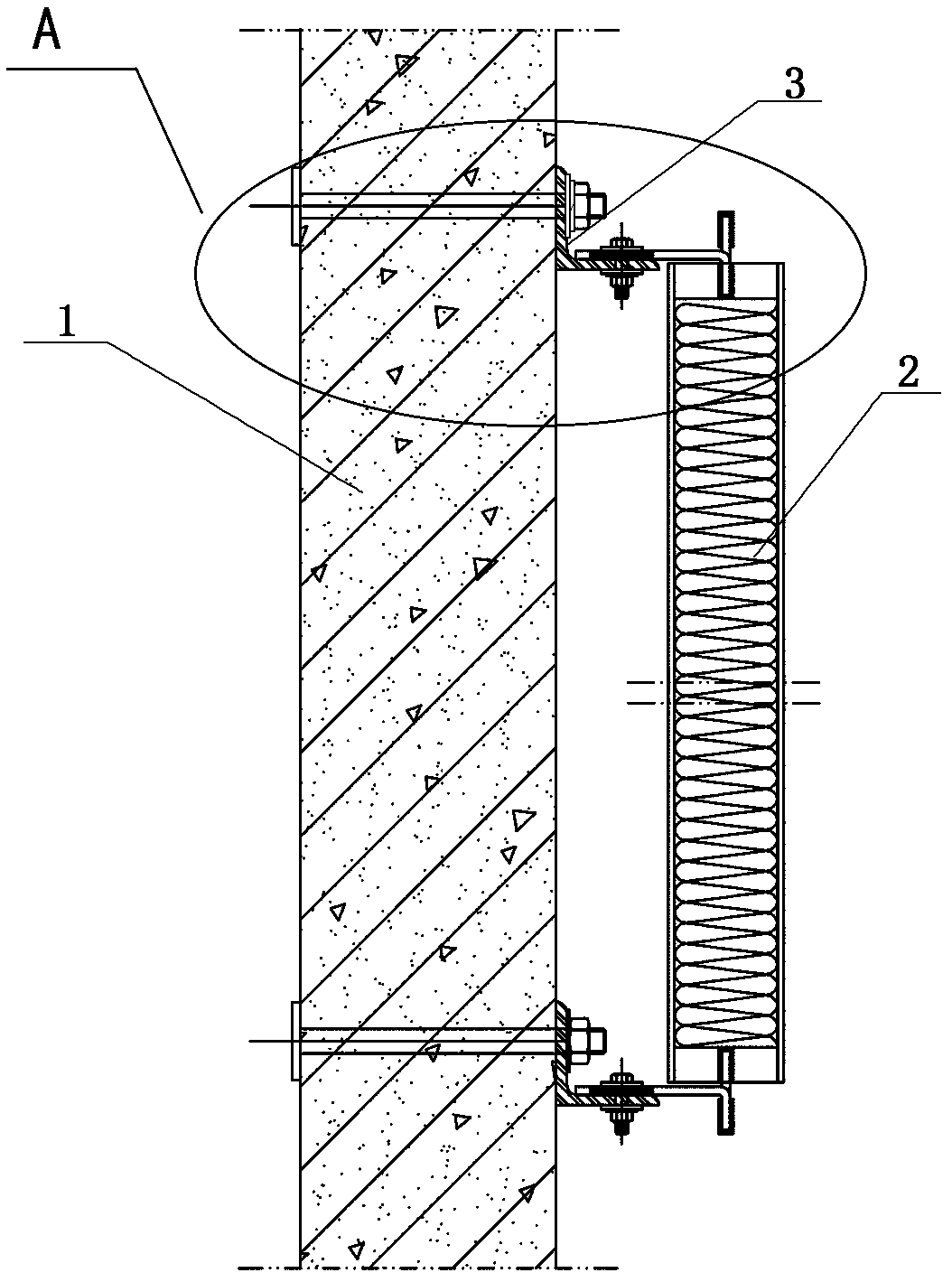

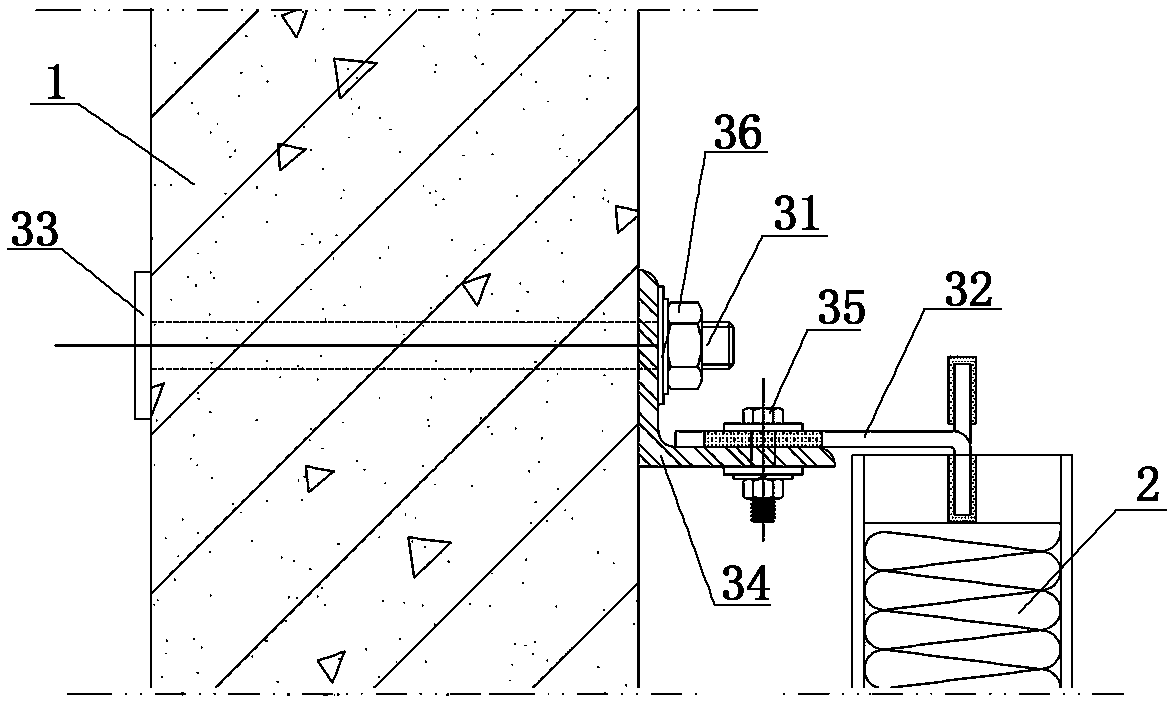

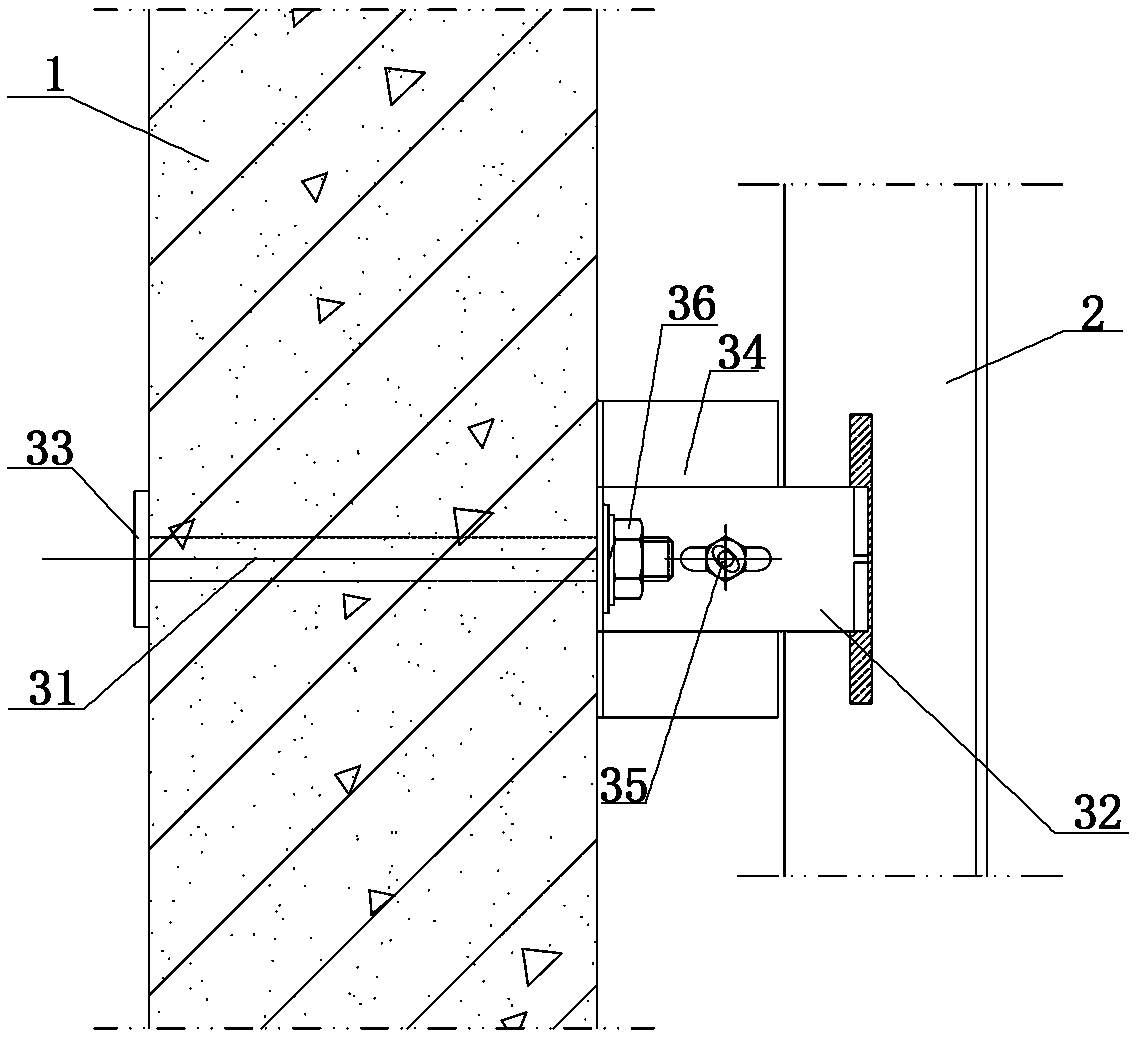

Multi-stage damping flat beam-floor system based on solid-web spiral spring pin connection

ActiveCN112049500AAvoid wet workSimple and fast constructionFloorsProtective buildings/sheltersEarthquake resistanceFloor slab

The invention discloses a multi-stage damping flat beam-floor system based on solid-web spiral spring pin connection, and belongs to the technical field of assembly type steel structure earthquake resistance. The system is composed of columns, short beams, flat beams, number-sign-shaped integral floor slabs, perforated plate type metal dampers, solid-web spiral spring pins for connecting the floorslabs and the flat beams, a filling layer and various connecting pieces for connecting the short beams and the flat beams. The system adopts prefabricated assembly construction, wet-method operationis not needed, and the construction period can be effectively shortened; under the action of an earthquake, the number-sign-shaped integral floor slabs can slide relative to the flat beams, the solid-web spiral spring pins can generate shear plastic deformation, a weakening joint and a weakening beam section can generate plastic deformation, the perforated plate type metal dampers can generate plastic deformation under the tension and compression action of the floor slabs, and the above-mentioned plastic deformation all can dissipate earthquake energy; and the effect of protecting overall safety of a building is achieved, meanwhile, the plastic deformation is controlled in a specific area so that post-earthquake component replacement can be conveniently realized so as to achieve the purpose of structural repairability.

Owner:BEIJING UNIV OF TECH

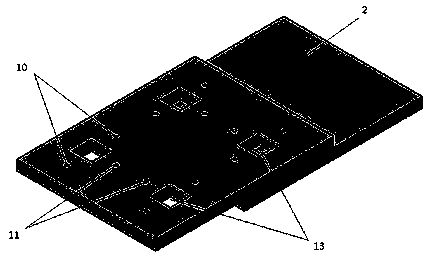

Segmentation method for prefabricated basic module of ring main unit and mounting and connection method for prefabricated basic module of ring main unit

ActiveCN110565682AShorten the construction periodReduce social impact and environmental impactFoundation engineeringSite managementWorkload

The invention discloses a segmentation method for a prefabricated basic module of a ring main unit. The segmentation method comprises the following steps of dividing the prefabricated basic module ofthe ring main unit into a first plate module, a second plate module, a third plate module, a fourth wall module, a fifth wall module, a sixth beam module, a seventh wall module, an eighth wall moduleand a ninth beam module. The modules are mutually connected through self-compacting grouting or bolts and screw rods, so that construction is simple, wet operation at a construction site is basicallyavoided, the site management and control workload is reduced, and the safety civilization construction degree is increased; and meanwhile, by saving turnover materials, such as templates and scaffolds, the labor cost is greatly saved, the site construction cost, the labor cost and the management cost are greatly lowered, and the construction safety risk caused by long-time operation in a foundation pit is reduced at the same time.

Owner:南京电力设计研究院有限公司

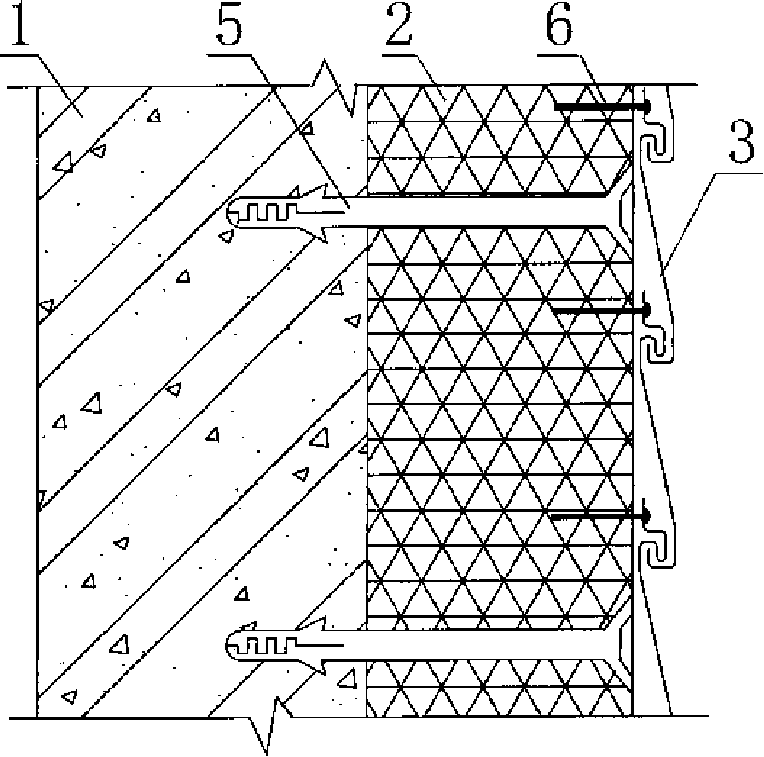

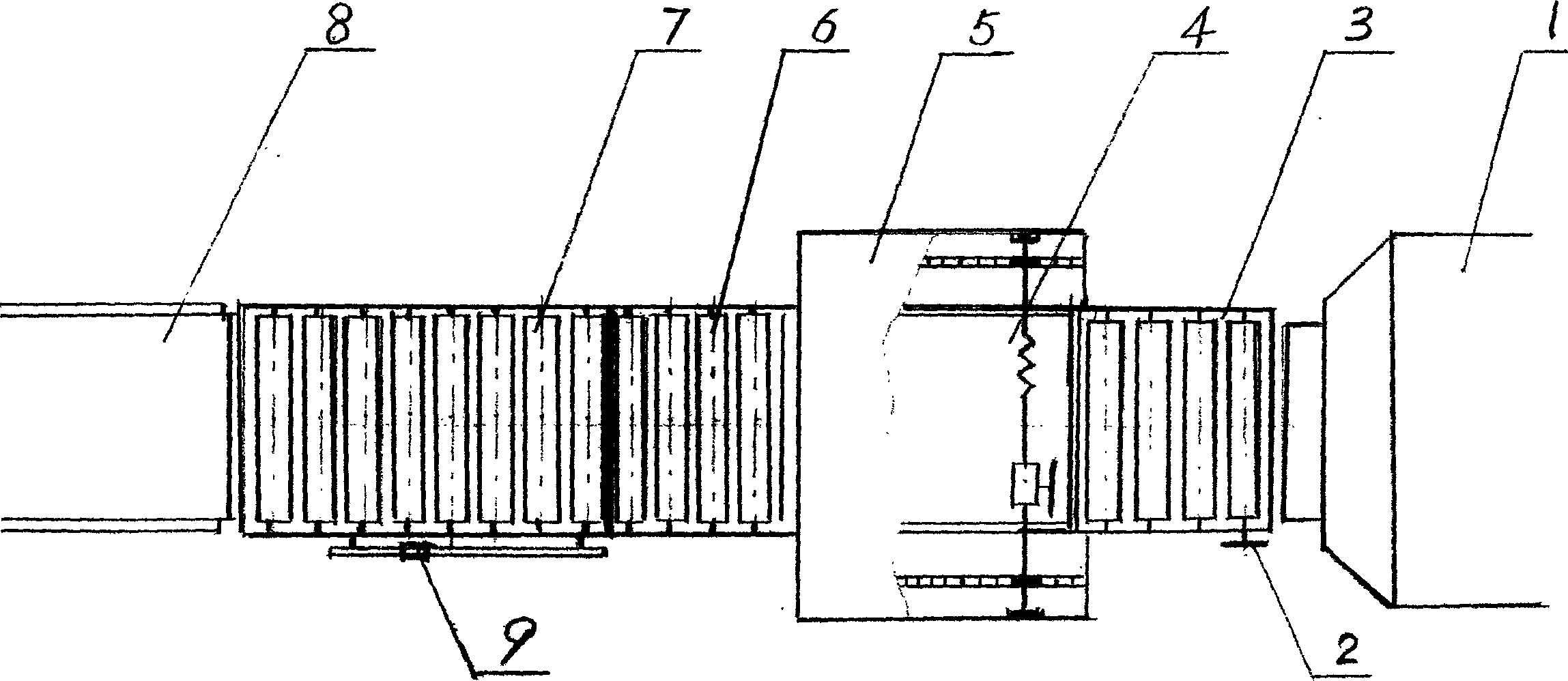

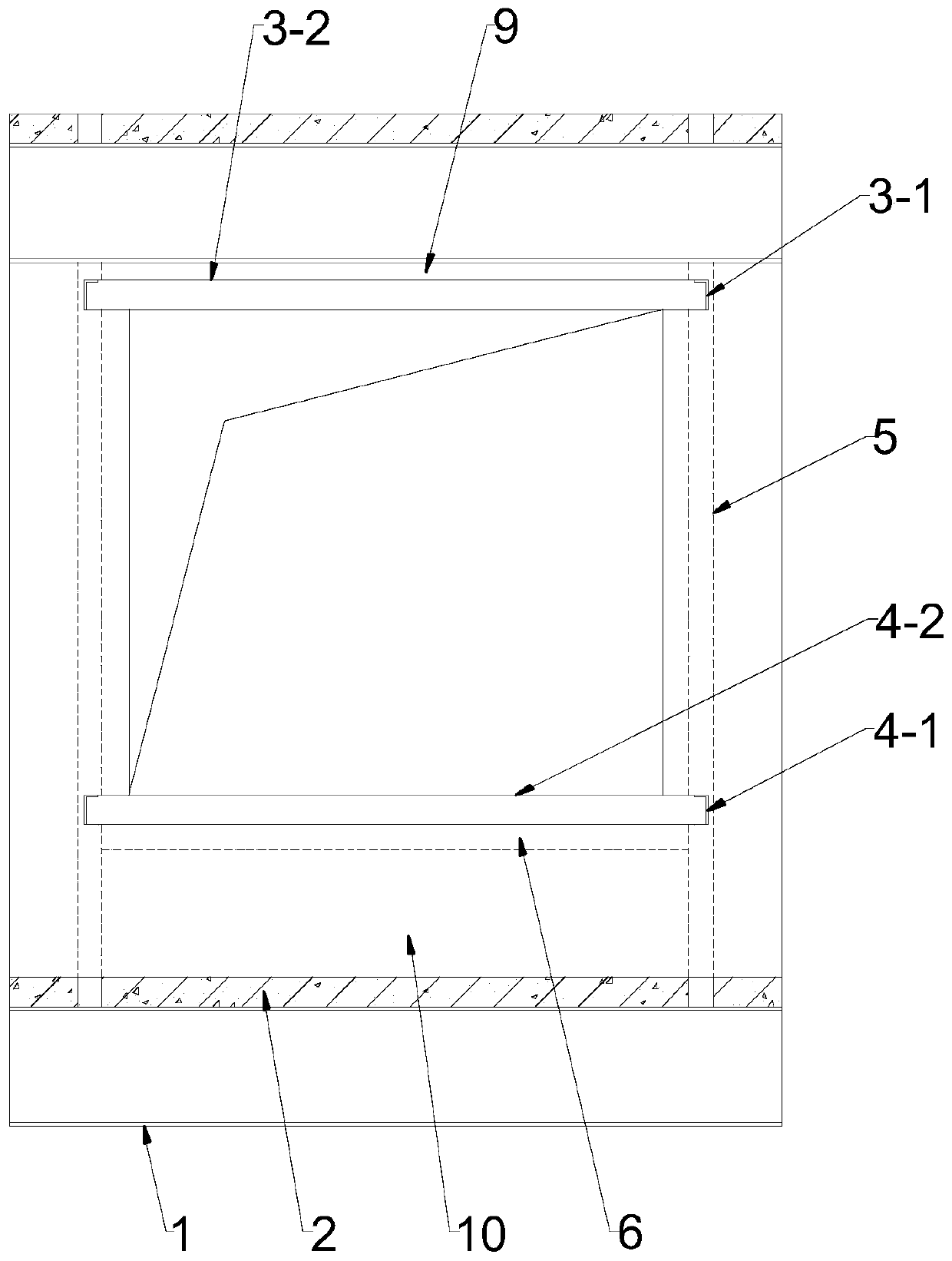

Flexible Steel Frame—Prefabricated Recycled Concrete Wall Panel and Manufacturing Method

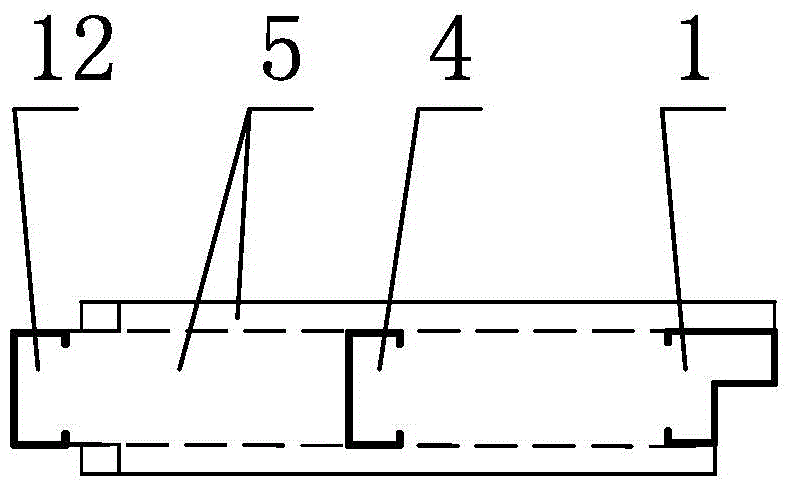

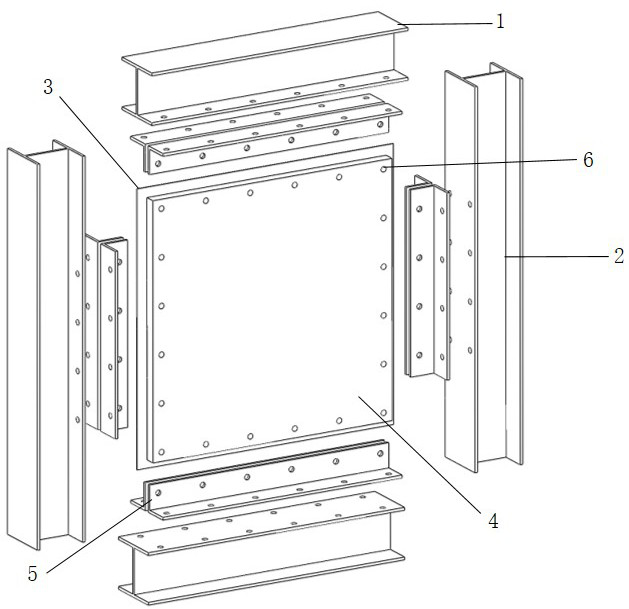

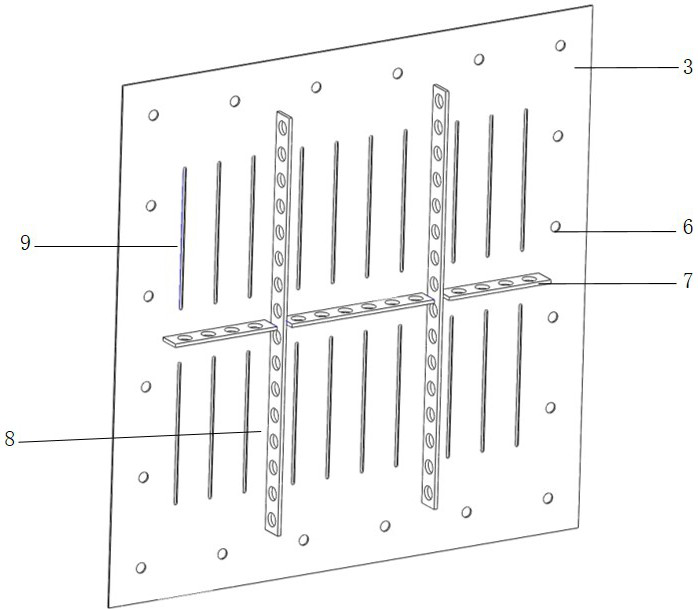

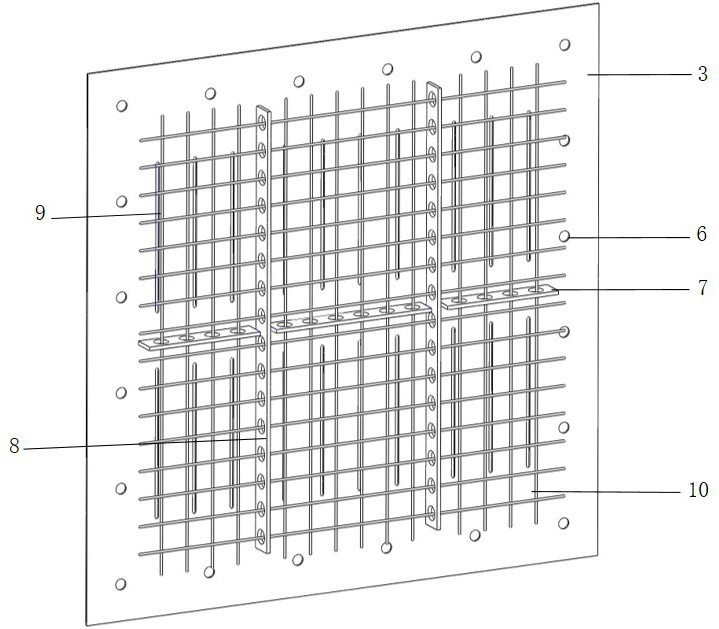

ActiveCN104746790BIncrease lateral stiffnessImprove bearing capacityConstruction materialCeramic shaping apparatusSteel frameSteel columns

The invention discloses a flexible steel framework-prefabricated assembling type recycled concrete wallboard. The flexible steel framework-prefabricated assembling type recycled concrete wallboard comprises a steel framework, wherein the steel framework is formed by connecting a steel beam between a pair of steel columns; a column reinforcing rib is arranged on each steel column; the column reinforcing ribs are located at the corresponding positions of the steel columns and the steel beam; end plates are arranged at the two ends of the steel beam respectively, and are connected with the pair of steel columns by node connection bolts; the bottom of the steel beam is connected with a lug plate and the lug plate is connected with a T-shaped piece by a lug plate reinforcing rib; the bottom end of the T-shaped piece is connected with a plurality of U-shaped ribs; the T-shaped piece and the U-shaped ribs are pre-buried in a recycled concrete wallboard; the recycled concrete wallboard is connected with the lug plate by a connection piece bolt; and a steel rib net piece is further arranged in the recycled concrete wallboard, and the steel rib net piece is connected with the T-shaped piece. A manufacturing method comprises the step of connecting all the parts according to a connection relation and a position relation. According to the structure system, the framework is cooperated with a wall body, the lateral rigidity resistance and the bearing capability are improved and the anti-seismic property is good; and the flexible steel framework-prefabricated assembling type recycled concrete wallboard has a simple structure, saves energy and is environmentally friendly, and standardized construction is facilitated.

Owner:广西建工轨道装配式建筑产业有限公司

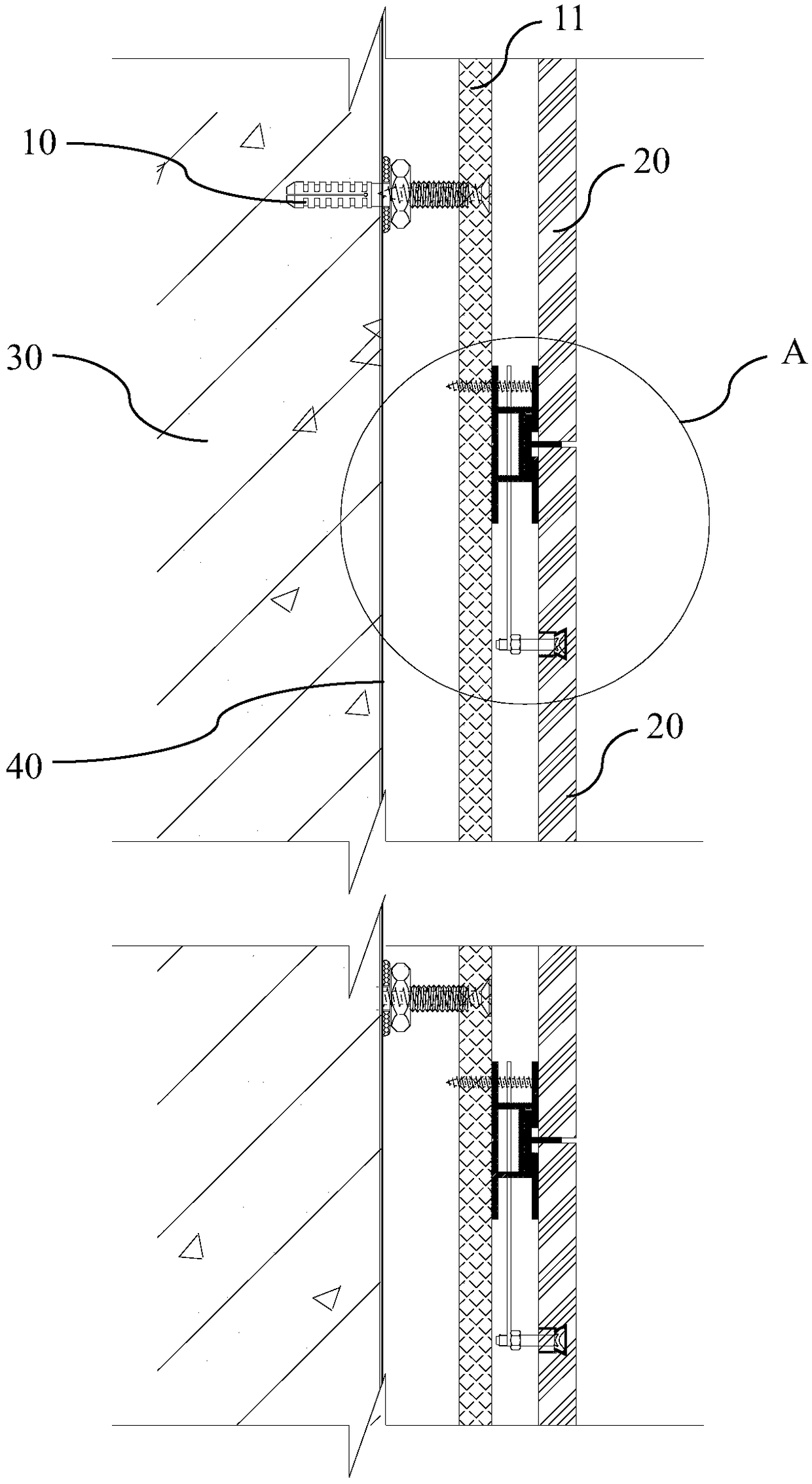

A combination anchoring system and construction method of point-hanging thermal insulation decorative panels on light exterior walls

The invention discloses a light external wall point-hang heat-insulation and decorative plate combined anchoring system and a method for constructing the same. The light external wall point-hang heat-insulation and decorative plate combined anchoring system is characterized in that a heat-insulation and decorative integrated plate is directly hung on a light wall by combined anchoring members, the combined anchoring members comprise wall penetrating screws and hang members, and an end of each hang member is hung in a corresponding hang groove of the heat-insulation and decorative integrated plate; a vertical bottom plate is welded at the end, which is positioned on the inner side of the light wall, of each wall penetrating screw and clings to the surface of the inner side of the light wall, and the wall penetrating screws are fixedly connected with the hang members by middle L-shaped through connection members. The light external wall point-hang heat-insulation and decorative plate combined anchoring system and the method have the advantages that the L-shaped through connection members are fixed onto the light wall by the aid of the wall penetrating screws, the hang members which are traditionally mounted on steel keels are directly mounted on the L-shaped through connection members, the heat-insulation and decorative integrated plate is mounted on the hang members in a direct point-hang manner, accordingly, a novel point-hang application technology is free of keels and adhesion mortar, the light external wall point-hang heat-insulation and decorative plate combined anchoring system is simple in structure, construction can be facilitated, the method is applicable to constructing heat-insulation and decorative plates for diversified light walls, and popularization and application of the heat-insulation and decorative integrated plates can be promoted.

Owner:北京东华绿源建筑装饰工程技术有限公司

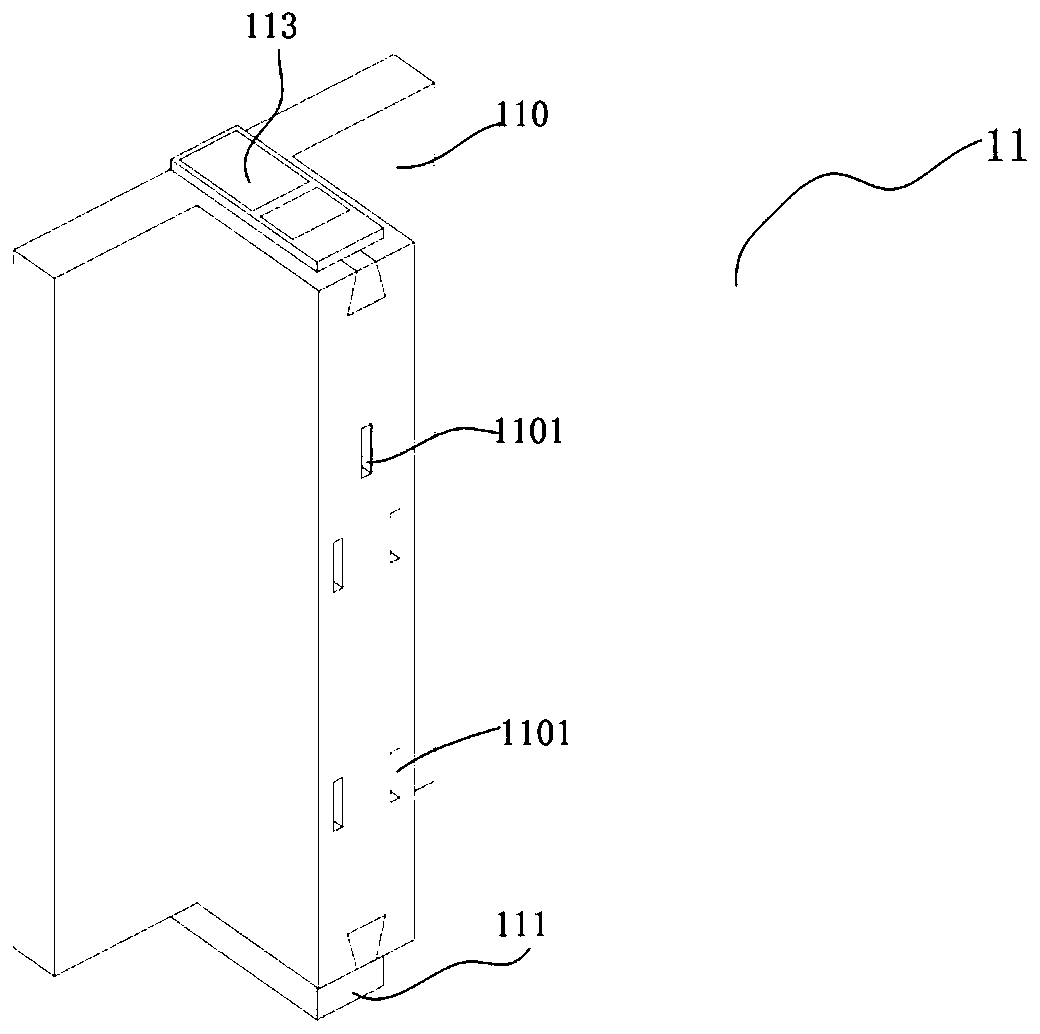

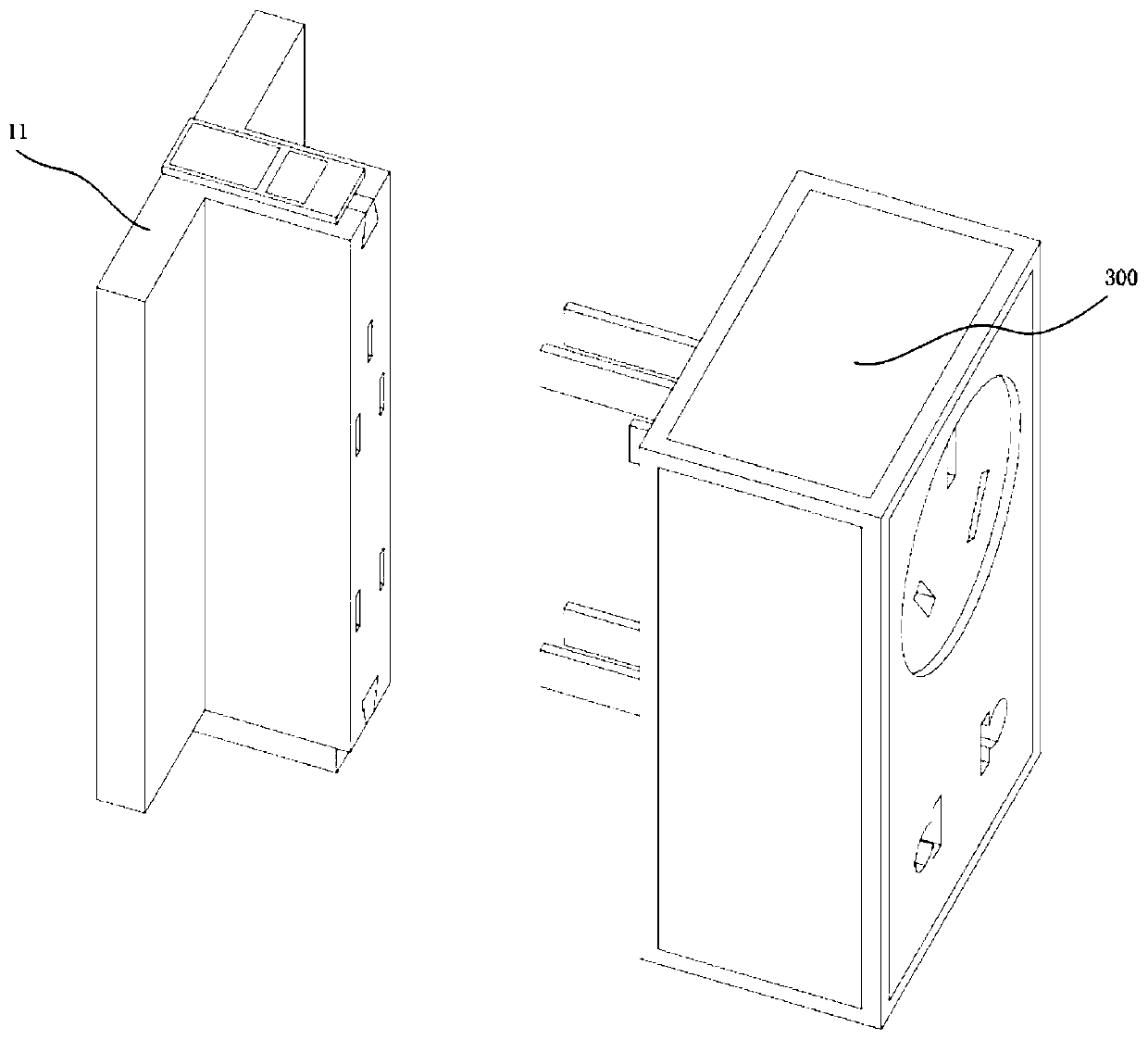

Light prefabricated combined wall

The invention discloses a light prefabricated combined wall. Three kinds of light prefabricated wall sections with identical composition are spliced through adapting steel columns or directly through bolts / self-tapping screws to from a straight combined wall, an L-shaped wall, a T-shaped wall or a cross-shaped wall; the light prefabricated wall sections are straight wall sections as a whole, a plurality of vertical steel wall columns, upper guide rails transversely connected with tops of the steel wall columns and upper guide rails transversely connected with two sides of bottoms of the steel wall columns respectively form a framework, and the wall sections are filled with light concrete; L-shaped steel wall columns or C-shaped steel wall columns are arranged at two ends of each light prefabricated wall section. With the adoption of the prefabricated combined wall, the wet operation of in-place concrete pouring is avoided, anti-pull connecting pieces are convenient to mount, the wall mounting accuracy is easy to control, the construction cost is low, and the prefabricated combined wall is suitable for mass production of light steel keel and light concrete combined houses.

Owner:WUHAN SKYSTEEL BUILDING TECH

Fabricated ECC-steel plate combined energy dissipation shear wall

PendingCN112814206AImprove seismic performanceImprove shear resistanceWallsClimate change adaptationSteel platesRebar

The invention discloses a fabricated ECC-steel plate combined energy dissipation shear wall. The fabricated ECC-steel plate combined energy dissipation shear wall comprises an embedded steel plate, perforated plate connecting pieces, an outer pouring ECC plate and an edge frame; a vertical seam is formed in the embedded steel plate, and the perforated plate connecting pieces are welded on the embedded steel plate; the ECC plate is bidirectionally provided with reinforcements, and the reinforcements penetrate through holes of the connecting pieces; the combined energy dissipation shear wall is in bolt splicing with the edge frame through angle steel. According to the fabricated ECC-steel plate combined energy dissipation shear wall, as a main lateral force resistant component of a structure, shear bearing capacity is high, resistant-lateral rigidity is high and ductility is good, a concept of multiple anti-seismic defense lines is achieved, and the advantages of being high in durability and good in fire resistance are possessed; meanwhile, massive wet operation on a construction site can be avoided, and construction is convenient and fast.

Owner:南京彼卡斯建筑科技有限公司 +1

Building body with decorative blocks and construction method of building body

PendingCN110273492AQuality improvementReduce manufacturing costCovering/liningsWallsKeelBuilding construction

The embodiment of the invention discloses a building body with decorative blocks. The building body comprises a wall body, outer decorative blocks and first connecting strips; the outer decorative blocks are mounted on the wall body by the first connecting strips, wherein mounting grooves with T-shaped cross sections are formed in the outer wall of the wall body, and the cross sections of the first connecting strips are in a I shape; one wings of the first connecting strips are connected into the mounting grooves in an inserted mode, and the other wings of the first connecting strips protrude out of the wall body; first protruding strips and first strip-shaped grooves are correspondingly arranged on the opposite two side surfaces of the outer decorative blocks, the first protruding strips are located outside the first strip-shaped grooves, and the first protruding strips and the first strip-shaped grooves penetrate through the two side surfaces of the outer decorative blocks up and down; and the other wings of the first connecting strips are connected into the first strip-shaped grooves of every two adjacent outer decorative blocks in an inserted mode. The outer decorative blocks are connected with the wall body by connecting clamping strips in a clamping mode, and the combination of the outer decorative blocks and the wall body is more firm, the hollowing and cracking of the outer decorative blocks bonded by mortar in the prior art are avoided, and keels are not used, so that the installation is convenient, construction is convenient, and an engineering application effect is good.

Owner:金点石(北京)建筑设计咨询服务有限责任公司

Prefabricated bay window and connection node between prefabricated bay window and main body of steel structure

PendingCN111219124AReduce weightAvoid wet workFrame fasteningWindow/door framesSteel tubeEnvironmental geology

The invention discloses a prefabricated bay window and a connection node between the prefabricated bay window and a main body of a steel structure. The prefabricated bay window comprises two symmetrically arranged vertical pipes; a horizontal pipe, a bay window bottom plate and a bay window top plate are horizontally arranged between the two vertical pipes in sequence from bottom to top; one end of the bay window bottom plate is erected on the horizontal pipe; the other end of the bay window bottom plate extends in a direction away from the vertical pipes; one end of the bay window top plate is located between the two vertical pipes; the other end of the bay window top plate extends in a direction away from the vertical pipes and is flush with one end, away from the vertical pipes, of thebay window bottom plate; and the vertical pipes and the horizontal pipe are steel pipes. The prefabricated bay window is simple in structure, lighter in weight, and lower in on-site construction difficulty, the prefabricated bay window can be connected with the main body of the steel structure only through welded connection or bolted connection, local casting is not required, the installation andconstruction efficiency is high, and the prefabricated bay window can be produced in batch in a factory.

Owner:龙元明筑科技有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com