Fabricated ECC-steel plate combined energy dissipation shear wall

A prefabricated, shear wall technology, applied in the direction of walls, protective buildings/shelters, building components, etc., can solve problems such as spalling, damage to concrete slabs, and insufficient durability and fire resistance of concrete cover slabs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0025] The construction process of the assembled ECC-steel plate composite energy-dissipating shear wall includes the following steps:

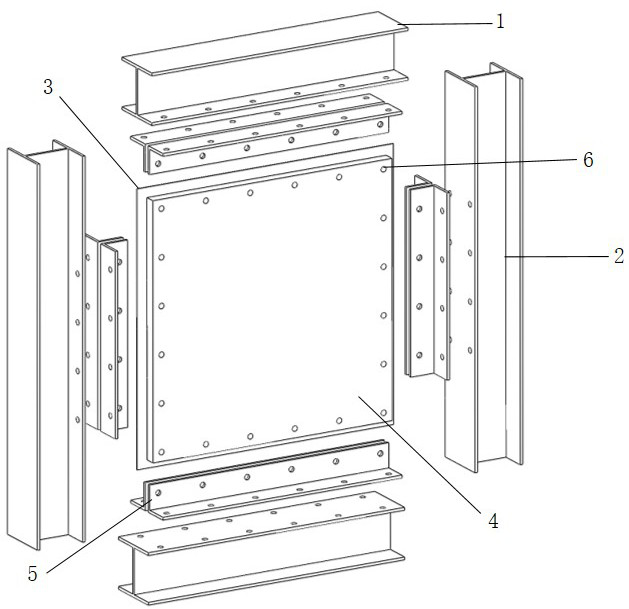

[0026] (1) Complete the prefabrication of steel columns, steel beams and ECC-steel plate composite energy-dissipating shear walls in the factory:

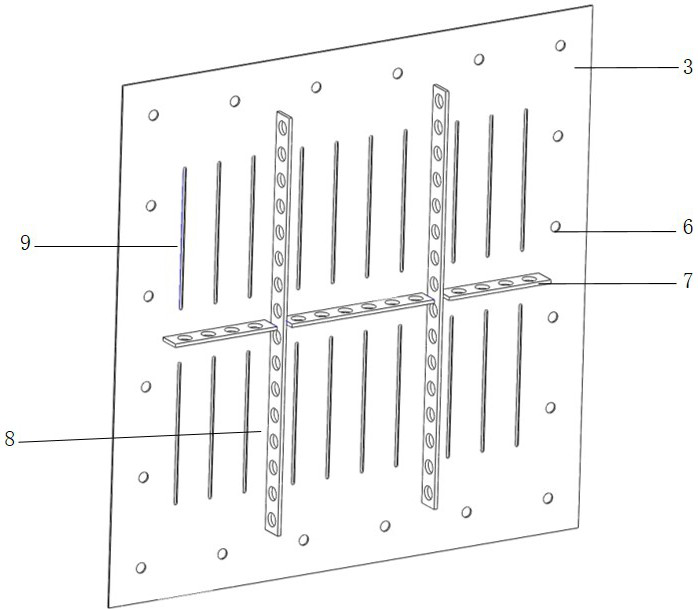

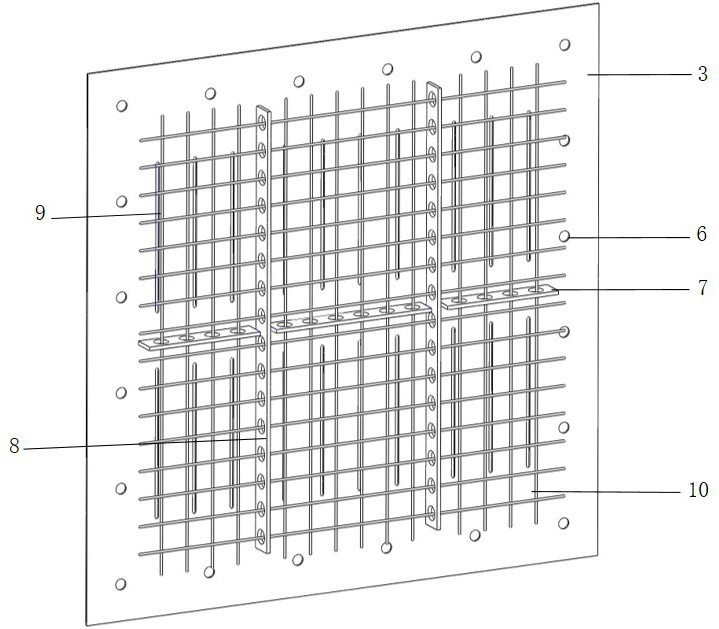

[0027] According to the design requirements, a certain number and size of vertical joints are opened on the embedded steel plate, and the corresponding horizontal and vertical perforated plate connectors are welded. The ECC plate adopts two-way reinforcement, and the steel bars pass through the reserved holes of the open-hole plate connectors for positioning and binding. The ECC is poured with a special formwork, so that a gap of a certain width and thickness is reserved at the edge of the ECC plate, and the angle steel is inserted when connecting. A certain number of bolt hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com