Pole tower prefabricated assembly type concrete stepped foundation and assembling method thereof

A ladder-shaped foundation, prefabricated assembly technology, applied in infrastructure engineering, construction, etc., can solve the problems of inability to meet the requirements of construction work surface, affecting traffic and residents' travel, and large work surface required for construction, so as to improve safety and civilization. The degree of construction, the reduction of social and environmental impacts, and the effect of on-site management and control workload reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

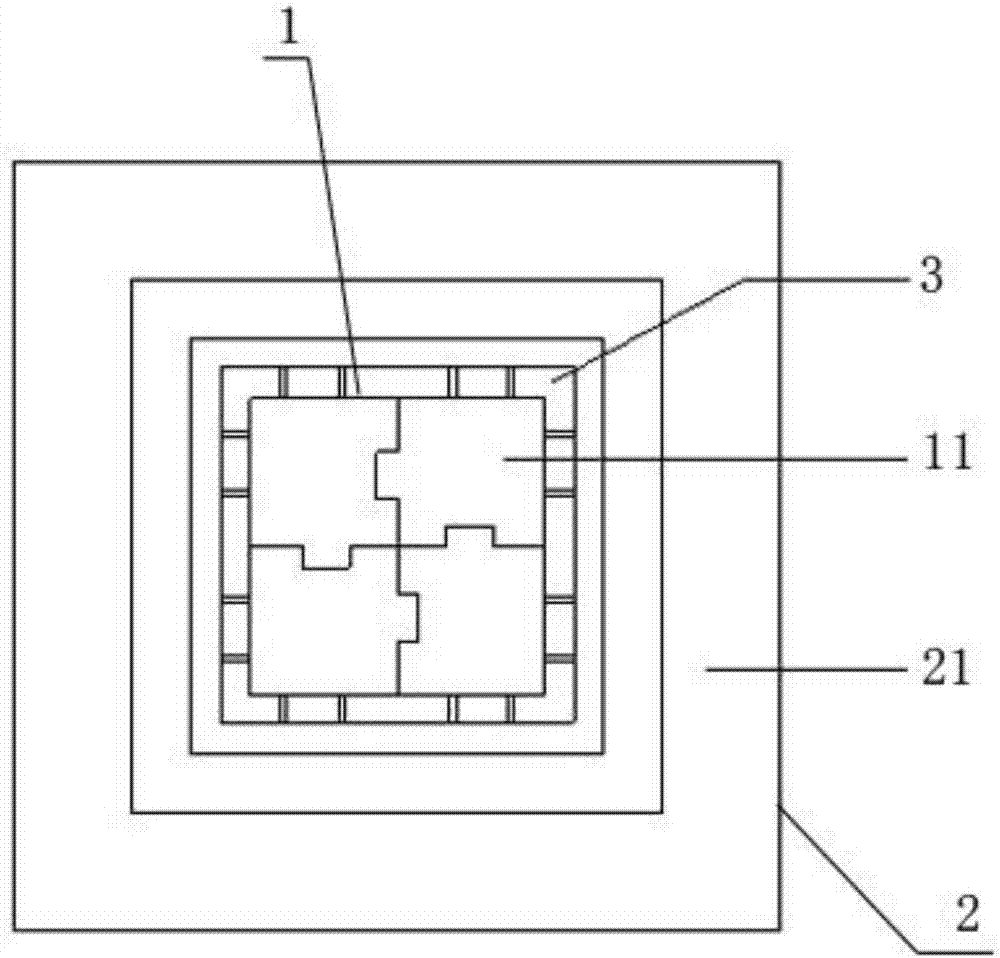

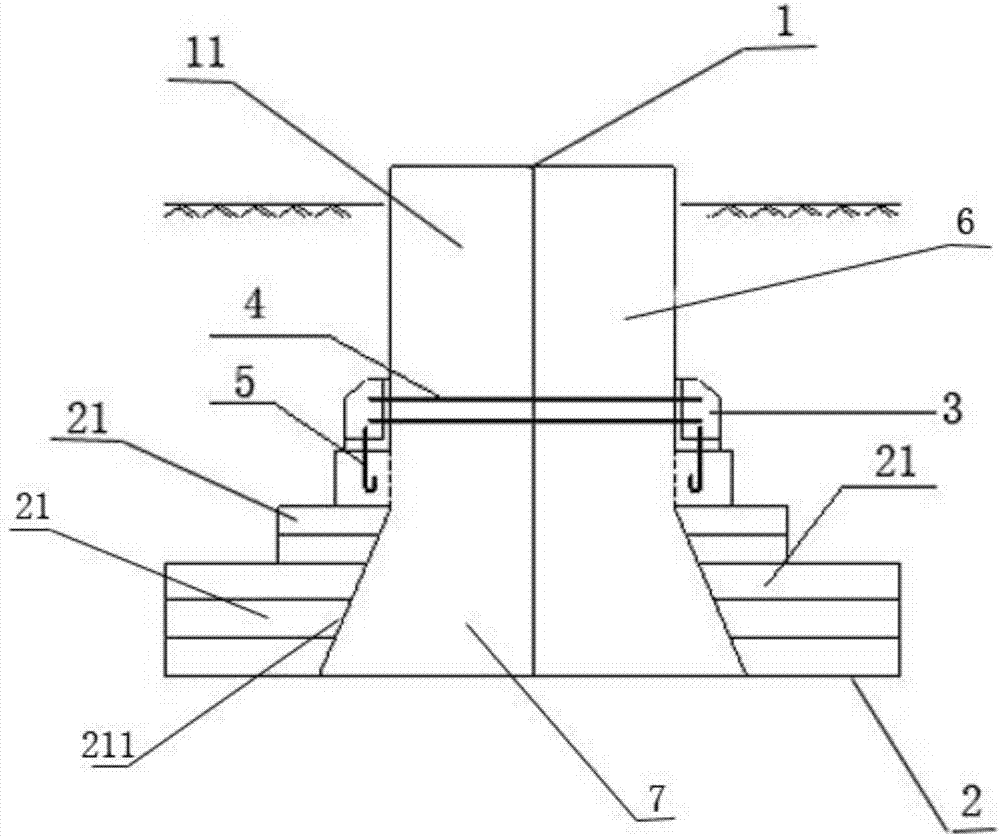

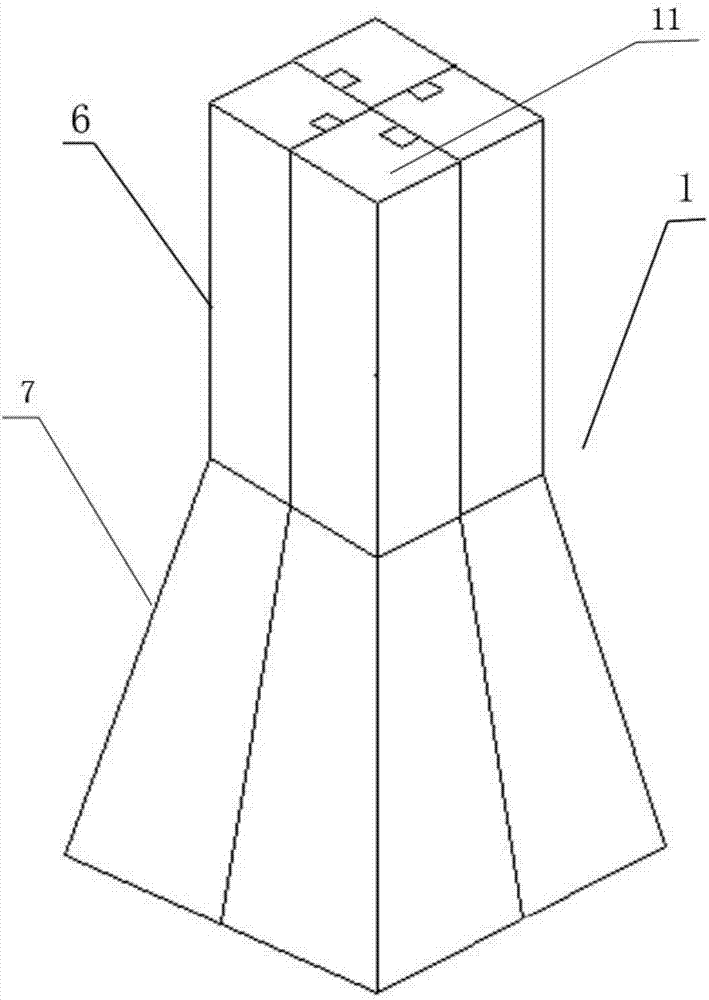

[0023] A tower prefabricated concrete stepped foundation of this embodiment, such as Figure 1-4 As shown, including core column, step ferrule, steel plate connecting key. The core column includes several splicing columns, and the splicing columns have the same structure. Adjacent sides of the splicing column are provided with inwardly concave splicing grooves and outwardly protruding splicing bars, the splicing grooves and the splicing bar structures are matched with each other, and the splicing columns are sequentially spliced into a core column through the splicing grooves and the splicing bars. The core column includes an upper column body and a lower prism body fixed on the lower end of the upper column body. The stepped ferrule includes a plurality of annular sleeves with different outer and inner diameters. A plurality of annular sleeves are sleeved on the outer bottom of the core column, so that the annular sleeve is sleeved on the outer side of the lower prism bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com