T-shaped light-weight steel frame, T-shaped light-weight steel assembling type compound wall plate and installation method thereof

A composite wallboard and assembly technology, which is applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problem of low efficiency of filling insulation materials for the insulation performance of the sandwich insulation layer, enhanced reliability of the connection between the wall and the main board, insulation, Insufficient heat insulation performance and other problems, to achieve the effect of enhancing connection reliability, improving horizontal shear resistance, and reducing wet work in factories

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Now in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

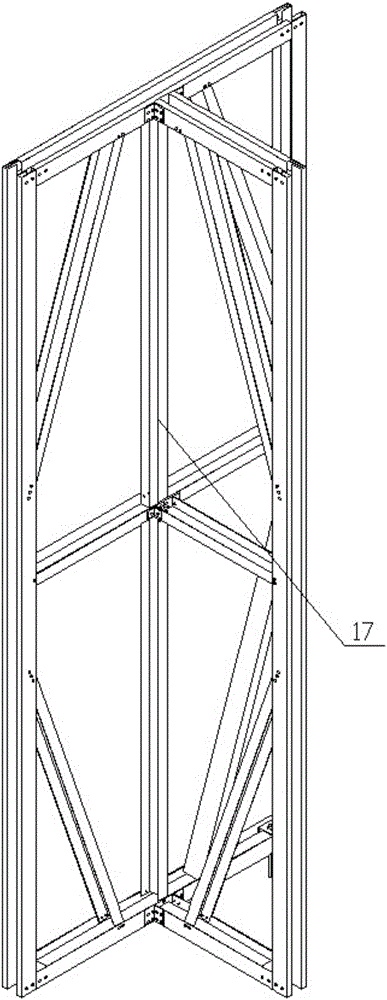

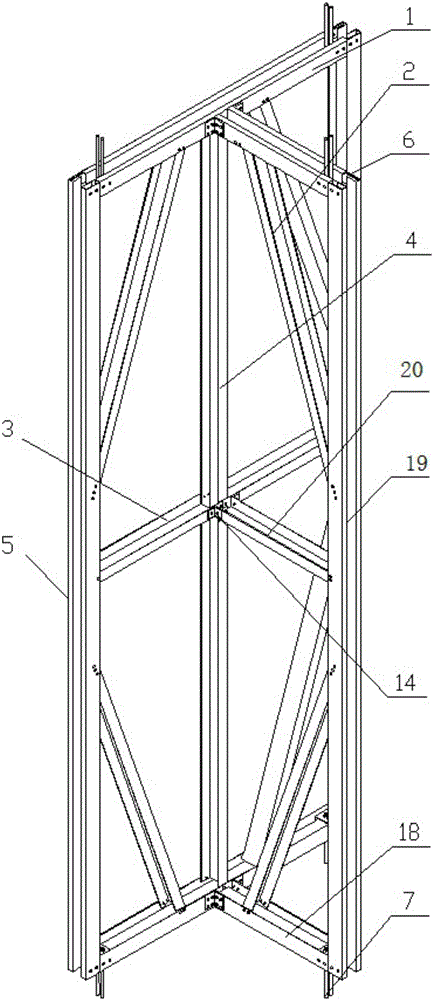

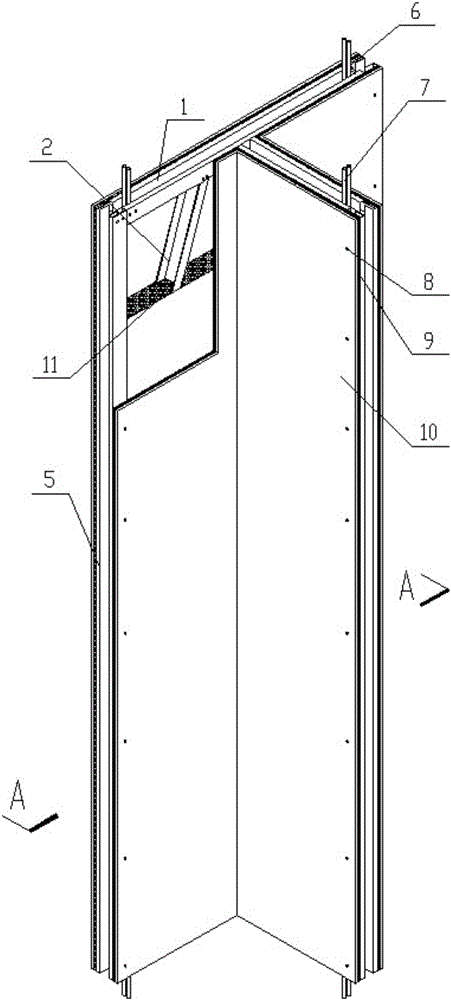

[0065] like Figure 1-7 As shown, the T-shaped light steel frame 17 includes a first transverse M-shaped steel 1, a first transverse C-shaped steel 3, a vertical C-shaped steel 4, a first vertical M-shaped steel 5, an L-shaped connector 14, and a second transverse M-shaped steel 18 , the second vertical M-shaped steel 19, the second horizontal C-shaped steel 20;

[0066] The T-shaped light steel frame is a T-shaped structure, including the first frame and the second frame, and the second frame is vertically fixed in the middle of the first frame; the fixing position of the second frame can be located in the horizontal center of the first frame or other non-end parts Location.

[0067] First frame: the outer frame of the first frame includes the first transverse M-shaped steel and the first vertical M-shaped steel; the first frame includes at least on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com