Fully-prefabricated assembled concrete column-concrete beam buckling-restrained energy-consuming joint

A technology for preventing buckling and energy dissipation, concrete column, applied in the direction of earthquake resistance, building components, etc., can solve the problem of not adapting to the requirements of the seismic performance of the structure, damage and damage repair and subsequent use difficulties, etc., to avoid the overall failure of joints, strong engineering The effect of usability and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

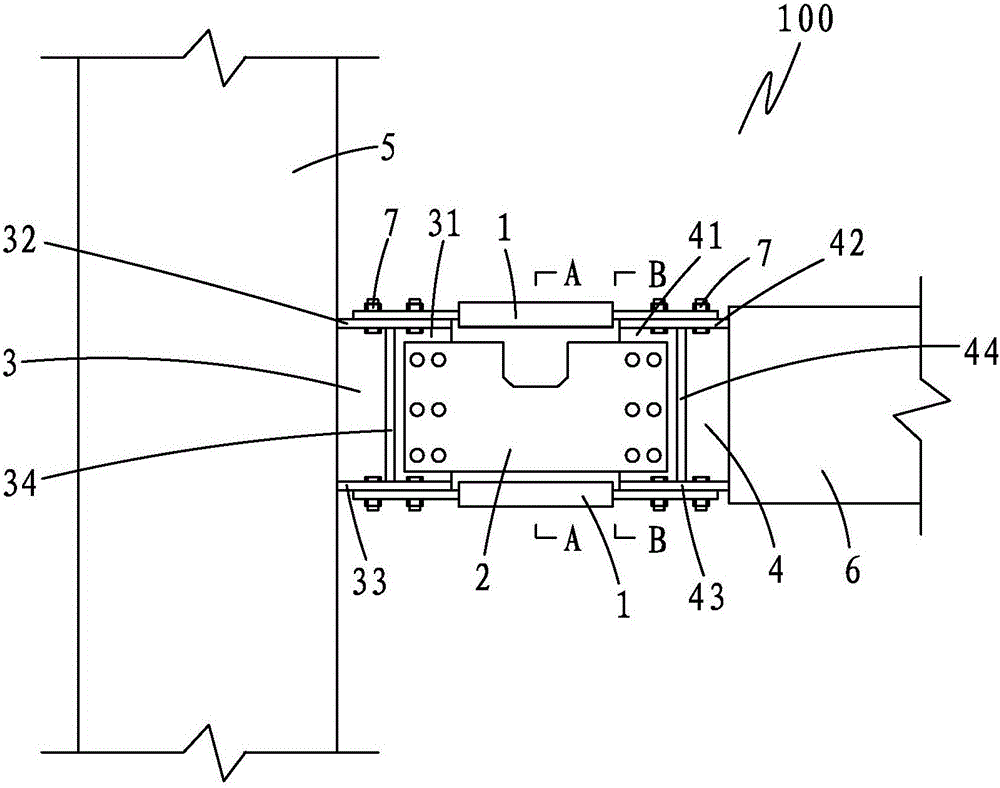

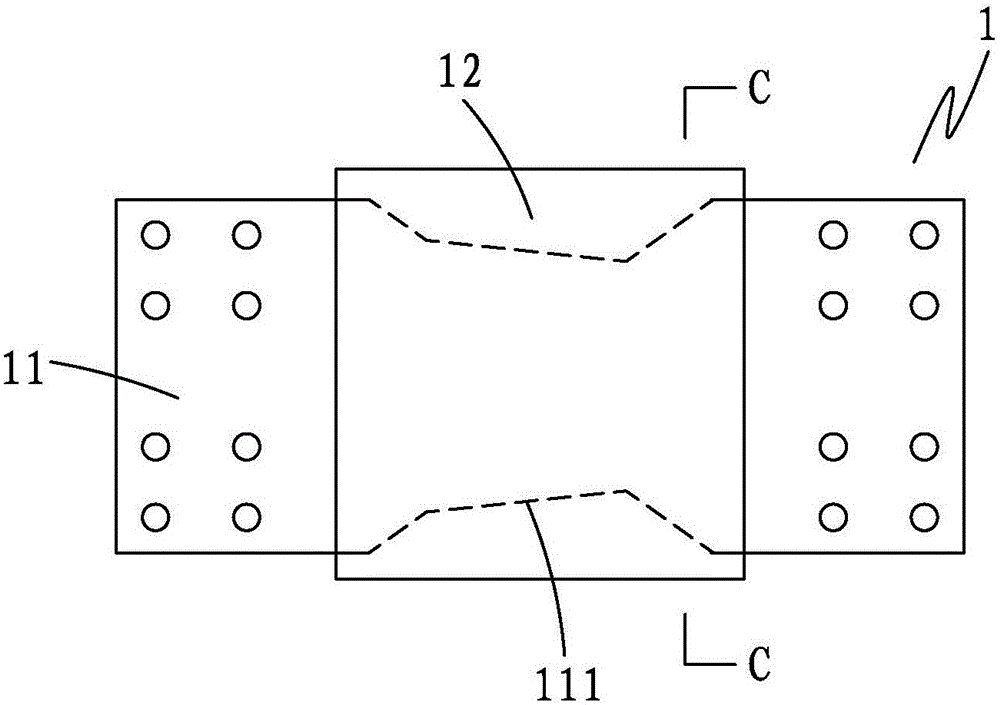

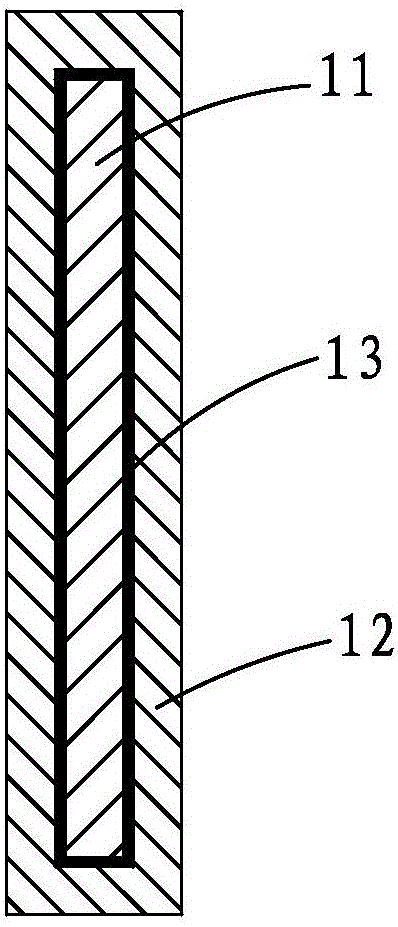

[0027] Please refer to Figure 1 to Figure 8 As shown, the fully prefabricated assembled concrete column 5-concrete beam 6 buckling-resistant energy-dissipating node 100, the buckling-restrained energy-dissipating node 100 includes two buckling-restrained flange metal plate energy-dissipating dampers (English name: Buckling-RestrainedPlateDamper, Abbreviation: BRPD) 1, two high-strength web connecting plates 2, a first embedded steel beam 3 and a second embedded steel beam 4;

[0028] One end of the first pre-embedded steel beam 3 is embedded in the concrete column 5, and the other end protrudes from the column surface, and the length of the outward extension can be set according to actual construction requirements; the second pre-embedded steel beam One end of 4 is embedded in the concrete beam 6, and the other end protrudes outward from the end face of the beam, and the length of the outward extension can be set according to actual construction requirements; the first pre-em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com