Non-shear wall system of fully-fabricated building and wallboard module prefabricating method of non-shear wall system

A shear wall and fully assembled technology, applied in buildings, building components, building structures, etc., can solve the problems of poor coordination performance of the old and new concrete bonding interface, prefabricated walls not participating in force, and low degree of assembly. , to achieve the effect of strengthening collaborative work performance, shortening decoration time, and good overall work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

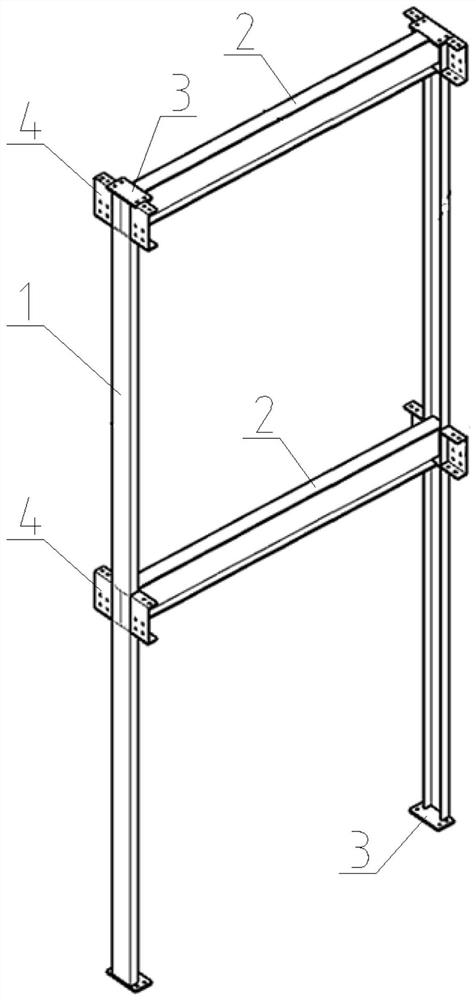

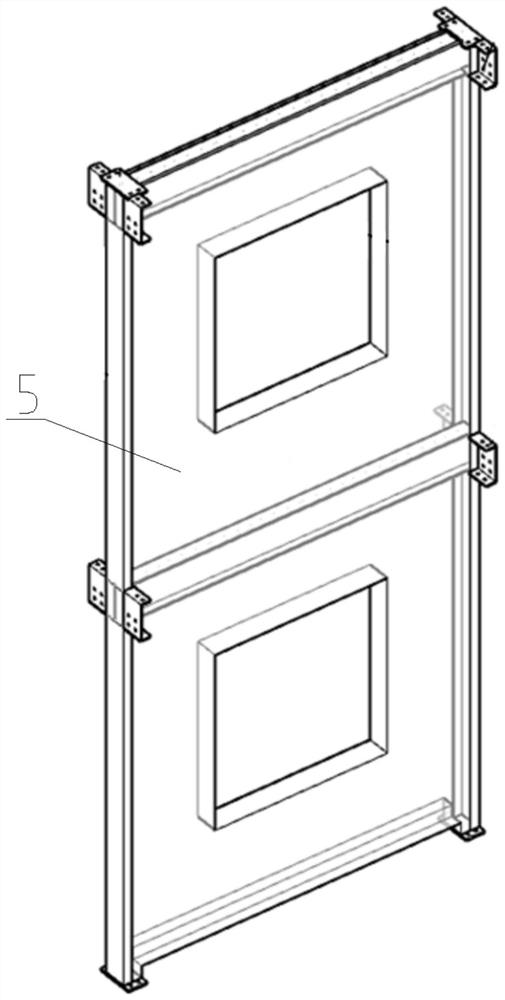

[0025] combine Figure 1 to Figure 5 It can be seen that in the non-shear wall system of the fully prefabricated building disclosed in this embodiment, the corresponding height of the steel frame wall panel module is two stories high, and the steel frame wall panel module includes a steel frame and a thermal insulation wall plate.

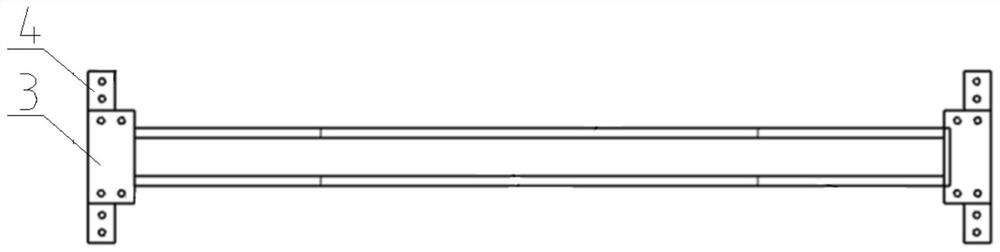

[0026] The steel frame includes the two side columns 1 and the connection beams 2 fixed at the corresponding storey height positions between the two side columns, that is, the connection beams 2 are respectively fixed at the middle position and the top of the side columns 1 .

[0027] The side column 1 is made of channel steel, the connecting beam 2 is made of I-beam, and the width of the wing plate of the connecting beam 2 is smaller than the notch width of the side column 1.

[0028] The two ends of the side column 1 are respectively connected to the rectangular plate 3 as the wall column connecting member. The outer side of the rectangular plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com