Combined wall formed by single prefabricated wall sections and construction method

A construction method and prefabricated wall technology, applied in the direction of walls, building components, buildings, etc., can solve problems such as inability to overcome hanging, insufficient assembly, complex structure, etc., achieve small calculation length, not easy to overall and local instability, earthquake resistance good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

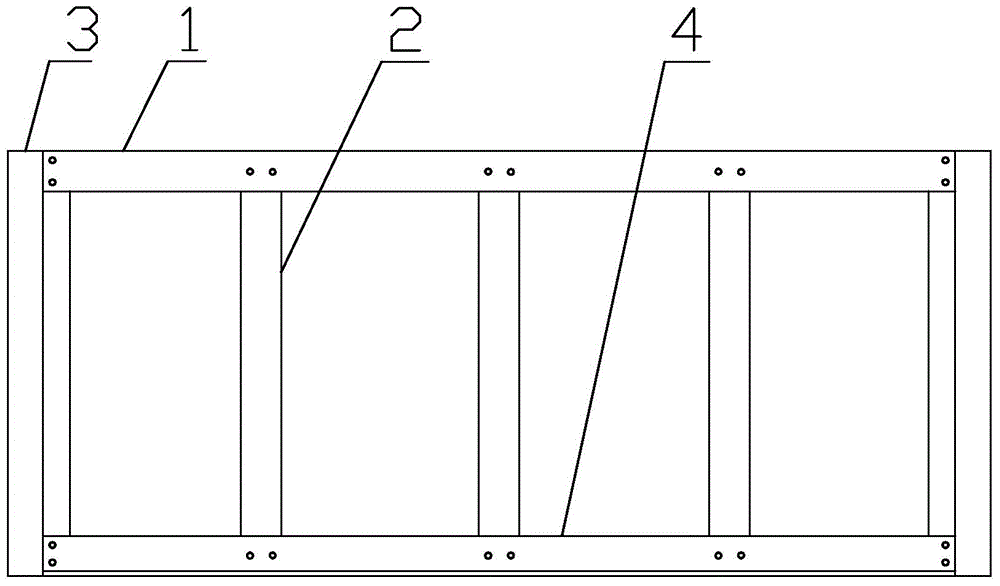

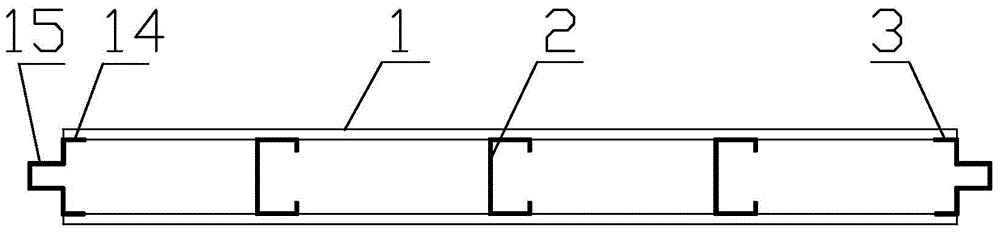

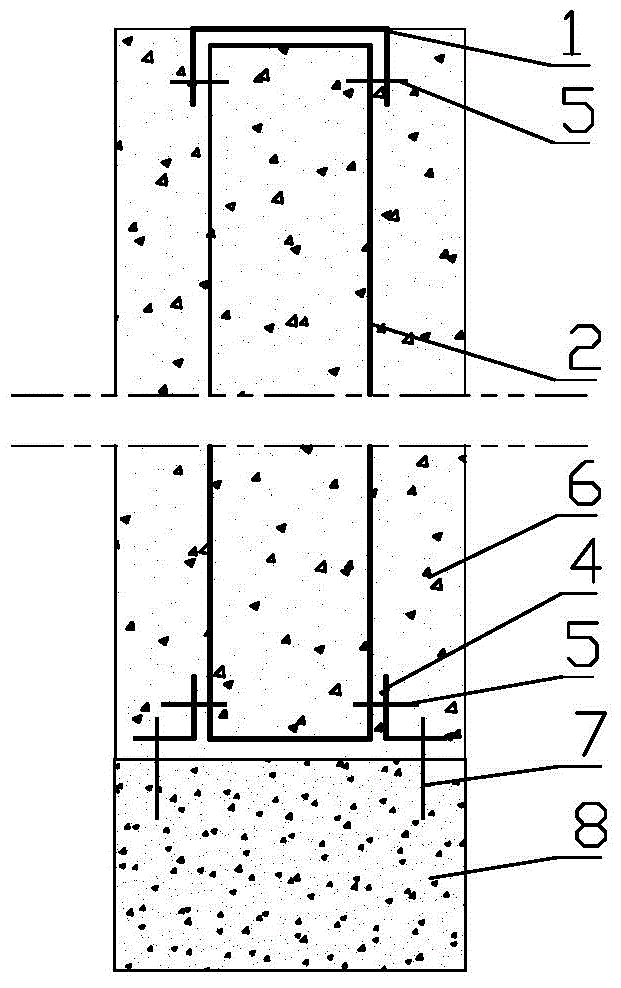

[0047] The present invention will be further described below in conjunction with the accompanying drawings and embodiments: a schematic diagram of the structure of a combined wall body is as follows: Figure 10 As shown in the figure, the prefabricated wall section 13 composed of only one structure is combined into a wall through the transfer square steel 11, and the prefabricated wall section can be calculated as a unified length or several set lengths, and the U-shaped connector 12 The transfer square steel 11 is spliced into a building wall, and the building wall includes: such as Figure 8 The combination of straight walls, such as Figure 7 The combination of L-shaped right-angle wall, such as Image 6 The combination of T-shaped wall, such as Figure 5 combination cross-shaped wall.

[0048] like figure 1 , 2 , the prefabricated wall section 13 is a straight wall section filled with fillers, both ends and the middle are provided with cold-formed thin-walled steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com