Patents

Literature

211 results about "Cold-formed steel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

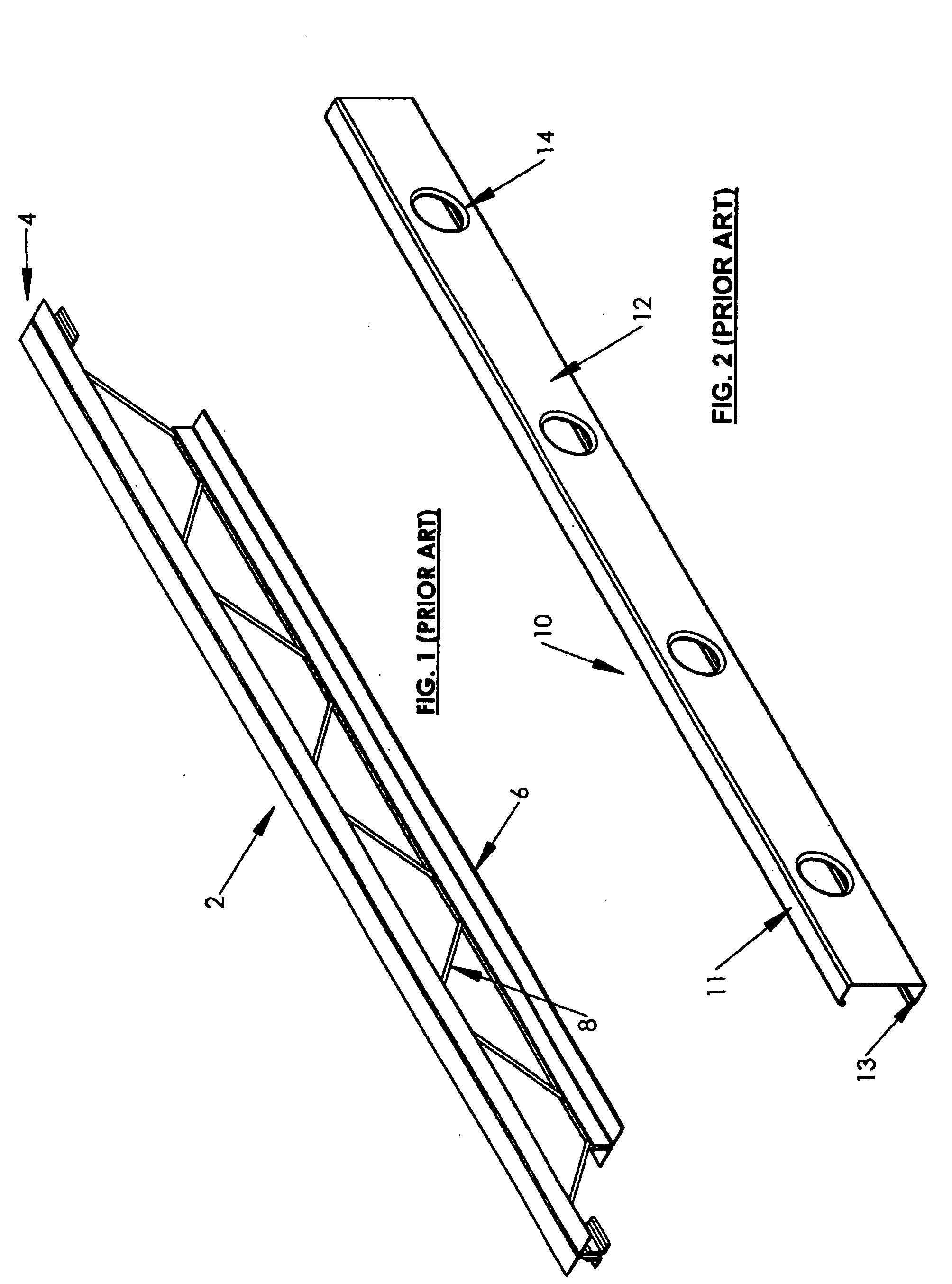

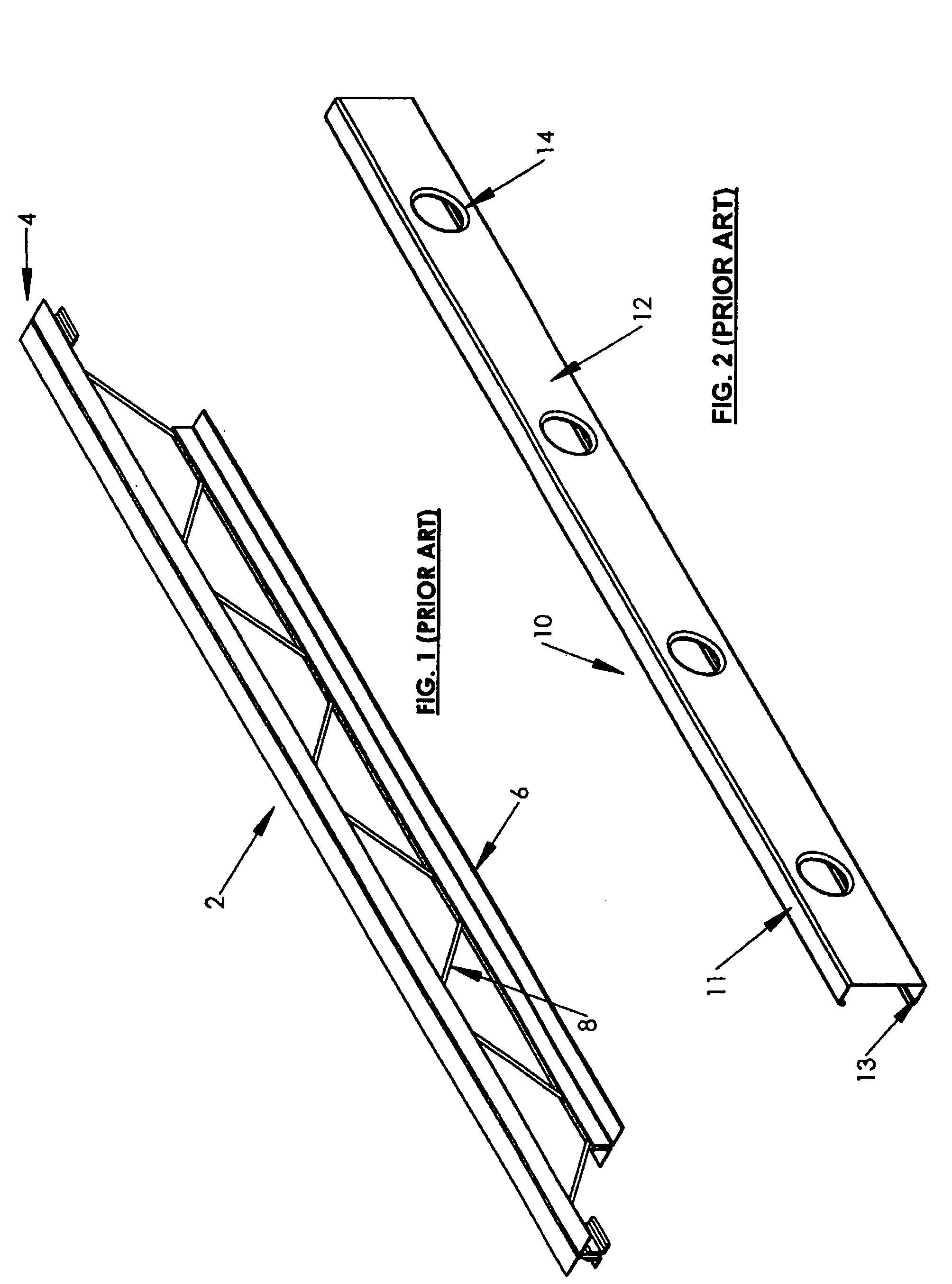

Cold-formed steel (CFS) is the normal term for steel items formed by cool working procedures done close to room temperature, for example, moving, squeezing, stepping, twisting, and so on. Stock bars and sheets of cold-moved steel (CRS) are generally utilized in every aspect of assembling. The terms are against hot-framed steel and hot-moved steel.

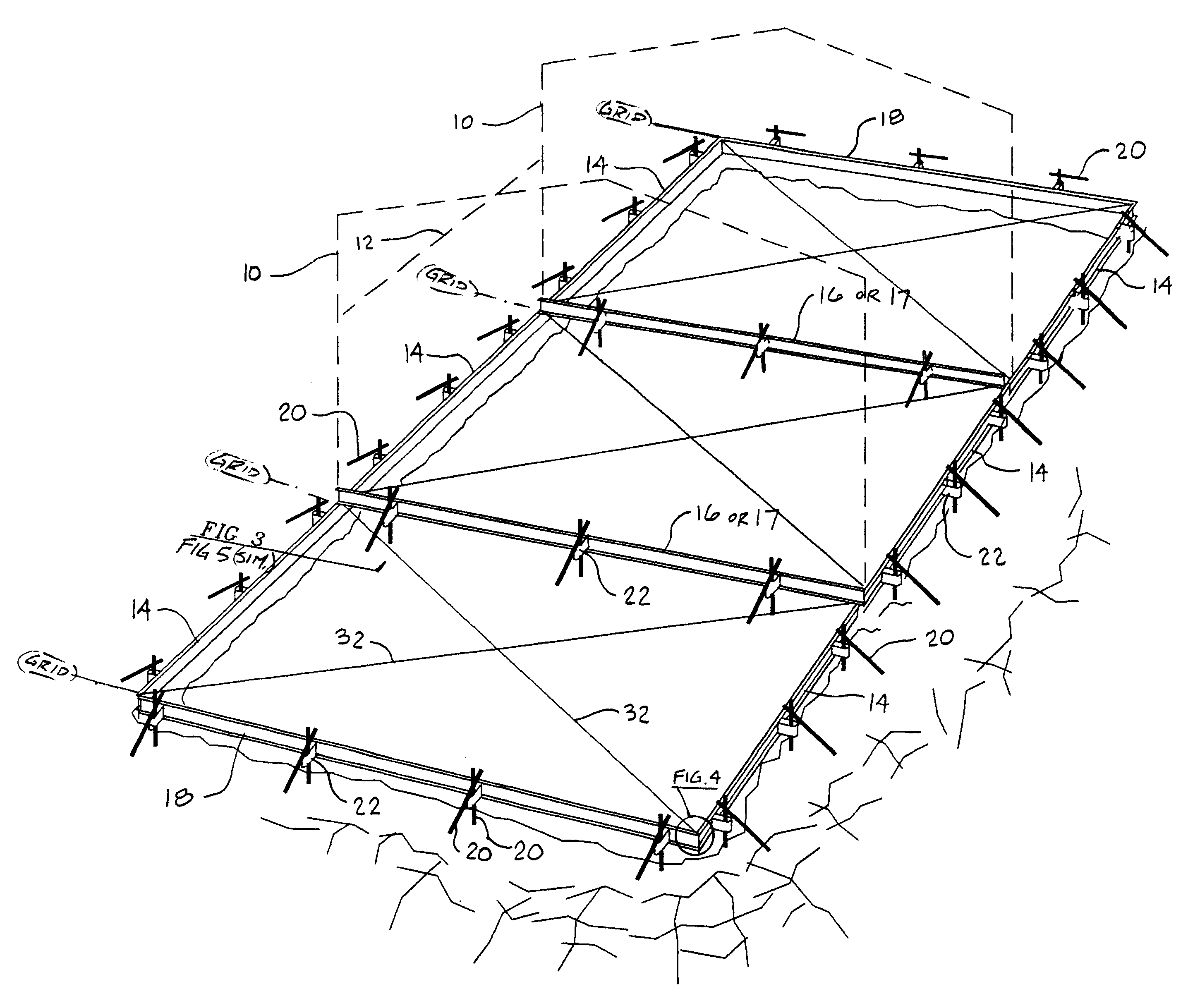

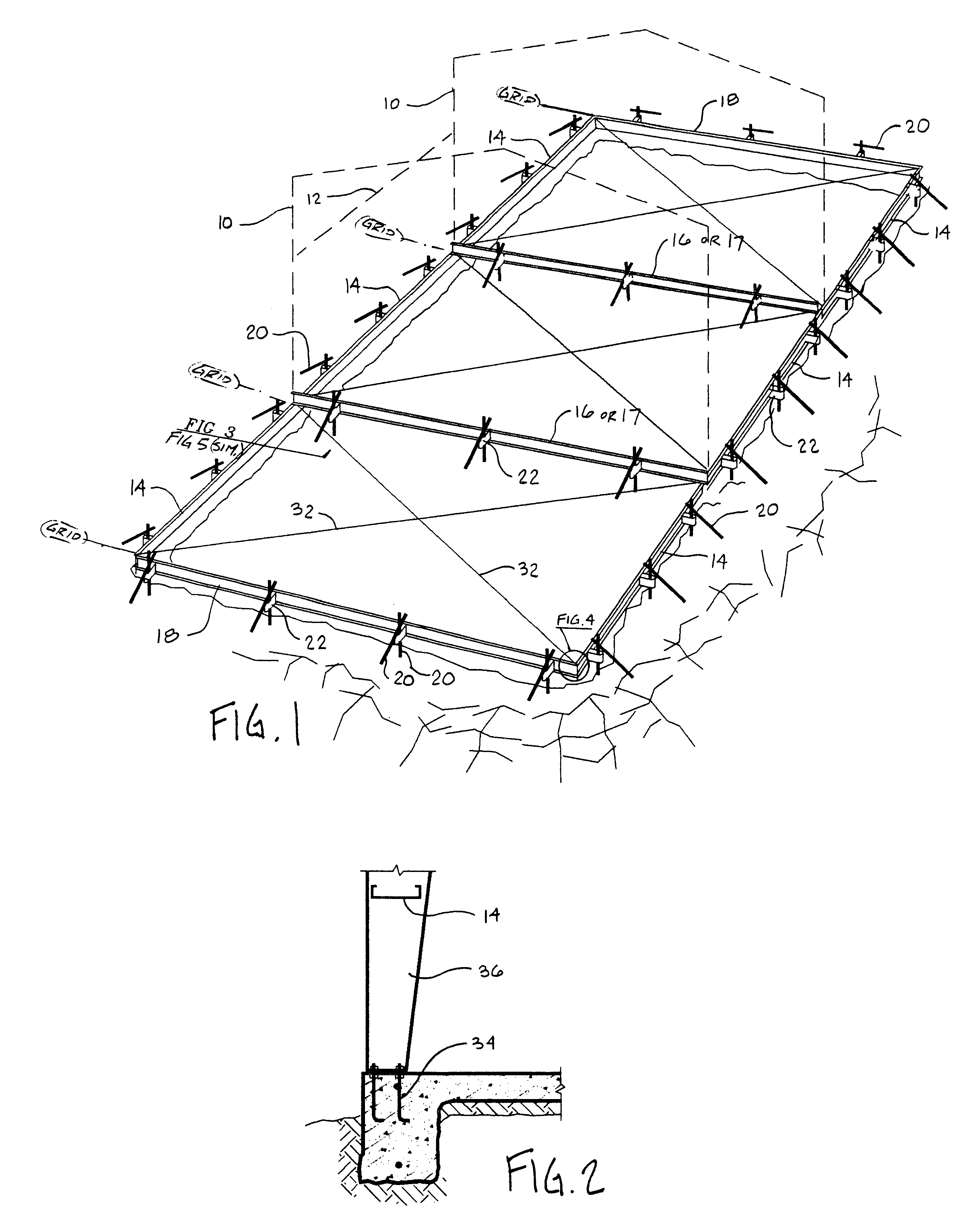

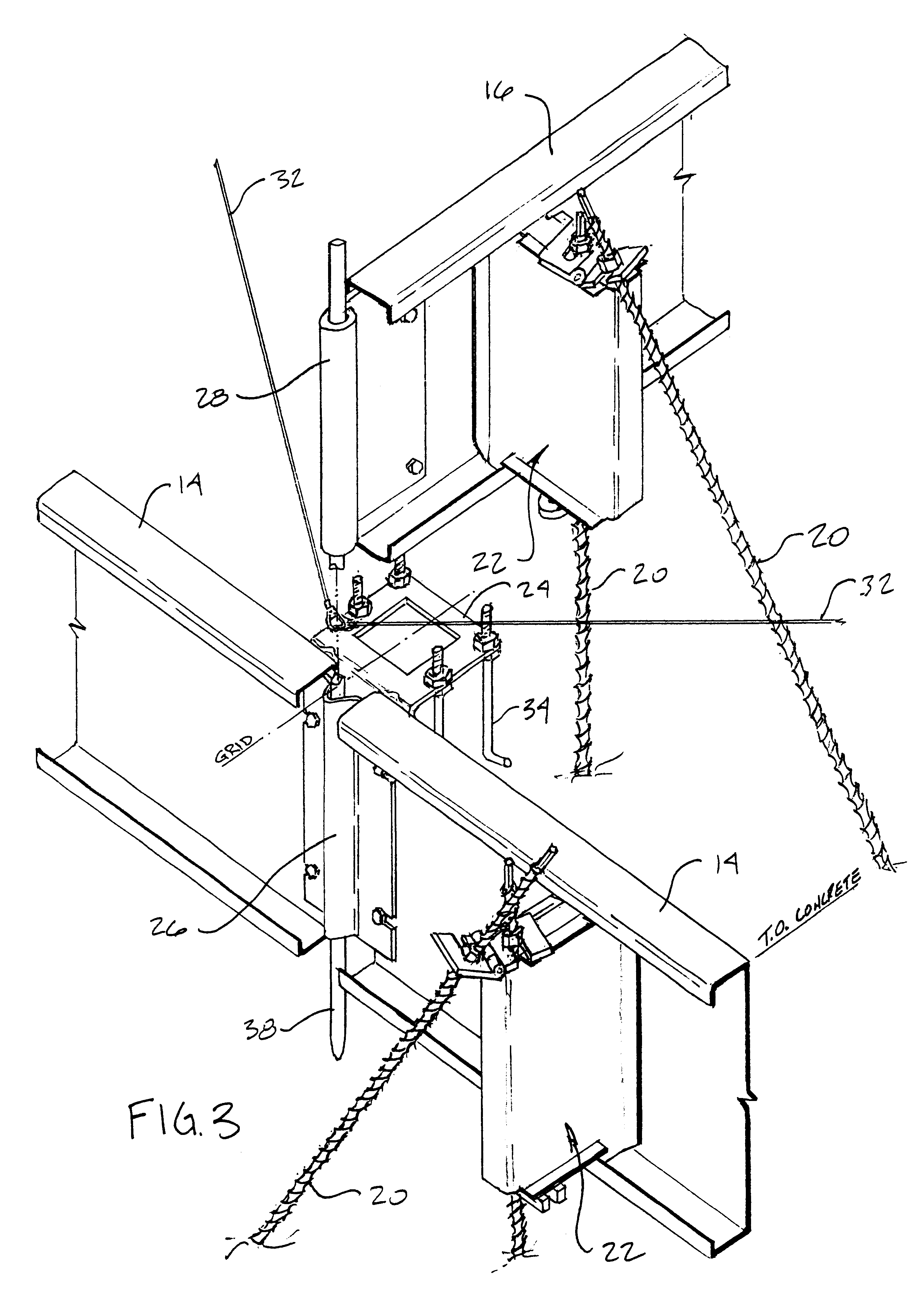

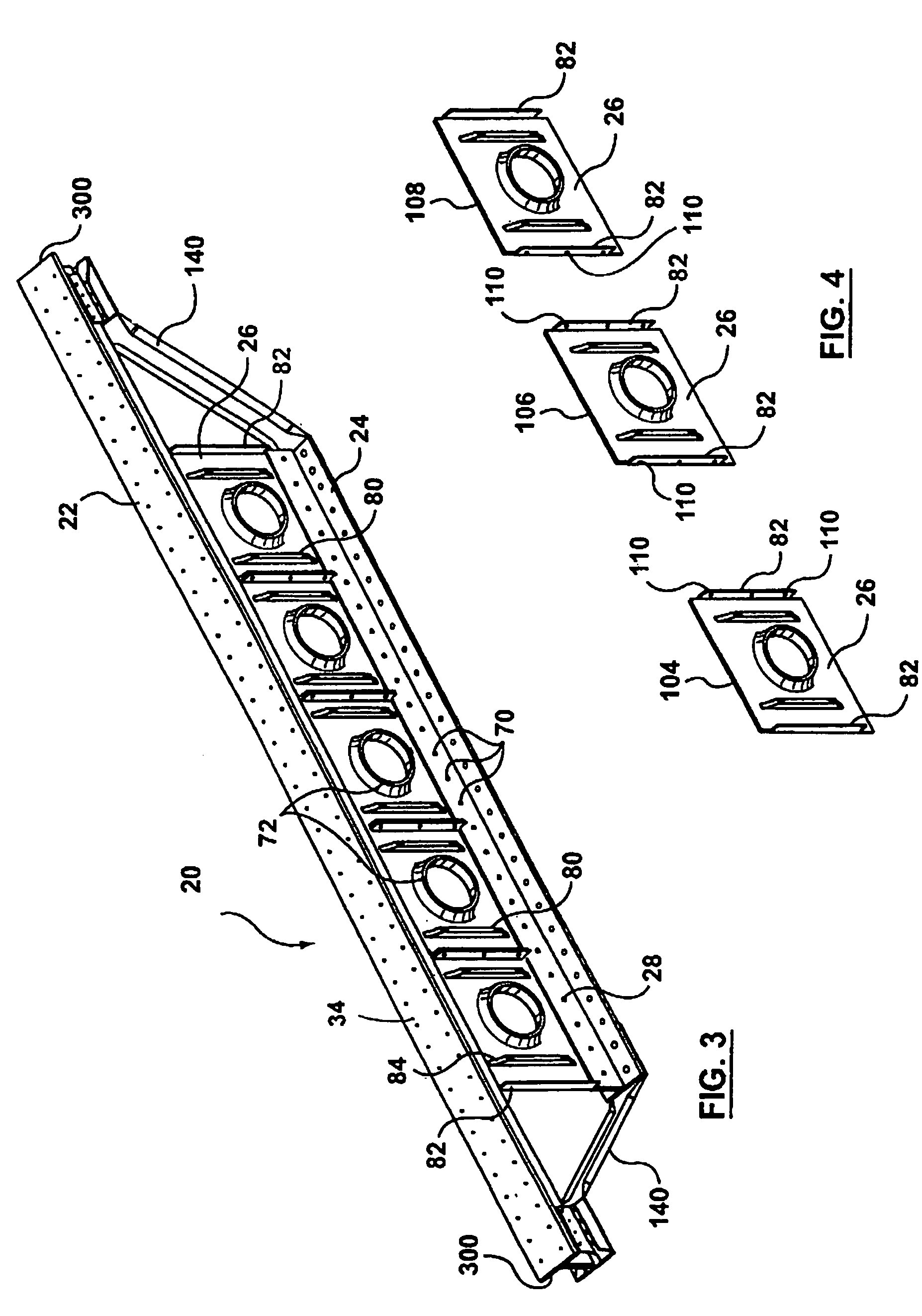

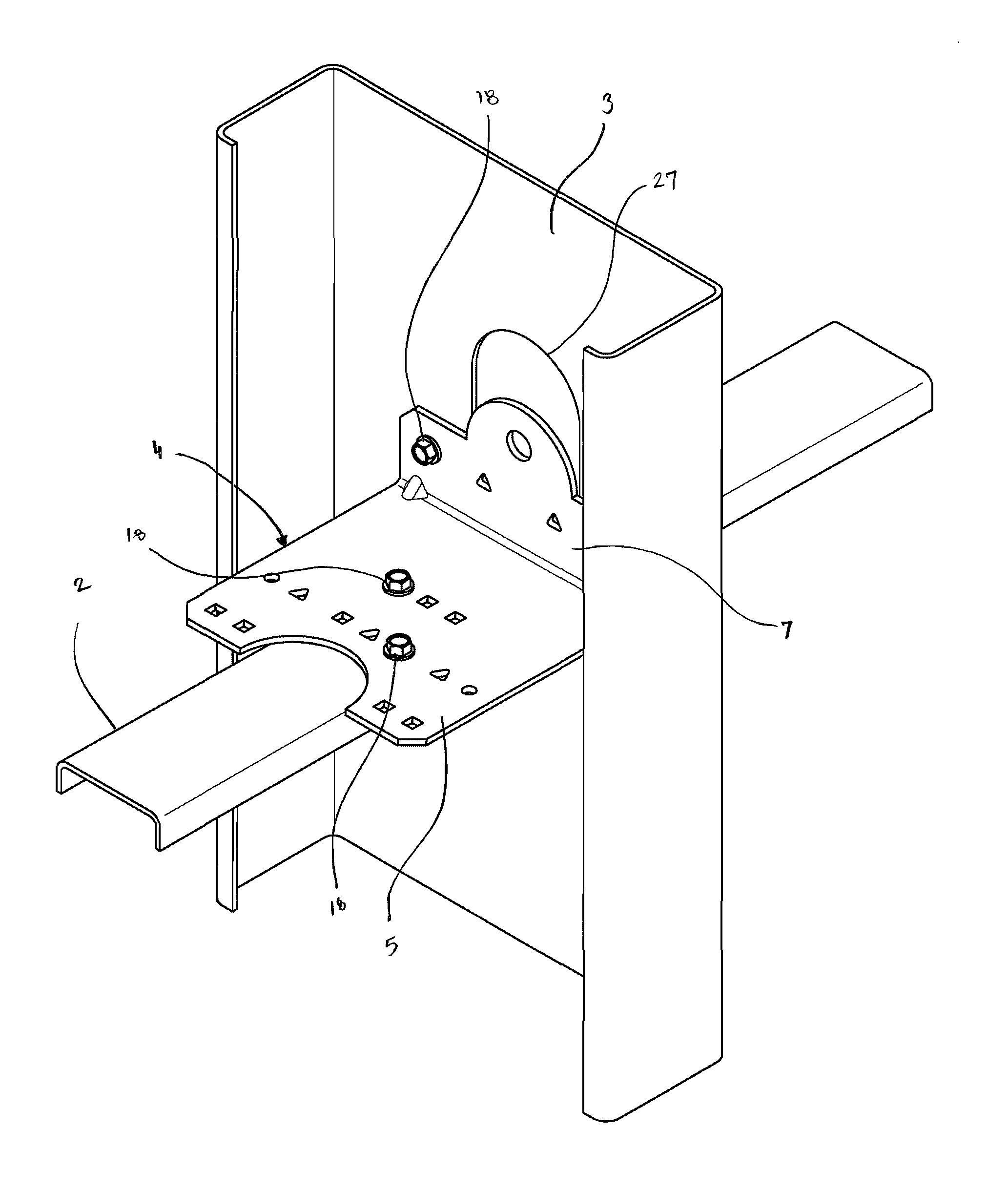

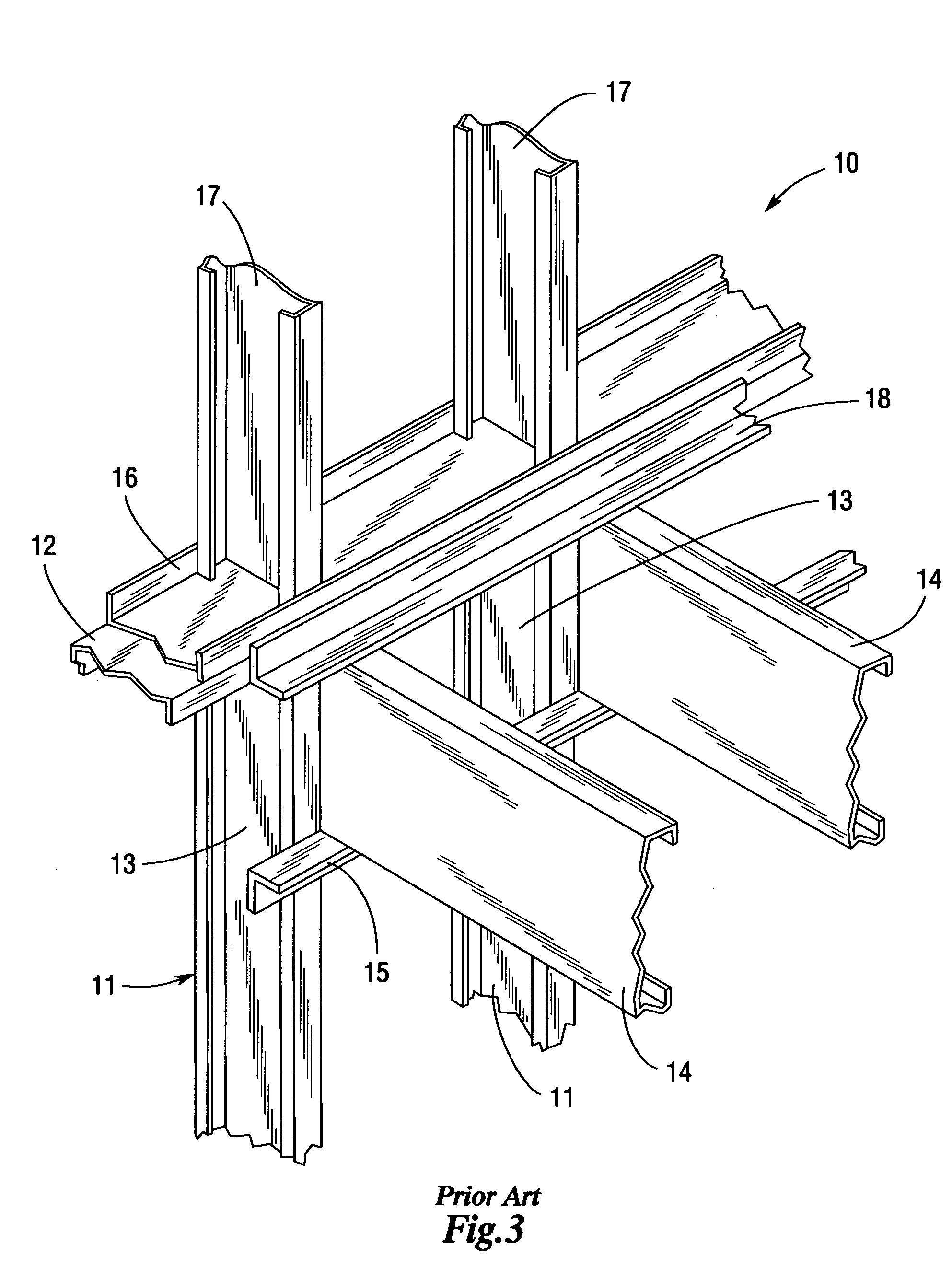

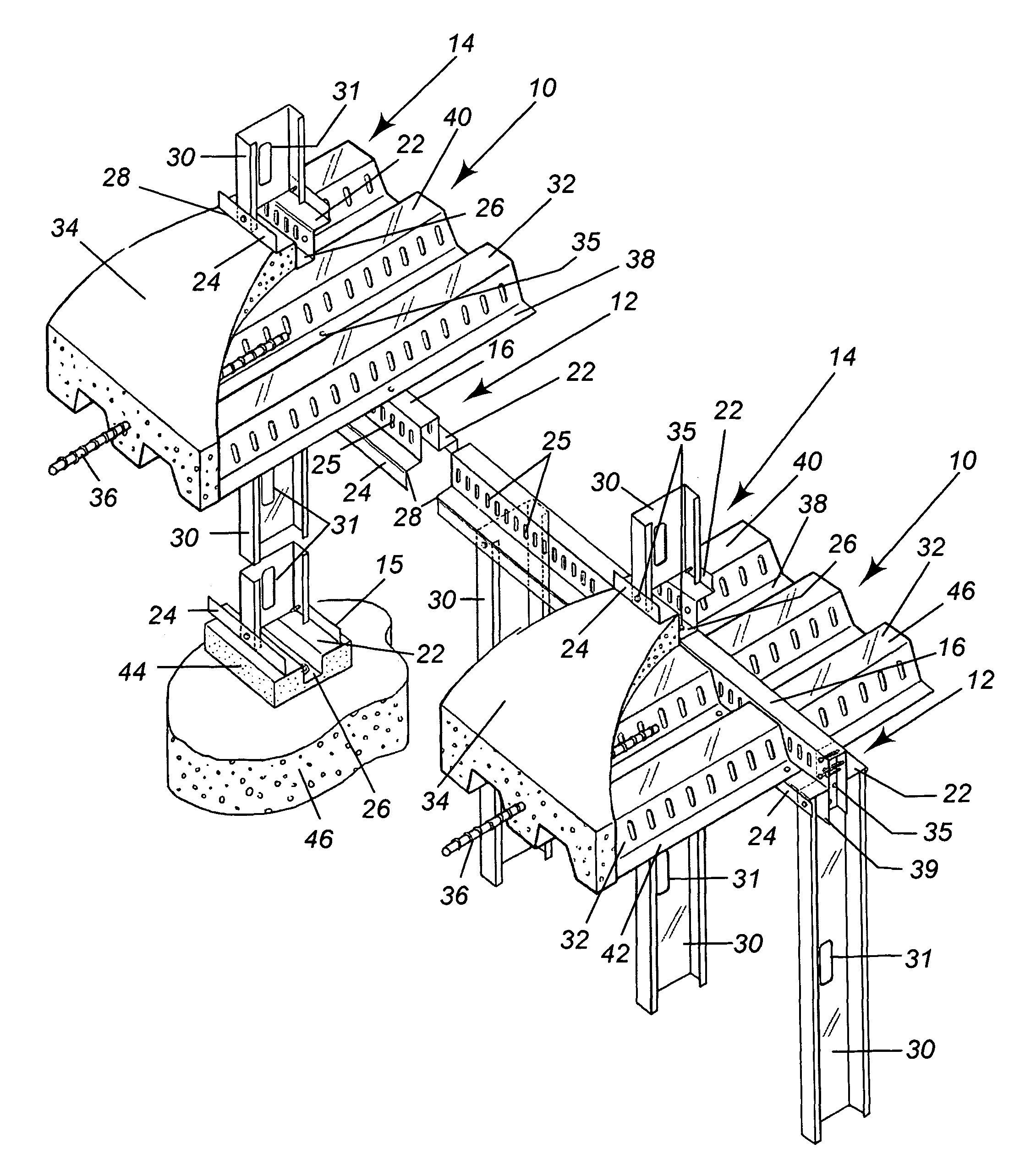

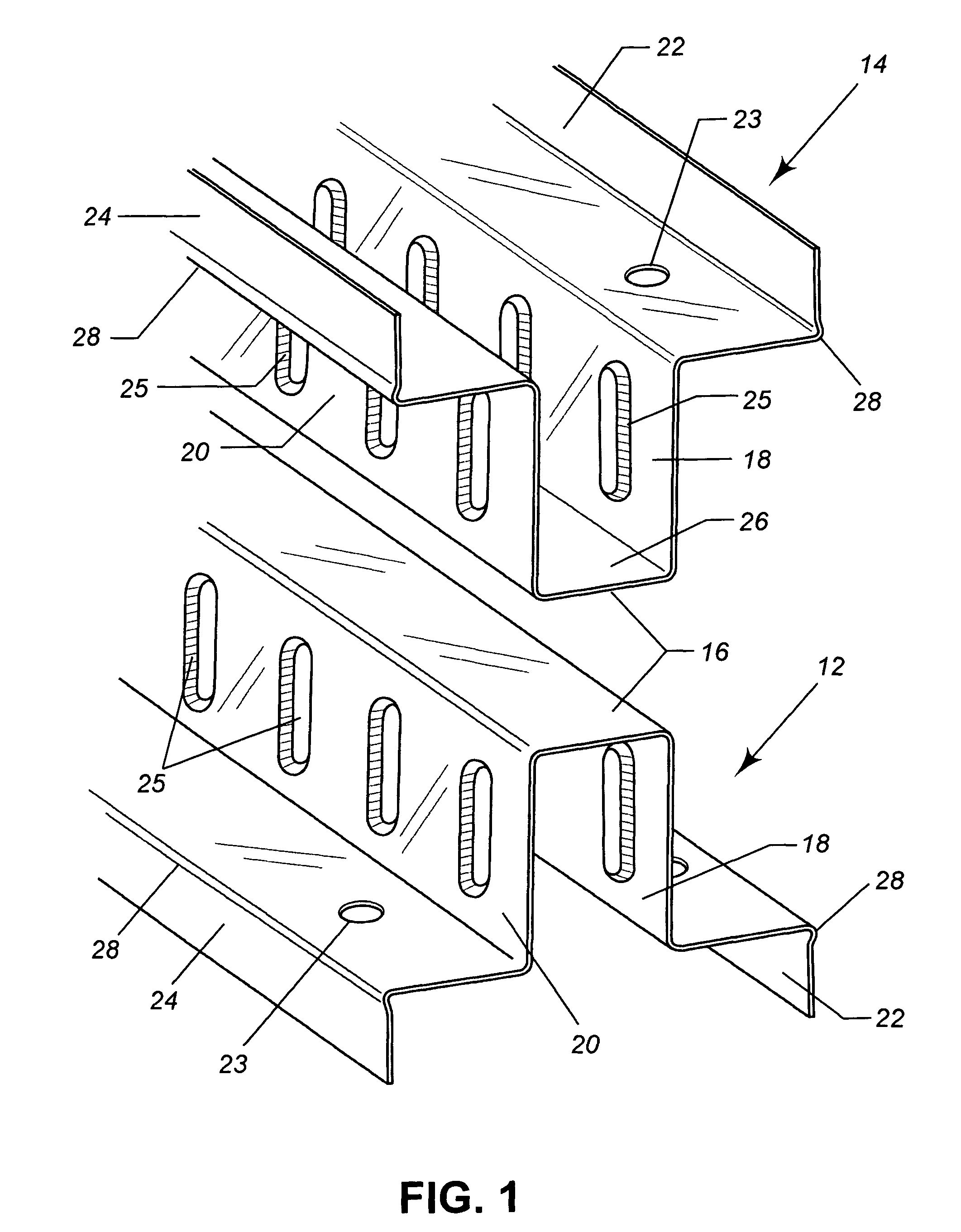

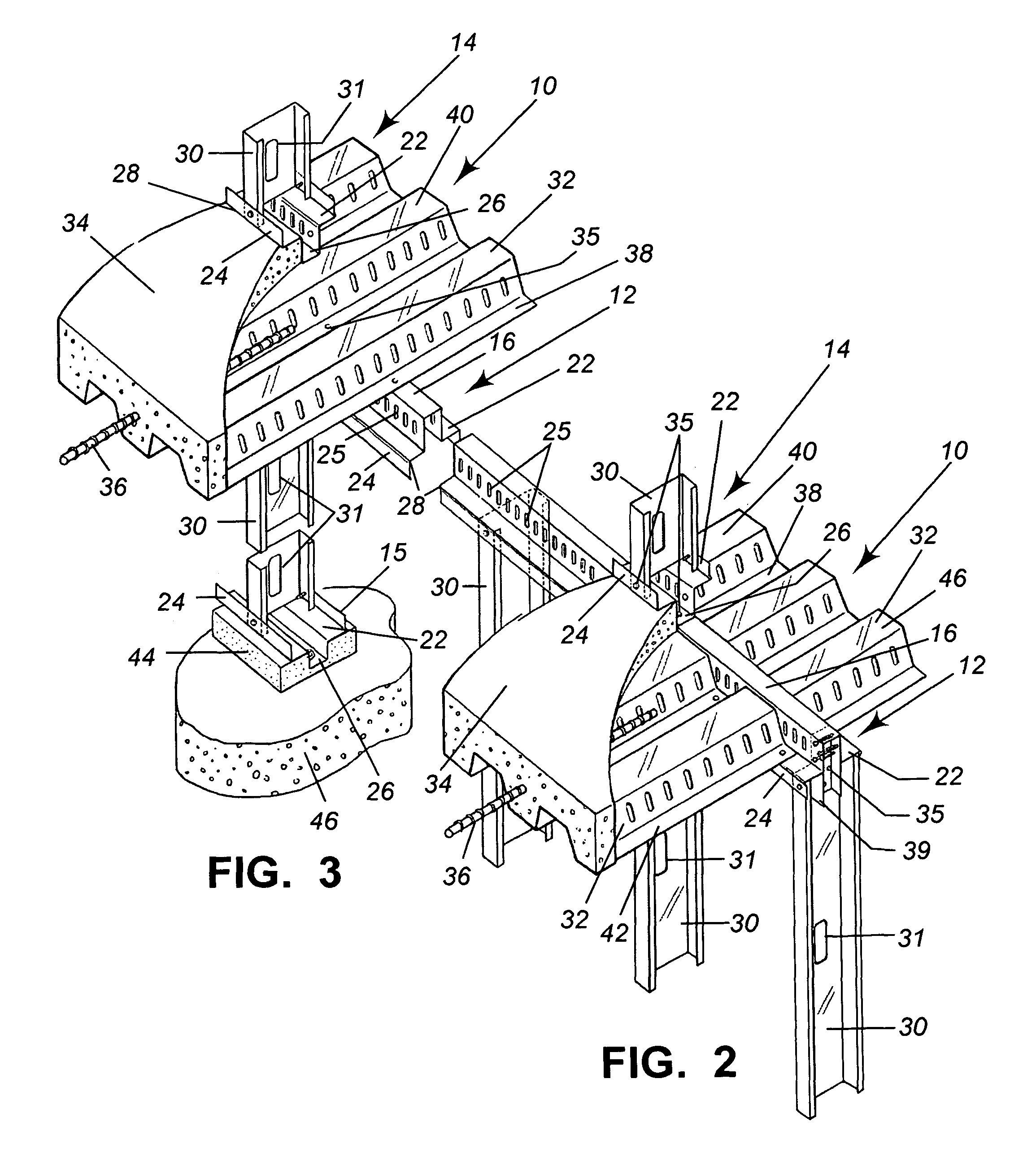

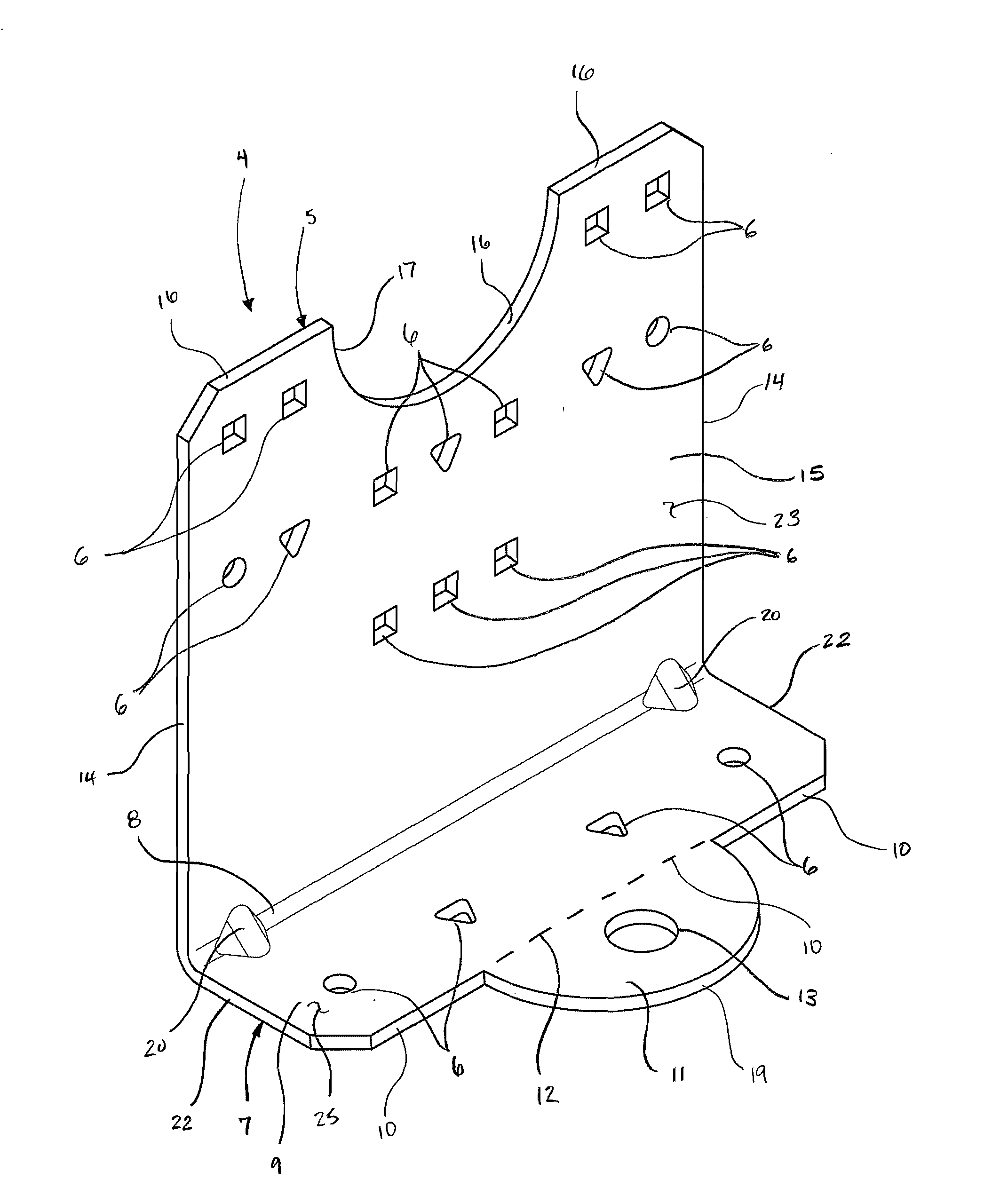

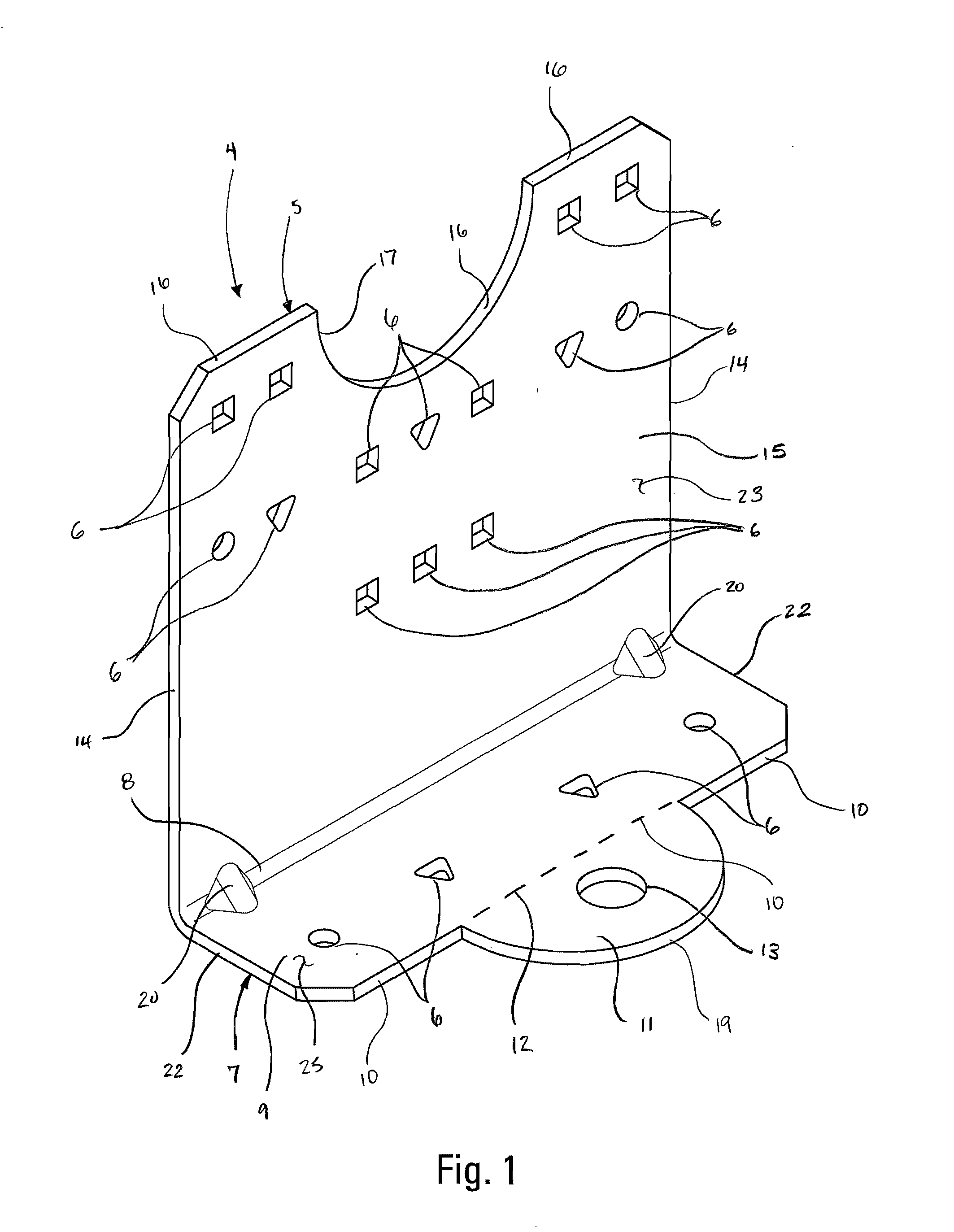

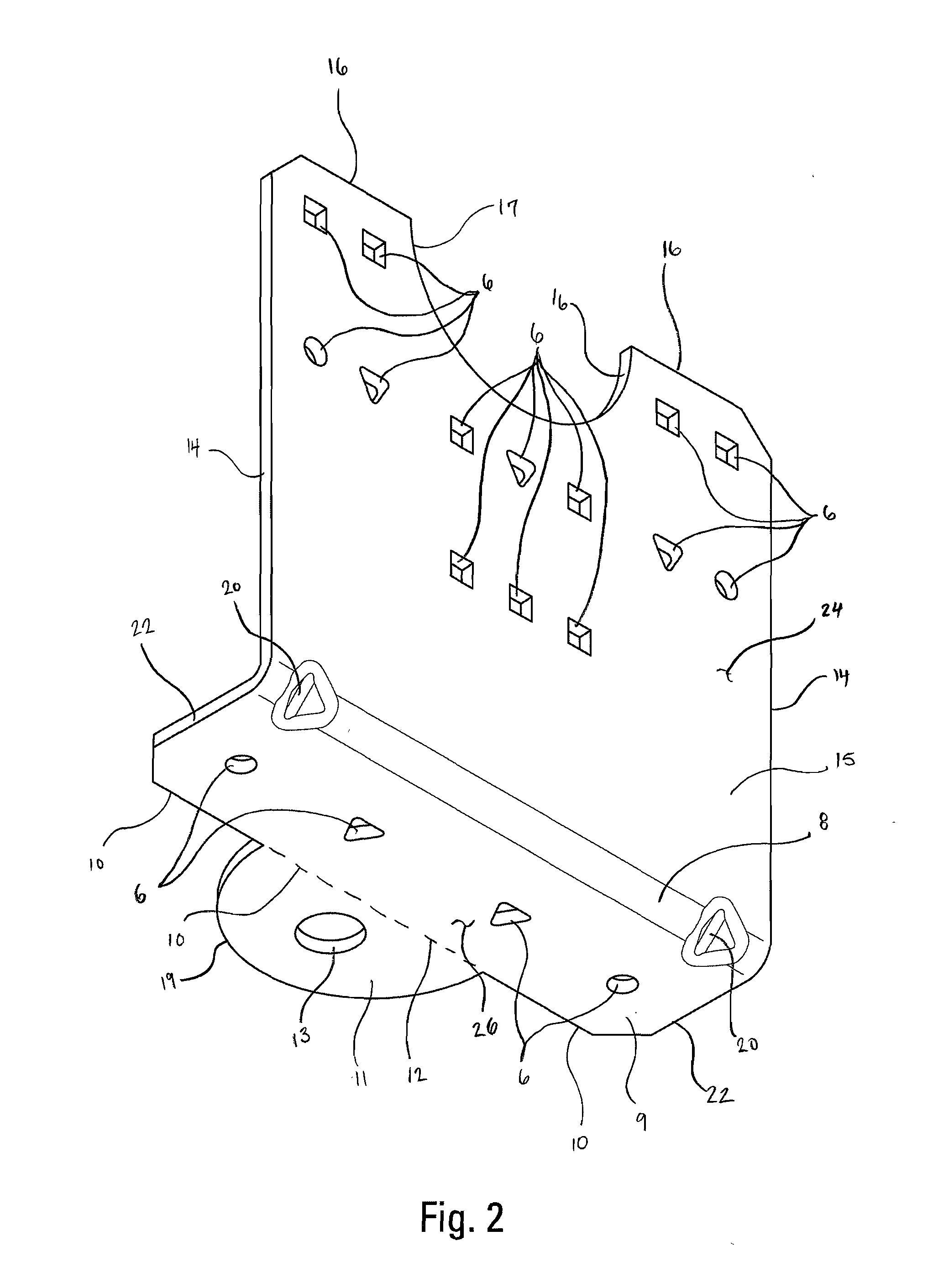

Slab foundation construction fixture, particularly as adapts standard girts for pre-use as foundation forms

InactiveUS6550213B1Easy to adjustLess laborFloorsBuilding repairsSteel moment frameCold-formed steel

A system for forming concrete slabs has been developed for commercial buildings having a steel moment-frame structure. This system utilizes the cold-formed-steel framing members, such as the wall girts shipped with a particular building package, to be first utilized as slab foundation forming elements before being framed into the building. The system defines foundation geometry upon simple assembly of the forming elements, and efficiently provides for placement of anchoring hardware which corresponds exactly to the connections of the structural frames.

Owner:BUTLER MICHAEL G

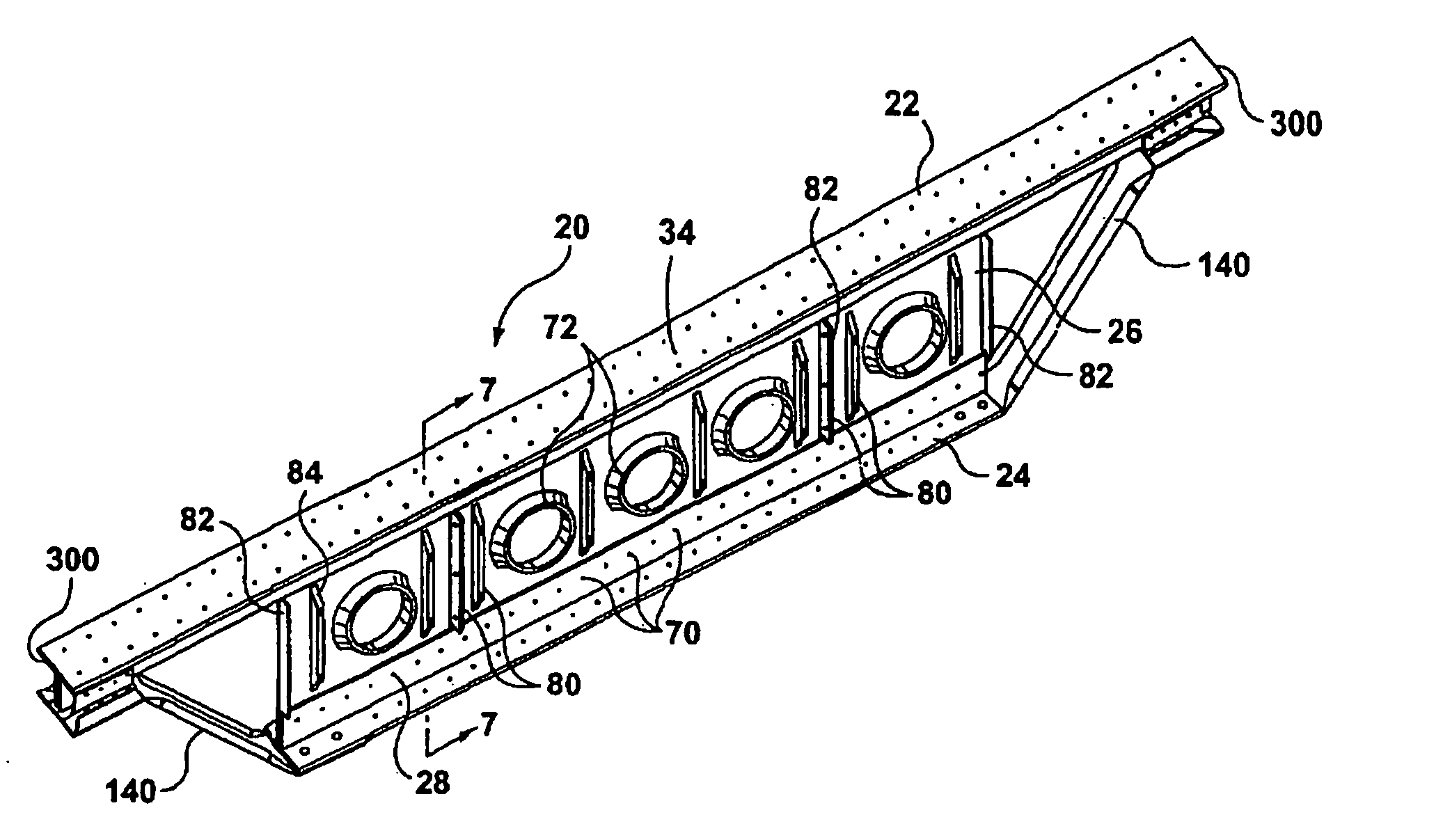

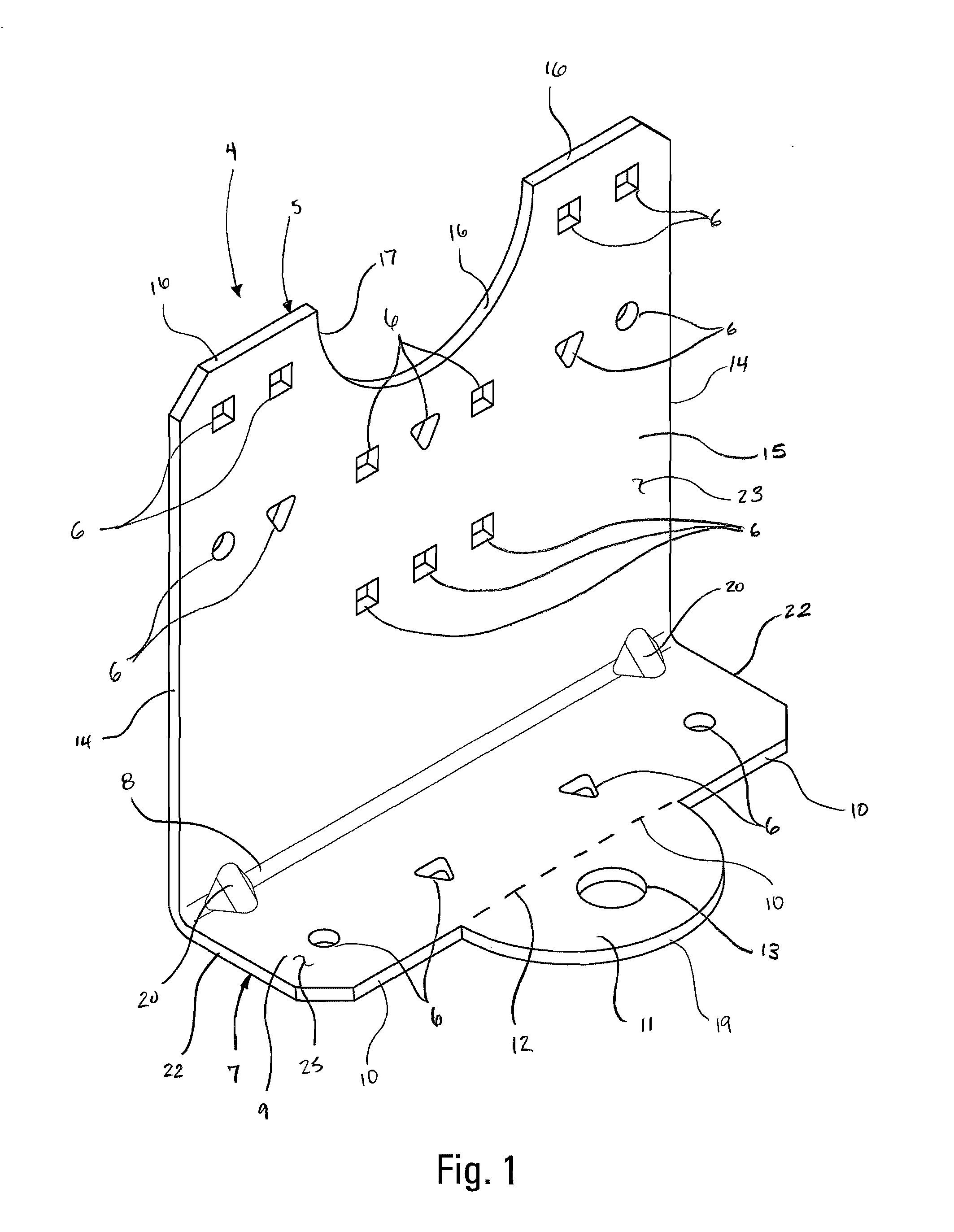

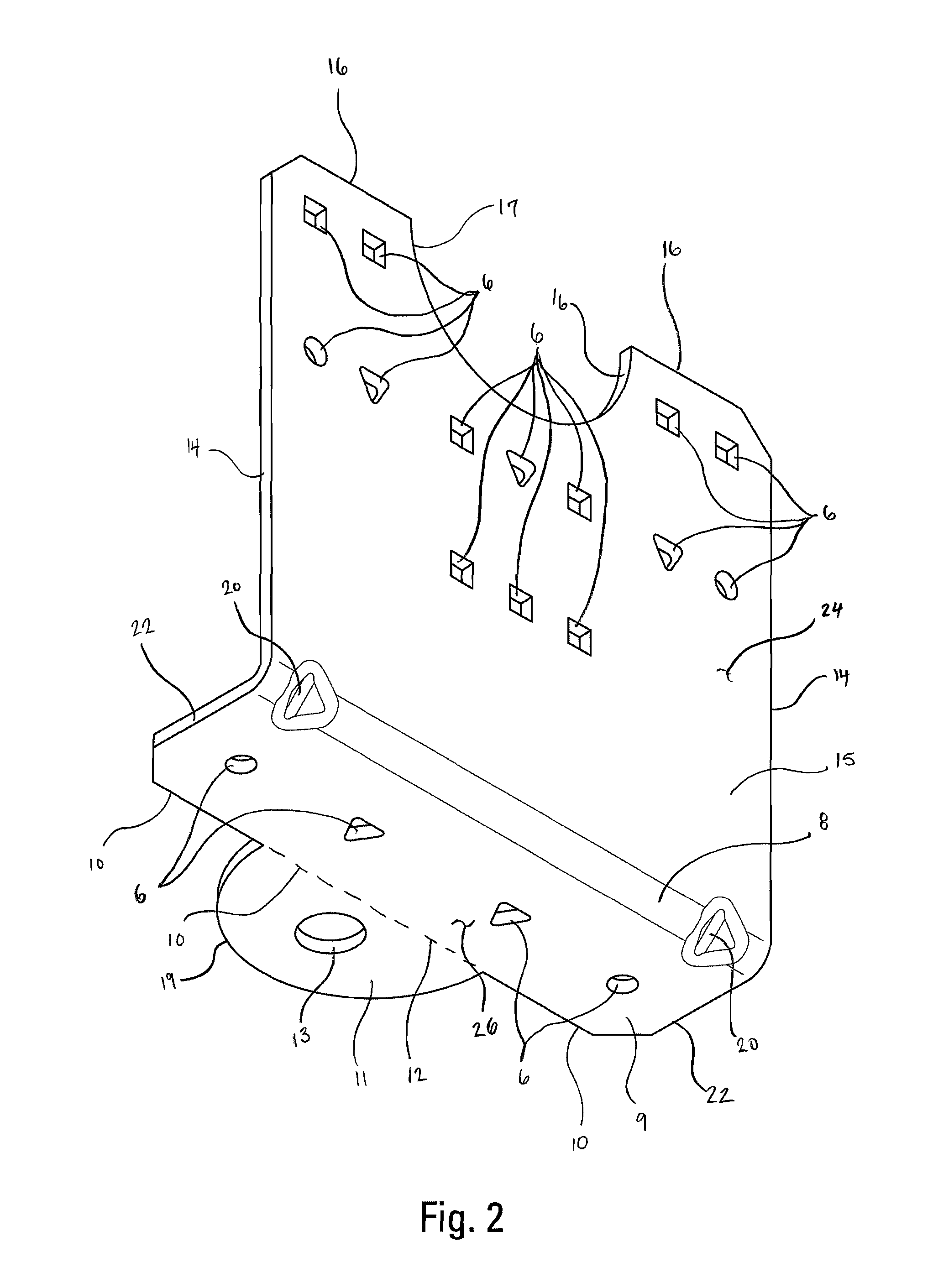

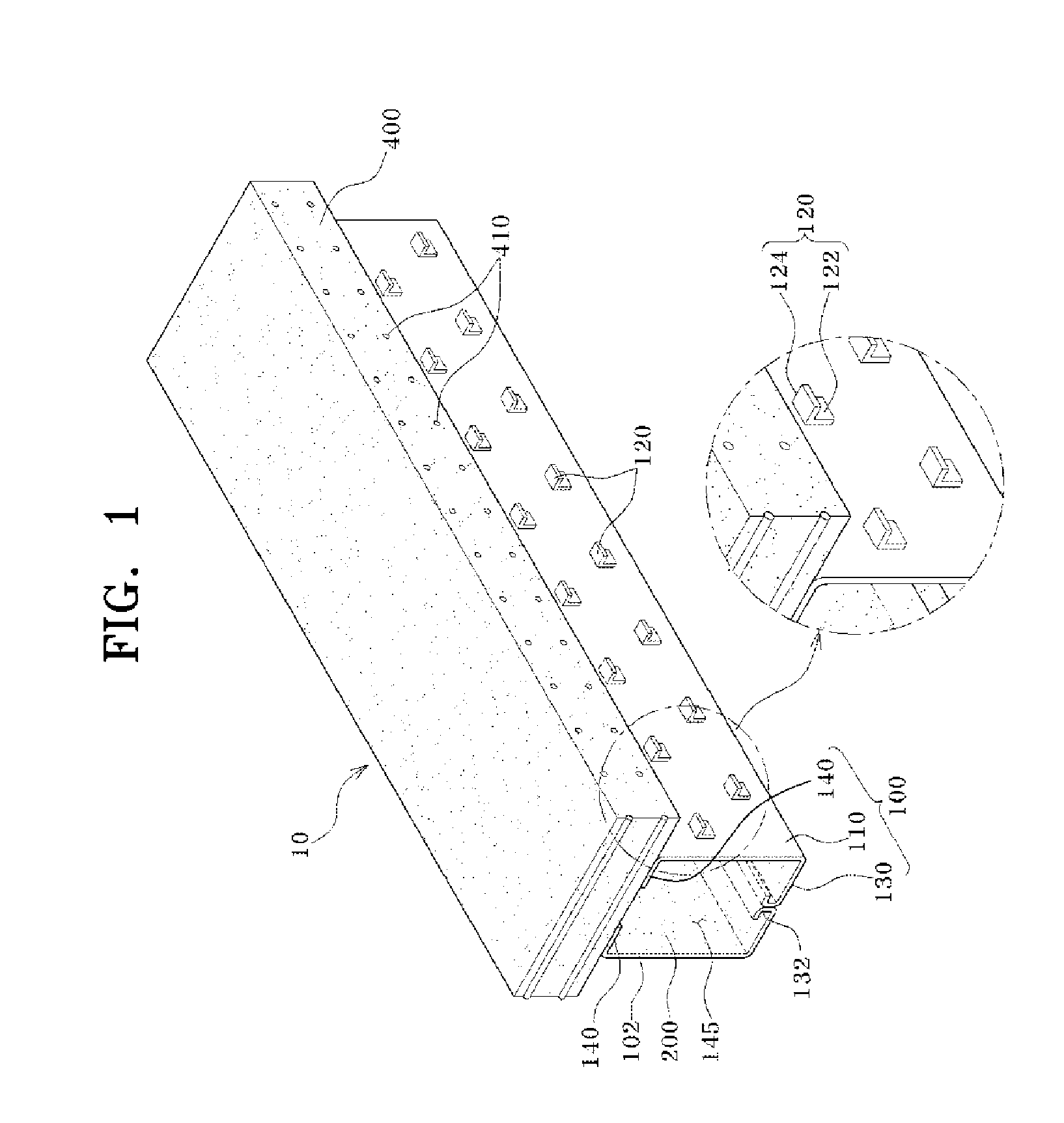

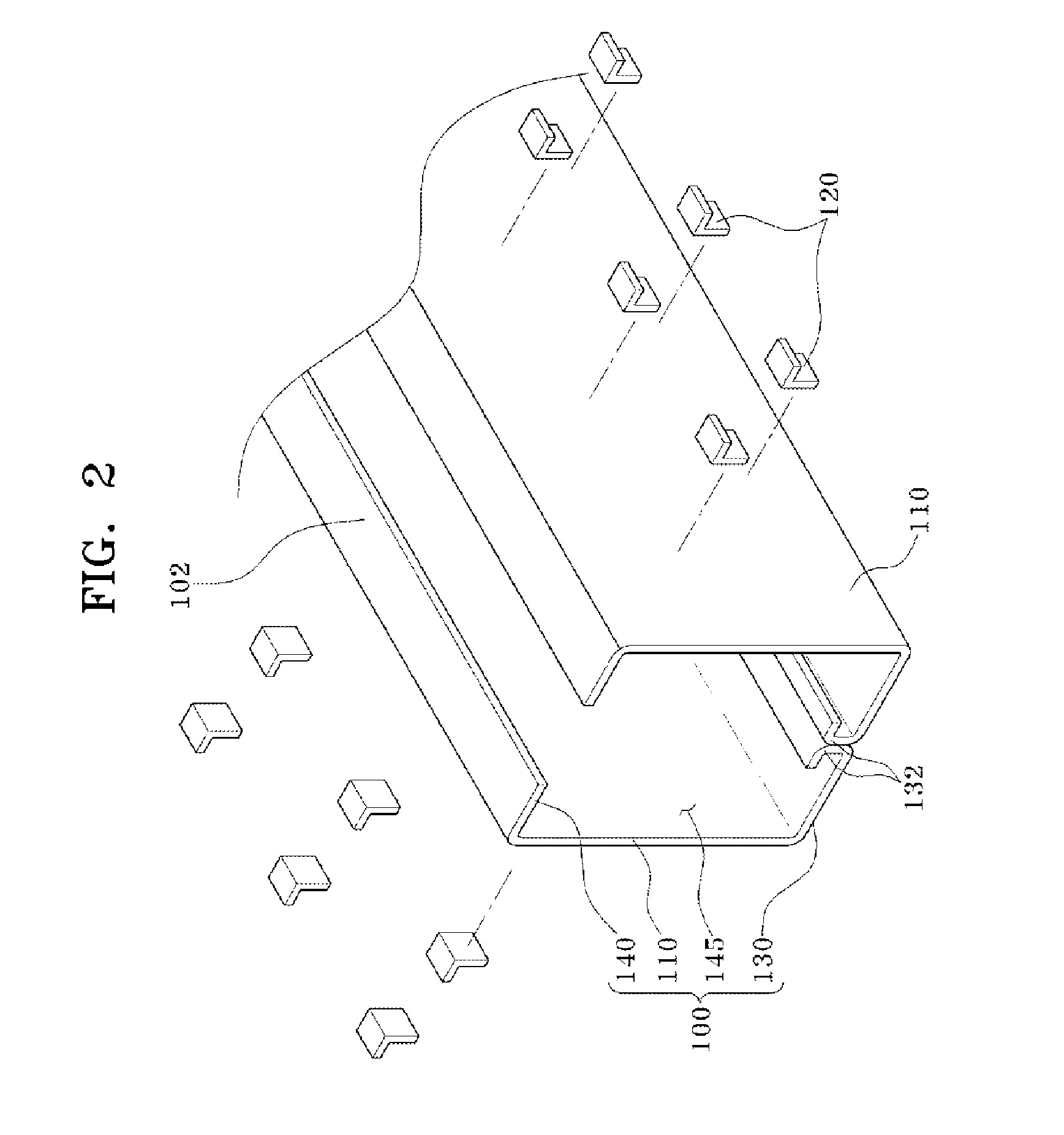

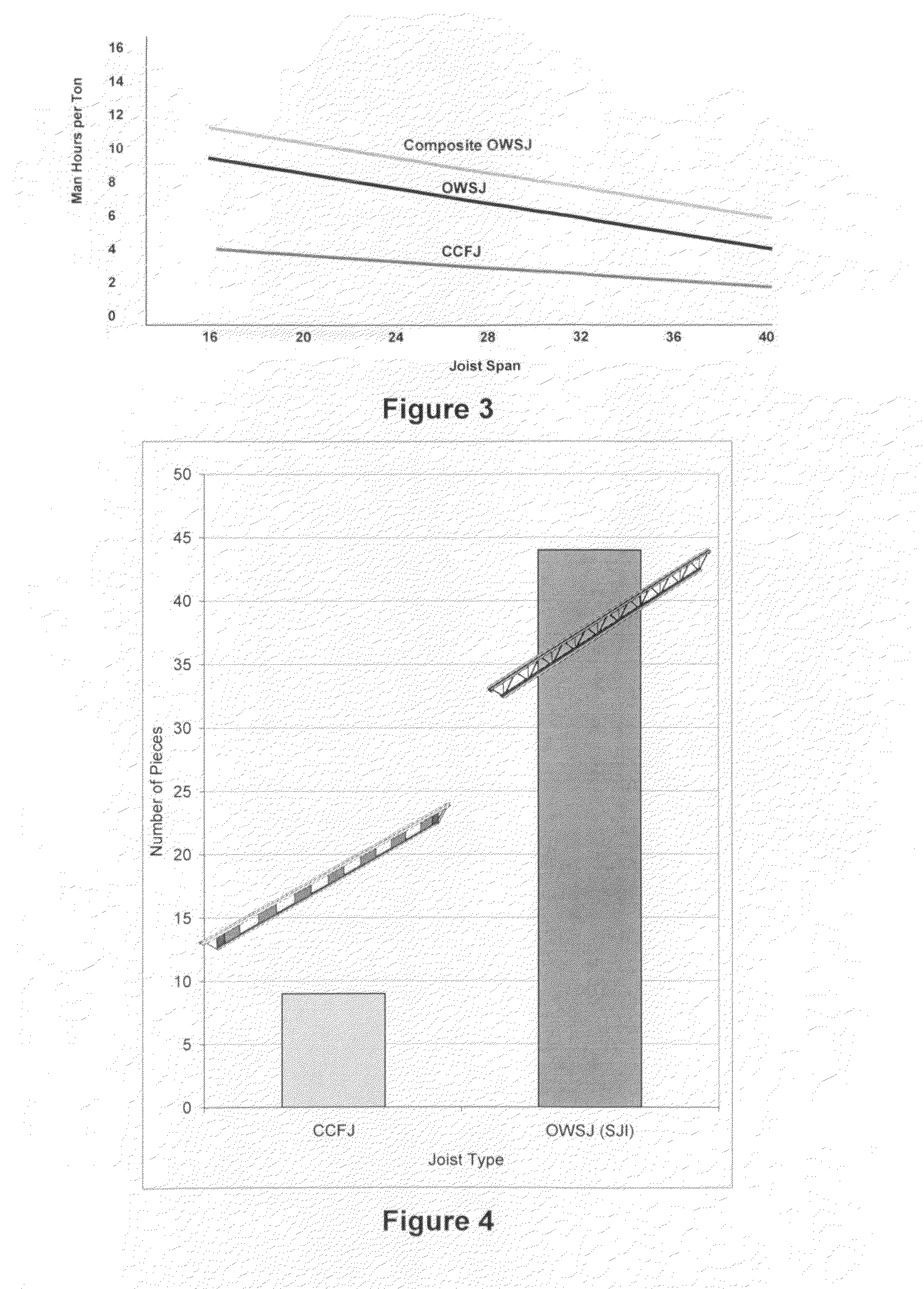

Cold-formed steel joists

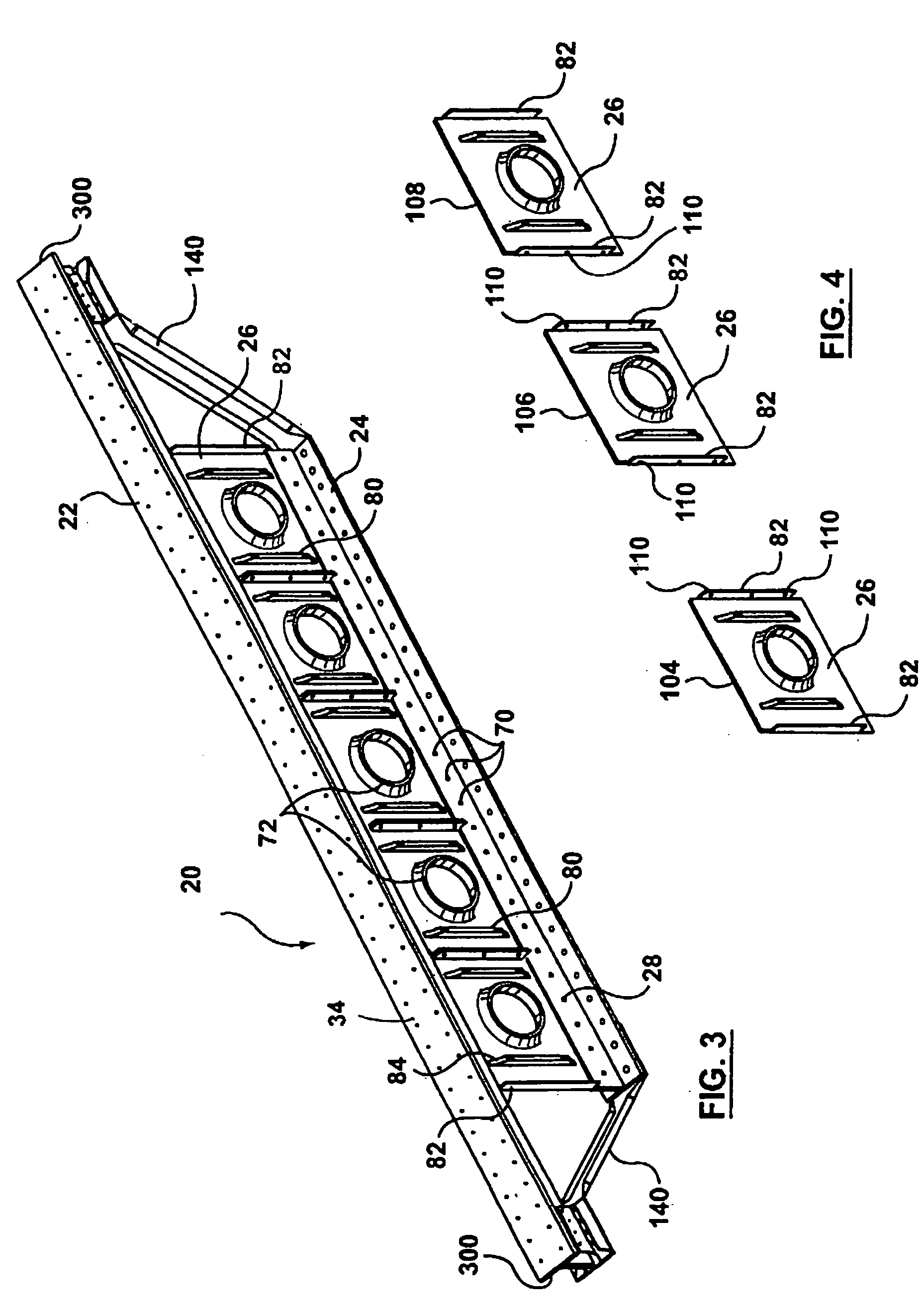

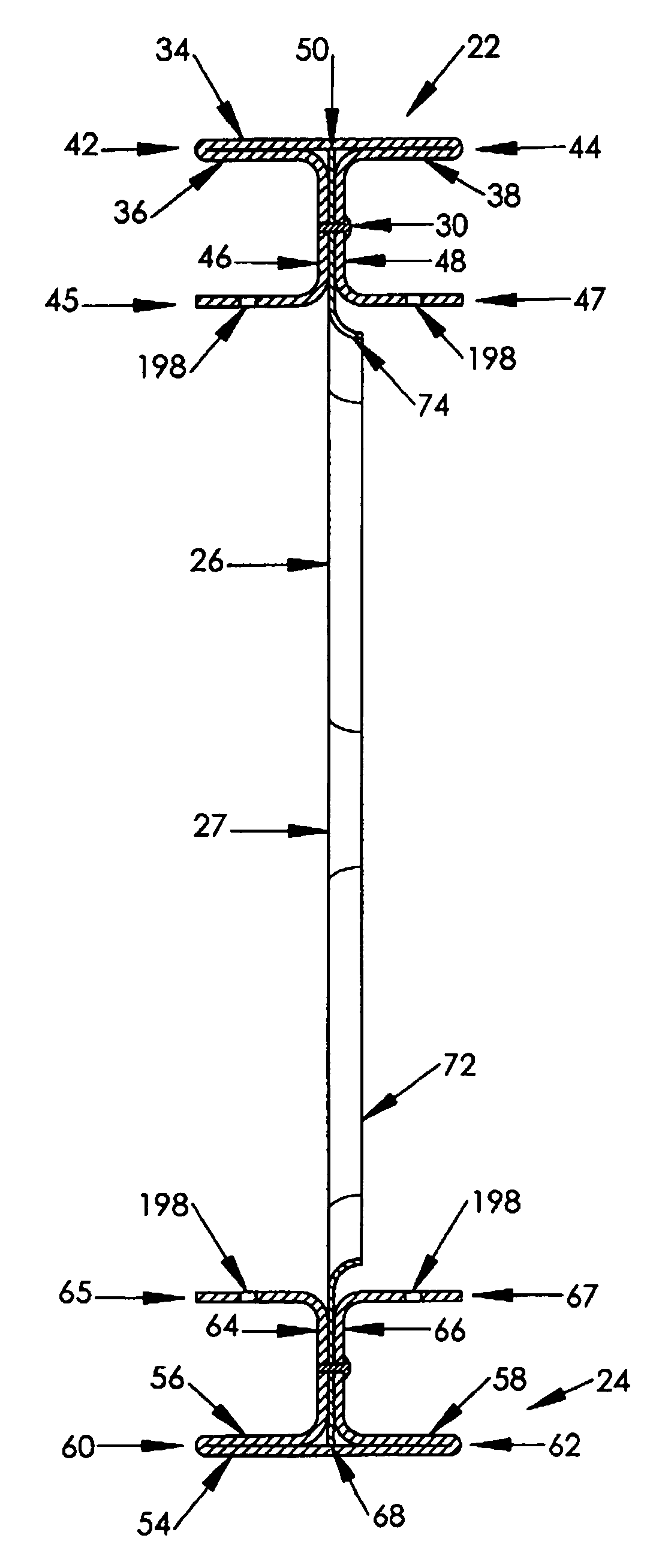

A joist comprised of at least one cold-formed steel elongated chord member; a cold-formed steel web having a plurality of web members and means for securing said web to said chord member. A plurality of joists are generally for use in a support system for a platform or a deck in the construction of floors and roofs. The support system is of particular use in a composite floor and roof systems.

Owner:ISPAN SYST LP

Cold-formed steel joists

A joist comprised of at least one cold-formed steel elongated chord member; a cold-formed steel web having a plurality of web members and means for securing said web to said chord member. A plurality of joists are generally for use in a support system for a platform or a deck in the construction of floors and roofs. The support system is of particular use in a composite floor and roof systems.

Owner:ISPAN SYST LP

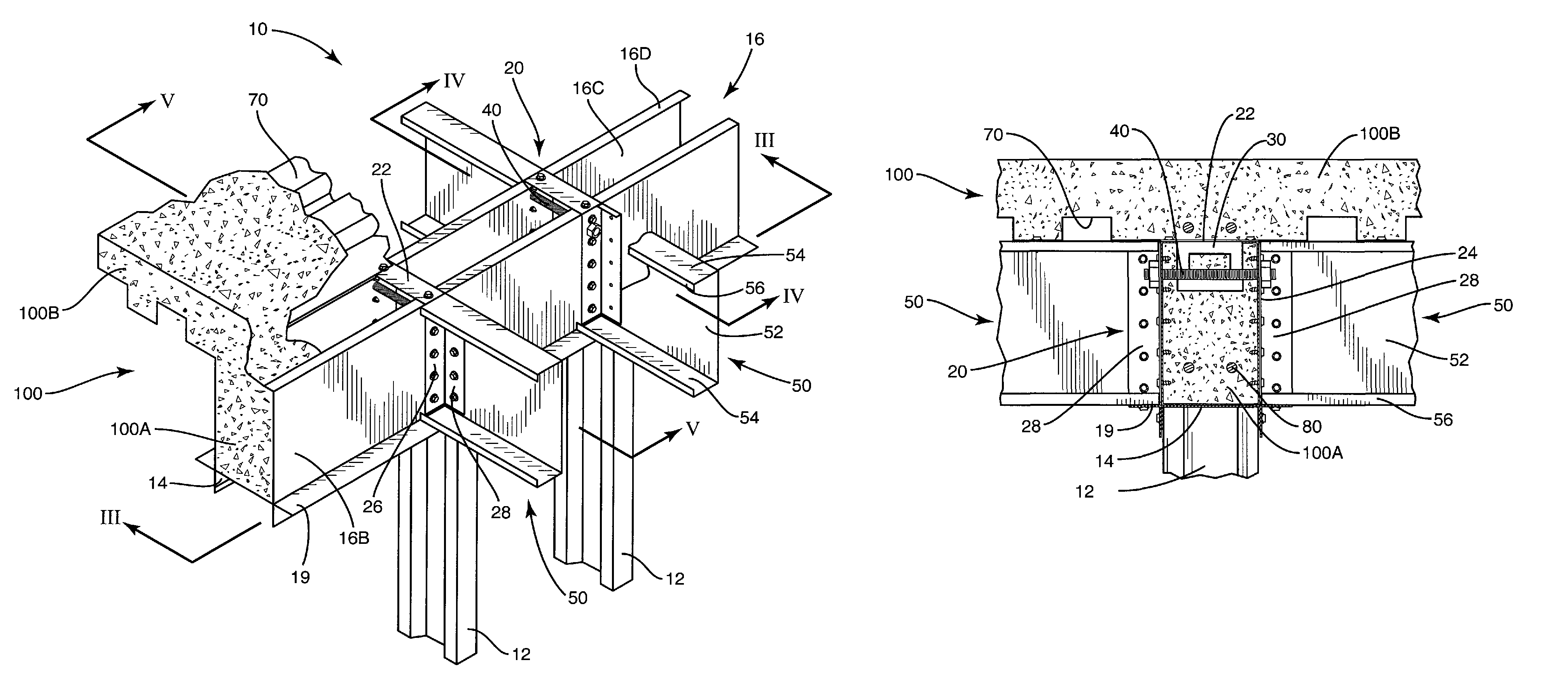

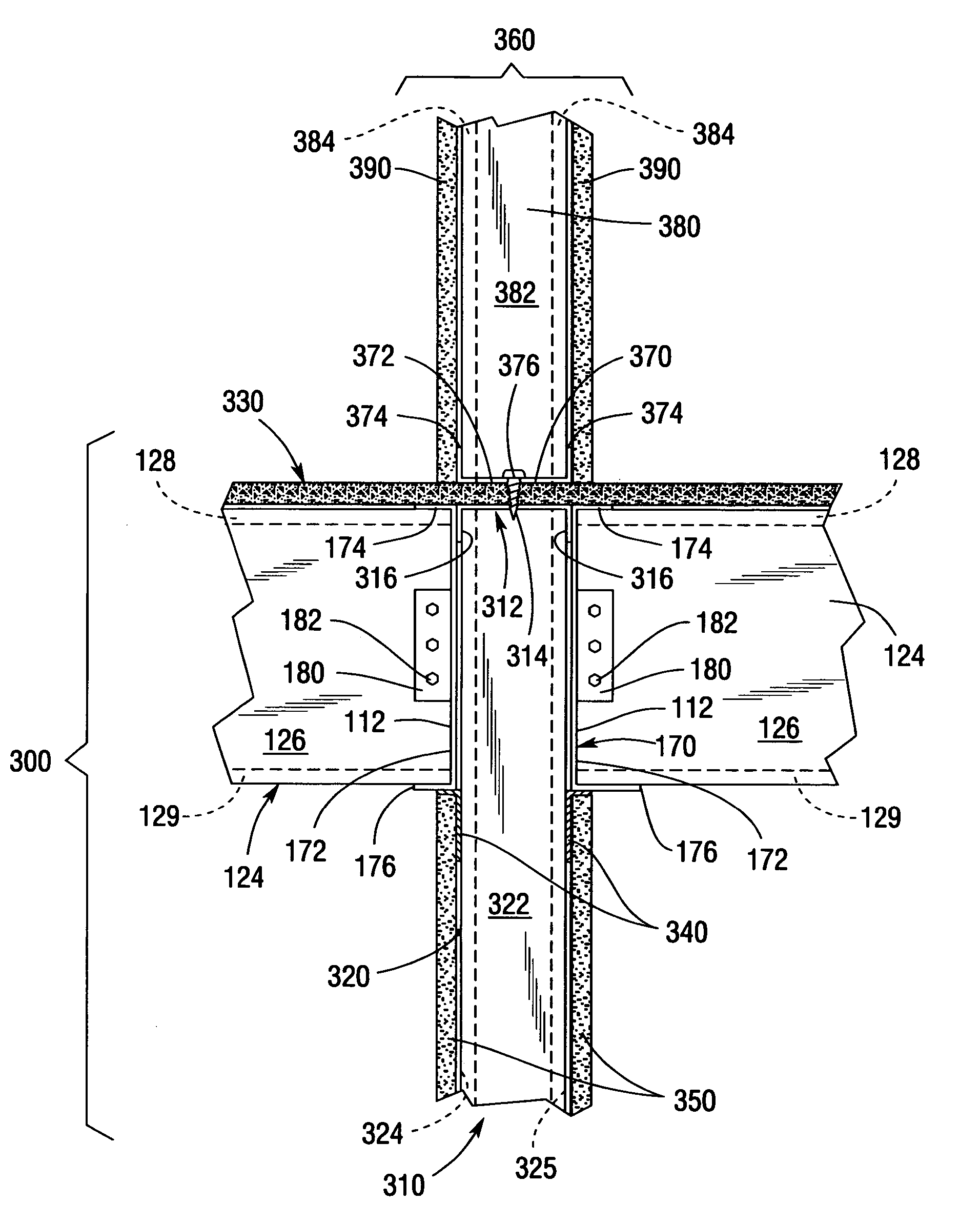

Concrete and light gauge cold formed steel building structure with beam and floor extending over a load bearing stud wall and method of forming

A series of spaced-apart light gauge cold formed steel studs underlie an elongated light gauge cold formed steel channel or box. A series of joist supports are connected to the channel and a series of joists, formed of a light gauge cold formed steel, are connected to the joist supports and extend outwardly from the box. Decking is supported on the joist. Concrete is poured into the channel to form a reinforced header or beam, and concrete is also poured onto the decking to form a concrete floor. Together, the concrete floor and header form a monolithic concrete structure that enables the joist to be misaligned with studs.

Owner:THE STEEL NETWORK

Multipurpose concrete anchor clip

ActiveUS9091056B2Reduce consumptionAvoid serious wasteWallsBuilding reinforcementsMaterial consumptionEngineering

Owner:SIMPSON STRONG TIE

Building construction systems and methods

Various building components and building construction techniques are disclosed. One embodiment comprises a joist end bearing condition wherein a joist rim is supported on a support structure adjacent to a bearing wall and attached thereto. Joists are attached to the joist rim and noncombustible board may be supported on the joists to form a floor surface. Other embodiments include metal joist rims that also function as headers for walls and headers for window and door openings in walls. Various methods of constructing walls from prefabricated panels formed from cold-formed steel components are also disclosed.

Owner:DIETRICH IND

Cold-formed steel joists

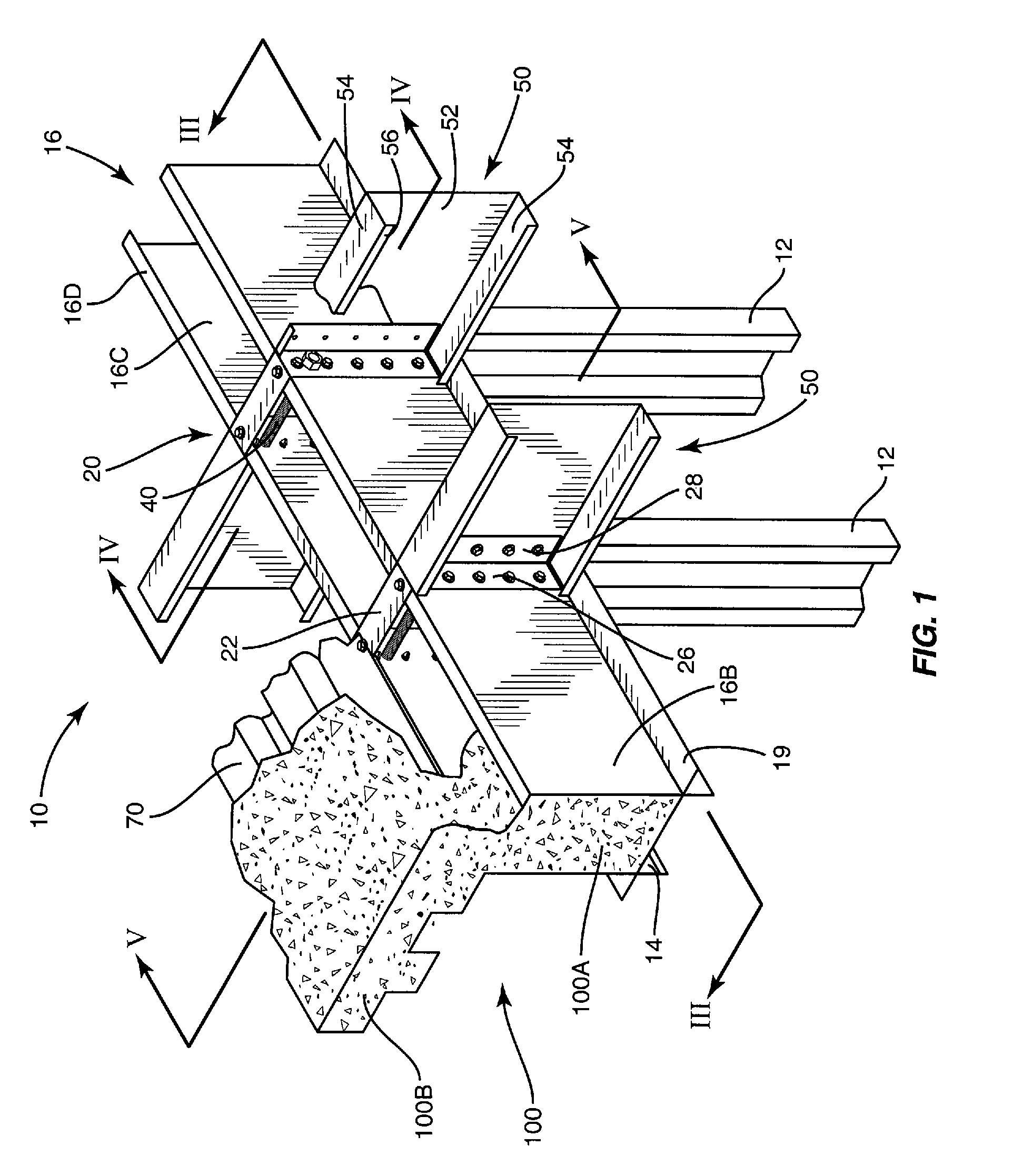

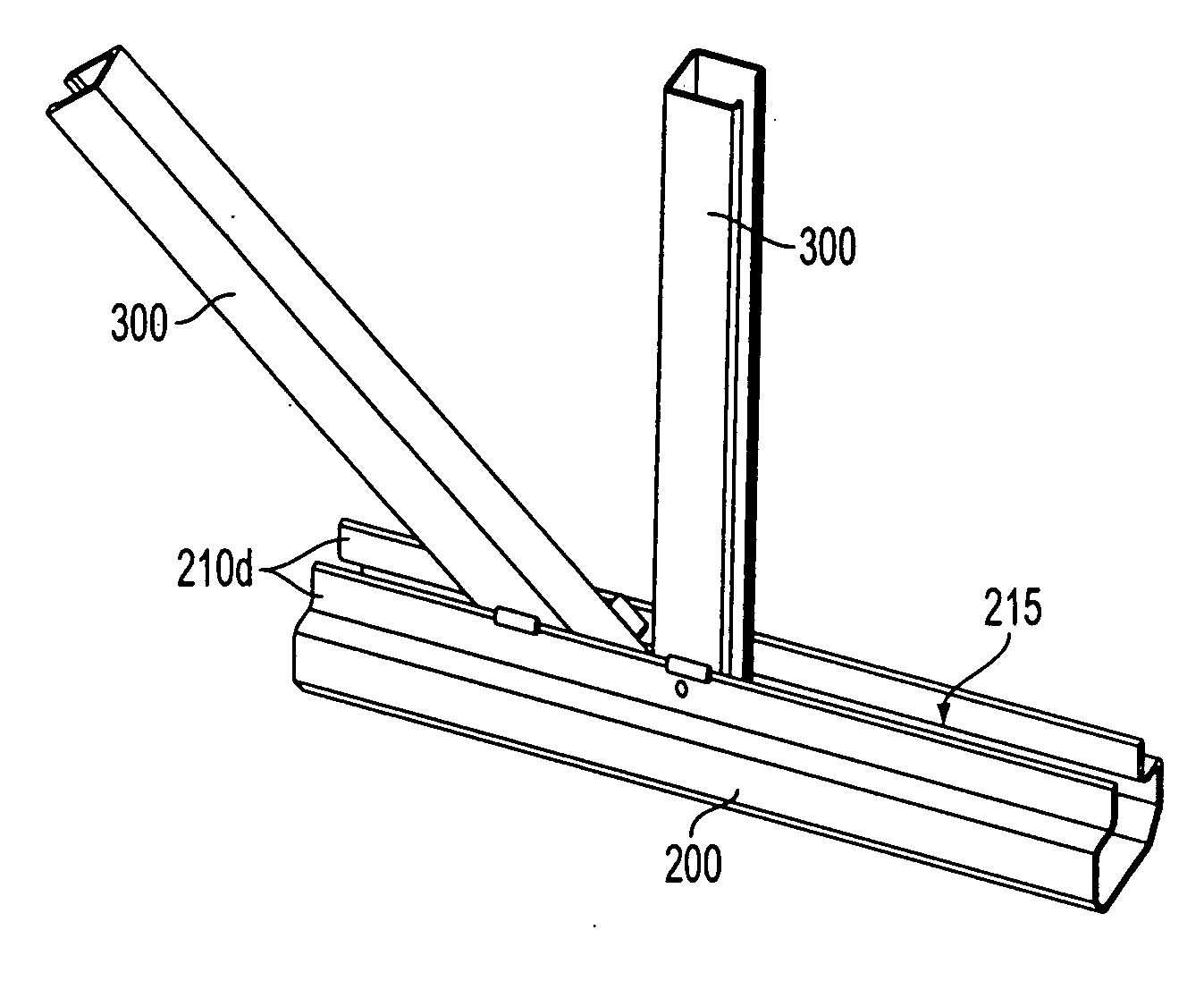

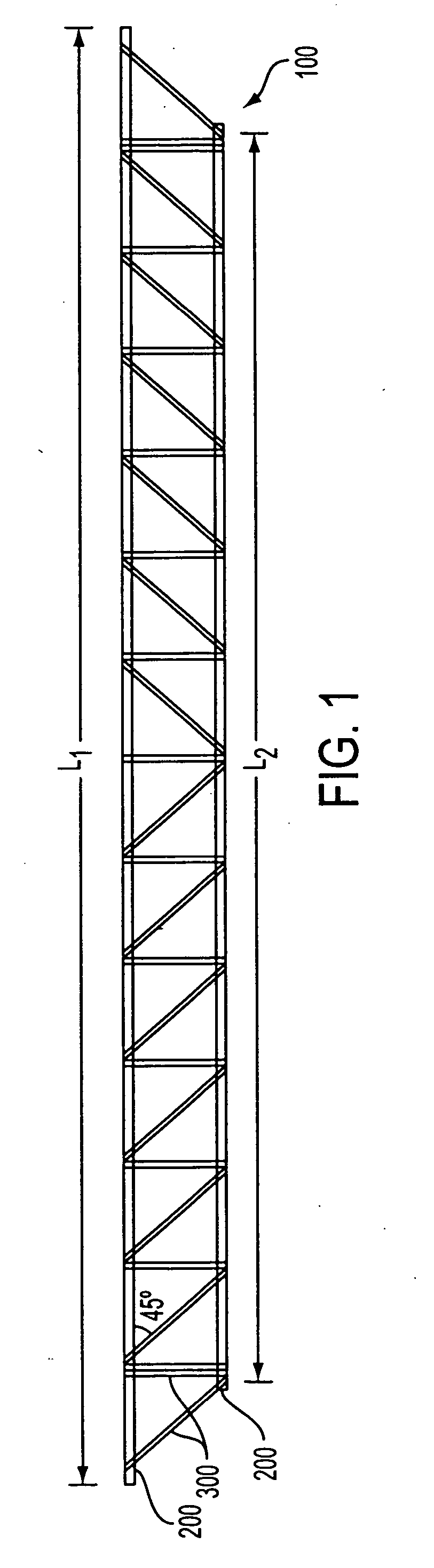

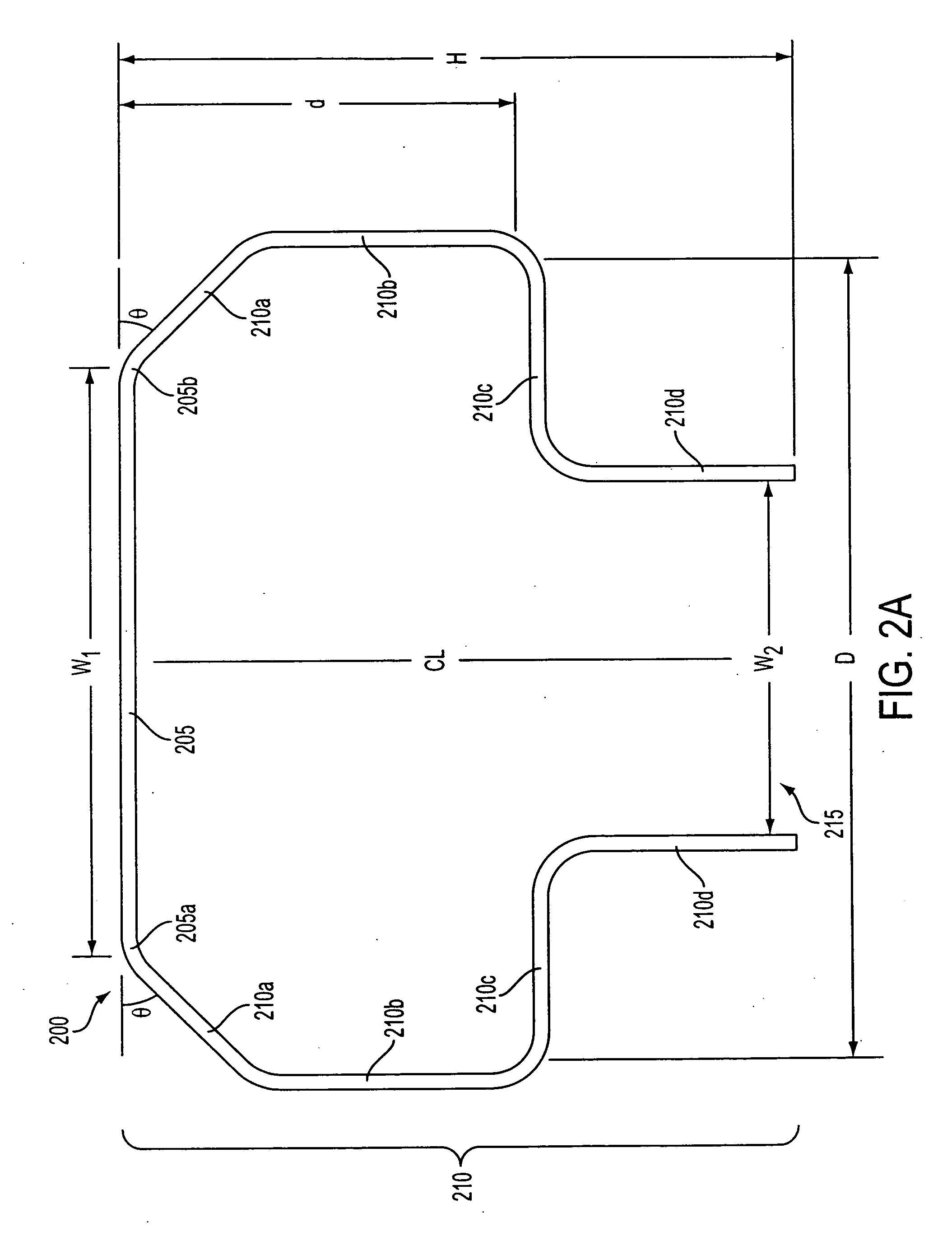

A metallic joist is provided comprising cold-formed top and bottom chords, and cold-formed metallic truss web members arranged in a vertical and diagonal fashion shop welded to the chords. End connections, or “seats” are each shop welded to the top chord and to one of the webs. Each seat comprises a pair of vertical metallic planes that act as shear plates, welded to and extending outwardly and upwardly of the end portion of the top chord of the joist, and portions extending horizontally either side of the chord and punched with holes for easy field bolting to beams or other supporting elements. Each of the chords comprises a planar base and a pair of legs. Each leg comprises a chamfered portion extending downward and outward from one edge of the base at an acute angle to the horizontal; e.g., about 45 degrees, for stiffening the longitudinal edges of the base, to accommodate axial and moment forces. An upper vertical portion, perpendicular to the base, extends downward from a lower end of the chamfered portion to provide a planar width of material to accommodate axial and moment forces. An inwardly recessed portion parallel to the base extends towards the chord's center line from a lower end of the upper vertical portion; and an attachment portion, perpendicular to the base, extends downward from an inner end of the inwardly recessed portion. The inventive chord imparts the joist of the present invention with enough strength and stiffness to span up to 100-foot lengths.

Owner:WATSON DENNISP +2

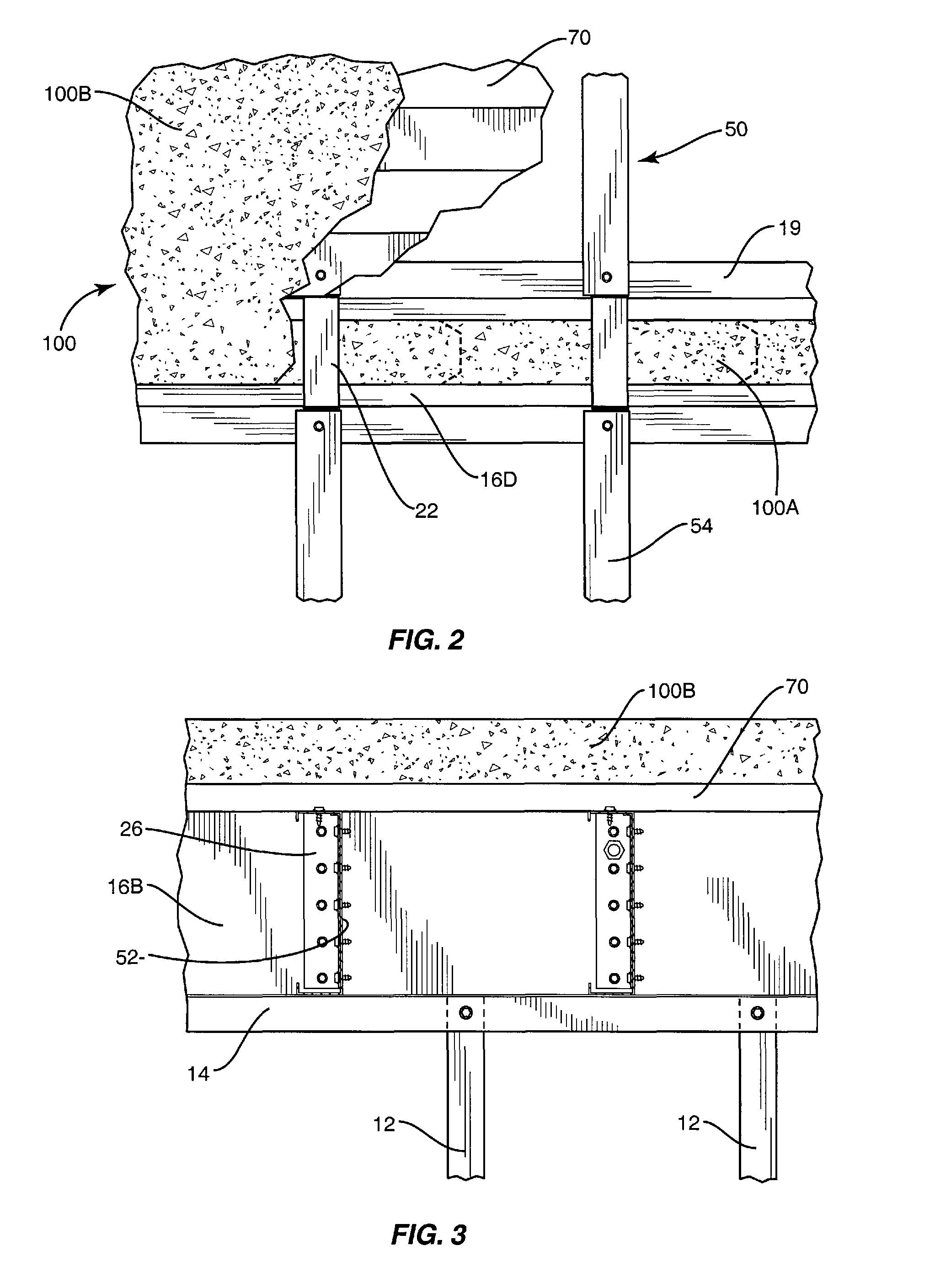

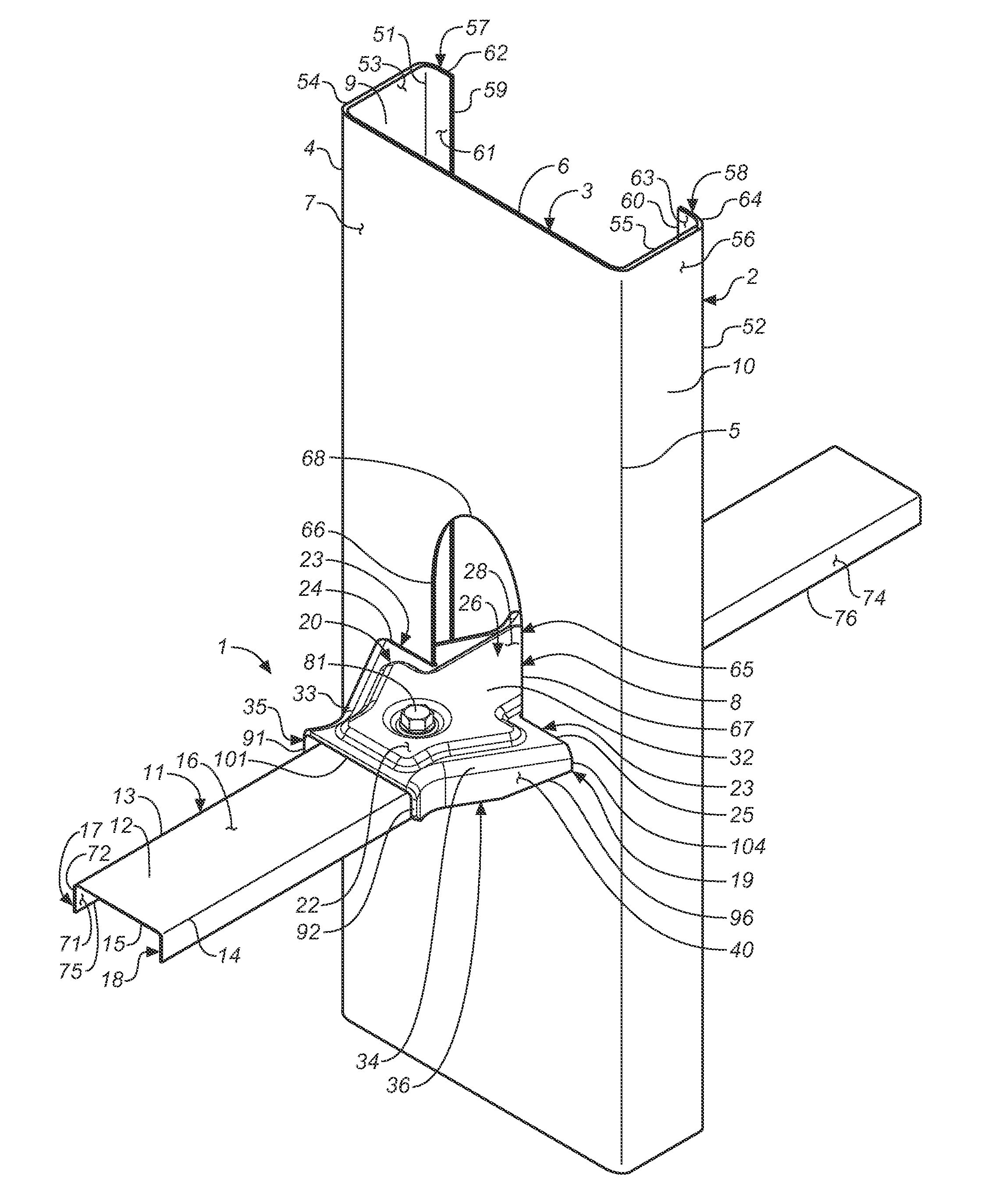

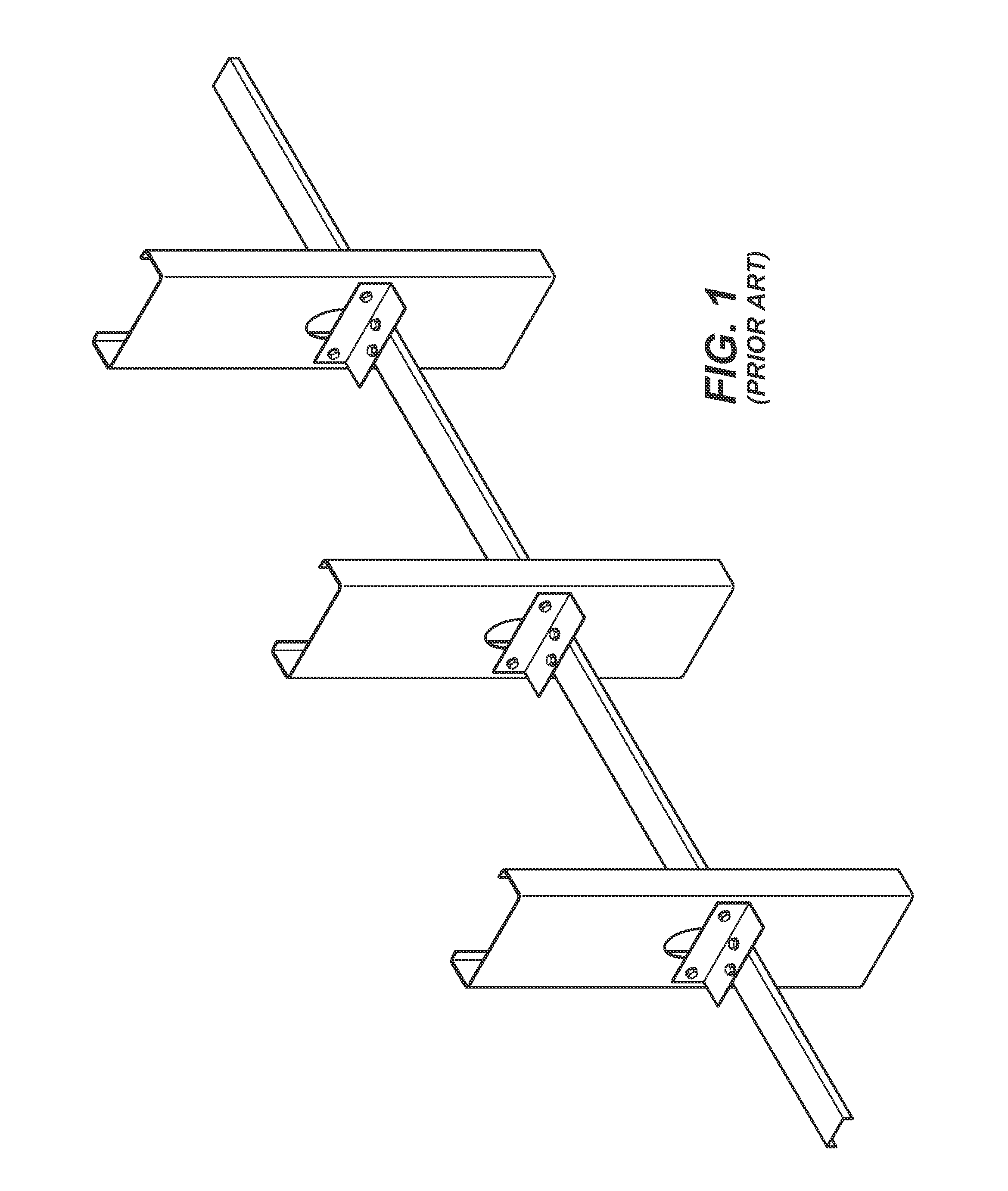

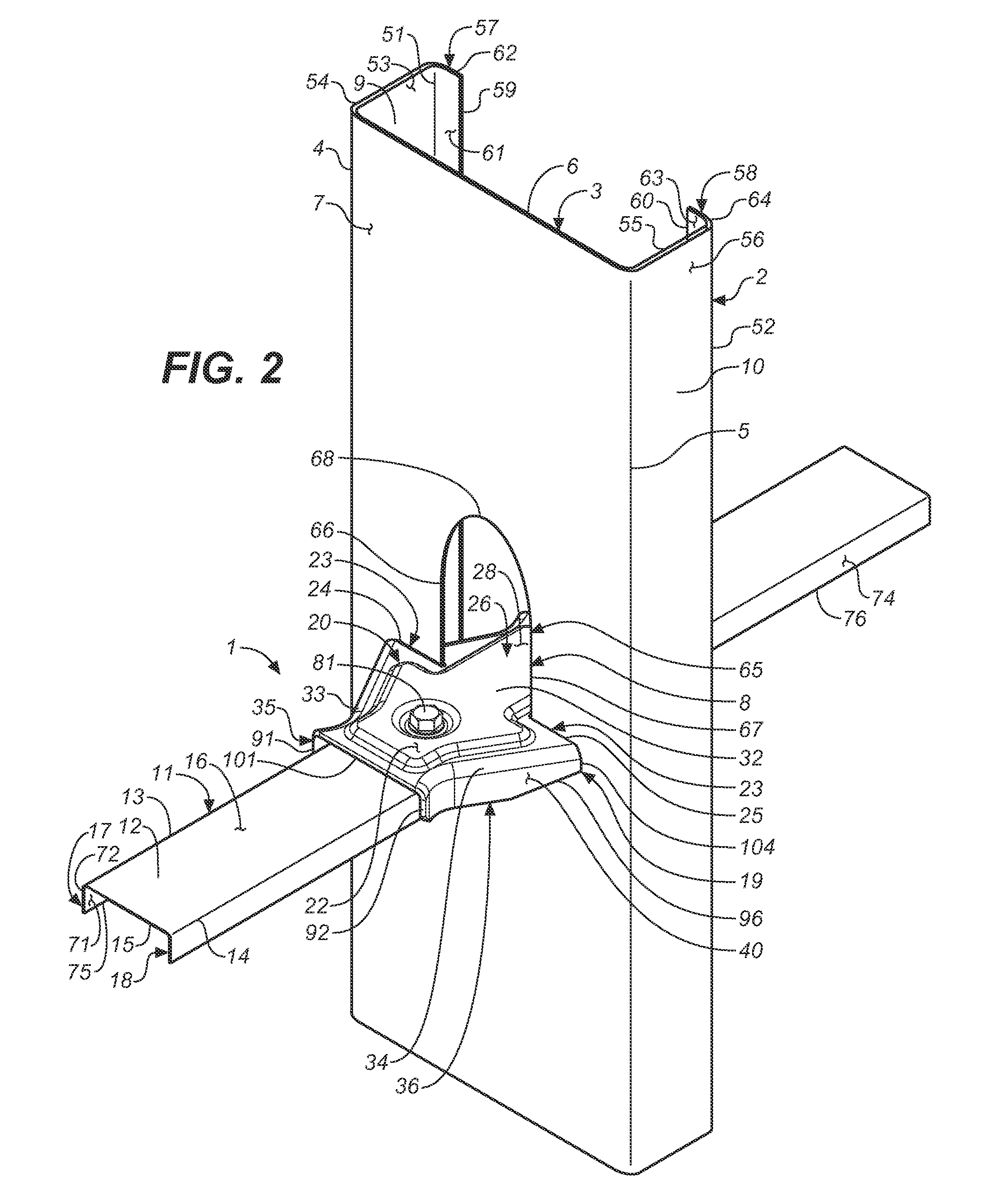

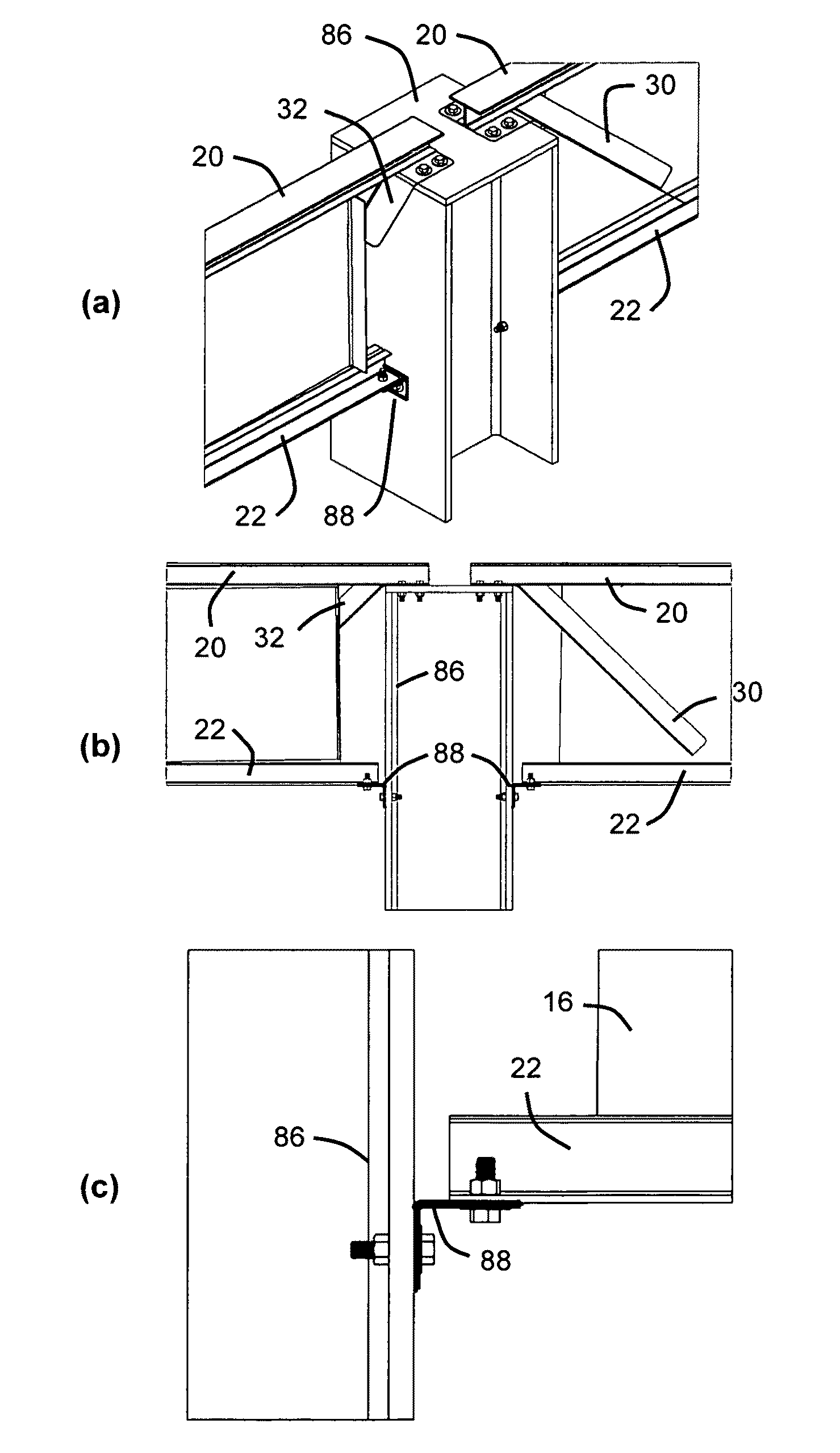

Bridging connector

ActiveUS20130104490A1Torsional rigidityExceptional strengthCeilingsCovering/liningsWall studPilaster

A building connection between a substantially vertical wall stud and a substantially horizontal bridging member, using a separate and distinct bridging connector that attaches the wall stud to the bridging member. The wall stud is typically one of several sequentially-arranged, cold-formed steel studs in the frame of a building wall. The bridging member is typically a separate cold-formed steel member that interfaces with and spans a plurality of wall studs.

Owner:SIMPSON STRONG TIE

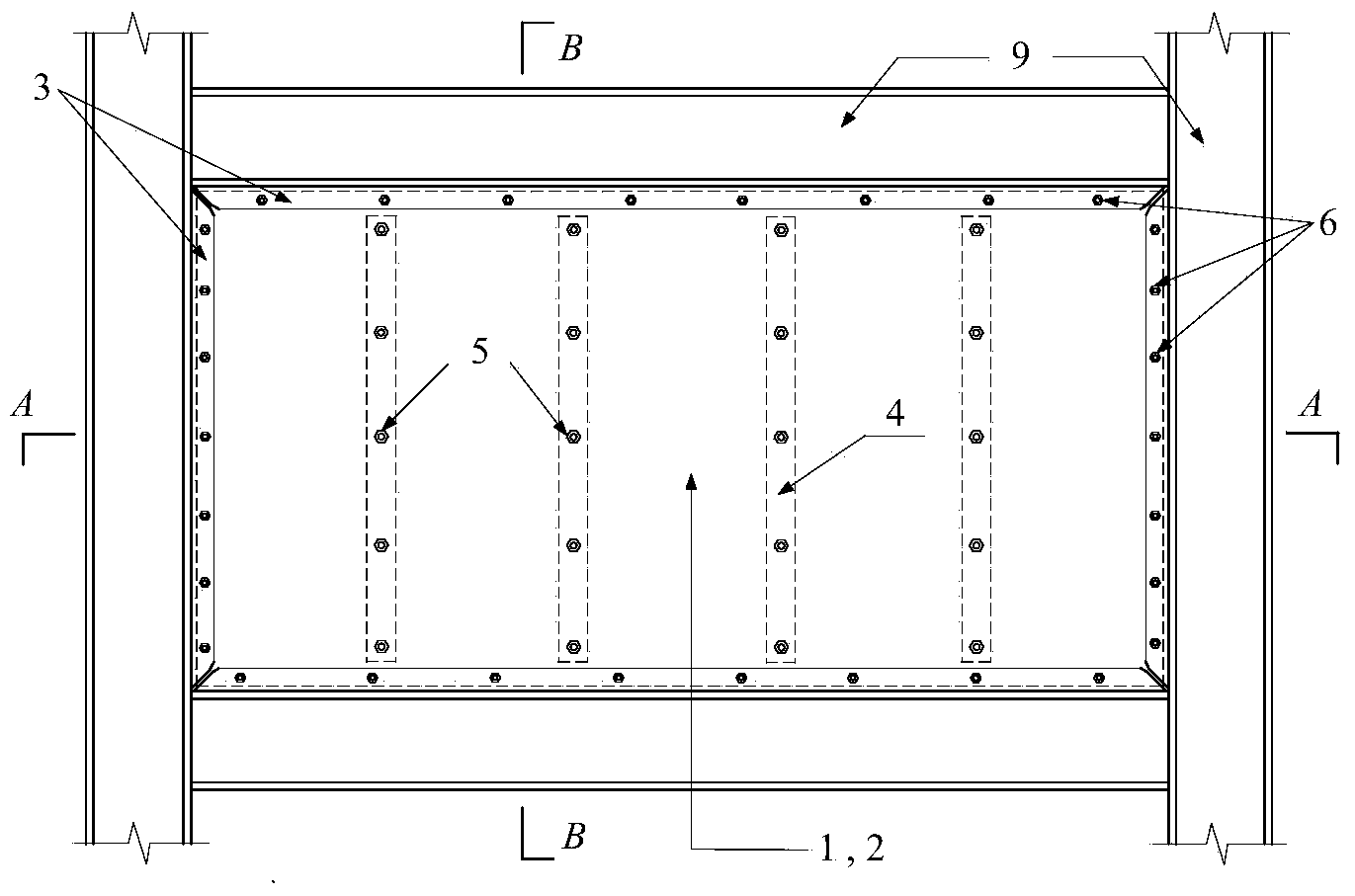

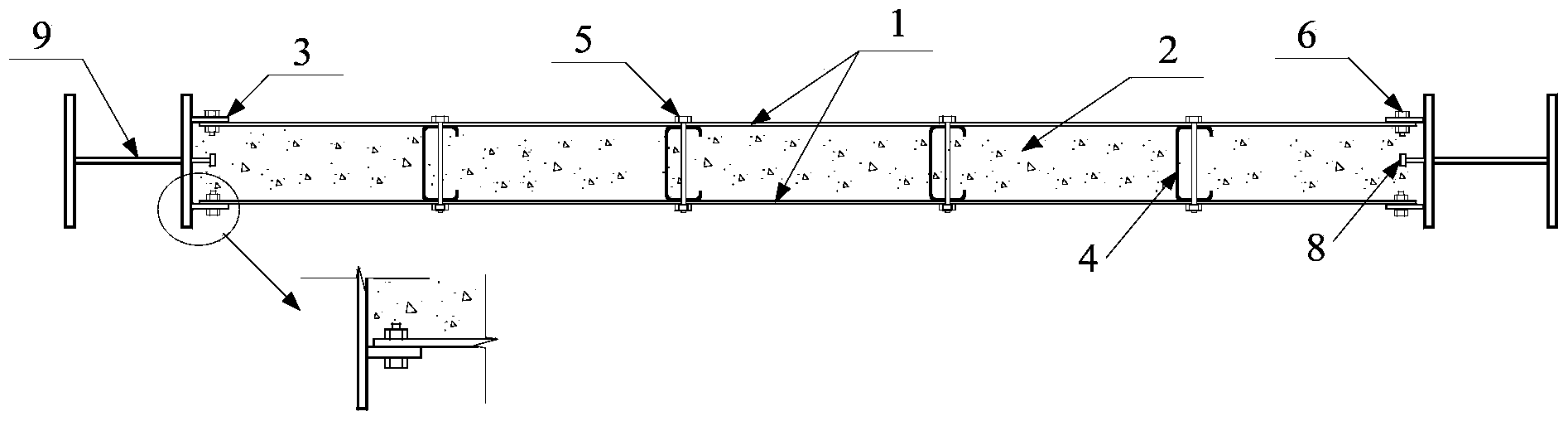

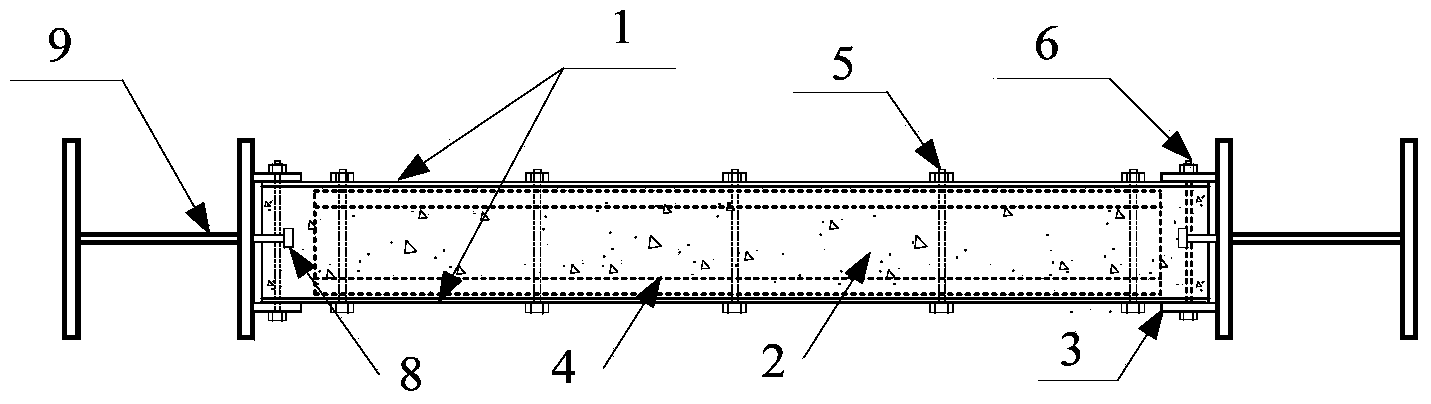

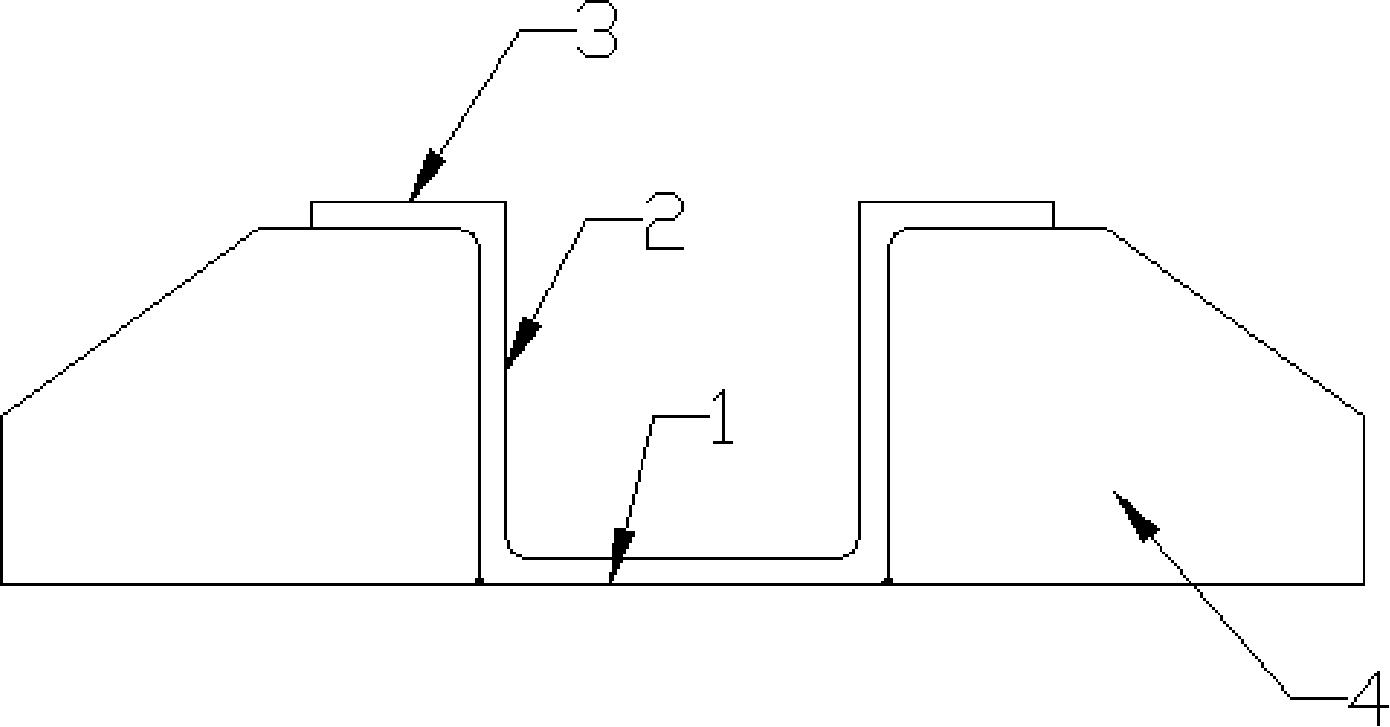

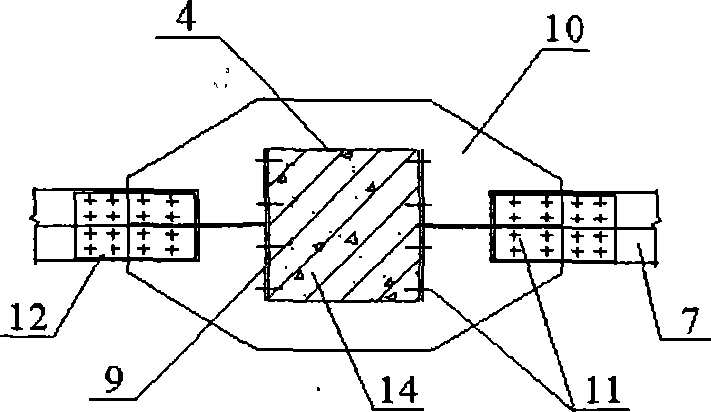

Internal stiffened composite steel plate shear wall connected through high-strength bolts

InactiveCN103410248AFull play to strengthenMake the most of the connectionWallsSheet steelReinforced concrete

The invention relates to an internal stiffened composite steel plate shear wall connected through high-strength bolts and belongs to the field of structural engineering. The composite steel plate shear wall is characterized by being composed of a dual-layer flat steel plate, concrete, stiffening section steels, high-strength bolts, connection steel plates and the like and being embedded in a peripheral frame. The stiffening section steels disposed along the height direction are arranged between two layers of steel plates of the dual-layer flat steel plate, the stiffening section steels and the dual-layer flat steel plates are fastened through the high-strength long-screw bolts applying pretension force, and the concrete is poured in cavities between the stiffening section steels and the dual-layer flat steel plates. The stiffening section steels are made of cold rolled section steels with C-shaped sections or rectangular sections or hot rolled section steel with groove-shaped sections or rectangular sections. If the peripheral frame is a steel frame, the dual-layer flat steel plate is connected with fishplates through friction type high-strength bolts, and then the fishplates are in welded connection with the peripheral frame. If the peripheral frame is a reinforced concrete frame, the dual-layer flat steel plate is connected with the connection steel plates through the friction type high-strength bolts, and shearing resistant studs are arranged on the connection steel plates and buried in the peripheral frame.

Owner:TSINGHUA UNIV

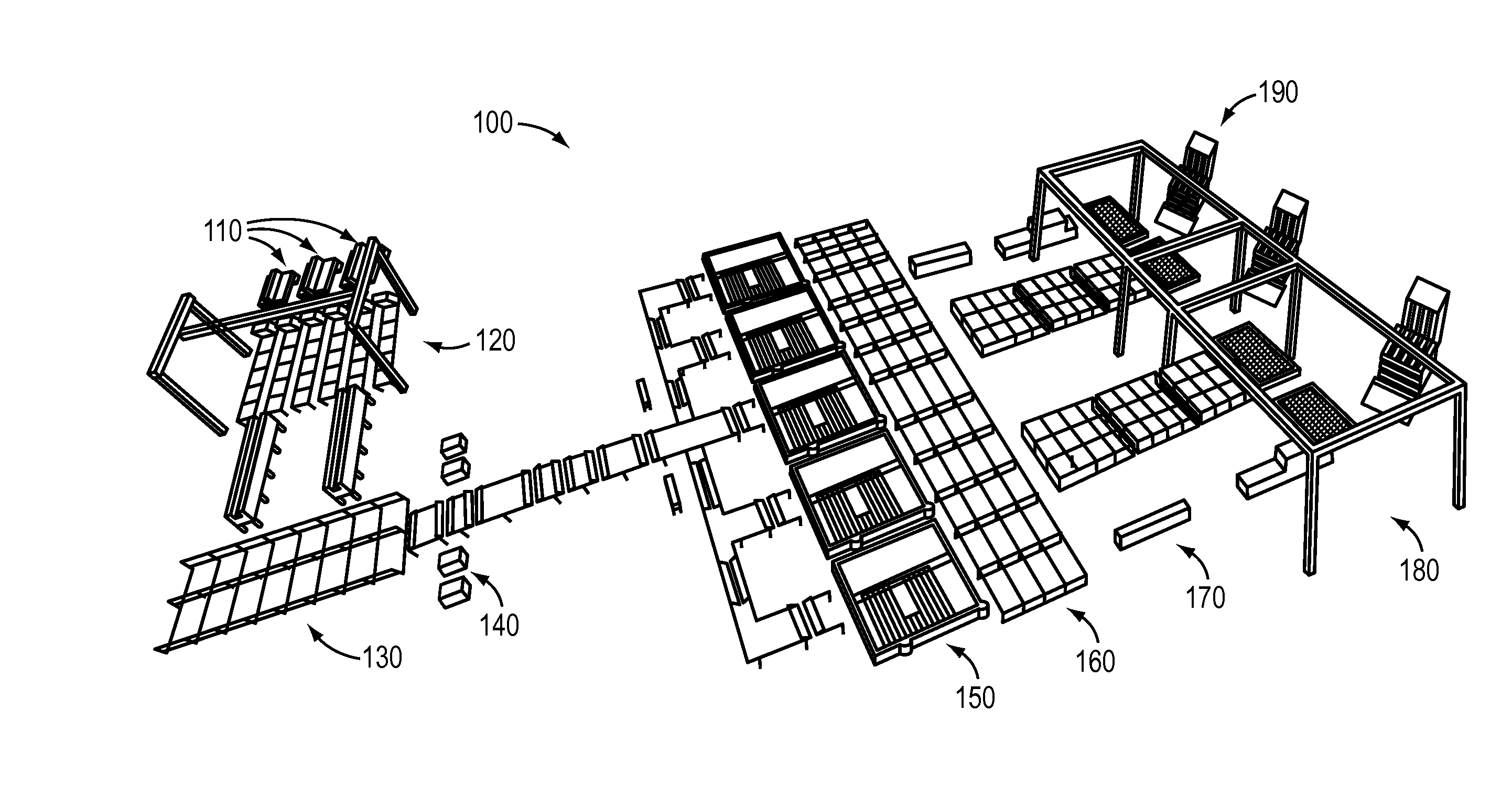

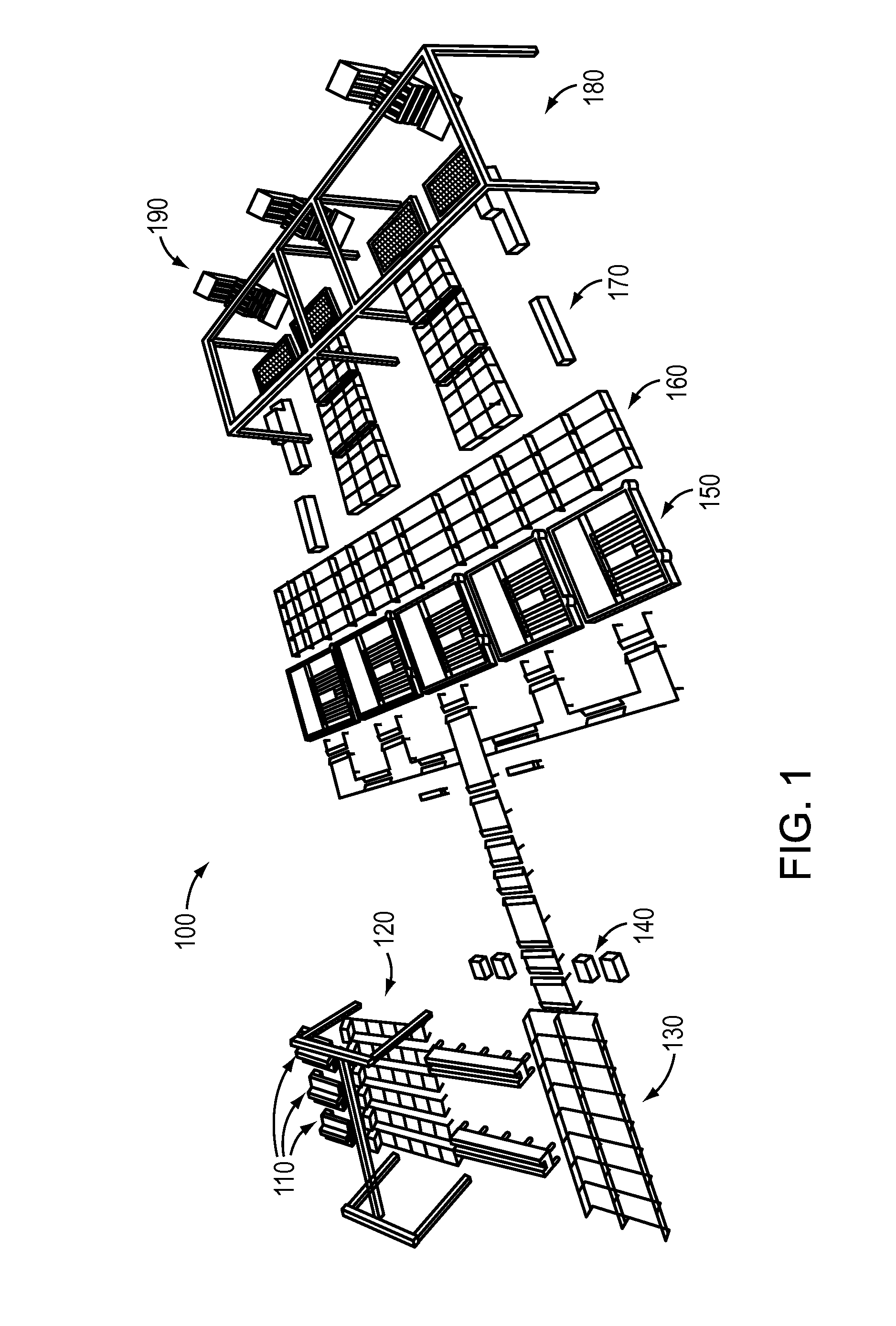

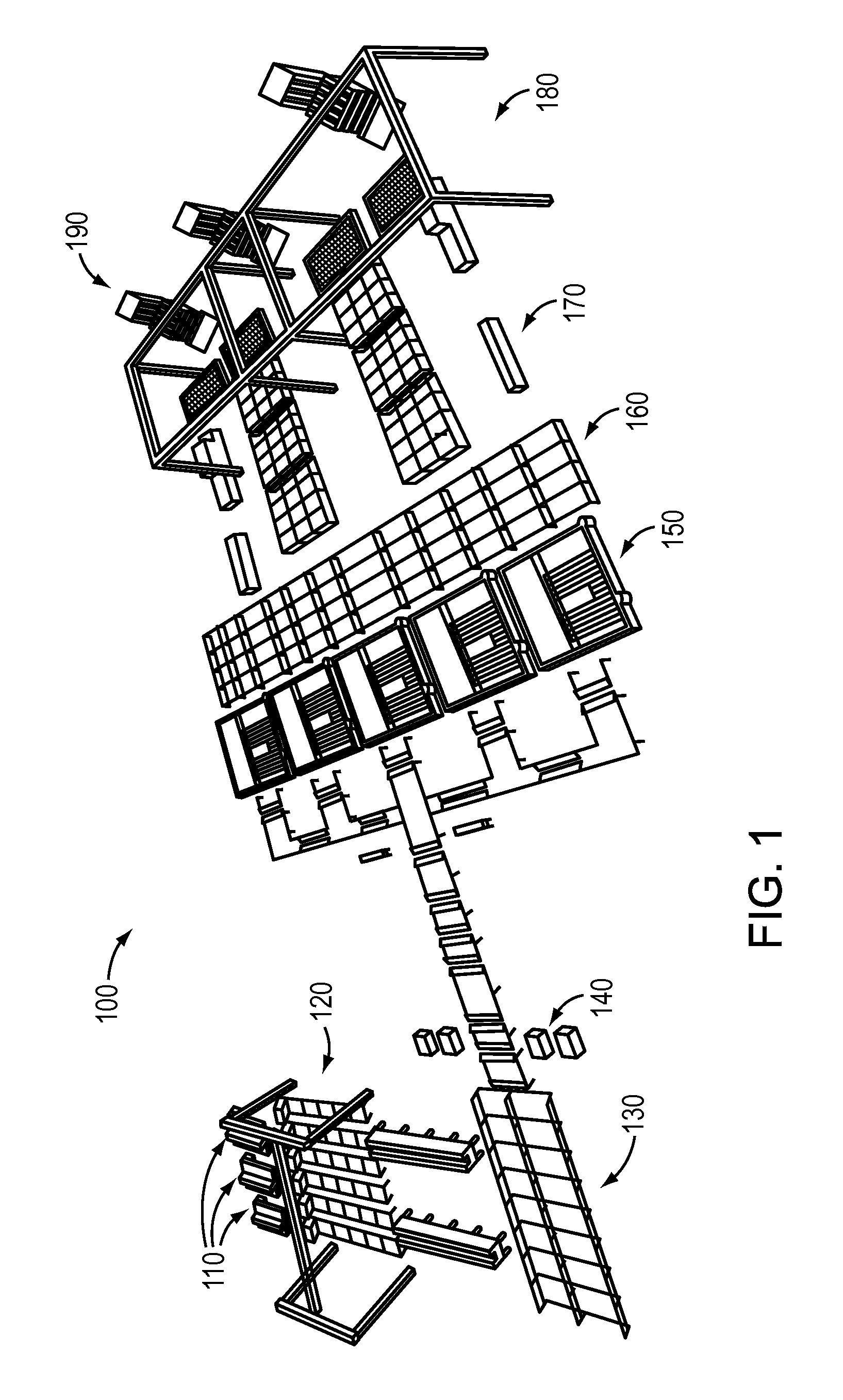

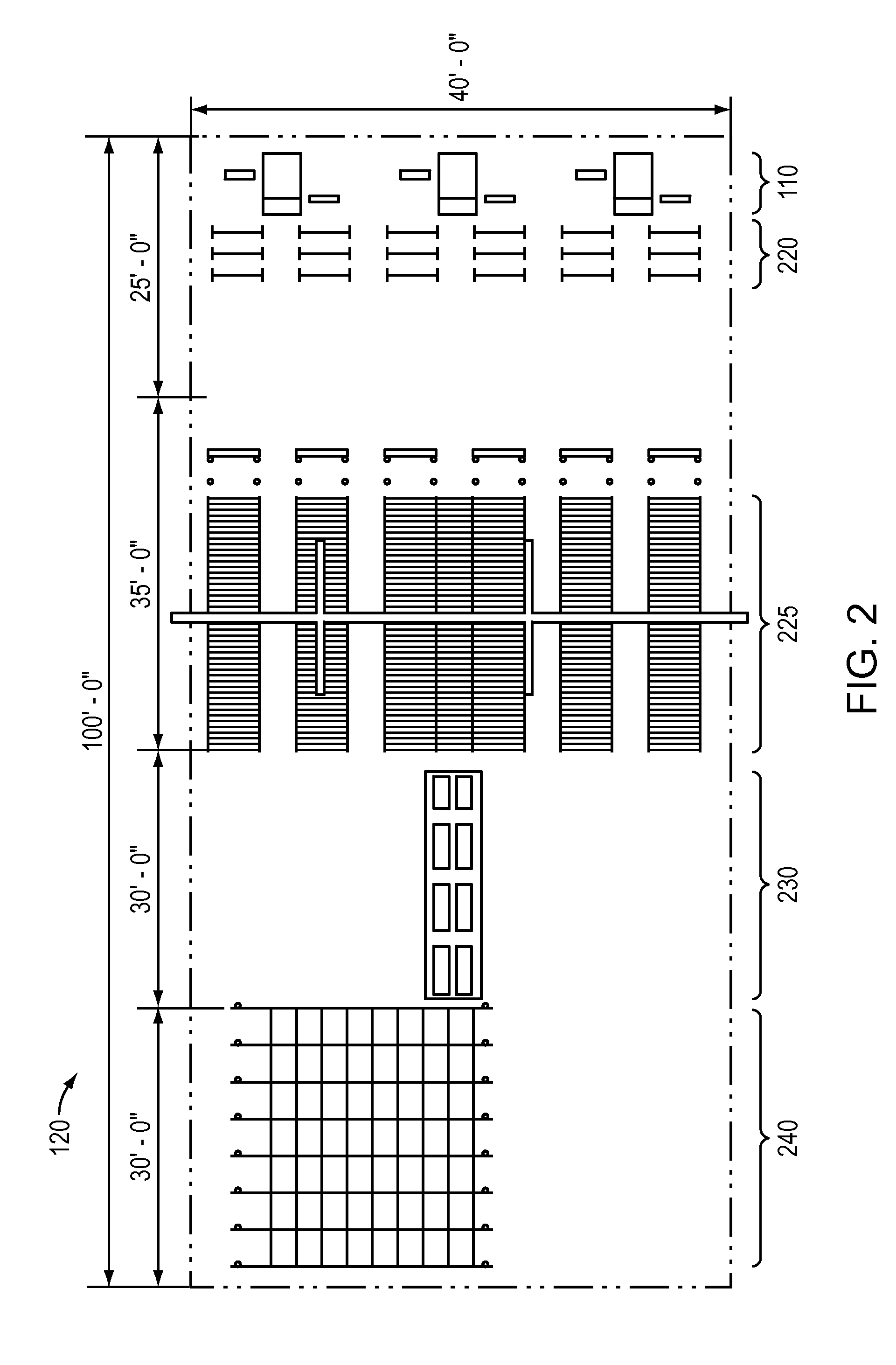

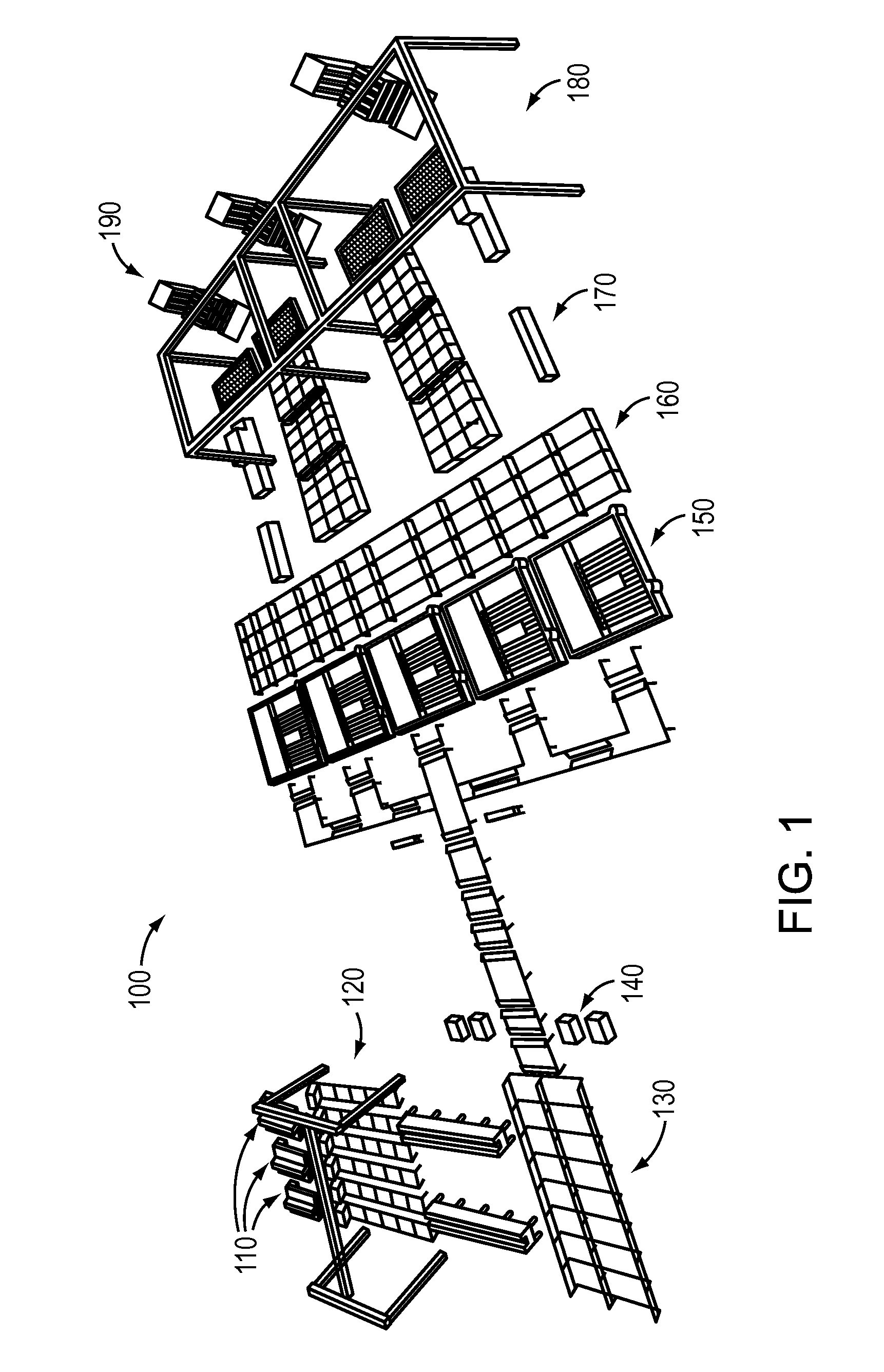

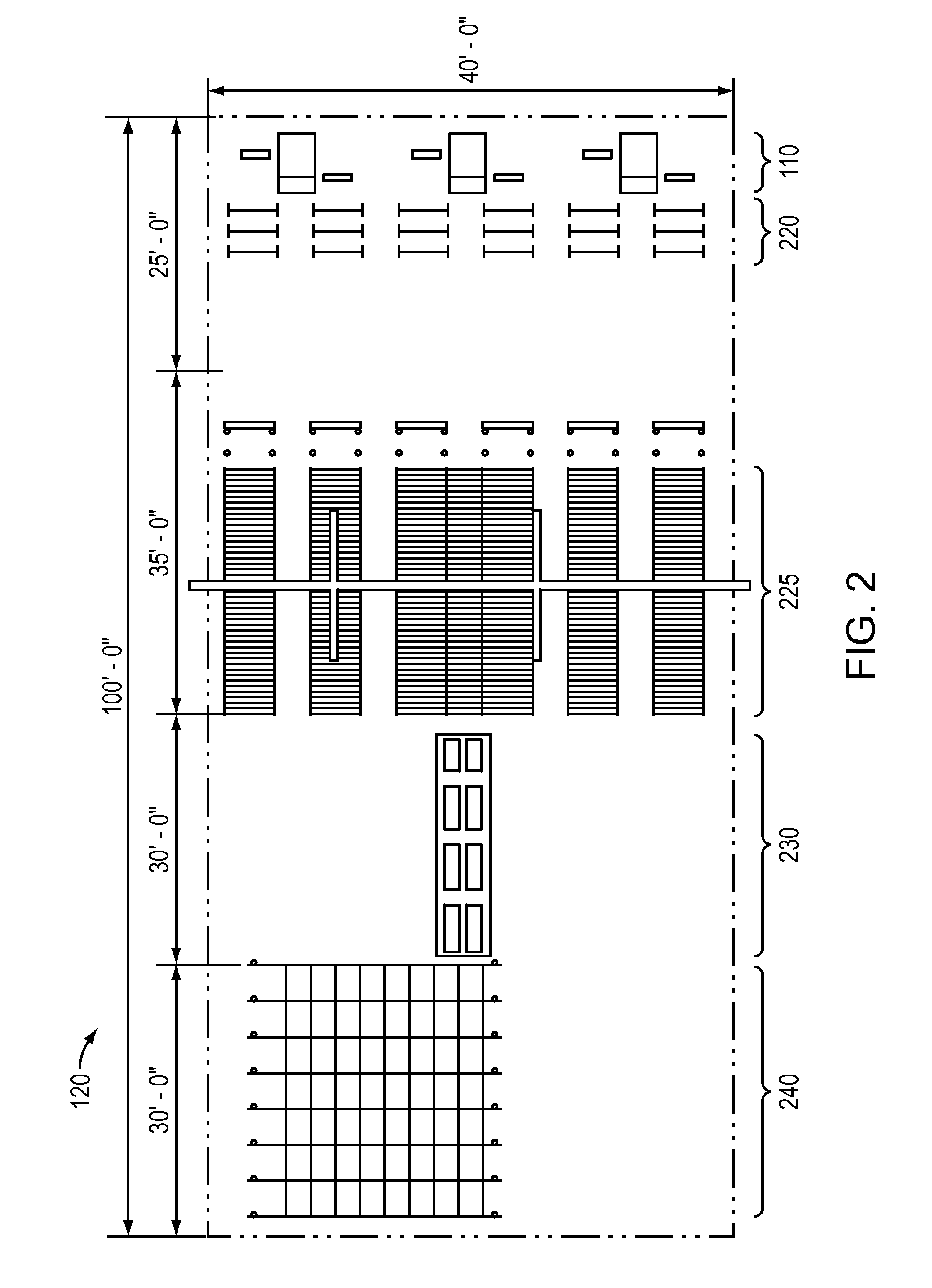

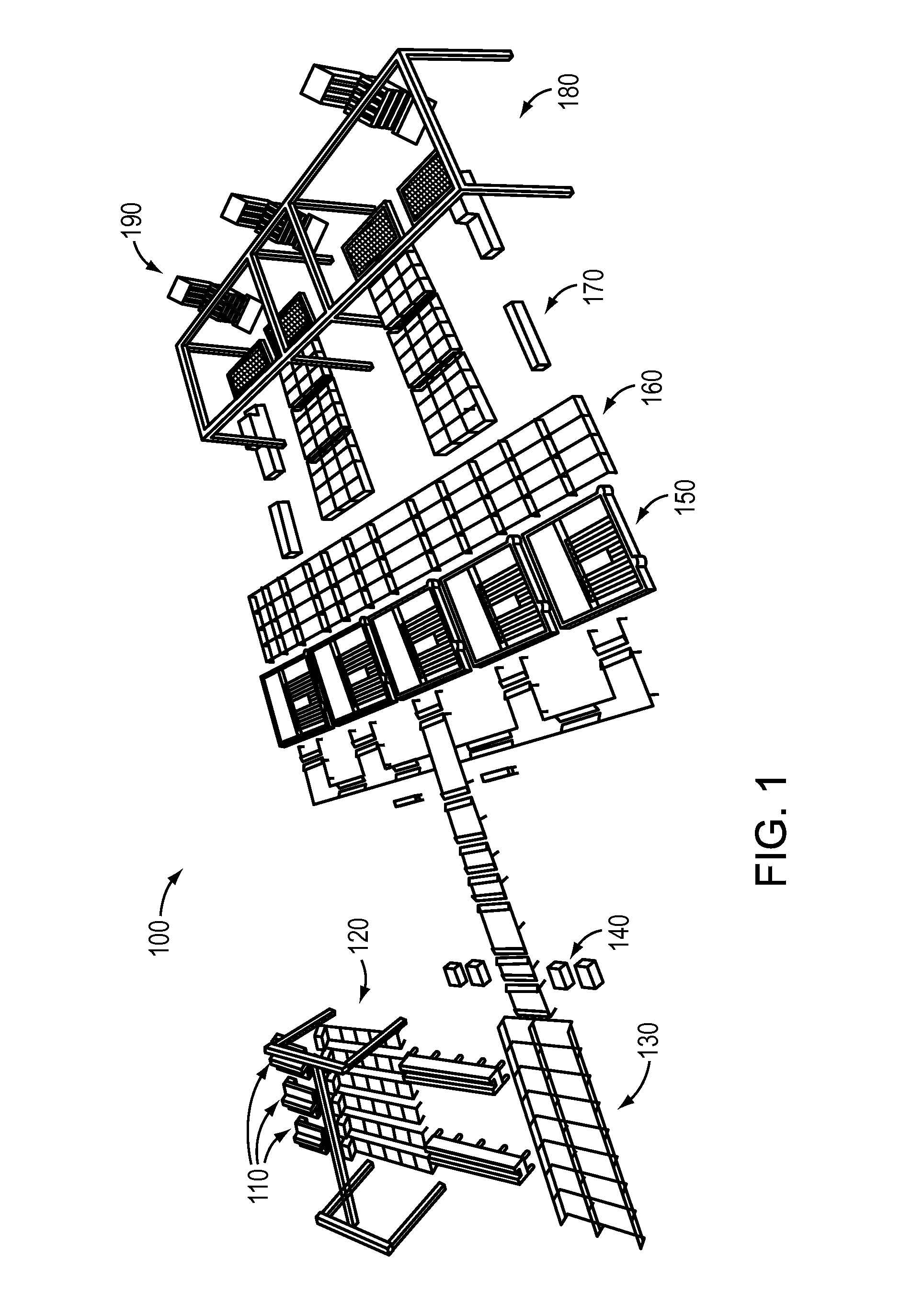

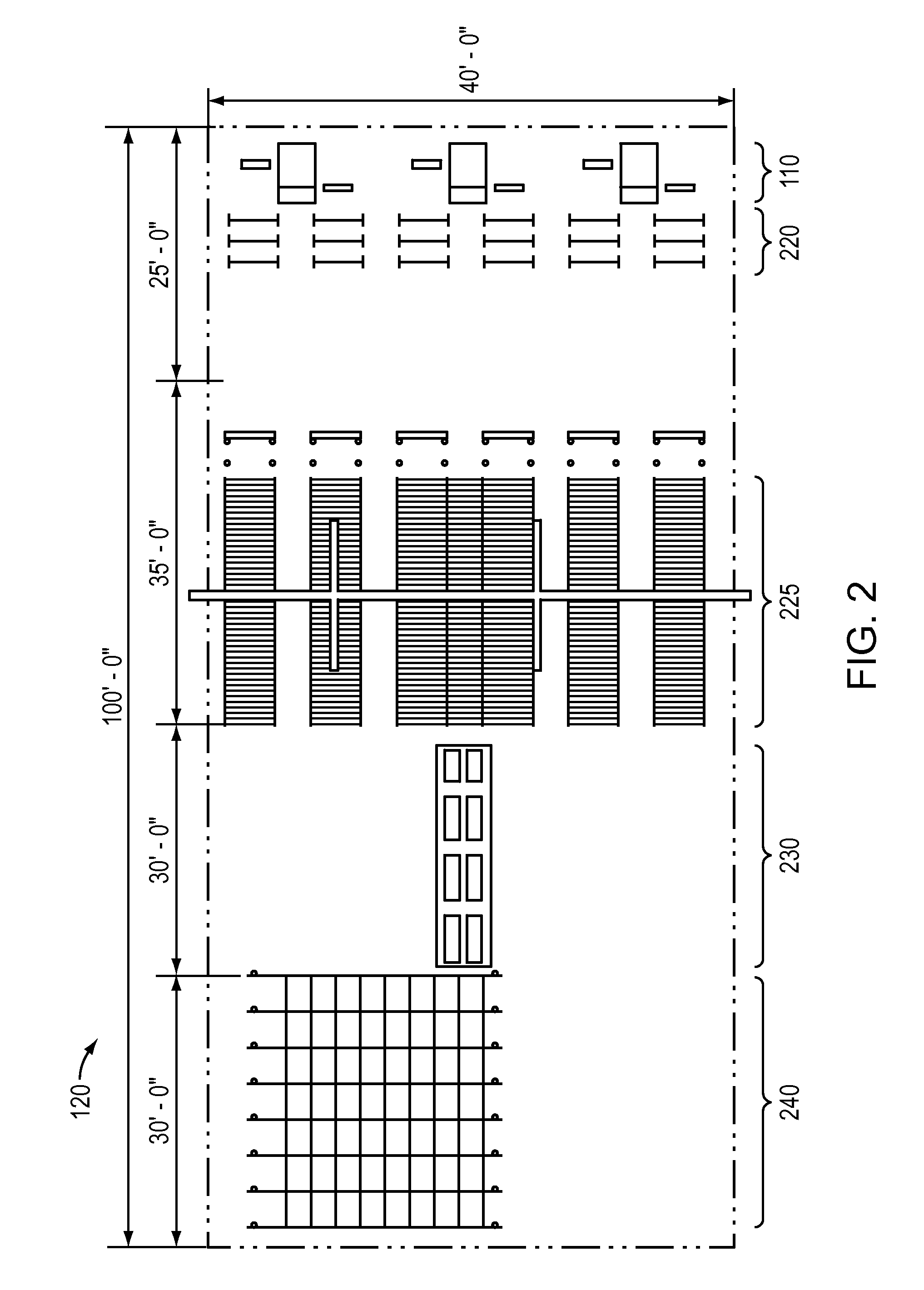

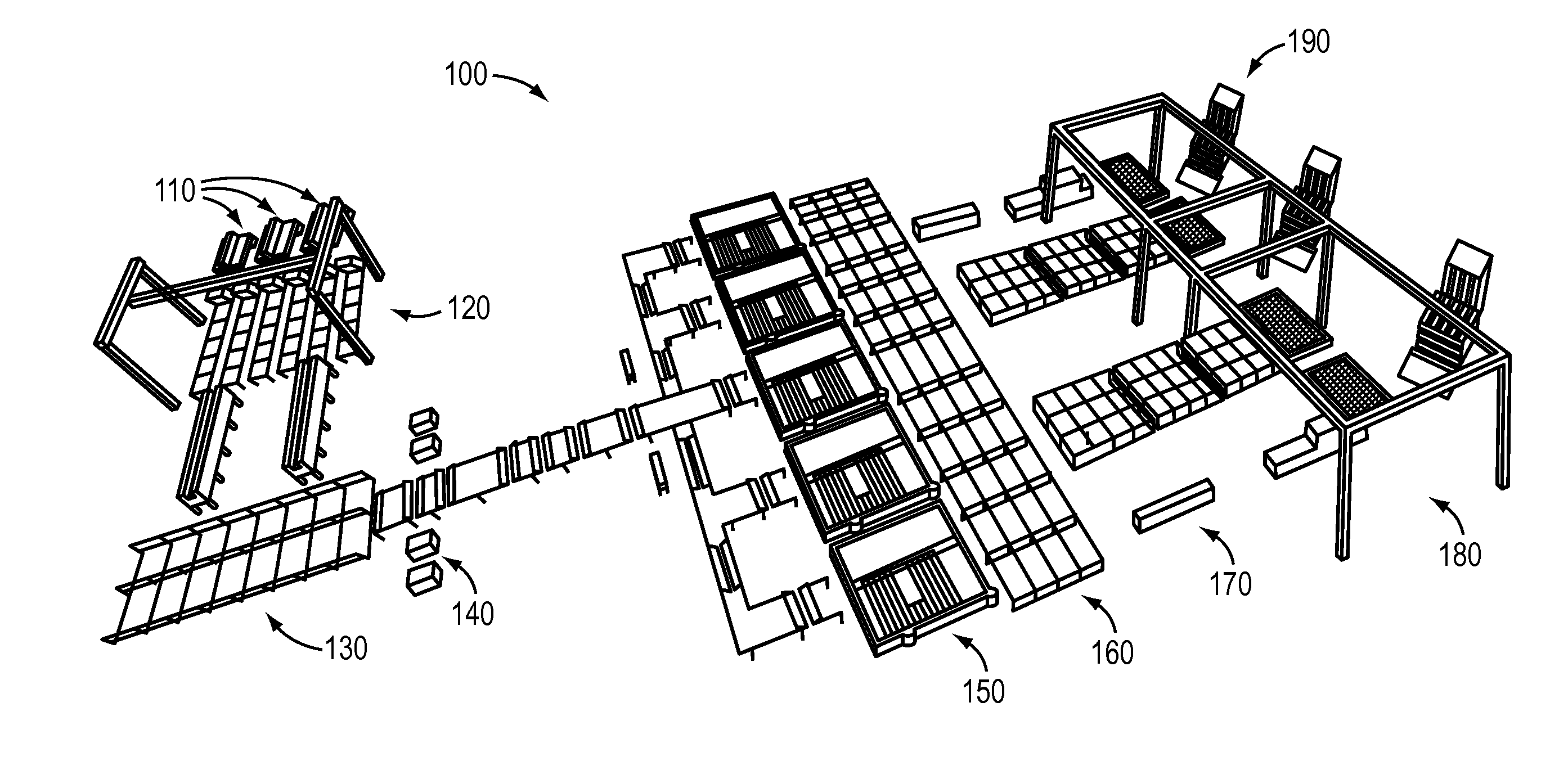

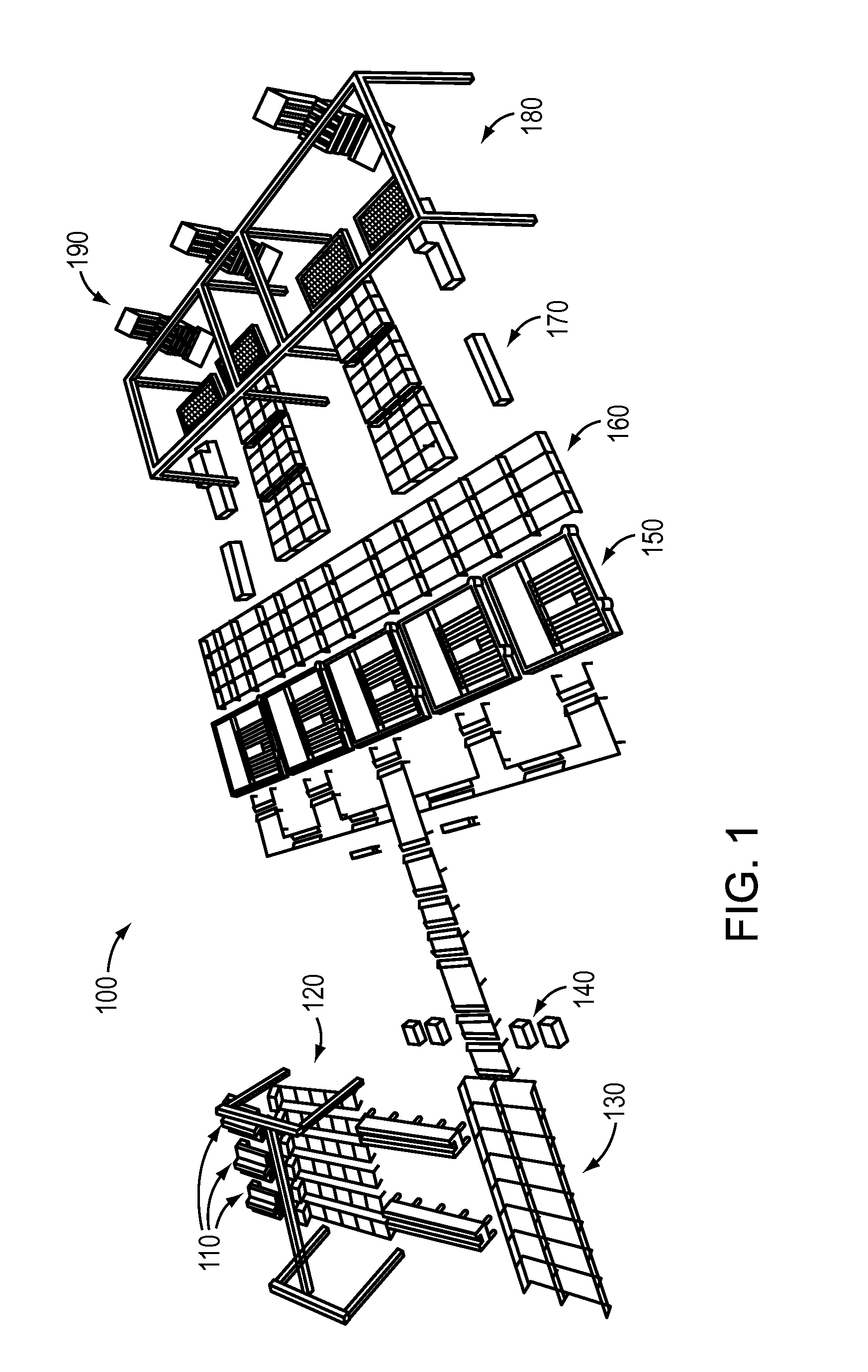

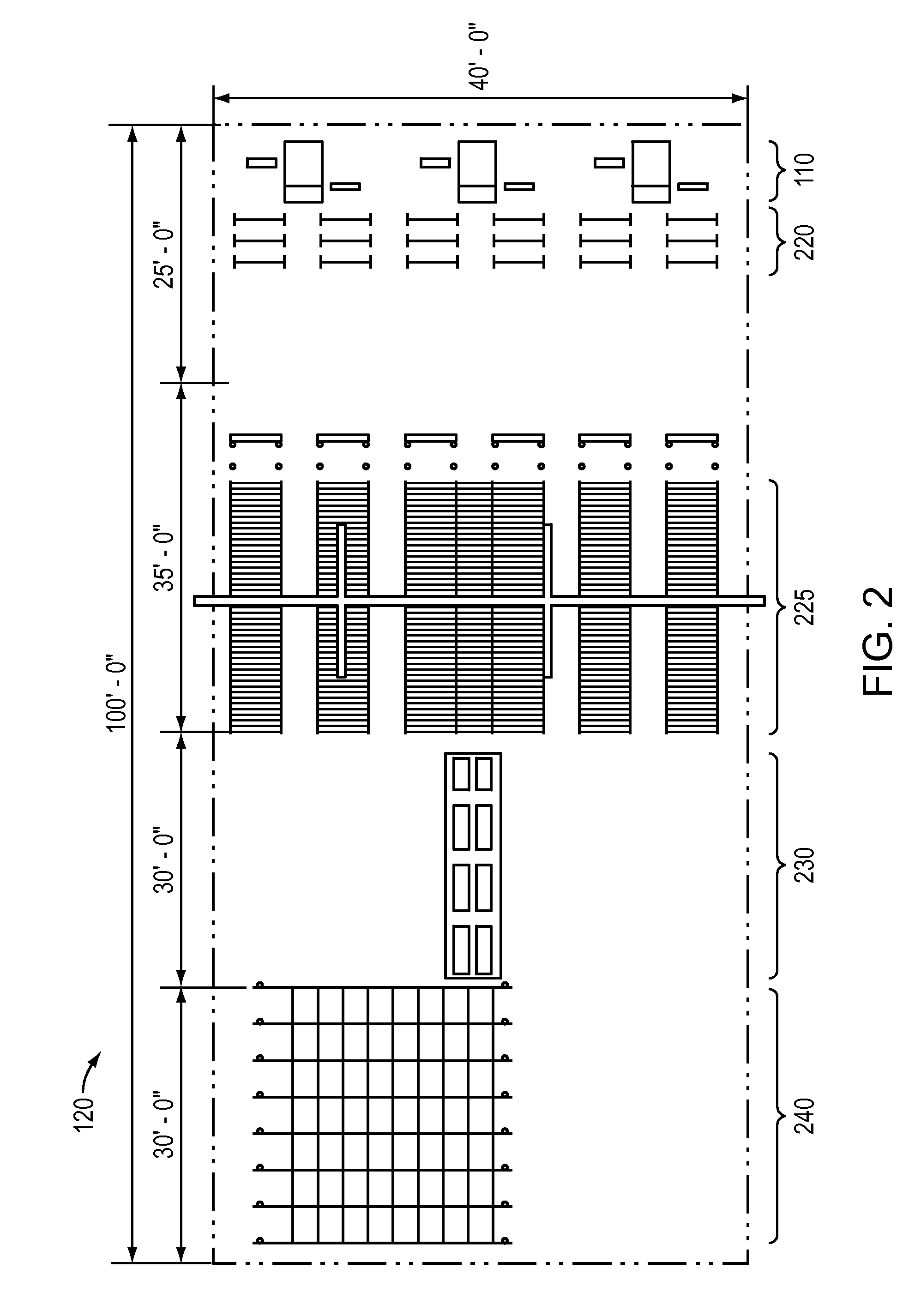

Framing table for building panel assembly

InactiveUS20070256391A1Transport is impairedImprove construction qualityAssembly machinesWire networkCold-formed steelBuilding construction

Owner:GENESISTP INC

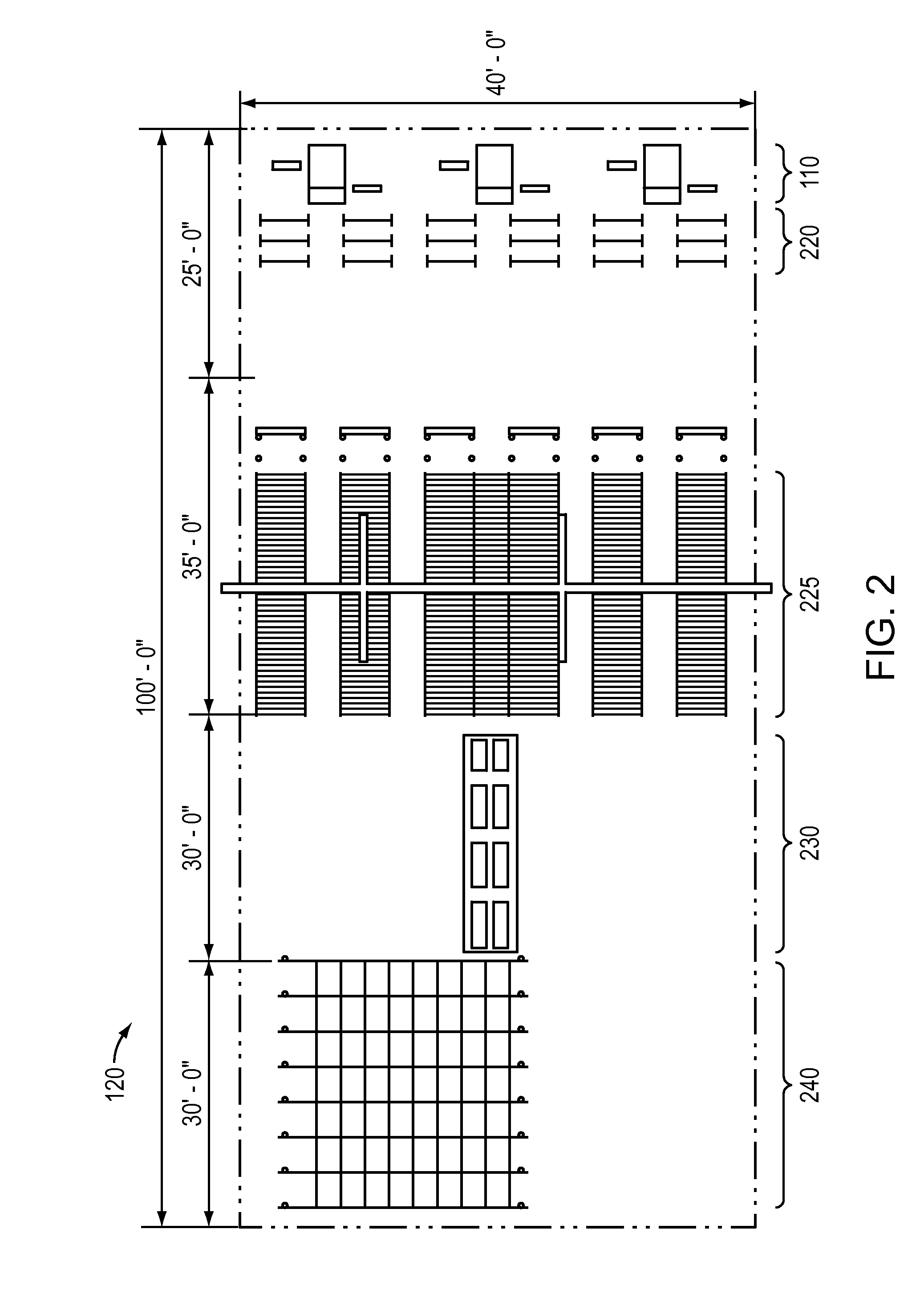

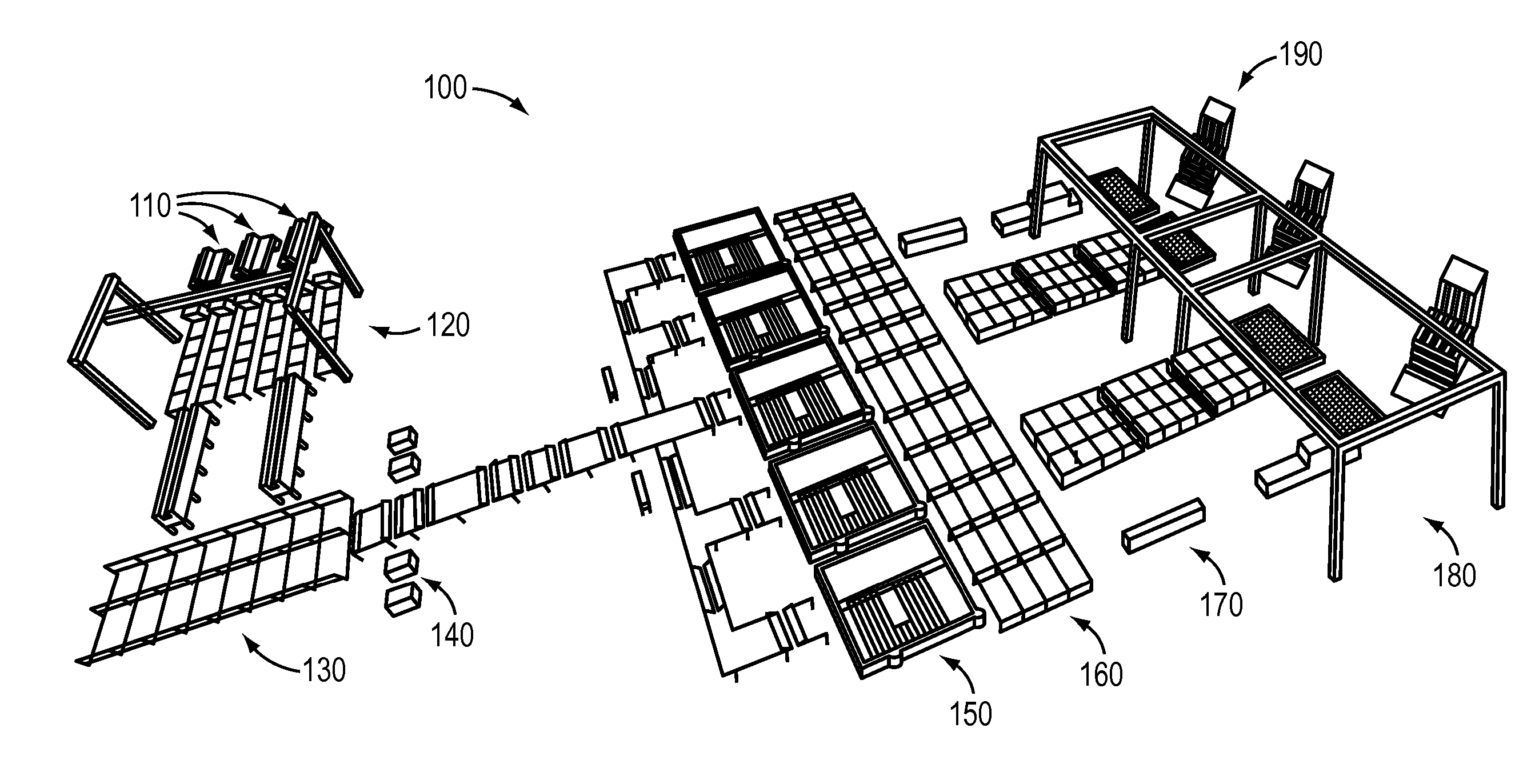

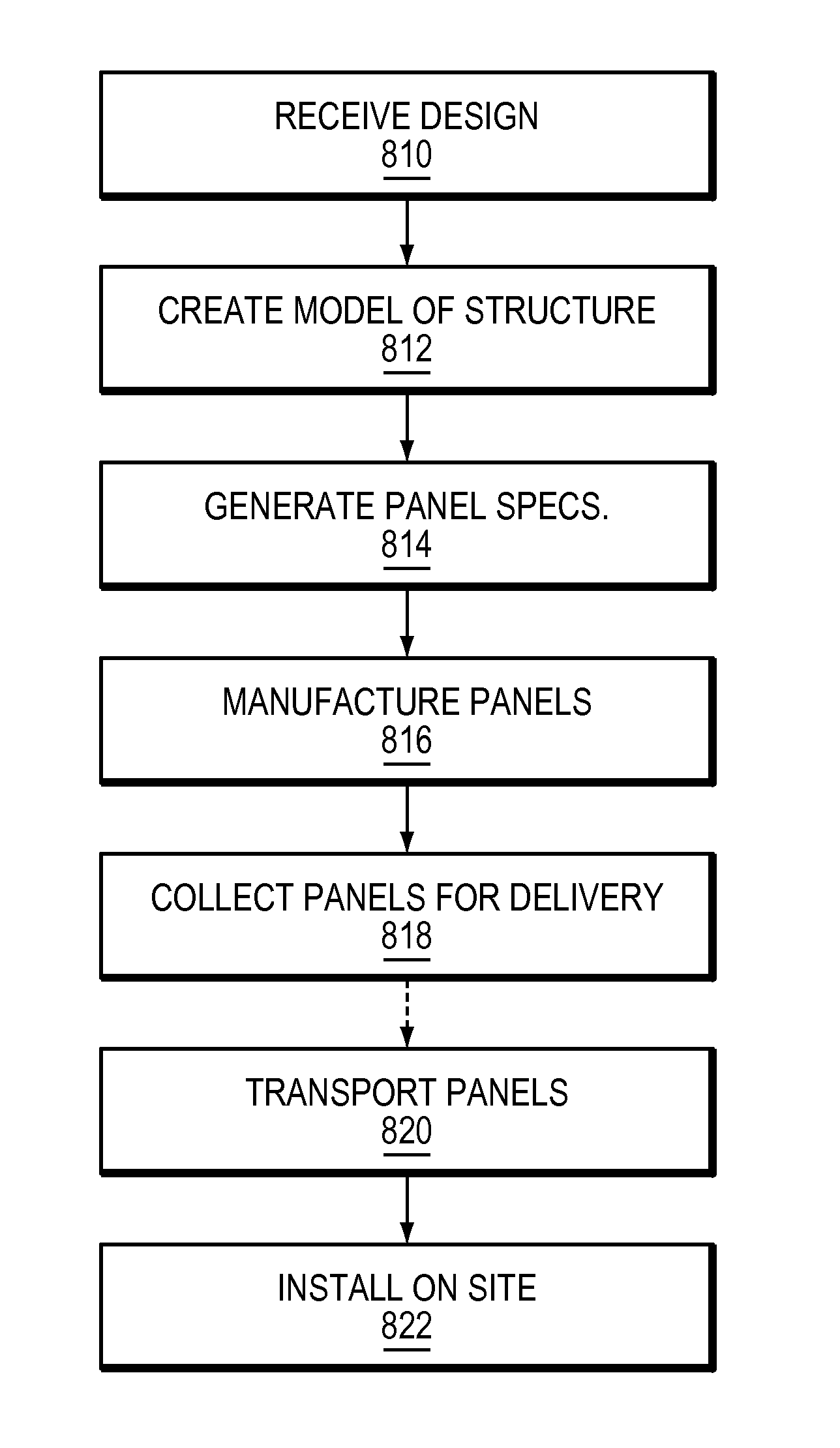

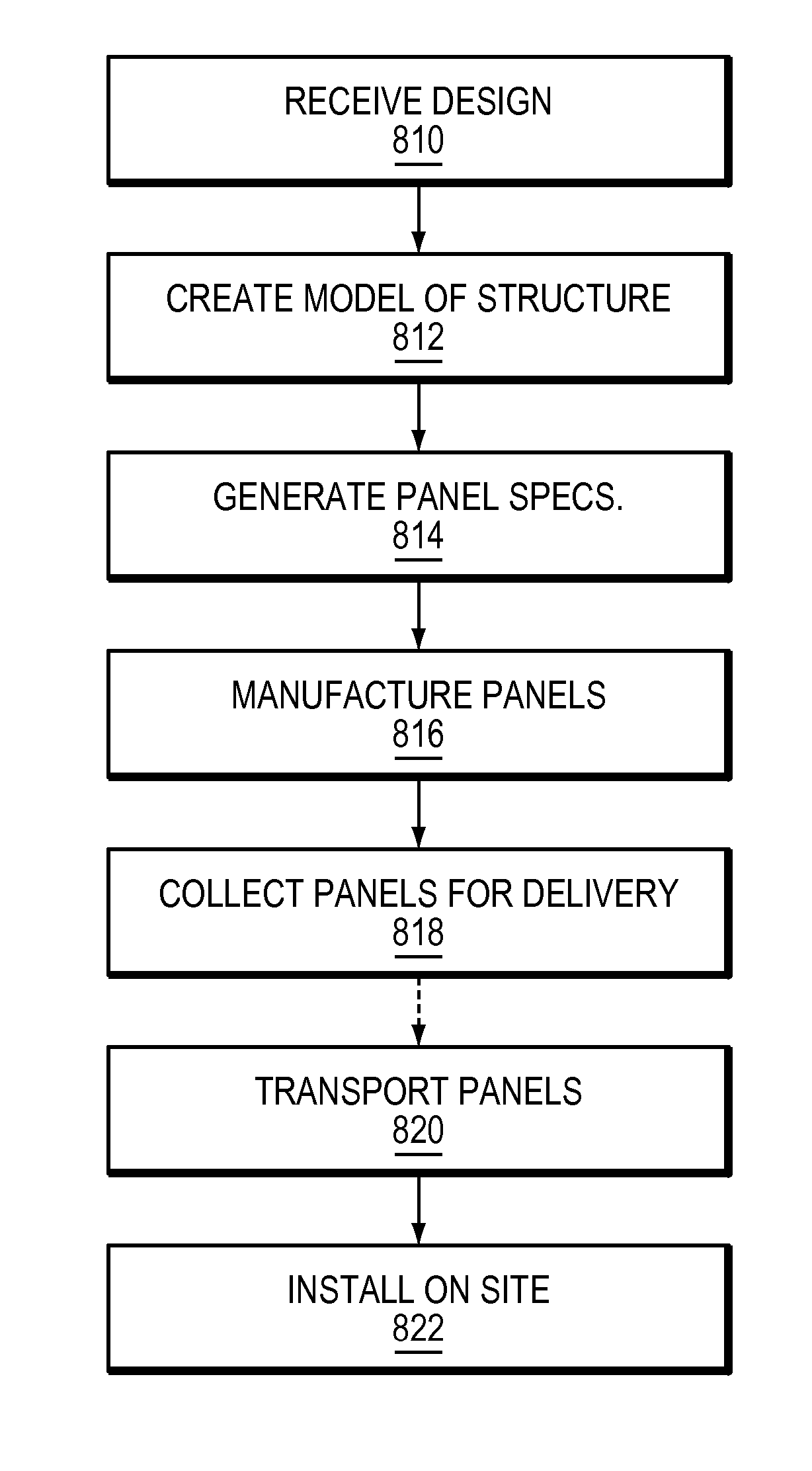

Information technology process for prefabricated building panel assembly

InactiveUS20070265724A1Improve construction qualitySolve the slow construction speedDigital data processing detailsWire networkCold-formed steelBuilding construction

Owner:GENESISTP INC

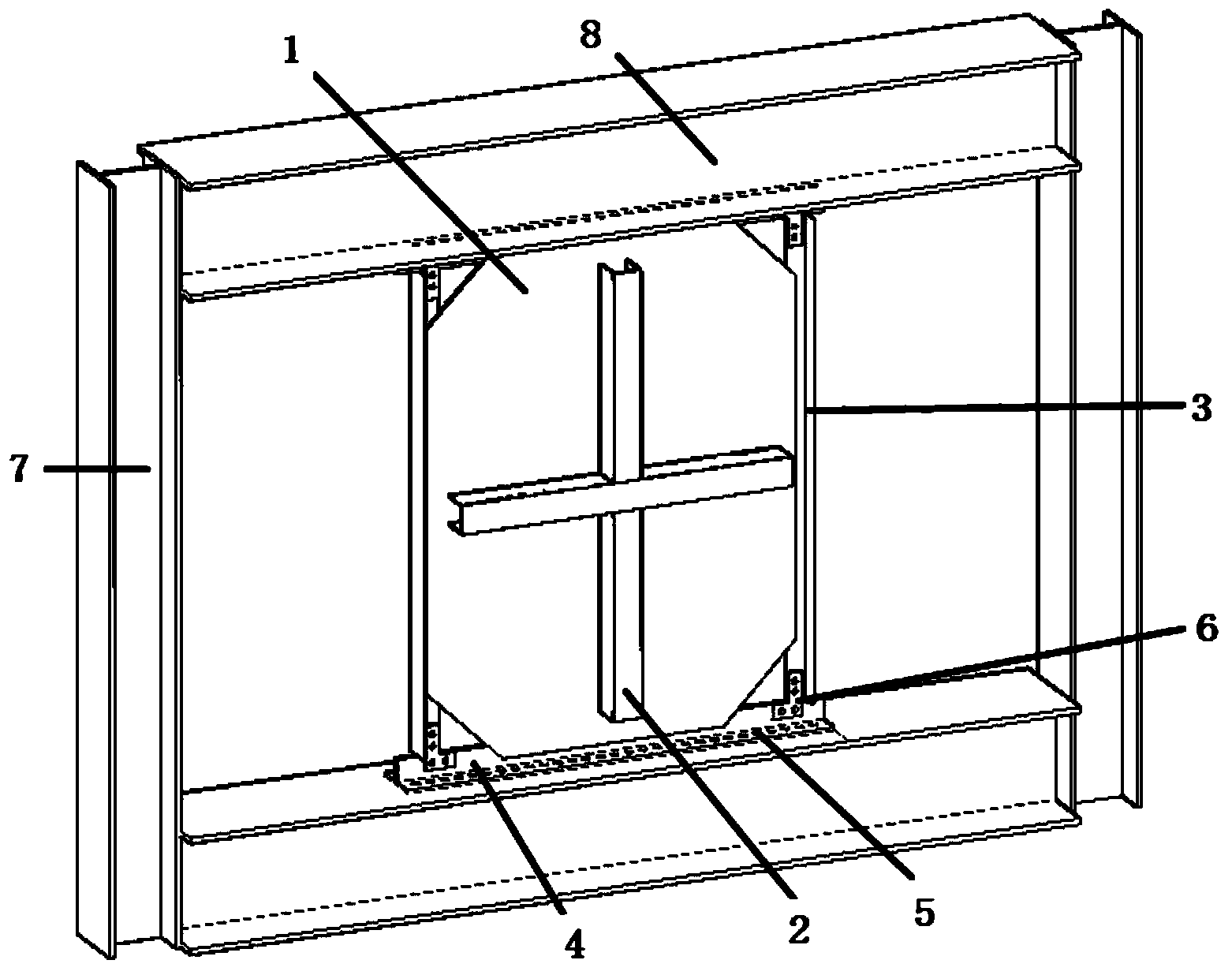

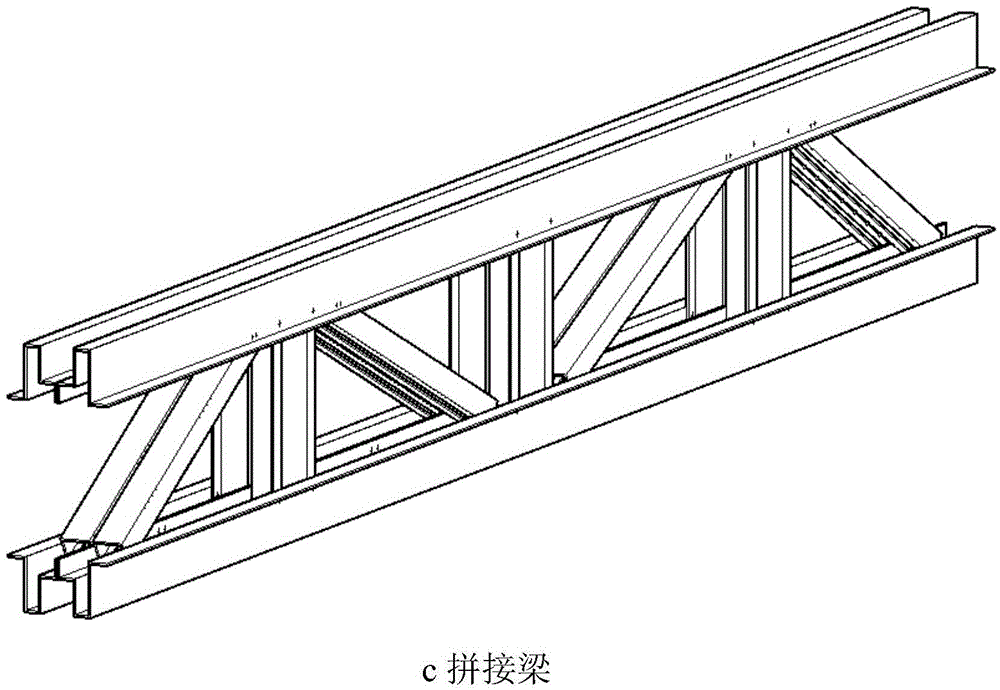

Multilayer cold-formed steel integrally prefabricated house and splicing method thereof

ActiveCN105696817AReduce on-site construction workloadHigh degree of industrializationBuilding material handlingDwelling buildingFloor slabEngineering

Owner:SOUTHEAST UNIV

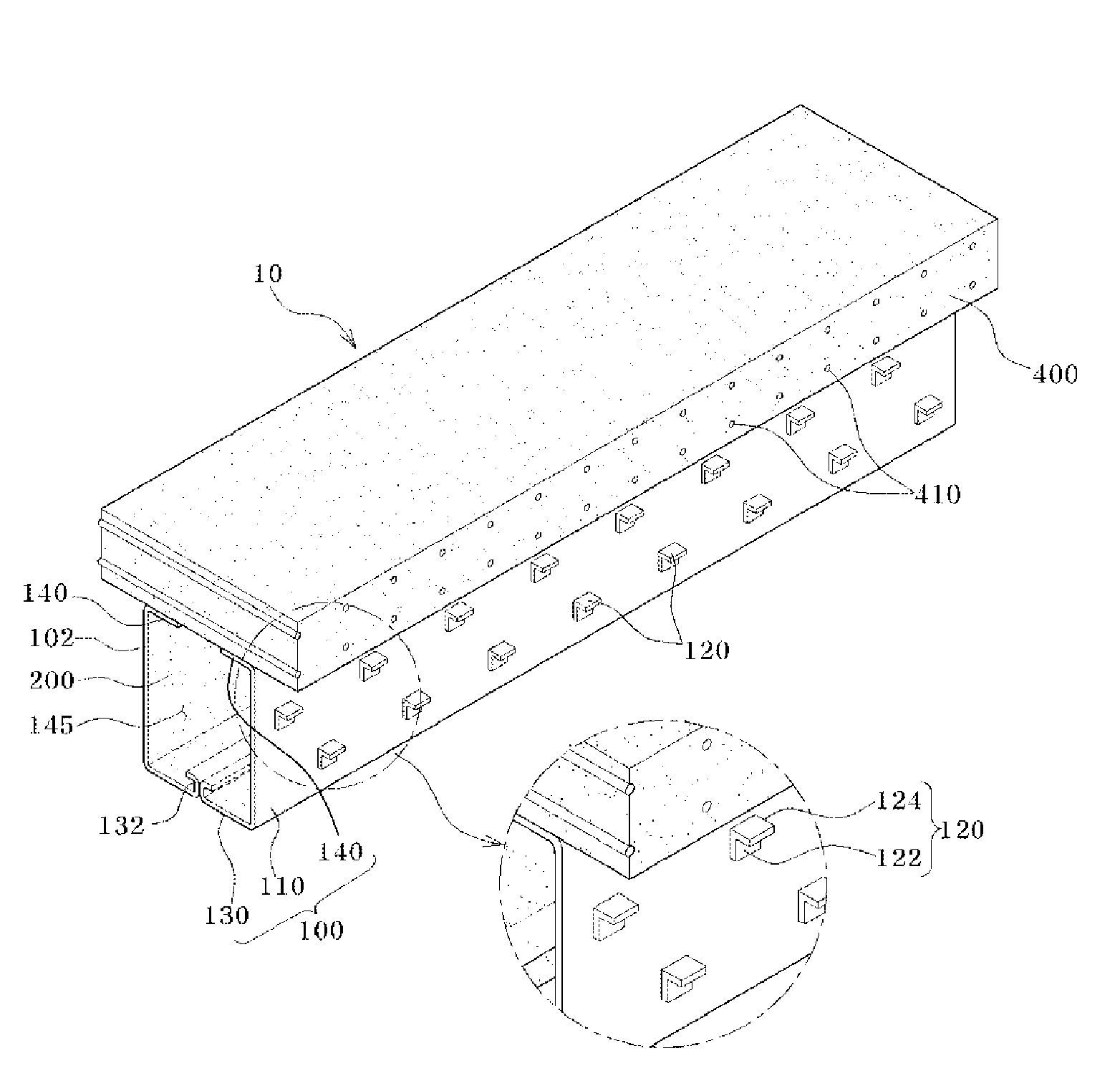

Structural composite hybrid beam(SCHB) consisting of cold-formed steel and cast-in-place concrete having attached fire-resistant coating material and constructing method of the schb

InactiveUS20100287878A1Improve performanceEven mixing ratioFloorsSynthetic resin layered productsSheet steelSteel frame

A structural composite hybrid beam having an attached fire-resistant coating material, the structural composite hybrid beam including: a cold-formed steel plate beam, which is formed into a form shape having a space where concrete is placed; a concrete slab installed on the cold-formed steel plate beam and that is integrally connected to the concrete; and a flow preventing member protruding from a pair of side plates of the cold-formed steel plate beam, and preventing the fire-resistant coating material sprayed on each of the pair of side plates from flowing down so that the fire-resistant coating material is firmly attached to the each of the pair of side plates. A thickness of the fire-resistant coating material is reduced as the concrete inside the structural composite hybrid beam absorbs heat, and thus construction expenses are reduced. Accordingly, the structural composite hybrid beam has excellent fire-resistant performance unlike a general steel-frame beam.

Owner:SENVEX +1

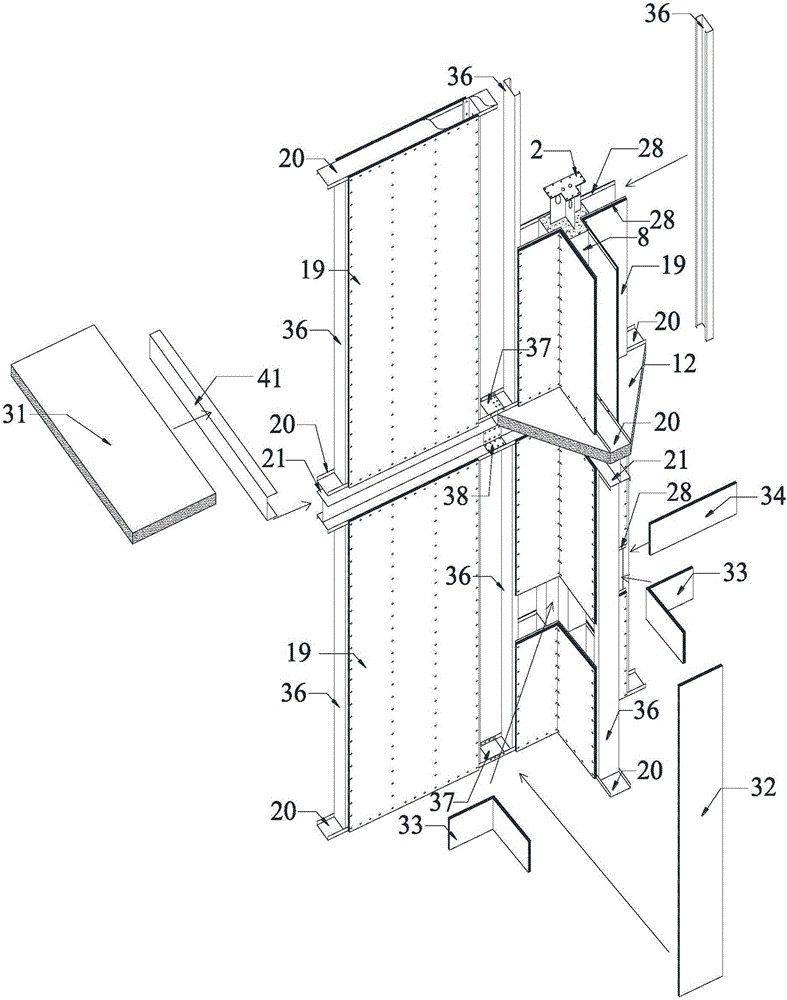

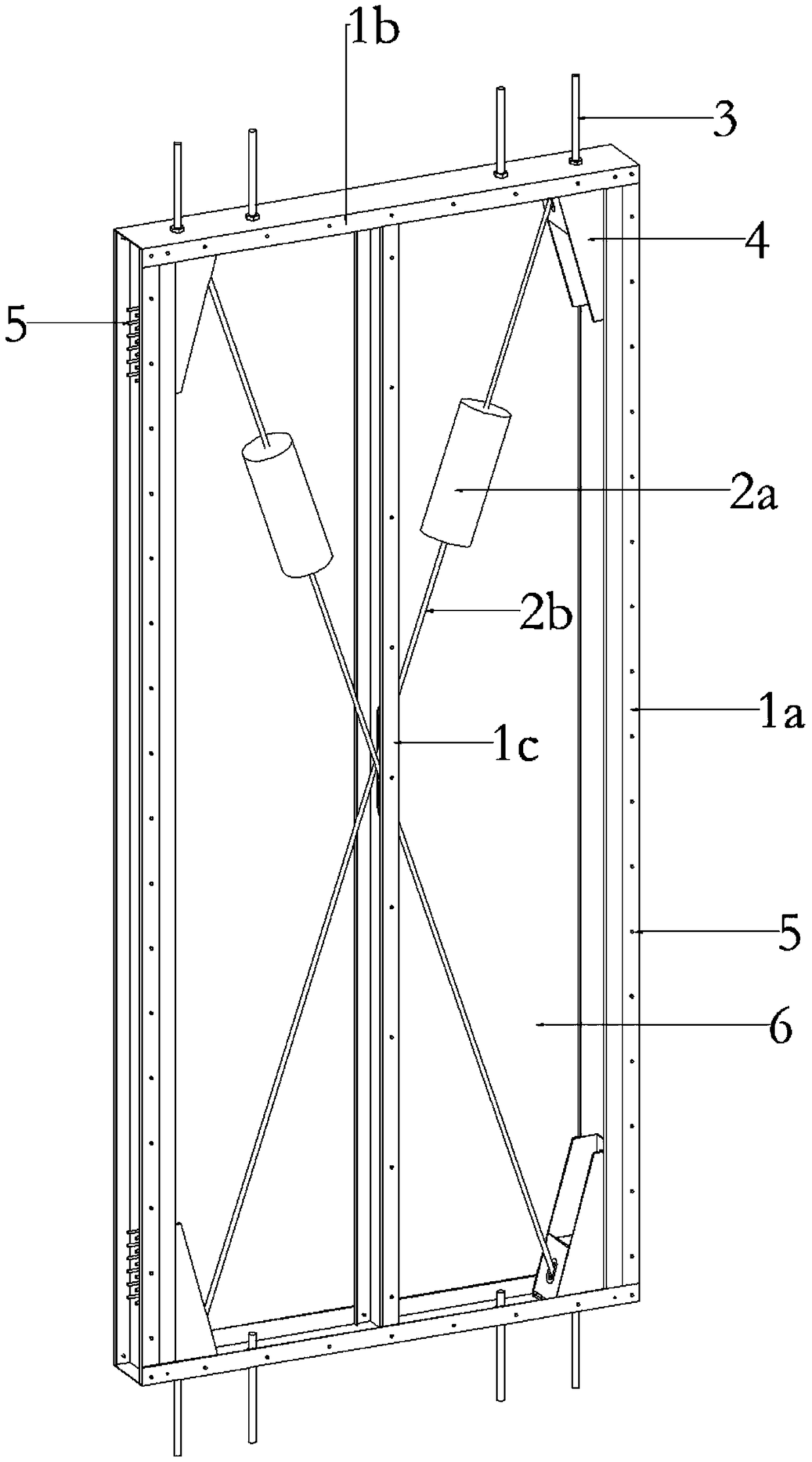

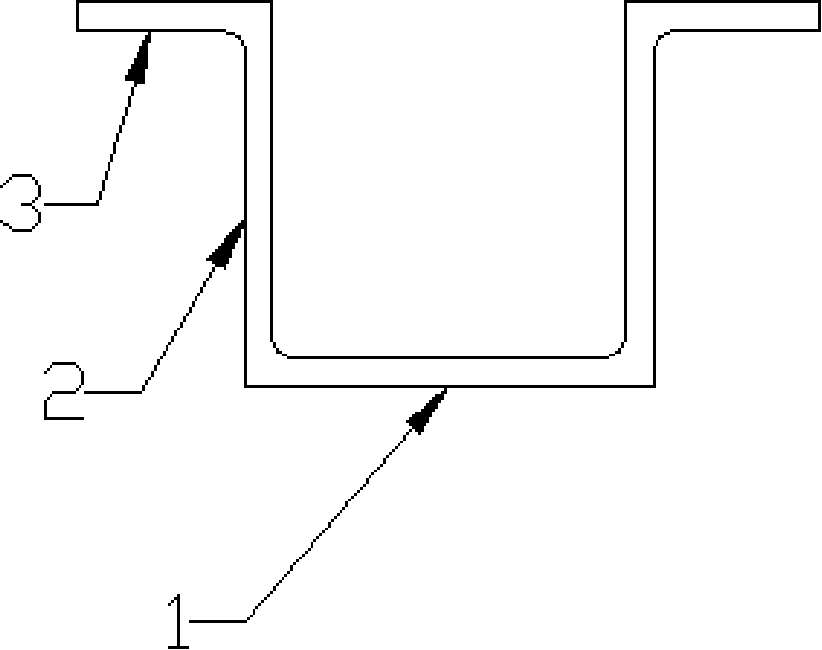

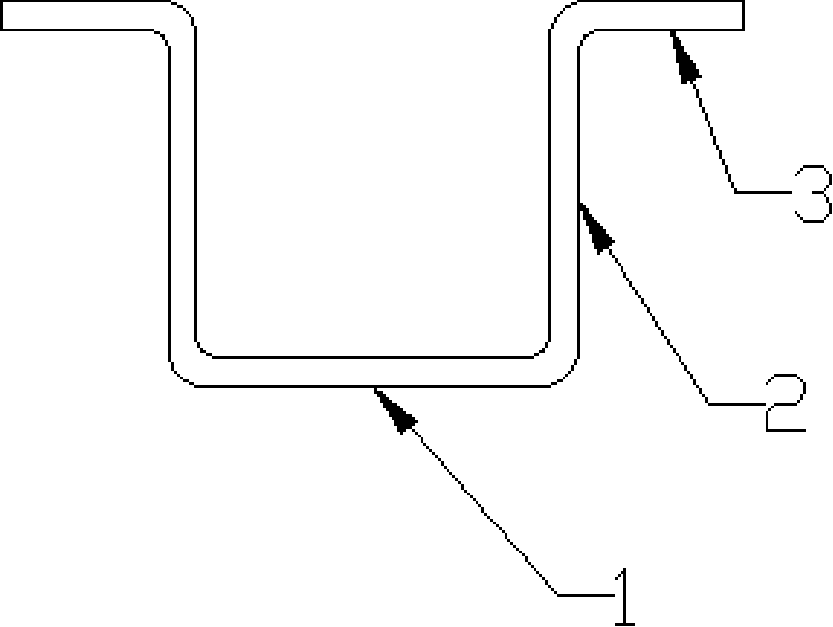

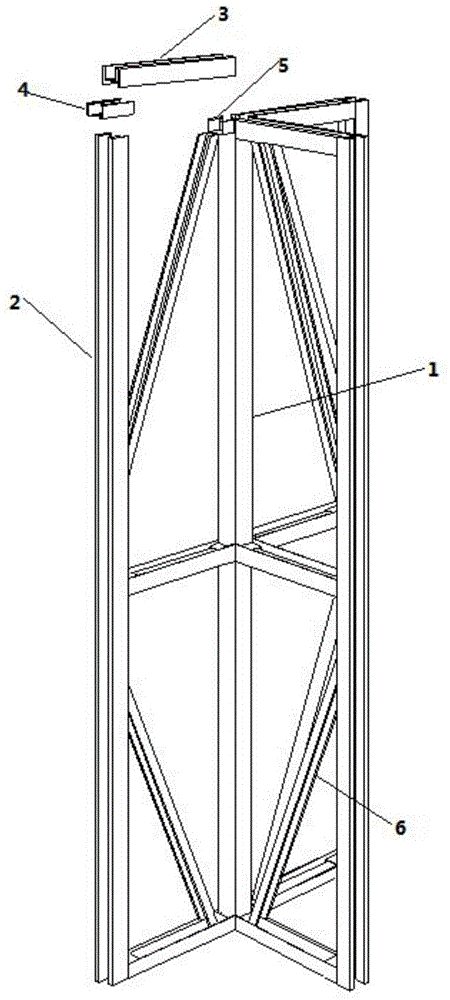

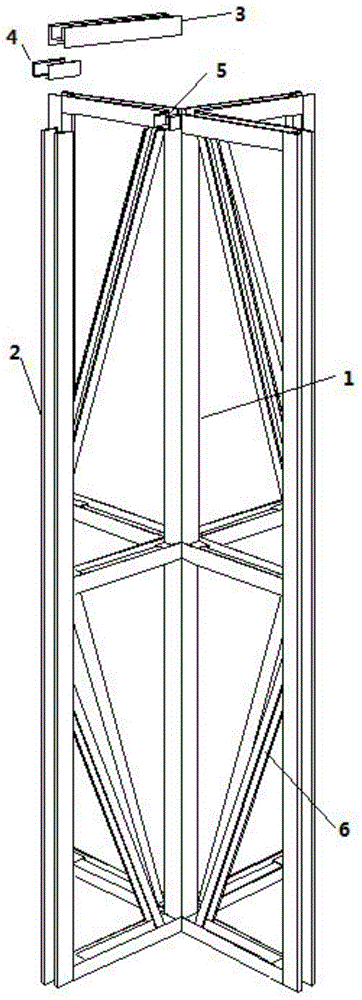

Fabricated thin-walled cold-formed steel combined damping wall

InactiveCN109457860AIncreased shear capacityImprove energy consumptionWallsProtective buildings/sheltersSupporting systemThermal insulation

The invention discloses a fabricated thin-walled cold-formed steel combined damping wall. A thin-walled cold-formed steel wall framework is a rectangular framework system formed by upper and lower U-shaped horizontal guide rails, H-shaped vertical side columns and a C-shaped vertical center column. Each energy-dissipation damping unit is a diagonal supporting system formed by a self-reset damper,a steel pull rod, a cylindrical rotating clamp and a retaining bolt. The two systems are connected into a whole through anti-pulling connection parts and operate jointly. A wall panel and the thin-walled cold-formed steel wall framework are connected through tapping screws, and the thin-walled cold-formed steel wall framework, the energy-dissipation damping units, a rock wool thermal insulating layer and the wall panel form the fabricated thin-walled cold-formed steel combined damping wall jointly. The fabricated thin-walled cold-formed steel combined damping wall integrates stress, damping, thermal insulation and fire prevention and is simple in structure, convenient to construct, high in performance, practicality and economy and suitable for industrial production and has a promising market prospect.

Owner:BEIJING UNIV OF TECH

Cold-formed steel structural wall and floor framing system

InactiveUS8720154B1Simplification of current construction practiceReduces and eliminates problematic issueBuilding roofsFloorsFloor slabWall stud

A cold-formed steel structural wall and floor framing system used for the construction of commercial and residential buildings. The framing system includes a plurality of horizontal, elongated, top and bottom spanning tracks. The spanning tracks are used for supporting a plurality of spaced apart vertical wall studs. Also, the spanning tracks are used to support a plurality of different floor systems, including but not limited to spanning steel floor decks with a concrete floor topping, composite floor joists, steel or wood joists, roof trusses and window and door headers.

Owner:HORNE JAMES P

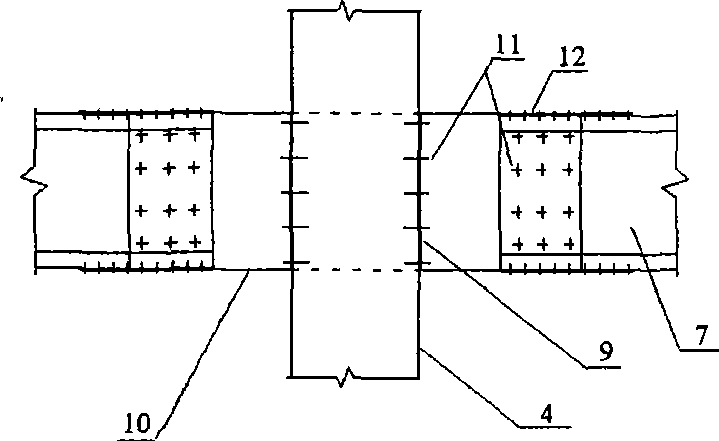

Assembling type reinforcing steel plate shear wall

InactiveCN103883029ALimit Out-of-Plane DeformationIncrease lateral stiffnessWallsShock proofingHysteresisLoad resistance

The invention relates to an assembling type reinforcing steel plate shear wall and belongs to the technical field of structure engineering. The assembling type reinforcing steel plate shear wall comprises an embedded steel plate, a reinforcing rib, a vertical edge component, a horizontal edge component, a high-intensity bolt, an L-shaped connecting plate, a frame column and a frame beam. The embedded steel plate is a thin steel plate. The reinforcing rib is thin-walled cold-formed steel. The vertical edge component and the horizontal edge component are T-shaped steel. The L-shaped connecting plate is a steel plate with a bolt hole. The embedded steel plate is connected with the vertical edge component and the horizontal edge component. The horizontal edge component is connected with the frame beam. The vertical edge component and the horizontal edge component are connected through the L-shaped connecting plate. The frame beam and the frame column are connected. The assembling type reinforcing steel plate shear wall is a novel lateral-load-resistance component of a high-rise building structure or other structures, the assembling type reinforcing steel plate shear wall has the advantages of being good in anti-seismic property, high in ductility, full in energy dissipation hysteresis ring and the like, and the assembling type reinforcing steel plate shear wall is a great anti-seismic energy-dissipation component.

Owner:BEIJING UNIV OF TECH

Heating and forming method for cold bending sectional steel and cold bending sectional steel produced by the same

InactiveCN101168224AImprove plasticityImprove liquidityMetal-working apparatusSheets/panelsThermoplasticMetallurgy

The invention discloses a method for heat forming of cold-pressing steel and cold-pressing steel produced by the method. The invention has the advantages of capability of increasing the welding quality. The method for heat forming of cold-pressing steel is characterized in that the method includes the steps including that firstly, circular vertical angle section steel block is manufactured by an ordinary hole-typed cold-pressing forming machine group, secondly, the formed circular vertical angle section steel block is on-line heated by a heating device to enable the blank in the portion of the circular angle of the circular vertical angle section steel to form an austenite structure, thirdly, the circular vertical angle section steel block is pressed to form sharp vertical angle section steel. The blank in the position of the circular portion is transformed into the austenite structure after being on-line heated the conventional circular vertical angle section steel block by the heating device, and the heating temperature is defined by the austenite transforming temperature of various steel, thereby the deformed portion and the dangerous portion can be processed thermoplastic, and the plasticity and fluidity of the deformed portion and the dangerous portion can be improved, enabling the circular vertical angle section steel block to be not easy to deform and difficult to be cracked in the pressed opening, consequently, the integral load of the machine group is greatly reduced.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Tools and methods for designing a structure using prefabricated panels

InactiveUS20070271073A1Improve construction qualitySolve the slow construction speedWire networkAssembly machinesCold-formed steelBuilding construction

Owner:GENESISTP INC

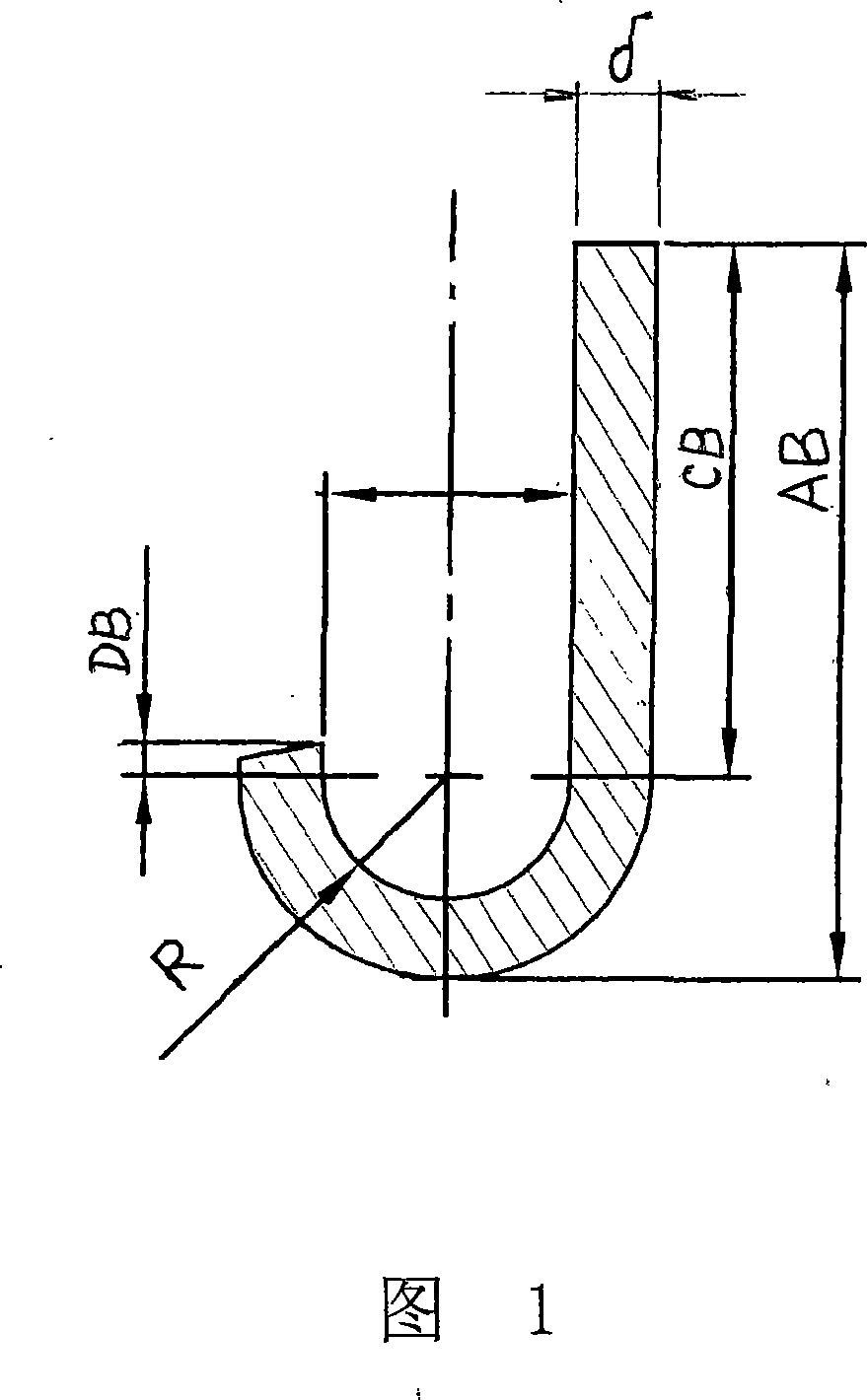

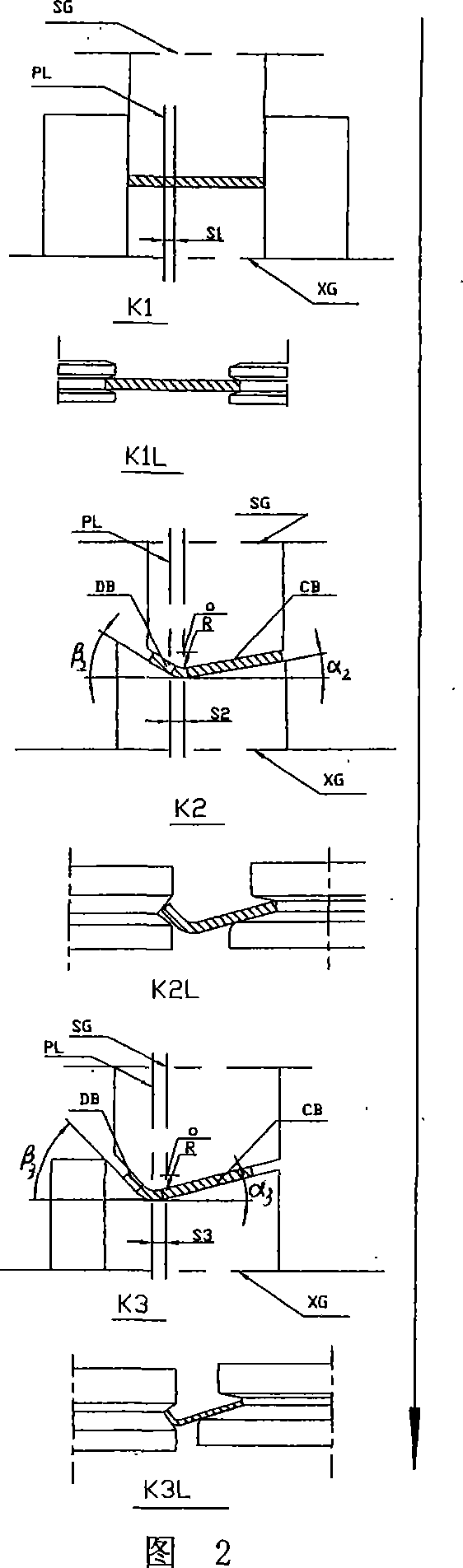

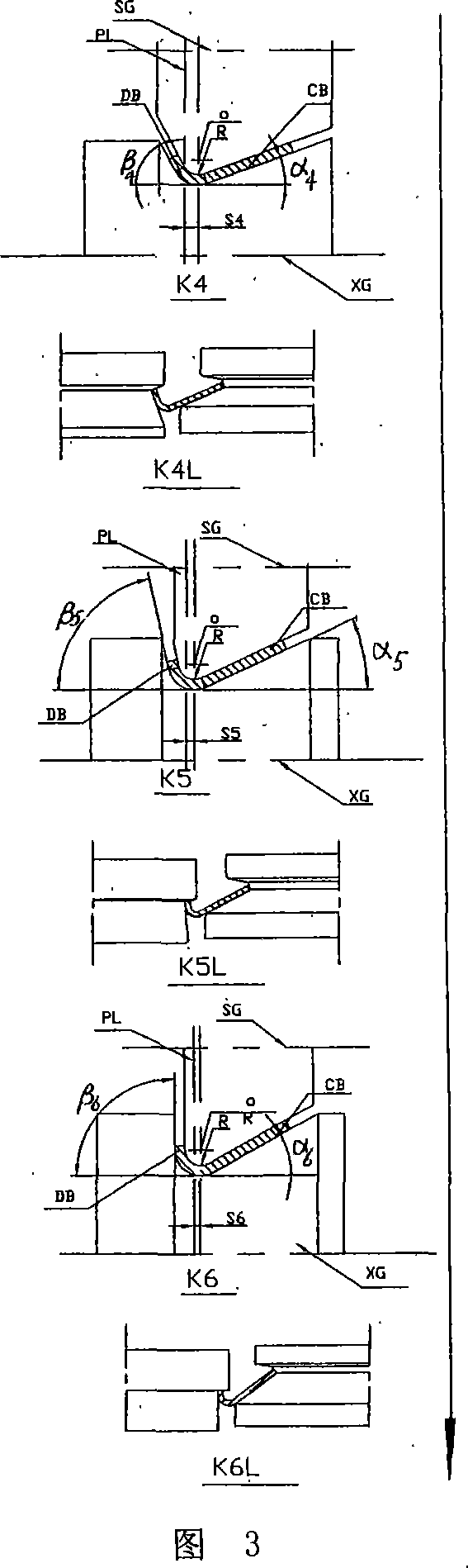

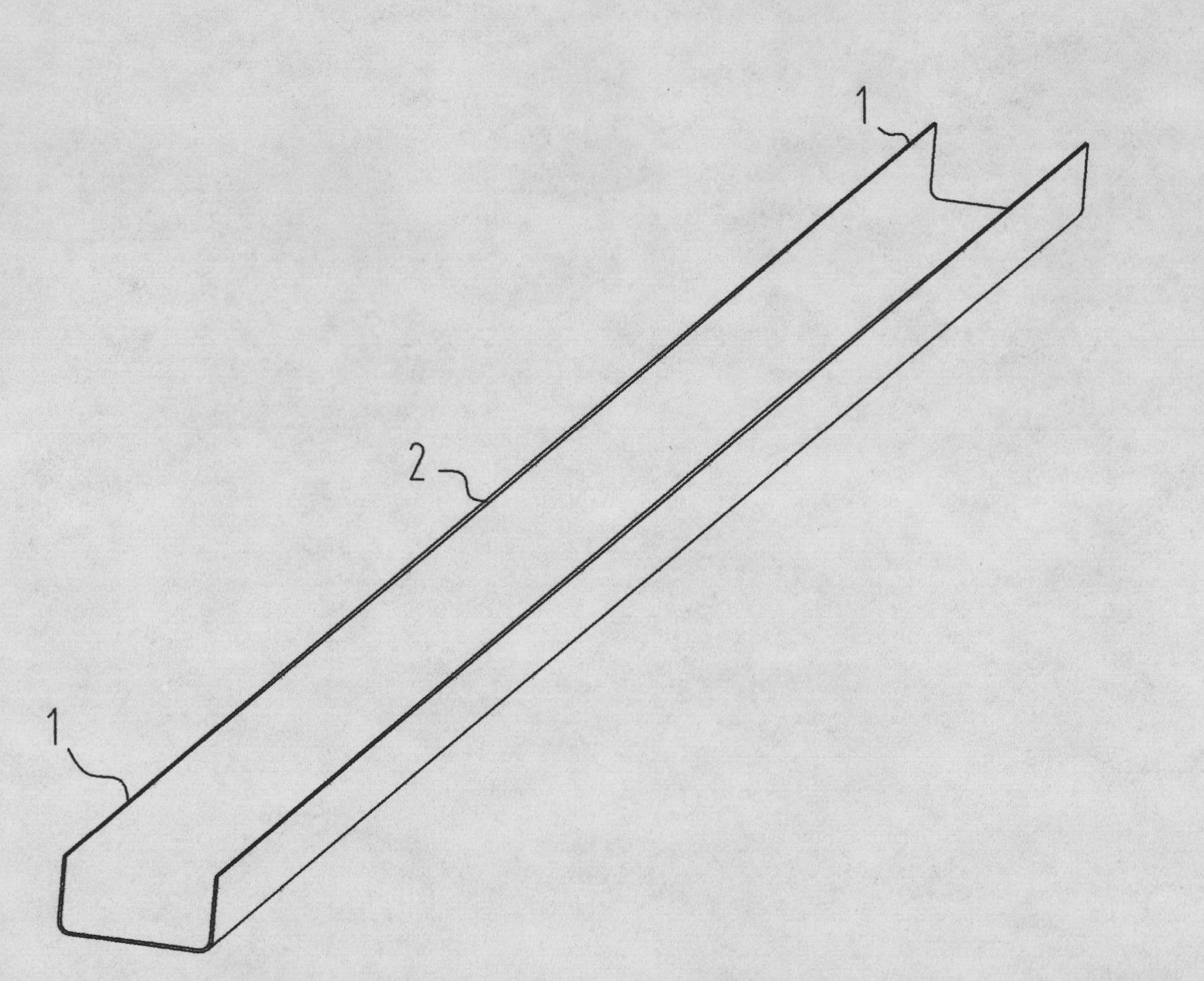

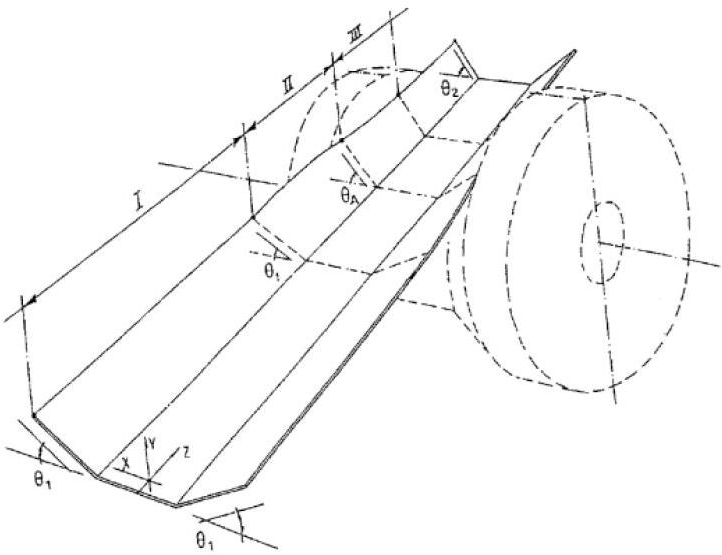

J-shape cold bend steel steel and rolling technology

InactiveCN101067470ADegree of reductionMinimize the difference in calenderingElongated constructional elementsMetal rolling arrangementsMetallurgyDistortion

The invention relates to a J shape cooled steel structure and the rolling process. The structure has the asymmetry length and the ration of the thickness and inner arc radius can reach above 80%. The technology scheme is to roll the steel by the roller continuously until the steel changing the shape, the rolling distortion process is divided into 12 times. It uses the up / down binate plain-barrel roll, the matched leading vertical roller, the three rollers frame and two straightening machines to make straight. The short lift angle is bigger than the long side in rolling process. The arc center departures the rolling line from big to 0. the steel of the invention has the asymmetry arc lengths which is above 16 times and reach to the difference +-0.1 to assure the quality.

Owner:上海佳冷冷弯科技股份有限公司

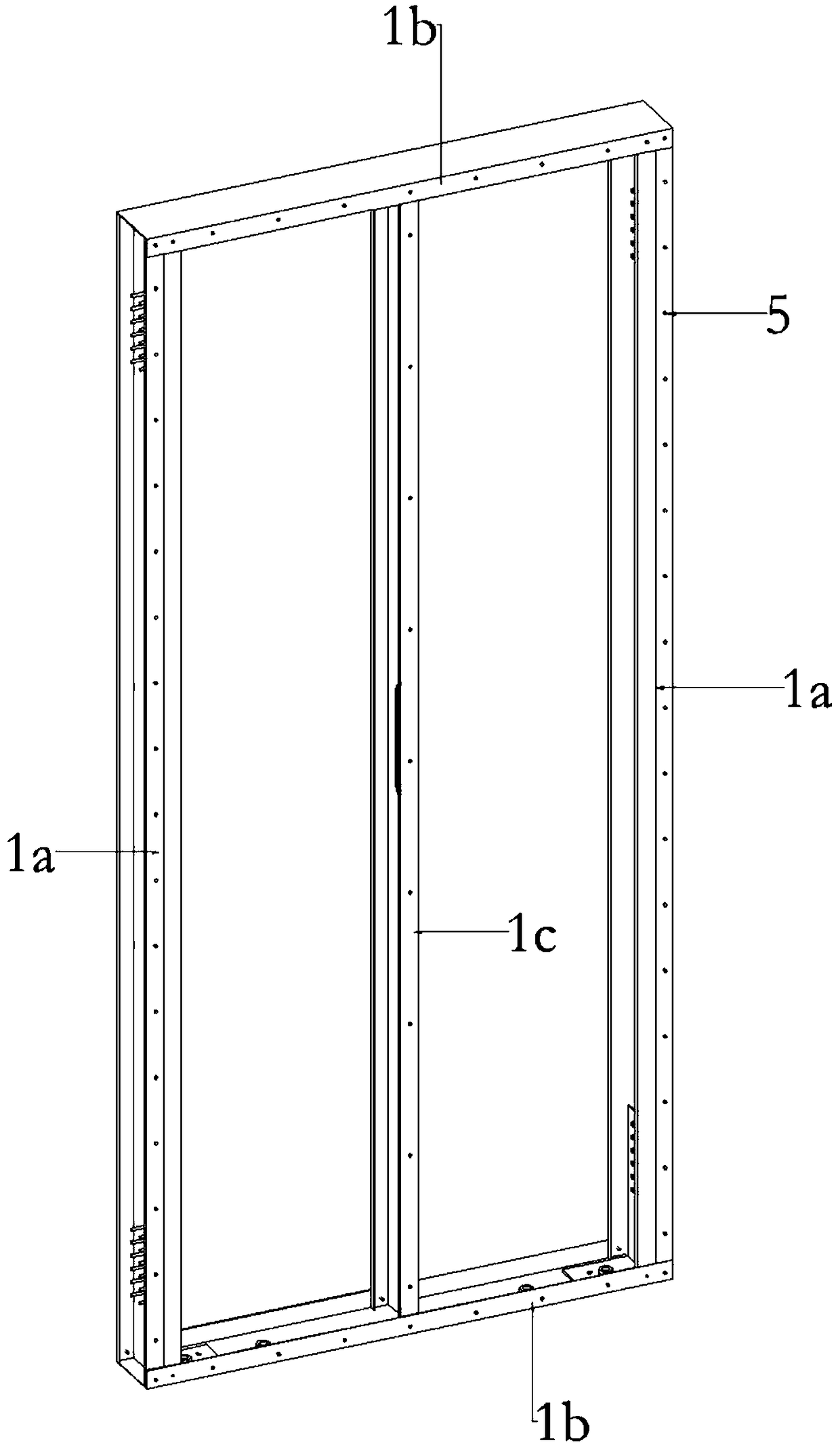

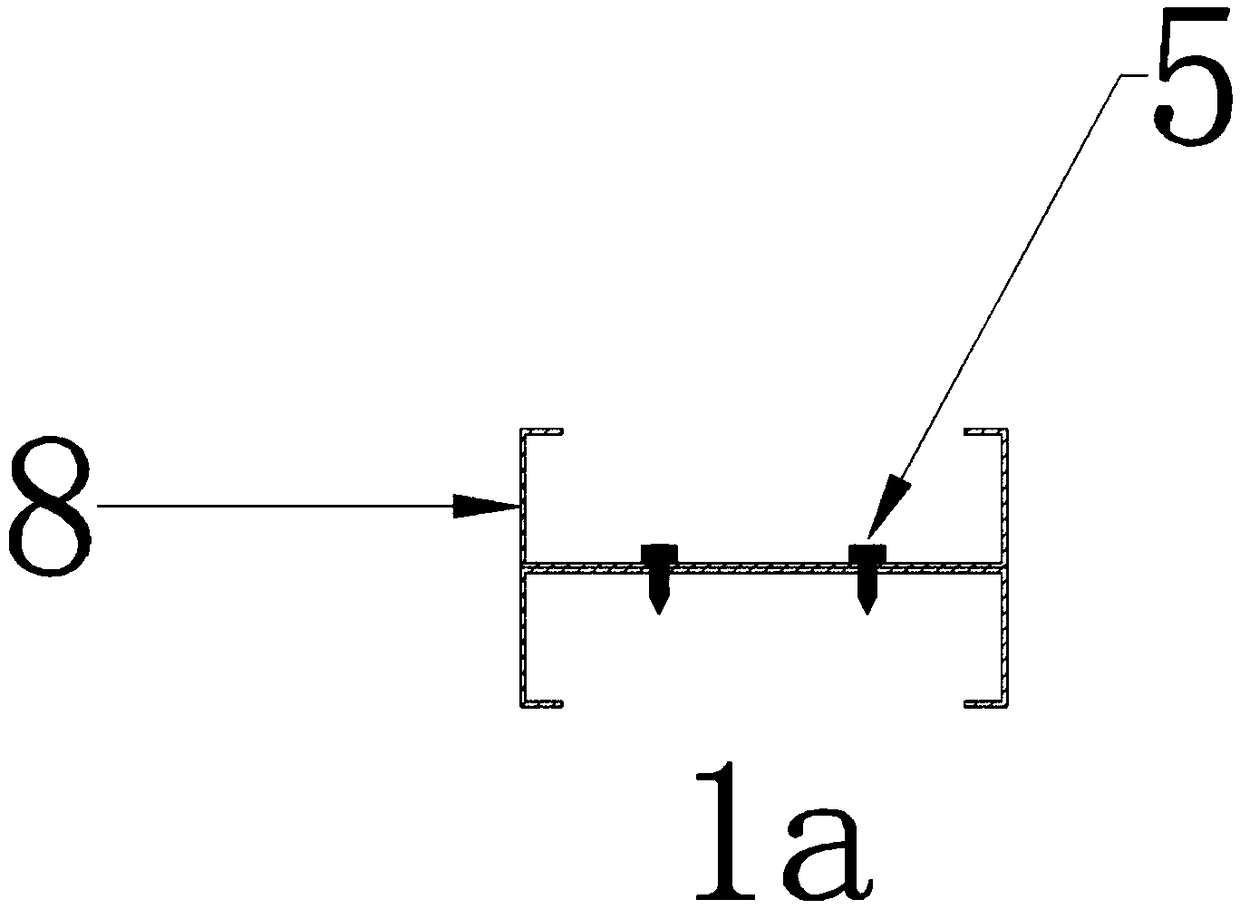

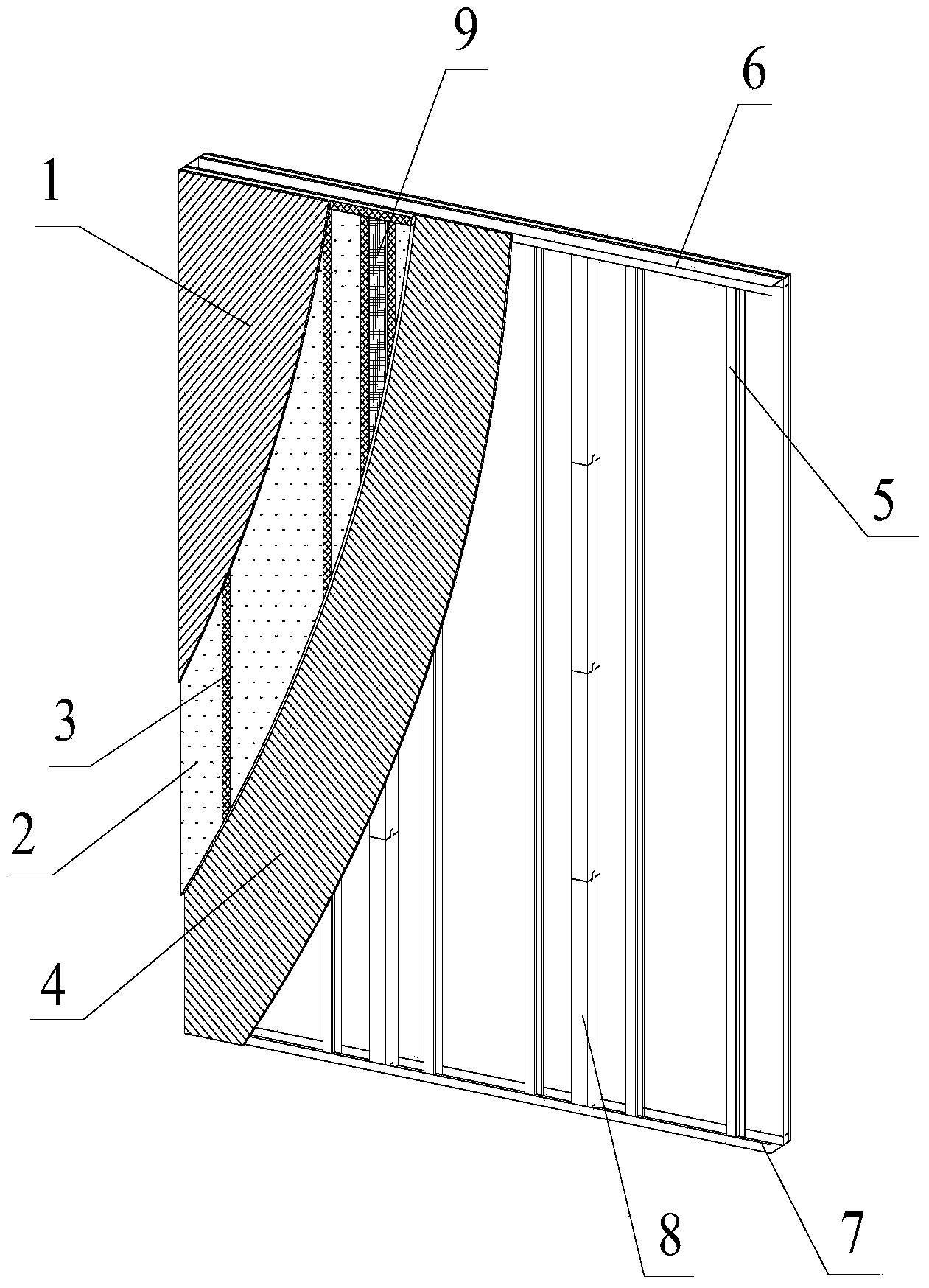

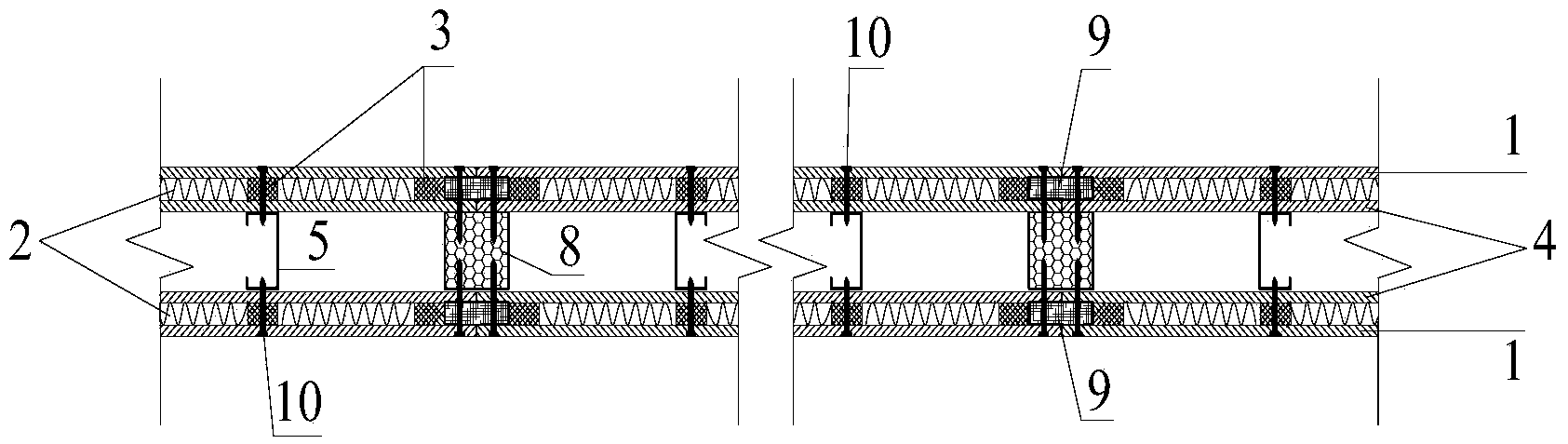

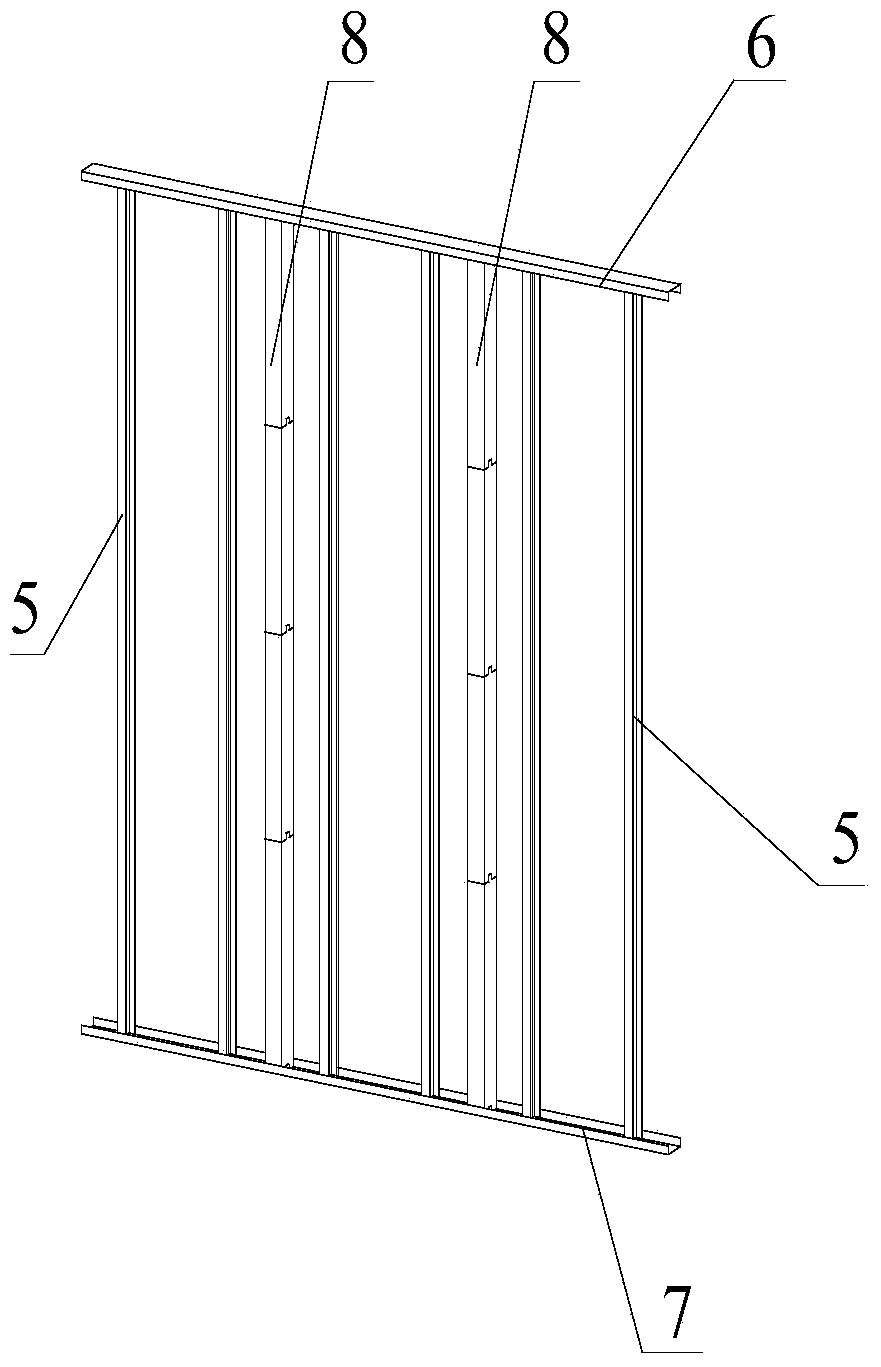

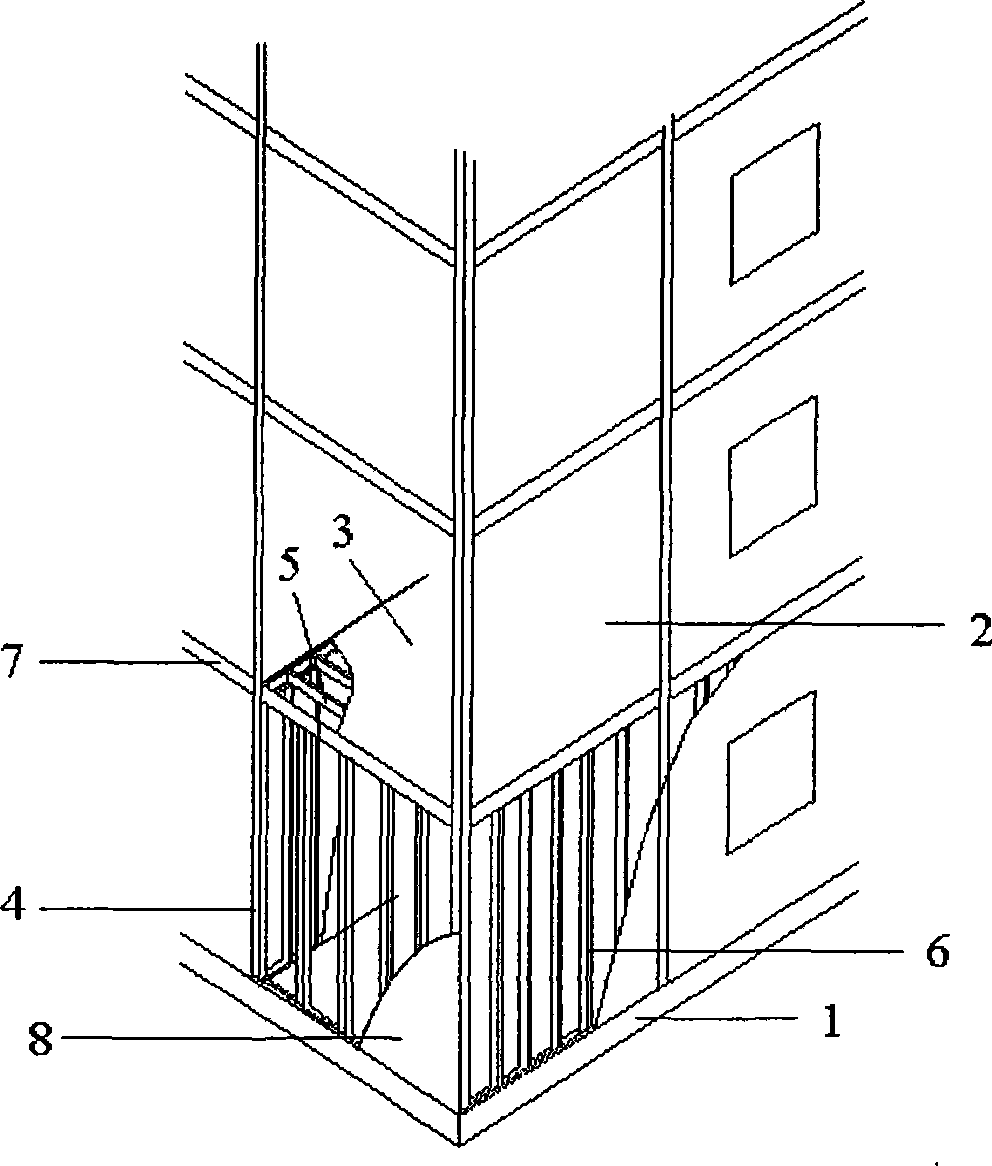

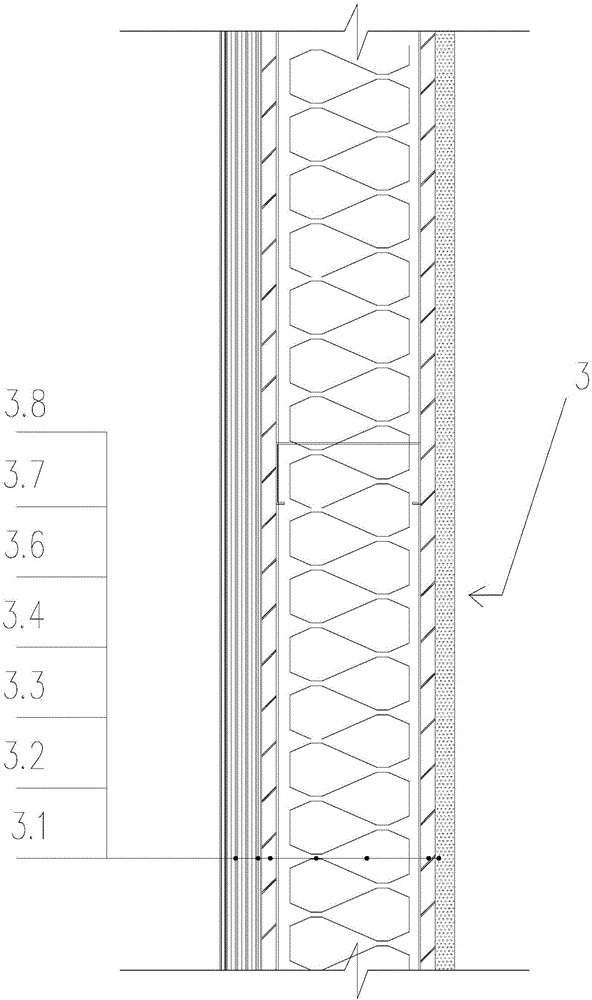

Prefabricated light steel fireproof load-bearing combined wall structure

InactiveCN103437463AFacilitate batch prefabricationNo significant effect on fire resistanceWallsHeat proofingThermal insulationKeel

The invention discloses a prefabricated light steel fireproof load-bearing combined wall structure which is formed by fixedly connecting sandwich wallboard units on two sides and a light steel joist framework unit at the middle. Each sandwich wallboard unit comprises an A-side wall board and a B-side wall board; and an autoclaved aerated concrete slat (3) and thermal insulation cotton (2) are spaced between the A-side wall board and the B-side wall board. The light steel joist framework unit is formed by fixedly connecting a cold-formed steel upright (5), a cold-formed steel guide rail and an autoclaved aerated concrete short column (8) of which the thickness is equal to the height of a web of the cold-formed steel upright. Adjacent sandwich wallboard units on the same side are inserted into an autoclaved aerated concrete butt-joint slat (9) through grooves (13) in the long sides thereof to realize splicing. The sandwich wallboard units and the light steel joist framework unit are connected through self-tapping screws to realize wall splicing. By adopting the structure disclosed by the invention, full prefabrication can be realized, the structure is light, and the steel consumption is reduced; and moreover, the structure has the characteristics of thermal insulation, sound insulation and fire resistance and is suitable for a load bearing wall system of a multi-story building.

Owner:SOUTHEAST UNIV

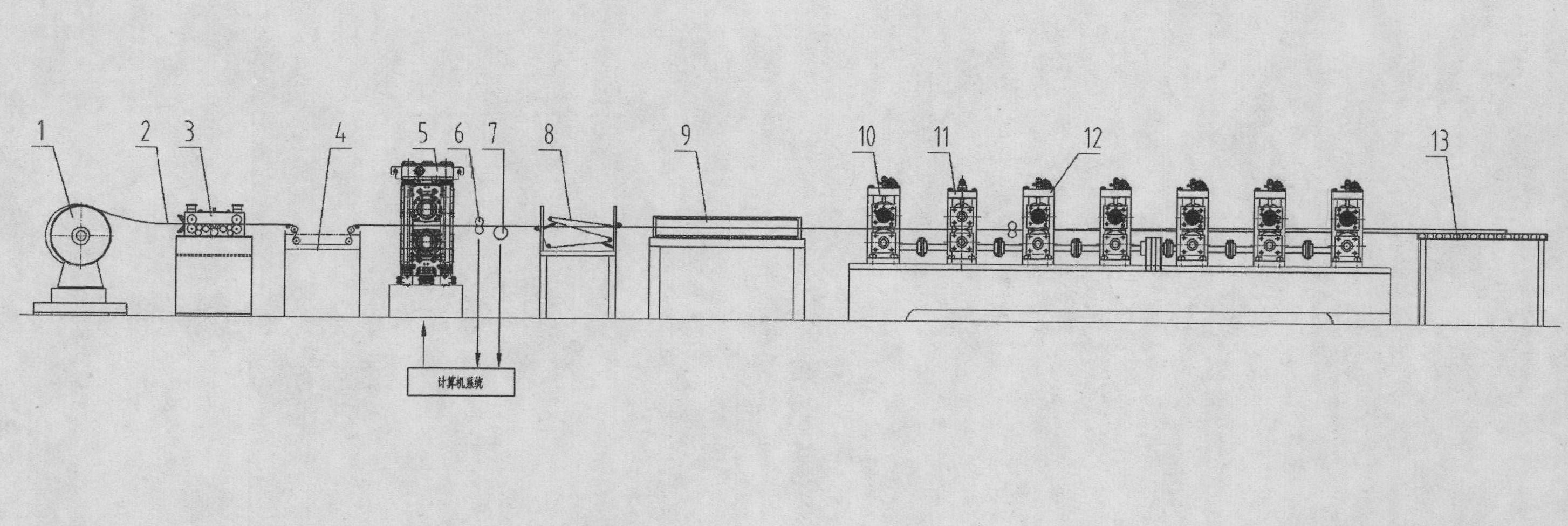

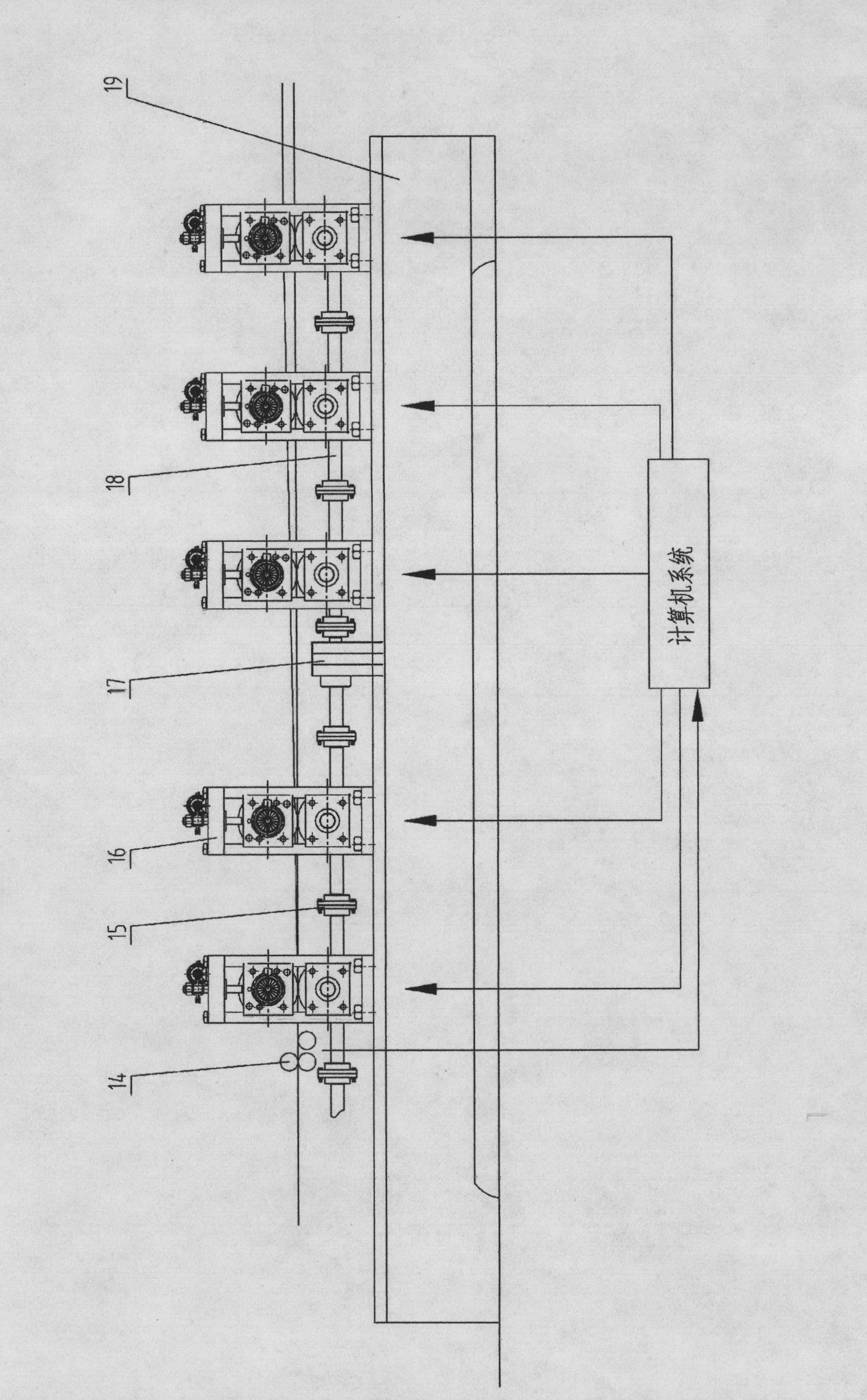

Method for forming longitudinal variable-thickness cold-bent section bars in continuous rolling manner and device thereof

ActiveCN102513806ASheet savingReduce weightMeasuring devicesOther manufacturing equipments/toolsVariable thicknessPolymer science

The invention relates to a method for forming longitudinal variable-thickness cold-bent section materials in a continuous rolling manner and a device thereof, belongs to the field of section material processing technologies and equipment, and aims to solve the problems in the prior art that only constant-thickness cold-bent section steel can be produced, and materials cannot be fully utilized. The invention adopts the technical scheme that constant-thickness coiled materials are used as raw materials; after being uncoiled, the constant-thickness materials are flattened and pickled and then enter a variable-thickness rolling system to be rolled in a variable-thickness manner; afterwards, the constant-thickness materials are degreased and tempered in an on-line manner, and then longitudinal continuous variable-thickness plate materials are formed; the longitudinal continuous variable-thickness plate materials are smoothly rolled and longitudinally sheared and then enter a roller forming device, and the final section materials are formed; the final section materials enter a material discharging platform; and the following processes further comprise cutting-off, binding, packaging, and the like. The invention further provides the roller forming device for the cold-bent section materials according to the method. The roller forming device is provided with a computer system, a detecting device, the material discharging platform, a working table, and the like. Through adopting the method and the device, the aims of forming the variable-thickness cold-bent section materials, fully utilizing the materials, and the like are achieved.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

Component manufacturing system for a prefabricated building panel

InactiveUS20070260345A1Improve construction qualitySolve the slow construction speedWire networkAssembly machinesManufacturing systemsCold-formed steel

Owner:GENESISTP INC

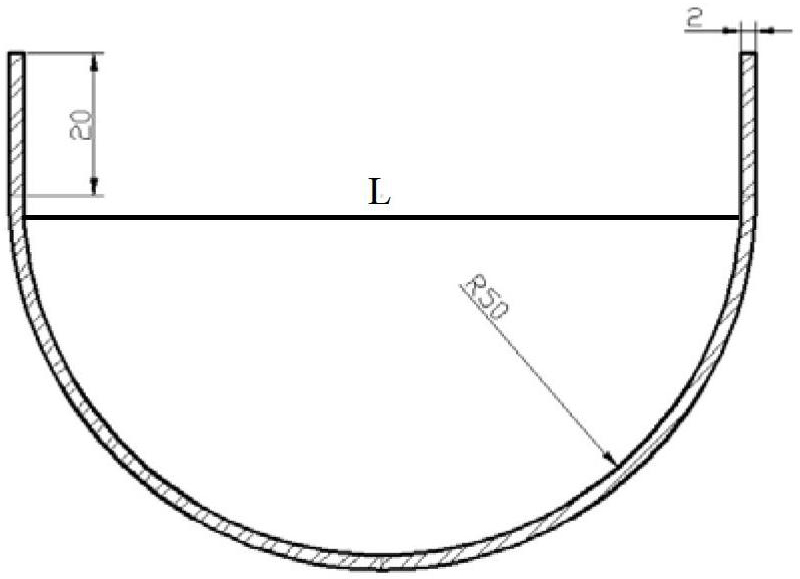

Method for producing cold-formed steel of U-shaped davit arm

The invention relates to a method for producing the cold-formed steel of a U-shaped davit arm. The method comprises the following steps of: leading strong-strength sheet steel or a strong-strength steel coil into a roll for first formation, wherein the strong-strength sheet steel or the strong-strength steel coil is formed totally for 3 to 6 times; between the first formation and second formation, arranging induction heating equipment, and while forming profile steel, performing induction heating and stretching and straightening the sheet steel by utilizing roll speed differences produced by different roll diameters in the formation of each time by using the induction heating equipment; actually measuring the actual temperature of the sheet steel in the formation of each subsequent time in field according to sheet steel feeding velocity v, and controlling the temperature in an additional heating way; and performing subsequent operation such as cooling and shearing until strong-strength semicircular large-radius profile steel meeting target requirements is formed. The processes of induction heating, synchronous stretching and straightening of the roll, and the like are introduced into the conventional cold forming process, so that the low cost and high efficiency of the cold-formed steel and the characteristics of weak forming force, optimized size and the like of heat-formed sheet steel are integrated.

Owner:UNIV OF SCI & TECH BEIJING

Multipurpose concrete anchor clip

ActiveUS20150184371A1Optimal material consumptionAvoid serious wasteWallsBuilding reinforcementsMaterial consumptionBolt connection

A connector with two flanges for making a variety of connections between structural members, in particular cold formed steel structural members, with the added utility of a accommodating a heavy bolted connection to one of the structural members with an extended tab on one flange that matches a recess on the other for optimal material consumption and minimal waste in manufacturing.

Owner:SIMPSON STRONG TIE

Residential structure of multi-layer cold-formed section steel assembled house

The invention relates to a residential structure of multi-storey cold-formed steel composite building, which comprises a plurality of wall body units, roof units and joist guide rail which is connected with the wall body and the roof respectively, wherein, the residential structure of multi-storey cold-formed steel composite building also comprises square tubular columns arranged vertically at two ends of the wall body units, the roof units comprise a flat plate part and a joint embedded in the flat plate part, the materials of the flat plate part are light weight building boards, and the wall body units are provided with strengthened section columns for bearing the joint load of the roof units. The invention is applicable to constructing multi-storey buildings.

Owner:SOUTHEAST UNIV

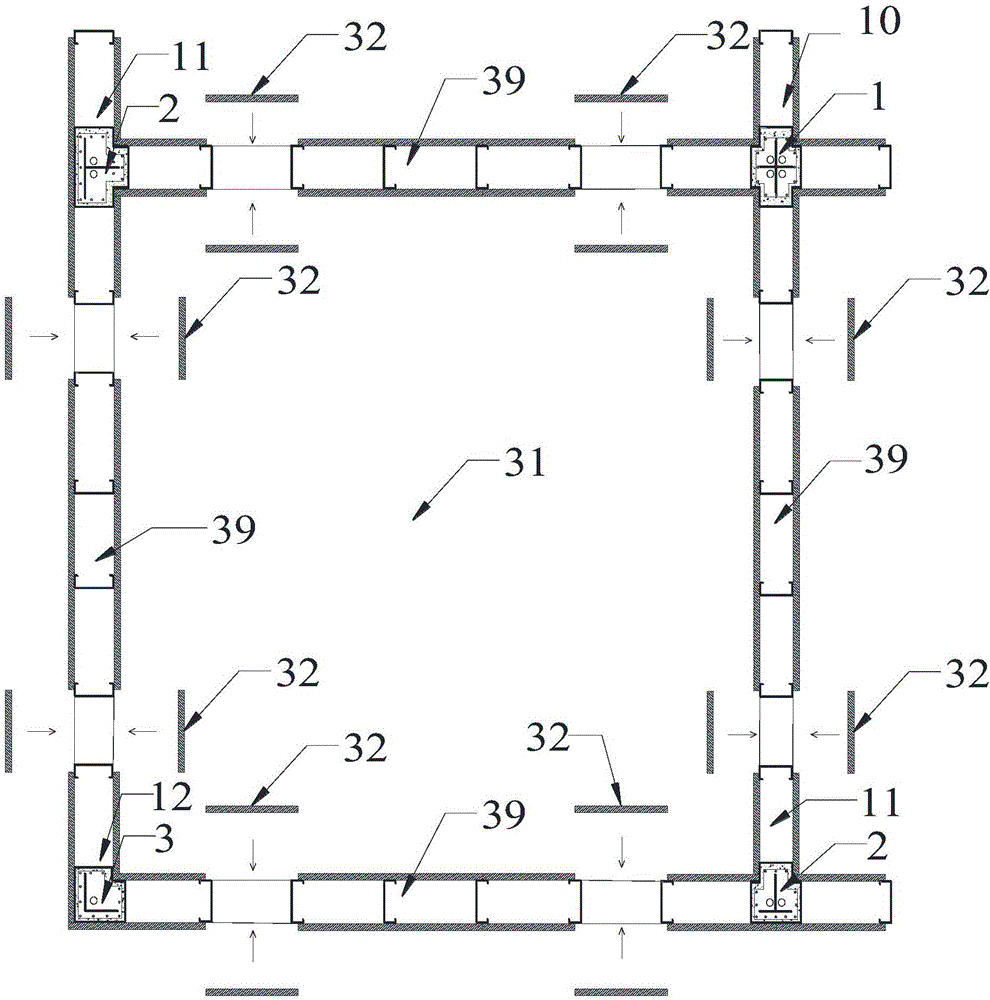

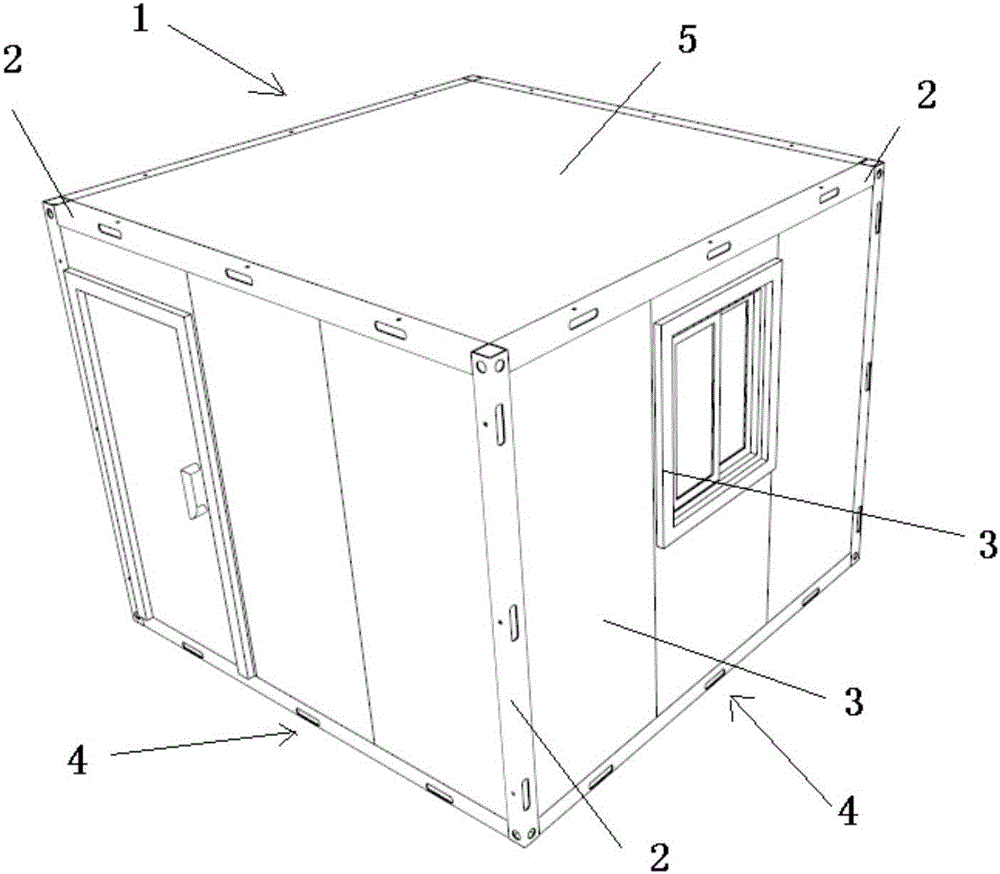

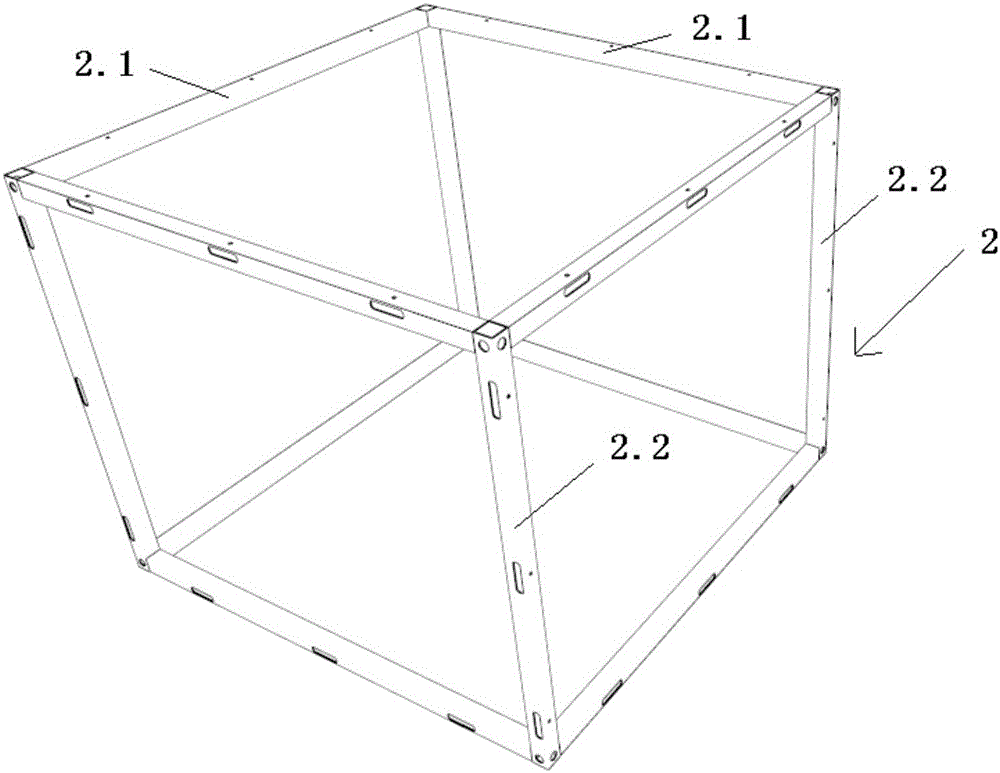

Modularized-assembly house system

The invention discloses a modularized-assembly house system. The modularized-assembly house system is characterized in that the modularized-assembly house system comprises one or more houses (1) formed by modularized production; the houses (1) within two layers extend horizontally infinitely; each house (1) comprises a steel-structure frame (2), thin-walled cold-formed steel system wallboards (3), a thin-walled cold-formed steel system floor slab (4) and a thin-walled cold-formed steel system roof (5); the steel-structure frame (2) comprises cross beams (2.1) and stand columns (2.2), the upper cross beams (2.1) are parallel to the lower cross beams (2.1), and the stand columns (2.2) are connected vertically with the cross beams (2.1); eight corners formed by encircling of the cross beams (2.1) and the stand columns (2.2) are connected through connectors (7). The modularized-assembly house system has the advantages that the defects of inconvenience in assembly and disassembly, poor combination and unsuitability for complex environments in the prior art are overcome, and disassembly, interchange and addition or reduction are achieved.

Owner:武汉迈特绿色建筑科技股份有限公司

Overhead gantry for use in building panel construction

InactiveUS20070262040A1Improve construction qualitySolve the slow construction speedBase supporting structuresBraking devices for hoisting equipmentsEngineeringCold-formed steel

Owner:GENESISTP INC

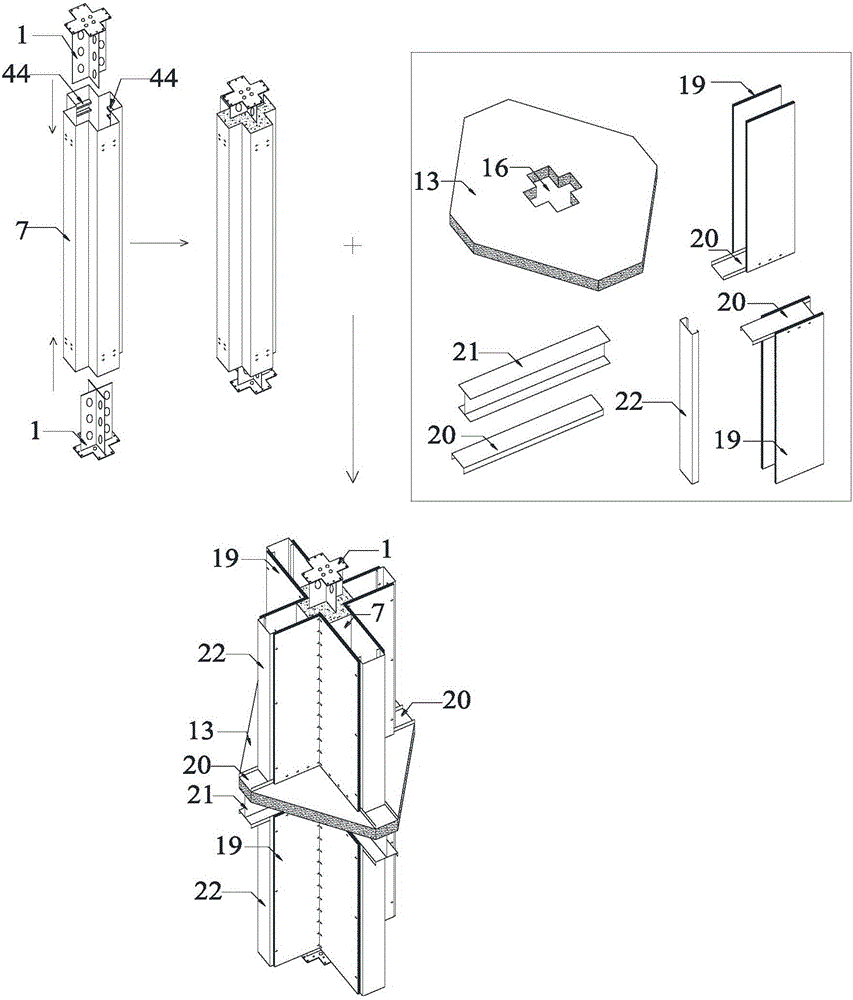

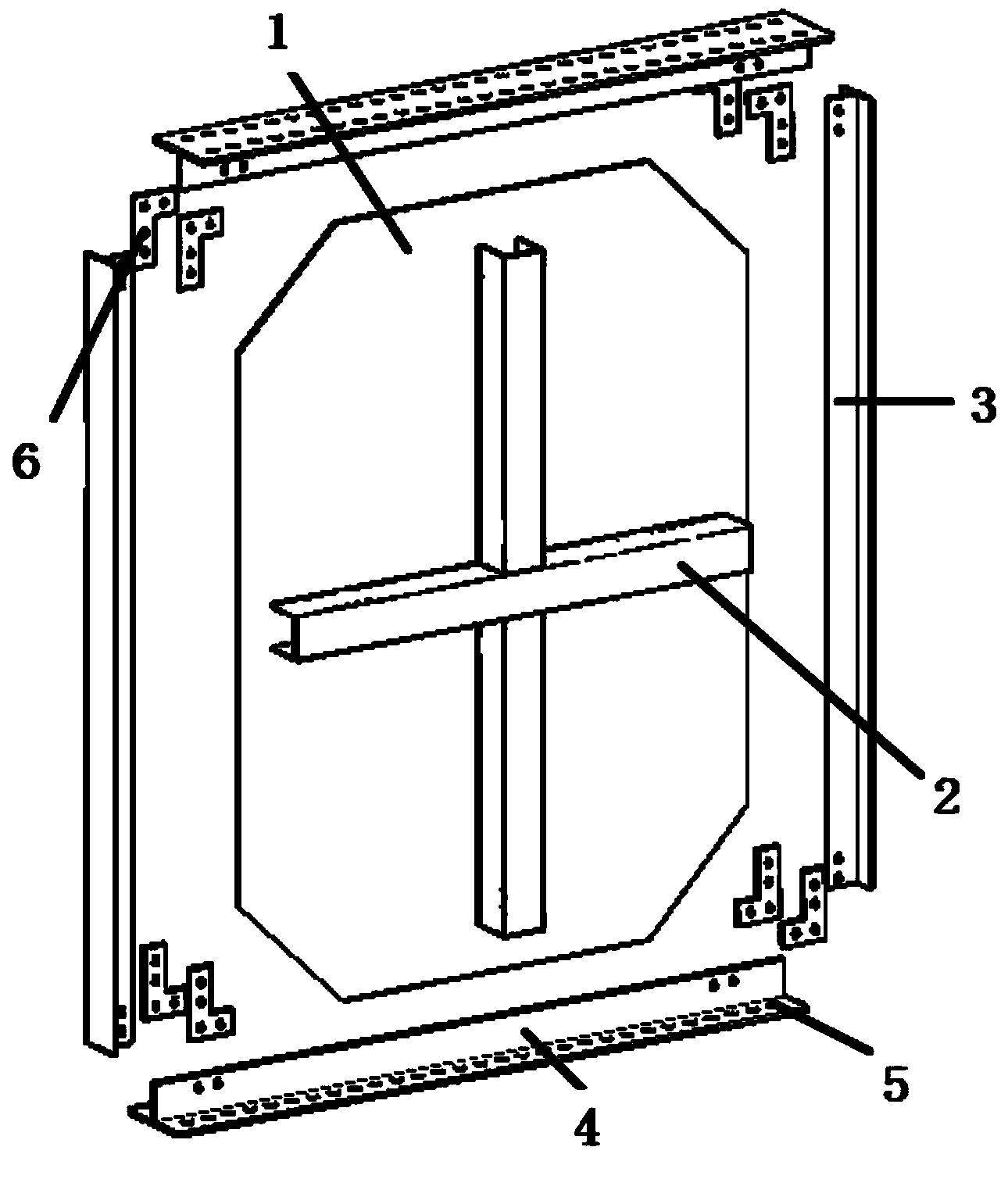

Assembly-type special-shaped composite wall made by thin-walled cold-formed steel

Provided is an assembly-type special-shaped composite wall made by thin-walled cold-formed steel. The assembly-type special-shaped composite wall is divided into three kinds including an L shape, a T shape and a cross shape. M-shaped horizontal edge members are connected with M-shaped vertical edge members by means of U-shaped connecting pieces. The M-shaped horizontal edge members are connected with a square steel tube by means of C-shaped connecting pieces. Due to the fact that different special-shaped middle frames are made by different positions of the C-shaped connecting pieces and the horizontal edge members are connected with the vertical edge members and the square steel tube by means of self-tapping screws, the special-shaped wall can bear horizontal load and vertical load at the same time. Displacement of a wall on the other side is restricted by the spatial torsional effect of the special-shaped wall so that the overall stability of the special-shaped wall is improved. The assembly-type special-shaped composite wall made by thin-walled cold-formed steel has following advantages: the assembly-type special-shaped composite wall is low in weight, high in bearing capability and production efficiency, great in assembly degree and low in cost and is endurable, sound-insulating, water-tolerant and is resistance to cracks and impact; and a connection mode of the assembly-type special-shaped composite wall is rapid in speed of construction and installation and low in installation cost and does require no scaffold.

Owner:山东永固钢结构集团有限公司

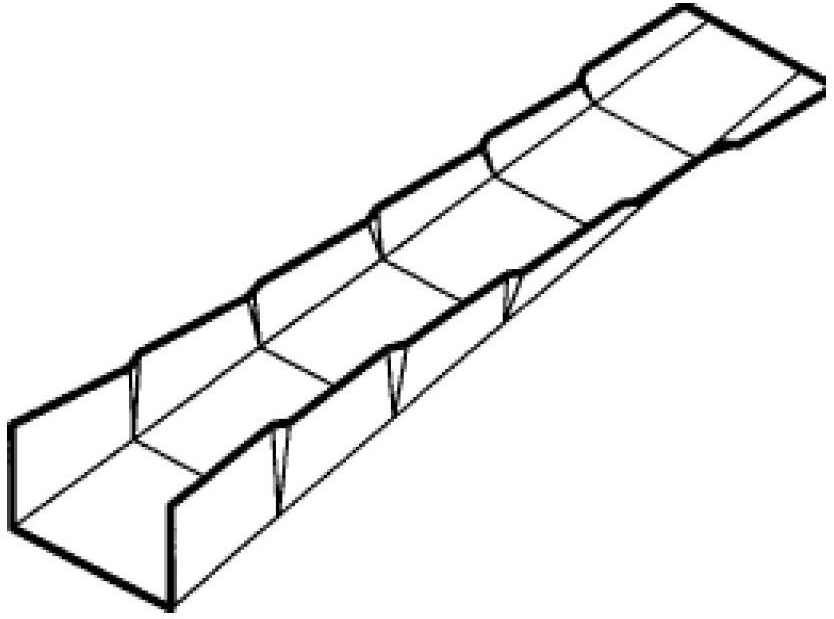

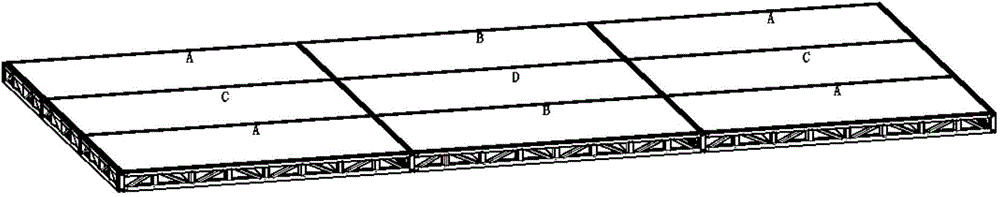

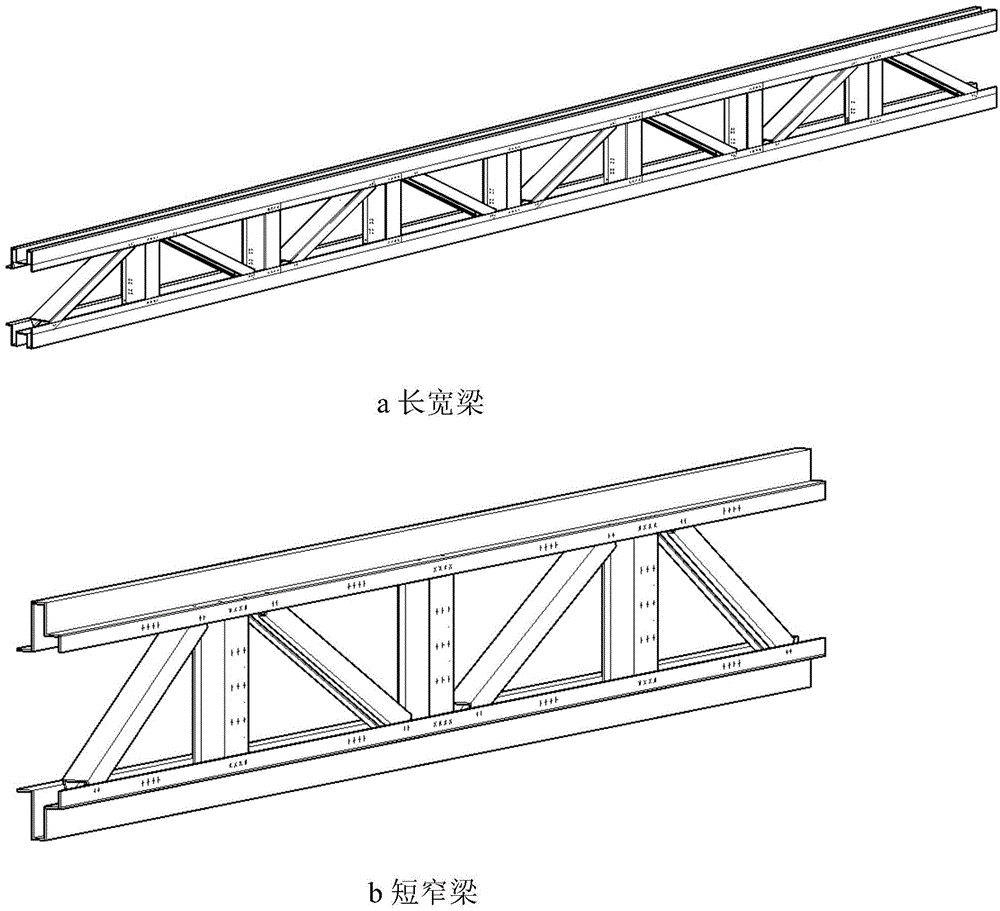

Novel modular assembled lower-layer thin-walled cold-formed steel floor module

Provided is a novel modular assembled lower-layer thin-walled cold-formed steel floor module. The floor module is formed by connecting A, B, C, and D four kinds of sub-units. The four kinds of sub-modules use a truss girder and profiled steel sheet and foam cement composite floor system. A concave (called a wide beam) thin-walled cold-formed steel section or a thin-walled cold-formed steel section which can be spliced into a concave shape (called a narrow beam) in a pairwise manner are used in the upper boom and the lower boom of the truss girder. A C-shaped section is used in the web plate of the truss girder. A surface plate comprises foam cement, a reinforcing mesh, and a cold-bending steel plate from top to bottom in sequence. The wide beam, the narrow beam, and the surface plate are assembled together, so as to form A, B, C, and D four kinds of floor sub-units. Through expanding, combining, and splicing the four kinds of floor sub-units, modular assembling of floor systems in different dimensions is realized. The floor module system combines modulization, factorization, and assemblage, and realizes factory-like production and fast assembling on site. The floor module is a green and environmentally-friendly structural system.

Owner:BEIJING UNIV OF TECH

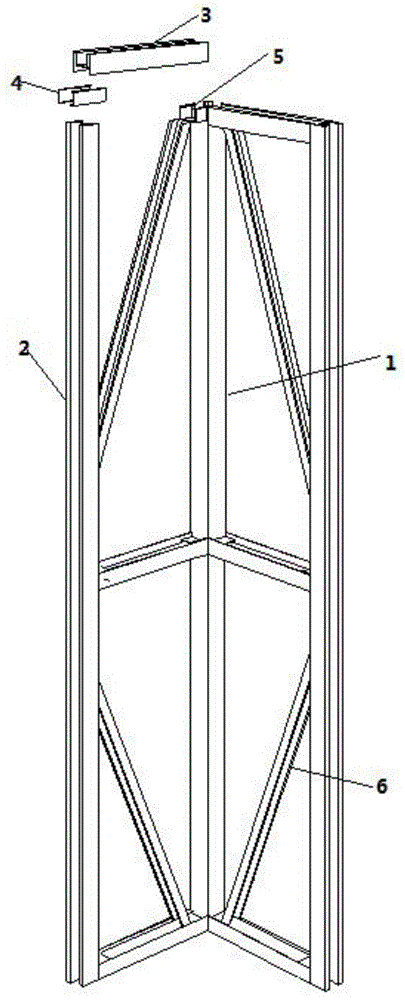

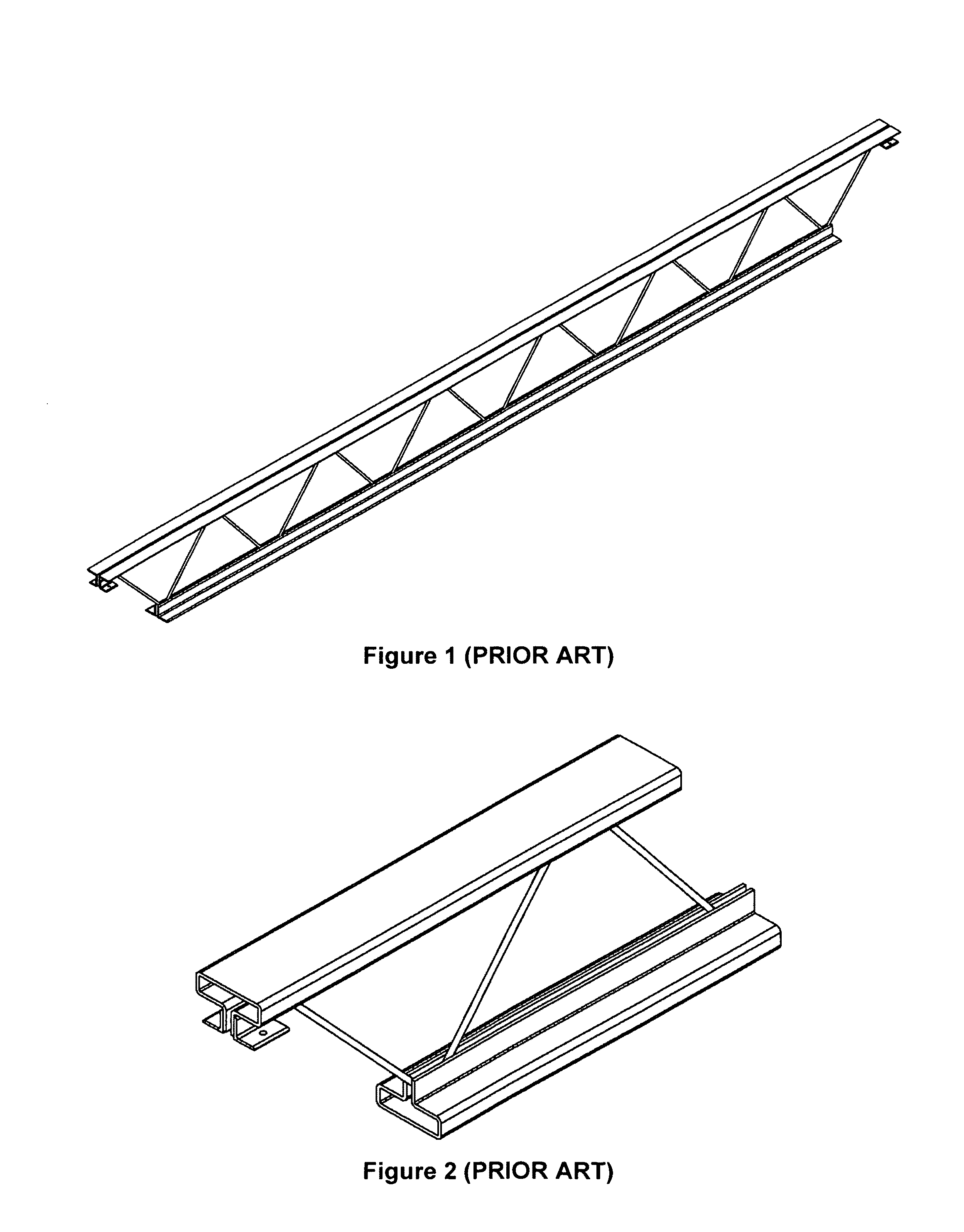

Cold-formed steel joist

ActiveUS20100139201A1Easy to customizeEasy to useFloorsLoad-supporting pillarsJoistCold-formed steel

An upper chord bearing joist comprising a top chord member and a bottom chord member, each having a flange portion and a web receiving portion including two web receiving tabs, each made from a unitary piece of metal; a generally planar steel web, a portion of the web being attached to the the top chord member and to the bottom chord member, wherein a top portion of the web is between the two web receiving tabs of the top chord member and a bottom portion of the web is between the two web receiving tabs of the bottom chord member; and a first and second pair of support members, each support member including a shoe portion, a web attaching portion, and an angled portion, the web attaching portion portion being attached to the web receiving tabs and the angled portion being in contact with the web. The joist may be cambered, have reinforcement stiffeners, and have a rotatable joint at either end. The joists may be used in composite with concrete or with wood.

Owner:ISPAN SYST LP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com