Assembly-type special-shaped composite wall made by thin-walled cold-formed steel

A technology of cold-formed thin-walled steel and assembly, which is applied in the direction of walls, building components, buildings, etc., can solve the problems of inability to form a unified node design standard, the gap between the modularization of the whole wall, and not many, so as to improve the level of shear resistance capacity, improved carrying capacity, and the effect of high carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

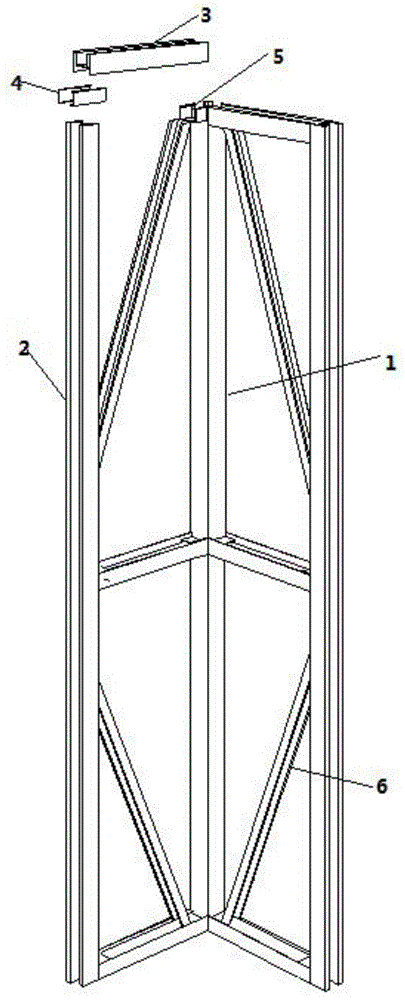

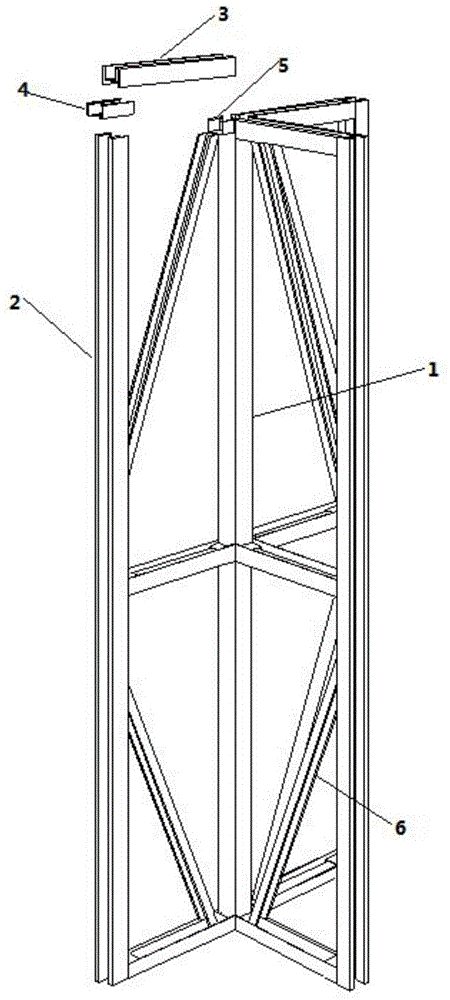

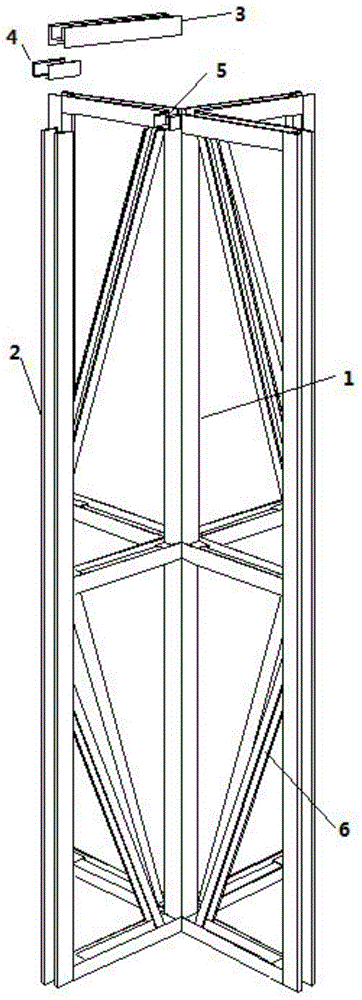

[0047] The best embodiment of the present invention will be described in detail below in conjunction with the technical solution and the drawings.

[0048] Production of modular assembly special-shaped cold-formed thin-wall steel composite wall:

[0049] In the specific implementation, the square steel tube (1) and the C-shaped connector (5) are cut according to the module size of the modular assembled composite wall that is actually required. According to the C-shaped connector (5) and the square steel tube (1) ) The welding position is different, as attached Image 6 , 7 , 8, pre-welded in the factory to form square steel pipes (1) and C-shaped connectors (5) for L-shaped, T-shaped, and cross-shaped composite walls, and then C-shaped connectors are made by tapping screws (5) To connect with the M-shaped horizontal edge member (3), insert one side of the diagonal brace (6) into the M-shaped steel horizontal edge member (3), and fix the position; use the self-tapping screw (8) to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com