Internal stiffened composite steel plate shear wall connected through high-strength bolts

A high-strength bolt and steel plate shear wall technology, applied to walls, building components, buildings, etc., can solve the problems of inconvenient construction, uneconomical thick plates, inconvenient production and construction, etc., and achieve the effect of avoiding material deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

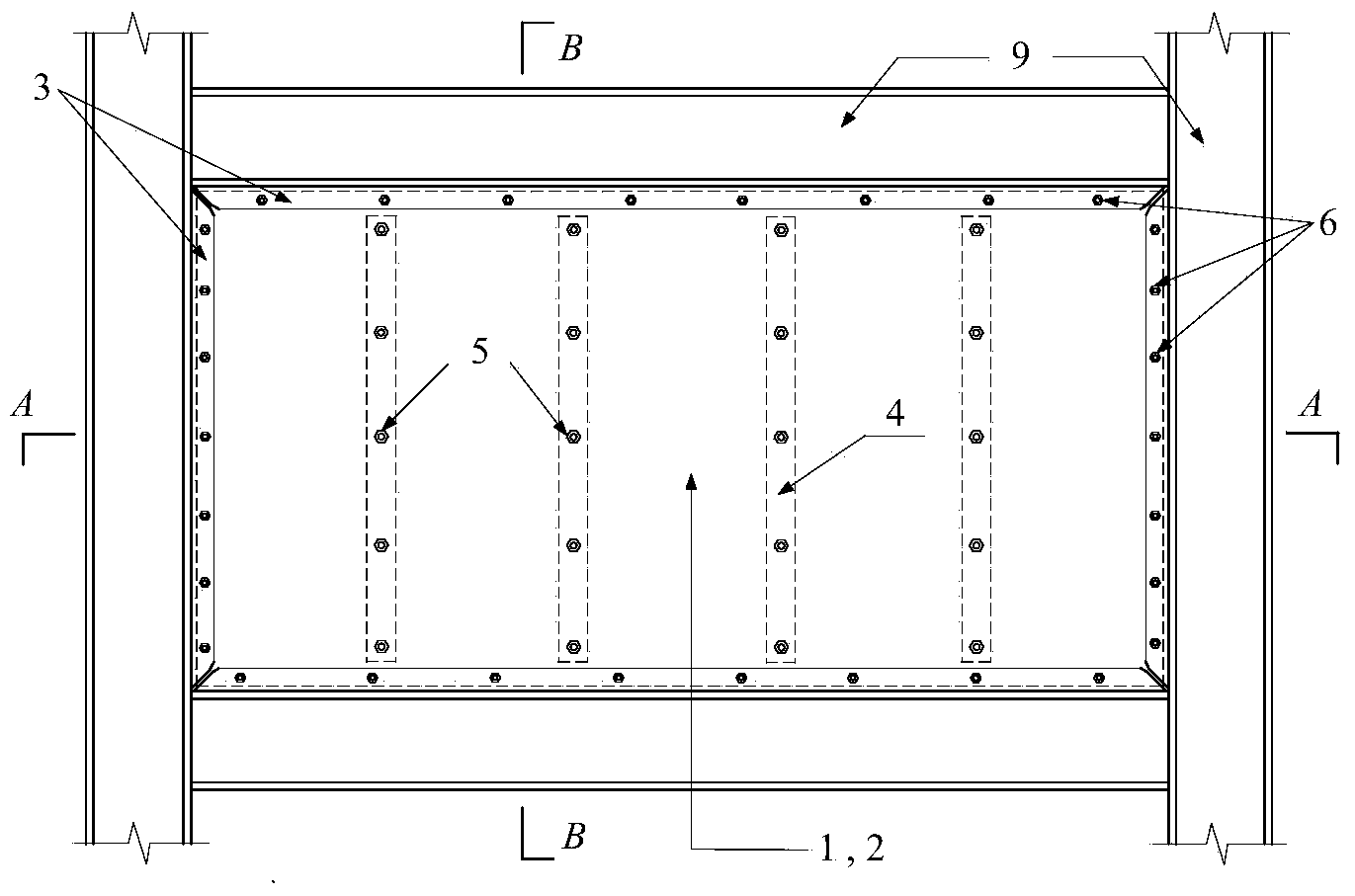

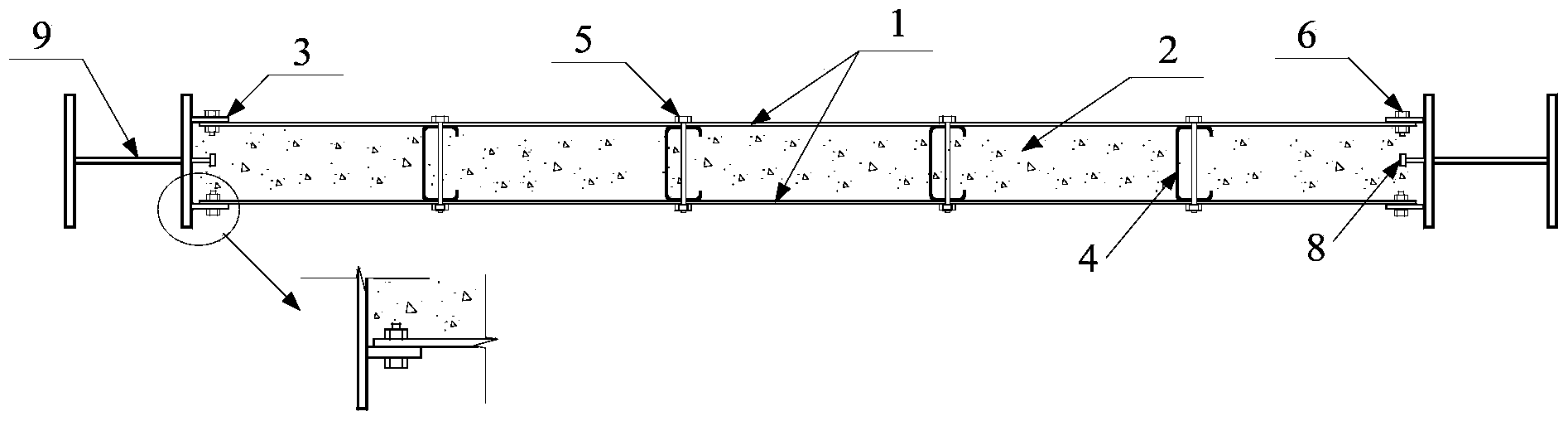

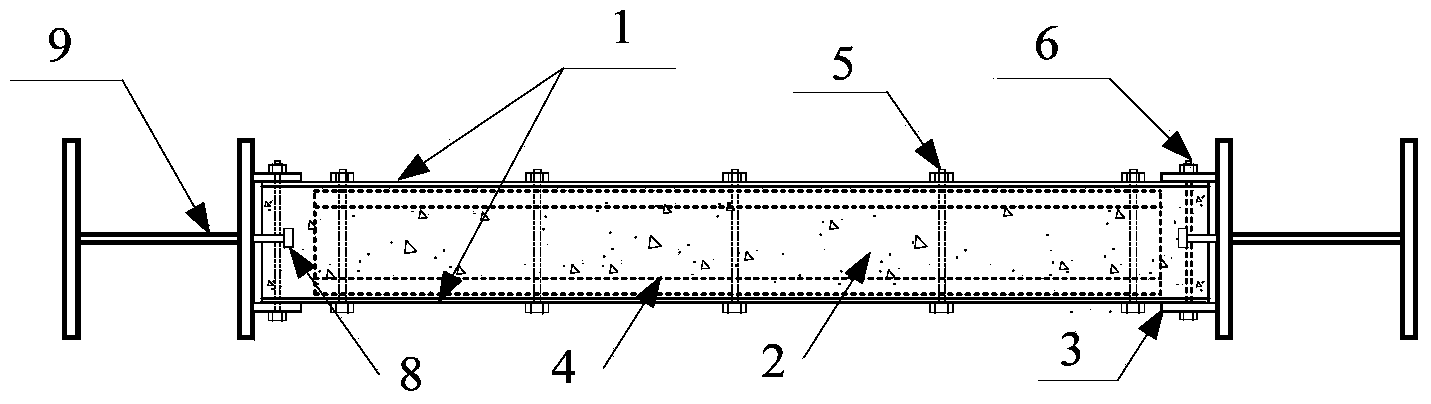

[0014] Attached below Figure 1-6 , to describe the implementation of the present invention in detail.

[0015] As shown in the figure, an internally stiffened composite steel plate shear wall connected by high-strength bolts includes the following components:

[0016] 1——Double-layer flat steel plate;

[0017] 2 - Concrete;

[0018] 3 - fish plate;

[0019] 4——Strengthening section steel;

[0020] 5——Long screw high-strength bolts;

[0021] 6——Friction type high-strength bolts;

[0022] 7 - connecting steel plate;

[0023] 8——shear stud;

[0024] 9 - Edge frame.

[0025] The present invention proposes an internally stiffened composite steel plate shear wall connected by high-strength bolts, which consists of the double-layer flat steel plate (1), concrete (2), fishplate (3), stiffening steel (4), long It is composed of screw high-strength bolts (5), friction-type high-strength bolts (5), connecting steel plates (6) and shear studs (8), and is embedded in the edge fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com