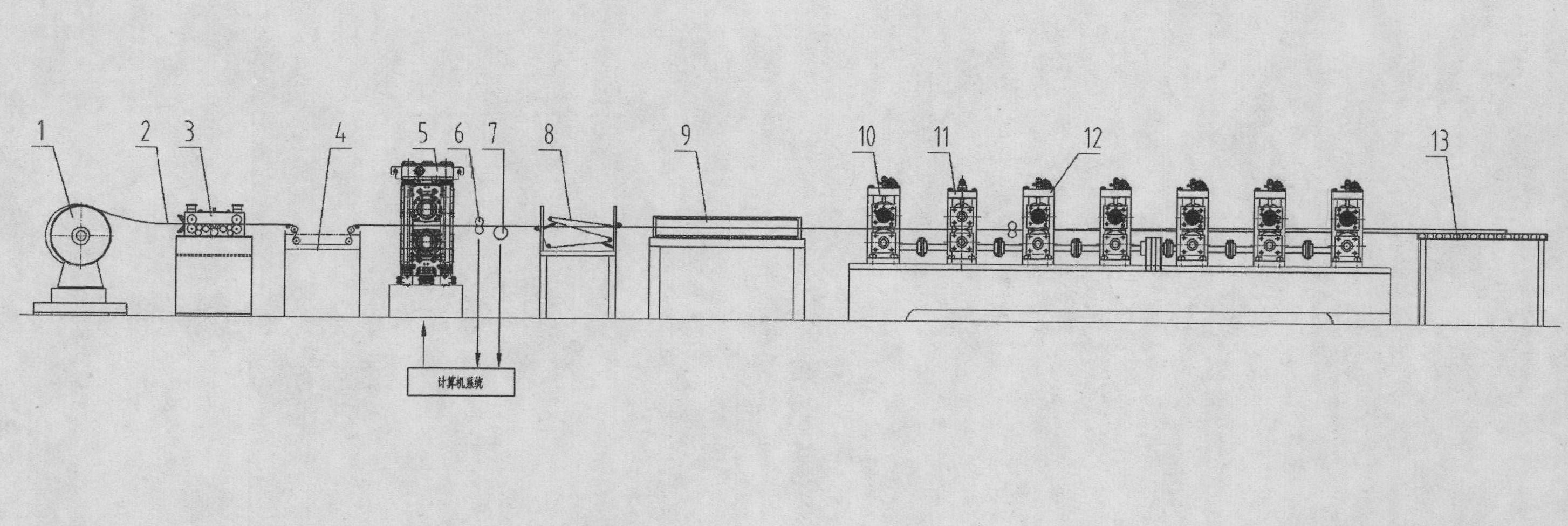

Method for forming longitudinal variable-thickness cold-bent section bars in continuous rolling manner and device thereof

A longitudinal variable thickness and variable thickness rolling technology, applied in the field of profile processing, can solve the problems of high use cost, low efficiency, poor flexibility of forming molds, etc., and achieve the effects of high production efficiency, reduced production cost, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

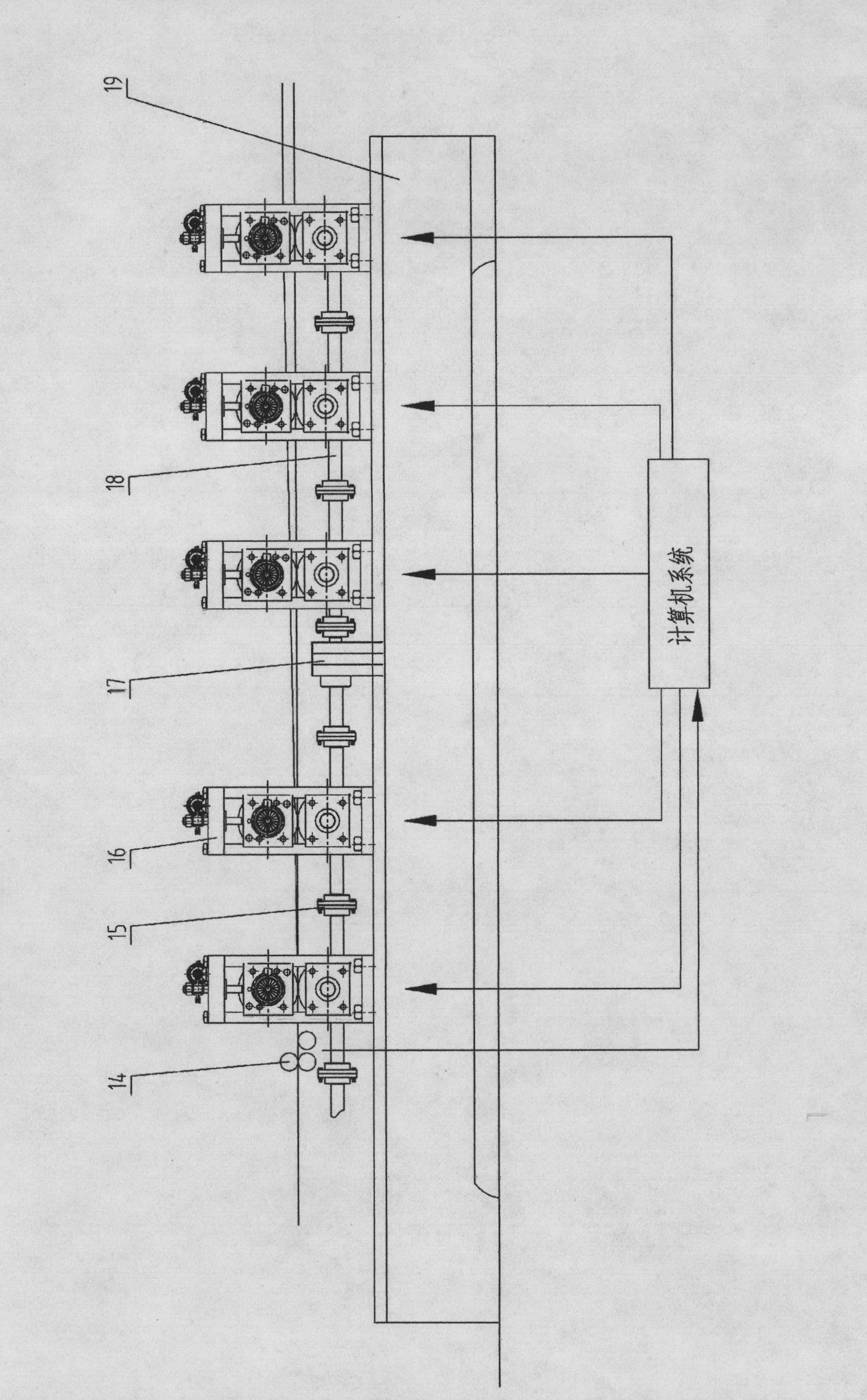

Method used

Image

Examples

Embodiment

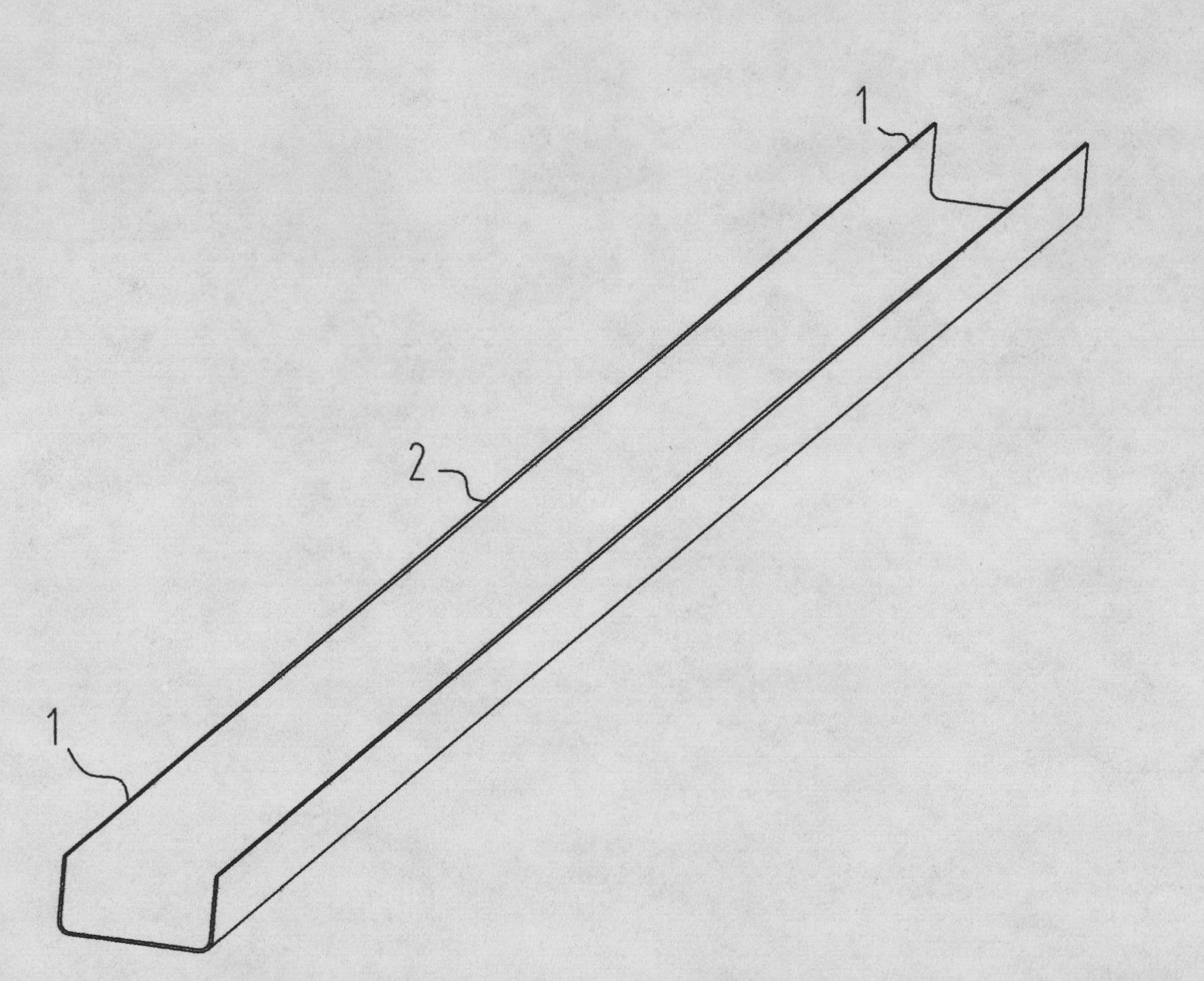

[0026] The continuous rolling and rolling forming device for cold-formed profiles with longitudinally variable thickness is adopted, and the forming of U-shaped profiles is taken as an example. The forming section is as follows Figure 3B , 3C. The material is Q235 equal-thickness plate with a width of 140mm and a thickness of 2mm as the raw material, the forming speed is 20mm / s, the slitting width of the plate after flexible rolling is 120mm, and the tempering temperature is 500°C. get as Figure 3A U-profile shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com