J-shape cold bend steel steel and rolling technology

A cold-formed steel, J-shaped technology, used in metal rolling, slender components, building components, etc., can solve the problem of difficult to ensure technical requirements and product quality, reduce the difference in rolling, easy to straighten , the different effects of reducing the degree of work hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

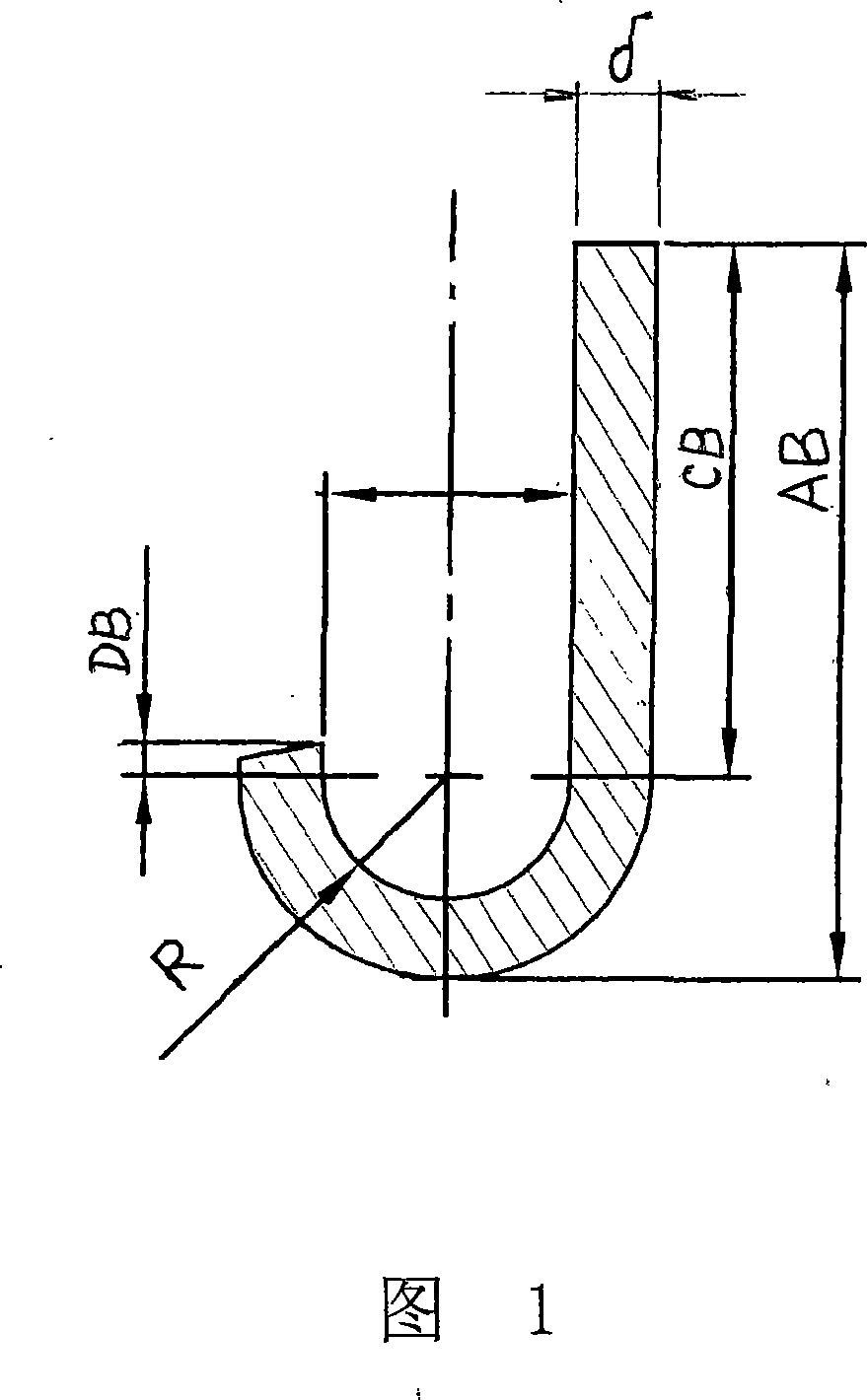

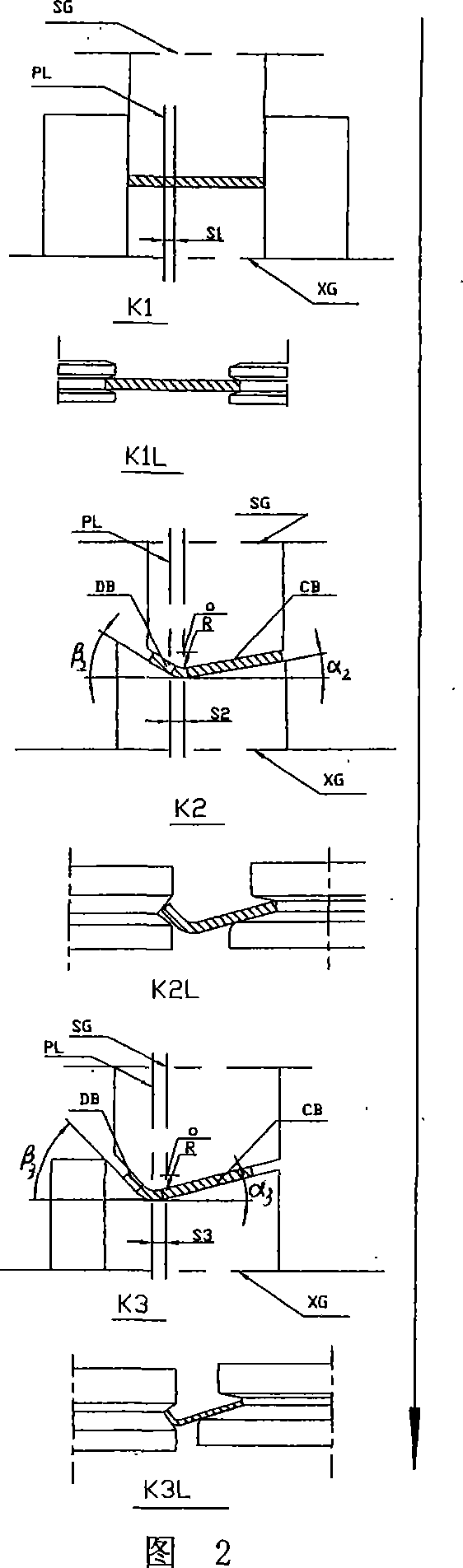

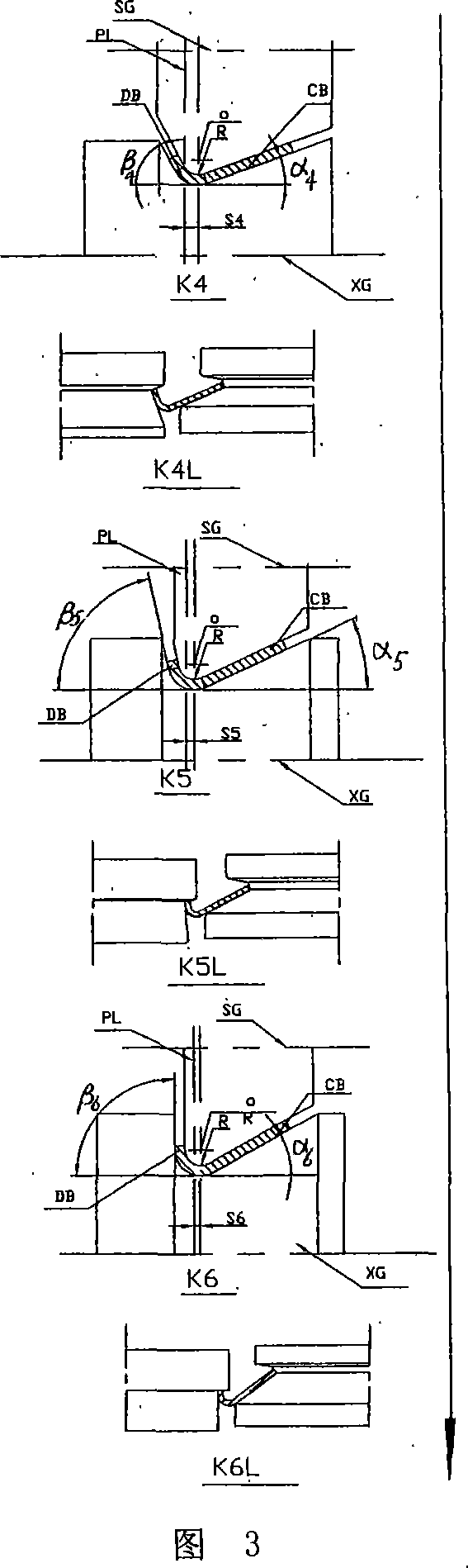

[0025] Below is an embodiment of the present invention, the present invention is further described in conjunction with the structure of accompanying drawing 1 and the rolling process diagram of accompanying drawing 2 to accompanying drawing 5: present embodiment is a kind of J-shaped steel, and the structural size of steel is The thickness δ is 6mm, the arc radius R is 7.5mm, the long side CB is 32mm, the short side DB is 2mm, the overall height AB of the section steel is 45.5mm, and the specification is 68*6, the grade is 1cr17 stainless slitting steel strip for processing production. The specific rolling process is as follows:

[0026] (1) The first rolling stand K1 is the upper and lower flat rolls and the guide vertical roll K 1L With the control of raw materials, there is no deformation at this time, including the guide vertical roller K in the next few steps 1L 、K 2L 、K 3L 、K 4L 、K 5L 、K 6L It is all to control the product to enter the next roll smoothly, and at t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Arc radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com