Multilayer cold-formed steel integrally prefabricated house and splicing method thereof

A technology of integral prefabrication and section steel, which is applied in the direction of residential buildings, buildings, building structures, etc., can solve the problems of slowing down the construction progress of structures, prolonging the construction period, and heavy workload, so as to simplify the on-site construction process and reduce the construction workload , The effect of simple construction scheme

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In conjunction with accompanying drawing, the concrete implementation process of the present invention is described in detail:

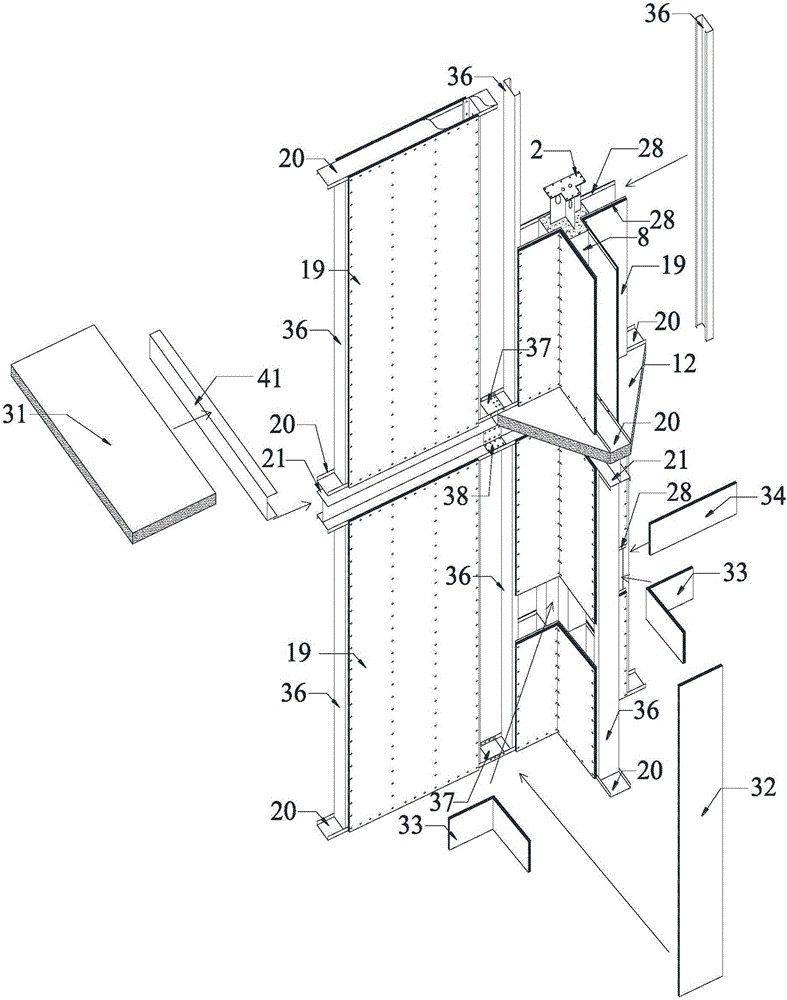

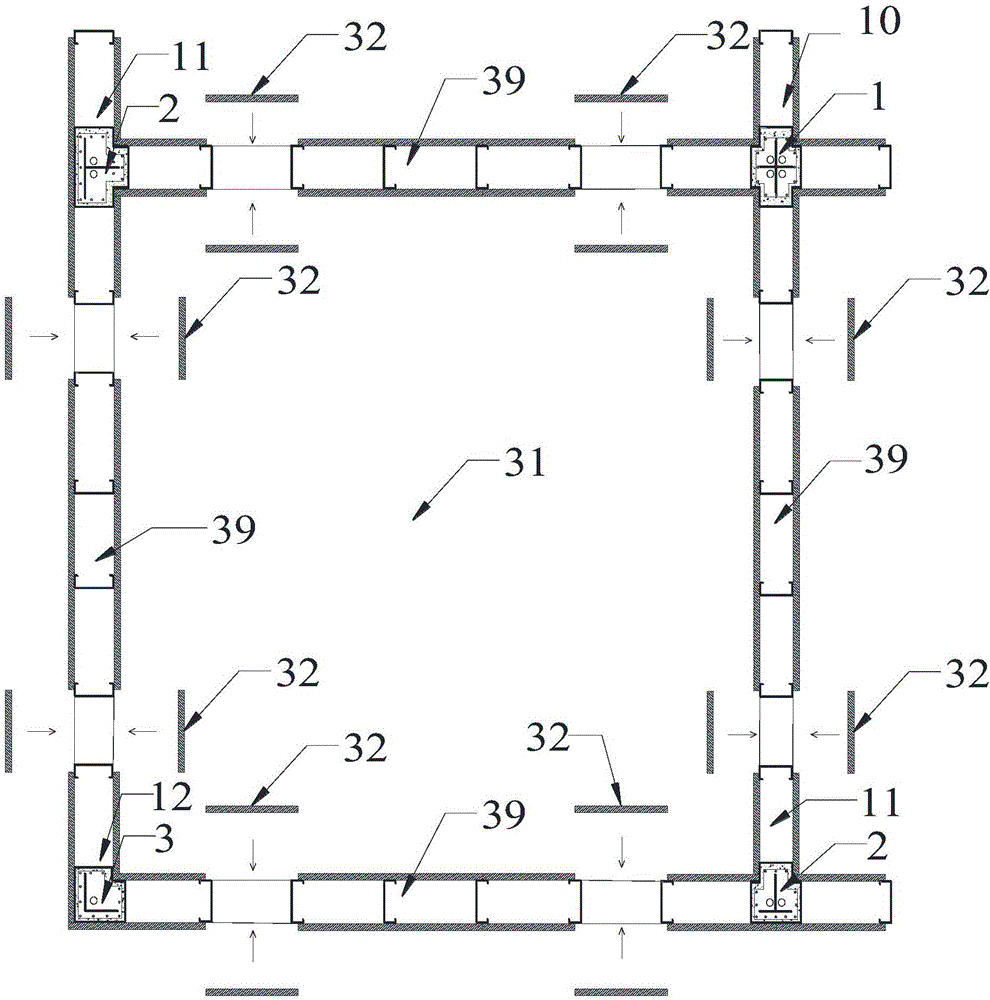

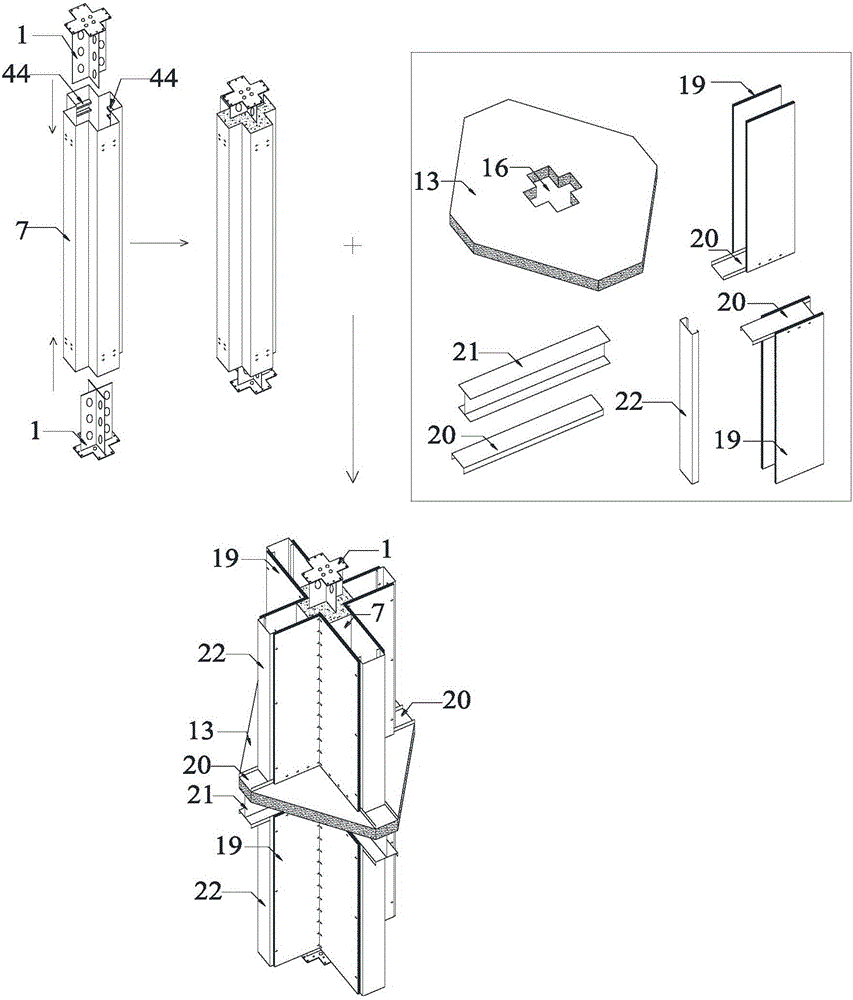

[0048] The schematic diagram of the partial structure assembly and connection of the multi-layer cold-formed steel integral prefabricated house of the present invention is as follows figure 1 as shown, figure 2 Shown is a schematic plan view of the on-site assembly and splicing of each module in the house structure. Depend on figure 1 , figure 2 As shown, the house structure is divided into central column modules, side column modules, corner column modules, wall modules, prefabricated floor slabs and connectors. Each column module and wall module can be prefabricated and assembled in the factory, transported to the site for hoisting, positioning the placement of each module, and using small lifting machinery (0.5t-2t) to hoist each part on site. The specific connection method includes the following process: Step 1: Prefabricate each colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com