Assembly type buckling restrained brace capable of visually inspecting segmented restraint

A buckling restraint, prefabricated technology, applied in protective buildings/shelters, building components, earthquake-proof, etc., can solve the problems of damage observation and waste of supports that cannot be buckling restraint, so as to reduce construction workload and avoid material waste. , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

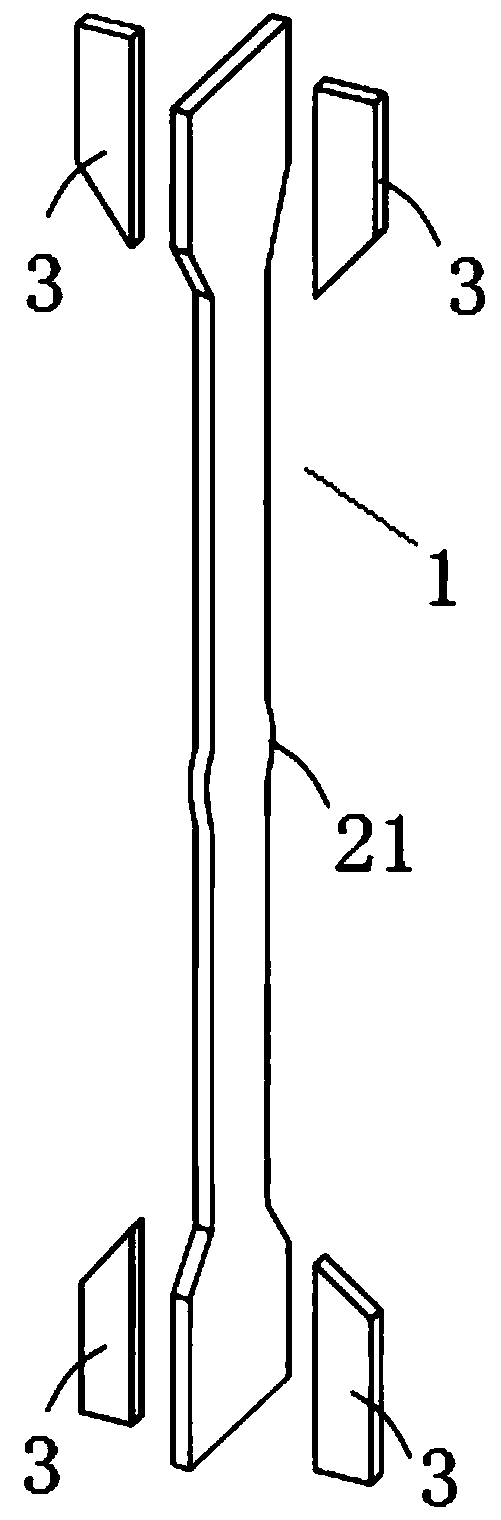

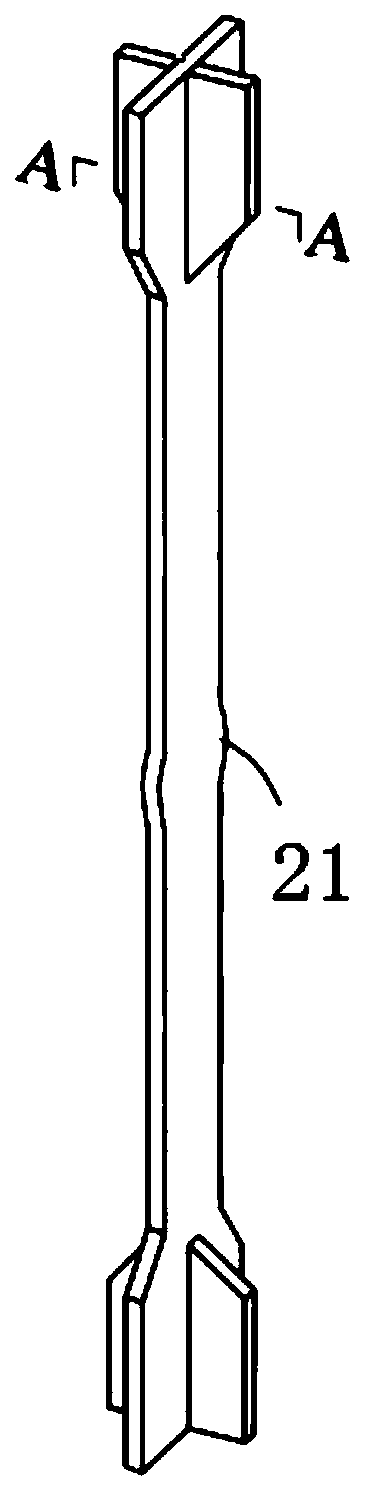

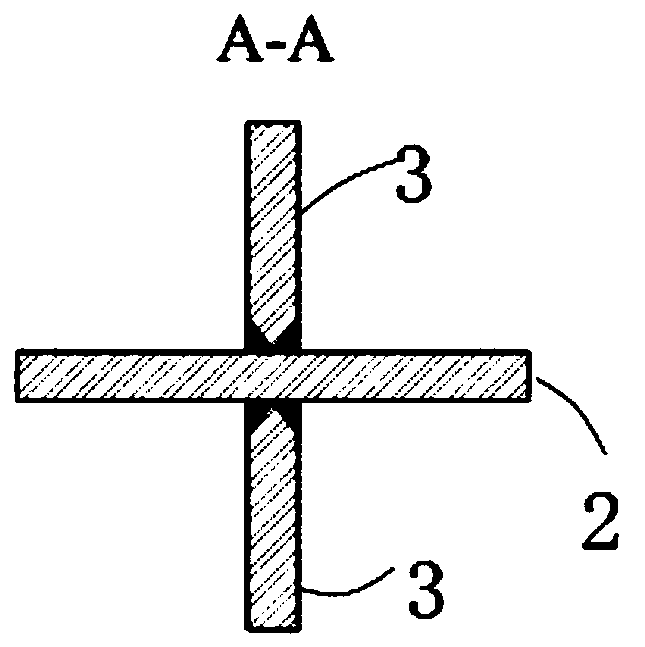

[0052] A fabricated buckling-restrained brace with visual inspection of segmental constraints, such as Figure 1-3 As shown, it includes a supporting inner core 1. The supporting inner core 1 includes an inline core plate 2 and a first reinforcing rib 3. The edges on both sides of the middle part of the inline core plate 2 have limit protrusions 21. The first reinforcing ribs Two ribs 3 are fixedly connected to both ends of the inline core plate 2, and symmetrically distributed on the two surfaces of the ends of the inline core plate 2, and welded perpendicularly thereto;

[0053] Such as Figure 4-5 As shown, along the length direction of the supporting inner core 1, there are sequentially detachably connected a first end peripheral restraint device 5, a middle peripheral restraint device 6 and a second end peripheral restraint device 4; the first end peripheral restraint device 5 is set as Two groups, relatively distributed on the two surfaces of one end of the supporting i...

Embodiment 2

[0062] Different from Embodiment 1, the supporting inner core 1 is composed of a cross-shaped core plate 22 and a second reinforcing rib 31. The edges on both sides of the middle part of the cross-shaped core plate 22 have limit protrusions 21, and the ends of the cross-shaped core plate 22 The fillet welds on both sides of the second rib plate 31 are connected between two adjacent core plates at the top; correspondingly, the end constraining plate 9 and the middle constraining plate 14 are all symmetrical structures, and the end constraining plate 9 has a wide cross-section The two middle parts are provided with a notch for accommodating the second reinforcing rib 31 along the vertical direction, and the middle part of the narrow section is also provided with a through groove adapted to the cross-shaped core plate 22; The through groove for the cross-shaped core plate 22; the side where the end connecting plate 11 is close to the cross-shaped core plate 22 is also provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com