Integrated foldable beam and plate construction template

A technology of folding beams and templates, which is applied in the field of pouring concrete on site and fixing buildings, can solve the problems of low turnover times, soaring labor costs, low labor productivity, etc., to reduce damage, expand the force-bearing area, and reduce external forces The effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

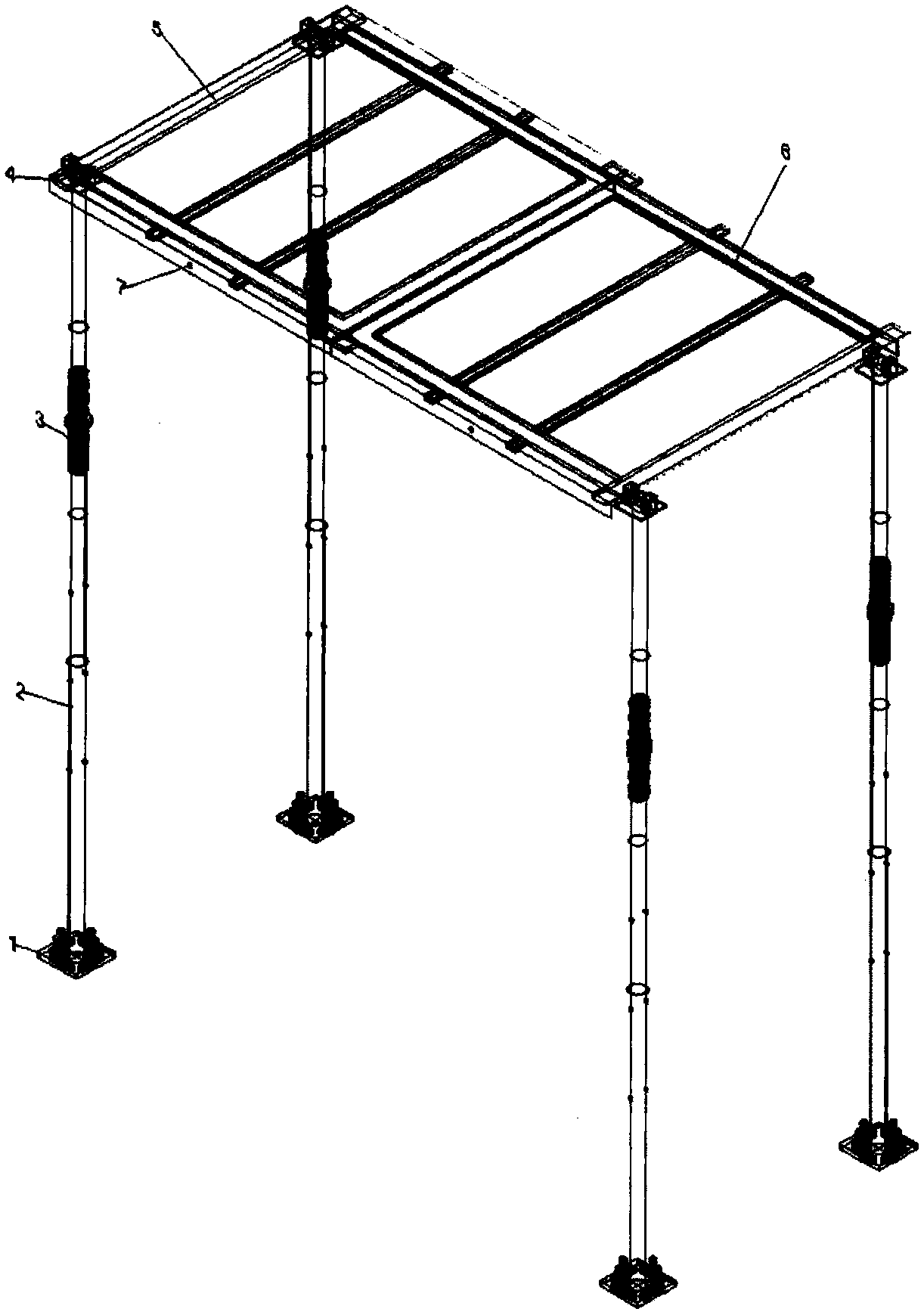

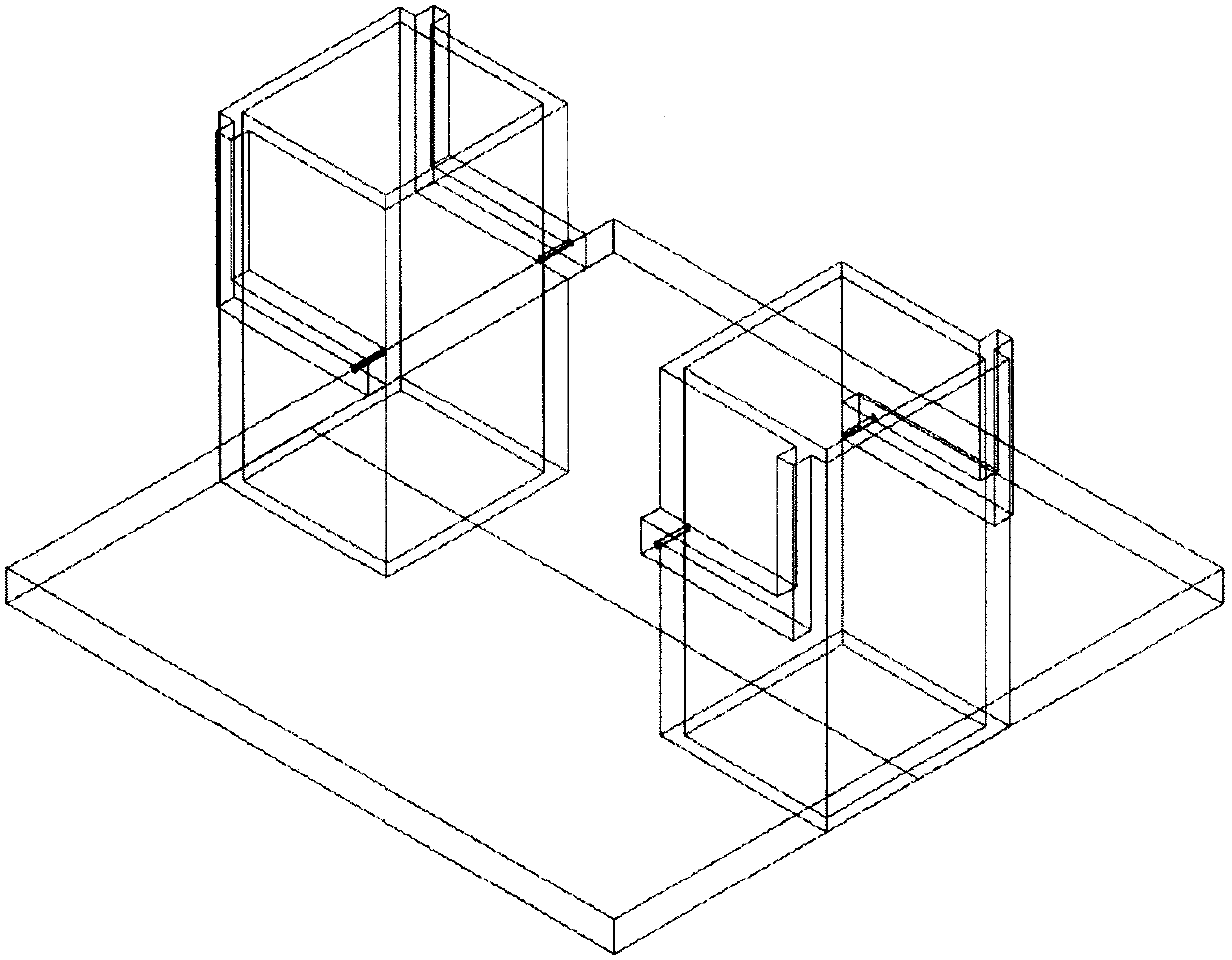

[0019] An integrated foldable construction beam and slab formwork, the implementation process includes: factory modular production formwork components, on-site assembly, transport to the working face to unfold, link each formwork, remove the formwork after the scheduled time, fold and transport to the next working surface. details as follows:

[0020] 1. According to the standard modular production template standard parts, according to the actual size of the project to produce non-standard parts, parts transported to the site for parts assembly.

[0021] 2. Set out the wires on site to determine the position of the formwork system on site.

[0022] 3. Hoist a row of formwork system to the working surface, adjust the anchor bolts until the rollers touch the ground, and realize the formwork unfolding. 4. Roughly adjust the height of the pole according to the height requirements, and then fine-tune the height of the pole to meet the requirements.

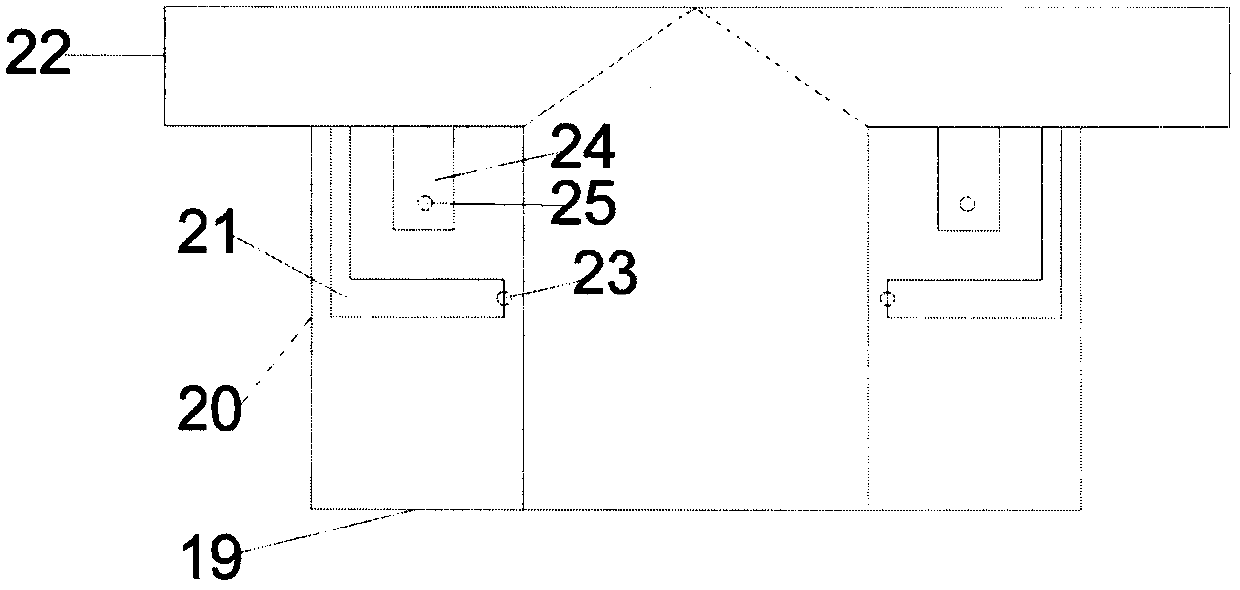

[0023] 5. Adjust the anchor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com