Low driving force self-cleaning and heat transfer enhancement rotor in heat exchange tube

A technology that enhances heat transfer and driving force. It is applied in the direction of cleaning heat transfer devices, heat transfer modification, and cleaning of rotating equipment. It is beneficial to anti-fouling and descaling, increasing the effective area and increasing the degree of turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

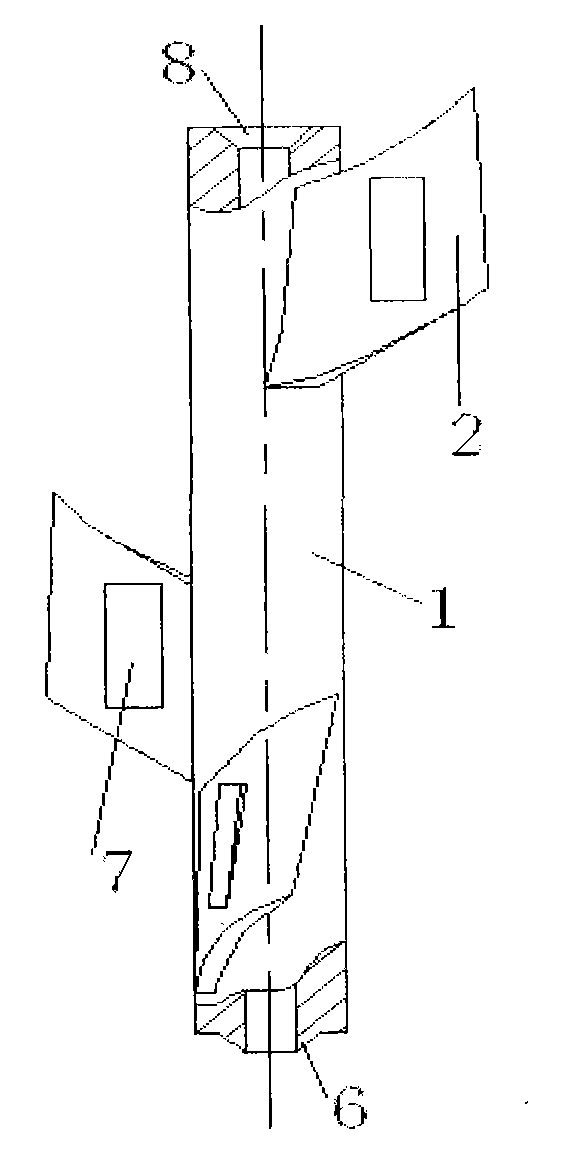

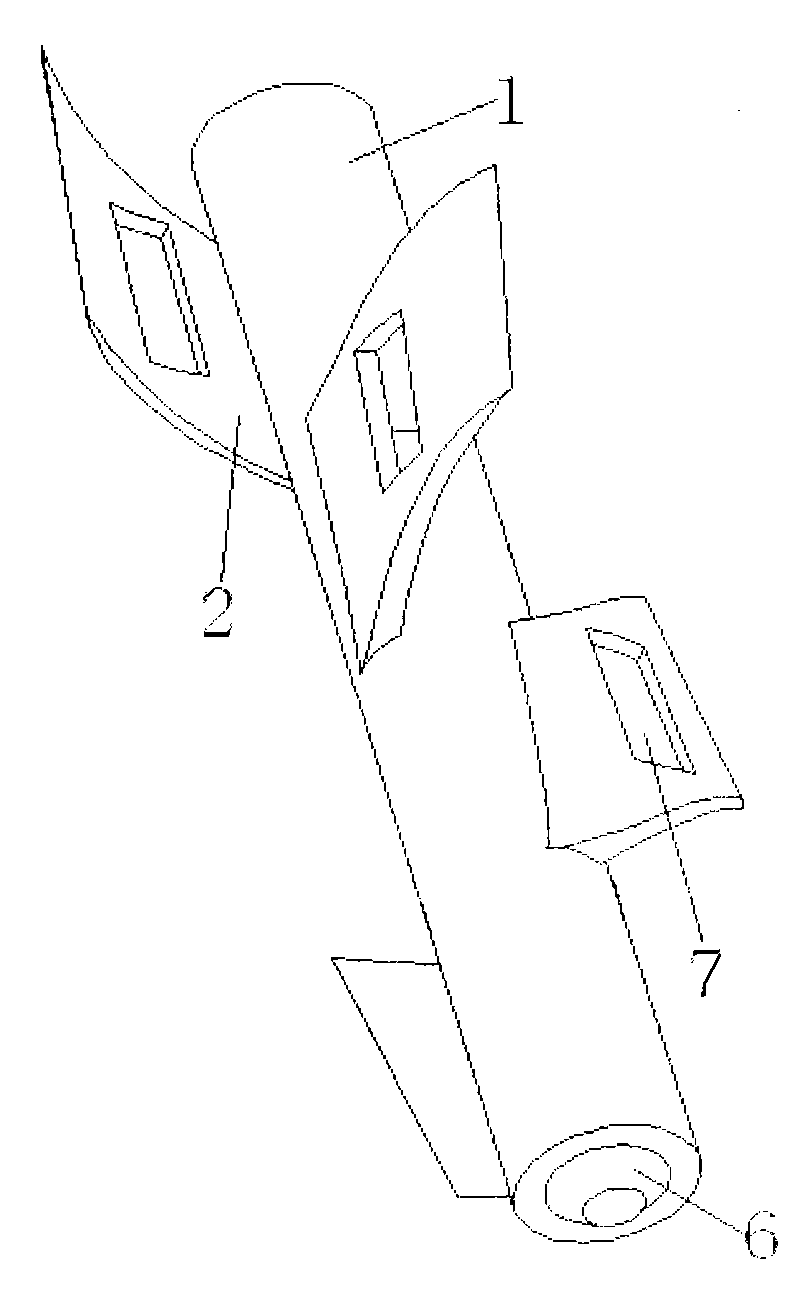

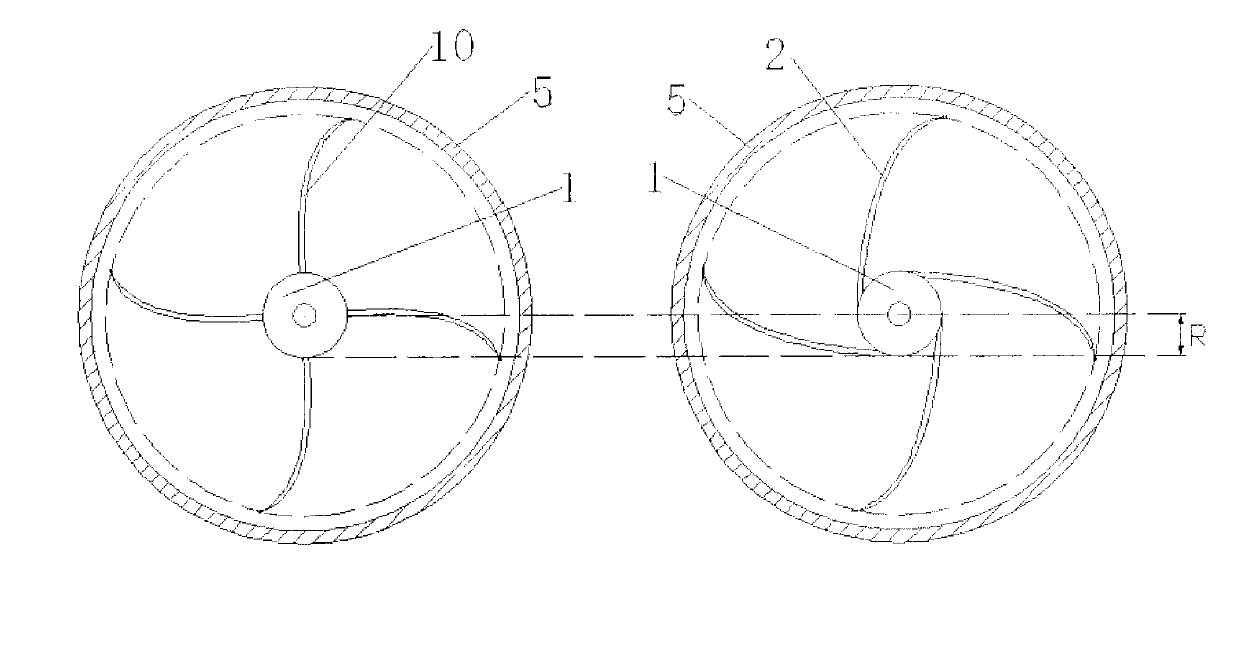

[0025] Such as Figure 8 As shown, an implementation example of a low driving force self-cleaning and enhanced heat transfer rotor in the heat exchange tube of the present invention, the rotor is composed of a hollow cylinder 1 and blades 2, and the blades 2 are uniformly fixed on the hollow cylinder 1 in sections , the outer surface 11 of the blade is tangent to the edge of the hollow cylinder 1, and the tangent line track is not parallel to the axis of the hollow cylinder 1, so that the blade is in the shape of a curved surface, forming a barrier to the axial flow of the fluid, and the rotor obtains rotational power. The rotor of the present invention is mounted on the rotating shaft 4 and placed in the heat exchange tube 5 with the pendant 3 , the pendant 3 is fixed at both ends of the heat exchange tube, and the two ends of the rotating shaft 4 are respectively fixed on the pendant 3 by rivets 9 .

[0026] Figure 1 to Figure 6 Shown is that the cross-sectional shape of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com