Chassis system of light steel structure assembly and decoration integrated building

A light steel structure and building technology, applied in the direction of building, building components, building structure, etc., can solve the problems of the adverse impact of the original ecological environment of the building site, the positioning error of the column anchor bolt, and the cumbersome construction steps, so as to avoid the wall and scattered water damage, improve strength and stiffness, and reduce the effect of on-site construction workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings.

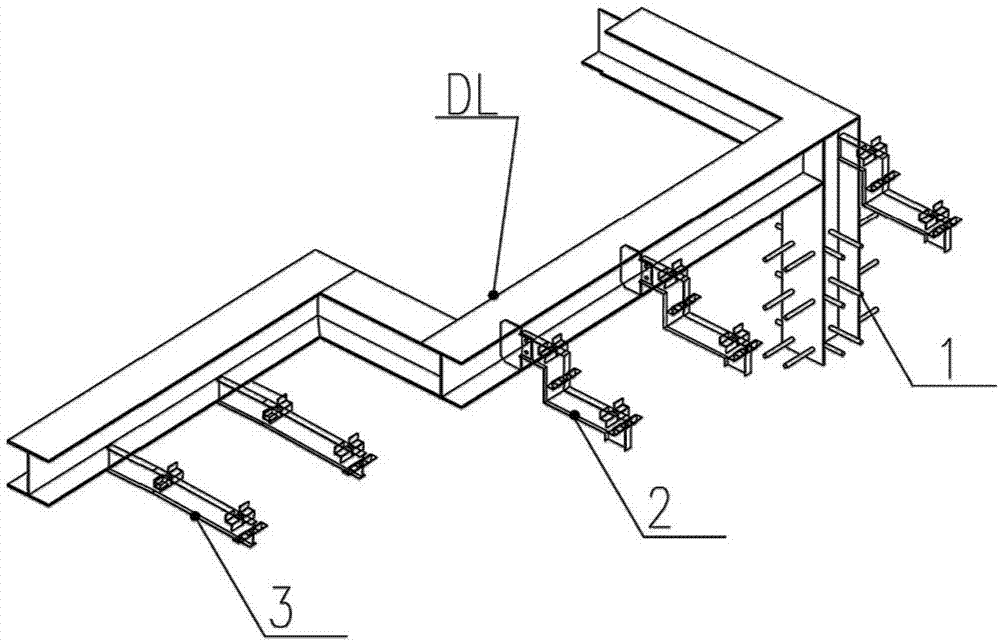

[0042] Such as Figure 1-Figure 3As shown, a light steel structure assembly and decoration integrated building chassis system of the present invention is characterized in that it includes the foundation 1 of the assembly and decoration integrated building, the water distribution system 2 of the assembly and decoration integrated building and the assembly and decoration integrated building. outdoor steps 3,

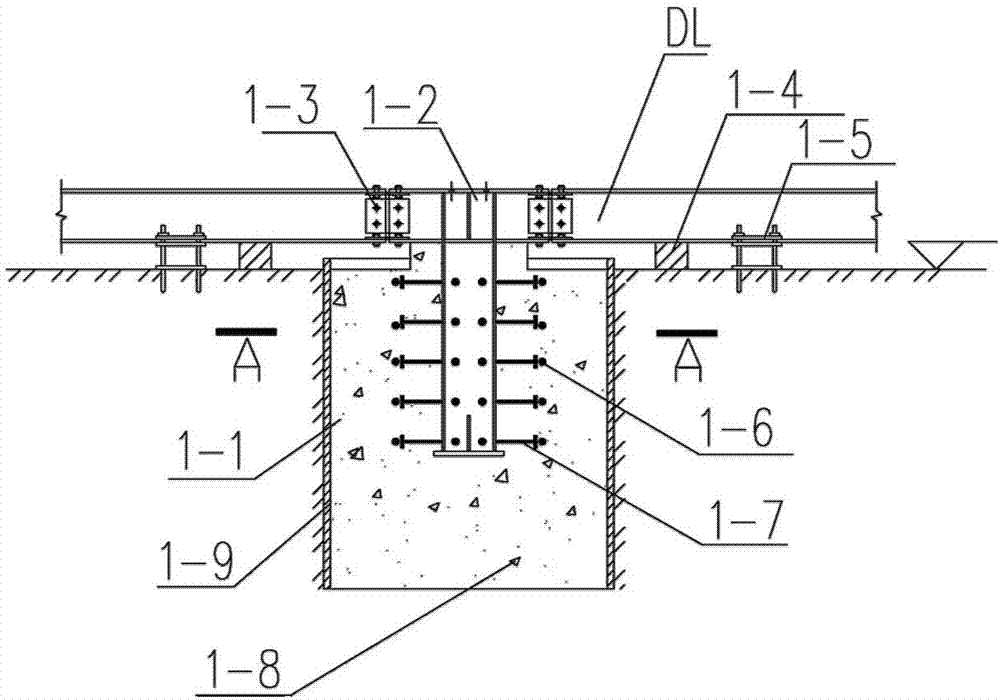

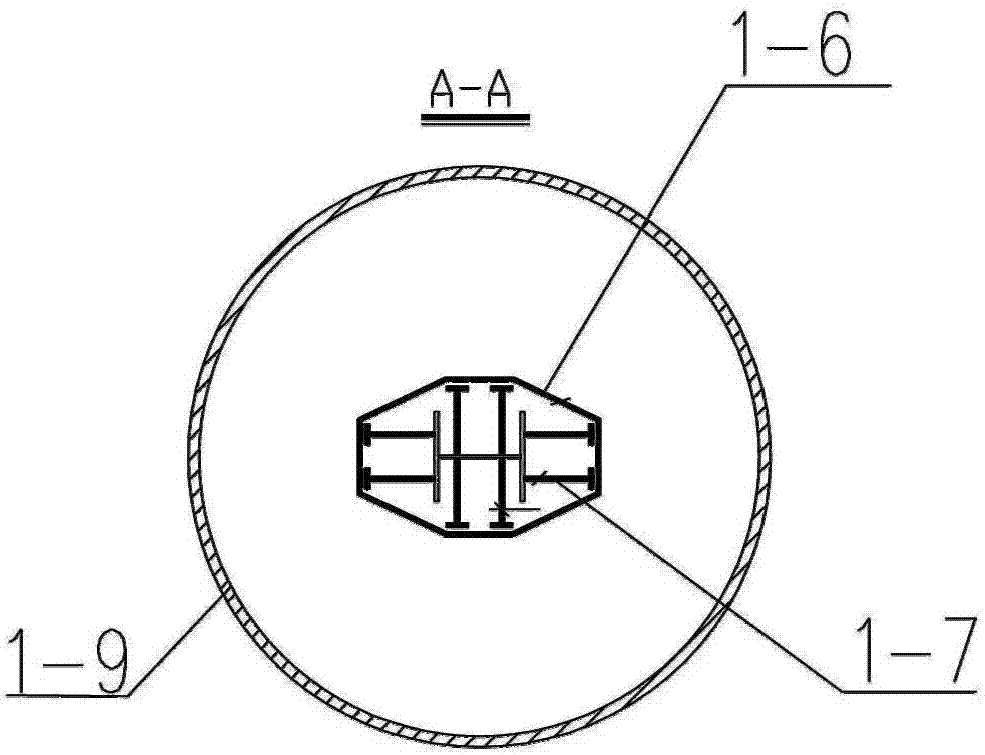

[0043] The foundation 1 of the integrated assembly and decoration building includes a foundation pit 1-1, a foundation pit retaining wall 1-9 arranged on the inner wall of the foundation pit 1-1, a section steel column foot 1-2, and pouring in the foundation pit 1-1 Concrete 1-8, the foundation pit retaining wall is a thin-plate cylindrical retaining wall, and the material of the thin-plate cylindrical retaining wall is thin steel plate.

[0044] The lower part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com