Modularized-assembly house system

A modular and systematic technology, applied in the direction of roofing, roof decoration, climate change adaptation, etc., can solve the problems that the wall cannot be easily interchangeable, does not fully conform to the modularity, and cannot achieve permanent housing, etc. The effect of project investment recovery period, shortening investment recovery period, ensuring construction safety and civilized construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, they are only examples, and the advantages of the present invention will become clearer and easier to understand.

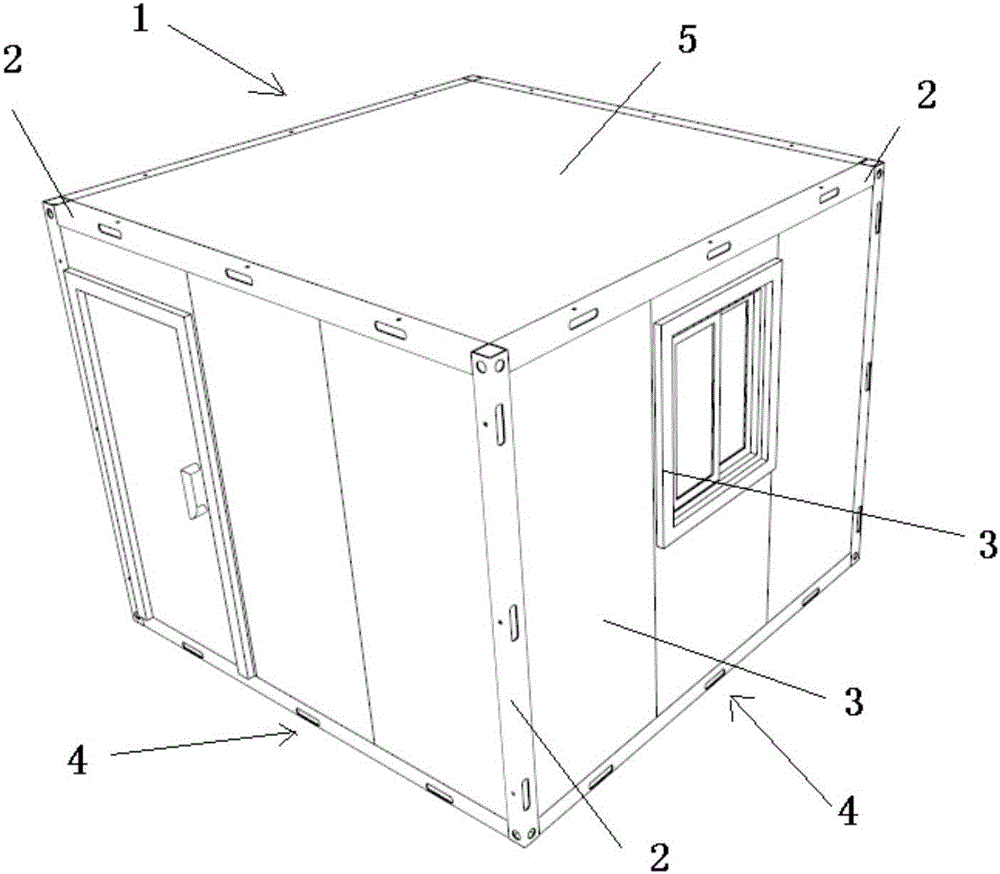

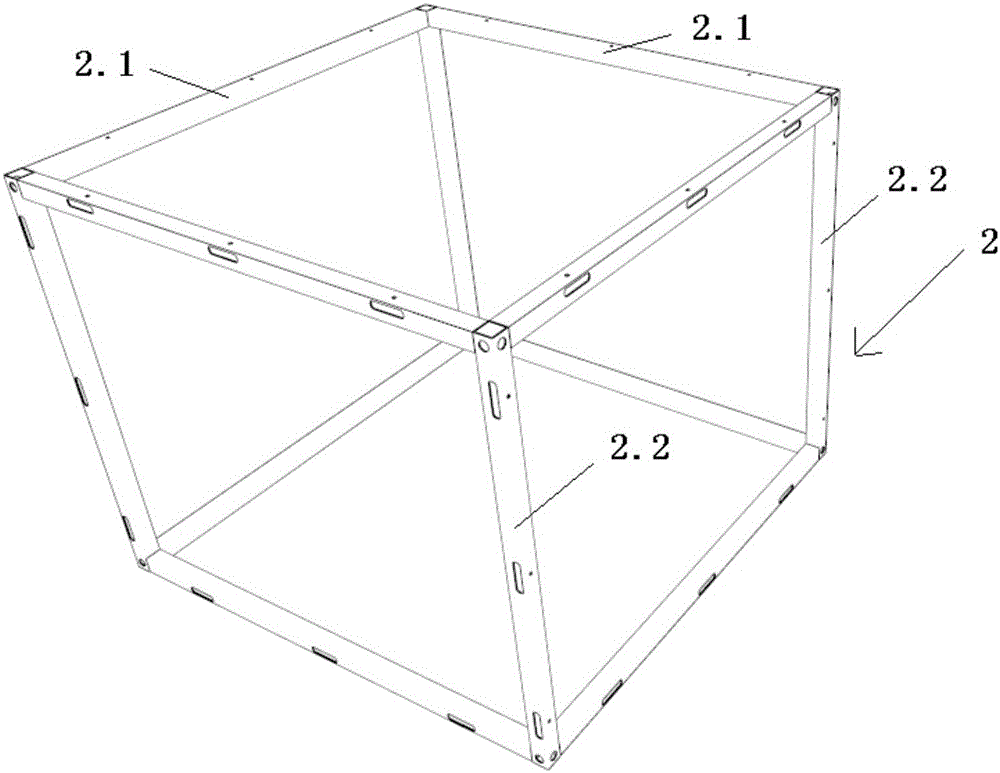

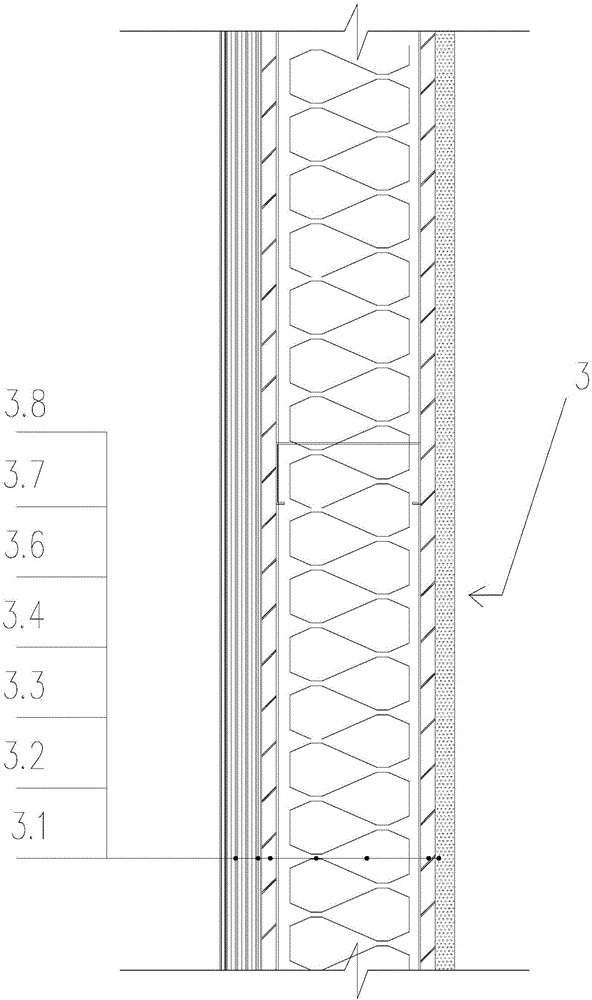

[0037] refer to Figure 1-14 As shown: the modular assembly house system of the present invention is characterized in that it includes one or more modular houses 1, and the houses 1 within two floors extend infinitely in the horizontal direction, and each of the houses The house 1 is composed of a steel structure frame 2, a cold-formed thin-walled steel system wall panel 3, a cold-formed thin-walled steel system floor slab 4 and a cold-formed thin-walled steel system roof 5; the steel structure frame 2 includes beams parallel to each other up and down 2.1 and the vertically connected column 2.2, the eight corners surrounded by the beam 2.1 and the column 2.2 are all co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com