Patents

Literature

30results about How to "Guarantee civilized construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

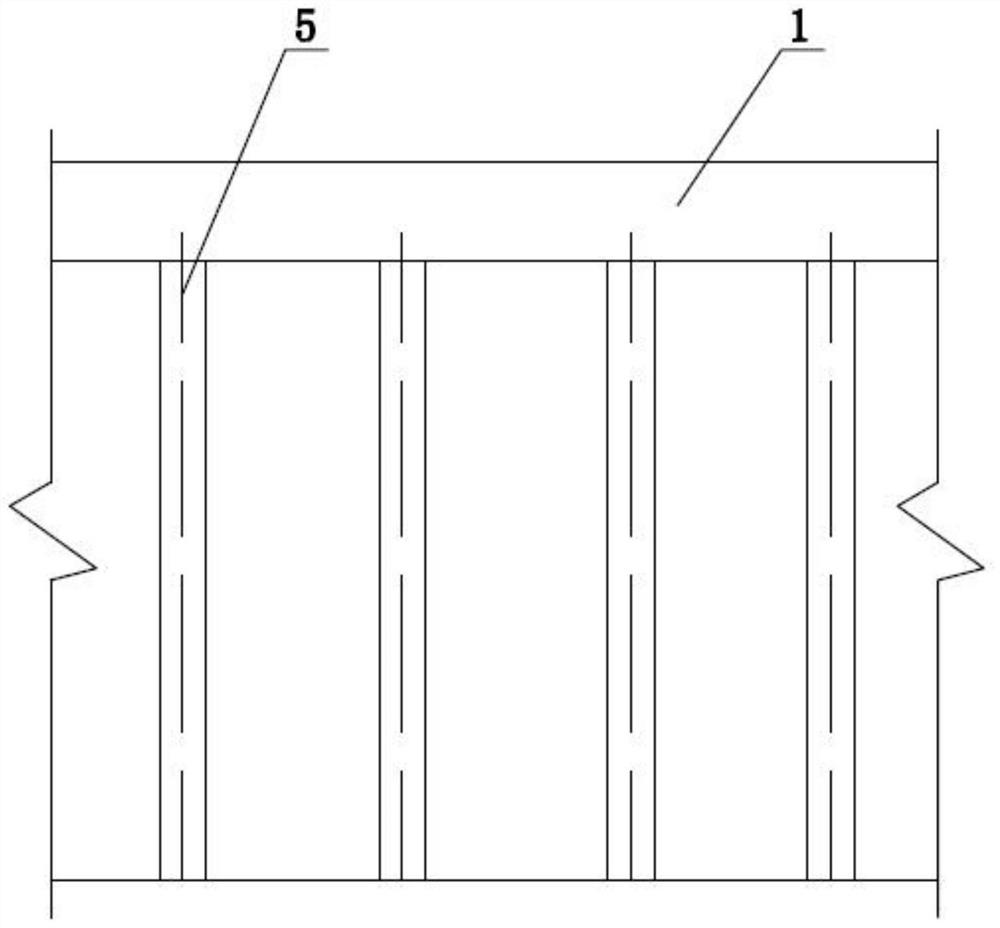

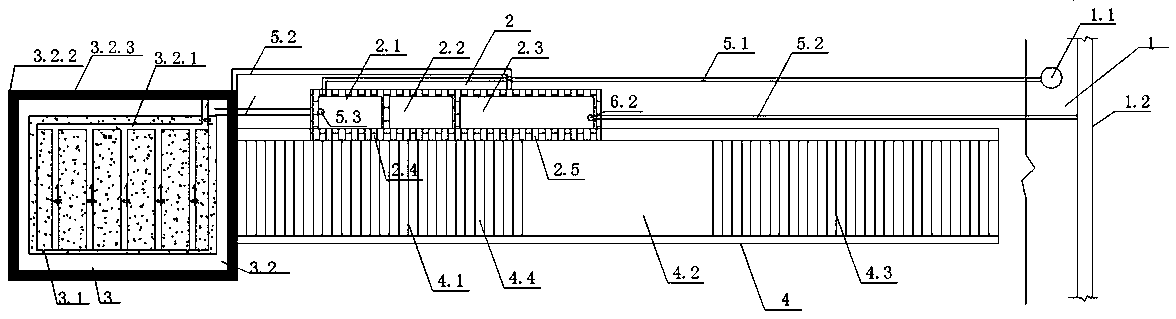

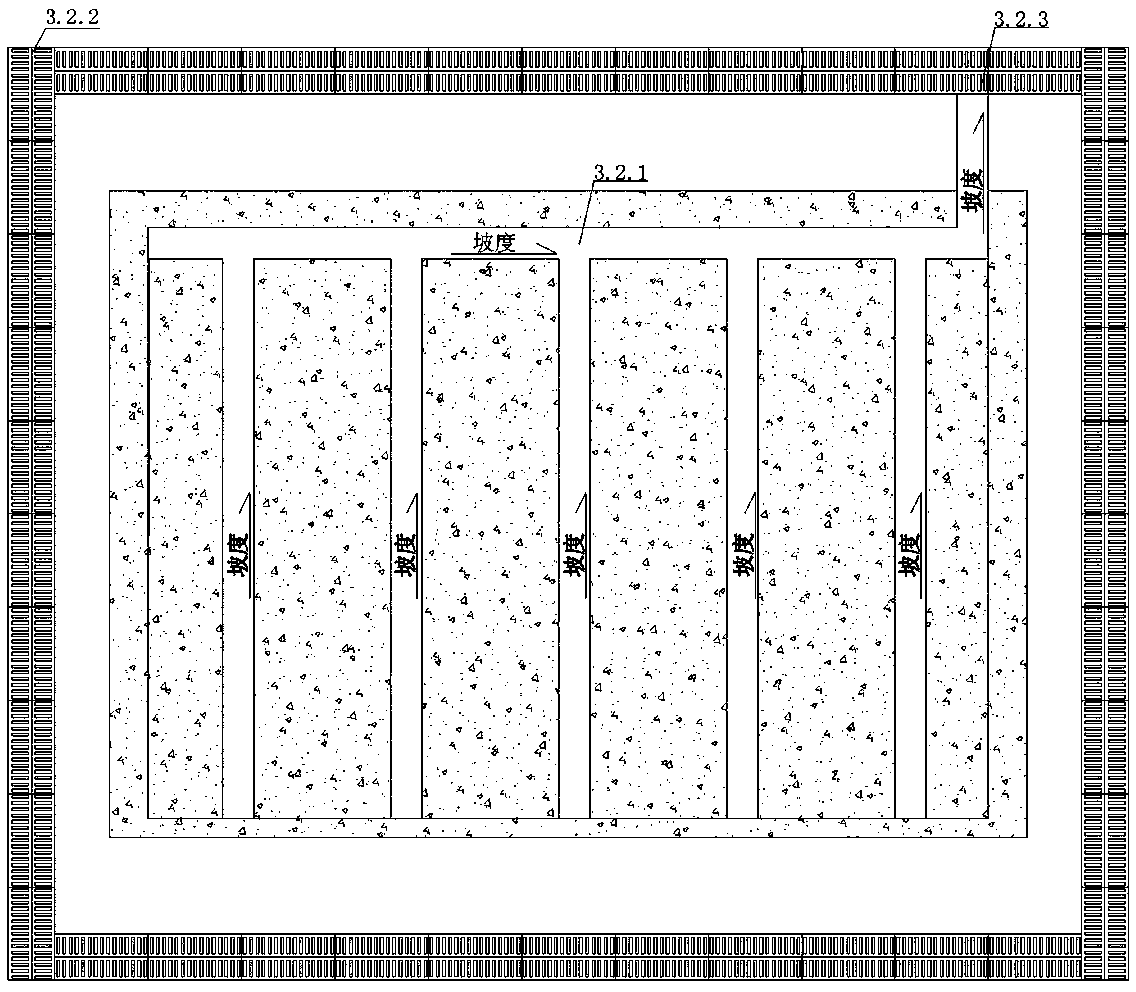

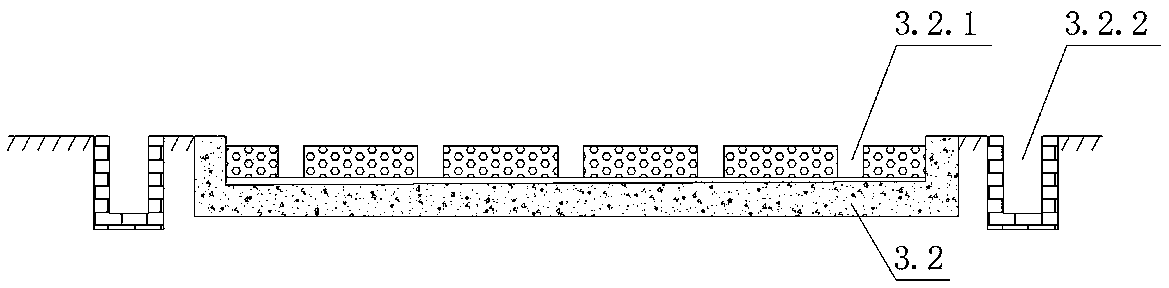

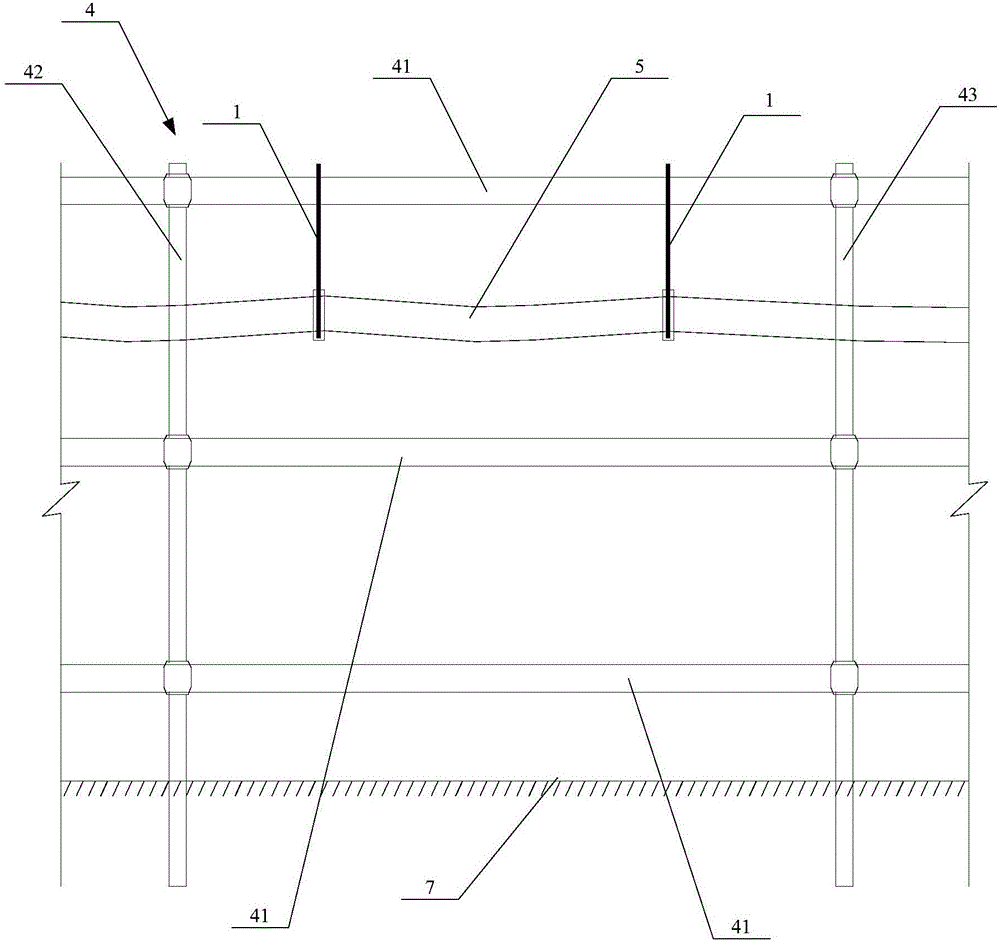

Method and system for self-cleaning water-saving type comprehensive vehicle washing for civil construction site

ActiveCN105966366ANovel and simple methodNovel and simple structureTreatment involving filtrationEnergy based wastewater treatmentWater storageWater saving

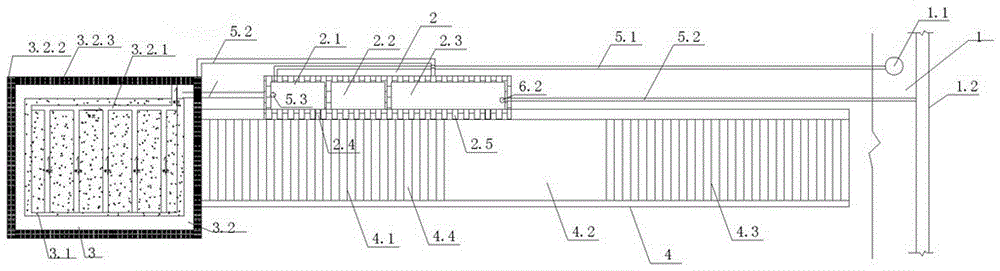

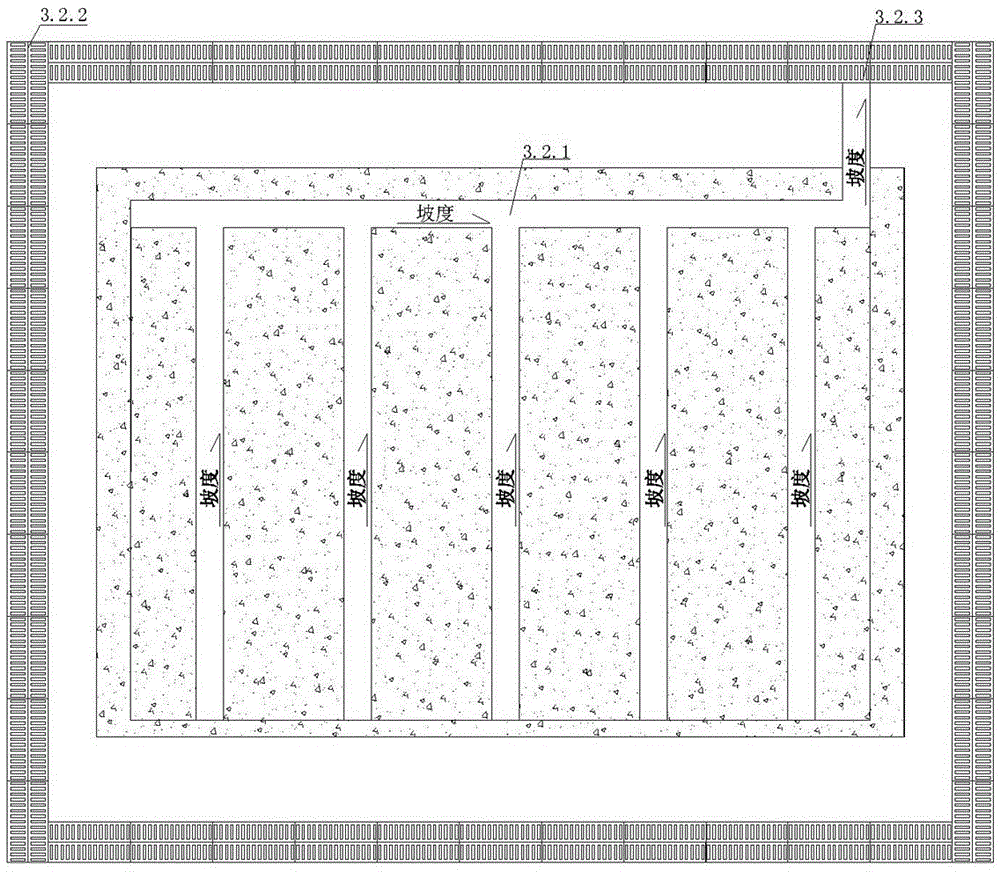

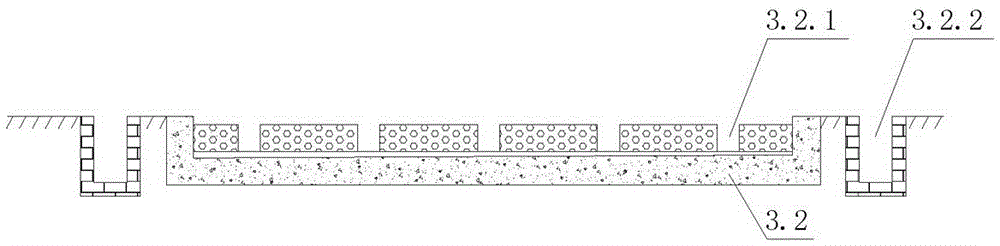

The invention belongs to a method and system for self-cleaning water-saving type comprehensive vehicle washing for a civil construction site. The method comprises the steps of foundation ditch precipitation well and drainage ditch system construction, cofferdam pool construction, construction of a wheel washing machine base, a water storage pool, a wheel washing pool, a filtering pool and a settling pool and the like. The system comprises the wheel washing pool used for conducting primary cleaning on tires of a muck vehicle and sludge on a vehicle body, the wheel washing machine base, a wheel washing machine, a foundation ditch precipitation well, a foundation ditch drainage ditch, a cofferdam pool, the water storage pool, the filtering pool and the settling pool. The method and system for self-cleaning water-saving type comprehensive vehicle washing for the civil construction site have the advantages that the method and structure are novel and simple, the vehicle washing efficiency is high, the vehicle washing effect is good, and environment beautifying, energy conservation, environment protection and water recovery circulation utilization are good.

Owner:CHINA CONSTR MUNICIPAL ENG +1

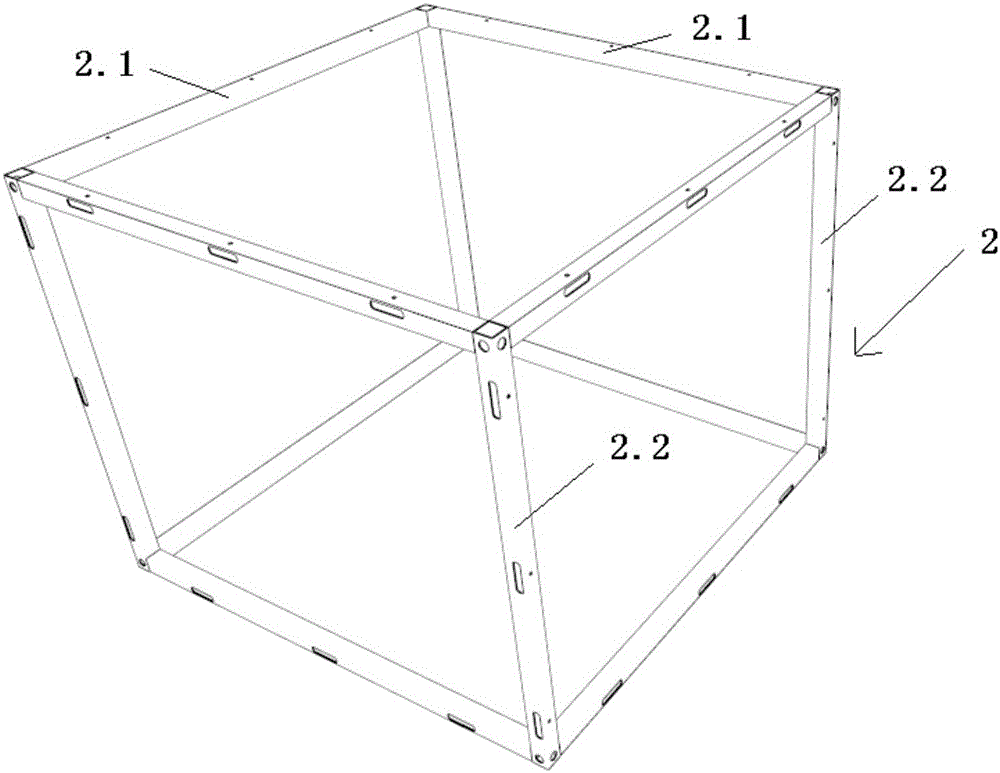

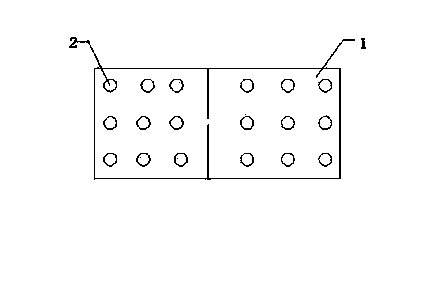

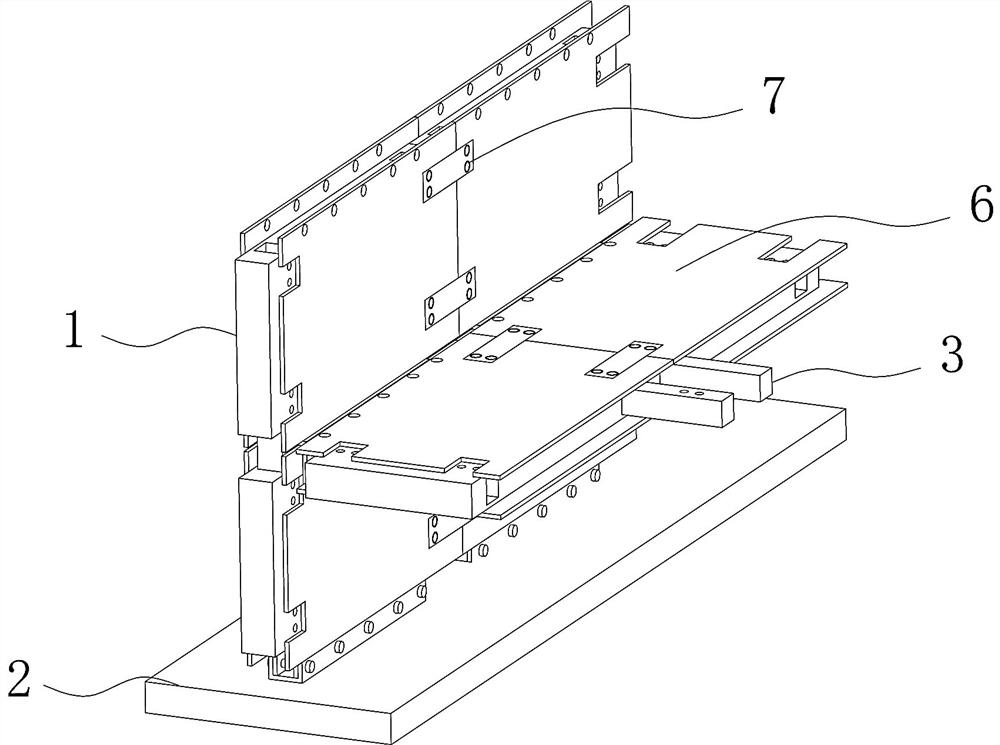

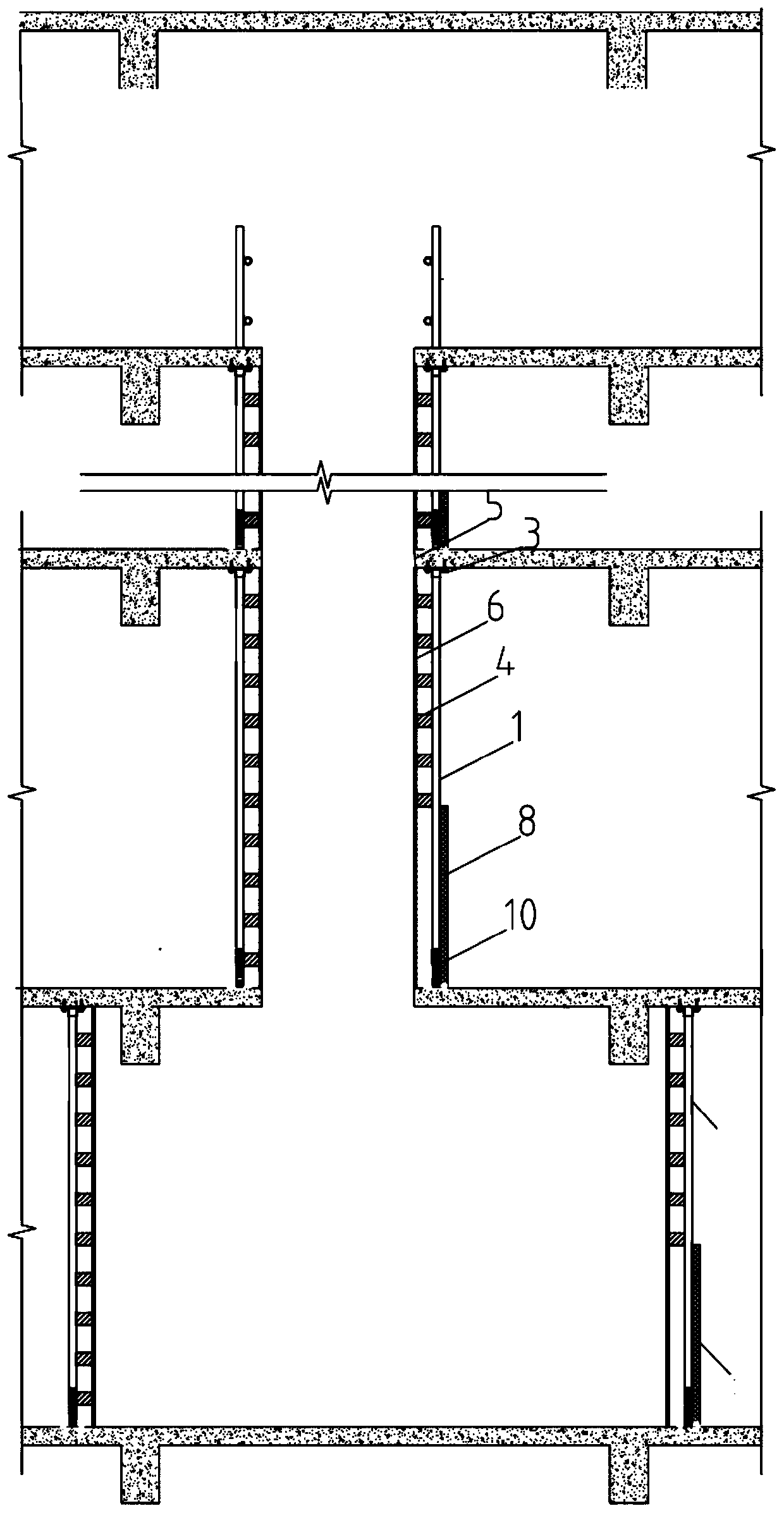

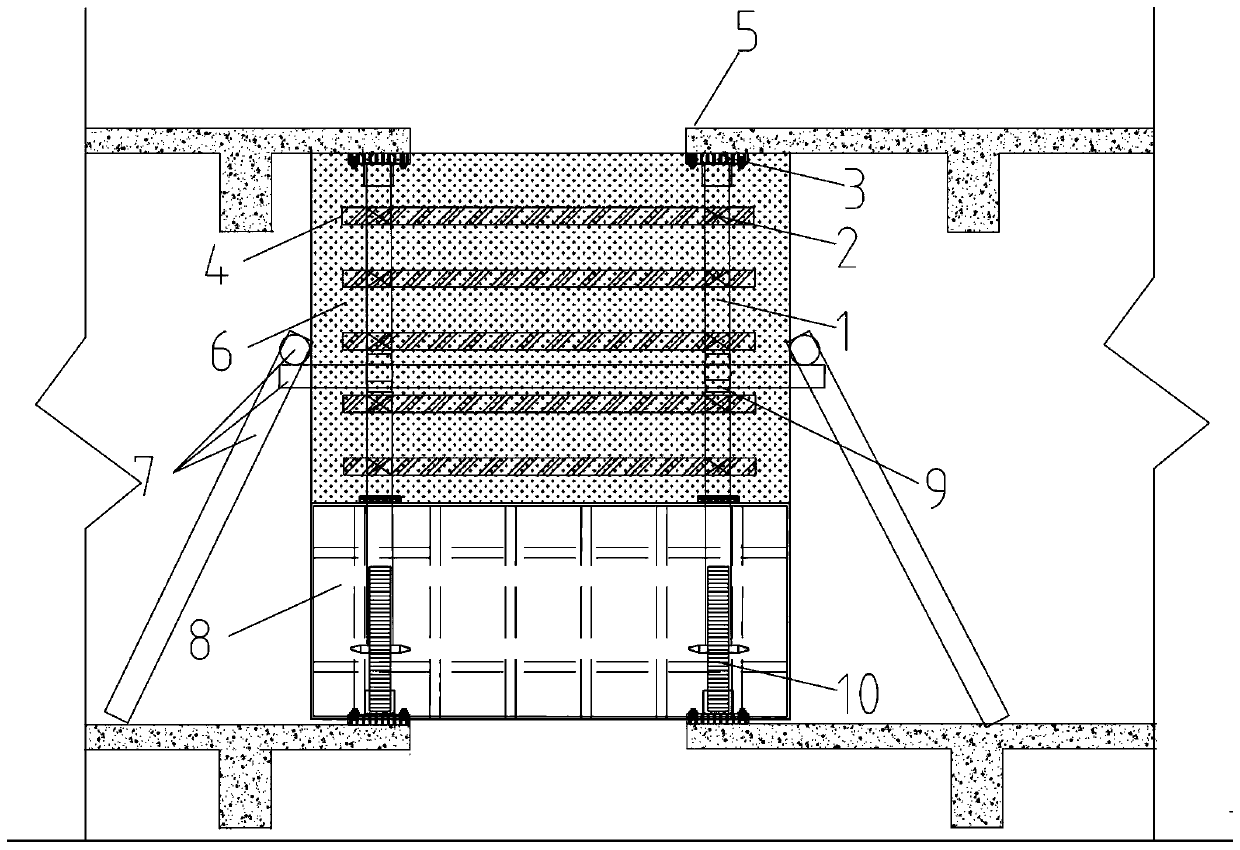

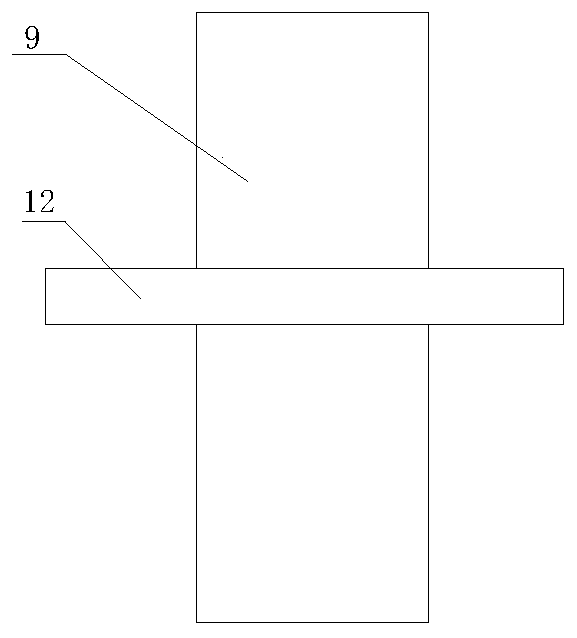

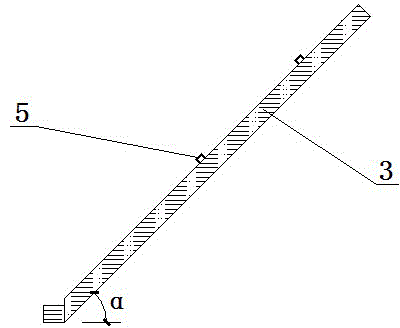

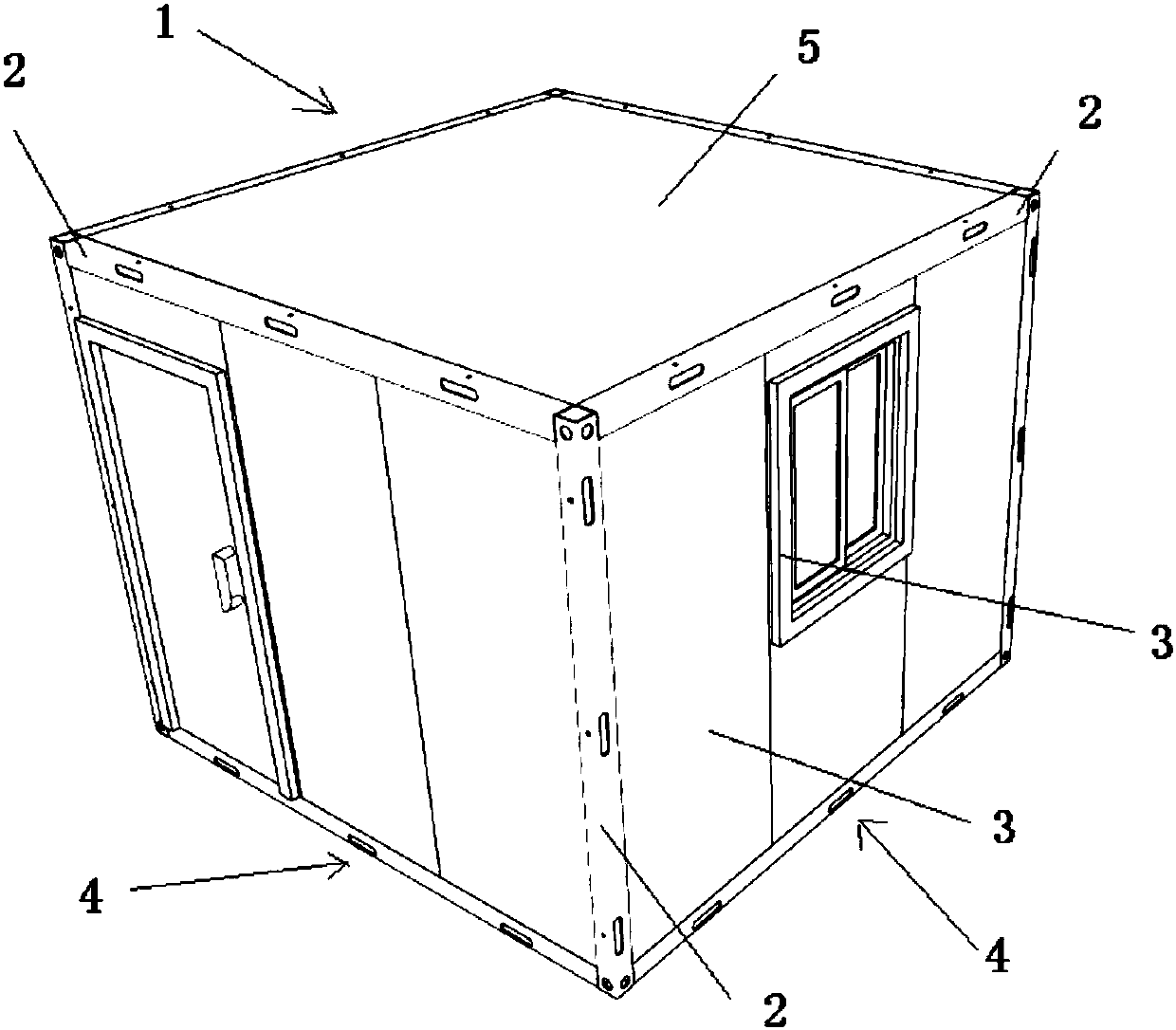

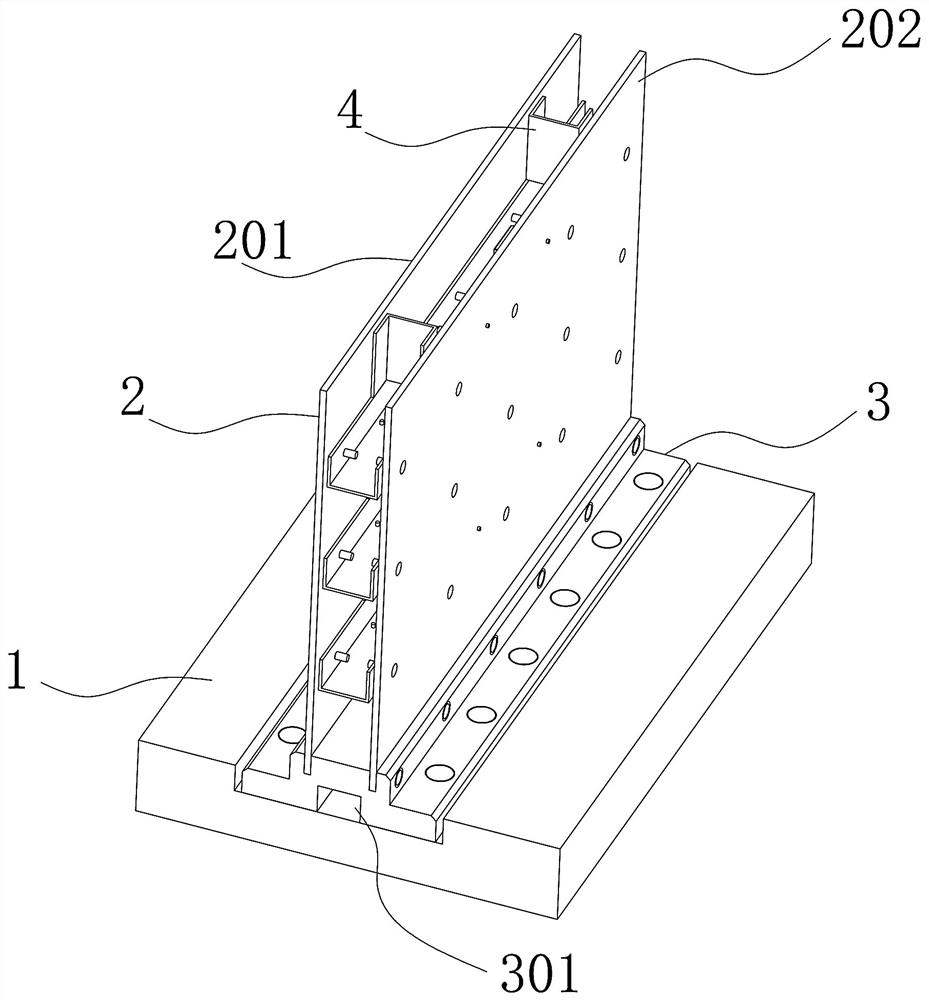

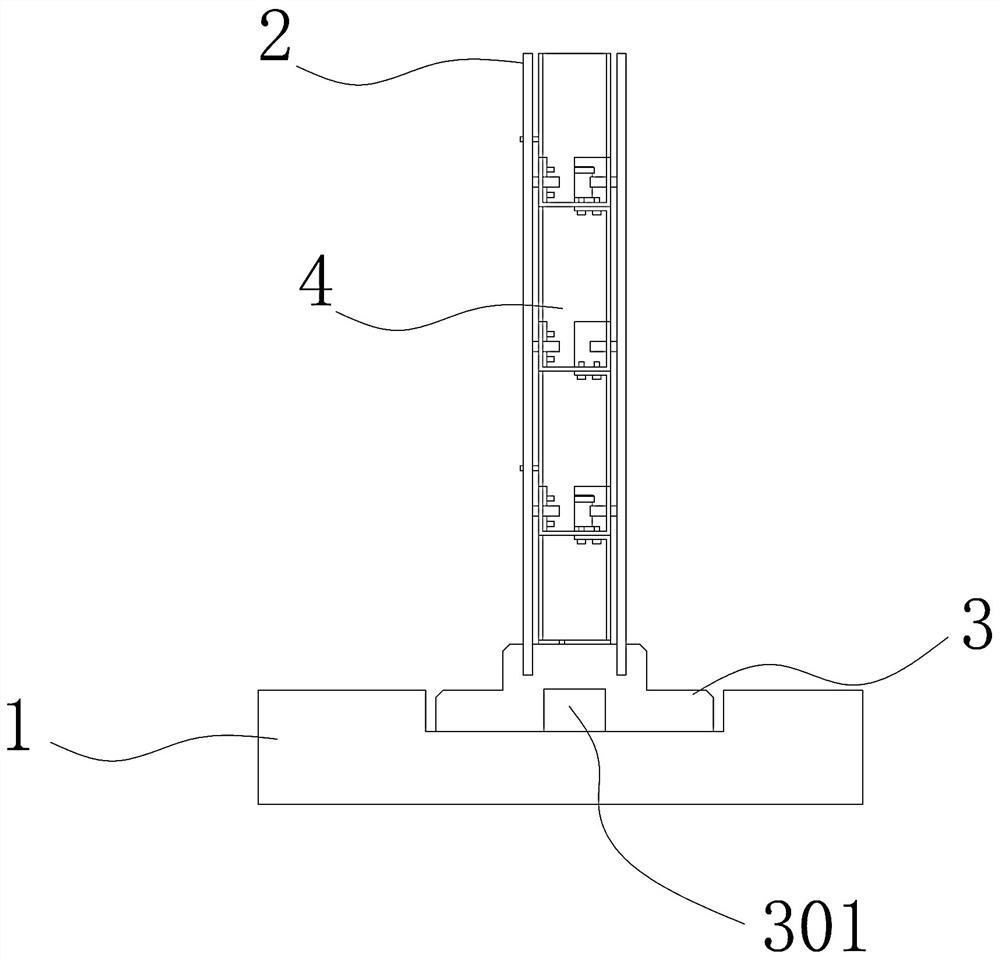

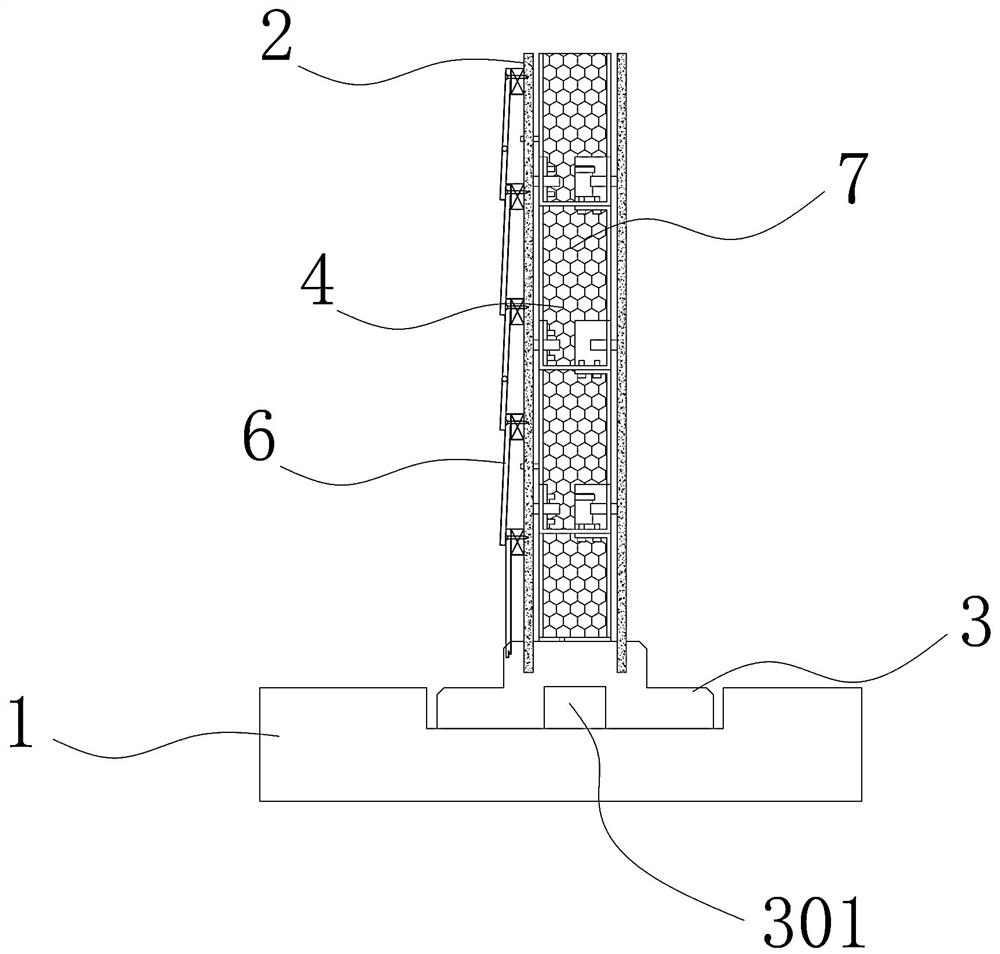

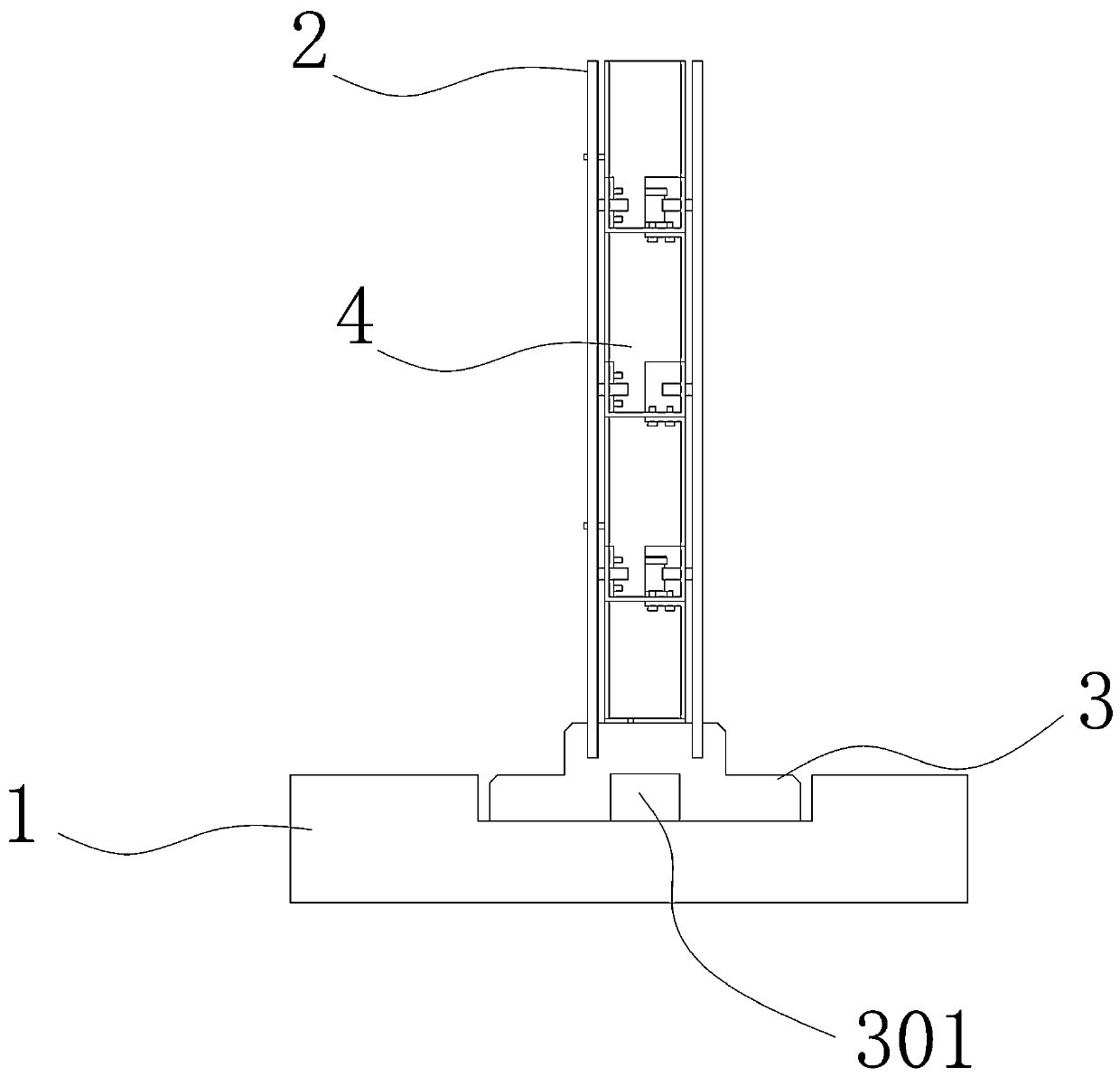

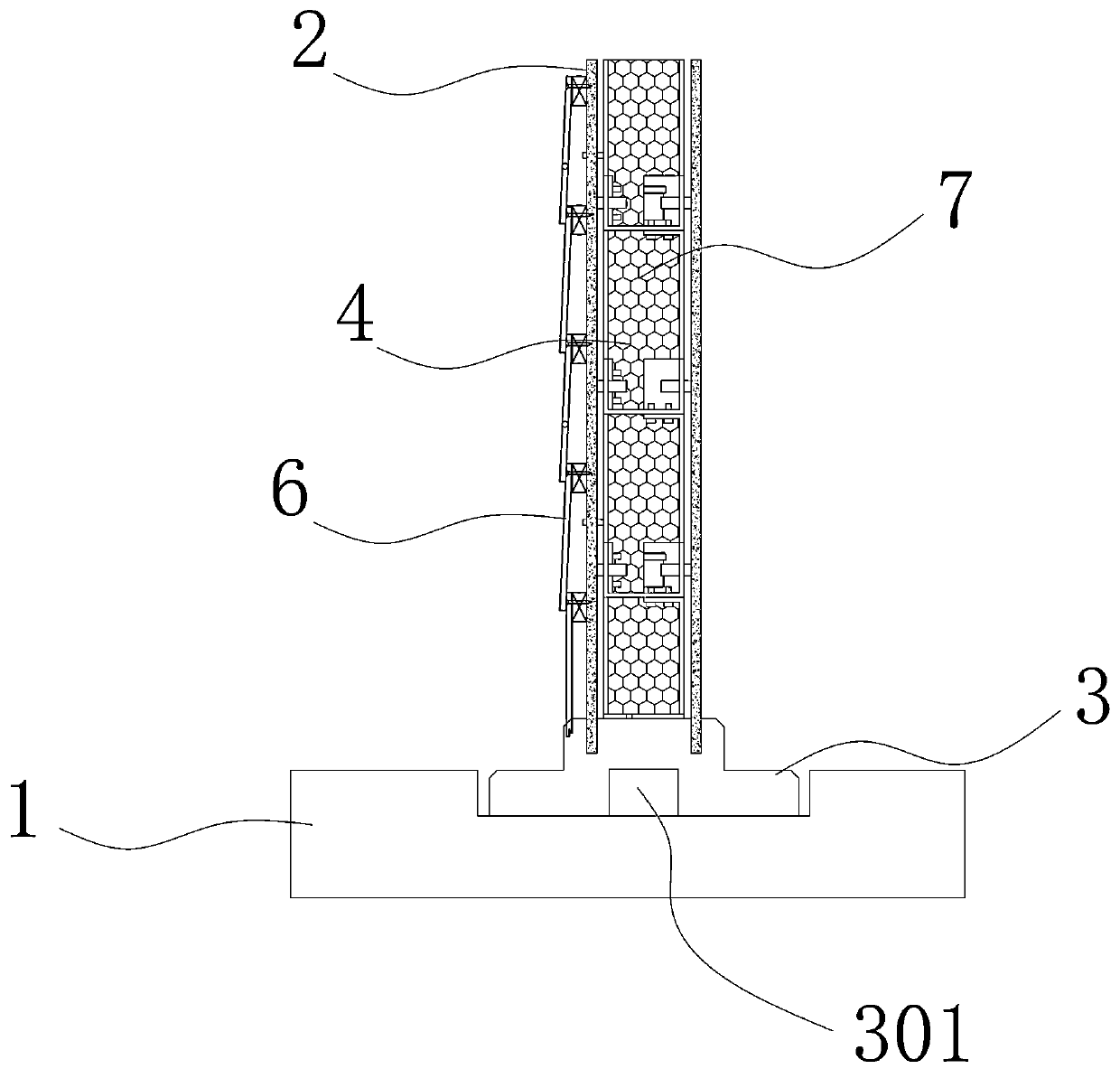

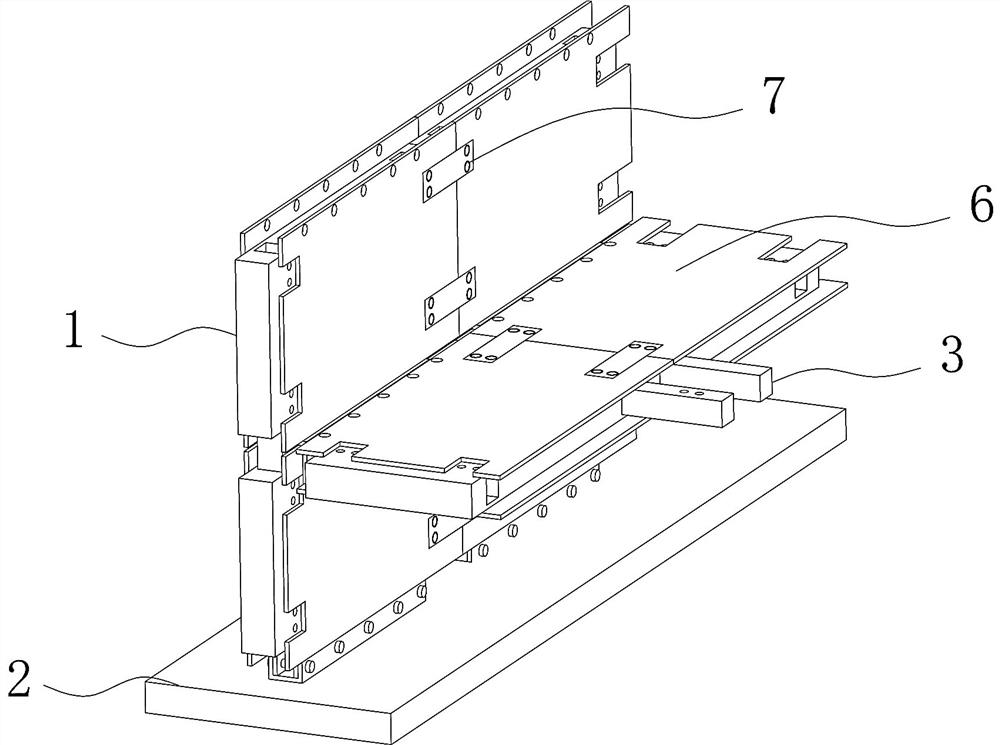

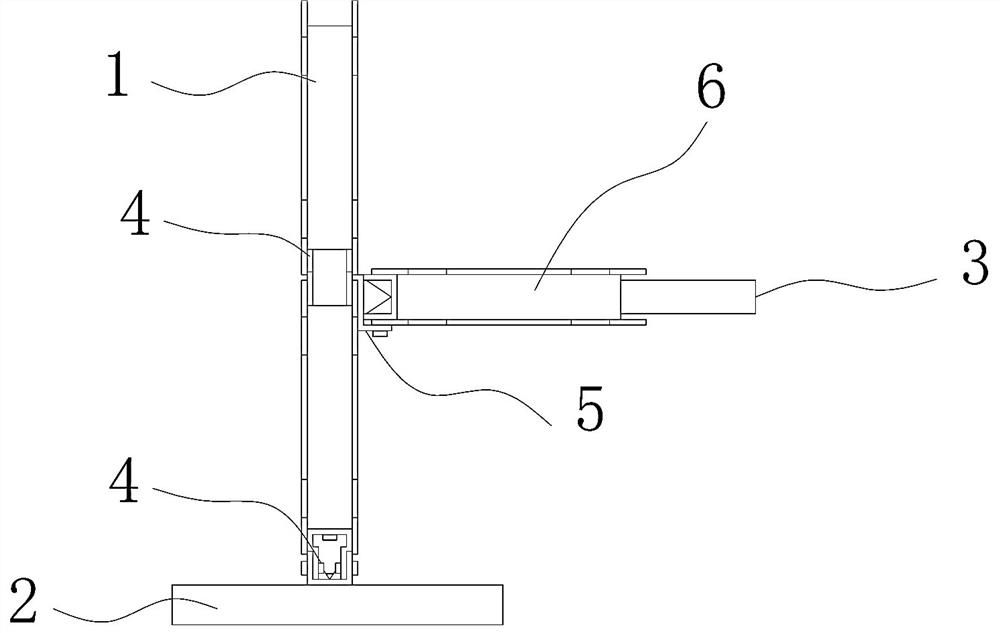

Modularized-assembly house system

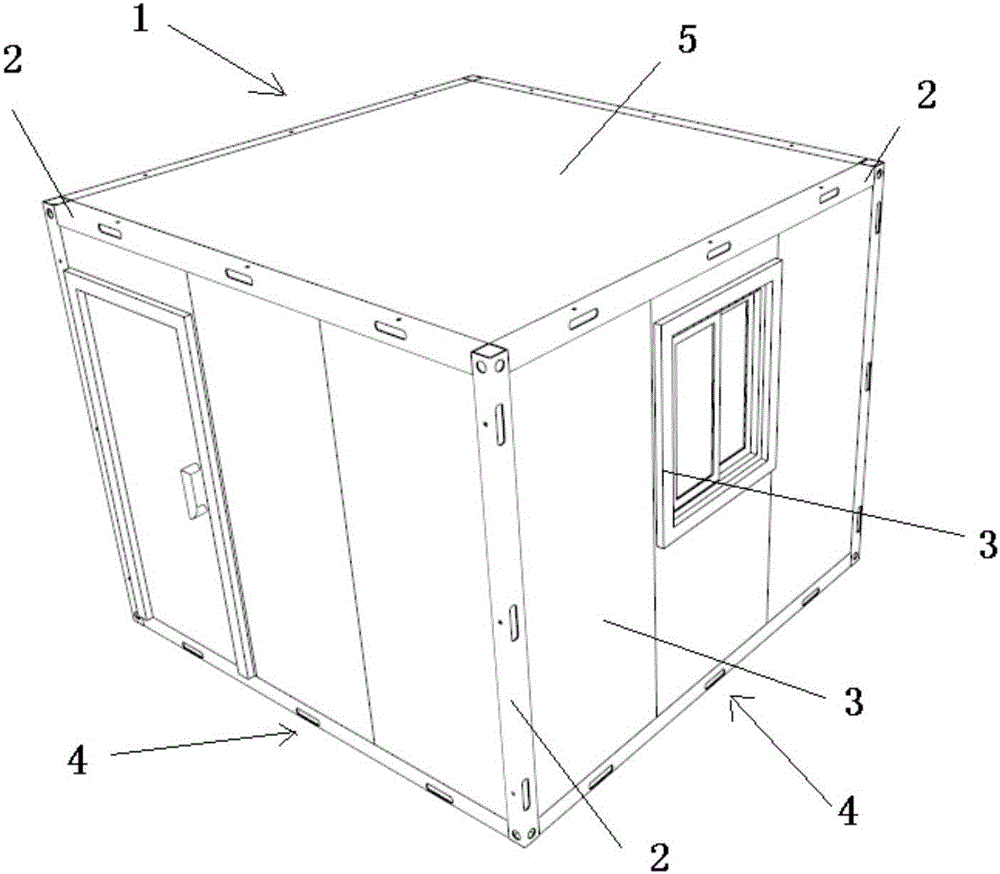

The invention discloses a modularized-assembly house system. The modularized-assembly house system is characterized in that the modularized-assembly house system comprises one or more houses (1) formed by modularized production; the houses (1) within two layers extend horizontally infinitely; each house (1) comprises a steel-structure frame (2), thin-walled cold-formed steel system wallboards (3), a thin-walled cold-formed steel system floor slab (4) and a thin-walled cold-formed steel system roof (5); the steel-structure frame (2) comprises cross beams (2.1) and stand columns (2.2), the upper cross beams (2.1) are parallel to the lower cross beams (2.1), and the stand columns (2.2) are connected vertically with the cross beams (2.1); eight corners formed by encircling of the cross beams (2.1) and the stand columns (2.2) are connected through connectors (7). The modularized-assembly house system has the advantages that the defects of inconvenience in assembly and disassembly, poor combination and unsuitability for complex environments in the prior art are overcome, and disassembly, interchange and addition or reduction are achieved.

Owner:武汉迈特绿色建筑科技股份有限公司

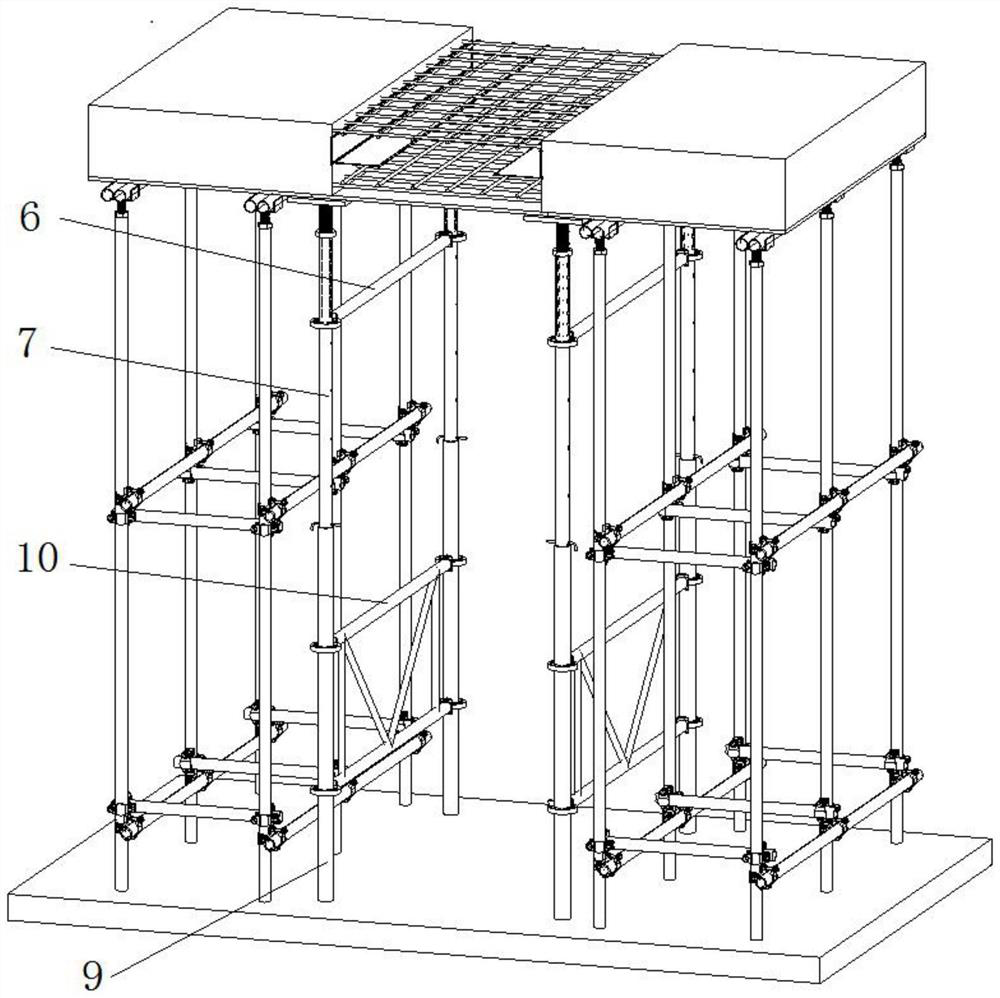

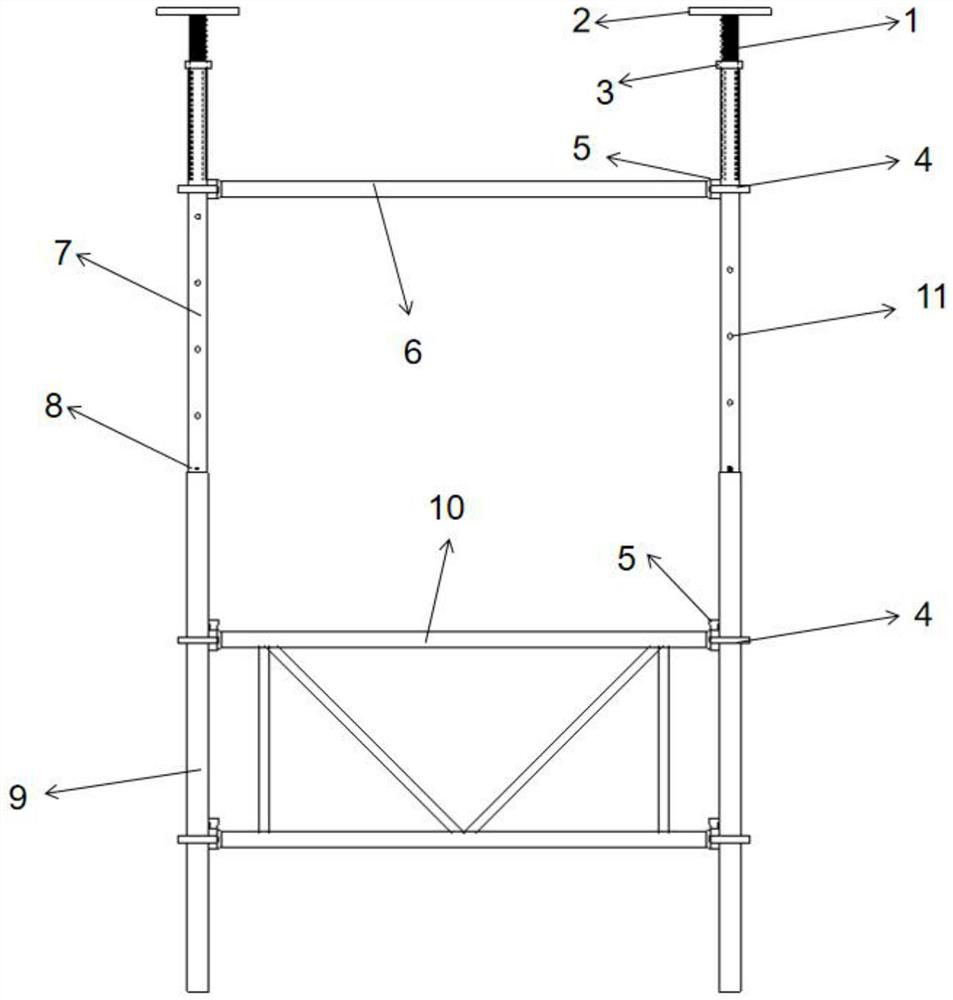

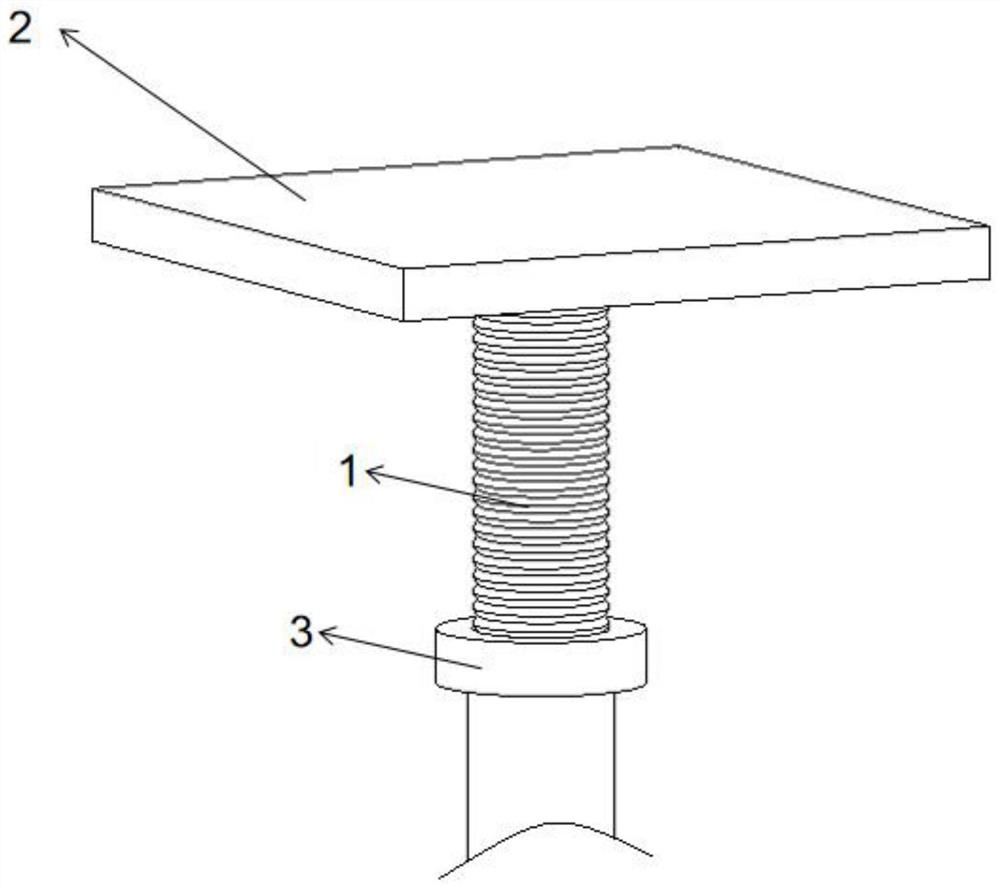

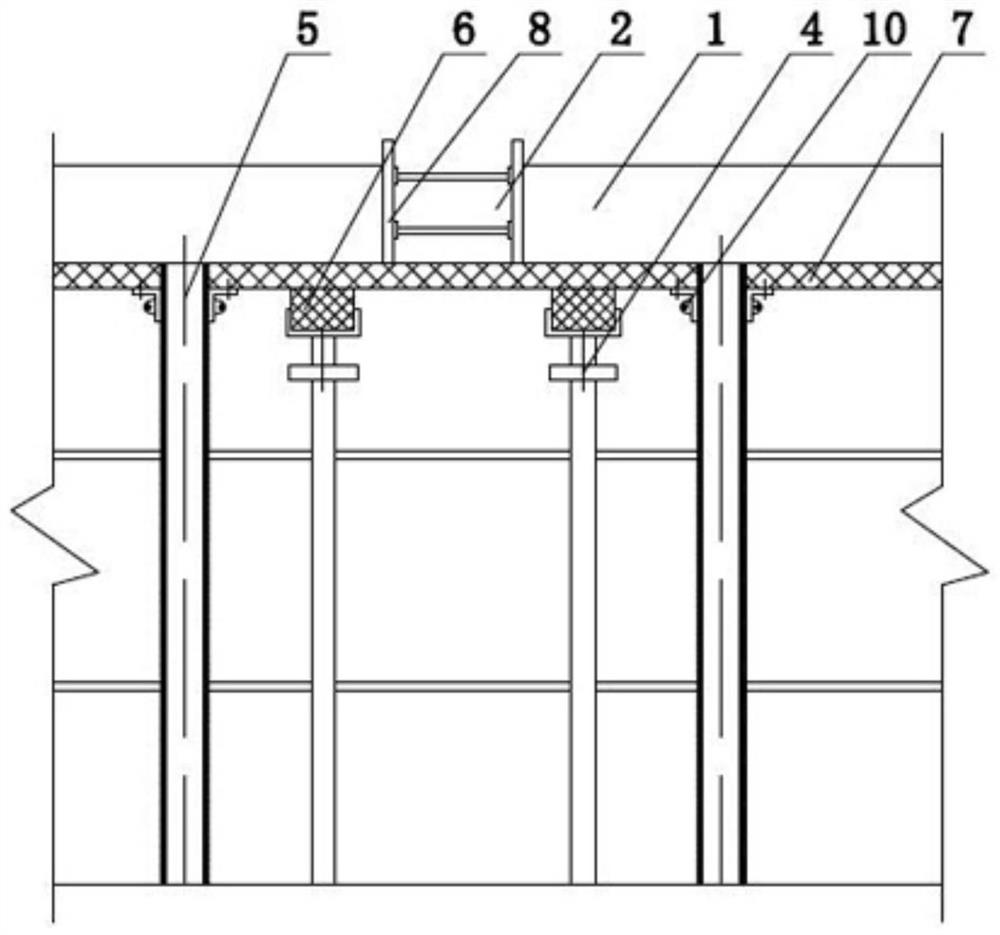

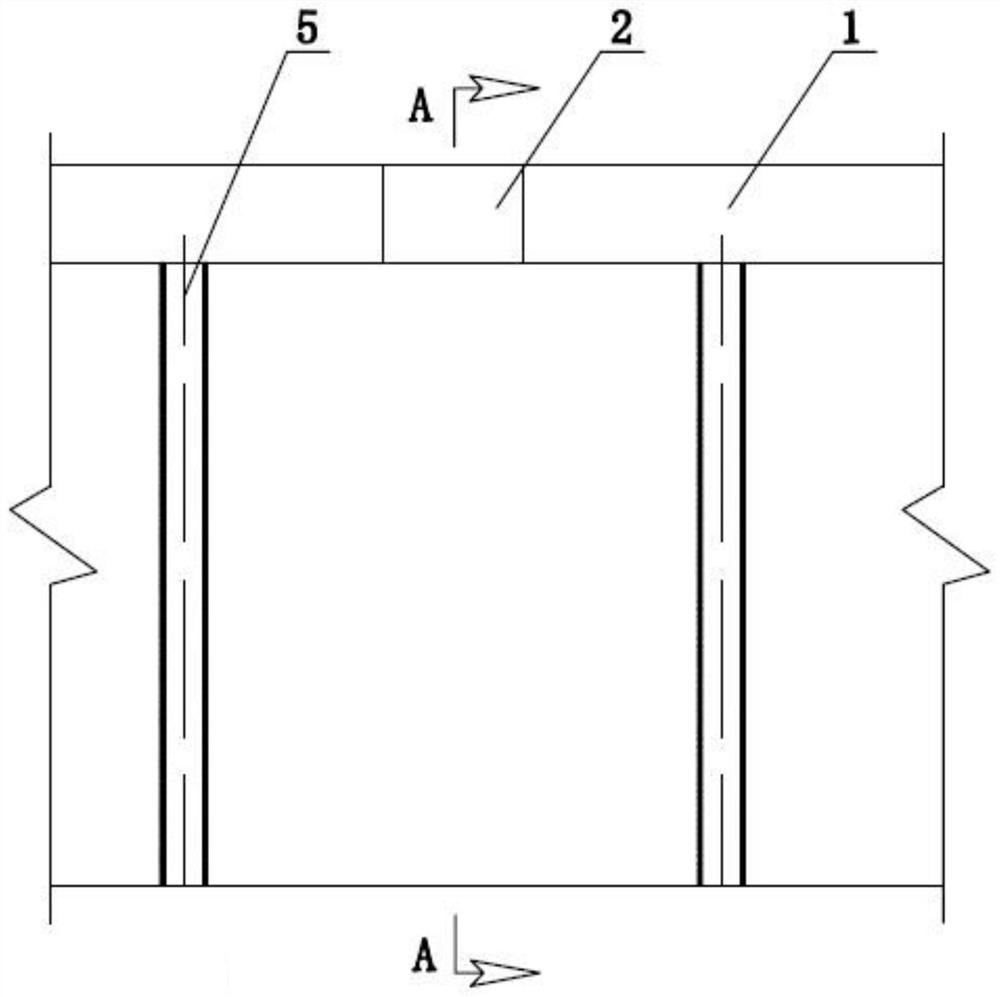

Construction method for backward supporting aluminum alloy independent column with post-cast strip

InactiveCN112609980ACompact designSolve the situation of separate erectionForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksSupporting systemUltimate tensile strength

The invention discloses a construction method for backward supporting aluminum alloy independent column with a post-cast strip, and belongs to the technical field of building construction. The construction method aims at solving the problems that a traditional top plate post-cast strip supporting system occupies a large number of formworks and supporting materials for a long time, daily management difficulty is large, the supporting materials are extremely easy to damage and even are manually dismantled, the formworks, square timber, jacks and other materials are easy to deform, decay, rust and the like, so that the post-cast strip formwork supporting system is loosened. The method comprises the following steps that a 200 mm * 200 mm hole is reserved in the formwork splicing position to serve as an aluminum alloy stand column backward supporting position, an aluminum alloy independent column support is kept all the time, the aluminum alloy independent column cannot be dismounted halfway, whole-course supporting of the aluminum alloy independent column is achieved, and the aluminum alloy independent column can be dismantled until post-cast strip concrete pouring is completed and forced formwork dismantling is achieved. The method has the advantages of being high in construction speed, convenient to install, reliable in quality, economical, reasonable, high in applicability, wide in application range, green and environmentally friendly.

Owner:CHINA CONSTR FOURTH ENG DIV

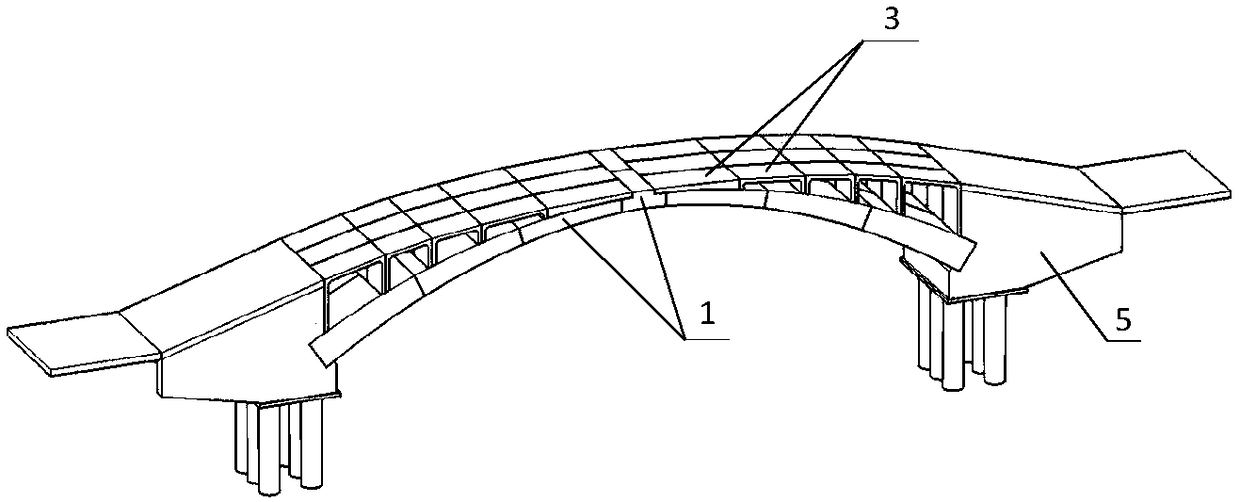

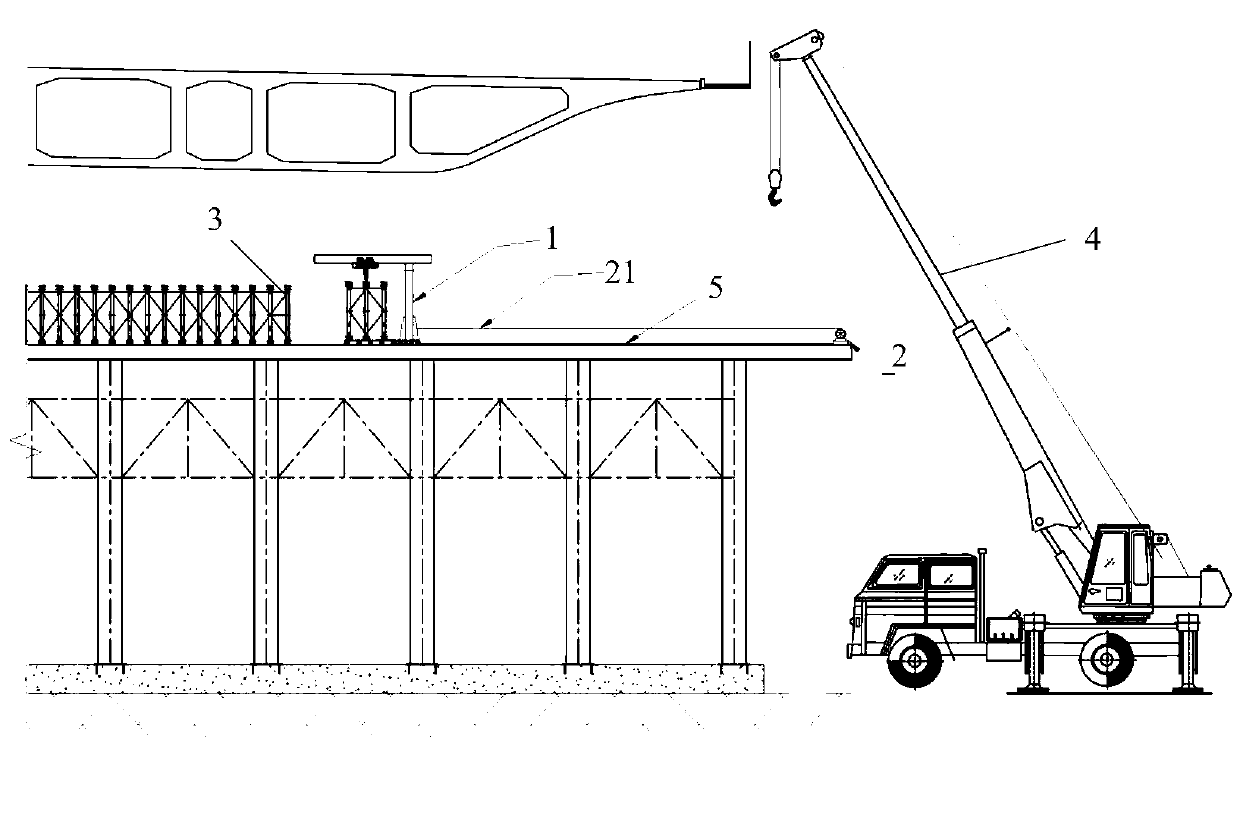

Structuring and constructing method for segment prefabricated spliced concrete arch bridge

InactiveCN108570920ARapid industrial constructionImprove constructabilityBridge erection/assemblyArch-type bridgeConstruction designCurve line

The invention discloses a structuring and constructing method for a segment prefabricated spliced concrete arch bridge. The method comprises the following steps: dividing an arch ring into a pluralityof wedged segments according to an arch ring curved line of a bridge for horizontal prefabrication and breaking up the whole into parts; connecting the arch ring prefabricated segments by adopting preburied steel hinges; in a hoisting and lifting process, forming curved line arch rings automatically and placing the same on an arch seat; after the arch rings are spliced in position, connecting thearch ring prefabricated segments in a manner of welding preburied steel plates permanently; hoisting soffit prefabricated segments symmetrically; and connecting the soffit prefabricated segments in amanner of welding preburied steel plates permanently. By means of the segment prefabricating splicing method, the arch bridge is quickly constructed, convenient to construct, reliable to connect, clear in structural stress, simple in operating process and high in safety degree. A template and a bracket are not arranged on site, the field construction speed is high, and the method meets the industrial theory of green construction, and is an advanced and reliable prefabricated concrete arch bridge construction design.

Owner:NORTHEAST FORESTRY UNIVERSITY

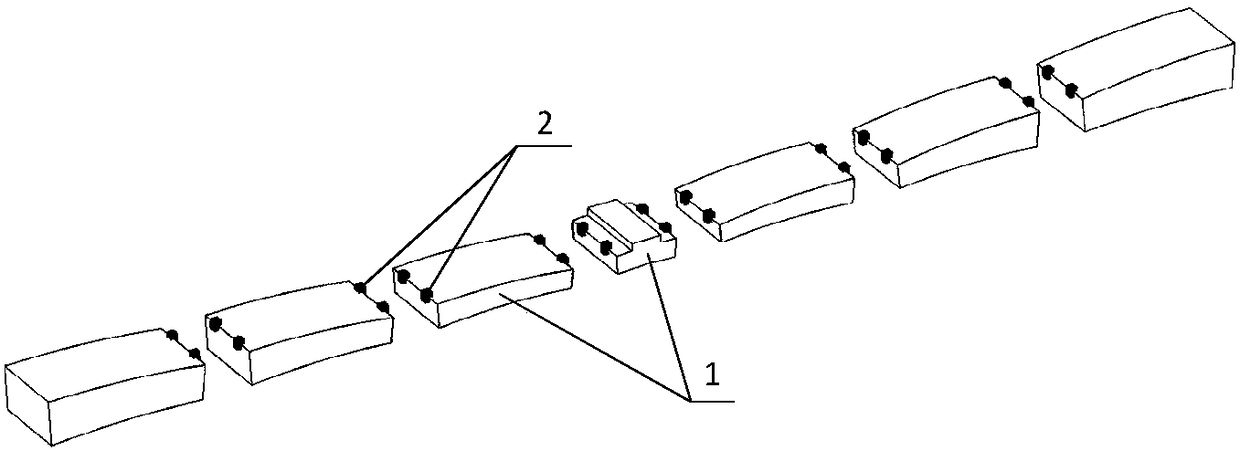

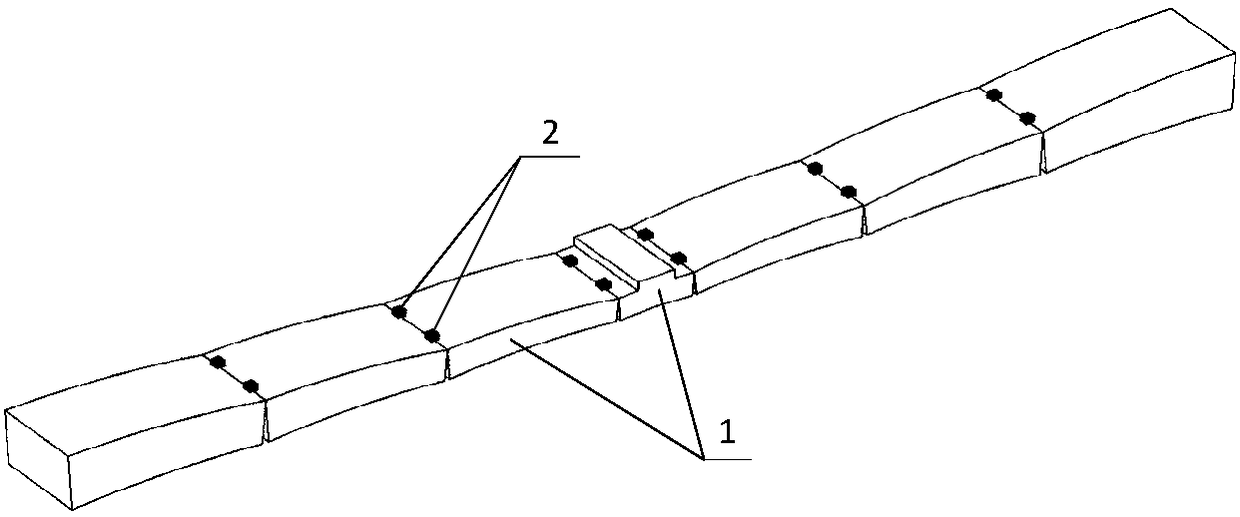

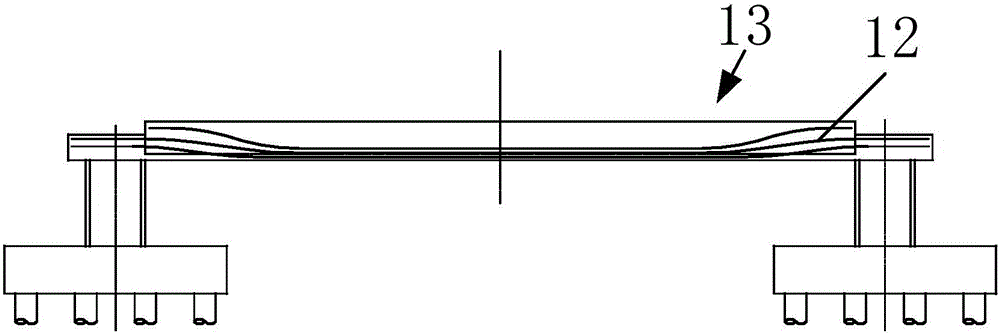

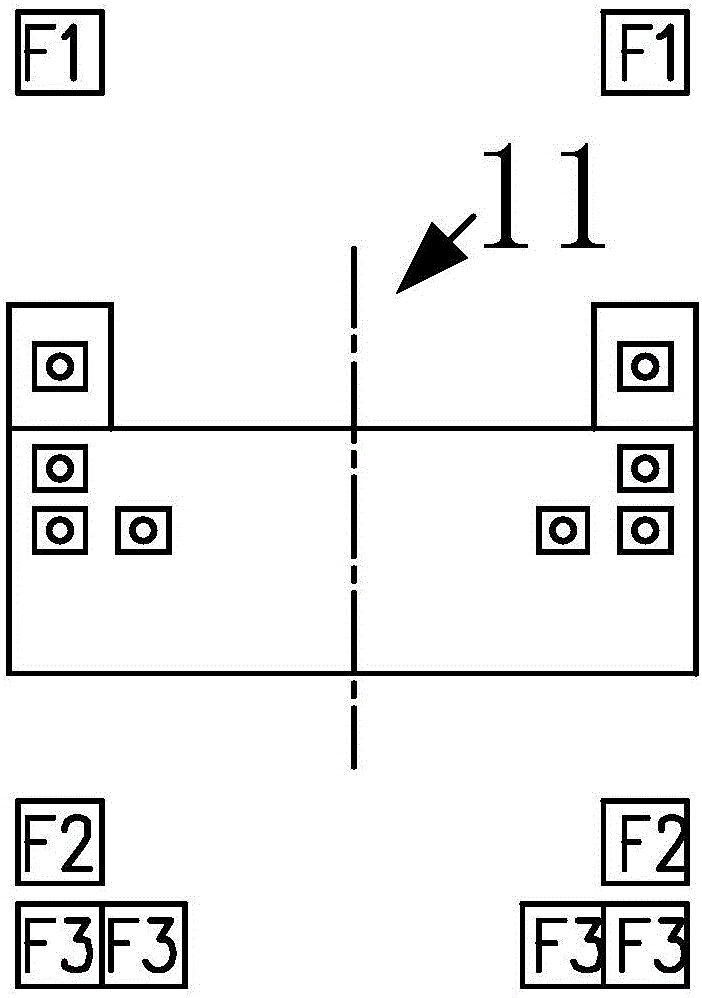

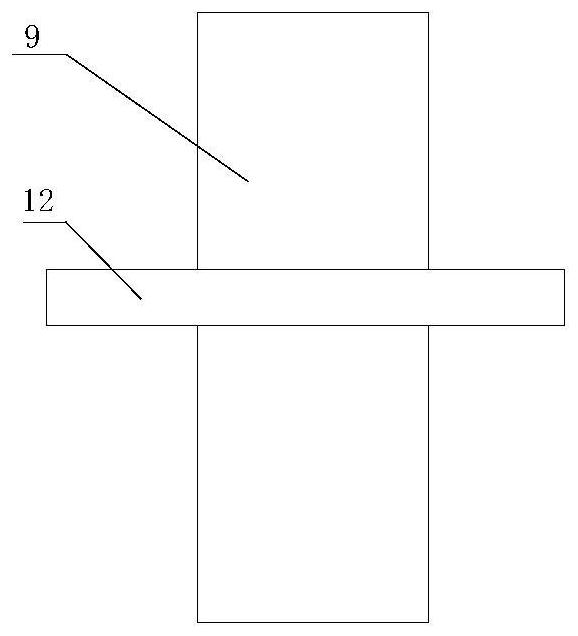

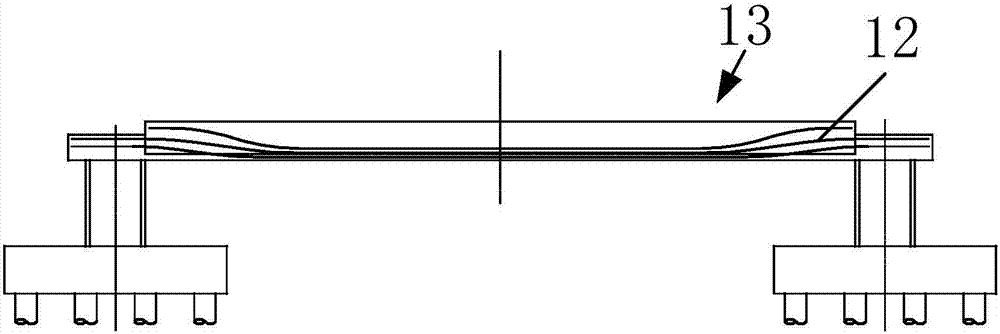

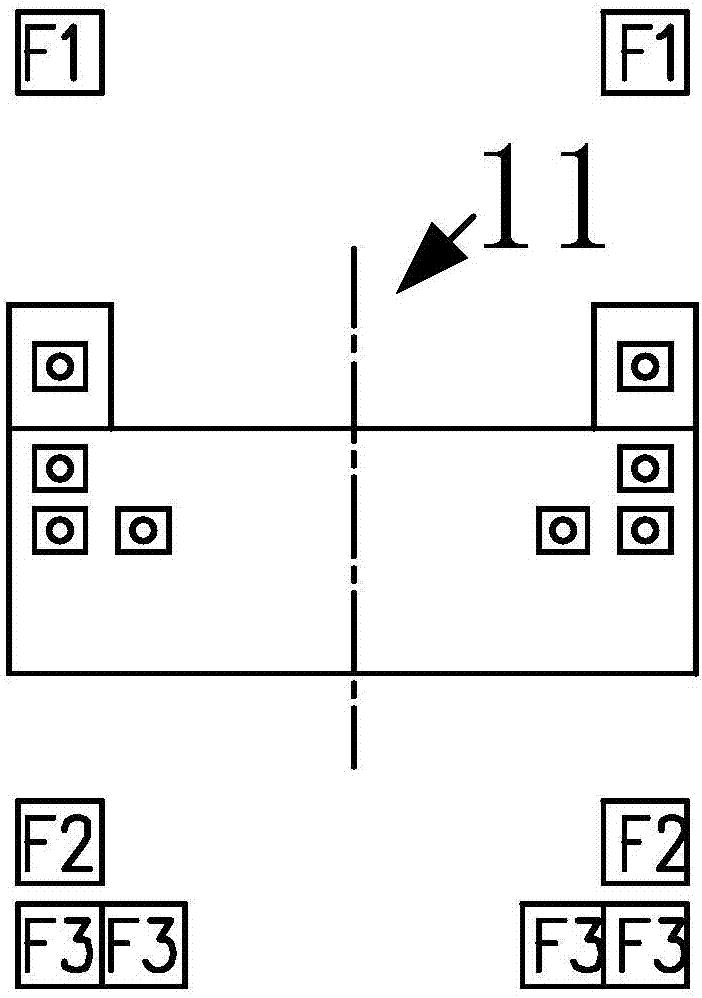

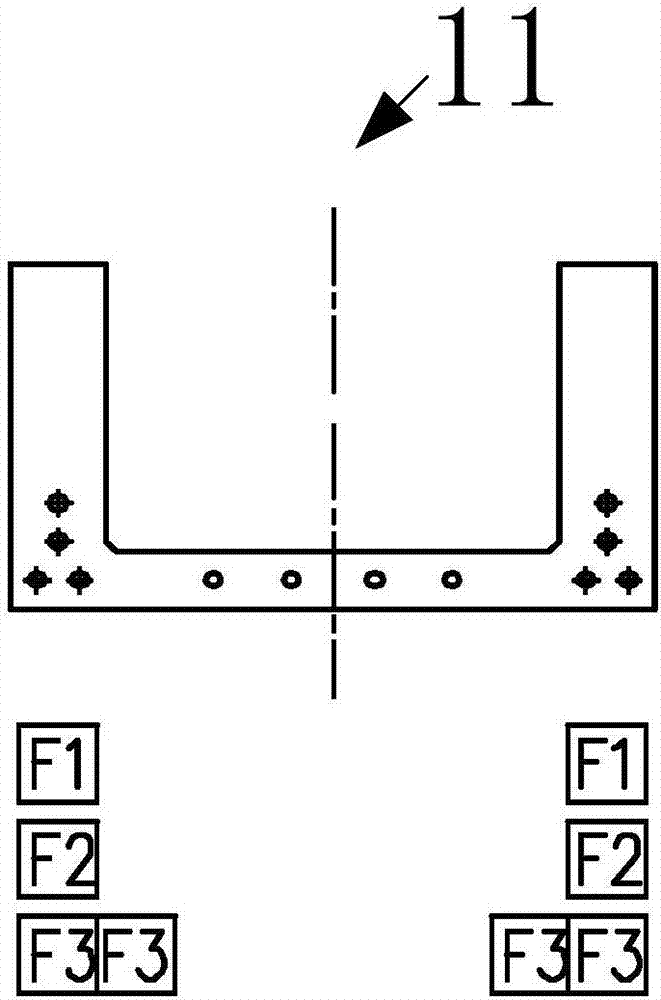

Large-span capping beam prefabrication and assembly method and large-span capping beam

ActiveCN105780663ANo impact on congestionImprove construction efficiencyBridge structural detailsBridge erection/assemblyShaped beamPre stress

The invention discloses a large-span capping beam prefabrication and assembly method and a large-span capping beam; according to the large-span capping beam prefabrication and assembly method, overall no-bracket construction of the large-span capping beam is carried out by adopting staged prefabricated casting on the whole and gradually tensioning steel beams in all stages; the method comprises the stages of S1, prefabricating a U-shaped beam component as a bottom die; forming a U-shaped rabbet in the U-shaped beam component, and tensioning at least four prestressed steel beams on the U-shaped beam component for reserving porous channels for subsequent prestressed tensioning; S2, after the U-shaped beam component is hoisted in place, casting a hollow part of the U-shaped rabbet in a way of cast-in-situ, and correspondingly tensioning at least six prestressed steel beams for reserving porous channels for subsequent prestressed tensioning; S3, casting the rest part of a cross section of the lower half part of the beam component in a way of cast-in-situ, and correspondingly tensioning at least ten prestressed steel beams; S4, completing the construction. After the large-span capping beam prefabrication and assembly method is adopted, not only is the construction efficiency high, but the traffic pressure is also greatly reduced. Furthermore, compared with the existing construction method, the large-span capping beam prefabrication and assembly method is also very environment-friendly.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

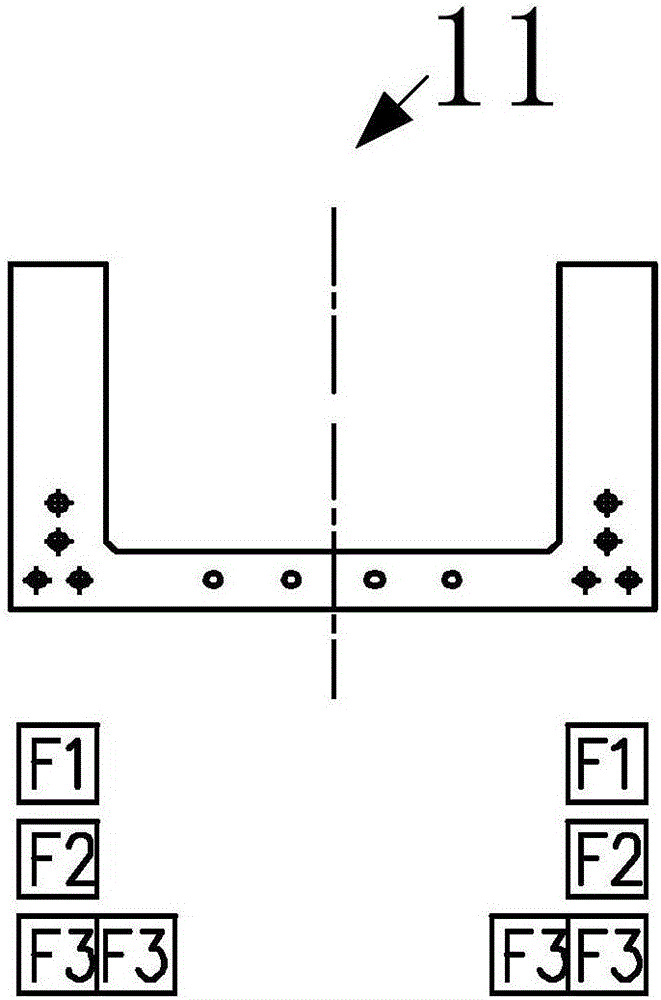

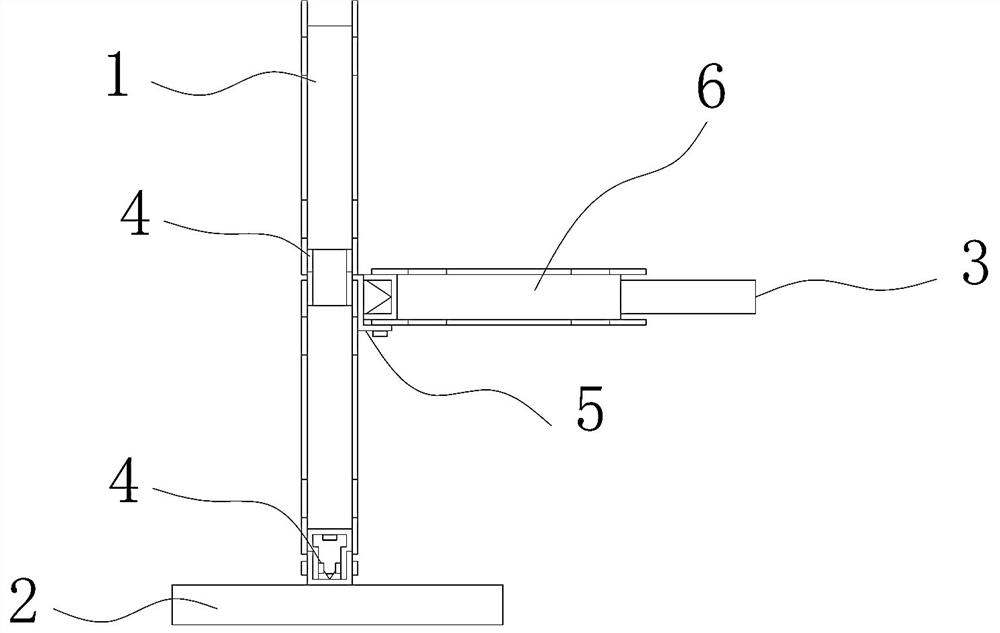

Bailey beam support dismantling device and Bailey beam support dismantling method

PendingCN110723658AReduce security risksPrevent fallingBridge erection/assemblyTravelling gearConstruction engineeringWinch

The invention relates to the technical field of bridge construction, and discloses a Bailey beam support dismantling device and a Bailey beam support dismantling method. The method comprises the following steps of 1, dismantling a full support above a Bailey beam, and dismantling the Bailey beam into a plurality of Bailey beam supports; 2, fixing a winch, and connecting a web plate of a cantilevercrane through a traction rope of the winch; 3, moving the cantilever crane to the position beside one Bailey beam support, hoisting the Bailey beam support by the cantilever crane, and starting the winch to pull the cantilever crane to a set position, thereby hoisting away the Bailey beam support; and 4, repeatedly carrying out the step 3 until all the Bailey beam supports are removed. By means of the device and the method, the problems of high noise, risk of unstability and falling of Bailey slices, and long construction time in the dismantling construction process can be effectively solved.

Owner:1ST ENG OF CHINA ZHONGTIE MAJORBRIDGE GROUP +1

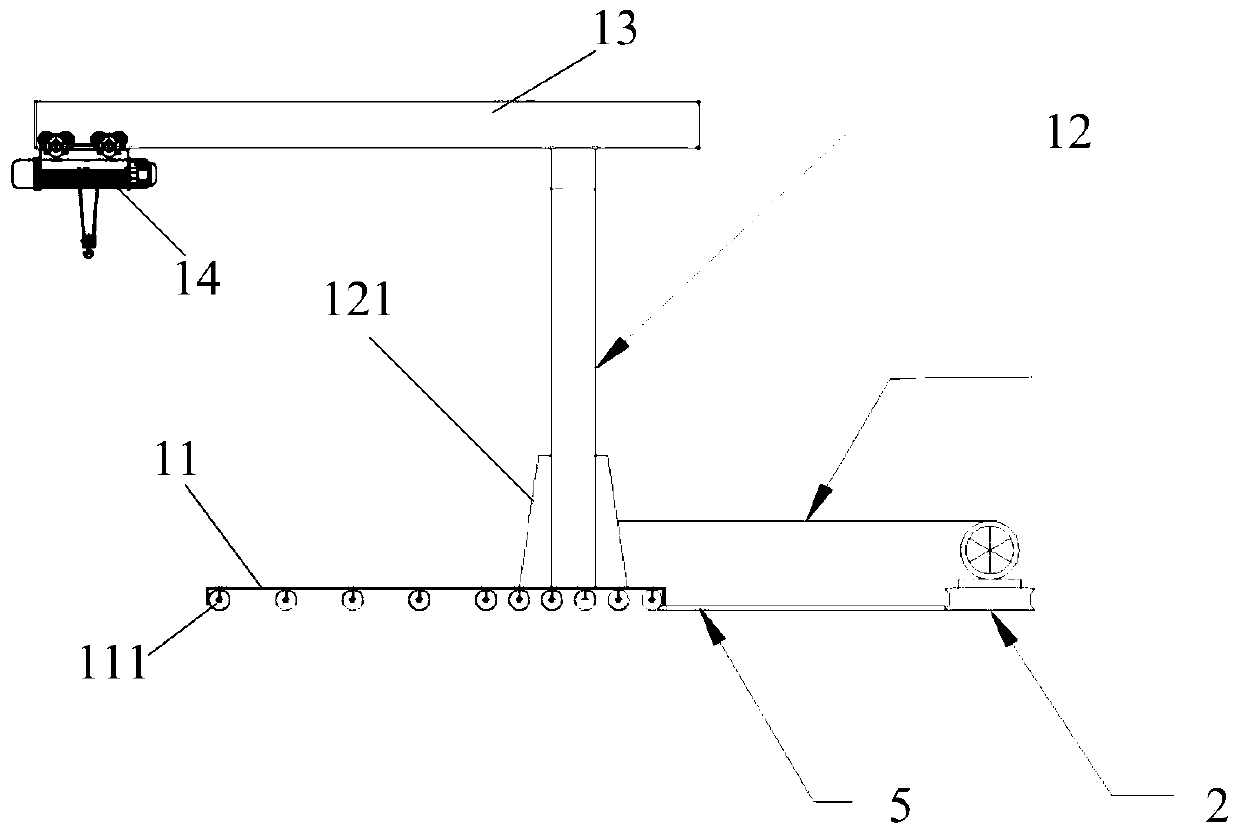

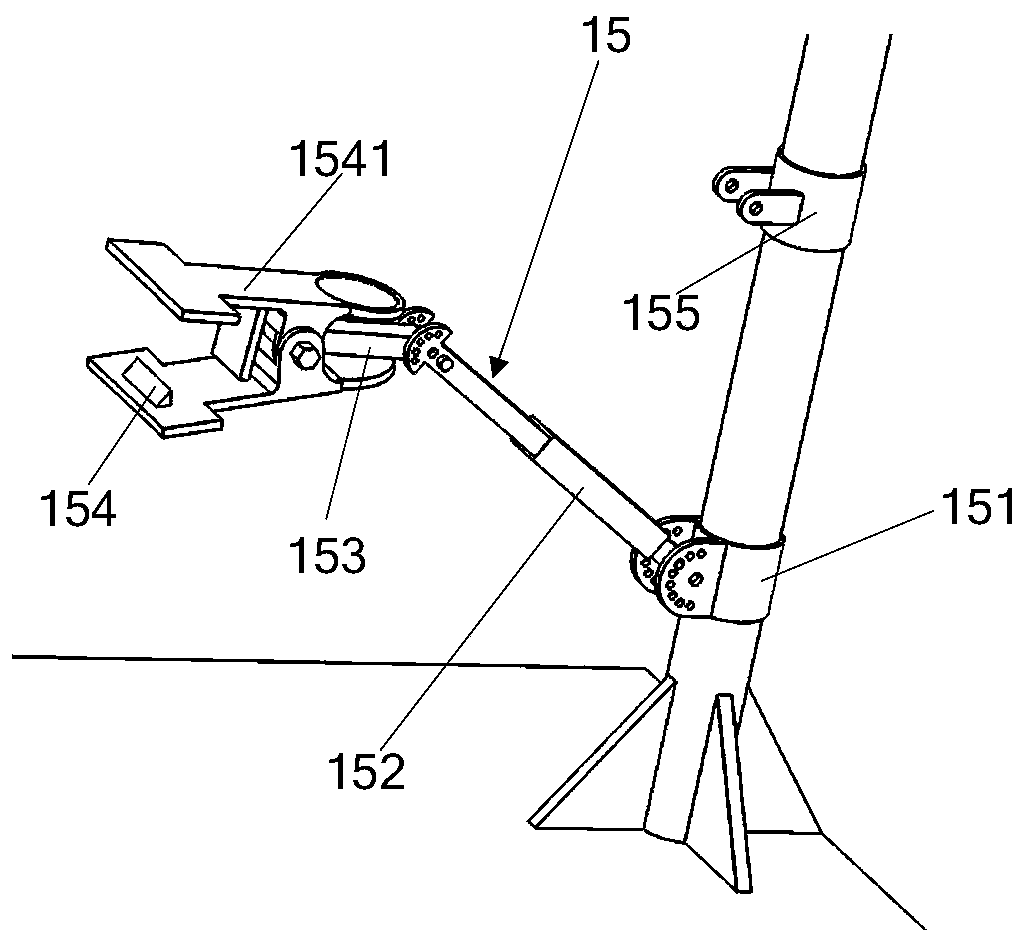

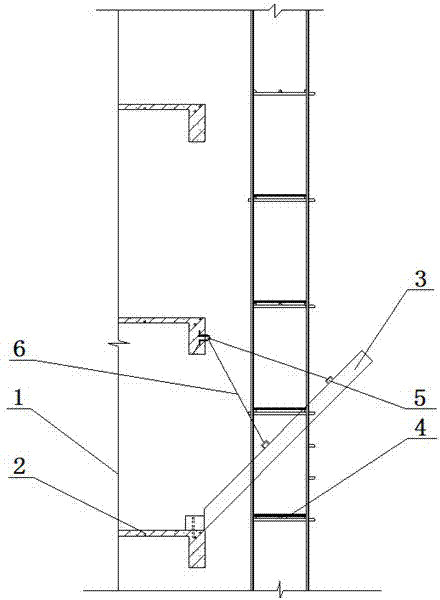

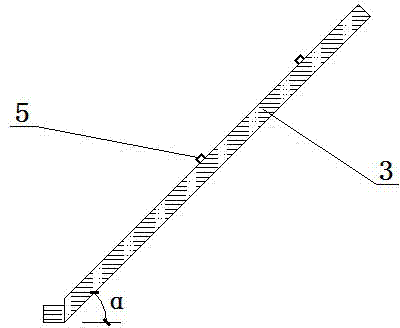

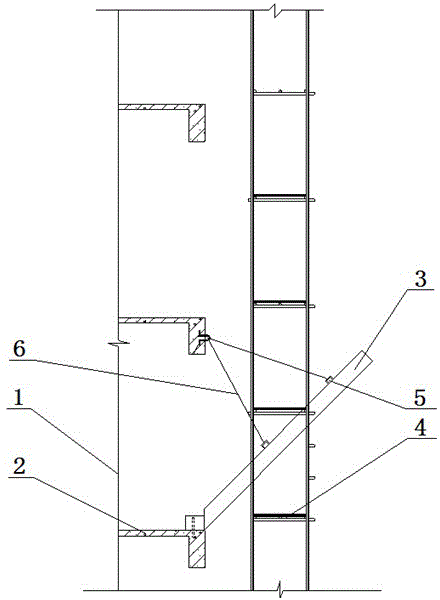

U-shaped slot unloading construction method for high buildings

ActiveCN102777038AAvoid the problem of not being able to transport to the construction floorLabor savingBuilding material handlingFalseworkEconomic benefits

The invention discloses a U-shaped slot unloading construction method for high buildings. The method comprises the following steps that: a platform is installed on a cantilever of the outer edge of a building matched with the floor height, and a sliding unloading plate which inclines towards the platform is installed on the platform of an operation level without contacting an outer scaffold; after the installing is finished, a constructor stands on the outer scaffold, operates a cableway bucket of a tower crane to unload on the sliding unloading plate, in this way, the material can slide downwards in the building so as to finish the unloading; lifting floor by floor is carried out after the construction of the operation level is finished, the sliding unloading plate is installed, and the unloading construction is performed till the unloading construction of all floors of the whole building are finished. Practices prove that, with the adoption of the U-shaped slot, a large amount of manpower and a large amount of trolley cost are saved; the construction method has the following characteristics of convenience, high speed, good economic benefit, reduced manpower, and ensured safe and civilized construction; and the construction is especially suitable for high buildings, ultra-high buildings, and multi-floor buildings with complex decoration engineering.

Owner:THE THIRD CONSTR & ENG OF CCFED

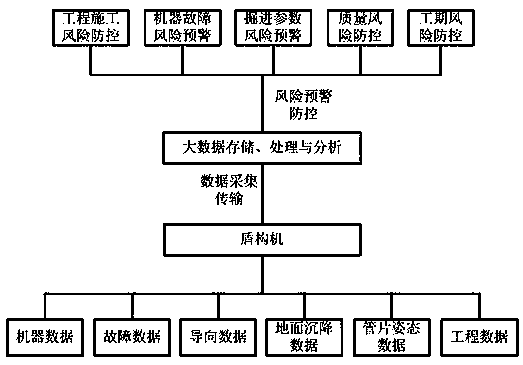

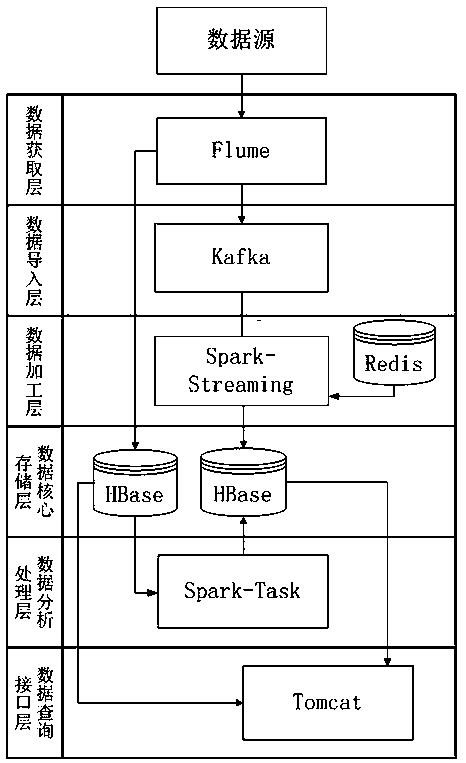

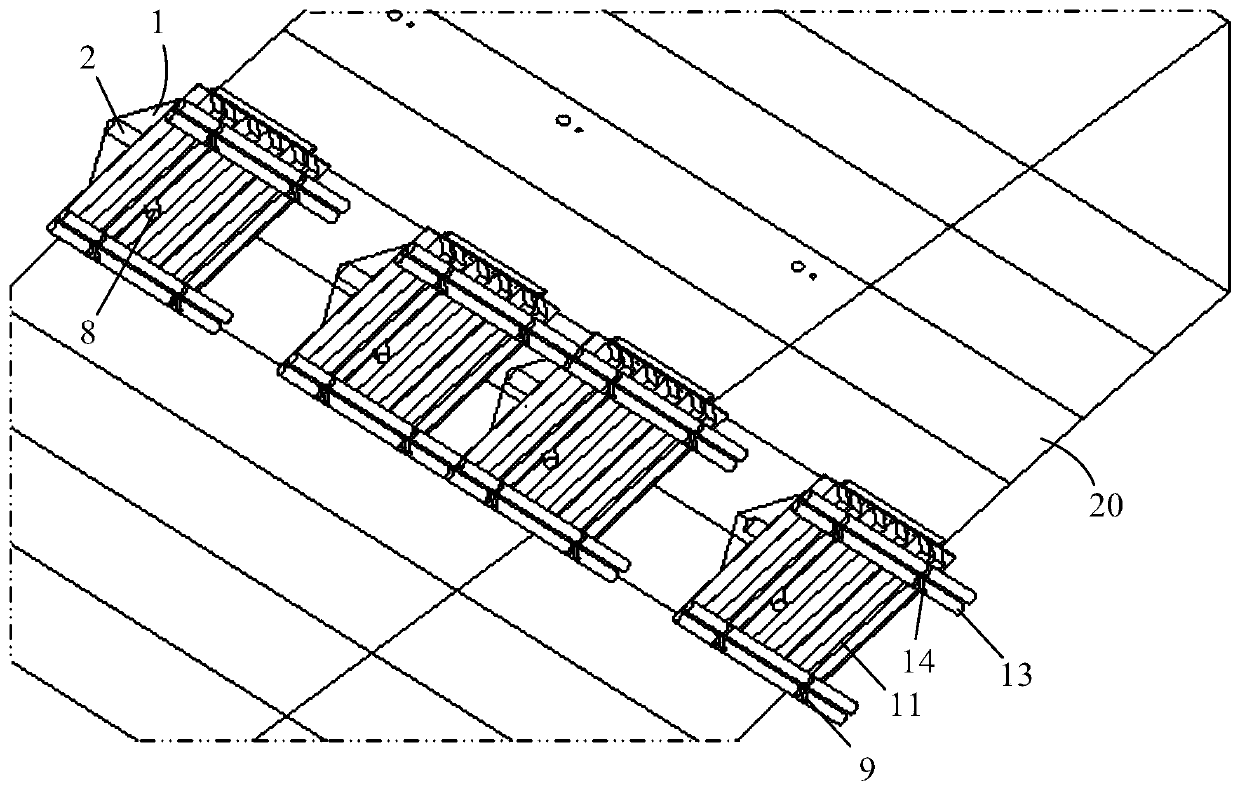

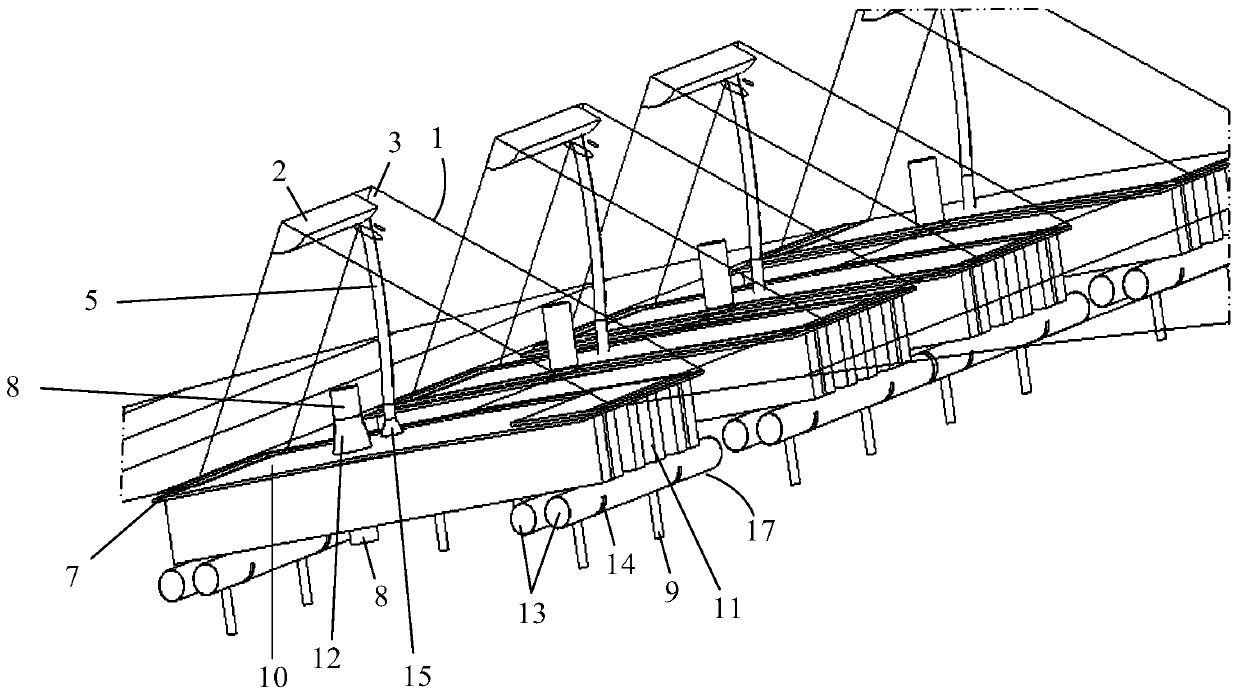

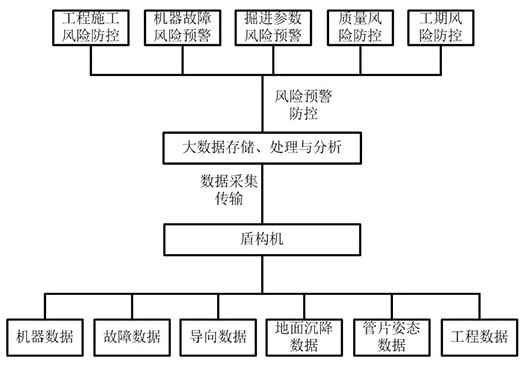

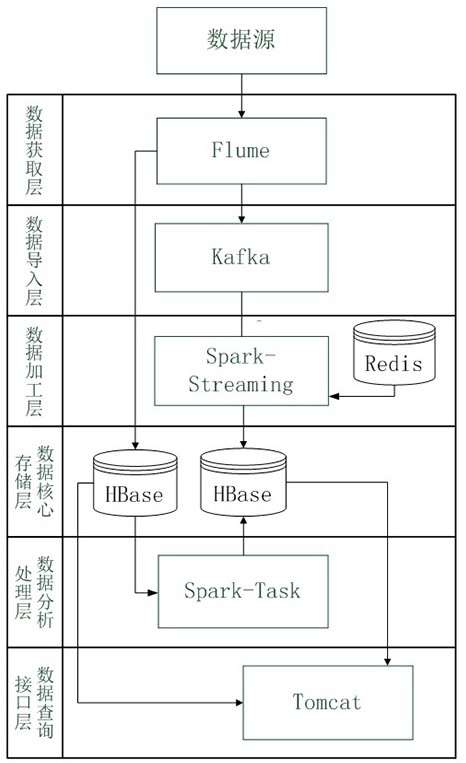

Construction risk prevention and control method and construction risk prevention and control system for shield tunneling machine

ActiveCN110359919AGood decision supportImprove risk prevention and control capabilitiesMining devicesResourcesRisk preventionDevice failure

The invention discloses a construction risk prevention and control method and a construction risk prevention and control system for a shield tunneling machine. The method comprises data acquisition and transmission, big date storage, processing and analyzing, risk recognition and early warning. The data mainly comprises machine data, fault data, guide data, ground settling data, duct piece gesturedata and engineering data. The big data storage and analysis and processing comprise a server and big data technology related software. The risk recognition and early warning comprise steps of engineering construction risk prevention and control, machine fault risk early warning, heading parameter early warning, quality risk prevention and control, construction period risk prevention and controland the like. The construction risk prevention and control method and the construction risk prevention and control system for the shield tunneling machine based on big data analysis can establish an informationized risk prevention and control system and avoid or reduce loss to a project due to risks such as equipment faults, staff operation errors and the like effectively, so that safe and efficient construction of the shield tunneling machine is guaranteed.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

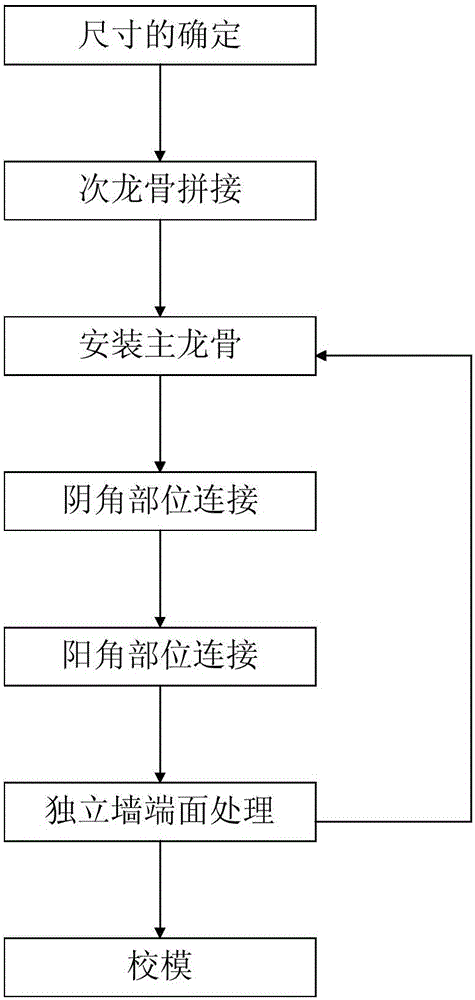

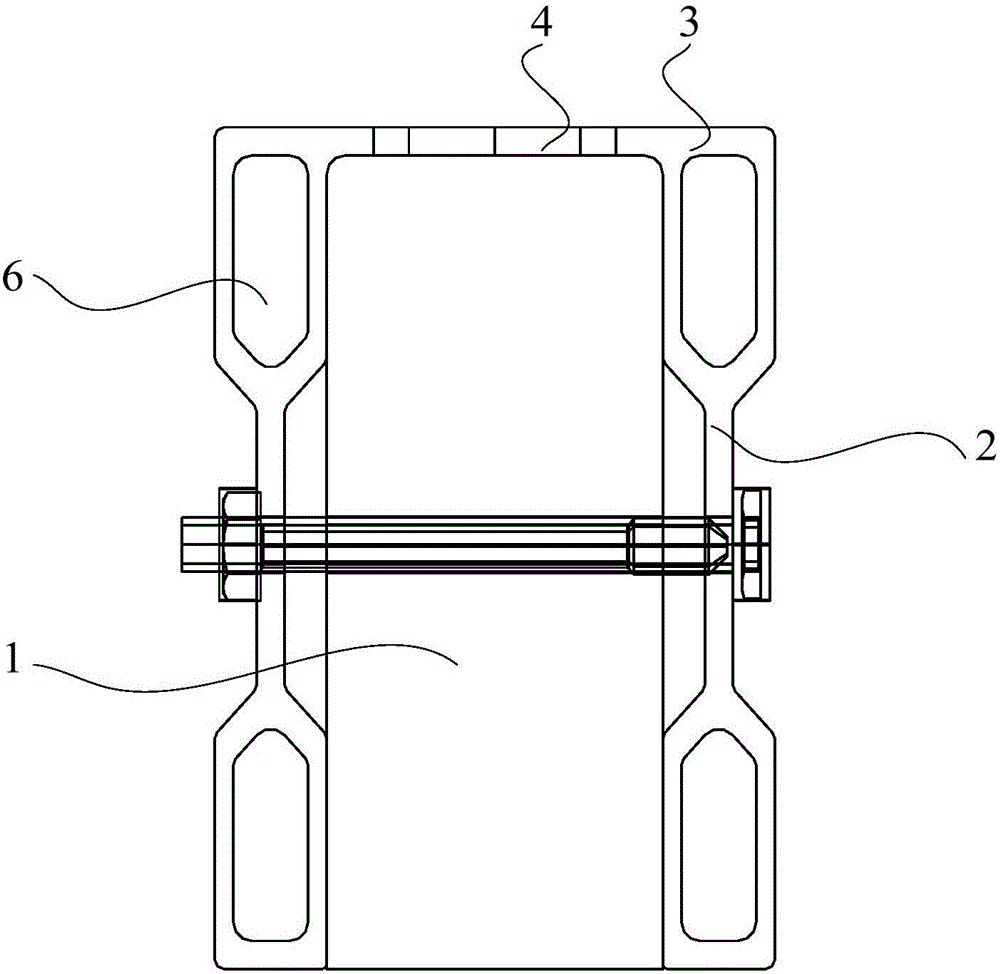

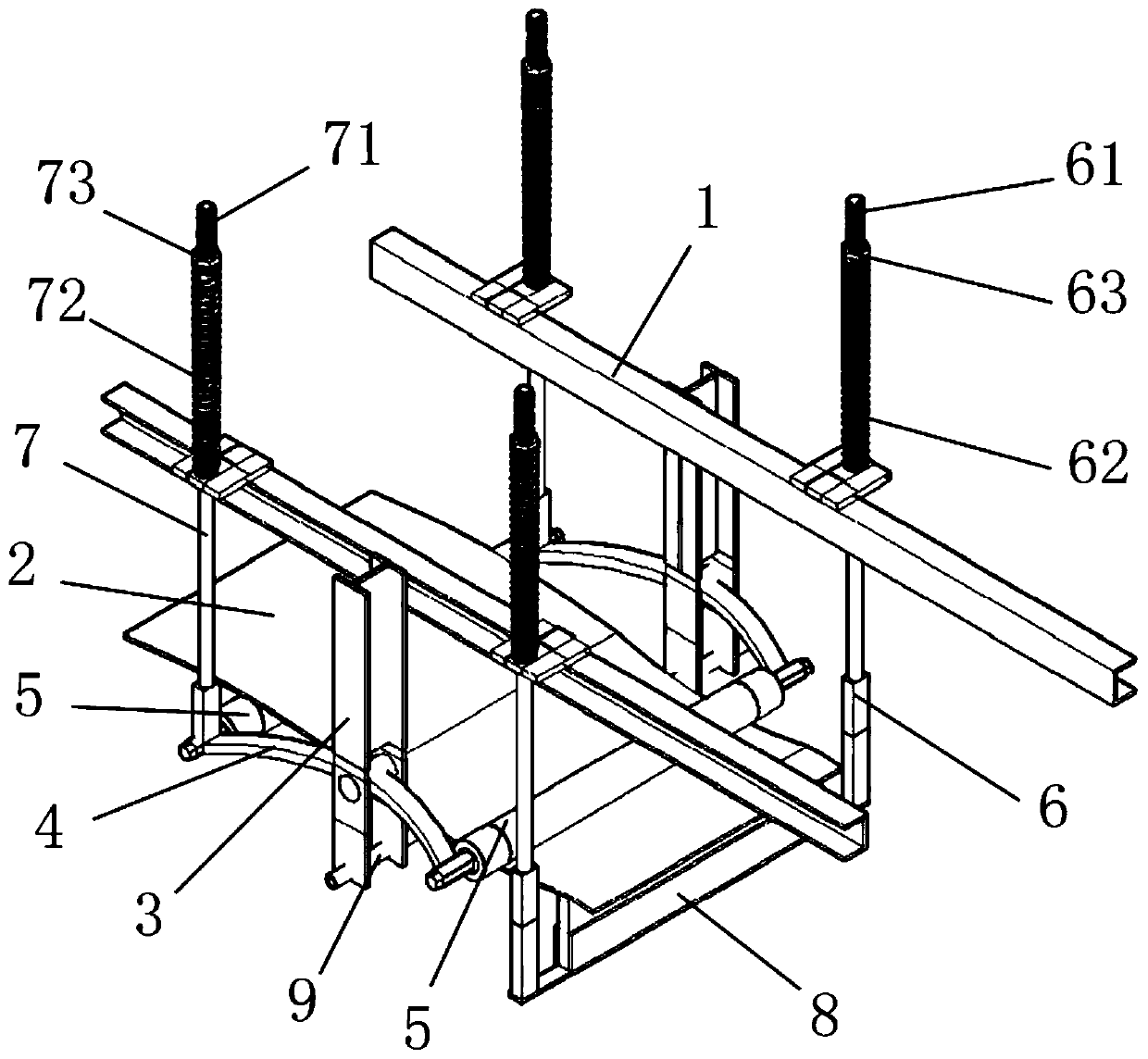

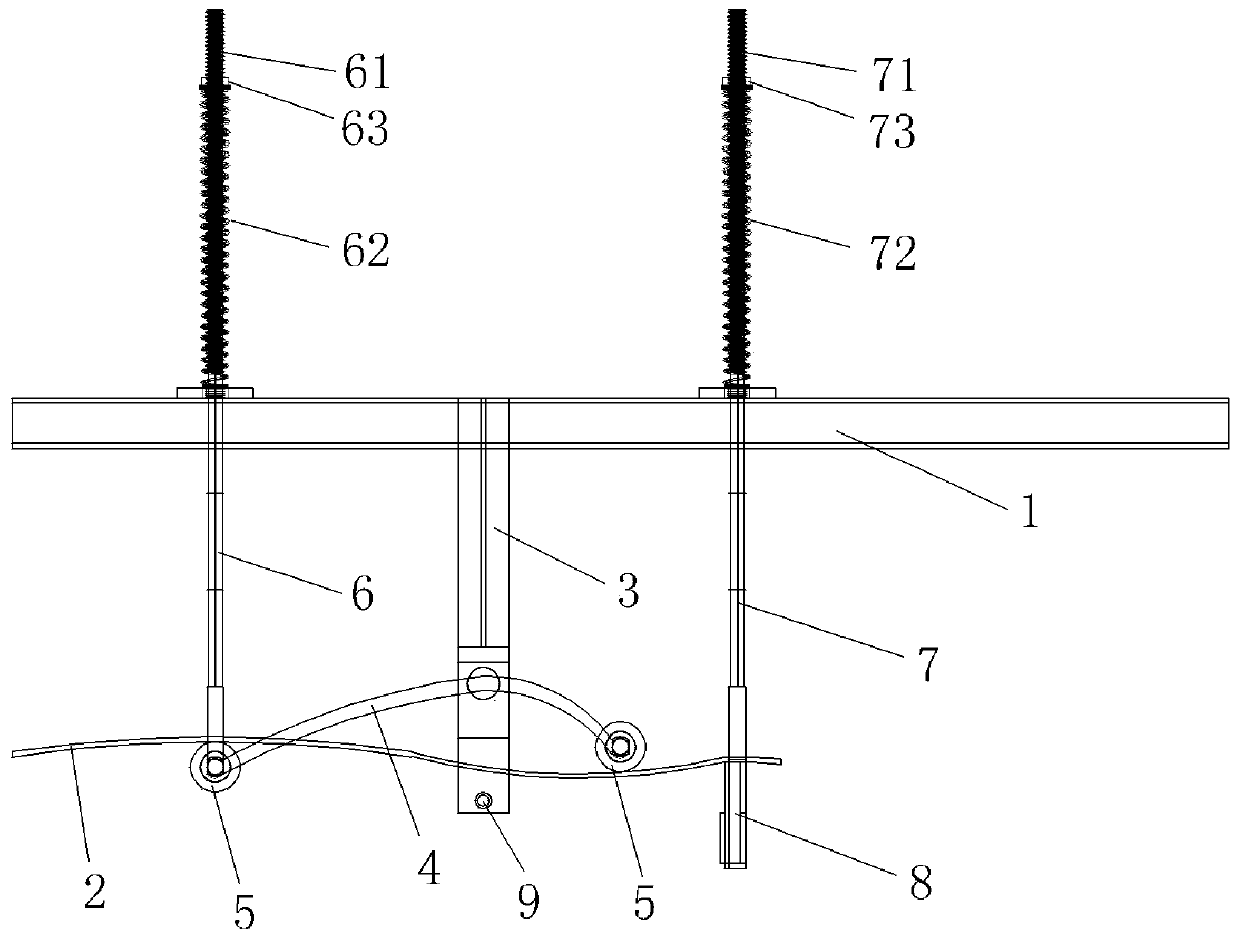

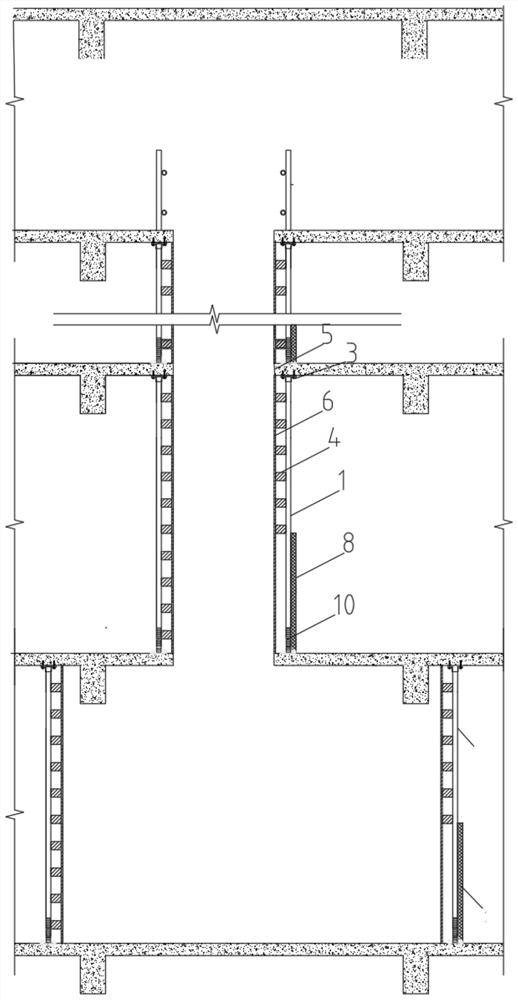

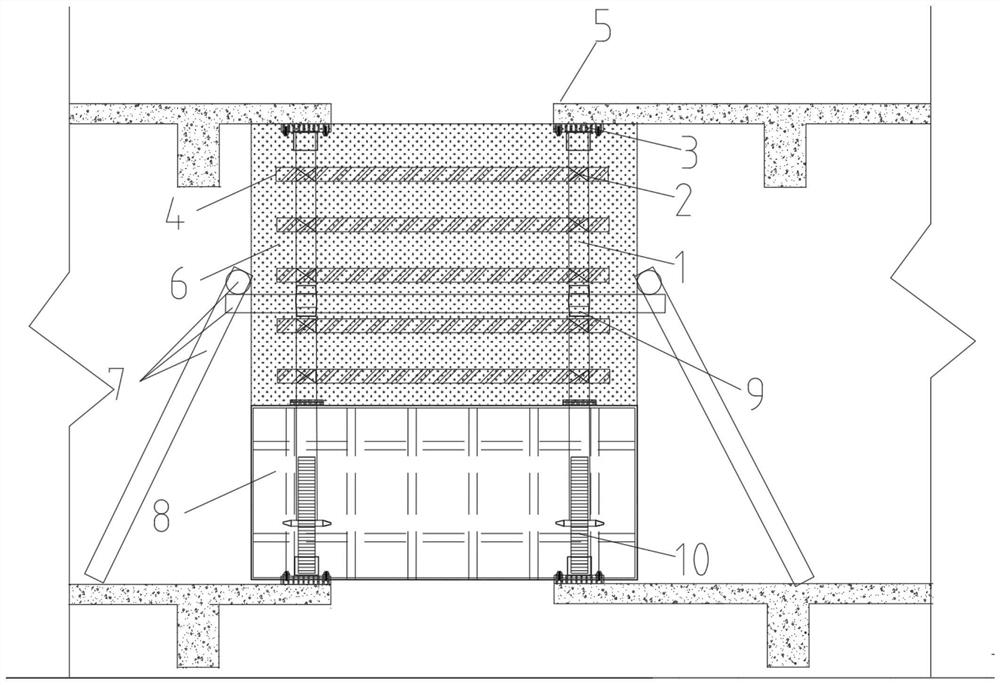

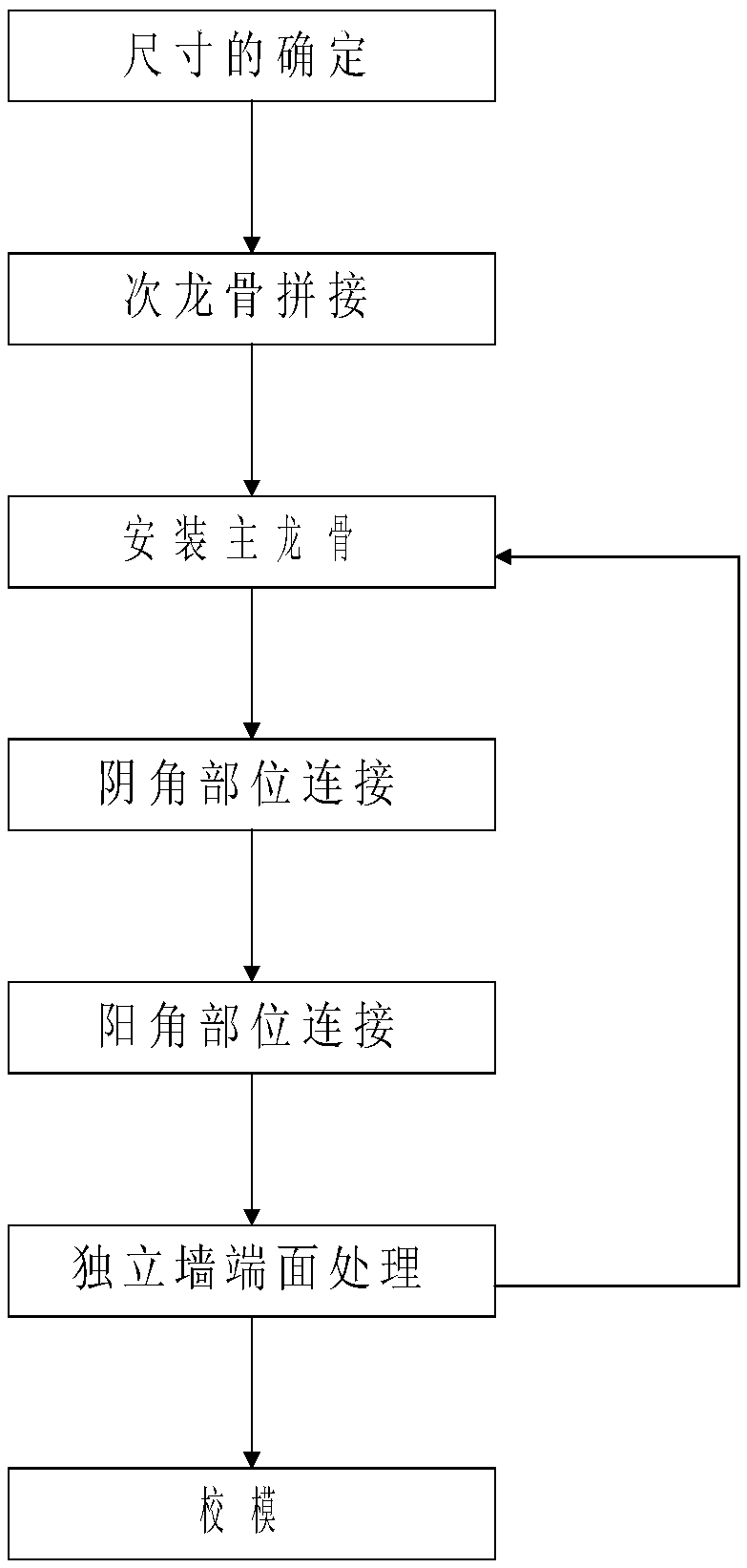

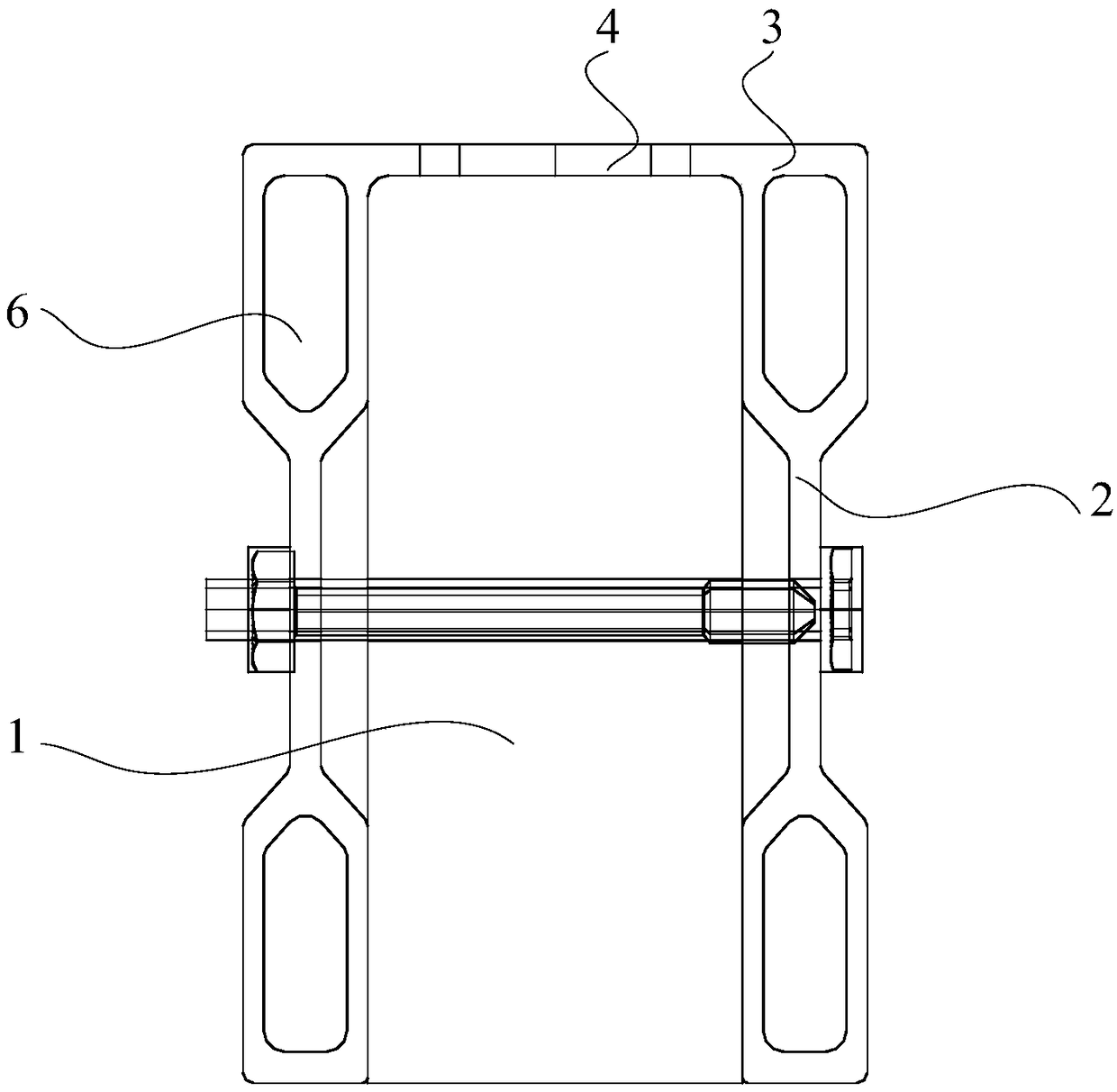

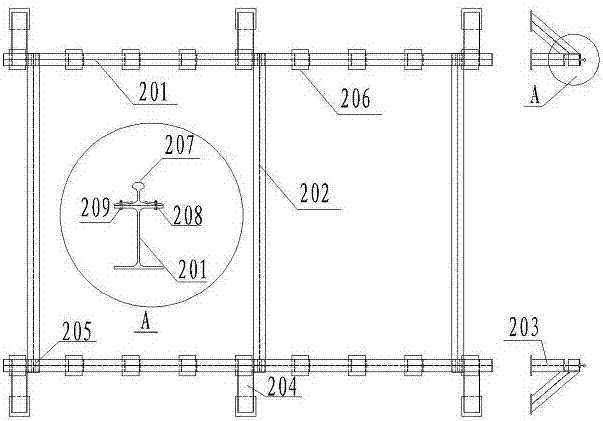

Novel reinforcing system for formwork and construction process of novel reinforcing system

ActiveCN106481077AReduce labor intensityReduce construction weightAuxillary members of forms/shuttering/falseworksKeelUltimate tensile strength

The invention discloses a novel reinforcing system for a formwork and a construction process of the novel reinforcing system. The novel reinforcing system comprises main keels, auxiliary keels, an internal corner connecting piece and an external corner connecting piece. The construction process comprises the following steps of determining the size of a wall body, designing a scheme, and calculating the lengths of the keels; splicing a plurality of auxiliary keels together, and using steel nails to connect seams between the forwork edge and the auxiliary keels; horizontally mounting the main keels in sequence; connecting the main keels on the two sides of an internal corner through the internal corner connecting piece; connecting the ends of the main keels on the two sides of an external corner through an external corner inclined pulling piece; conducting connection and fastening on a plug wall connecting external member and the main keels; and adjusting an external corner inclined pulling angle seat, the perpendicularity and the physical dimension of the formwork. According to the construction process of novel reinforcing system for the formwork, the accessories of a vertical steel and wood compounded keel, the horizontal main keels, the external corner connecting piece, an external corner inclined pulling connecting piece, a keel connecting piece, a plug plate reinforcing external member and the like are adopted, so that the construction weight is reduced, the labor intensity of a worker is reduced, the construction efficiency is improved, the cost is lowered, and the civilized construction is guaranteed.

Owner:河北易鼎行环保科技有限公司

Molten tin bath manufacturing and installing process

The invention discloses a molten tin bath manufacturing and installing process. A method comprises the following steps of leveling nine points at the field, assembling in pairs, welding, and laying a substrate in installing is adopted. The molten tin bath manufacturing and installing process saves materials, reduces the mechanical using, can control and adjust the central line of a molten tin bath and the flatness, reduces the danger coefficient during the construction process in assembling in pairs, welding and adjusting, and guarantees the civilized construction; steel plates are assembled in pairs, installed and laid at the field, the molten tin bath is easy to deform, and when in assembling in pairs and welding, the deformation is small and can be controlled easily, and the installation quality is ensured.

Owner:CHINA SIXTH METALLURGICAL CONSTR

Construction method of post-cast strip floor slab with independent support

InactiveCN113389379AShorten the life cycleQuality assuranceForms/shuttering/falseworksBuilding material handlingFloor slabPipe

The invention discloses a construction method of a post-cast strip floor slab with an independent support. The construction method aims at overcoming the technical defects of high construction cost, long formwork service cycle and the like. The construction method comprises the steps that a bottom formwork vertical supporting system is arranged; a group of vertical supporting PVC pipes are arranged at the connecting end of a floor slab and a post-cast strip; the upper ends of the PVC pipes communicate with the floor slab pouring area; concrete is poured into the floor slab, and the PVC pipes are filled with concrete; concrete curing is completed, and then the vertical supporting system is removed; the connection end of the floor slab and the post-cast strip after concrete pouring is supported by concrete stand columns in the vertical supporting PVC pipes; a post-cast strip pouring formwork is built again, and concrete of the post-cast strip is poured; and after concrete curing of the post-cast strip is completed, all formworks, the PVC pipes and the concrete in the PVC pipes are removed. The construction method has the beneficial effects that the service cycles of the formworks and supporting rods thereof are shortened, and the structural quality is ensured; and the cost is saved by 20% or above.

Owner:SHENZHEN CONSTR GRP

A self-cleaning water-saving comprehensive car washing method and system for civil construction sites

ActiveCN105966366BImprove car wash efficiencyGood car washEnergy based wastewater treatmentMultistage water/sewage treatmentWater storageEnvironmental resource management

The invention belongs to a method and system for self-cleaning water-saving type comprehensive vehicle washing for a civil construction site. The method comprises the steps of foundation ditch precipitation well and drainage ditch system construction, cofferdam pool construction, construction of a wheel washing machine base, a water storage pool, a wheel washing pool, a filtering pool and a settling pool and the like. The system comprises the wheel washing pool used for conducting primary cleaning on tires of a muck vehicle and sludge on a vehicle body, the wheel washing machine base, a wheel washing machine, a foundation ditch precipitation well, a foundation ditch drainage ditch, a cofferdam pool, the water storage pool, the filtering pool and the settling pool. The method and system for self-cleaning water-saving type comprehensive vehicle washing for the civil construction site have the advantages that the method and structure are novel and simple, the vehicle washing efficiency is high, the vehicle washing effect is good, and environment beautifying, energy conservation, environment protection and water recovery circulation utilization are good.

Owner:CHINA CONSTR MUNICIPAL ENG +1

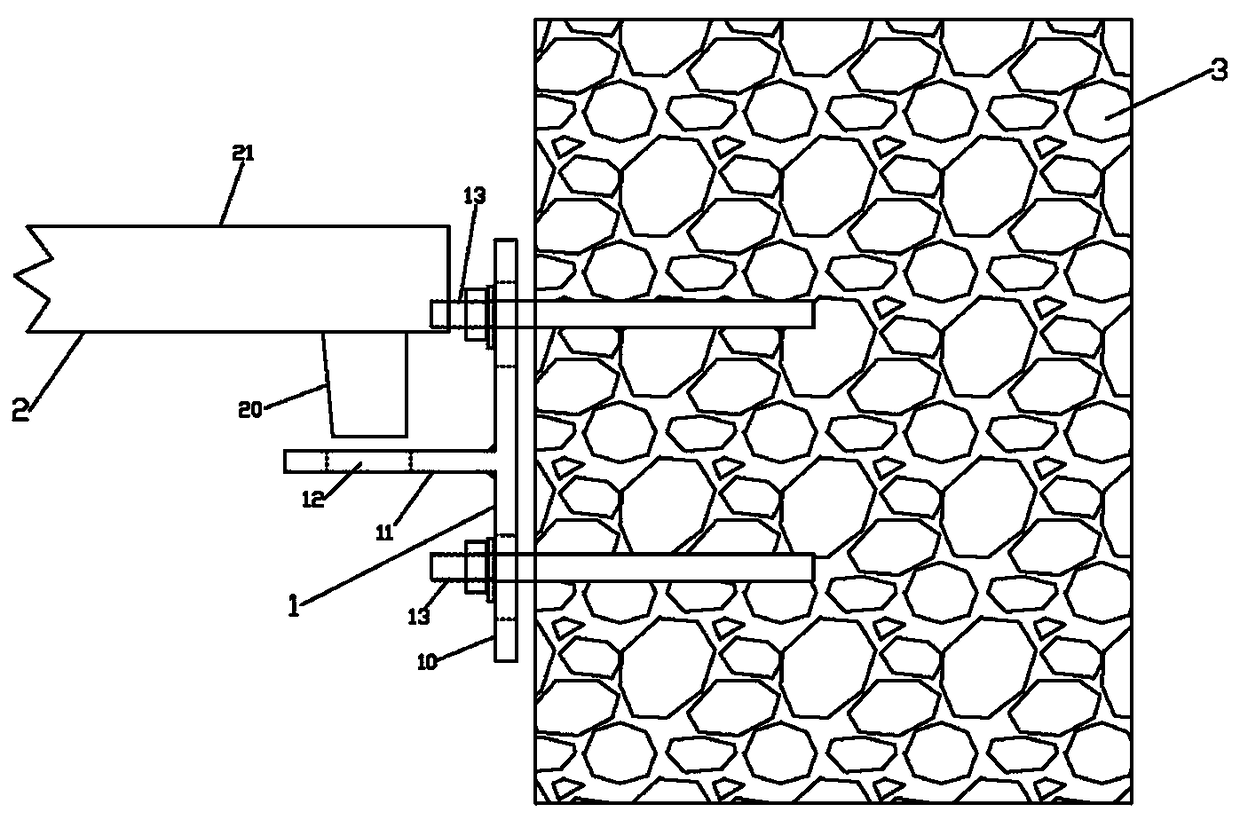

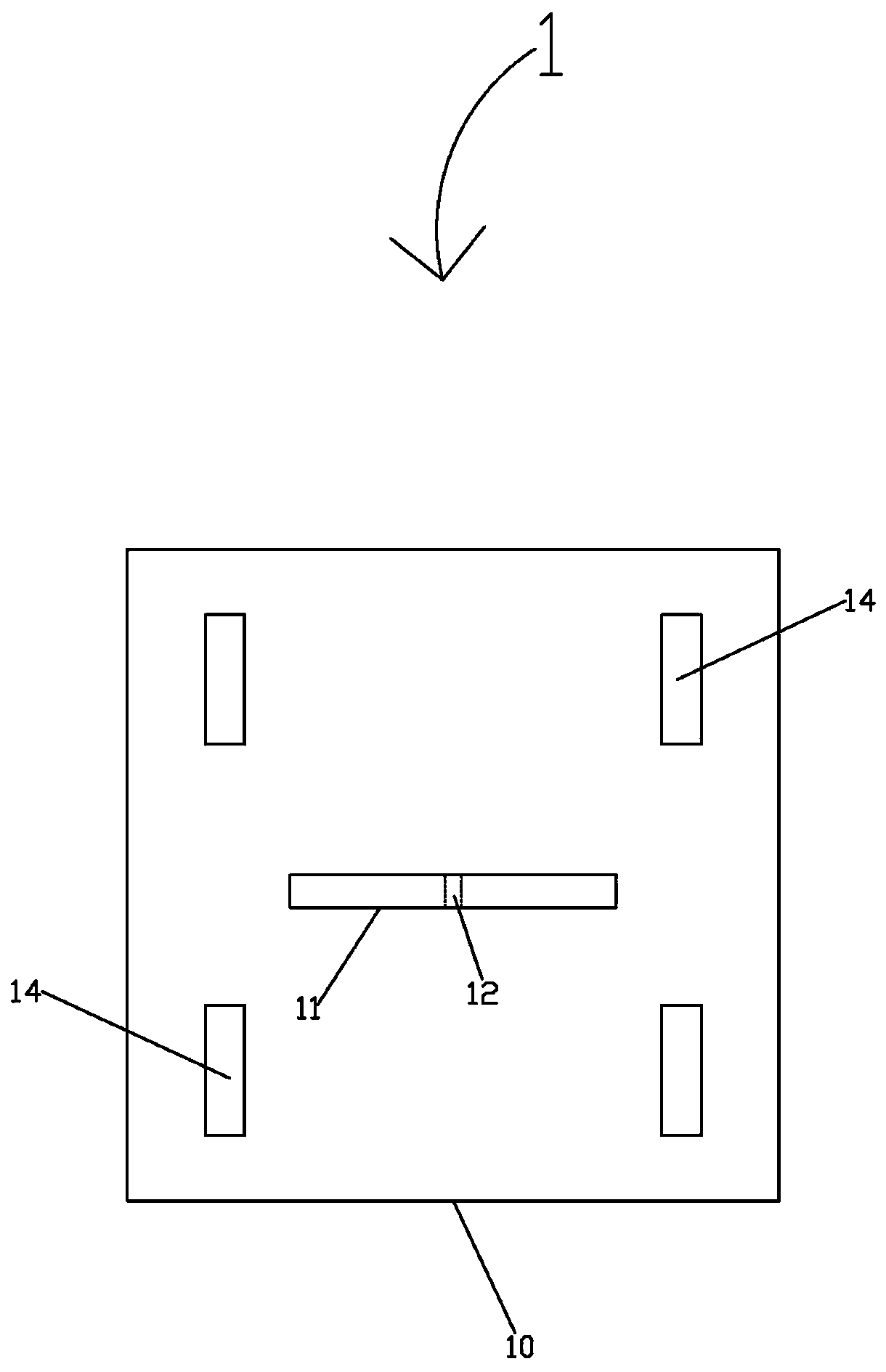

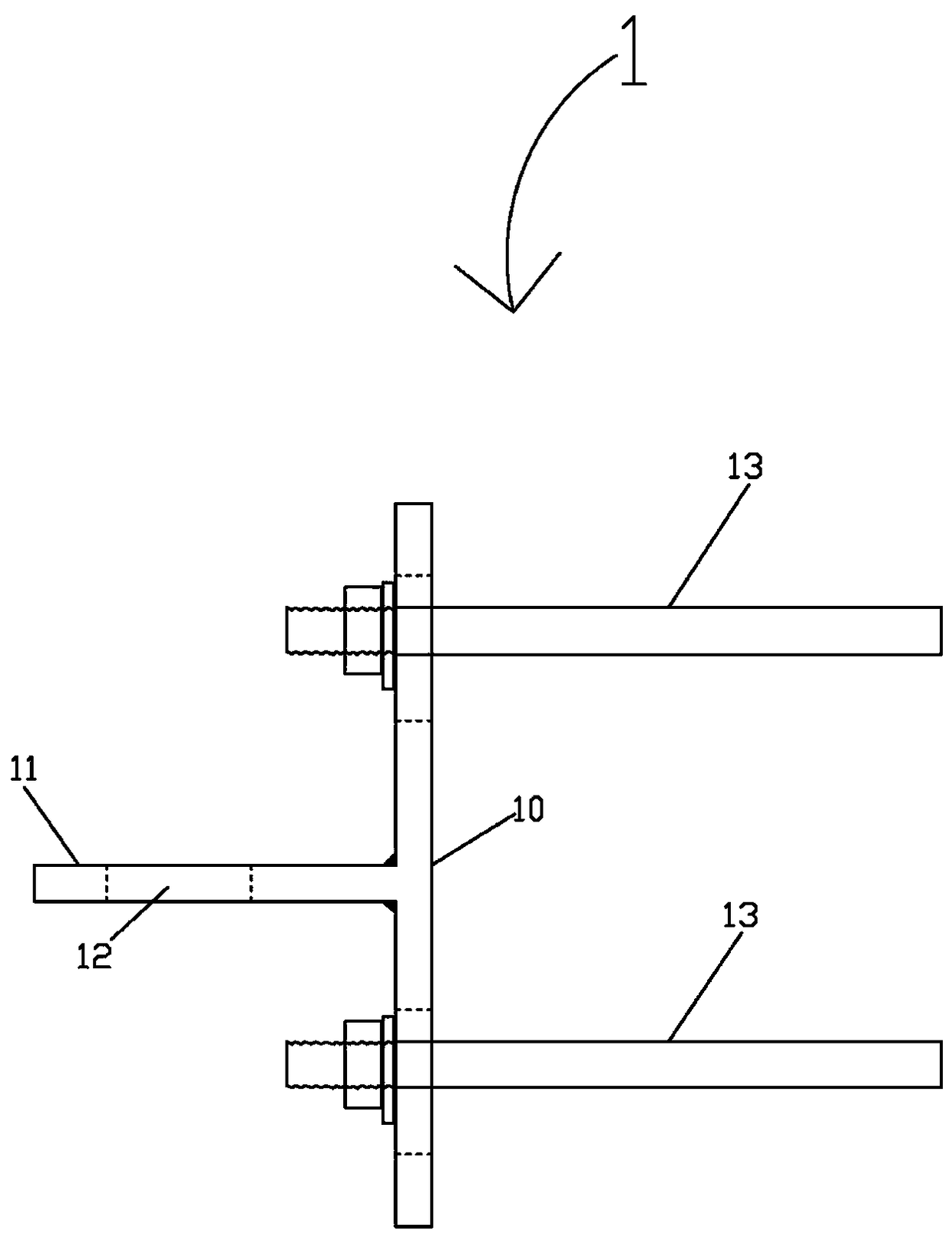

Postpositioned pre-buried wall-linking device and erecting construction method thereof

PendingCN108868107AEasy to useGuarantee securityScaffold accessoriesDesign technologyBuilding construction

The invention belongs to the technical field of building construction equipment and construction technology improvement and design, and particularly discloses a postpositioned pre-buried wall-linkingdevice. The device comprises a main body piece and an accessory, a back plate is arranged on the main body piece, several pin holes connected with expansion bolts are formed in the back plate, a connecting plate protruding out of the back plate is perpendicularly arranged in the middle of the back plate, and a through carrying opening is formed in the connecting plate; the accessory is composed ofa supporting rod and a carrying plate arranged on the supporting rod, and the carrying plate adapts to the carrying opening. The construction method can be widely applied to city beautifying, subsequent maintenance of outer walls and other aspects.

Owner:中建新疆建工集团第三建设工程有限公司

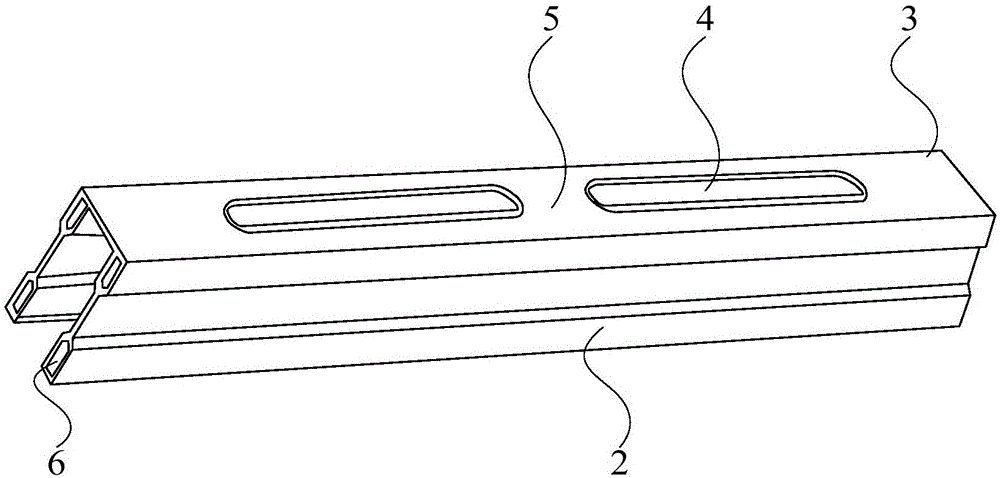

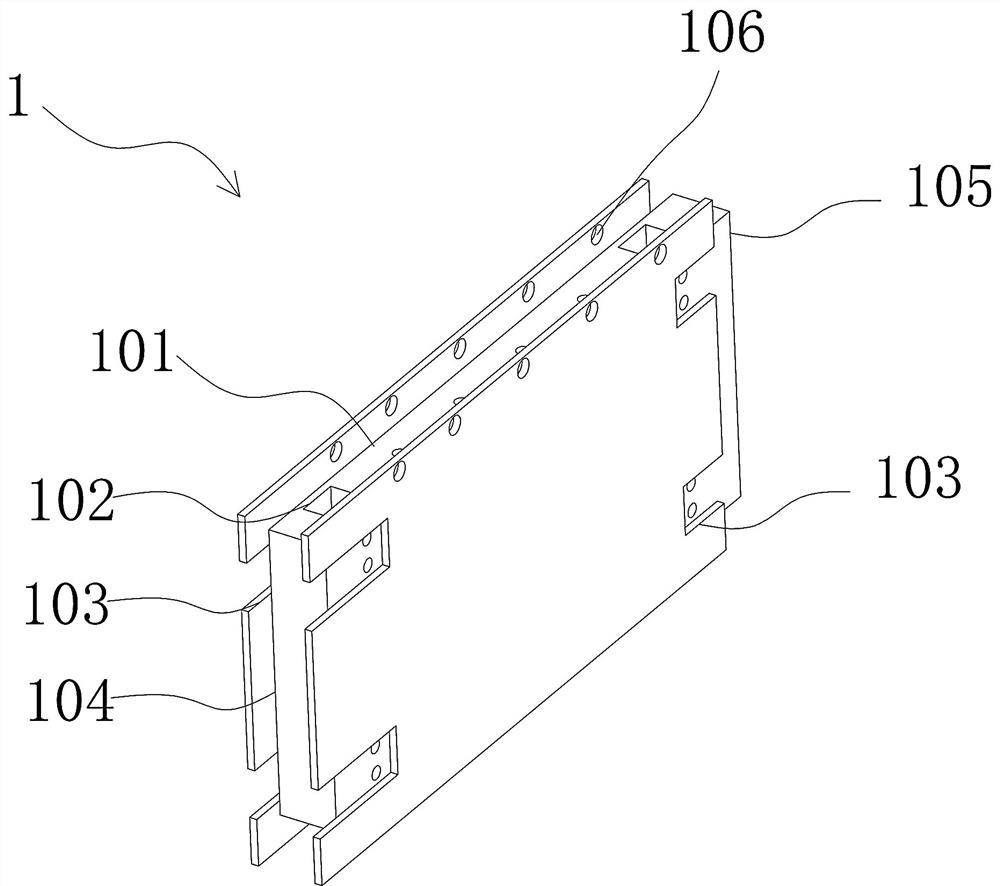

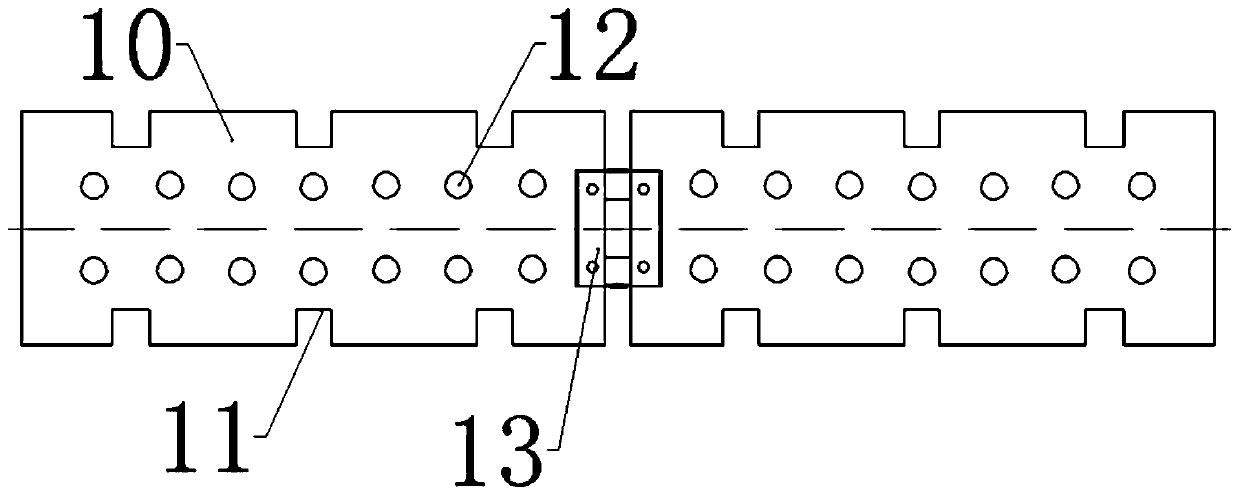

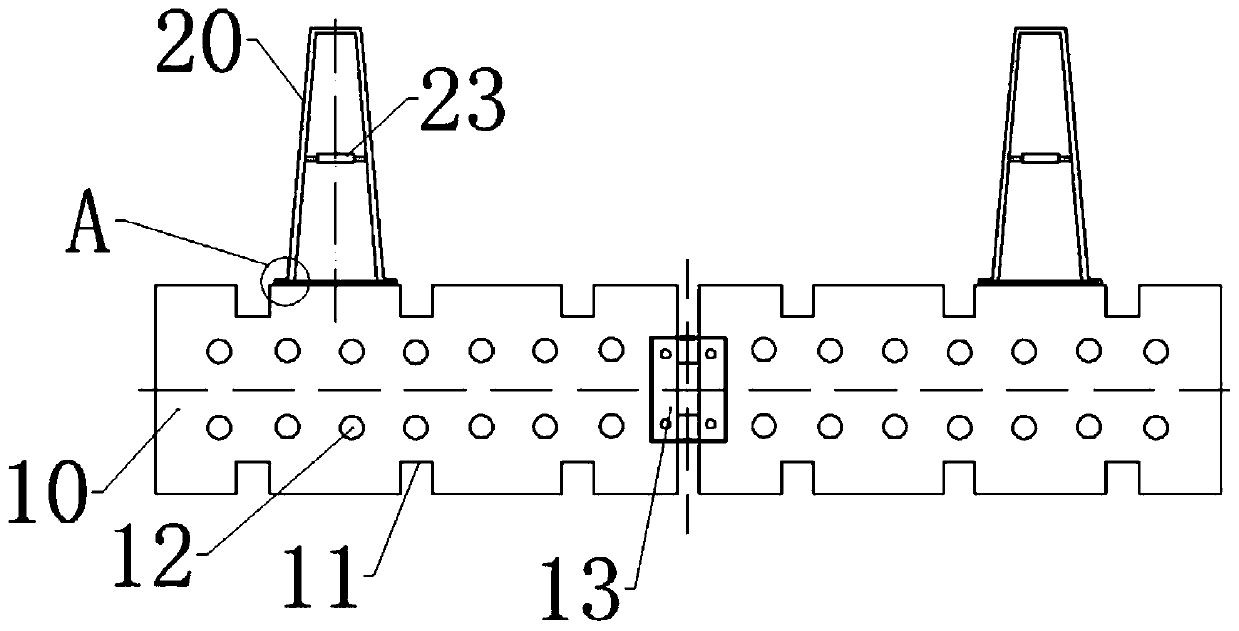

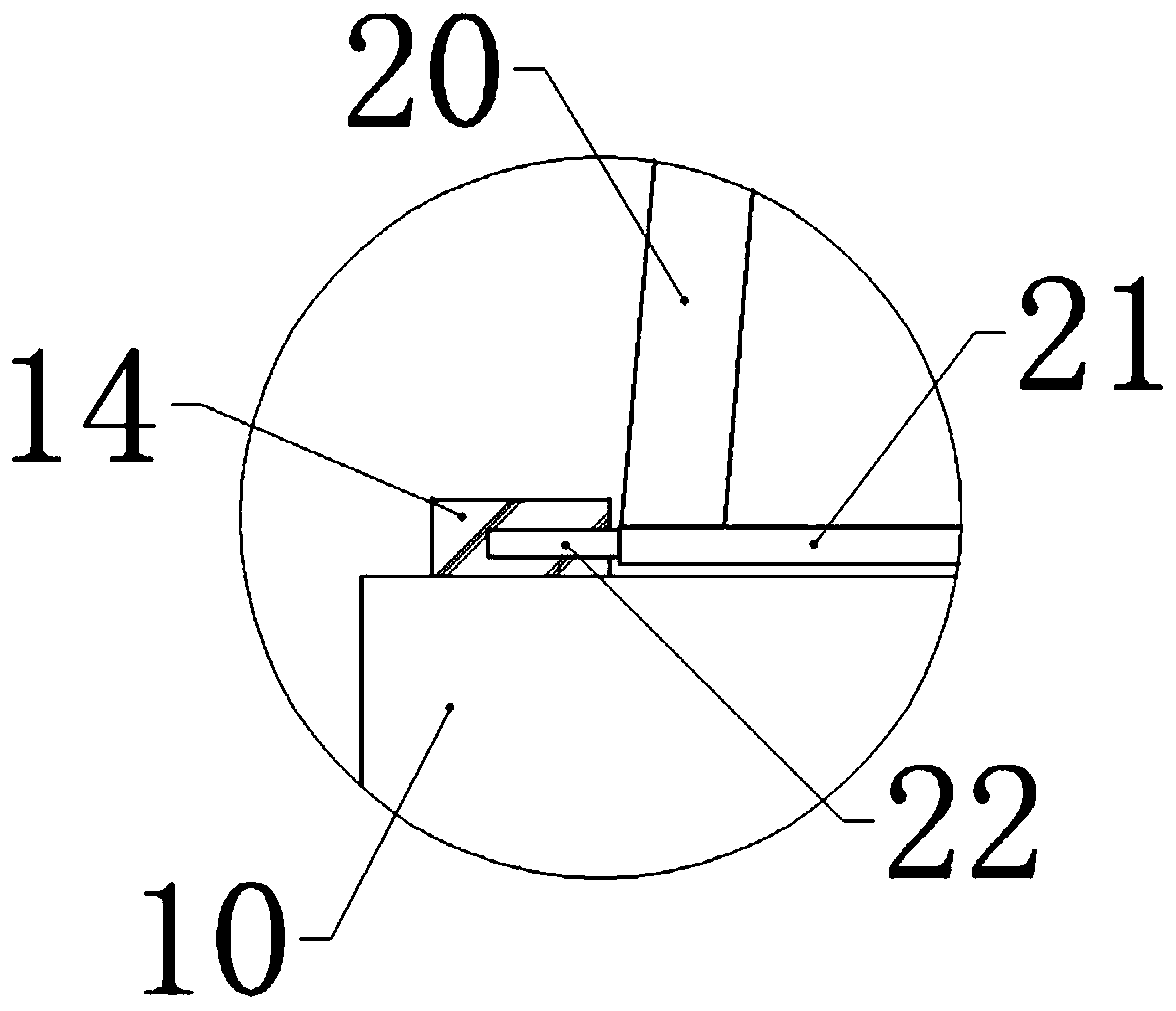

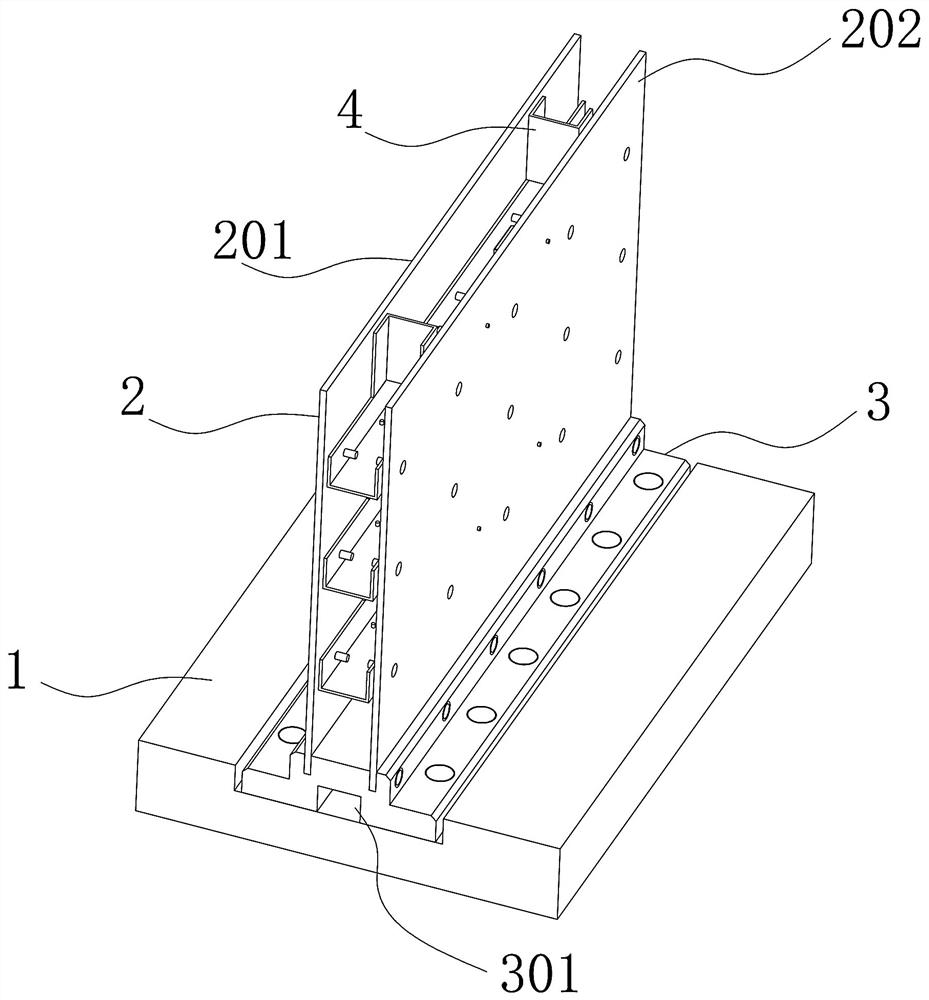

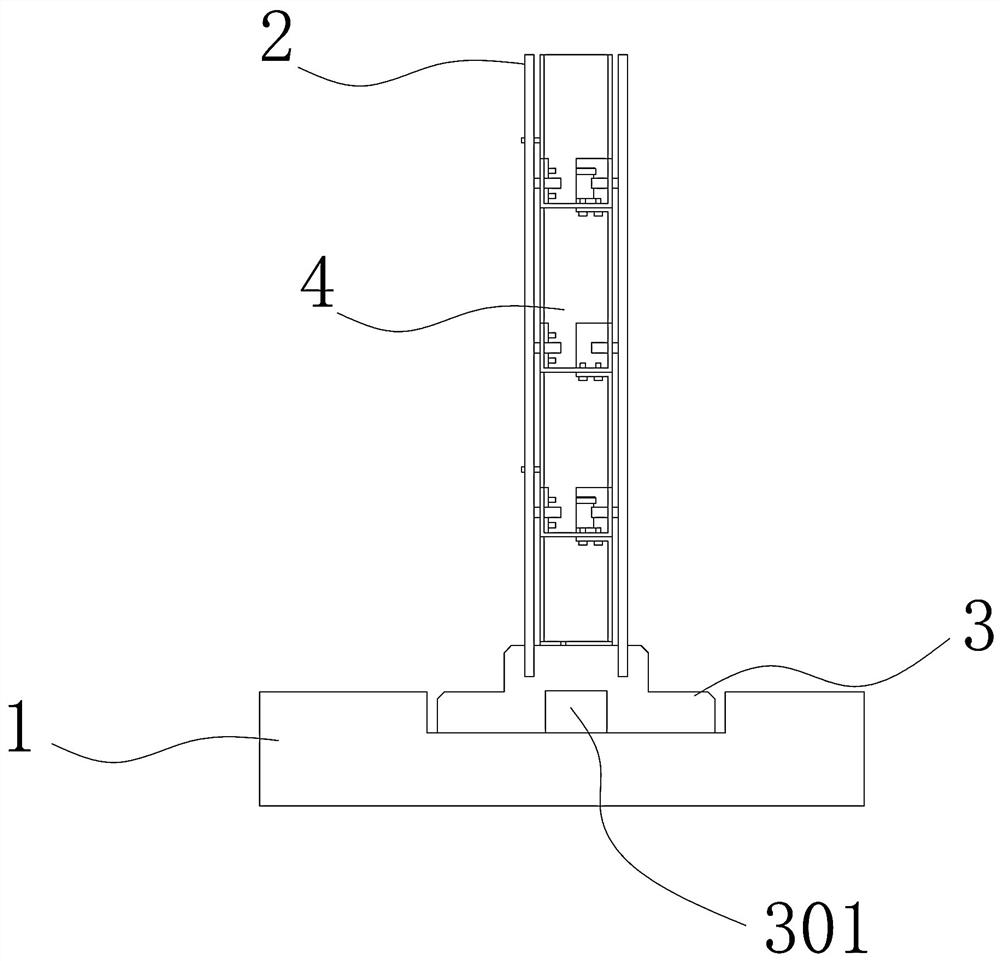

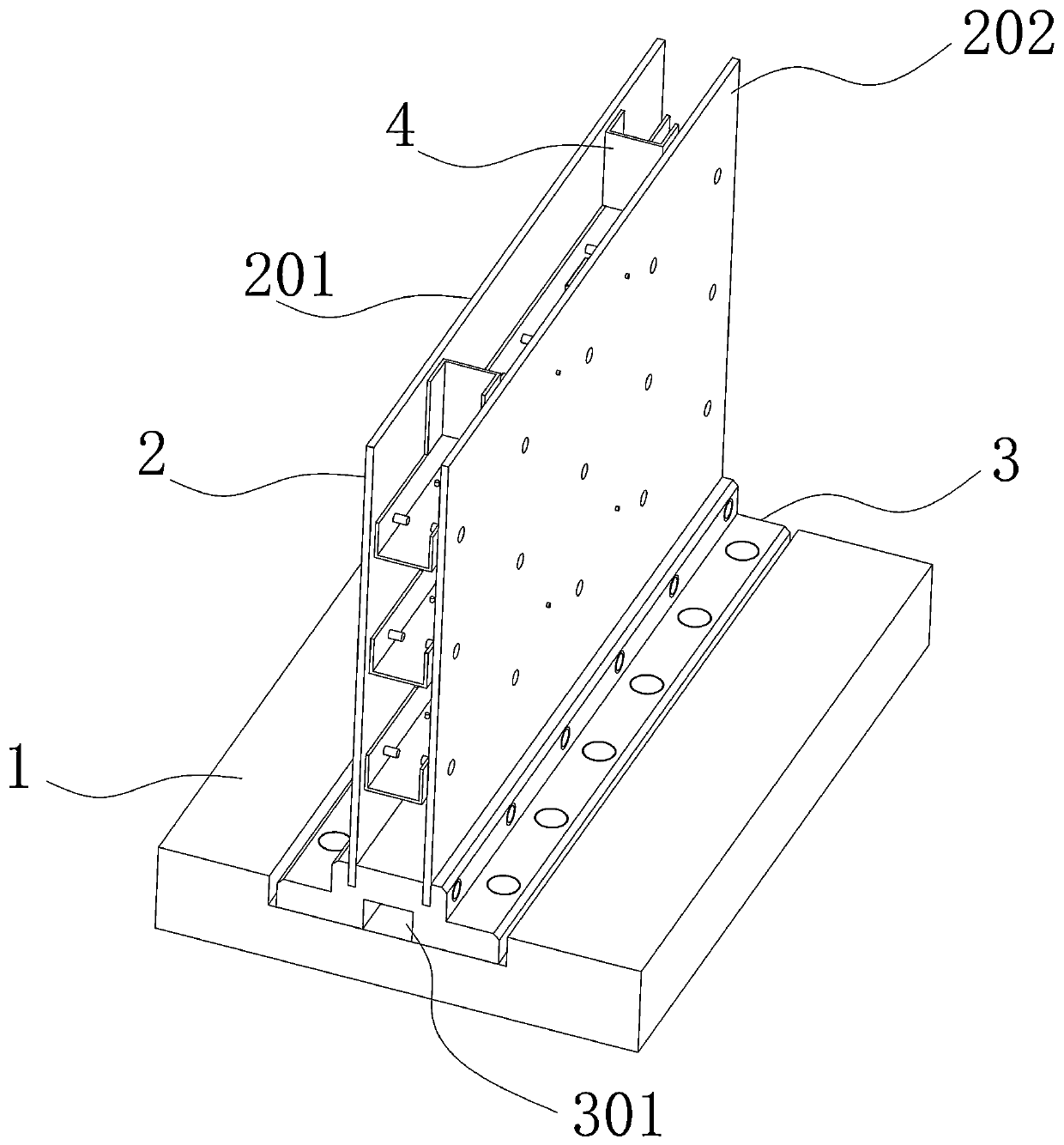

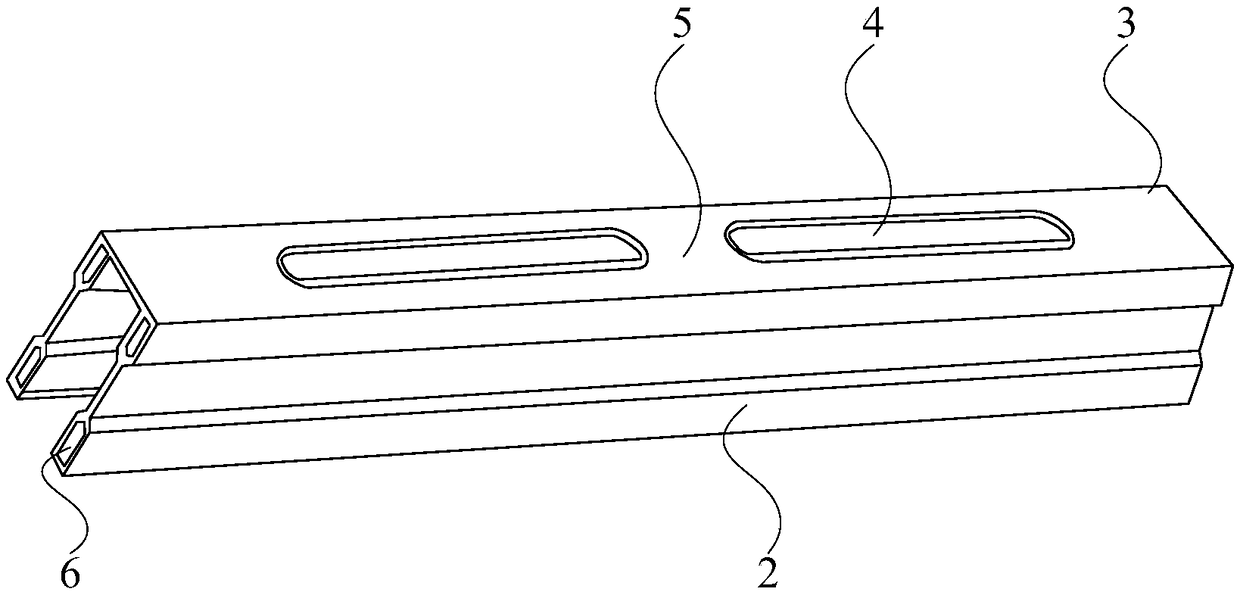

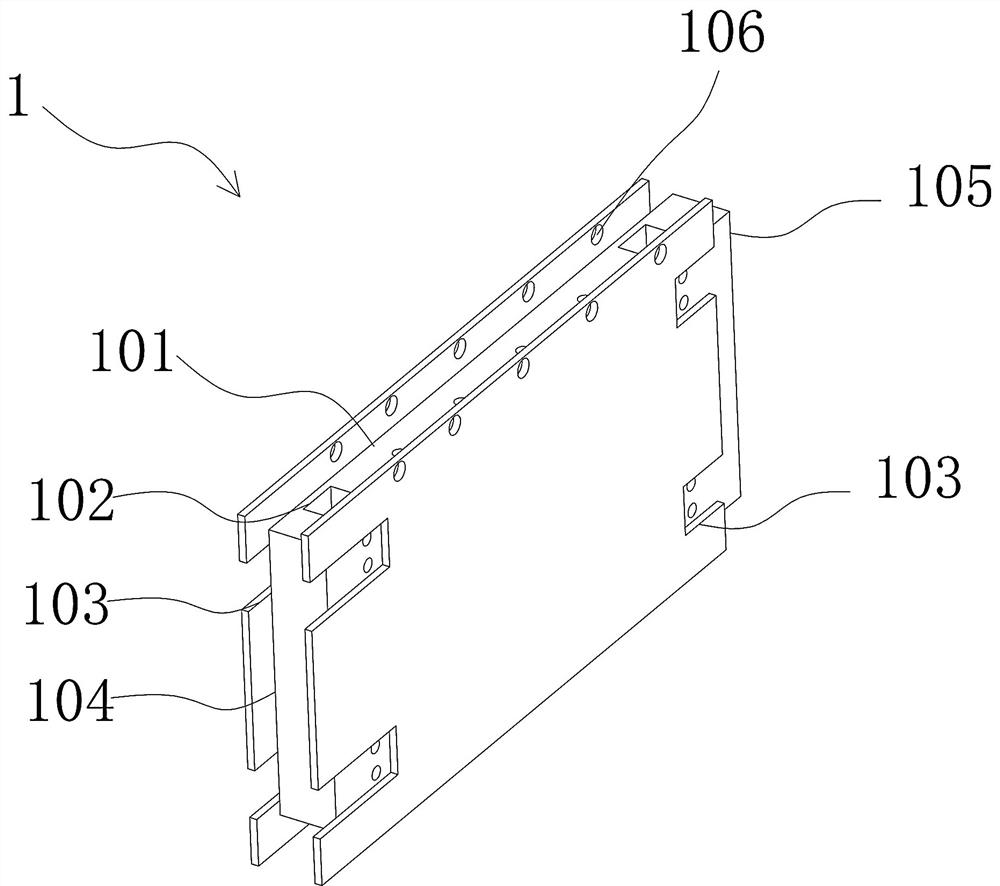

Modular assembled light steel house connecting frame

ActiveCN110512722BSave human effortIngenious designWallsStructural engineeringMechanical engineering

A modular assembly light steel house connecting frame, including a connecting frame connecting multiple assembled walls, the structure of the connecting frame is: the end of the first connecting frame is raised, the second connecting frame is a groove structure, the first connecting frame The raised part is inserted into the groove of the second connecting frame. A bracket mechanism is provided on one side of the second connecting frame. The bracket mechanism is used to install the transverse wall. The assembled wall is connected to the foundation through the connecting frame, and the connection of each plate is just It is particularly important that all plate connections are movable connections, which can be disassembled and installed many times, and can save manpower in the assembly of prefabricated light steel houses, making it more convenient to make prefabricated light steel houses, ingenious in design, low in cost, and easy to use.

Owner:武汉迈特绿色建筑科技股份有限公司

Cable storage device, system and method

InactiveCN107521864AEasy to placeAvoid random placementContainers for annular articlesClosuresElectricityEngineering

The invention provides a cable storage device, system and method. The device comprises a connector, a hooking body and a containing body, wherein the hooking body is connected to the first end of the connector and used for hooking a supporting device, and the containing body is connected to the second end of the connector and used for containing cables. According to the cable storage device, system and method, the hooking body hooks the supporting device, the cables are contained in the containing body, thus, the cables and the supporting device are relatively fixed, the cable storage position is determined, and the situation that the cables are stored at will is avoided; accordingly, the cables are effectively protected and avoided from being damaged, the safety of construction electricity is ensured, and safe and civilized construction is guaranteed; and moreover, operation is easy, the cables can be stored conveniently, the operation efficiency is effectively improved, meanwhile, the structure is simple, and the economical and practical effect is achieved.

Owner:MCC5 GROUP CORP SHANGHAI

Deslagging channel convenient to dismount and mounting method

ActiveCN110593526AEasy to install and disassembleEasy to get materialsVertical ductsFloor slabArchitectural engineering

The invention discloses a deslagging channel convenient to dismount. The channel comprises deslagging holes formed in an upper layer floor and a lower layer floor, sleeves are evenly arranged on the periphery of the deslagging holes, a deslagging channel combination part is arranged between the sleeves of the upper layer floor and the lower layer floor, the deslagging channel combination part is formed by connecting multiple sections of deslagging channel group units, each deslagging channel group unit comprises a right prism frame and a panel laid on the side face of the right prism frame, each right prism frame is composed of a steel pipe stand column, a batten cross beam and the panel, and the steel pipe stand columns on the lower end of the deslagging channel combination part and the sleeve of the lower layer floor are subjected to height adjusting through connecting of adjusting screws. The transport cost of building waste in the reinforcing or modification engineering can be reduced, and safety of building waste transport can be improved. The mounting method comprises the steps of fixing the sleeves, erecting the steel column stand columns, mounting the batten cross beams andthe panels, splicing the deslagging channel group units, mounting the deslagging channel combination part on the adjusting screws, performing jacking and finally sealing and mounting door leaves.

Owner:WUHAN CONSTR ENG

Foldable sawtooth punched-plate

PendingCN110005196AImprove integrityEasy to removeForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksRebarMaterials science

The invention relates to the technical field of building construction, and specifically discloses a foldable sawtooth punched-plate. The foldable sawtooth punched-plate comprises two rectangular steelplates and one stainless steel hinge, punched holes are punched in the steel plates, the steel plates are cut into serrated shapes along two long edges, the two short edges of the two steel plates are connected by the stainless steel hinge, the hinge is firmly welded between the two stainless steel plates, and the foldable sawtooth punched-plate is formed by the two steel plates and the hinge. The foldable sawtooth punched-plate aims to solve the problems of inaccurate positioning of reinforcing bar, too large or too small thickness of a reinforcing bar protective layer, poor civilized construction and inability of turnover using of a cement interception board.

Owner:CHINA RAILWAY CONSTR ENG GROUP

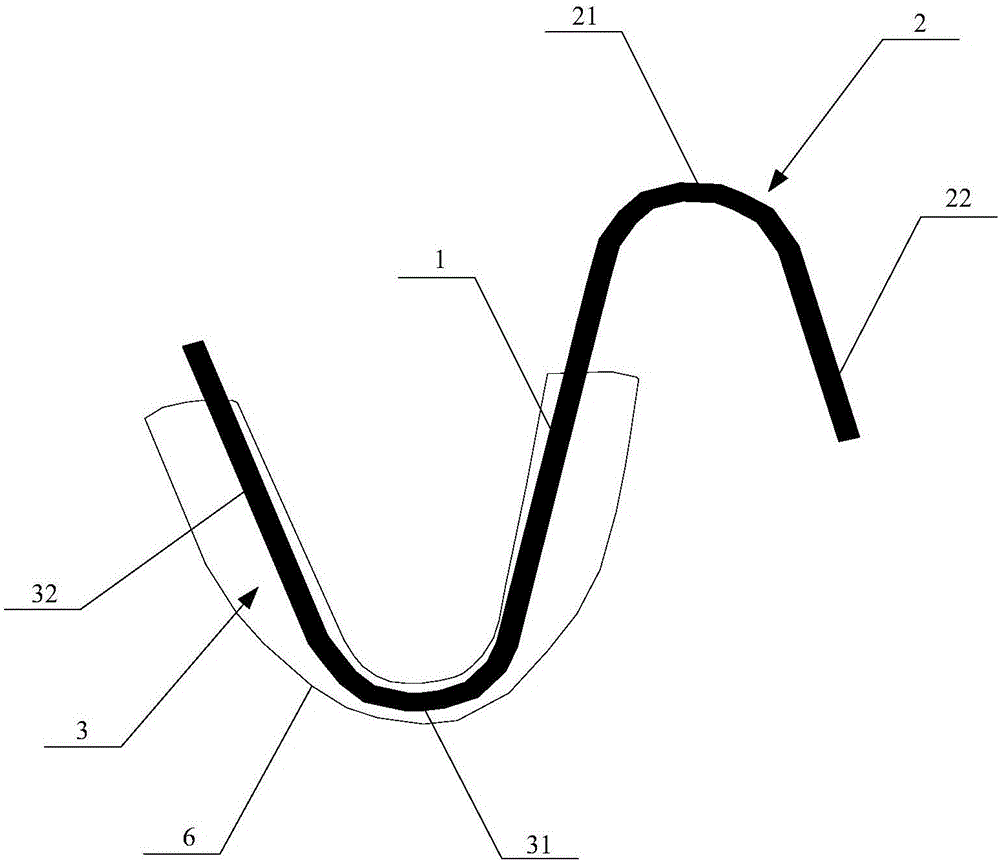

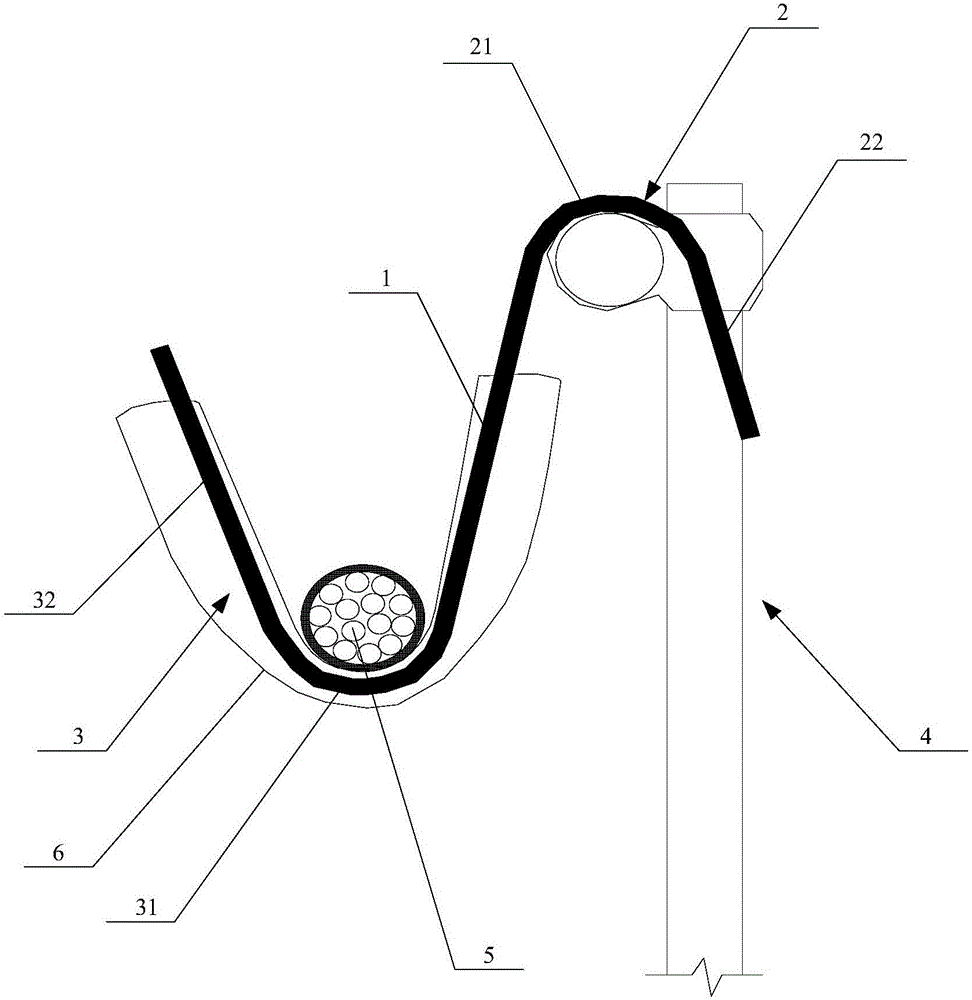

Inverted anchor recess anchor sealing device based on communicating vessel principle and construction process

PendingCN111395769ANot affectedReduce construction costsBridge structural detailsBridge erection/assemblyPre stressArchitectural engineering

The invention discloses an inverted anchor recess anchor sealing device based on a communicating vessel principle and a construction process. The inverted anchor recess anchor sealing device comprisesa bottom mold plate, a mold expansion preventing structure, a grout inlet pipe and an air outlet pipe, wherein the bottom mold plate is arranged at an anchor recess opening of an inverted anchor recess in the bottom of a prestressed concrete structure in a supported mode; the mold expansion preventing structure is installed on the outward surface of the bottom mold plate, and the bottom mold plate is fixed to the anchor recess opening through the mold expansion preventing structure, so that a closed space is formed in the anchor recess while the anchor recess opening is sealed by the bottom mold plate; the grout inlet pipe penetrates through the bottom mold plate from the outside of the anchor recess and extends into the anchor recess; and the air outlet pipe penetrates through the bottommold plate from the outside of the anchor recess and extends to the top in the anchor recess. According to the inverted anchor recess anchor sealing device based on the communicating vessel principleand the construction process, the problem that a traditional anchor sealing construction process cannot be well applied to the inverted anchor recess can be effectively solved.

Owner:CHINA RAILWAY CONSTR ENG GROUP

A shield machine construction risk prevention and control method and system

ActiveCN110359919BImprove construction risk prevention and control capabilitiesReduced construction risk prevention and control capabilitiesMining devicesResourcesInformatizationData acquisition

The invention discloses a construction risk prevention and control method and a construction risk prevention and control system for a shield tunneling machine. The method comprises data acquisition and transmission, big date storage, processing and analyzing, risk recognition and early warning. The data mainly comprises machine data, fault data, guide data, ground settling data, duct piece gesturedata and engineering data. The big data storage and analysis and processing comprise a server and big data technology related software. The risk recognition and early warning comprise steps of engineering construction risk prevention and control, machine fault risk early warning, heading parameter early warning, quality risk prevention and control, construction period risk prevention and controland the like. The construction risk prevention and control method and the construction risk prevention and control system for the shield tunneling machine based on big data analysis can establish an informationized risk prevention and control system and avoid or reduce loss to a project due to risks such as equipment faults, staff operation errors and the like effectively, so that safe and efficient construction of the shield tunneling machine is guaranteed.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +2

A construction method for unloading U-shaped trough of high-rise buildings

ActiveCN102777038BAvoid the problem of not being able to transport to the construction floorLabor savingBuilding material handlingFalseworkEconomic benefits

The invention discloses a U-shaped slot unloading construction method for high buildings. The method comprises the following steps that: a platform is installed on a cantilever of the outer edge of a building matched with the floor height, and a sliding unloading plate which inclines towards the platform is installed on the platform of an operation level without contacting an outer scaffold; after the installing is finished, a constructor stands on the outer scaffold, operates a cableway bucket of a tower crane to unload on the sliding unloading plate, in this way, the material can slide downwards in the building so as to finish the unloading; lifting floor by floor is carried out after the construction of the operation level is finished, the sliding unloading plate is installed, and the unloading construction is performed till the unloading construction of all floors of the whole building are finished. Practices prove that, with the adoption of the U-shaped slot, a large amount of manpower and a large amount of trolley cost are saved; the construction method has the following characteristics of convenience, high speed, good economic benefit, reduced manpower, and ensured safe and civilized construction; and the construction is especially suitable for high buildings, ultra-high buildings, and multi-floor buildings with complex decoration engineering.

Owner:THE THIRD CONSTR & ENG OF CCFED

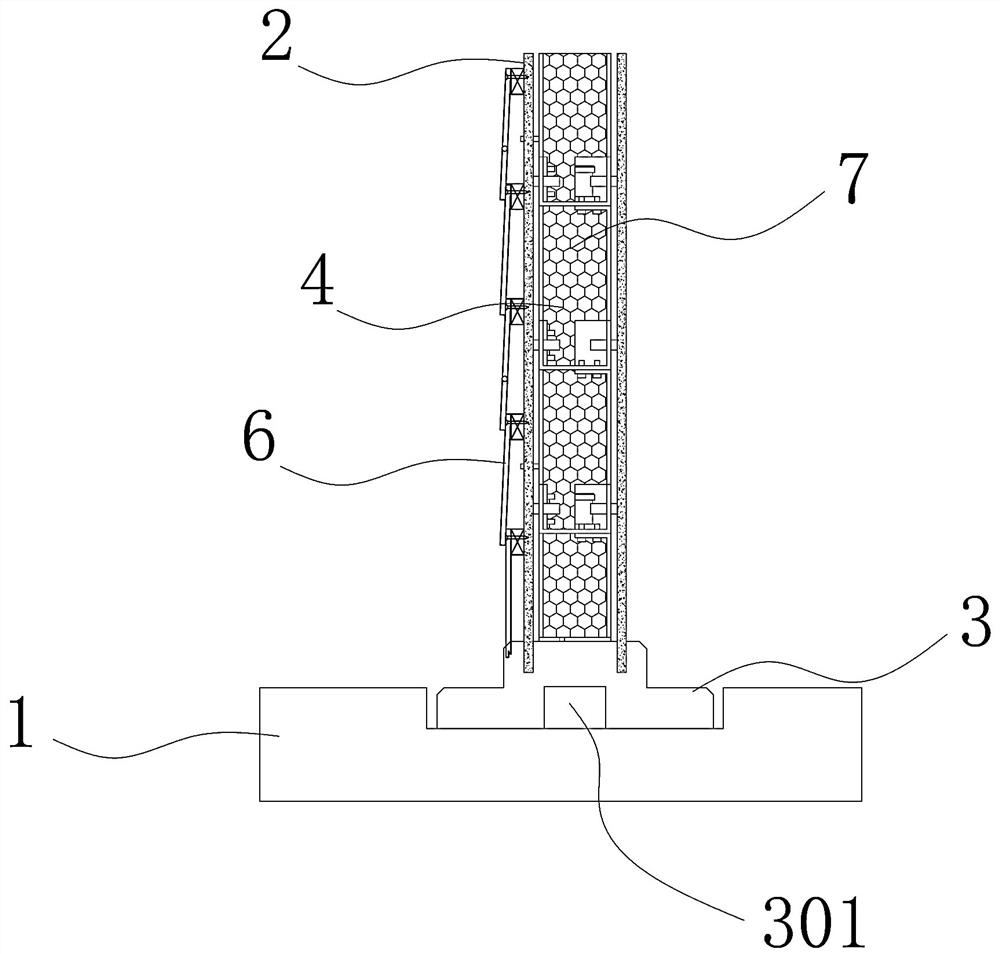

modular house system

ActiveCN105926981BConvenient sourceEasy to install on siteRoof improvementWallsFloor slabClassical mechanics

The invention discloses a modular assembly house system, which is characterized in that it includes one or more modular houses (1), and the houses (1) within two floors extend infinitely in the horizontal direction, Each house (1) is composed of a steel structure frame (2), a cold-formed thin-walled steel system wall panel (3), a cold-formed thin-walled steel system floor plate (4) and a cold-formed thin-walled steel system roof (5) Composition; described steel structure frame (2) comprises crossbeam (2.1) and vertically connected column (2.2) that are parallel to each other up and down, and the eight corners that described beam (2.1) and column (2.2) surround are all used The connecting piece (7) is connected; it overcomes the disadvantages of inconvenient folding and assembly in the prior art, poor combination, and unsuitability for complicated environments, and has the advantages of detachable, interchangeable, and increase-reducible.

Owner:武汉麦特建筑科技有限公司

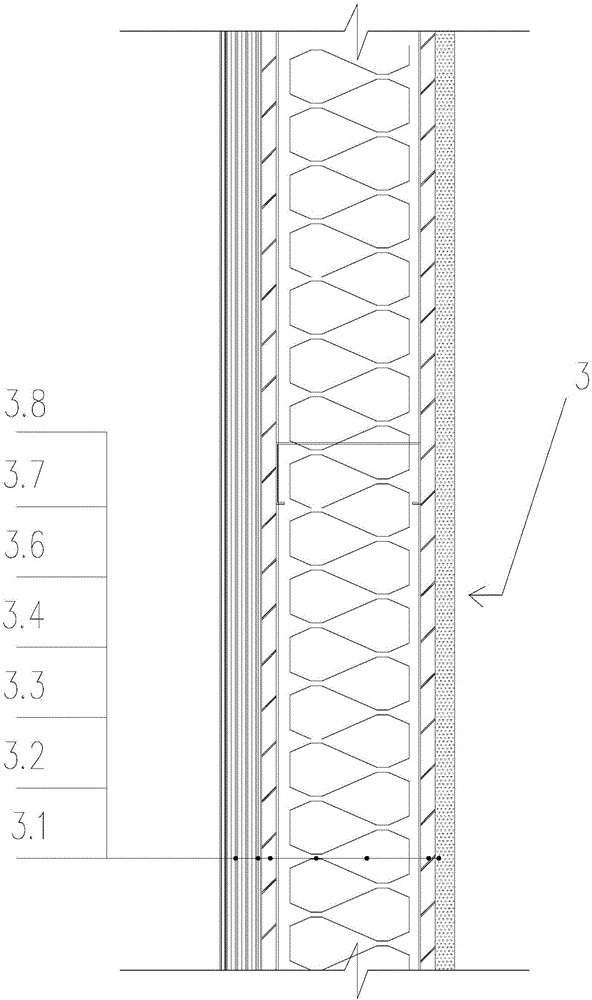

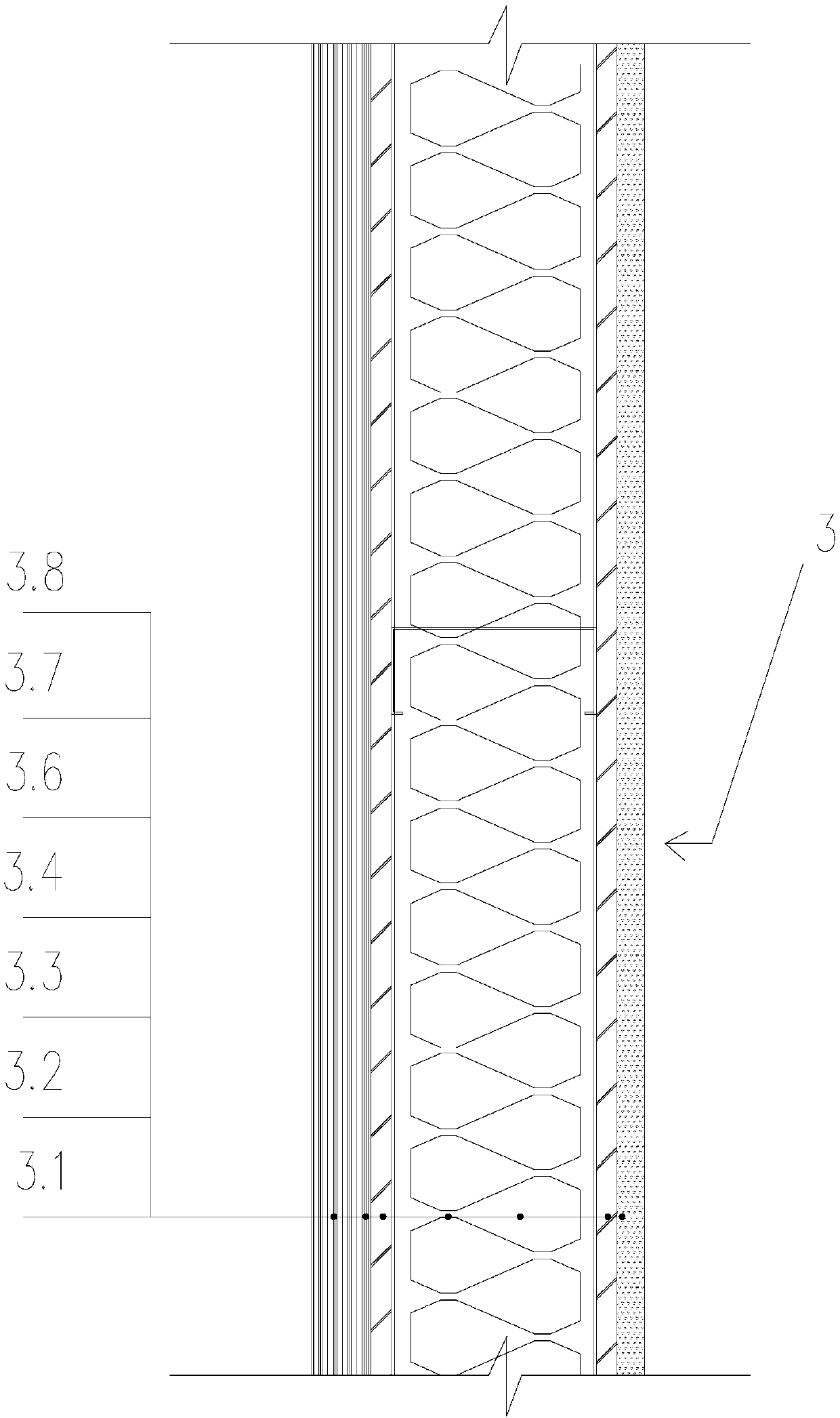

Prefabricated composite wall panel

ActiveCN110512769BTo achieve the goal of green environmental protection and energy savingImprove fire resistanceWallsFiberglass meshGlass fiber

Owner:武汉迈特绿色建筑科技股份有限公司

Movable belt adjusting device

PendingCN110510367AAvoid uneven forceUniform wearConveyorsCleaningFront and back endsAcceleration Unit

The invention discloses a movable belt adjusting device. A stress rod piece is fixed on a belt frame; a balance rod piece is rotationally mounted on the stress rod piece; two balance auxiliary piecesare mounted at the front and back ends of the balance rod piece; a belt penetrates through the balance auxiliary pieces at the front and back ends in sequence in a bonding mode, so that the balance auxiliary pieces at the front and back ends are staggered corresponding to the upper and lower positions of the belt; one side of a first adjusting pull rood is connected with the balance rod piece; oneside of a second adjusting pull rod is connected with a scraper; the other sides of the two adjusting pull rods penetrate through a belt frame, and adjusting limiting pieces are arranged on the sides; two adjusting springs sleeve the two adjusting pull rods; and the two ends of the adjusting springs are ejected against the belt frame and the adjusting limiting pieces. The device can inhibit flexible deformation and operation vibration of the belt in the operation process, prevents the wear acceleration caused by nonuniform stress of the scraper, and guarantees the scraping effect.

Owner:YSD RAIL TRANSIT CONSTR CO LTD +1

A kind of slag discharging channel which is easy to disassemble and its installation method

ActiveCN110593526BEasy to install and disassembleEasy to get materialsVertical ductsFloor slabArchitectural engineering

The invention discloses a deslagging channel convenient to dismount. The channel comprises deslagging holes formed in an upper layer floor and a lower layer floor, sleeves are evenly arranged on the periphery of the deslagging holes, a deslagging channel combination part is arranged between the sleeves of the upper layer floor and the lower layer floor, the deslagging channel combination part is formed by connecting multiple sections of deslagging channel group units, each deslagging channel group unit comprises a right prism frame and a panel laid on the side face of the right prism frame, each right prism frame is composed of a steel pipe stand column, a batten cross beam and the panel, and the steel pipe stand columns on the lower end of the deslagging channel combination part and the sleeve of the lower layer floor are subjected to height adjusting through connecting of adjusting screws. The transport cost of building waste in the reinforcing or modification engineering can be reduced, and safety of building waste transport can be improved. The mounting method comprises the steps of fixing the sleeves, erecting the steel column stand columns, mounting the batten cross beams andthe panels, splicing the deslagging channel group units, mounting the deslagging channel combination part on the adjusting screws, performing jacking and finally sealing and mounting door leaves.

Owner:WUHAN CONSTR ENG

Prefabricated assembly method of long-span cover beam and its large-span cover beam

ActiveCN105780663BNo impact on congestionImprove construction efficiencyBridge structural detailsBridge erection/assemblyShaped beamPre stress

The invention discloses a large-span capping beam prefabrication and assembly method and a large-span capping beam; according to the large-span capping beam prefabrication and assembly method, overall no-bracket construction of the large-span capping beam is carried out by adopting staged prefabricated casting on the whole and gradually tensioning steel beams in all stages; the method comprises the stages of S1, prefabricating a U-shaped beam component as a bottom die; forming a U-shaped rabbet in the U-shaped beam component, and tensioning at least four prestressed steel beams on the U-shaped beam component for reserving porous channels for subsequent prestressed tensioning; S2, after the U-shaped beam component is hoisted in place, casting a hollow part of the U-shaped rabbet in a way of cast-in-situ, and correspondingly tensioning at least six prestressed steel beams for reserving porous channels for subsequent prestressed tensioning; S3, casting the rest part of a cross section of the lower half part of the beam component in a way of cast-in-situ, and correspondingly tensioning at least ten prestressed steel beams; S4, completing the construction. After the large-span capping beam prefabrication and assembly method is adopted, not only is the construction efficiency high, but the traffic pressure is also greatly reduced. Furthermore, compared with the existing construction method, the large-span capping beam prefabrication and assembly method is also very environment-friendly.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

Prefabricated household wall compound wall

ActiveCN110512768BEasy to transportSolve the problem of damp and rotten wallsWallsEngineeringMechanical engineering

A prefabricated household wall composite wall, including a heat-insulating wall, the heat-insulating wall includes a first wall panel and a second wall panel, a keel frame is arranged between the first wall panel and the second wall panel, and the The keel frame includes a plurality of horizontal frames and vertical frames, the horizontal frames are clamped with the vertical frames, a base is provided under the heat insulation wall, and a mounting groove is provided on the base, and the first wallboard and the The second wallboard is arranged inside the installation groove. The first wall panel and the second wall panel are detachable structures, and the detachable dragon skeleton is used between the first wall panel and the second wall panel, which is convenient for transportation, transported to the construction site, and then spliced, which is more suitable for mountainous areas , transportation is also more convenient.

Owner:武汉迈特绿色建筑科技股份有限公司

Fabricated splitting wall composite wall

The invention discloses a fabricated splitting wall composite wall. The fabricated splitting wall composite wall comprises a heat-insulation wall body, the heat-insulation wall body comprises a firstwall plate and a second wall plate, a keel frame is arranged between the first wall plate and the second wall plate, the keel frame comprises a plurality of transverse skeletons and vertical skeletons, the transverse skeletons and the vertical skeletons are connected in a clamped mode, a base is arranged on the lower part of the heat-insulation wall body and provided with a mounting groove, and the first wall plate and the second wall plate are arranged inside the mounting groove. By adopting the first wall plate and the second wall plate which are each of a detachable structure, the detachable keel frame is adopted between the first wall plate and the second wall plate, transportation is convenient, the fabricated splitting wall composite wall is transported to a construction site and then spliced, and is suitable for mountain areas, and transportation is also convenient.

Owner:武汉迈特绿色建筑科技股份有限公司

A new formwork reinforcement system and its construction technology

ActiveCN106481077BReduce labor intensityReduce construction weightAuxillary members of forms/shuttering/falseworksKeelArchitectural engineering

The invention discloses a novel reinforcing system for a formwork and a construction process of the novel reinforcing system. The novel reinforcing system comprises main keels, auxiliary keels, an internal corner connecting piece and an external corner connecting piece. The construction process comprises the following steps of determining the size of a wall body, designing a scheme, and calculating the lengths of the keels; splicing a plurality of auxiliary keels together, and using steel nails to connect seams between the forwork edge and the auxiliary keels; horizontally mounting the main keels in sequence; connecting the main keels on the two sides of an internal corner through the internal corner connecting piece; connecting the ends of the main keels on the two sides of an external corner through an external corner inclined pulling piece; conducting connection and fastening on a plug wall connecting external member and the main keels; and adjusting an external corner inclined pulling angle seat, the perpendicularity and the physical dimension of the formwork. According to the construction process of novel reinforcing system for the formwork, the accessories of a vertical steel and wood compounded keel, the horizontal main keels, the external corner connecting piece, an external corner inclined pulling connecting piece, a keel connecting piece, a plug plate reinforcing external member and the like are adopted, so that the construction weight is reduced, the labor intensity of a worker is reduced, the construction efficiency is improved, the cost is lowered, and the civilized construction is guaranteed.

Owner:河北易鼎行环保科技有限公司

house modular assembly wall

ActiveCN110512760BModular Building ImprovementsDoes not affect integrationWallsStructural engineeringElectric cables

A modular assembled wall of a house, the assembled wall structure is: the upper and lower sides of the assembled wall are provided with connecting grooves, the two sides of the connecting groove are provided with a plurality of through holes, and the inside of the connecting groove is provided with at least one reinforcing hole. One end of the assembly wall is provided with a fixed groove, and the other end is provided with a fixed projection. There are multiple installation grooves on the wall surface of the assembly wall. Water pipes and cables are arranged inside the assembly wall. Fixed groove splicing, for the integrated panels, the interior, exterior, waterways, and circuits are all integrated into a single panel unit, which is a great improvement on traditional modular buildings.

Owner:武汉迈特绿色建筑科技股份有限公司

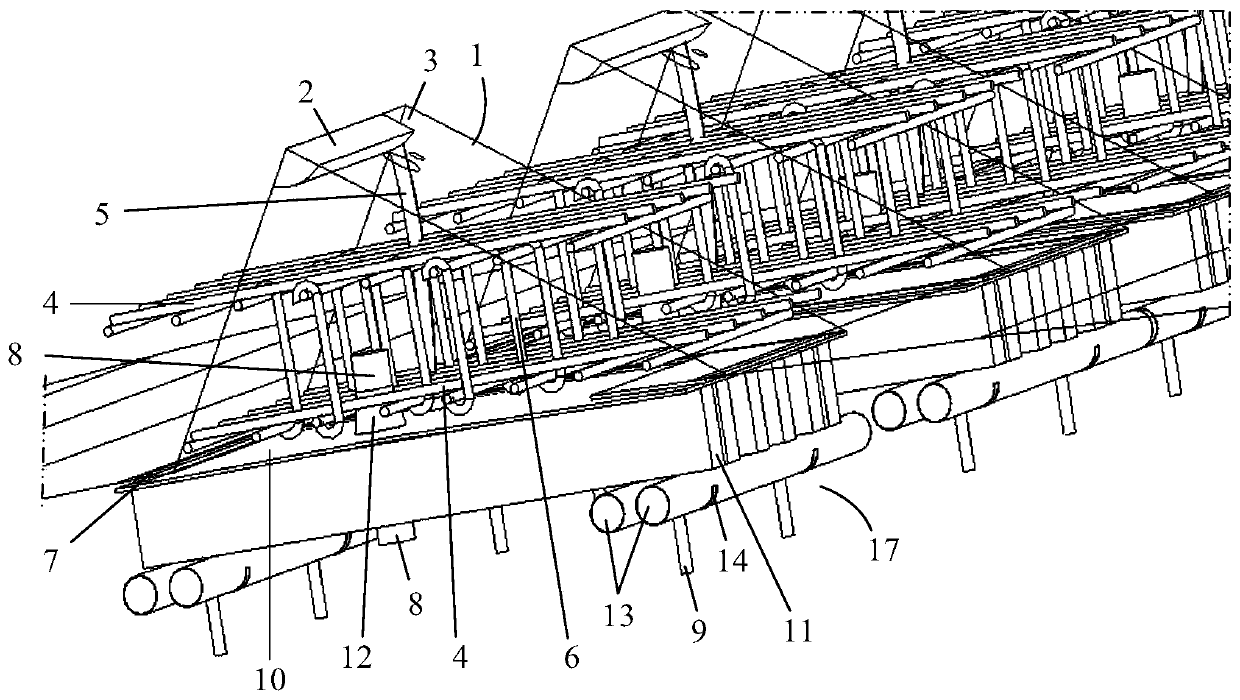

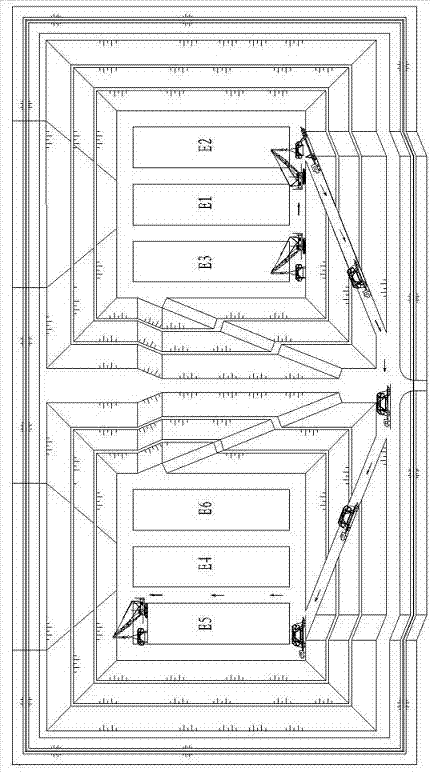

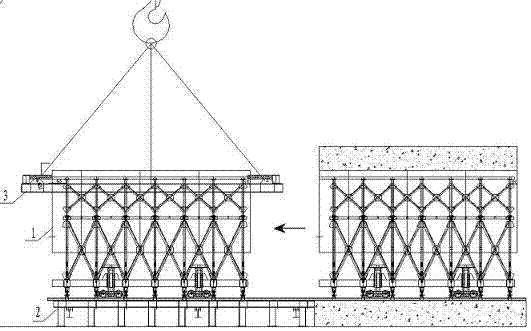

A construction method for the overall transfer of large steel formwork trolleys in the adjacent field

InactiveCN105781108BGuaranteed accuracyReduce the frequency of disassembly and assemblyArtificial islandsUnderwater structuresInterference factorEngineering

A construction method for the overall transfer of large-scale steel molds between adjacent sites. Through the analysis of the weight, size, and road conditions of the steel mold trolleys hoisted and transported, the walking track frame and lifting of the steel mold trolleys are reasonably designed. Spreaders, hauling and fixed frames, etc., are reasonably matched with mechanical equipment such as hoisting and transshipment, and adopt the method of "rail frame outlet pipe section cavity + large-tonnage crawler crane overall hoisting + heavy-duty low-bed semi-trailer trailer hauling", divided into sections Complete the overall transfer construction of the large steel formwork trolley. The design of the rail frame, hanger, and load-bearing beam bracket used in the present invention is reasonable, which is convenient for installation and removal on the construction site, reasonable allocation of lifting and transportation equipment, planning of hoisting and transportation routes in advance, ensuring the integrity of the steel mold trolley, and effectively connecting the processes to form Assembly line operation greatly reduces worker load, less interference factors, fast transition speed, meets construction schedule requirements, guarantees safe and civilized construction, and is suitable for large-scale promotion and application.

Owner:ERCHU CO LTD OF CHINA RAILWAY TUNNEL GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com