A construction method for unloading U-shaped trough of high-rise buildings

A high-rise building and construction method technology, applied in the processing of building materials, construction, building construction, etc., can solve the problems that construction elevators are difficult to meet the material transportation requirements, the loading capacity of bucket trucks is limited, and affect the civilized construction of projects, etc., to ensure that The effects of safe and civilized construction, saving purchase costs, and convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

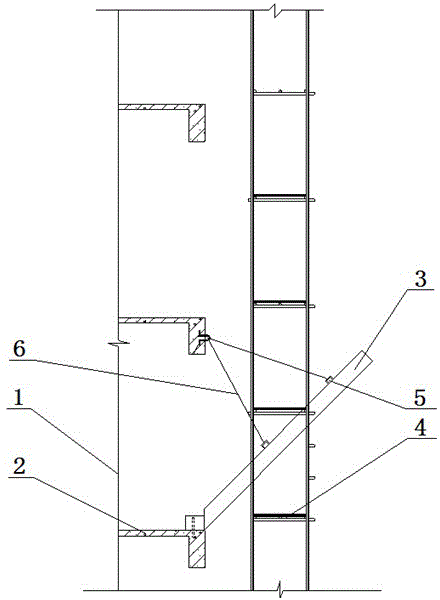

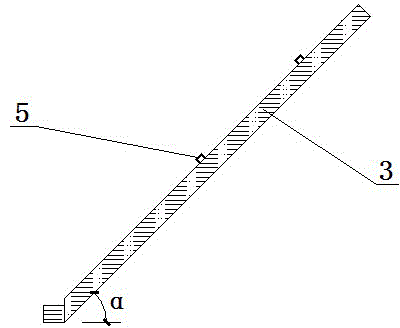

[0015] Embodiments of the present invention: as figure 1 As shown, first install the platform cantilevered on the outer edge of the building that matches the height of the floor, and install a sliding unloading plate inclined to it on the platform of the working layer (the working layer is the first floor of unloading construction), and slide unloading The boards are not in contact with the outer scaffolding. After the installation is completed, the construction personnel stand on the external scaffolding and operate the tower crane to unload the material onto the sliding unloading plate, and the material can slide into the building under the action of gravity to complete the unloading. After the construction of the working layer is completed, it will be lifted layer by layer, and the sliding unloading plate will be installed to carry out the unloading construction until the unloading construction of all floors of the entire building is completed. In order to save constructio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com