A construction method for the overall transfer of large steel formwork trolleys in the adjacent field

A technology for a steel form trolley and a construction method, which is applied to artificial islands, water conservancy projects, infrastructure projects, etc. The effect of reducing construction period requirements and reducing the frequency of disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

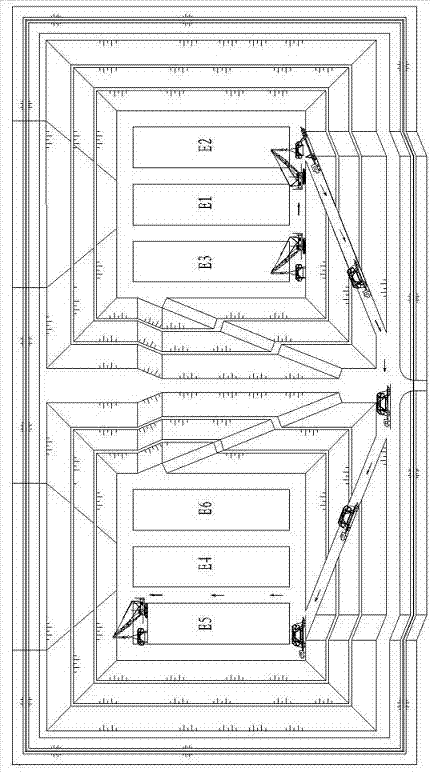

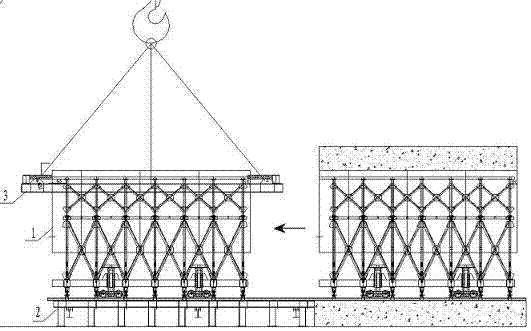

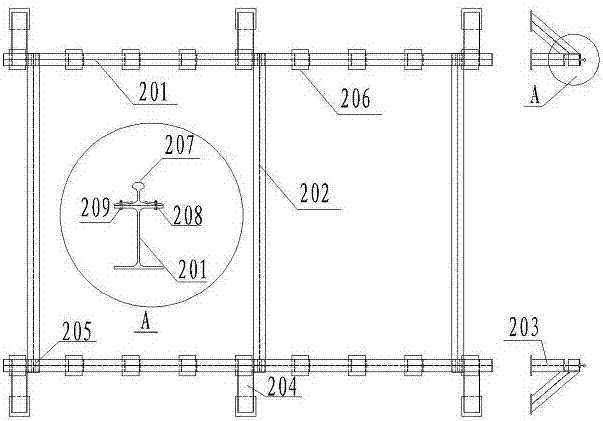

[0047] like Figures 1 to 10 As shown, a construction method of the present invention for the overall transfer of large-scale steel formwork trolleys between adjacent sites, the large-scale steel formwork trolleys do not need to be disassembled, reversed, and assembled one by one to be able to carry the rail frame 2 of the large-scale steel formwork trolley 1 In order to enter and exit the cavity platform of the pipe section, the hanger 3 whose maximum deformation meets the accuracy requirements when hoisting the large steel formwork trolley 1 is used as the hanger skeleton to meet the requirements of the overall size, weight and on-site construction conditions of the large steel formwork trolley 1 for lifting The crawler crane 4 is a hoisting device to meet the stability of the hauling flatbed truck 5 and the load-bearing beam support 6 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com