Molten tin bath manufacturing and installing process

An installation process and tin bath technology, applied in the field of tin bath production and installation technology, can solve the problems of danger, difficult welding, long construction period, etc., and achieve the effects of easy deformation, ensuring installation quality, and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

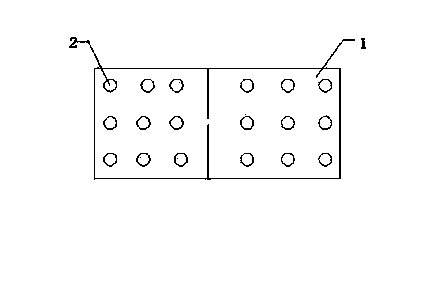

Image

Examples

Embodiment Construction

[0018] 1. Foundation acceptance before construction

[0019] According to the civil construction delivery data provided by the construction unit, the re-examination and acceptance will be carried out. If any problems are found, they will be raised immediately.

[0020] The longitudinal center line of the tin bath and the center mark of the center line of the 1# column (62200mm from the center line of the 1# small furnace of the kiln) are checked and accepted according to the standard embedded parts, and the paint triangle mark on the concrete foundation is not allowed.

[0021] The measurement reference point shall be buried on the column of the factory building with rivets or round head bolts, and it is not allowed to be buried on the floor slab, and it is not allowed to use expansion bolts instead.

[0022] The key points of the acceptance of the tin bath foundation are the positioning reference point, the elevation of the embedded parts, the relative size of the reserve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com