A new formwork reinforcement system and its construction technology

A construction technology and formwork technology, which is applied to the joints of formwork/formwork/work frame, the preparation of building components on site, construction, etc., and can solve the problem of secondary handling, increased number of wall-through wires, and irregular truncation of steel pipes, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

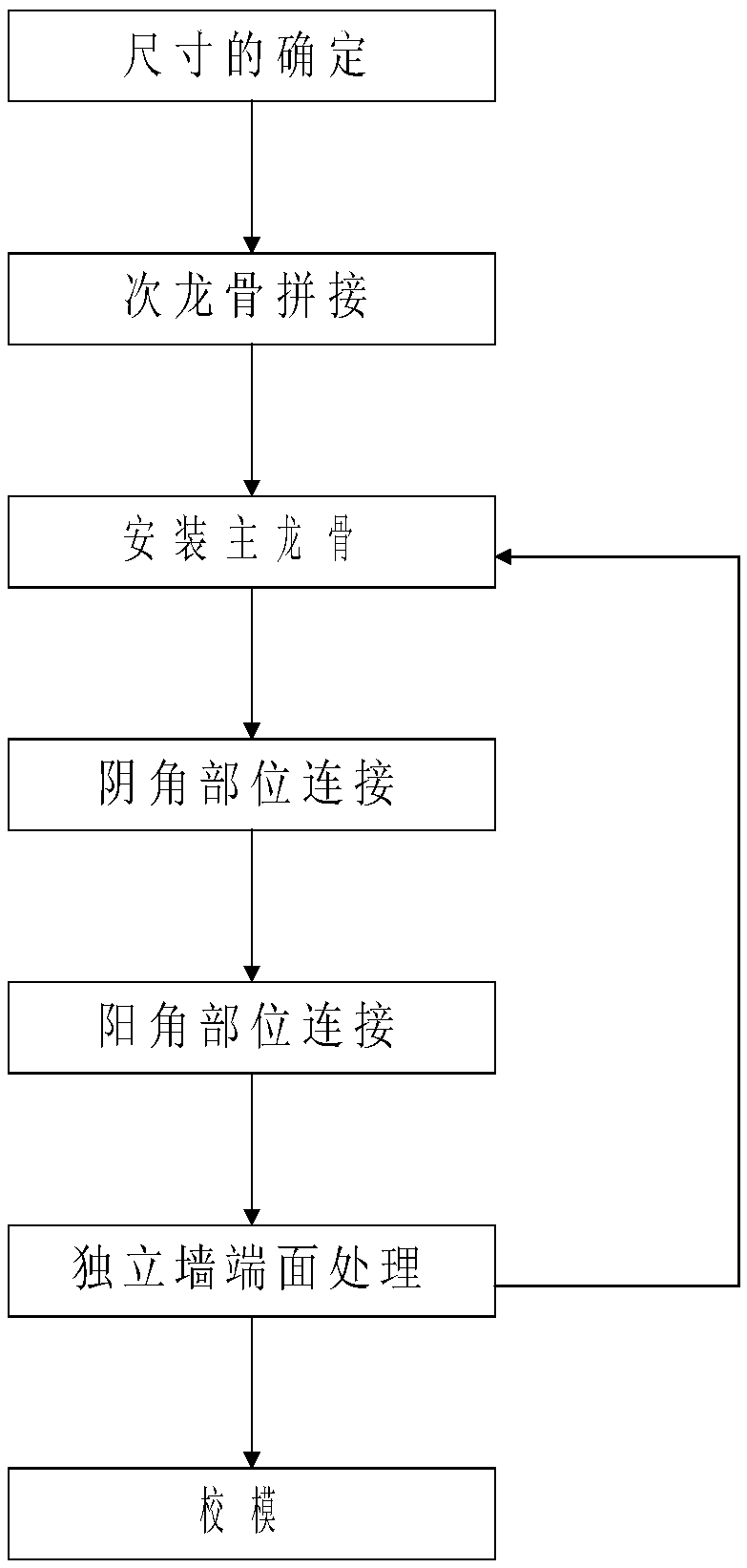

[0024] figure 1 It is a flow chart of a new type of formwork reinforcement system and its construction process embodiment of the present invention. As shown in the figure, the present invention provides a construction process of a new type of formwork reinforcement system. The construction process steps are as follows:

[0025] A. Determination of size: Determine the wall size and design plan according to the construction drawing, and calculate the length of the keel, the number of accessories and the position of the bolt holes through the wall;

[0026] B. Sub-keel assembly: Place several sub-keels in sequence at fixed intervals, use iron nails to connect the formwork and the joints of the sub-keels to obtain a spliced formwork, erect the formwork and fix it on the wall, according to the design Drill holes on the formwork with good spacing, and insert through-wall bolts;

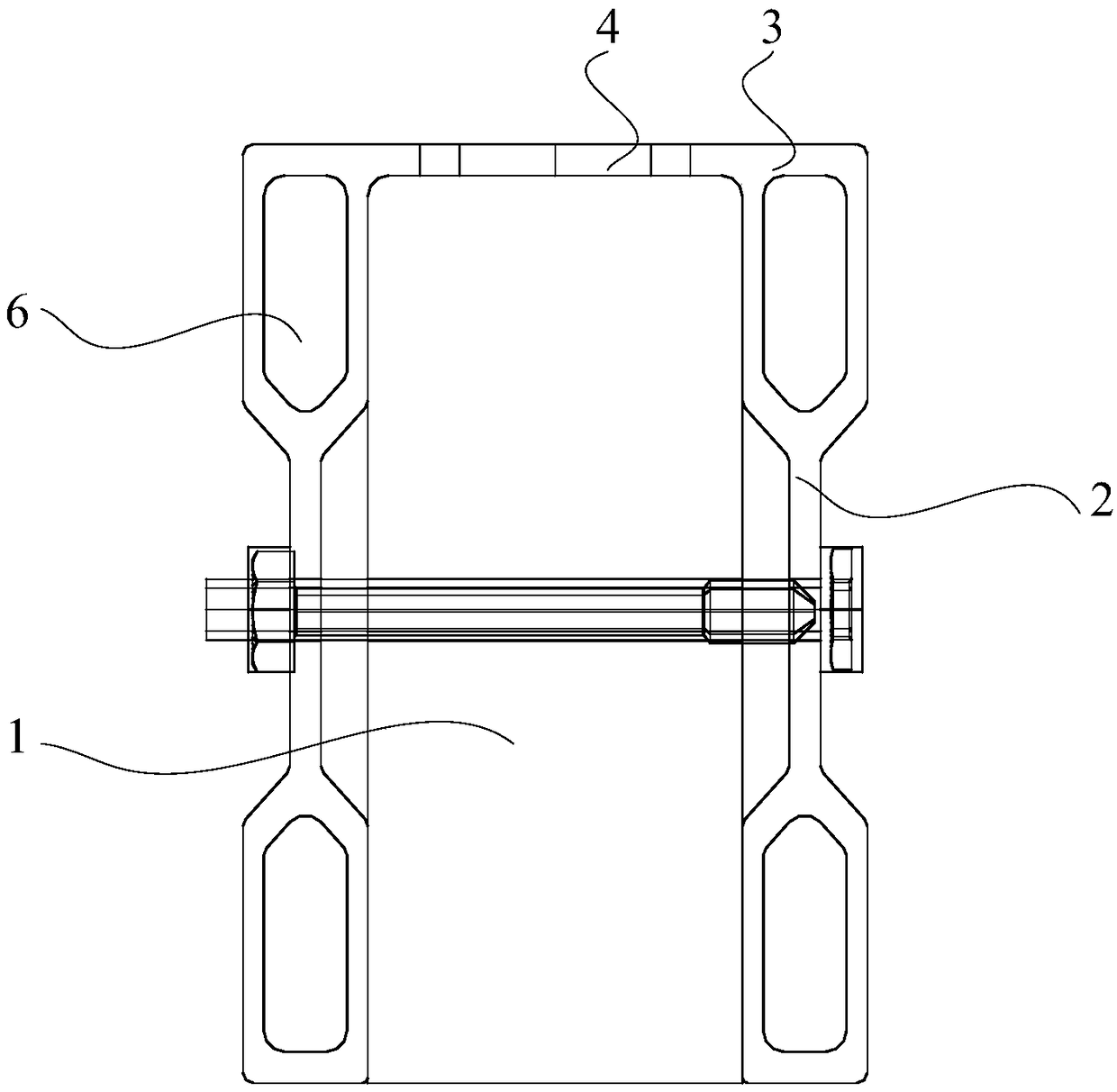

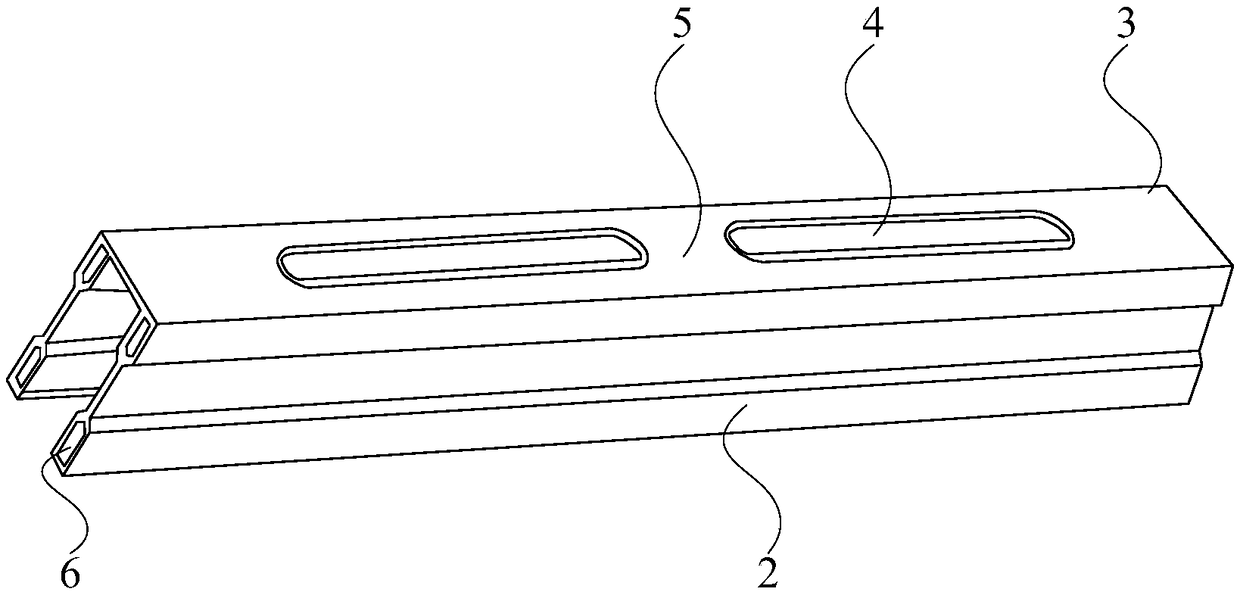

[0027] C. Install the main keel: Install the main keel horizontally on the wall-through bolt, the wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com