Large-span capping beam prefabrication and assembly method and large-span capping beam

A prefabricated assembly and large-span technology, applied to bridges, bridge parts, bridge construction, etc., can solve the problems of slow construction speed, long construction period, low construction efficiency, etc., to reduce the amount of concrete, ensure civilized construction, and reduce traffic The effect of pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

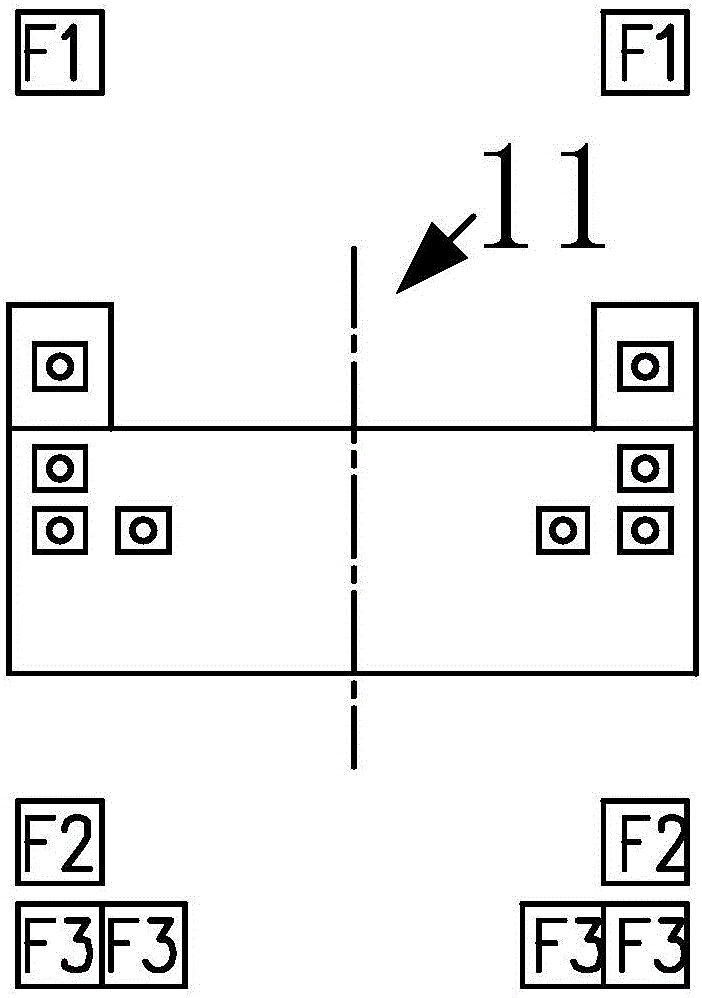

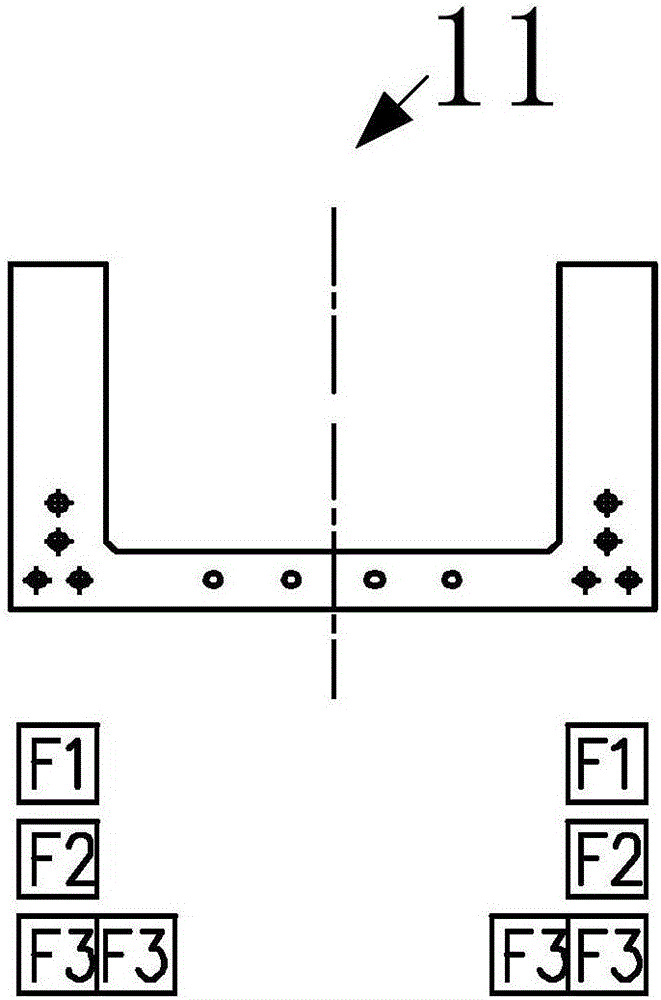

[0033] The purpose of the present invention is achieved through the following technical solutions: as Figure 1 to Figure 9 As shown, the prefabricated assembly method of the large-span cover beam provided in this embodiment generally adopts the method of batch precast pouring to achieve the construction without support, and the entire construction process of the large-span cover beam without support is gradually carried out in the following three stages :

[0034] The first stage:

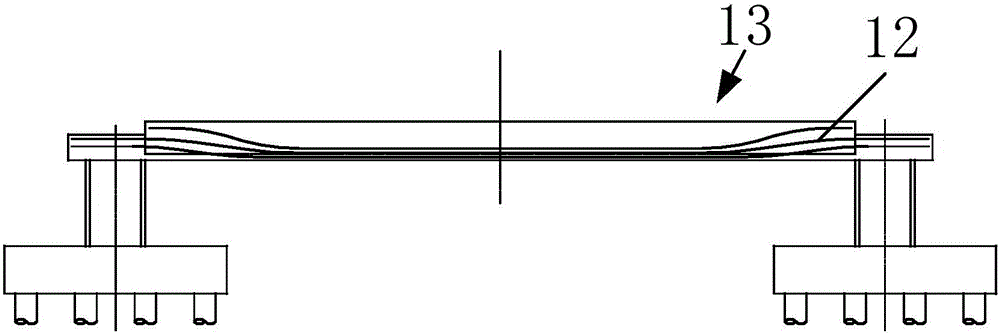

[0035] like Figure 1 ~ Figure 3 As shown, a U-shaped beam member 12 is prefabricated, the lower half of the prefabricated U-shaped beam member has a rectangular cross-section, and a U-shaped notch 13 is formed on the U-shaped beam member 12 . Furthermore, the support of the large-span cover beam 1 is pre-embedded with a solid cross-section column casing to enhance the load-bearing strength of the beam.

[0036] The total weight of the prefabricated components at this stage is about 210t. After...

Embodiment 2

[0050] Based on the large-span cap beam prefabricated assembly method of above-mentioned embodiment 1, as figure 1 As shown, the present embodiment also provides a large-span cover beam 1, at the bottom of the large-span cover beam 1 is formed a prefabricated component (i.e. the aforementioned prefabricated U beam member 12), and the prefabricated member is formed with a U-shaped notch 13 for subsequent in-situ pouring of concrete in the hollow part (see figure 1 shown).

[0051] like Figure 7 As shown, the large-span cover beam 1 erected by the prefabricated assembly method of the large-span cover beam of the above-mentioned embodiment 1 has a total length of 31.9m, a rectangular cross section, and the height and width of the large-span cover beam are respectively 3.0 m and 3.0m. Moreover, the total volume of the large-span cap beam 1 of the present invention is about 300m 3, with a total weight of 780t.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com