Postpositioned pre-buried wall-linking device and erecting construction method thereof

A wall-connecting and pre-embedded technology, which is applied in the direction of building structure support, building structure support, scaffolding accessories, etc., can solve the problems of inconvenient use of wall-connecting parts, labor-intensive wall fasteners, and low construction efficiency, etc., to achieve Easy to assemble and disassemble and use repeatedly, saving cost and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

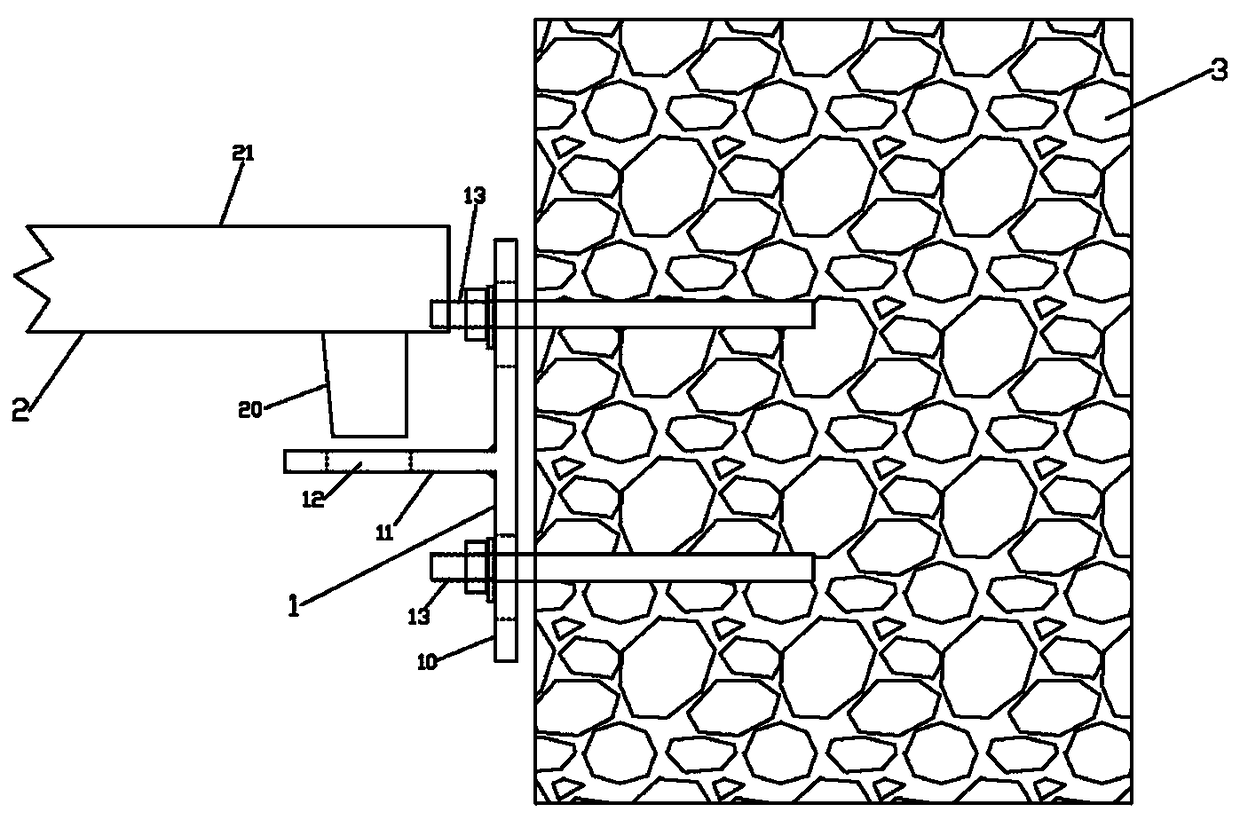

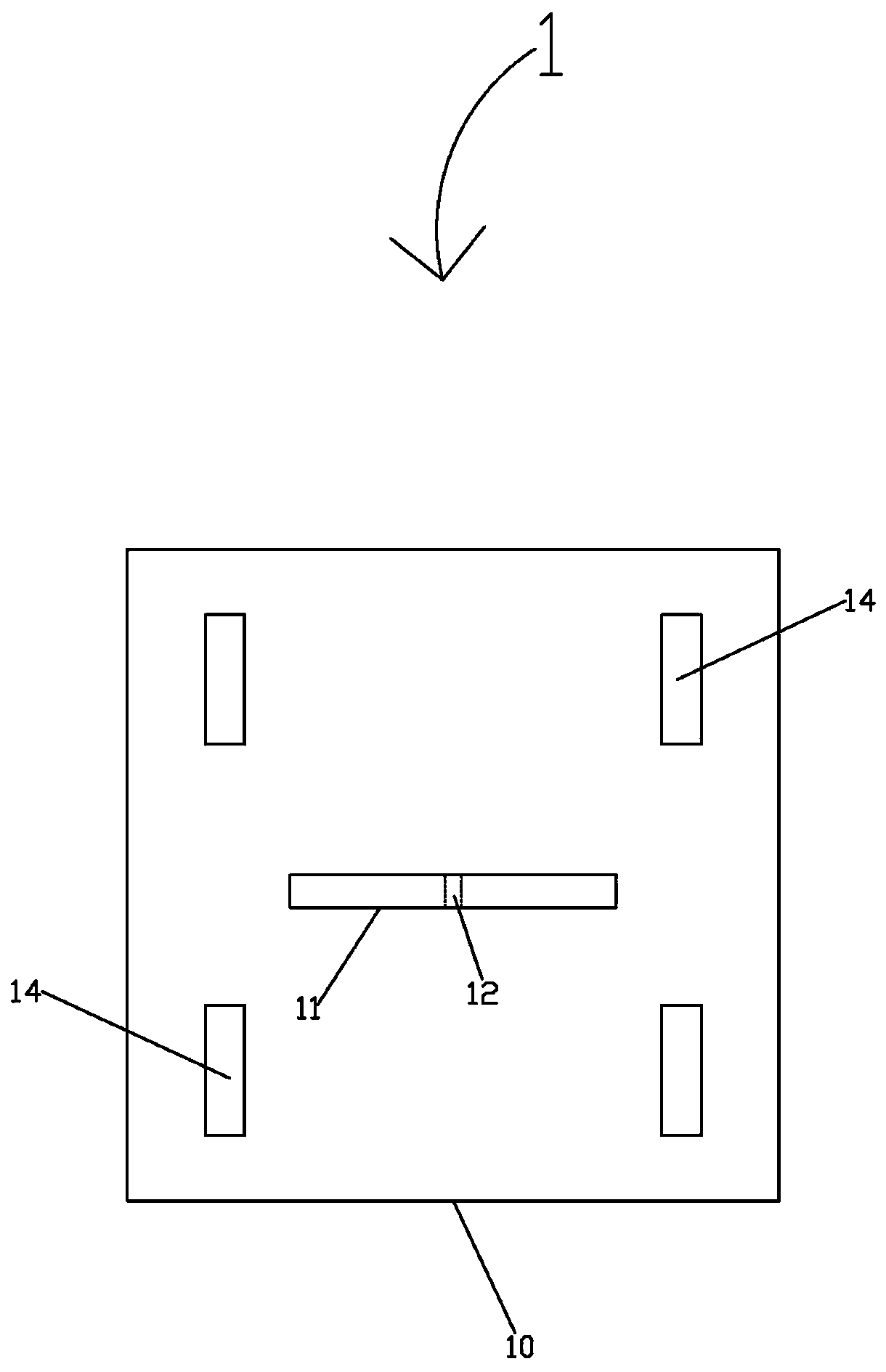

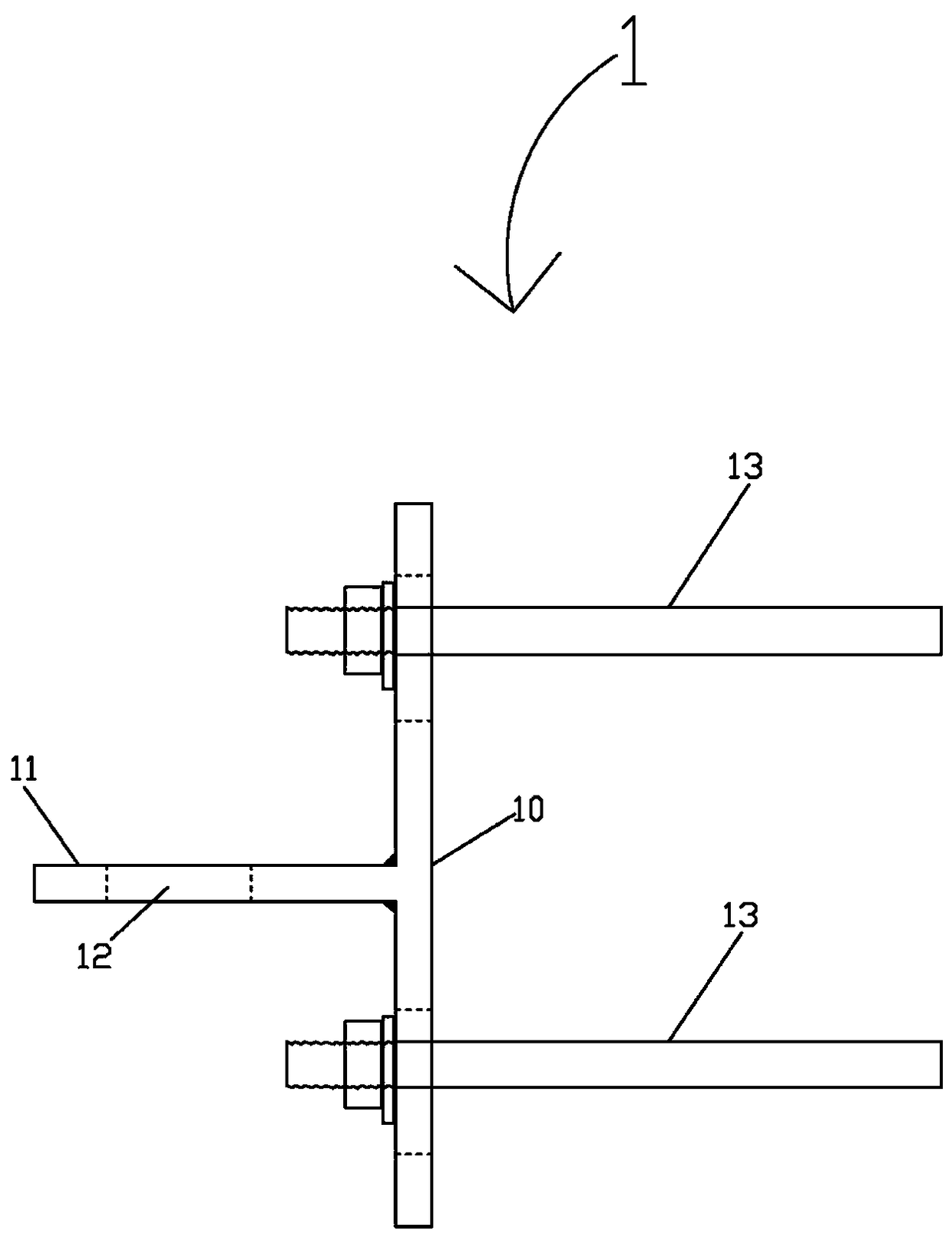

[0015] Embodiment 1. A rear pre-embedded wall connection device, such as Figure 1 to Figure 5 As shown, it includes a main body 1 and an accessory 2. The main body 1 is provided with a back plate 10, and several pin holes 14 for connecting expansion bolts 13 are arranged on the back plate 10. The connecting plate 11 of the plate 10 is provided with a through socket 12 on the connecting plate 11; the accessory 2 is composed of a supporting rod 21 and a receiving plate 20 arranged on the supporting rod 21, and the connecting plate 20 and the socket 12 fit.

[0016] According to actual conditions, the backboard 10 is rectangular or circular.

[0017] According to the actual situation, the backboard 10 is square.

[0018] According to actual conditions, the connection board 11 is vertically arranged at the center of the backplane 10 .

[0019] According to actual conditions, the socket 12 is arranged at the center of the connecting plate.

[0020] According to actual conditio...

Embodiment 2

[0022] Embodiment 2, a method for using the above-mentioned rear pre-buried connecting wall device for construction, as attached Figure 6 Said, the construction method steps are as follows:

[0023] (1) Determine the structure of the rear-mounted connecting wall device; (2) Check and calculate the step distance of the construction scaffold; (3) Determine the setting method of the connecting wall device and make the connecting wall device; (4) Set up floor-mounted scaffolding; (5) Determine the connecting wall (6) Percussion drill positioning and punching; (7) Installing expansion bolts 13; (8) Fixing the wall connection device; (9) Installing the wall connection horizontal support rod 21; (10) If the connection wall device position is not If it is suitable, adjust the position of the wall-connecting device; (11) Finally tighten the expansion bolt 13 nut; (12) Check the installation status of the wall-connecting device; (13) Accept the frame body, and construction is allowed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com