Deslagging channel convenient to dismount and mounting method

An installation method and channel technology, applied in vertical pipelines, building components, buildings, etc., can solve problems such as efficiency constraints, large safety hazards of dust, and multiple construction wastes, so as to avoid safety hazards, improve slag discharge efficiency, and reduce dust Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

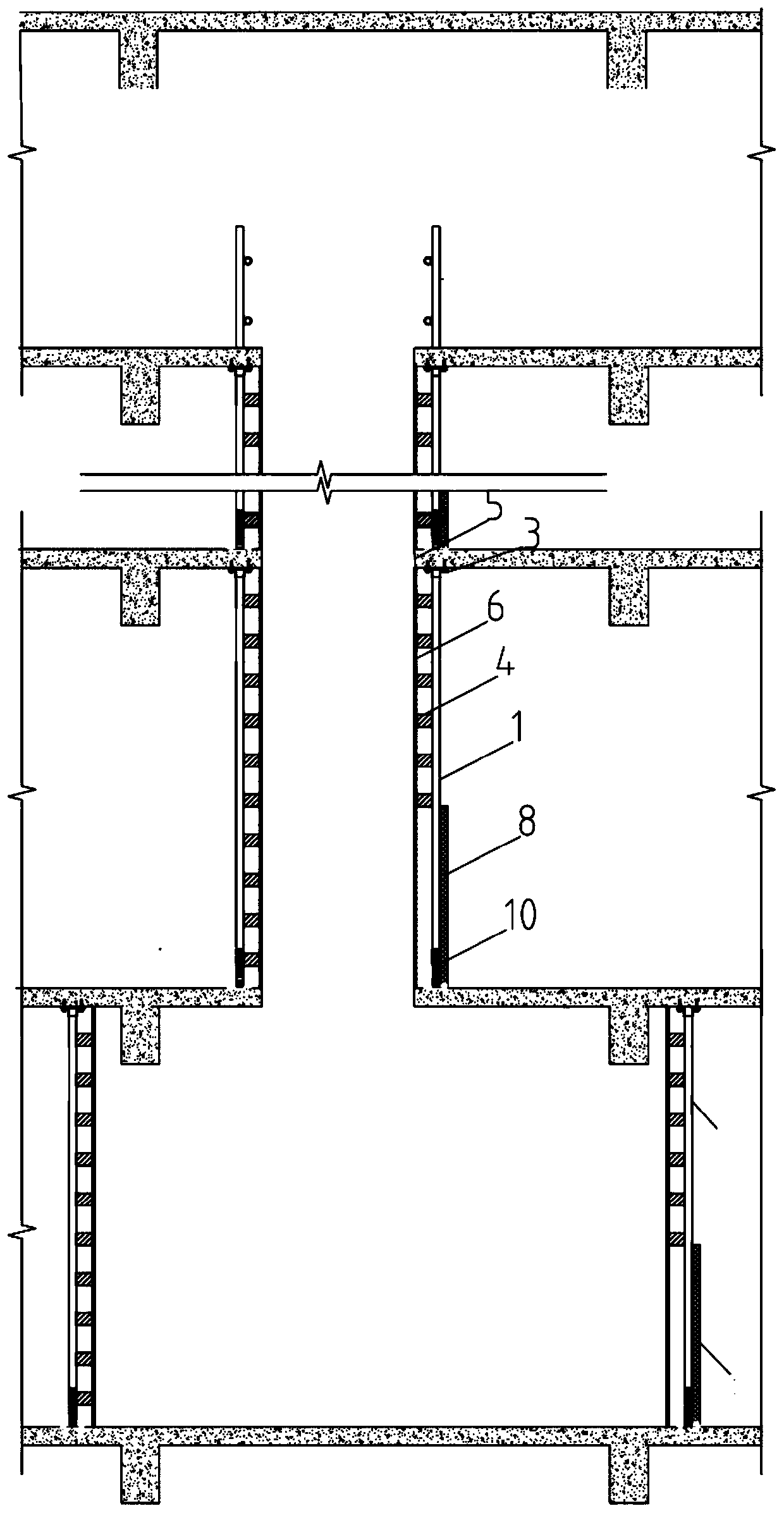

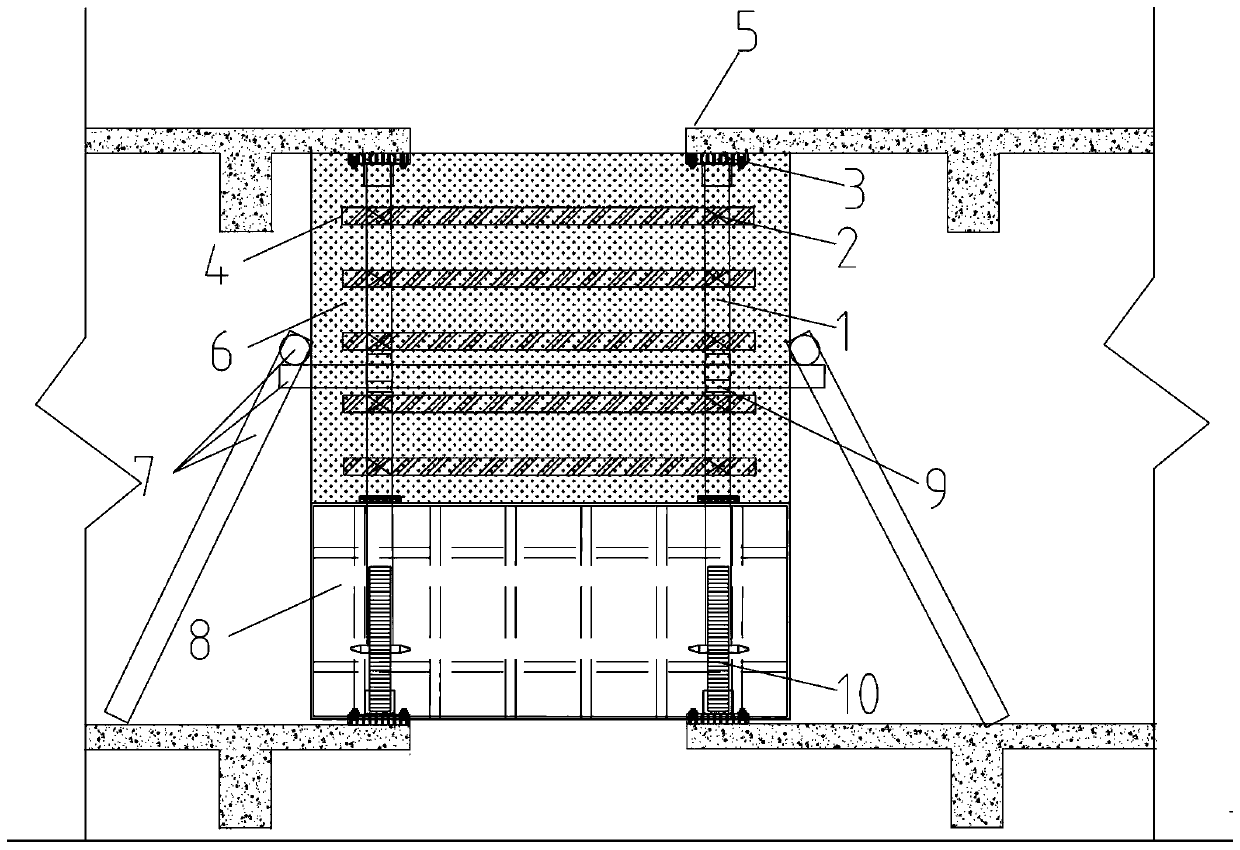

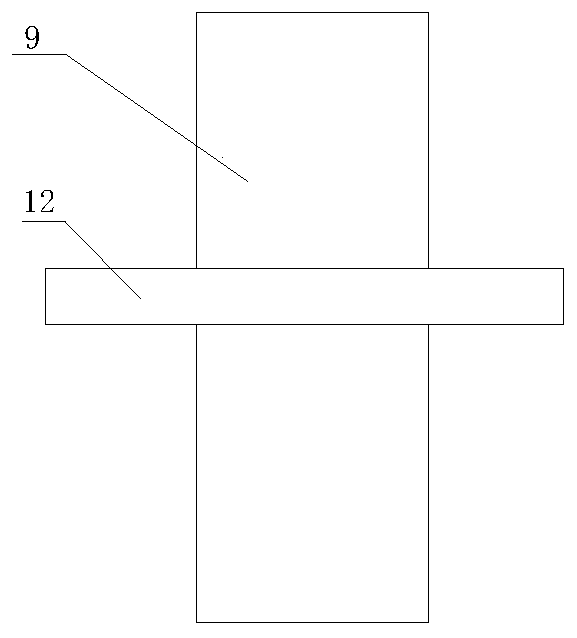

[0038] Such as figure 2 A slag discharge channel that is easy to disassemble. The width and shape of the slag discharge hole 5 are designed according to the amount of slag discharge. The slag discharge holes 5 of the upper and lower floors are coaxial. The sleeves 3 are evenly arranged around the slag discharge hole 5 as a fixed steel pipe column 1, the sleeve 3 of the lower floor is installed at the projection position of the sleeve 3 of the upper floor on the lower floor;

[0039] The main keel with the steel pipe column 1 as the side edge of the slag discharge channel stands in the sleeve 3; in the transverse direction of the steel pipe column 1, 2 steel wires are used to bind the wooden beam 4 for connection and fixation to form a straight prism frame, and then the wooden beam 4 As the pavement beam of the panel 6, the panel 6 is fixed by steel nail binding to form a slag discharge channel unit. The panel 6 can effectively control the dust and slag floating; the steel pip...

Embodiment 2

[0053] Such as figure 2 A slag discharge channel that is easy to disassemble. The width and shape of the slag discharge hole 5 are designed according to the amount of slag discharge. The slag discharge holes 5 of the upper and lower floors are coaxial. The sleeves 3 are evenly arranged around the slag discharge hole 5 as a fixed steel pipe column 1, the sleeve 3 of the lower floor is installed at the projection position of the sleeve 3 of the upper floor on the lower floor;

[0054] The main keel with the steel pipe column 1 as the side edge of the slag discharge channel stands in the sleeve 3; in the transverse direction of the steel pipe column 1, 2 steel wires are used to bind the wooden beam 4 for connection and fixation to form a straight prism frame, and then the wooden beam 4 As the pavement beam of the panel 6, the panel 6 is fixed by steel nail binding to form a slag discharge channel unit. The panel 6 can effectively control the dust and slag floating; the steel pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com