Modular assembled light steel house connecting frame

A connecting frame and prefabricated technology, applied in the direction of walls, buildings, building components, etc., can solve the problems of low prefabrication and low automation production, and achieve the effects of low cost, labor saving and ingenious design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

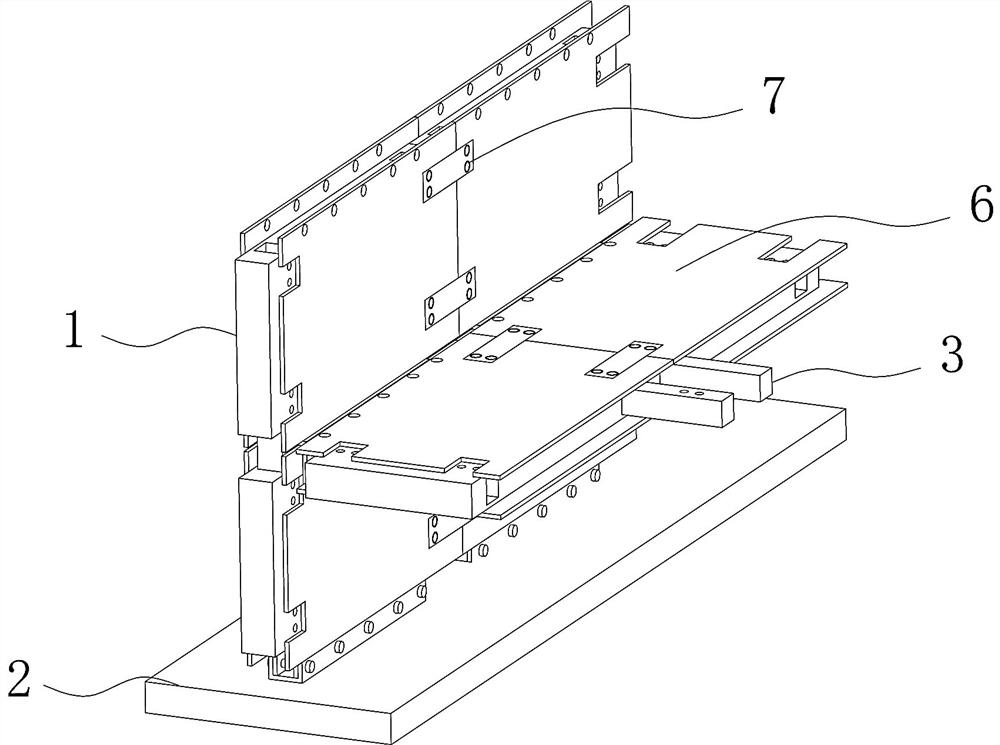

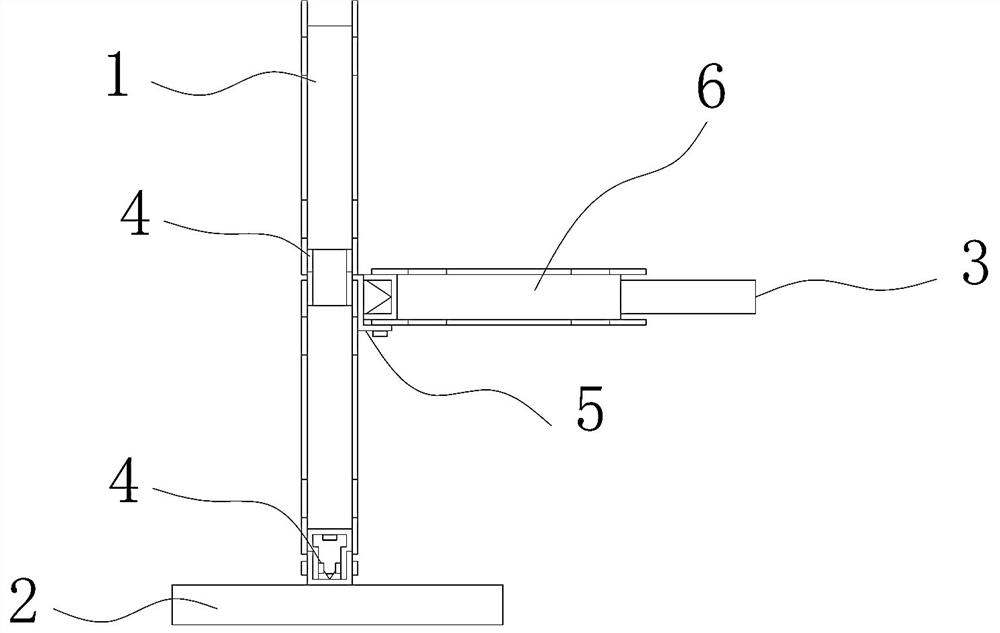

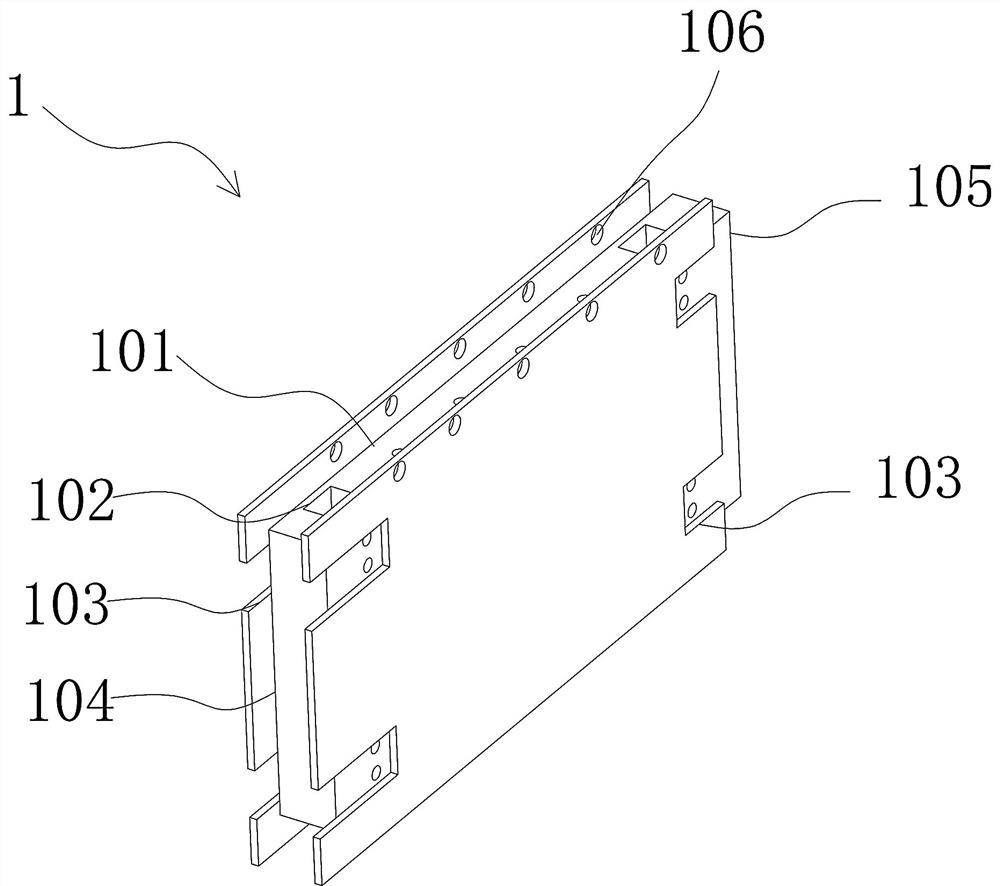

[0037] Such as Figure 1 ~ 14 As shown, a modular assembled light steel house connecting frame includes a connecting frame 4 connected to a plurality of pieces of assembly wall 1, and the connecting frame 4 structure is: the first connecting frame 401 end projection, the second connecting frame 402 is present The groove structure, the first connecting frame 401 convex portion is inserted into the groove of the second connecting frame 402, and the second connecting frame 402 is provided with a bracket mechanism 5, the bracket mechanism 5 is used to mount the crosswall 6, assemble The wall 1 is connected to the foundation 2, whereby the plurality of mounting walls 1 performs up and down by the connecting frame 4, and the connecting frame 4 can be mounted on the side surface of the bracket mechanism 5, the bracket mechanism 5 is used for mounting Horizontal wall 6, the connecting frame 4 is a detachable structure, the assembly of the assembled light steel house saves manpower, making ...

Embodiment 2

[0050] Further explanation in conjunction with Example 1, such as Figure 1 ~ 14 As shown, the first connecting groove 402 is attached to the connection recess 101 on both sides of the assembly wall 1, and the connection recess 101 of the assembly wall 1 is locked by the lock nut 403, and the suspension is used. When the machine is lifted, the first connecting frame 401 is caught inside the second connecting frame 402, and the lock nut 403 must be kept in line with the outer surface of the assembly wall 1.

[0051] Since the gap is left in the two-piece assembly wall 1, the gap is mounted at the mounting bracket mechanism 5, the horizontal wall 6 is consistent with the assembly wall 1, and the second connecting frame 402 is mounted in the horizontal wall 6, and the horizontal wall 6 is placed in the L-type On the fixed bracket 502, the second fixing nut 503 is directly passed through the horizontal wall 6 on the second connecting frame 402.

[0052] The left and right assembly wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com