Structuring and constructing method for segment prefabricated spliced concrete arch bridge

A prefabricated assembly and concrete technology, which is applied to arch bridges, erection/assembly bridges, bridges, etc., can solve the problems of long construction period, large support investment, and large construction interference, and achieve the effects of quality improvement, safety enhancement, and safety risk reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

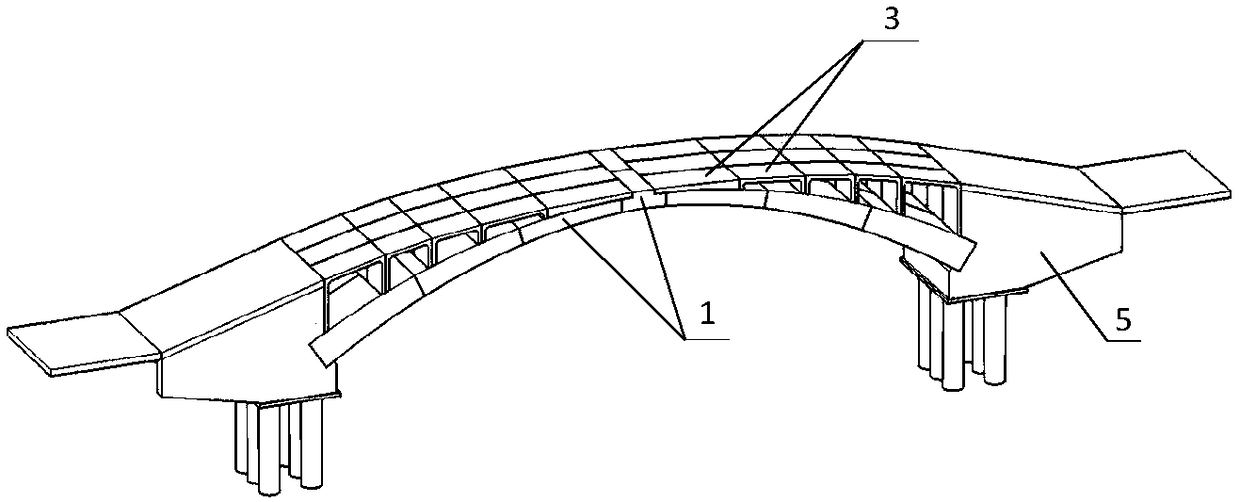

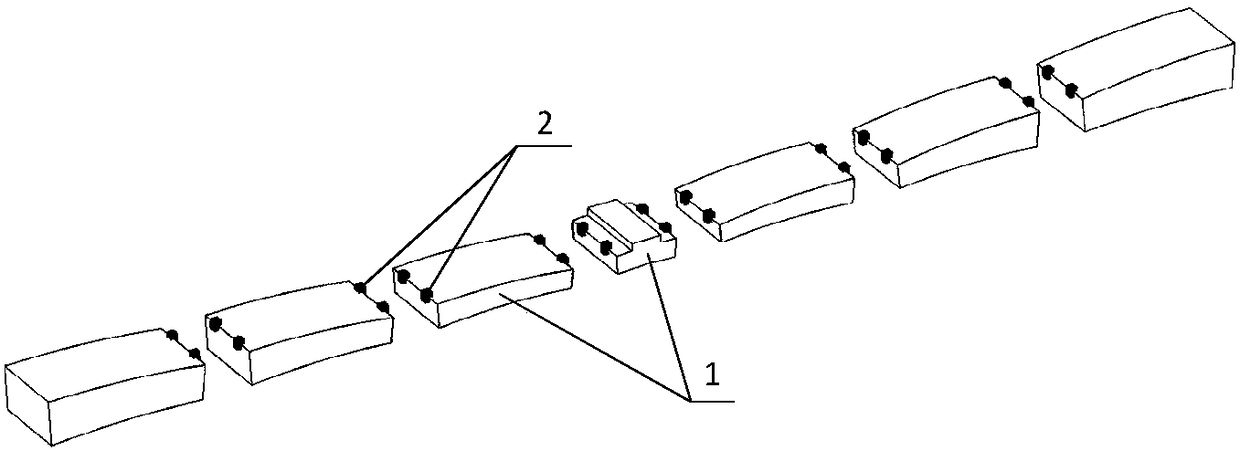

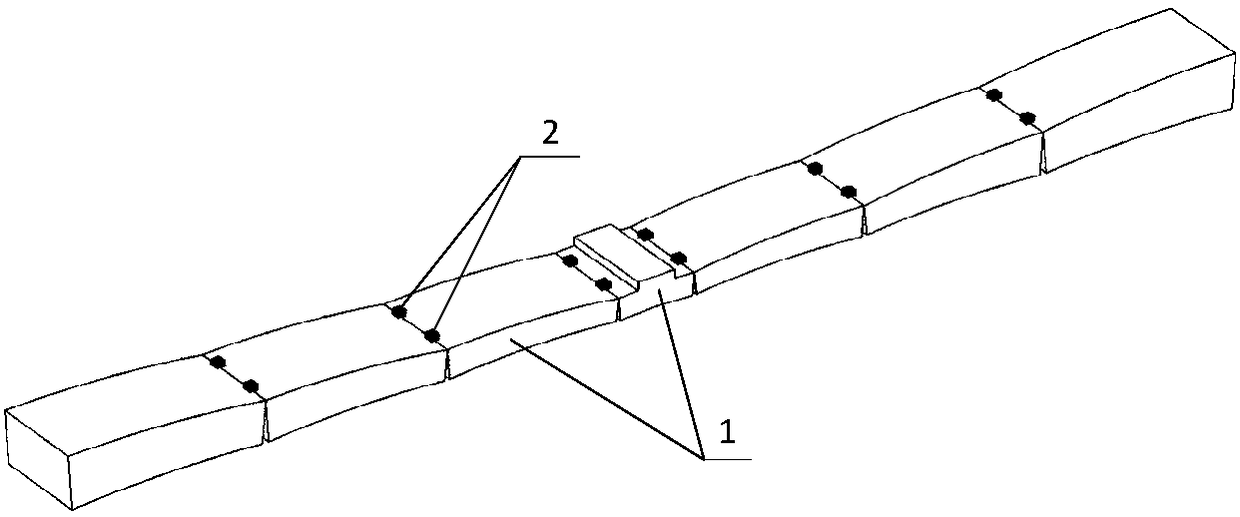

[0030] like Figure 1-7 As shown, the structure of a segmental prefabricated assembled concrete arch bridge includes a prefabricated segment 1 of an arch ring, a prefabricated steel hinge 2, a prefabricated segment 3 of a soffit, and a prefabricated steel plate 4; the arch ring is composed of a plurality of prefabricated segments The prefabricated segments 1 of the arch ring are connected by pre-embedded steel hinges 2. During the hoisting and lifting process, a curved arch ring is automatically formed. The arch ring is located on the concrete abutment 5, and the soffit is located on the arch ring , consisting of a plurality of prefabricated segments, the soffit prefabricated segments 3 are symmetrically hoisted, the prefabricated segments 1 of each arch ring and the prefabricated segments 3 of each abdominal arch are permanently connected by w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com