Patents

Literature

153results about How to "Relieve deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

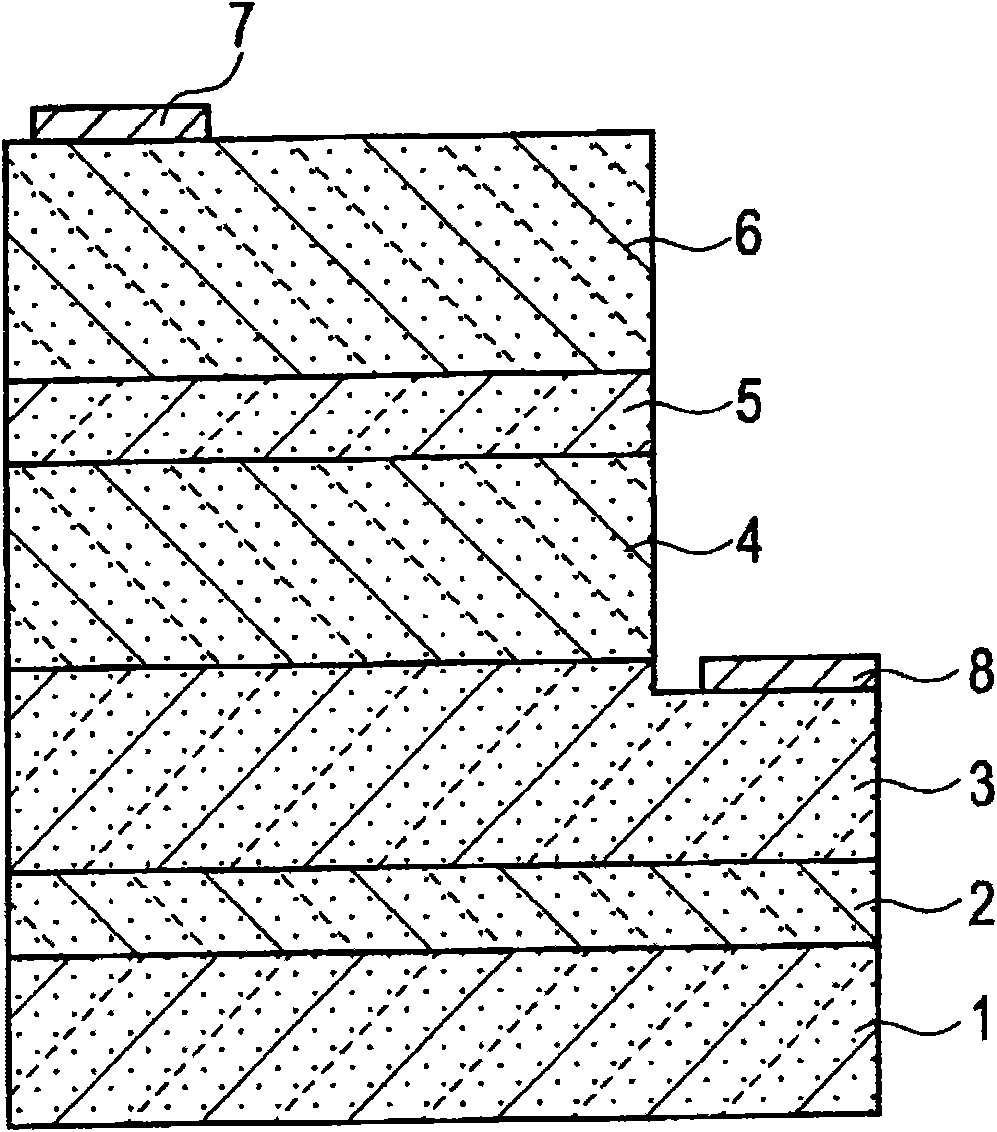

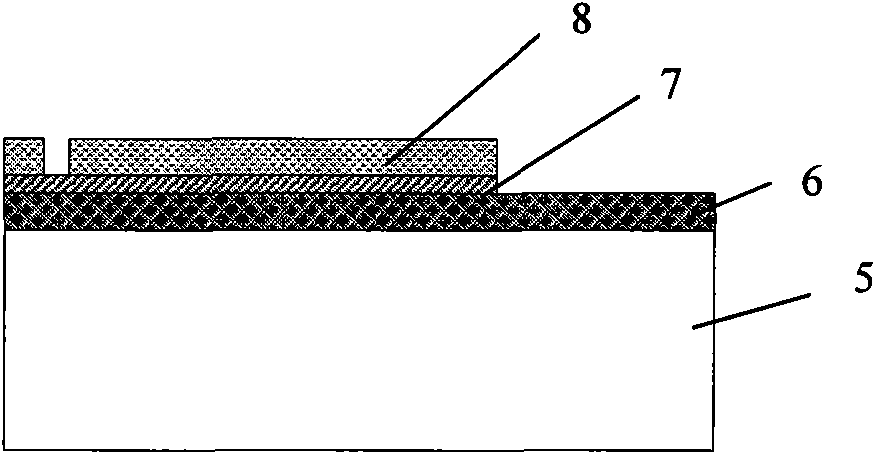

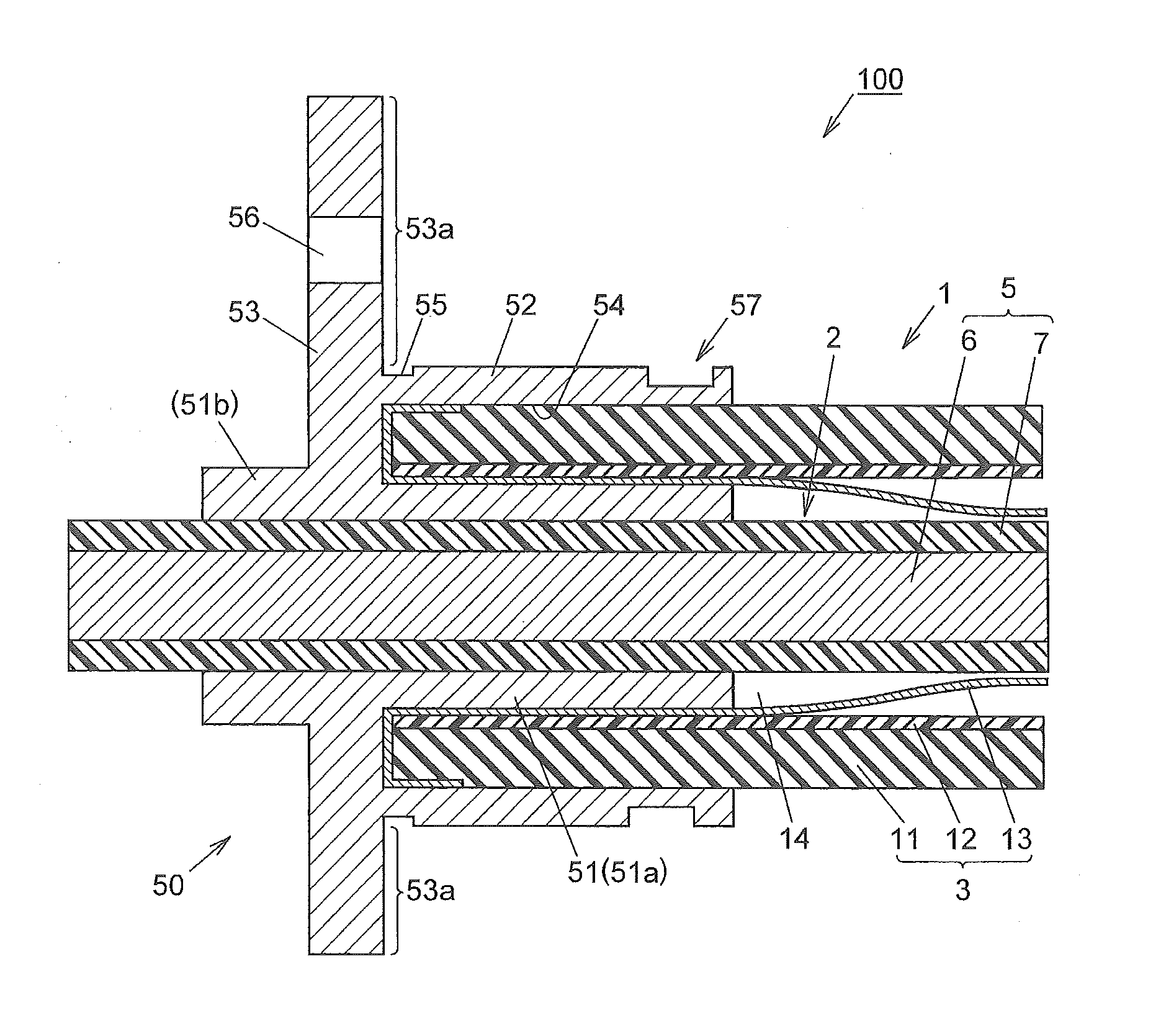

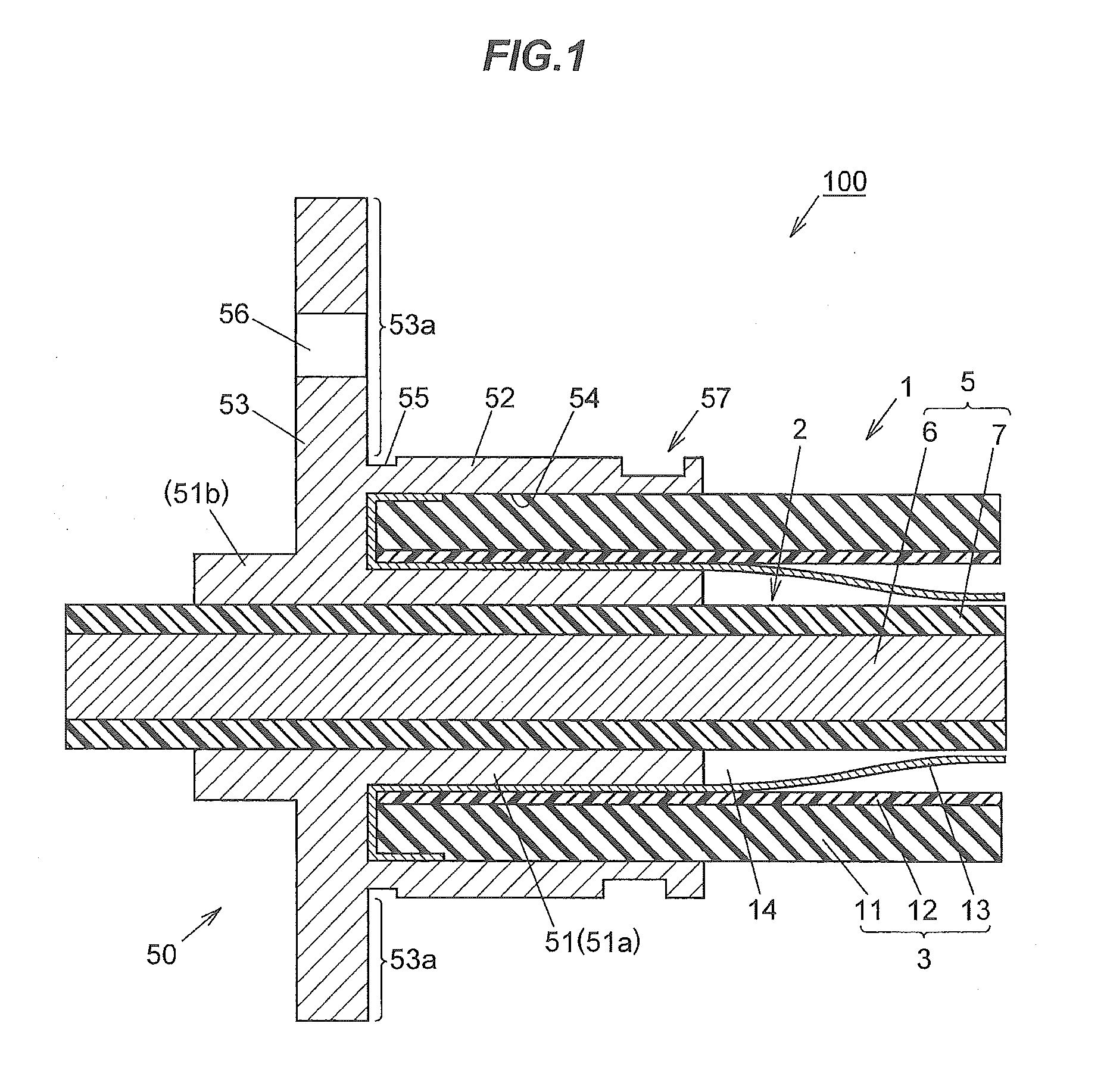

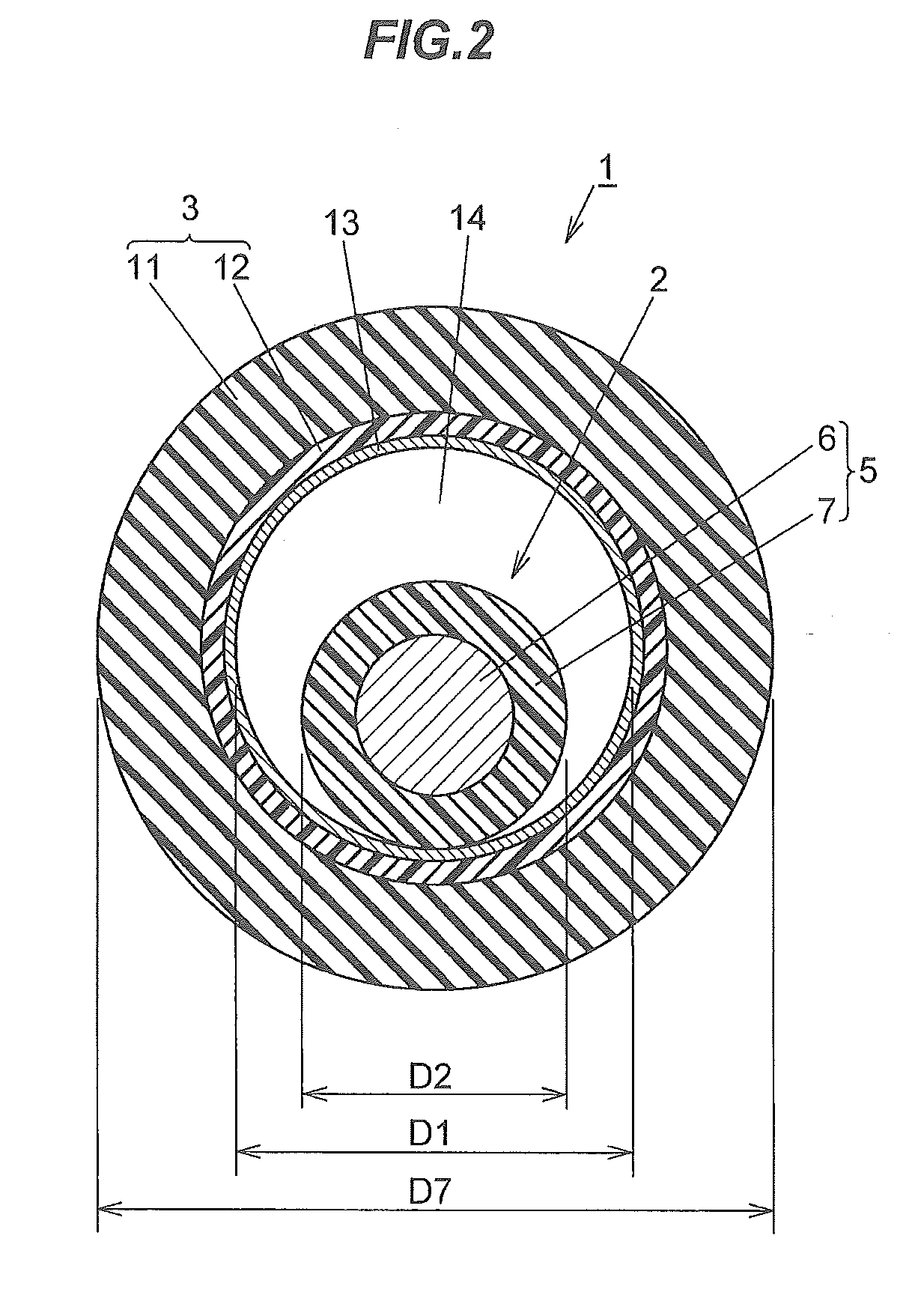

Semiconductor device connecting structure, liquid crystal display unit based on the same connecting structure, and electronic apparatus using the same display unit

InactiveUS20050056948A1Prevent excessive loadRelieve deformationTransducer detailsSemiconductor/solid-state device detailsLiquid-crystal displayElectricity

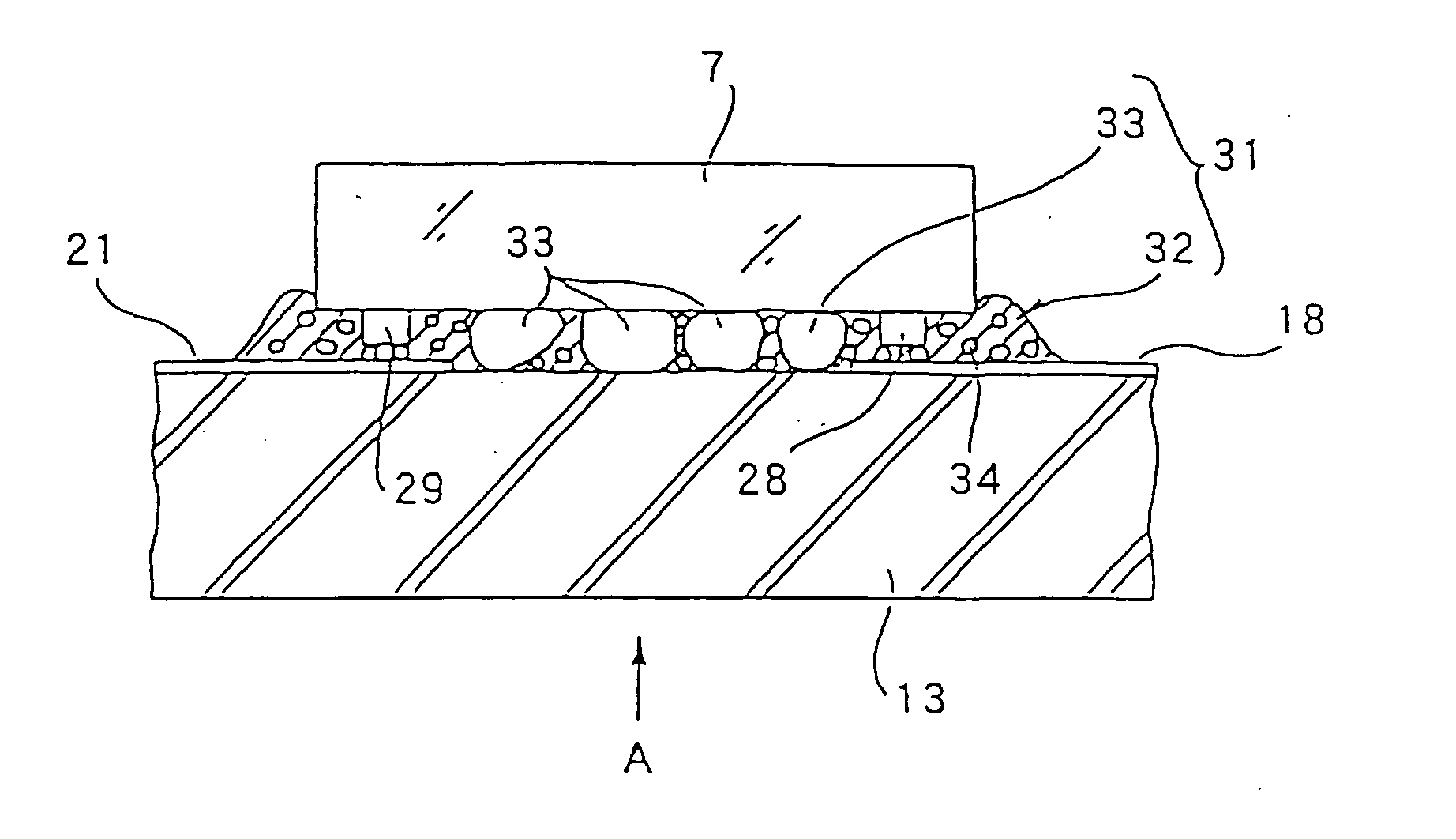

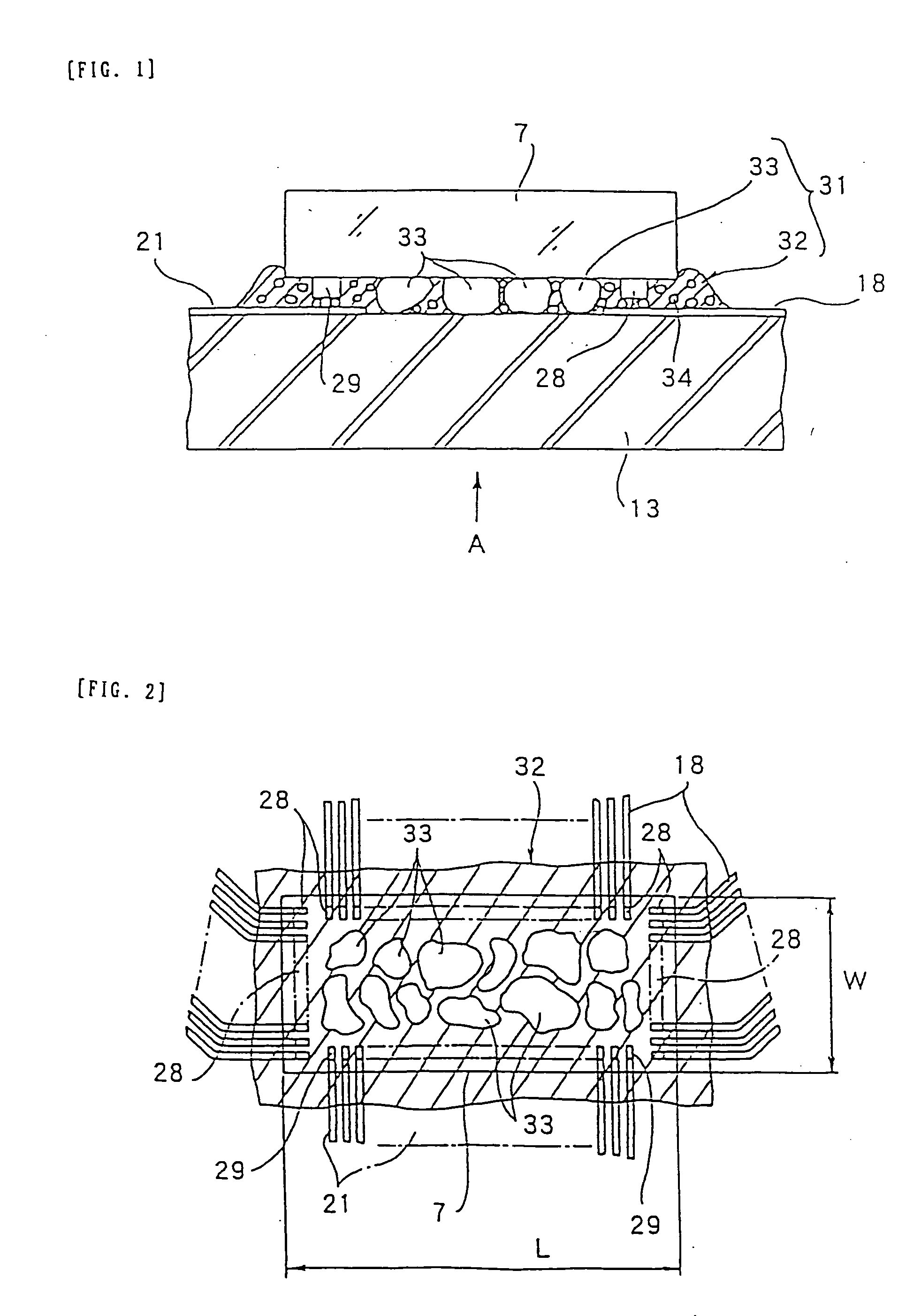

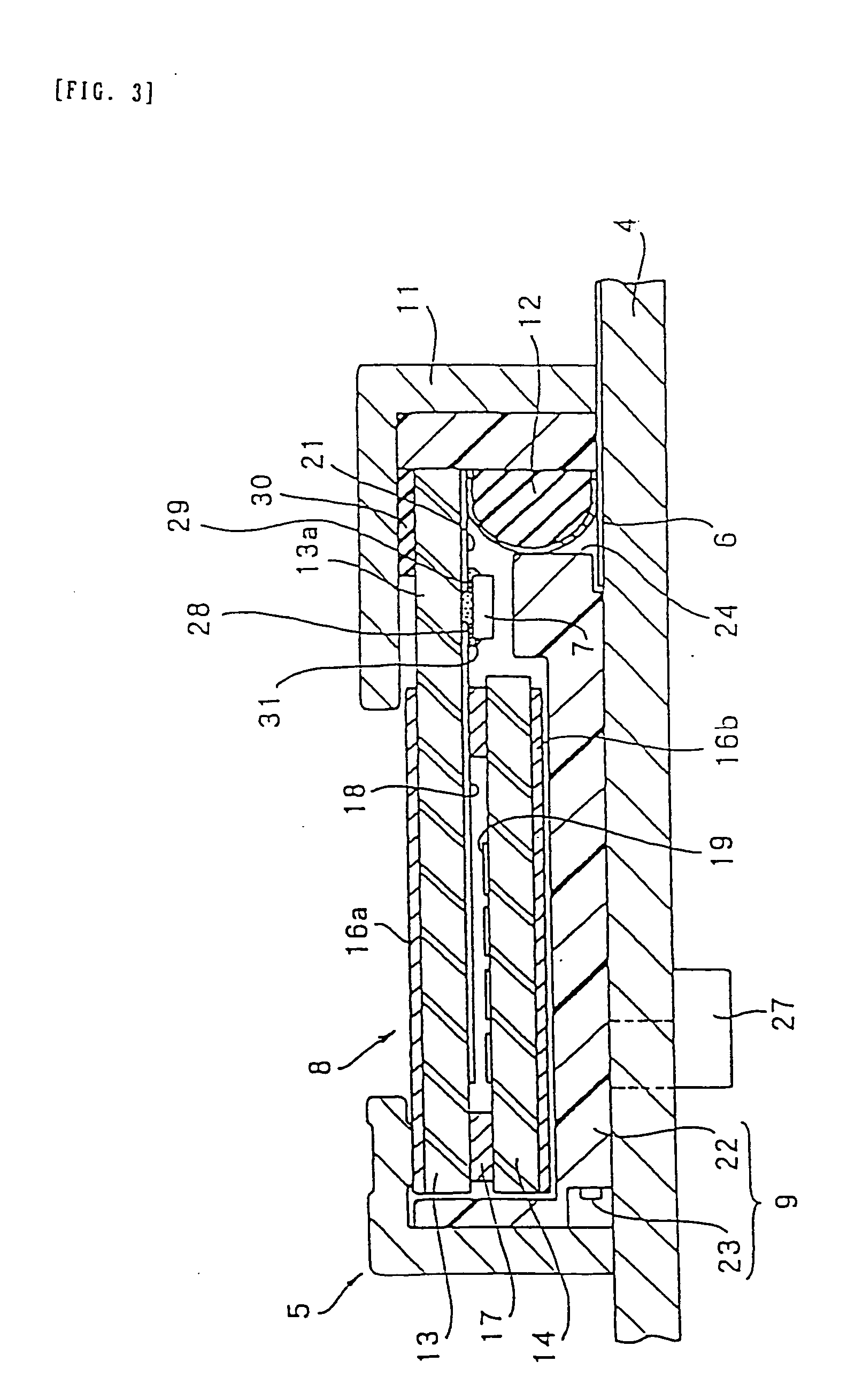

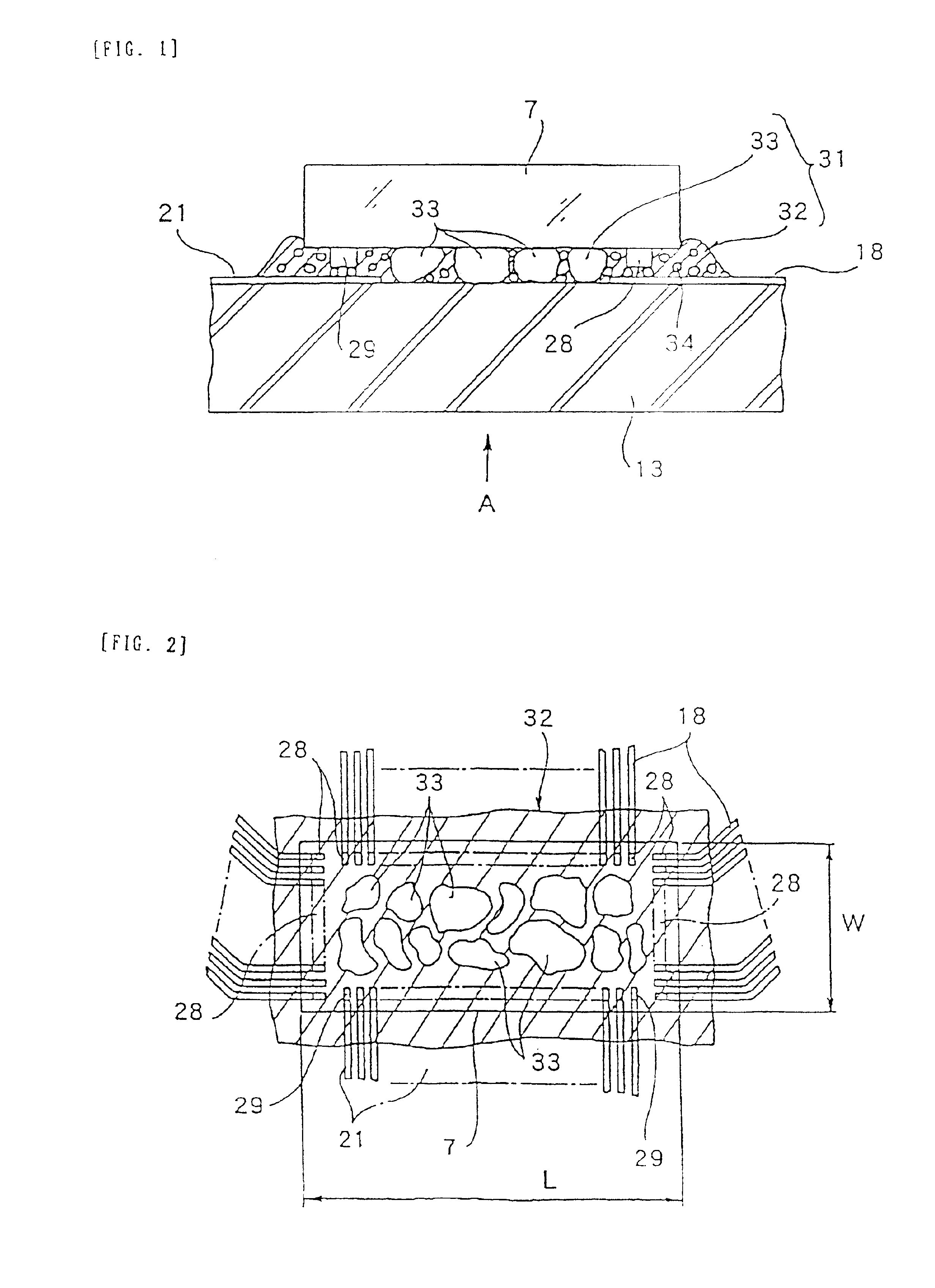

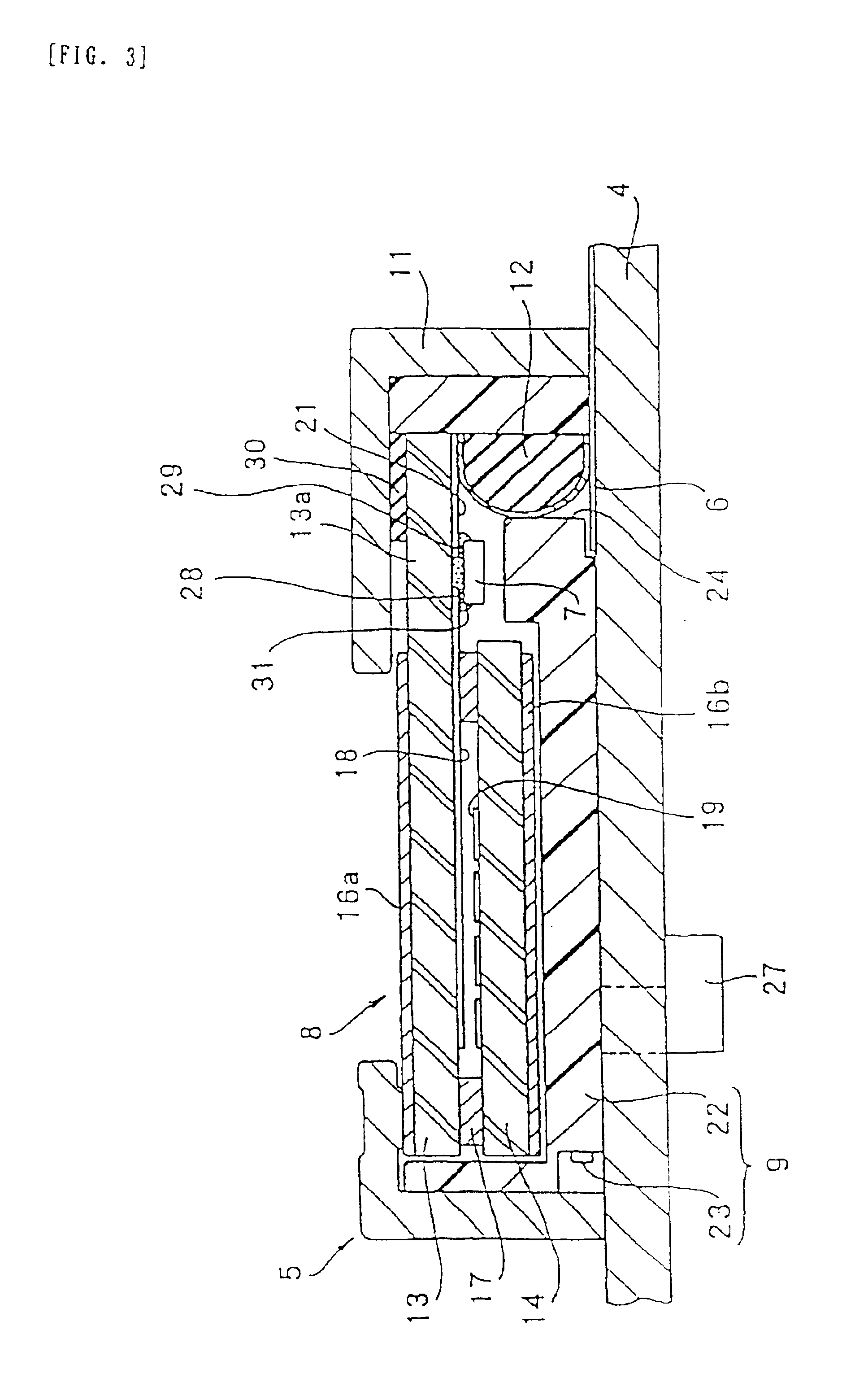

A semiconductor device connecting structure is provided for connecting a semiconductor IC to a substrate. A bonding layer is placed between the substrate and the semiconductor IC to accomplish adhesion therebetween. Sufficient heat and pressure are applied to the bonding layer to create spaces therein which deform during relative movement between the semiconductor IC and substrate thereby maintaining consistent electrical contact between the semiconductor contact bumps and electrodes on the substrate.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

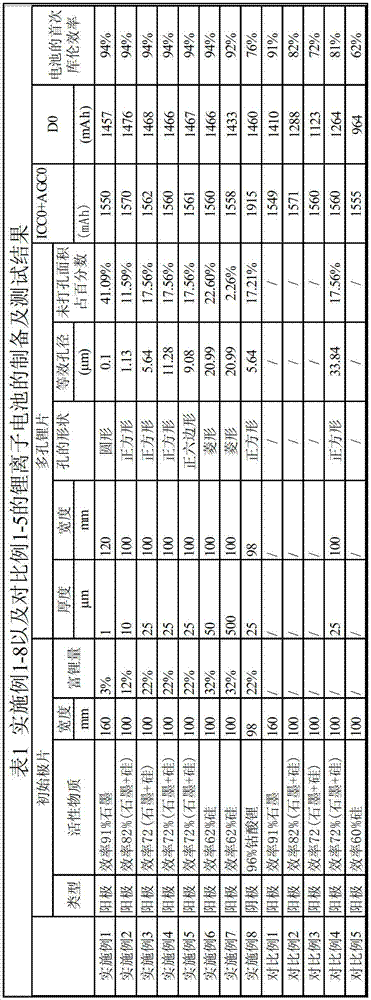

Lithium-rich pole piece of lithium ion battery and preparation method thereof

ActiveCN103199217AImprove the first Coulombic efficiencyIncrease energy densityElectrode manufacturing processesSecondary cellsAdhesivePole piece

The invention provides a lithium-rich pole piece of a lithium ion battery and a preparation method thereof. The lithium-rich pole piece comprises a current collector, a diaphragm and a porous lithium piece, wherein the diaphragm contains an active material and is formed on the current collector; the diaphragm and the current collector form an initial pole piece; and the porous lithium piece covers the diaphragm, and the capacity of the porous lithium piece is matched with the capacity of lithium added to the anode. The preparation method comprises the following steps of: preparing a slurry from the active material, a conductive agent, an adhesive and a solvent, and then applying the slurry on the current collector and drying to obtain the initial pole piece, so that the slurry applied on the current collector becomes the diaphragm after being dried; punching a metal lithium piece to obtain the porous lithium piece, so that the capacity of the porous lithium piece is matched with the capacity of lithium added to the anode; and covering the diaphragm surface of the initial pole piece with the porous lithium piece, to obtain the lithium-rich pole piece of the lithium ion battery. According to the invention, the lithium amount added to the anode can be precisely controlled, the lithium adding uniformity is increased, the first coulombic efficiency, the energy density and the electrochemical properties of the battery are increased, battery deformation is alleviated, the process is simple, and the cost is low.

Owner:DONGGUAN AMPEREX TECH

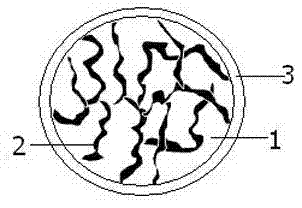

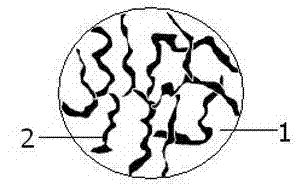

Composite anode material for lithium ion battery and preparation method thereof

ActiveCN103456928AAchieve cross-linkingIntegrity guaranteedManufacture by sprayingSilicon alloySodium-ion battery

The invention belongs to the technical field of lithium ion batteries, in particular relates to a composite anode material for the lithium ion battery. The composite anode material comprises an anode active substance and a coating layer coated on the surface of the anode active substance, wherein the anode active substance can be Si, SiOx or silicon alloy, the coating layer is polymer which is of a reticular structure, and the mass percent of the coating layer accounts for 1-20% of the anode material. Compared with the prior art, the composite anode material has the advantages that the polymer which is of the reticular structure and used as the coating layer is coated on the surface of the active substance in a cross-linking manner, the coating layer has the electron conduction property and the ion conduction property, so that the situation that the lithium ions can be inserted into and separated from the anode active substance particles smoothly is ensured; furthermore, the coating layer is of the reticular structure and has good mechanical strength, and therefore, the integrality of the anode active substance particles can be kept in the electrochemical cycle process, the deformation of an anode strip is relieved, the electrochemical cycle performance of the lithium ion battery is improved and the service life of the lithium ion battery is prolonged.

Owner:DONGGUAN AMPEREX TECH +1

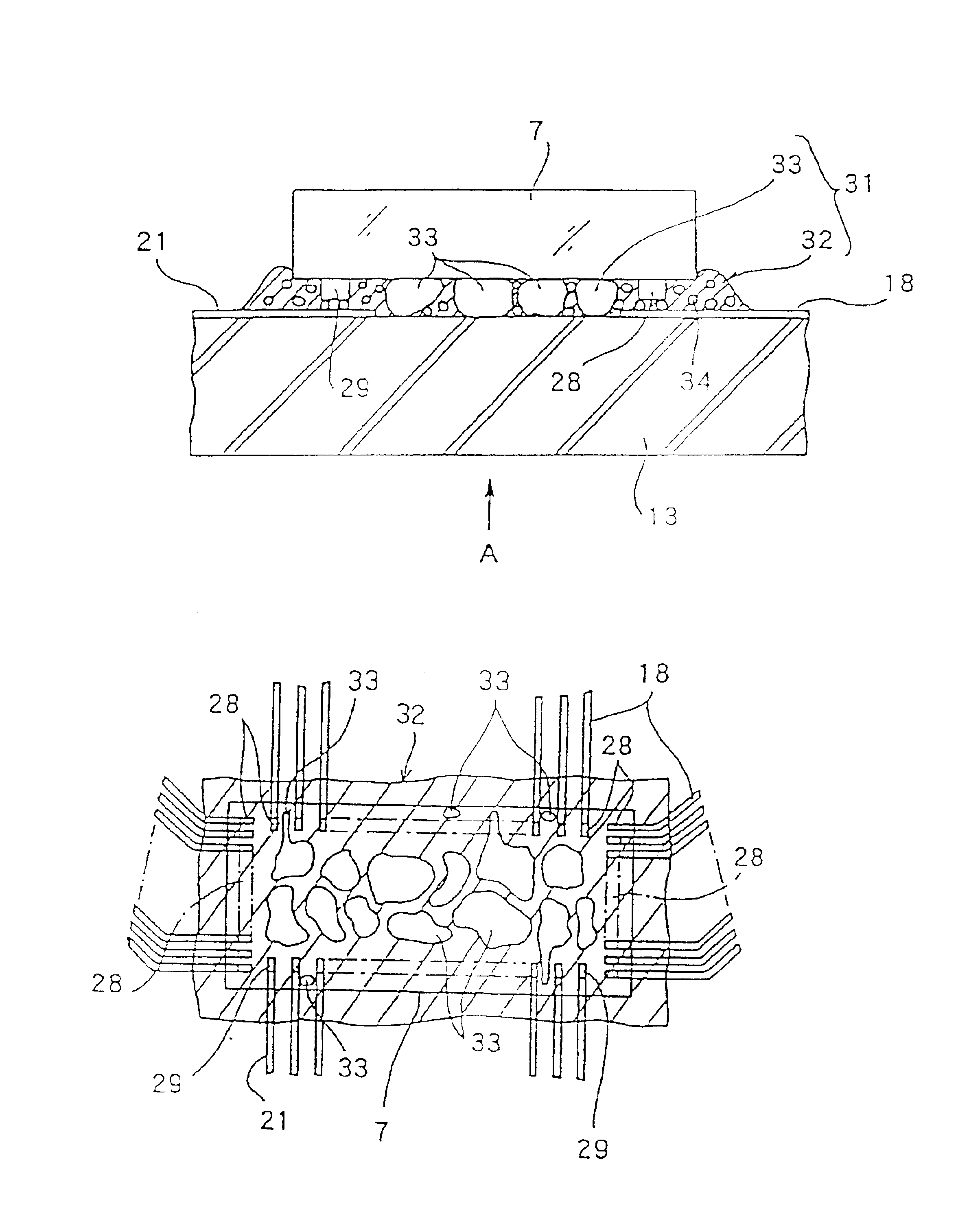

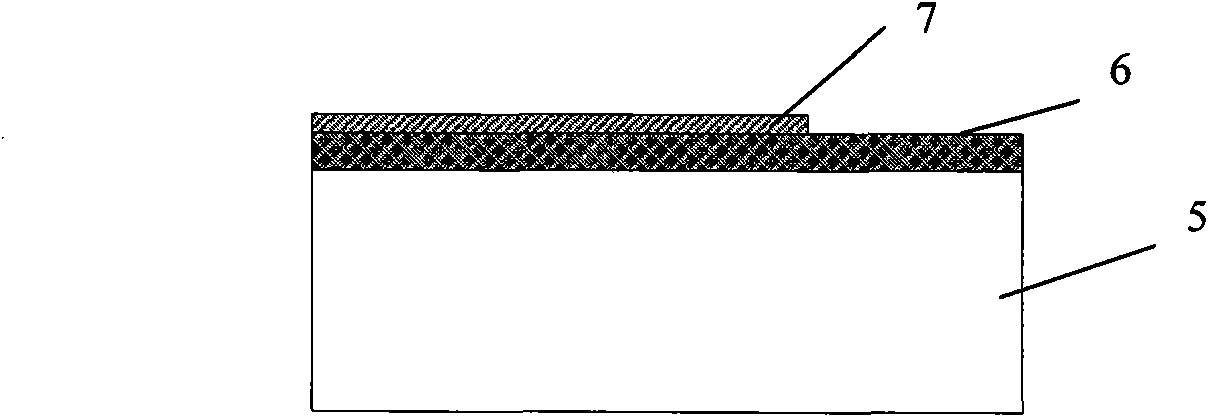

Semiconductor device connecting structure, liquid crystal display unit based on the same connecting structure, and electronic apparatus using the same display unit

InactiveUS6940180B1Avoid excessive loadsImprove connection conditionsSemiconductor/solid-state device detailsSolid-state devicesLiquid-crystal displayDevice material

A semiconductor device connecting structure for connecting a semiconductor IC 7 onto a substrate 13. A bonding layer 31 is placed between the substrate 13 and the semiconductor IC 7 to accomplish adhesion therein. This bonding layer includes an ACF 32 as a bonding material for joining said semiconductor IC 7 onto said substrate 13 and a space 33 formed within the ACF 32. Even if the IC 7 deforms due to heat or the like, the deformation is absorbed by the space a 33, whereupon the connecting conditions of bumps 28, 29 can not be unstable.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Nitride semiconductor light emitting element and method for manufacturing nitride semiconductor

InactiveCN101689586AGood lattice matchingImprove crystal qualityNanoopticsSemiconductor devicesActive layerNitride semiconductors

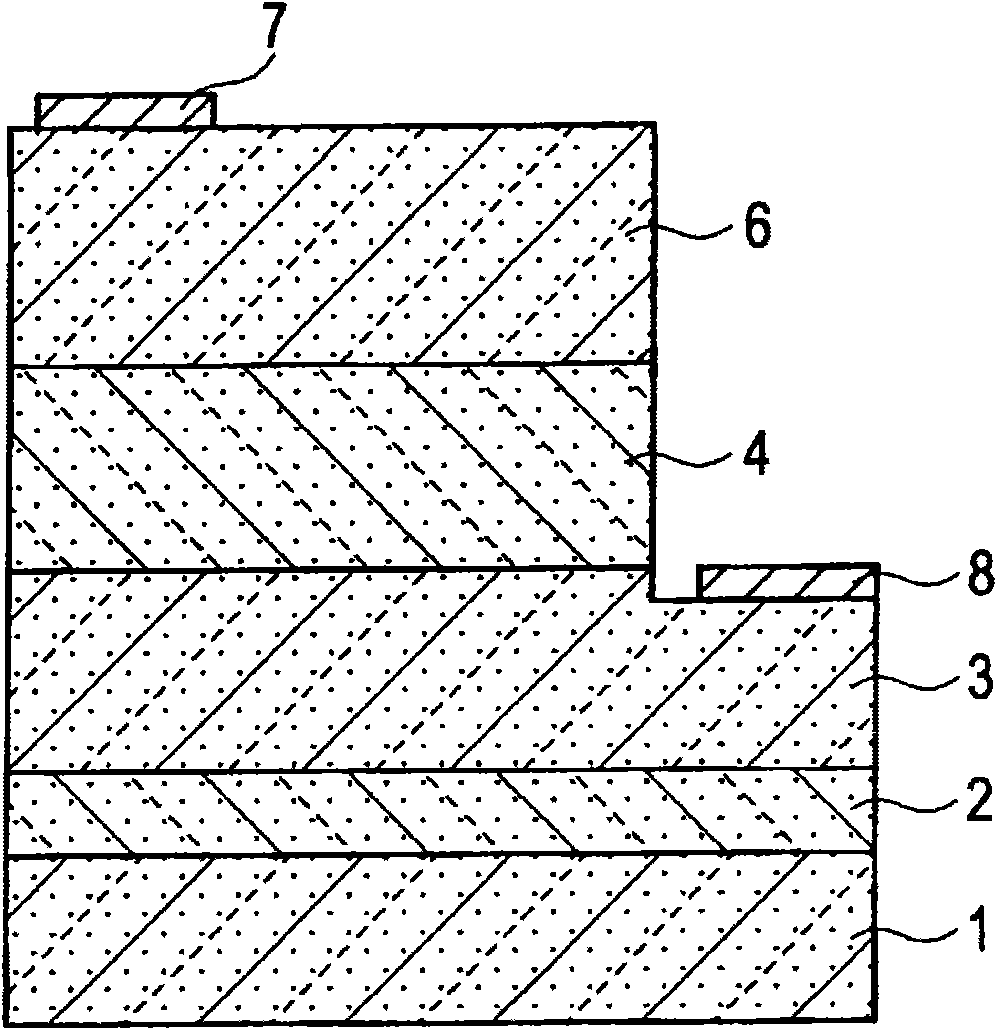

Provided is a nitride semiconductor light emitting element having improved optical output with improved qualities, such as crystal qualities, of a nitride semiconductor laminated on an AlN buffer layer. An AlN buffer layer (2) is formed on a sapphire substrate (1), and on the buffer layer, nitride semiconductors of an n-type AlGaN layer (3), an InGaN / GaN active layer (4) and a p-type GaN layer (5)are laminated in sequence. On the surface of the n-type AlGaN layer (3), an n-electrode (7) is formed, and on the p-type GaN layer (5), a p-electrode (6) is formed. The n-type AlGaN layer (3) operates as a clad layer for confining light and carriers. The AlN buffer layer (2) is manufactured by alternately supplying an Al material and an N material at a growing temperature of 900 DEG C or higher.

Owner:ROHM CO LTD

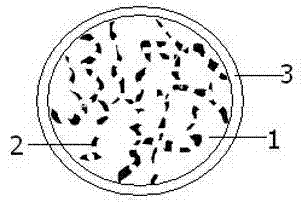

High-power-capacity lithium-ion-battery anode material and preparation method thereof

ActiveCN103208617ARelieve deformationAvoid consumptionCell electrodesVolume expansionLithium electrode

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a high-power-capacity lithium-ion-battery anode material. The high-power-capacity lithium-ion-battery anode material comprises a solid electrolyte layer and alloy particles. The particles disperse in the solid electrolyte layer, and the diameters of the particles range from 5 nanometers to 300 nanometers. Compared with the prior art, the high-power-capacity lithium-ion-battery anode material has the advantages that the solid electrolyte layer is adopted to protect the alloy particles with the diameters of 5-300 nanometers, so that powder fall-off of the alloy particles caused by large volume change is avoided, and volume expansion of the material can be controlled to relieve the deformation of anode strips; the solid electrolytes can also play a role in conveying lithium ions, and can isolate the reaction of the alloy particles and electrolytic solutions to avoid consumption of the electrolytic solutions and to protect stability of SEI (solid electrolyte interface) films on the surfaces of the anode strips, so that service life of batteries can be prolonged. In addition, the invention further discloses a preparation method of the anode material.

Owner:DONGGUAN AMPEREX TECH

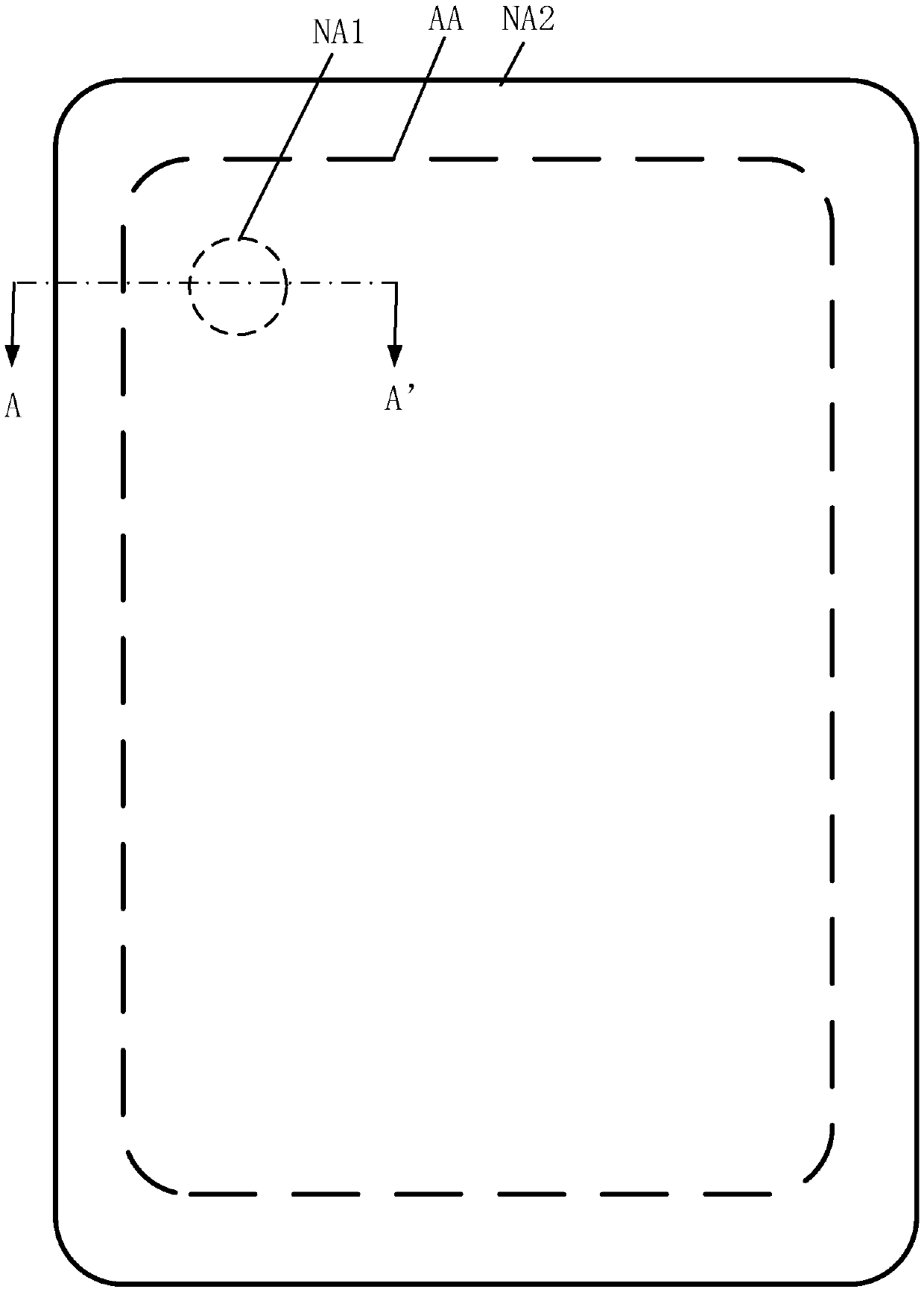

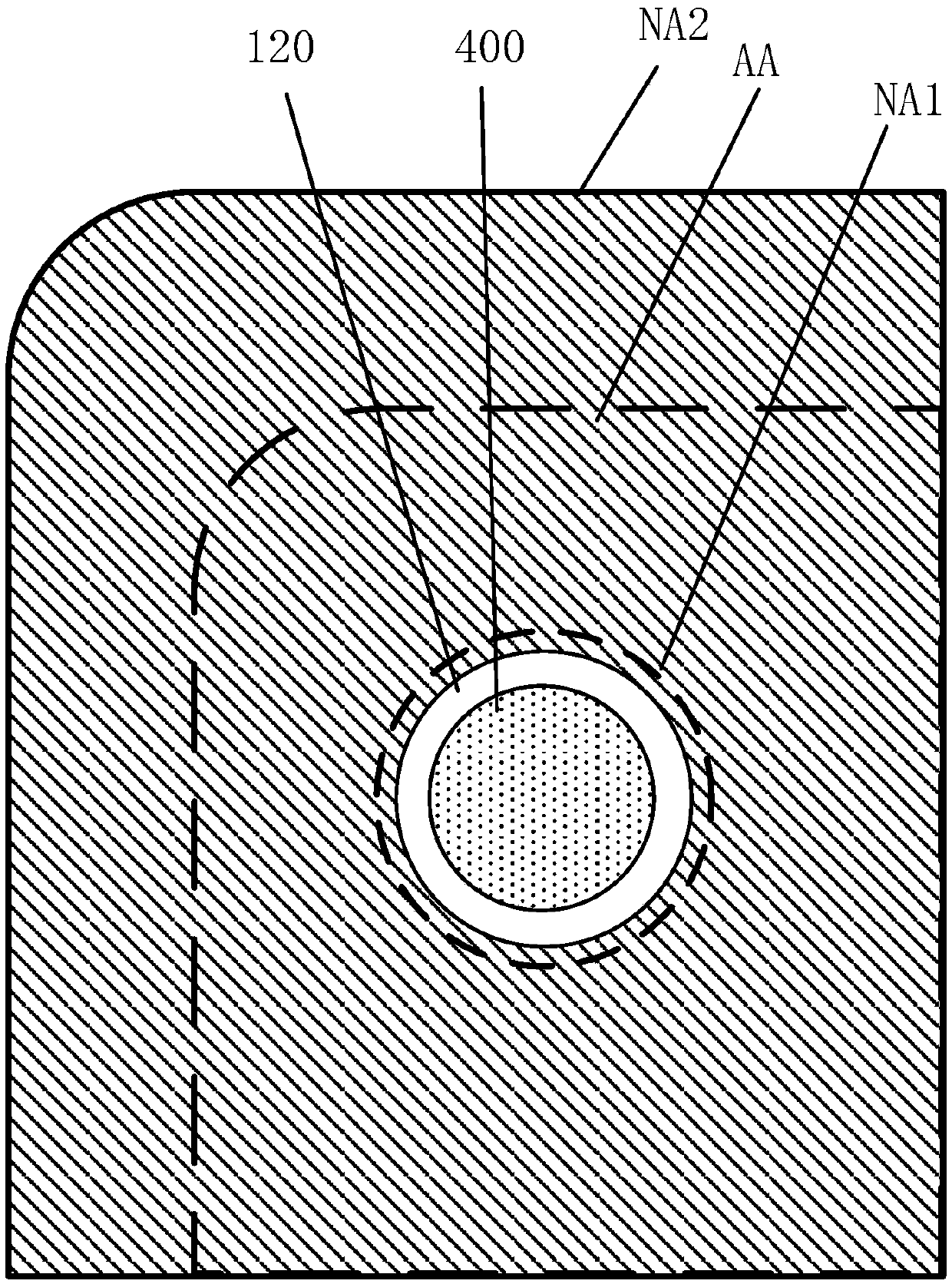

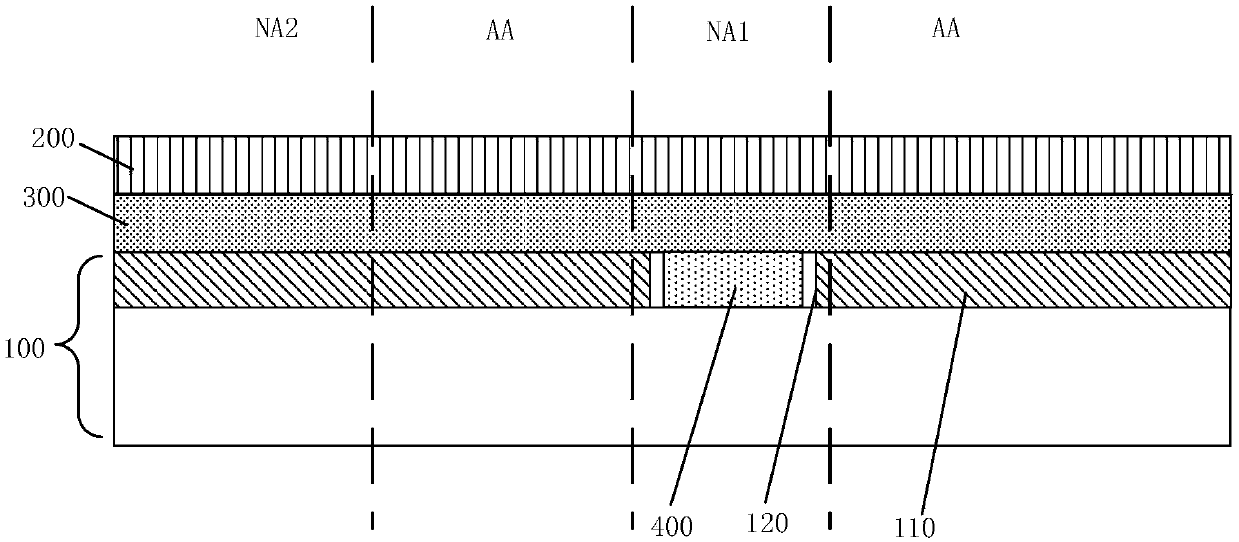

Display device and making method thereof

InactiveCN109637378AGood optical performanceEasy transferIdentification meansDisplay devicePolarizer

The invention discloses a display device and a making method thereof. The display device comprises a display panel, a cover plate and a glue layer between the display panel and the cover plate, wherein the cover plate is located on the light-exiting side of the display panel; the display panel comprises a display area, a high-light-permeability area and a non-display area, the display area surrounds the high-light-permeability area, and the non-display area surrounds the display area. The display panel comprises a first polarizer, a first through hole and a transparent filling body in the first through hole, wherein the first through hole runs through the first polarizer, the first polarizer is located on the side, close to the cover plate, of the display panel, and the first through holeis located in the high-light-permeability area. By means of the display device, the problems are effectively solved that part of area of the cover plate in a display device in the prior art is easilydeformed, and part of area of the display device yellows during display.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

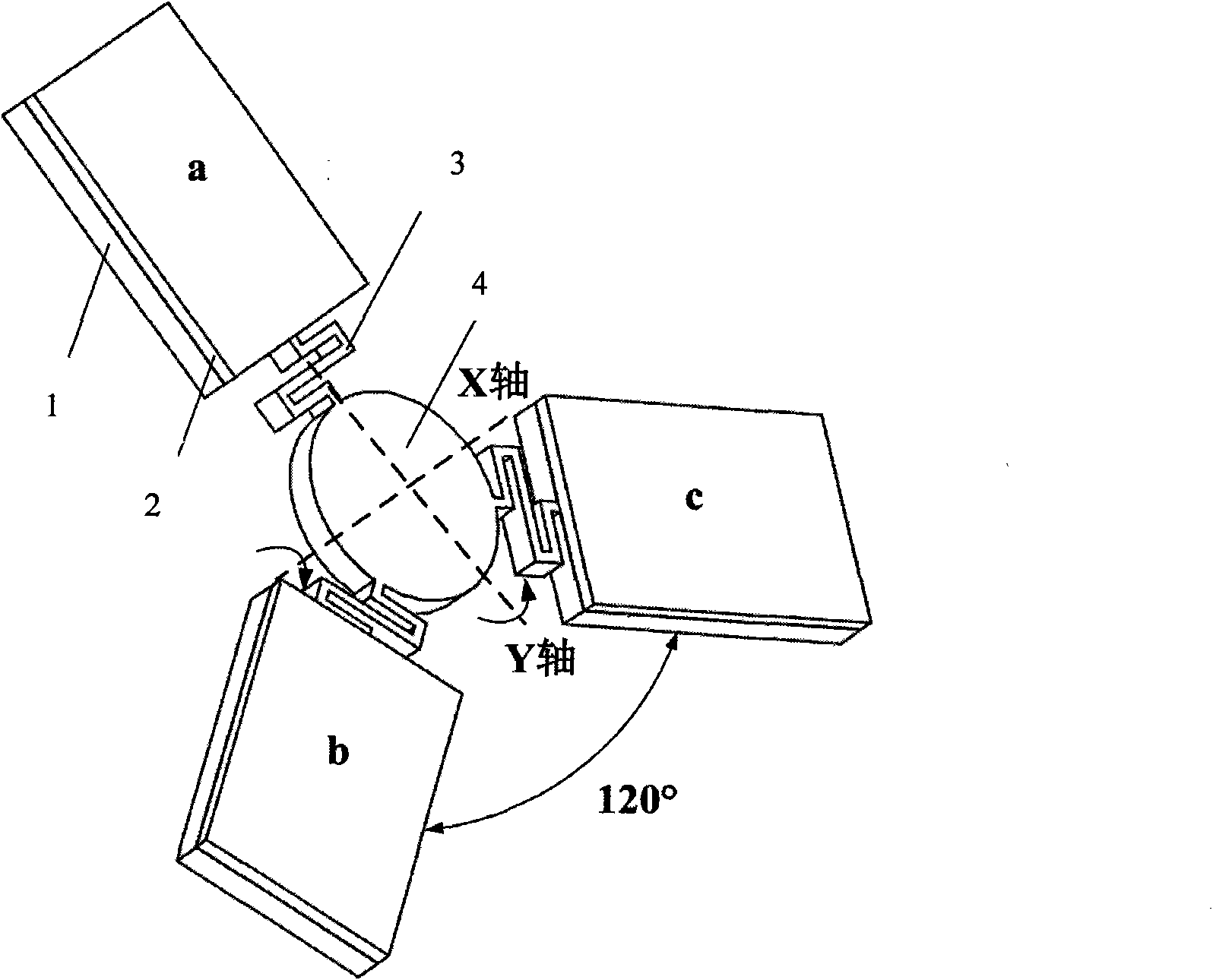

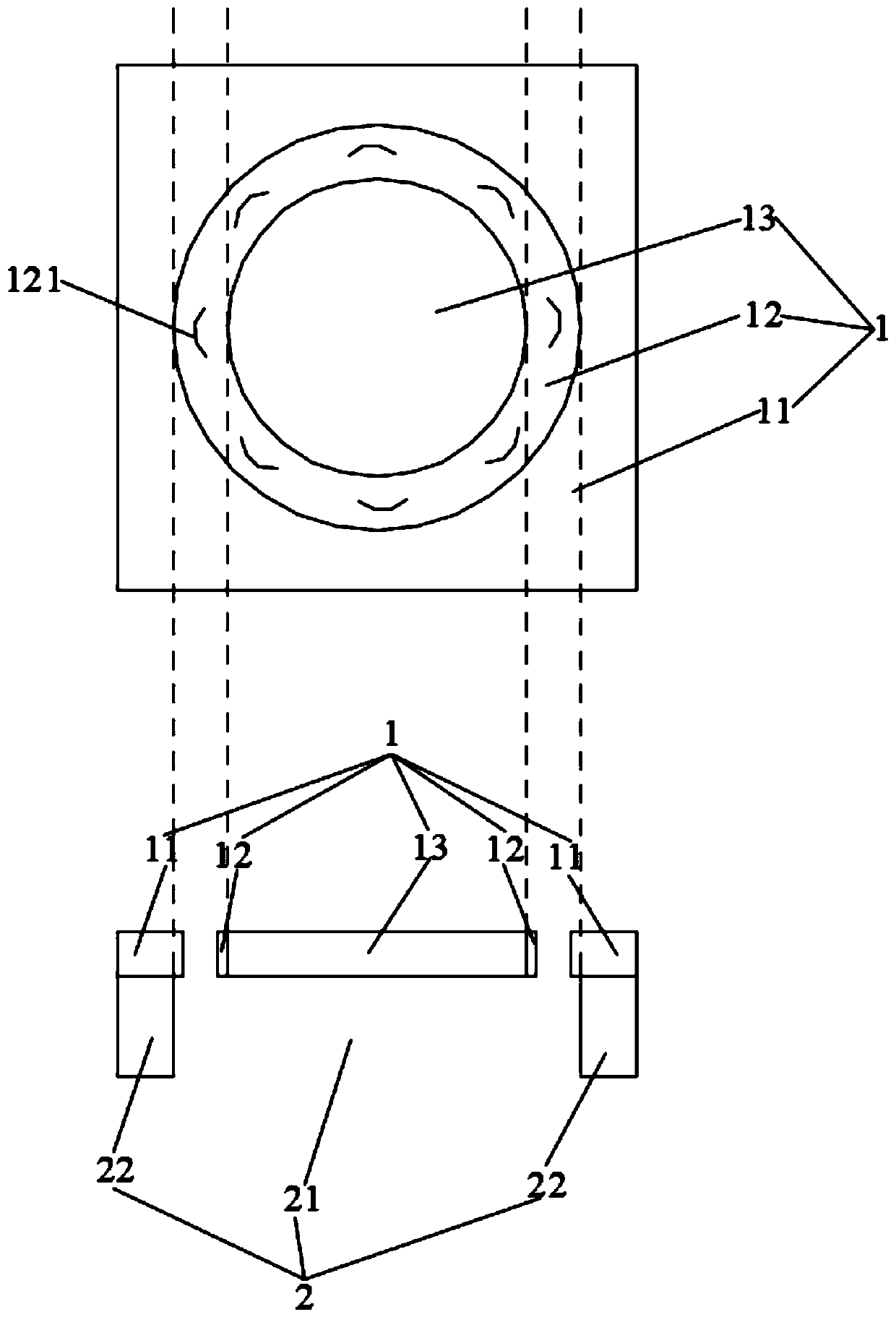

MEMS micro-lens driven by three piezoelectric cantilever beams and manufacturing method thereof

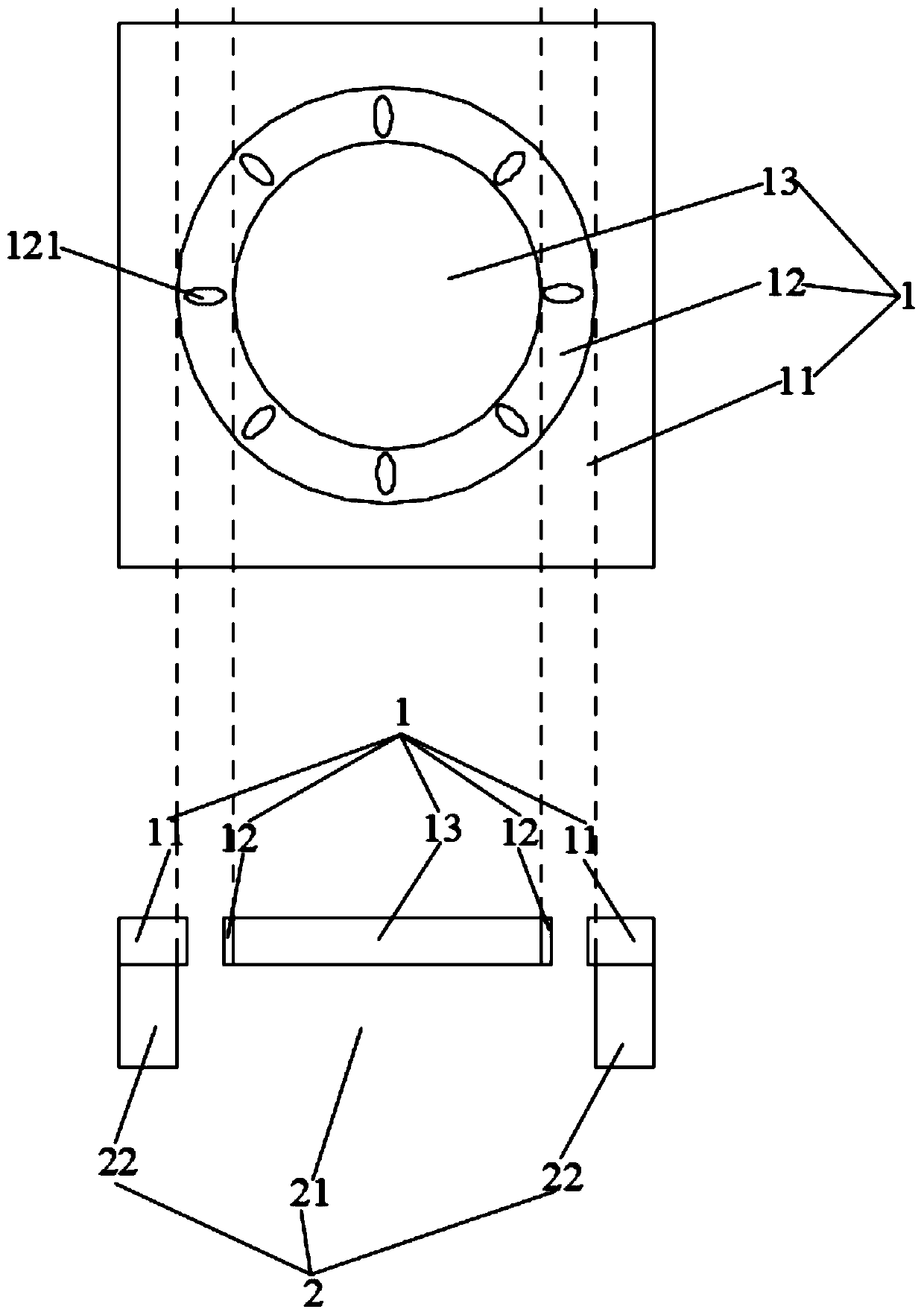

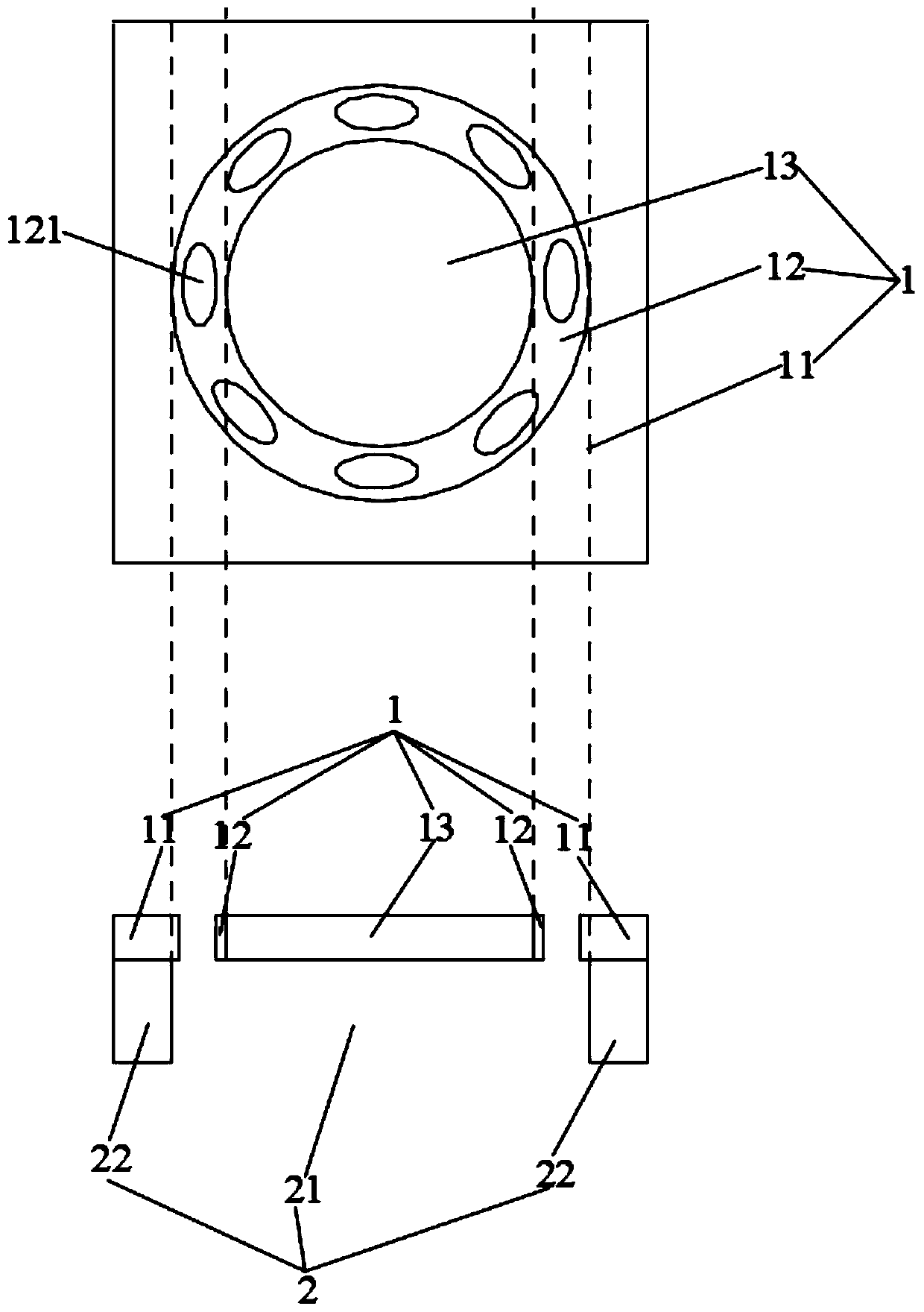

InactiveCN101937128ALow working voltageSmall sizeDecorative surface effectsChemical vapor deposition coatingSurface patternPiezoelectric mems

The invention relates to an MEMS micro-lens driven by three piezoelectric cantilever beams and a manufacturing method thereof and belongs to the technical field of piezoelectric MEMS appliance designs and integrated manufacturing. The MEMS micro-lens comprises a micro-reflecting mirror surface, the piezoelectric cantilever beams and arched bent elastic narrow beams, wherein each of the piezoelectric cantilever beams is formed by fixing a PZT driving membrane with more than 2 mu m thickness on the surface of a silicon cantilever beam; the three piezoelectric cantilever beams are connected with the micro-lens micro-reflecting mirror surface through three arched bent elastic narrow beams respectively; and the piezoelectric cantilever beams are distributed in a way that an included angle of 120 degrees is formed between every two piezoelectric cantilever beams. The manufacturing method comprises the following steps of: firstly, preparing a piezoelectric thick membrane on a substrate and etching piezoelectric cantilever beam patterns on the piezoelectric thick membrane; secondly, preparing a Au / Cr two-layer metal top electrode and a micro micro-reflecting mirror surface pattern on the PZT piezoelectric thick membrane; and finally, etching a Si substrate on the front and back faces so as to form the MEMS micro-lens driven by the three piezoelectric cantilever beams. The MEMS micro-lens has the advantages of many deflecting directions, strong driving force of the PZT thick membrane and low optical loss. The manufacturing process is compatible with the MEMS process, so that the MEMS micro-lens has the potential of mass production and can be widely applied in the field of optical communication.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

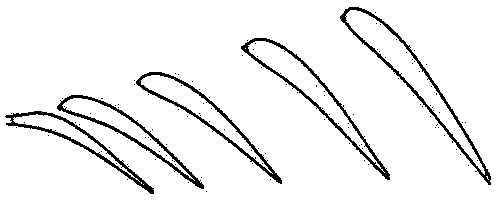

Aero-engine compressor blade and machining method thereof

The invention belongs to the technical field of aero-engines, and discloses a compressor blade machining method. The compressor blade machining method includes the steps that step 1, three-dimensionalmeasurement is carried out, specifically, a crest curve and a trough curve are built by extracting actual curve crest points and trough points of cross sections according to a three-dimensional diagram of a compressor blade; virtual curves of a blade body and a jog are built; step 2, point cloud is extracted, specifically, curvatures of the actual curve, the crest curve and the trough curve of the step 1 are analyzed, and the curves of the crest curve and the trough curve are regulated according to actual curve curvatures; a center line is built according to the crest curve and the trough curve; step 3, a hook face is rebuilt, specifically, a mesh hook face is built with center lines of the cross sections to generate a three-dimensional digital model; step 4, procedures are regulated, specifically, the blade three-dimensional digital model is imported to a three-dimensional software and corrected compared with blade master body data scanned by the three-dimensional software; and step5, numerical control machining is carried out, specifically, numerical control programming is carried out according to the blade three-dimensional digital model of the step 4, and a blade is subjectedto numerical control milling with a ball end milling. According to the compressor blade machining method, the blade precision and the surface roughness of a compressor can be effectively ensured.

Owner:株洲丰发精工实业有限公司

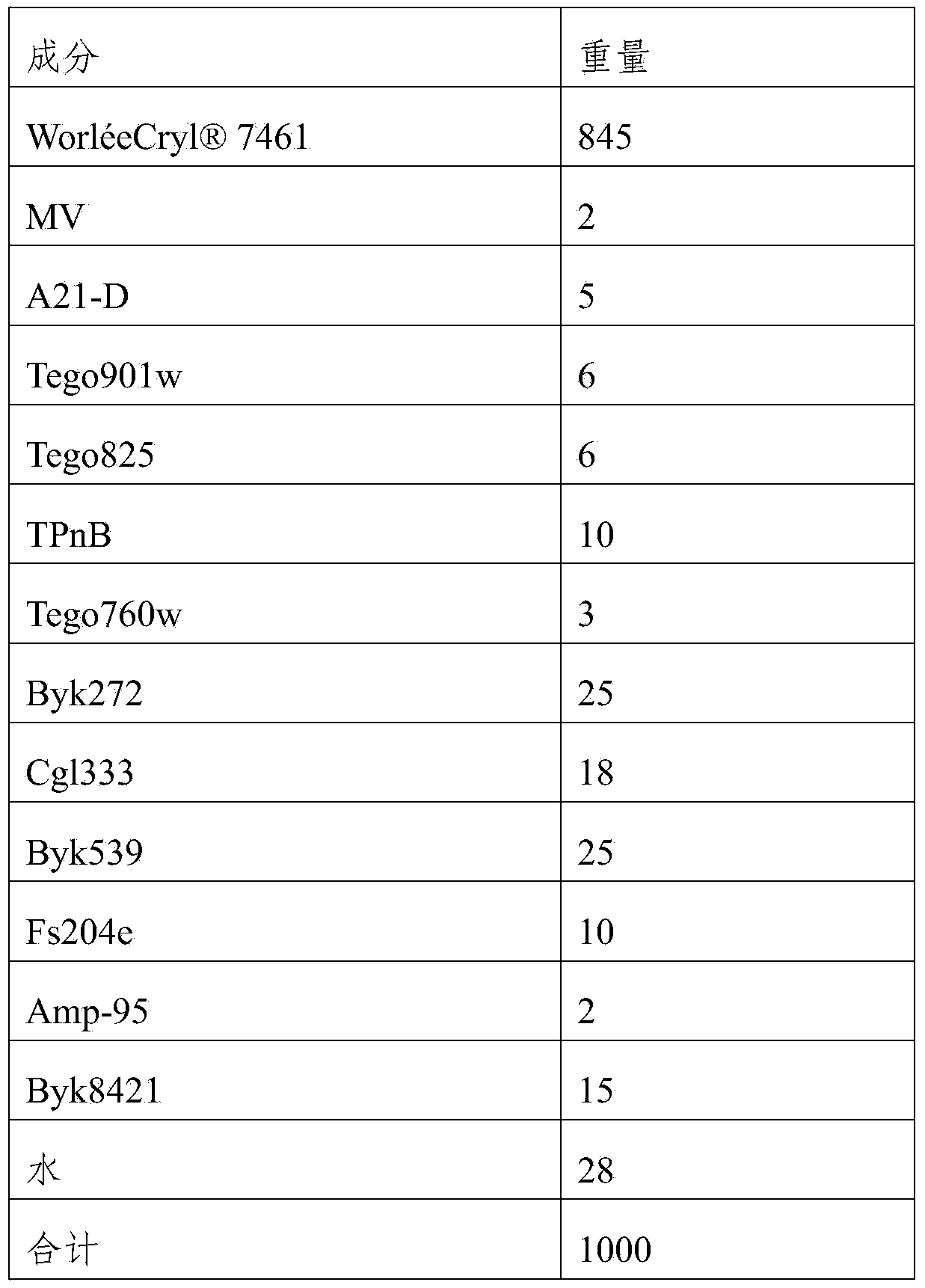

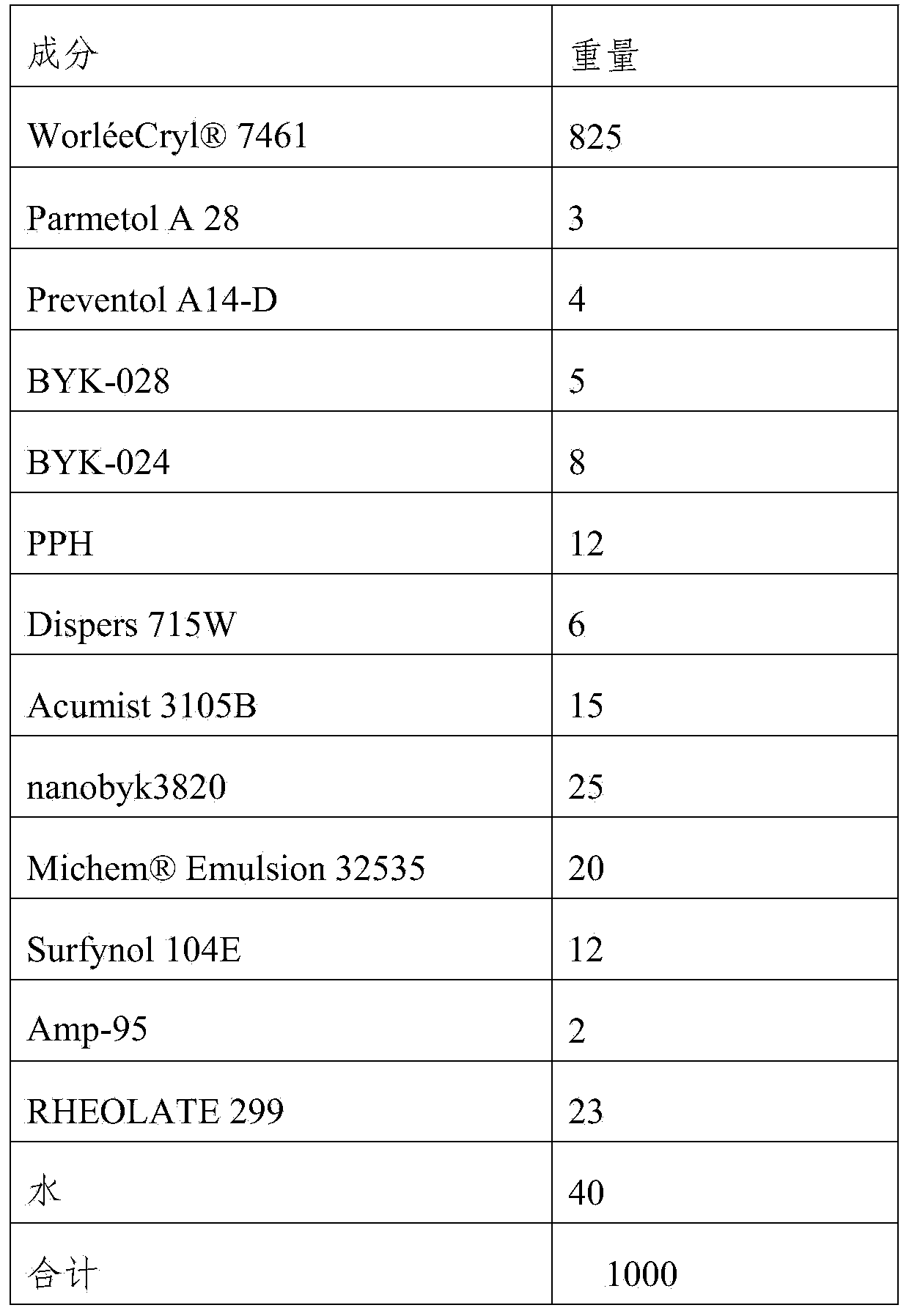

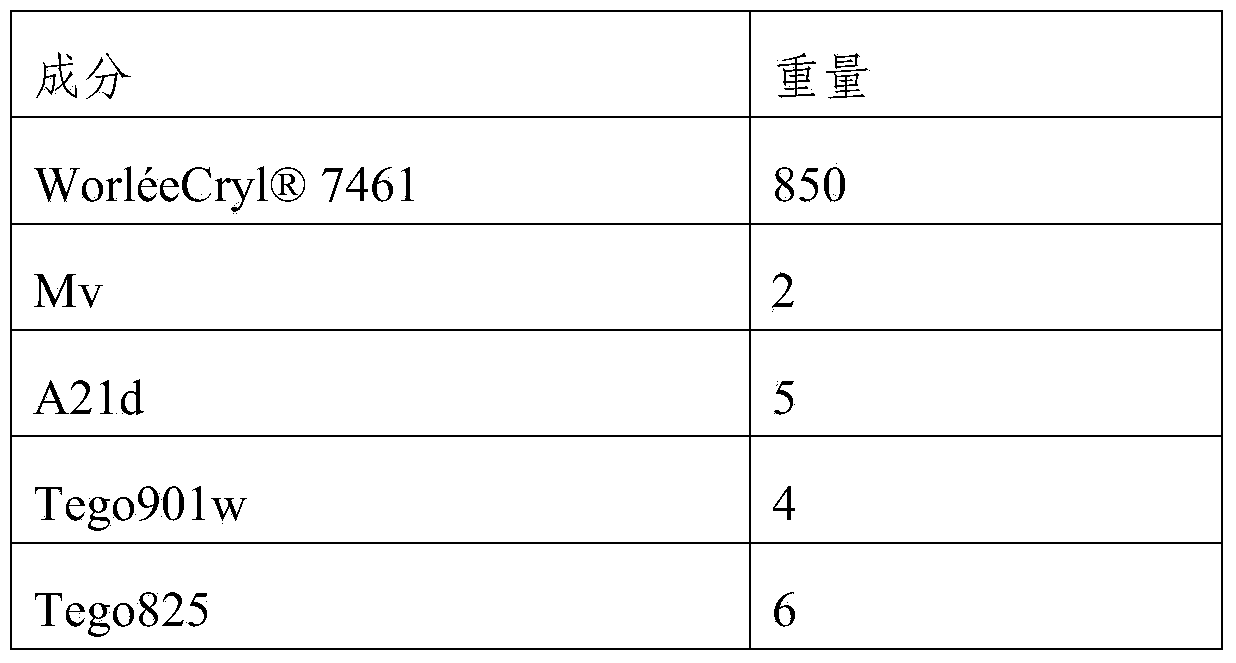

Water-based clear topcoat with high solid content and preparation method thereof

ActiveCN103881495AReduce contentImprove protectionLiquid surface applicatorsAntifouling/underwater paintsWaxPreservative

The invention relates to a water-based clear topcoat with high solid content, which is prepared from the following components in parts by weight: 750-900 parts of water-based resin, 1-4 parts of bactericide, 3-8 parts of dry film preservatives, 5-25 parts of coalescing agents, 5-15 parts of defoamer, 5-20 parts of base material wetting agents, 2-5 parts of pH adjuster, 10-35 parts of anti-sagging agents, 10-40 parts of extinction wax additives, 15-50 parts of special wax additives, 3-15 parts of dispersants, 15-35 parts of complex aging resistant additives, 0-100 parts of resin-type water-based coloring materials, and 0-60 parts of water. The product with high sold content is applicable to coating and protection on wood platforms, wood doors and windows, fences, leisure tables and chairs and other wood structures manufactured and formed outdoors. The water-based clear topcoat with high solid content is simple in preparation method, easy to operate, free of harm to an operator, and applicable to industrial popularization and application.

Owner:濮阳展辰新材料有限公司

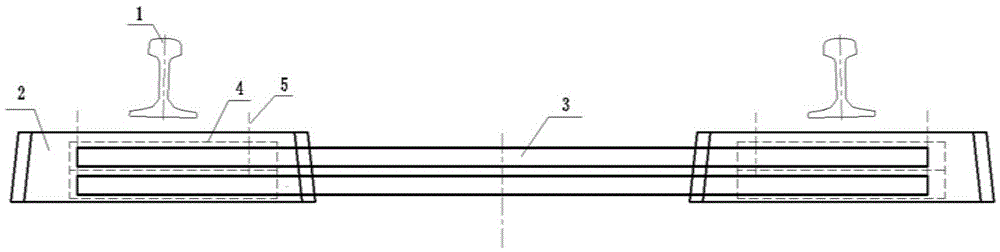

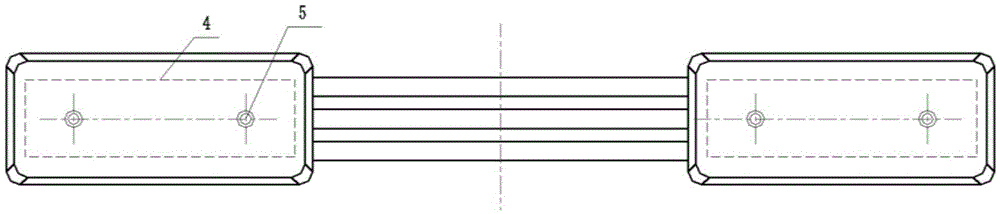

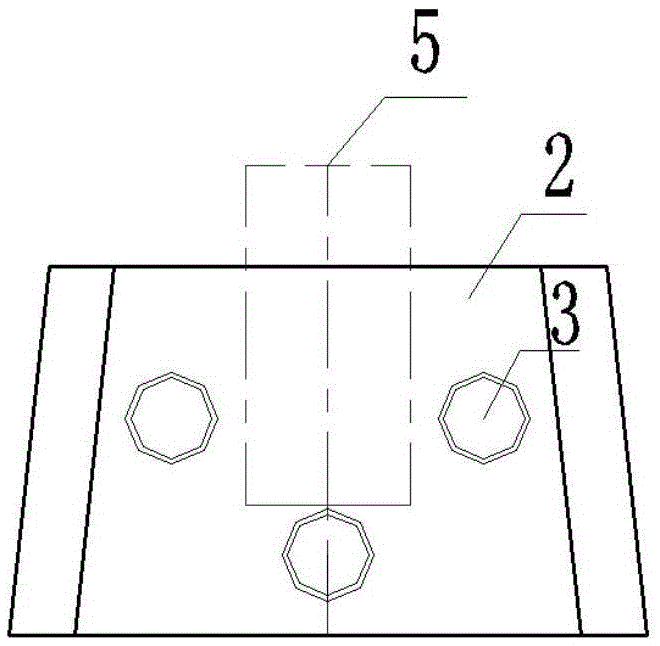

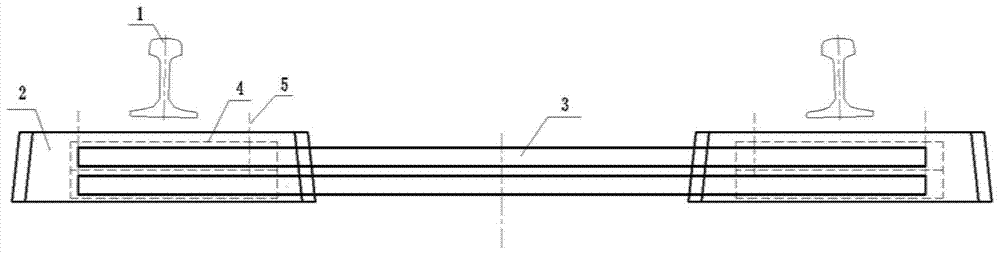

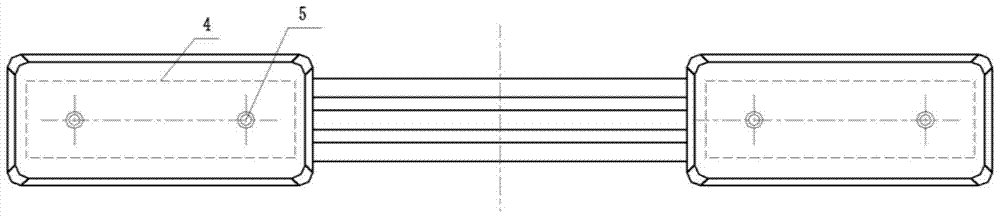

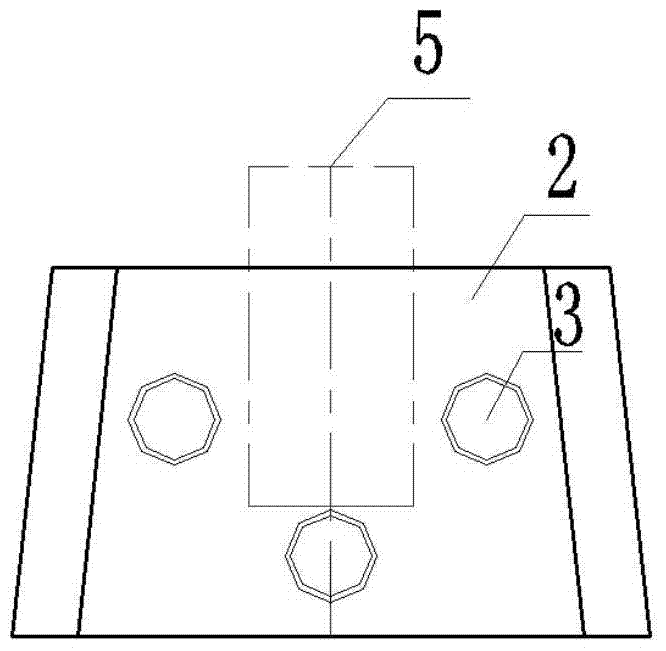

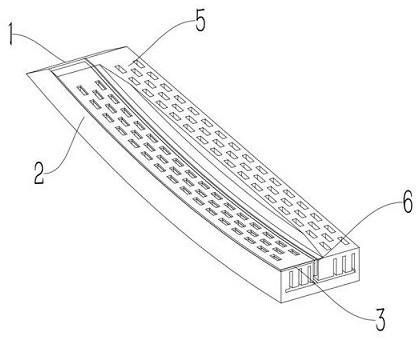

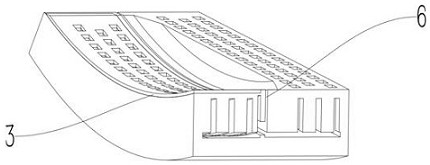

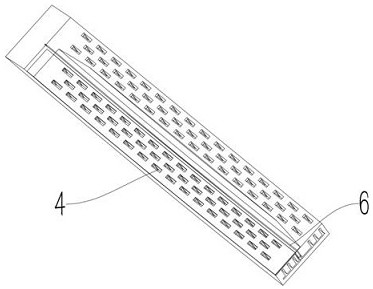

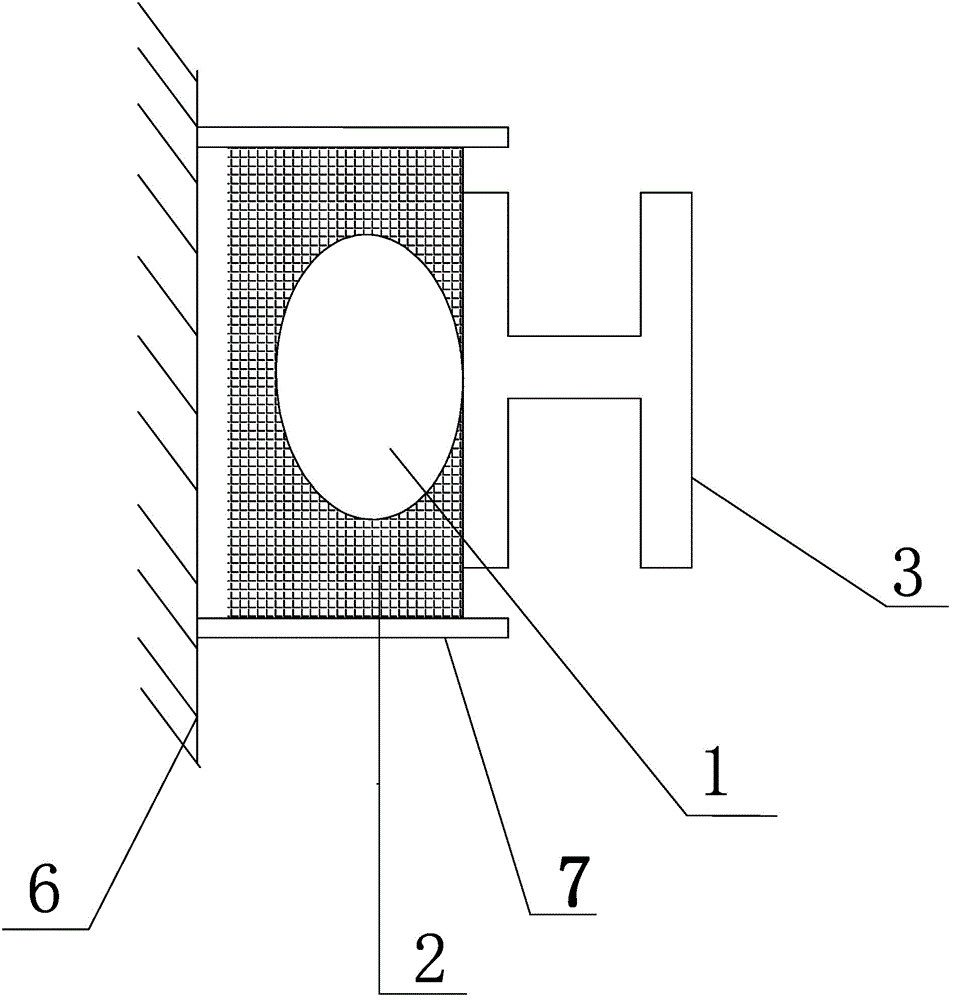

Concrete-filled steel tube sleeper for ballastless track

ActiveCN105463948ARelieve deformationMeet the requirements of bending and torsion resistanceBallastwayHollow coreSteel tube

The invention discloses a concrete-filled steel tube sleeper for a ballastless track. The concrete-filled steel tube sleeper for the ballastless track comprises two or more sleeper concrete blocks and sleeper connecting parts used for connecting the sleeper concrete blocks. Each sleeper concrete block is of a block-shaped structure and formed by pouring concrete, and each sleeper concrete block is internally provided with an embedded part for fixing the steel track and a steel-bar mesh or a stirrup connected with the corresponding sleeper connecting part. Each sleeper connecting part is composed of a plurality of hollow steel tubes transversely arranged between the corresponding sleeper concrete blocks. In the pouring process of the sleeper concrete blocks, the hollow steel tubes are filled with concrete at the same time, so that concrete-filled steel tubes are formed, and accordingly the sleeper connecting parts and the sleeper concrete blocks are integrated through pouring. The concrete-filled steel tubes are applied to the concrete sleeper for the ballastless track, the concrete-filled steel tubes are used as the sleeper connecting parts, and the concrete-filled steel tubes and the sleeper concrete blocks are formed integrally, so that the geometry retention capacity of the sleeper is effectively improved, and steel consumption is reduced; the sleeper has the advantages of being easy to manufacture, high in constructability and the like.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

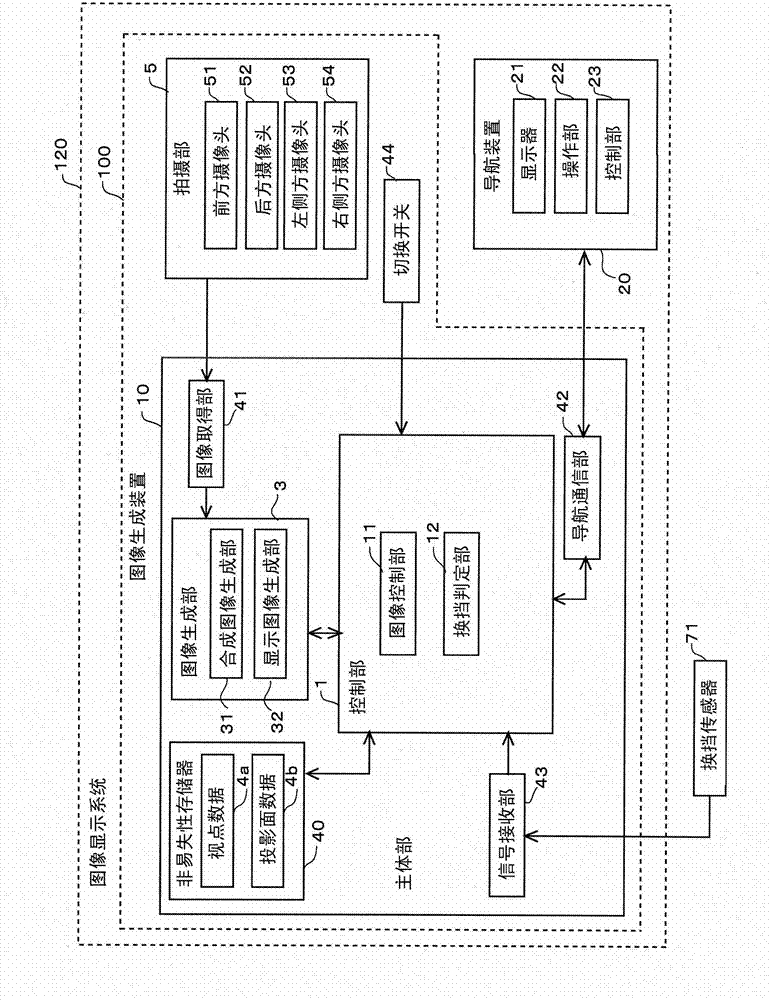

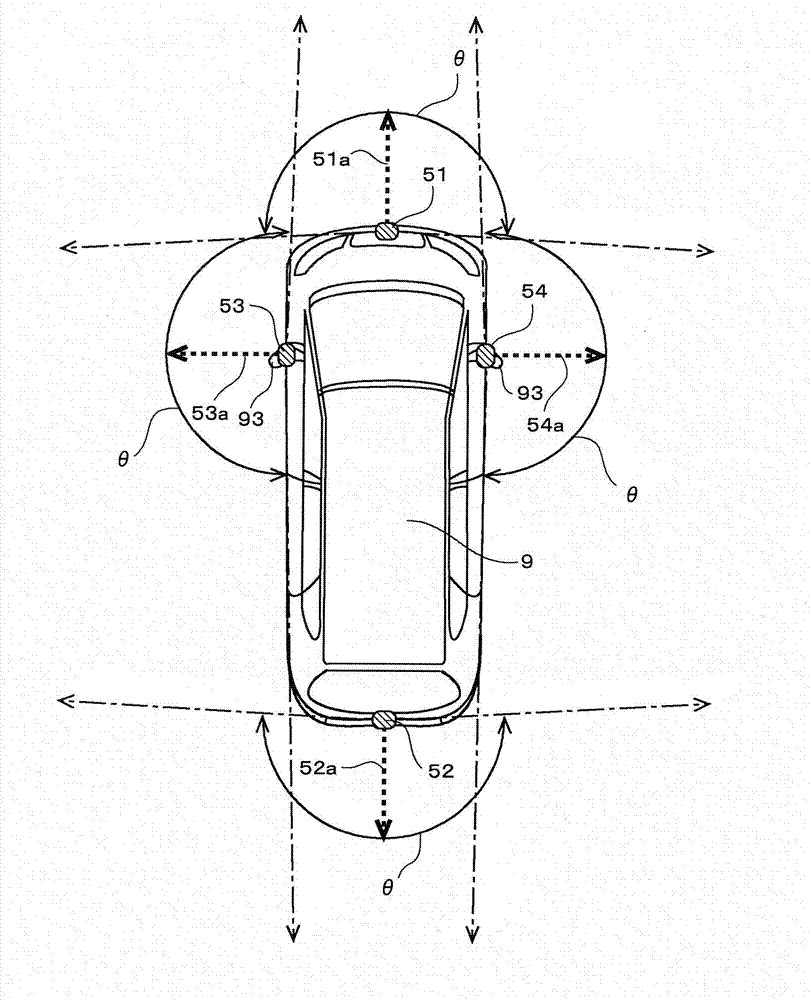

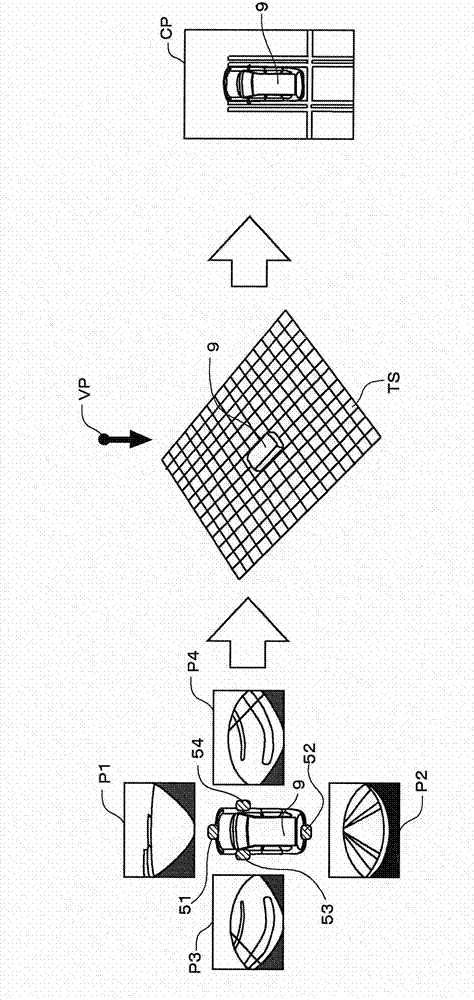

Image generation apparatus and image generation method

ActiveCN102821267AGrasp intuitiveEasy to graspTelevision system detailsColor television detailsViewpointsComputer graphics (images)

The invention provides an image generation apparatus and an image generation method through which a user can notice the object backward that exists in the direction opposite to the traveling direction of the vehicle. Therefore in the image display system, a shift determining part determines the traveling direction of a vehicle (9). The composite image CP1 which is generated by a composite image generator shows a peripheral area (A1) as the periphery of the vehicle (9) and a backward area (A2) as the area behind the vehicle (9) and includes the peripheral area (A1) that centers the image of the vehicle (9) and is viewed from a virtual viewpoint that looks down the vehicle (9). A display displays a display image (DP1) which includes the composite image (CP1). The display image (DP1) includes the composite (CP1) which shows the backward area (A2) which is opposite to the traveling direction of the vehicle (9). The user can notice the object backward that exists in the direction opposite to the traveling direction of the vehicle (9) by looking at the composite image (CP1).

Owner:FUJITSU GENERAL LTD

A Steel Tube Concrete Sleeper Suitable for Ballastless Track

ActiveCN105463948BRelieve deformationMeet the requirements of bending and torsion resistanceBallastwayTrackwayArchitectural engineering

The invention discloses a steel pipe concrete sleeper suitable for ballastless tracks, which comprises two or more sleeper concrete blocks and a sleeper connecting piece for connecting the sleeper concrete blocks, the sleeper concrete block is in a block structure, and is made of concrete It is made by pouring, and there are embedded parts for fixing the rails and steel mesh or stirrups connecting the sleeper connectors; the sleeper connectors are composed of a plurality of hollow steel pipes arranged horizontally between the concrete blocks of the sleeper. During the block pouring process, the hollow steel pipe is filled with concrete at the same time to form the concrete filled steel pipe, and then the sleeper connector and the concrete block of the sleeper are poured into one body. In the invention, the concrete-filled steel tube is applied in the concrete sleeper of ballastless track, the concrete-filled steel tube is used as the connector of the sleeper block, and the concrete-filled steel tube and the concrete block of the sleeper are integrally formed, so as to effectively increase the geometric shape and position retention capacity of the sleeper, reduce the amount of steel, and have the advantages of simple preparation , Strong constructability and so on.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Plant weight reducing enzymes and preparation method thereof

InactiveCN106072519AAchieve balanceGood for weight lossAcidic food ingredientsFood ingredient functionsAmino acid compositionColoring food

The present invention relates to the field of food processing and more particularly relates to plant weight reducing enzymes and a preparation method thereof. The preparation method of the plant weight reducing enzymes comprises the following steps: raw materials are screened, the screened raw materials are crushed, the crushed raw materials are mixed with water, brown sugar, white sugar, apple vinegar and protease are added, the mixture is mixed evenly, and the mixture is subjected to a closed fermentation for 3-6 months; after the fermentation is finished, a solid-liquid separation is conducted to obtain a first fermentation liquid, the first fermentation liquid is purified to obtain a first product, fermentation residues are subjected to a second fermentation to obtain a second fermentation liquid, and the second fermentation liquid is purified to obtain a second product; the first product and the second product are mixed to obtain the plant weight reducing enzymes; and the raw materials are five color food with the efficacies of reducing weight. The provided preparation method of the plant weight reducing enzymes is simple and low in costs. The obtained plant weight reducing enzymes mainly contain substances with special biologically activity and consisting of amino acids, can comprehensively regulate human body to be well, enable the human body to be healthier, at the same time achieve a good effect of weight reducing, and are high in safety.

Owner:北京解脂生物科技有限公司

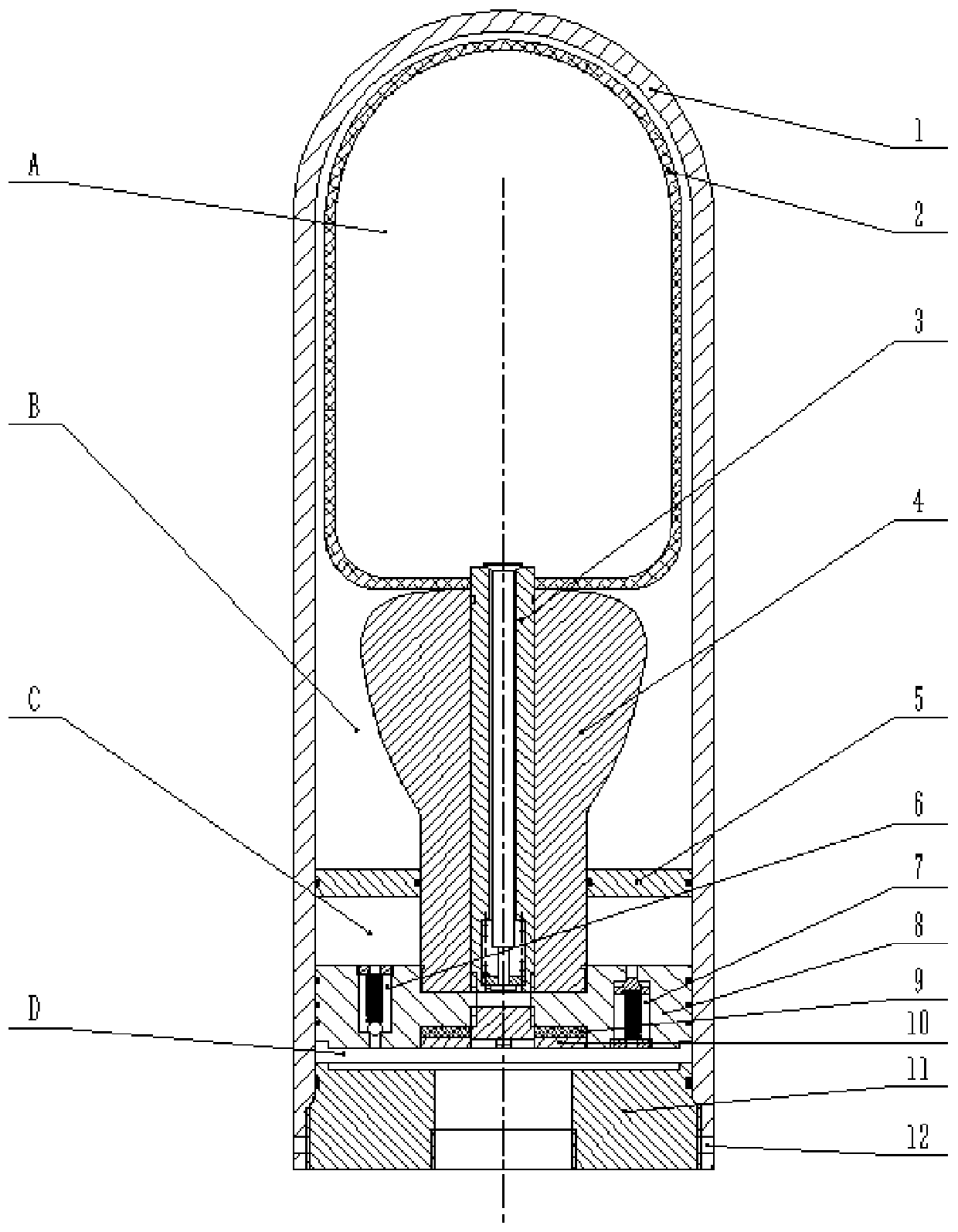

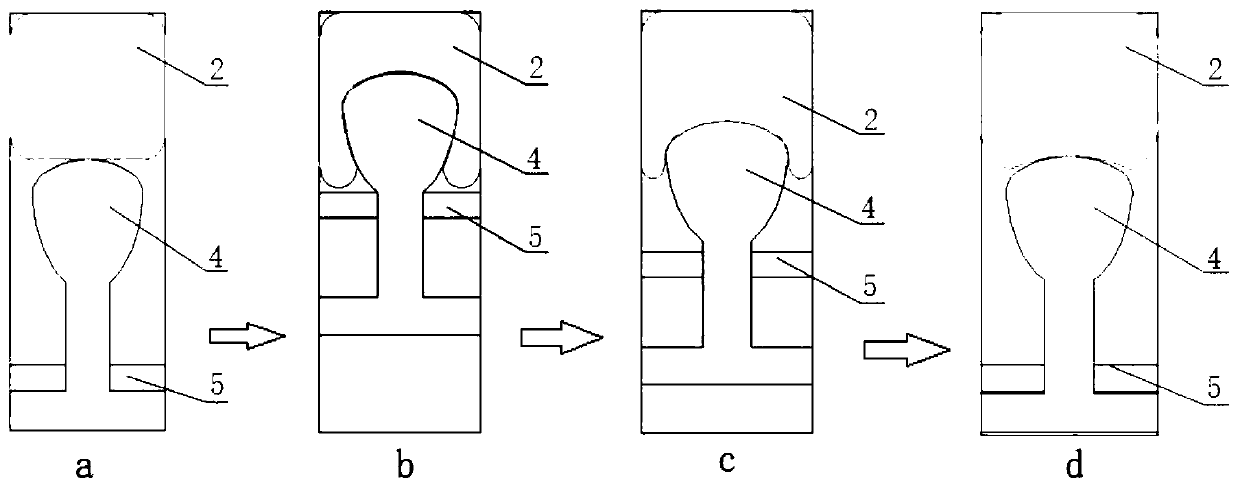

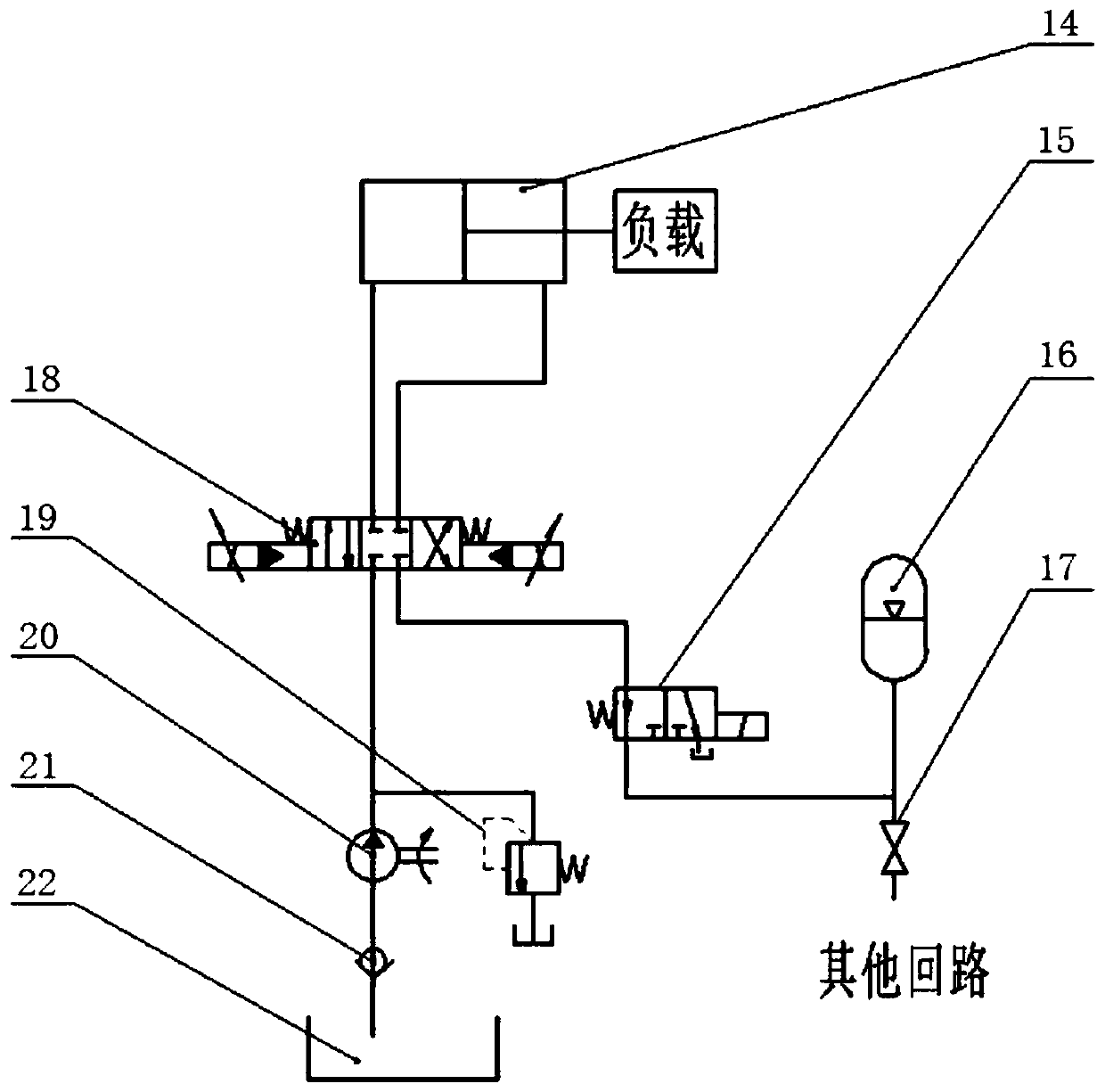

Large-volume leather bag type constant-pressure energy accumulator and application thereof

ActiveCN110374942AGuaranteed deformationRapid responseAccumulator installationsActuator accumulatorsPulp and paper industryPiston rod

The invention relates to a large-volume leather bag type constant-pressure energy accumulator and application thereof. The large-volume leather bag type constant-pressure energy accumulator comprisesa shell and further comprises a leather bag, a variable area piston, a floating piston, a piston and a flange which are arranged in the shell. The floating piston sleeves a piston rod of the variablearea piston. The bottom end of the piston rod of the variable area piston is connected with the piston, and a through hole is formed in the center axes of the variable area piston and the piston, an inflation valve is connected between the through hole and the leather bag, the bottom of the through hole is connected with a cover plate, the piston is provided with a one-way valve I and a one-way valve II, and the flange is connected with the inner wall of the bottom of the shell. The novel large-volume leather bag type constant-pressure energy accumulator has the advantages that leakage is notlikely to happen, the service life is long, inertia is small, the response is sensitive, and the applicable volume range is wide; and the novel large-volume leather bag type constant-pressure energy accumulator can be widely applicable to various hydraulic systems.

Owner:SHANDONG UNIV OF SCI & TECH

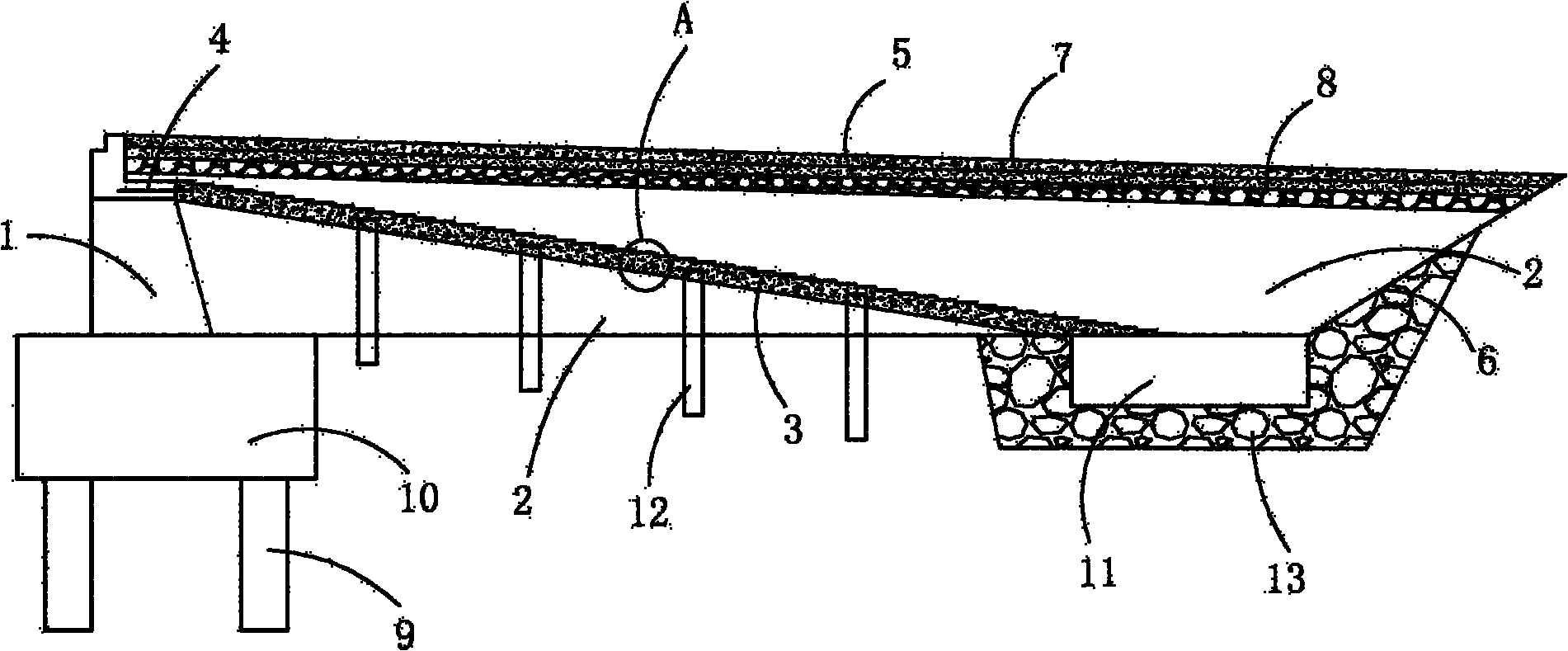

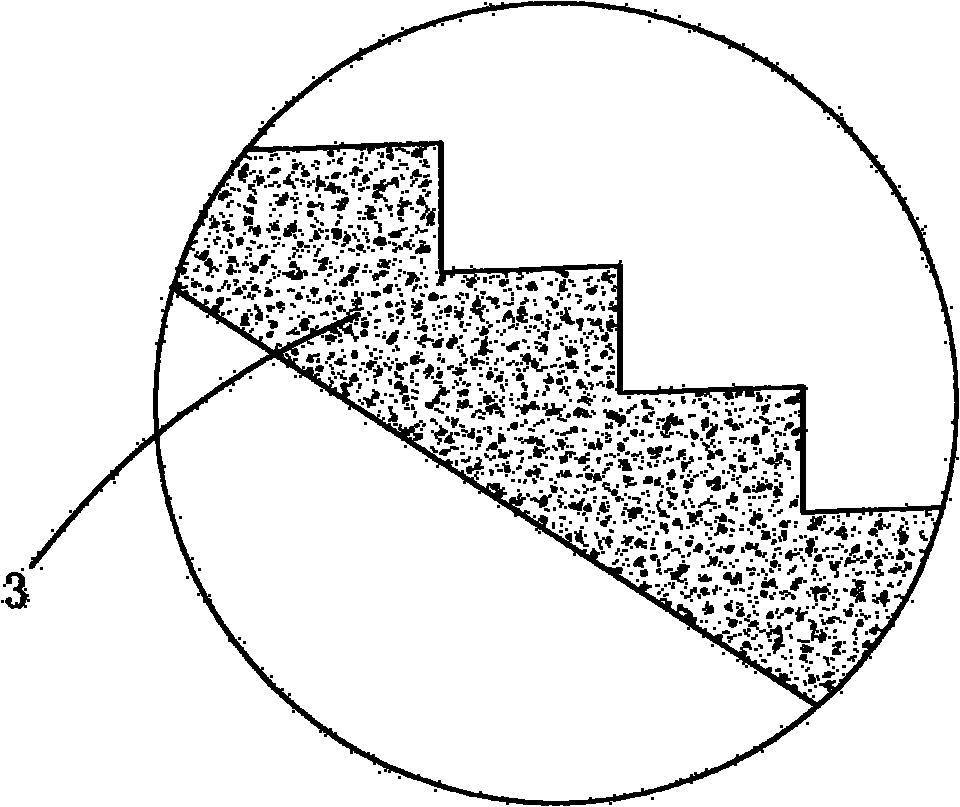

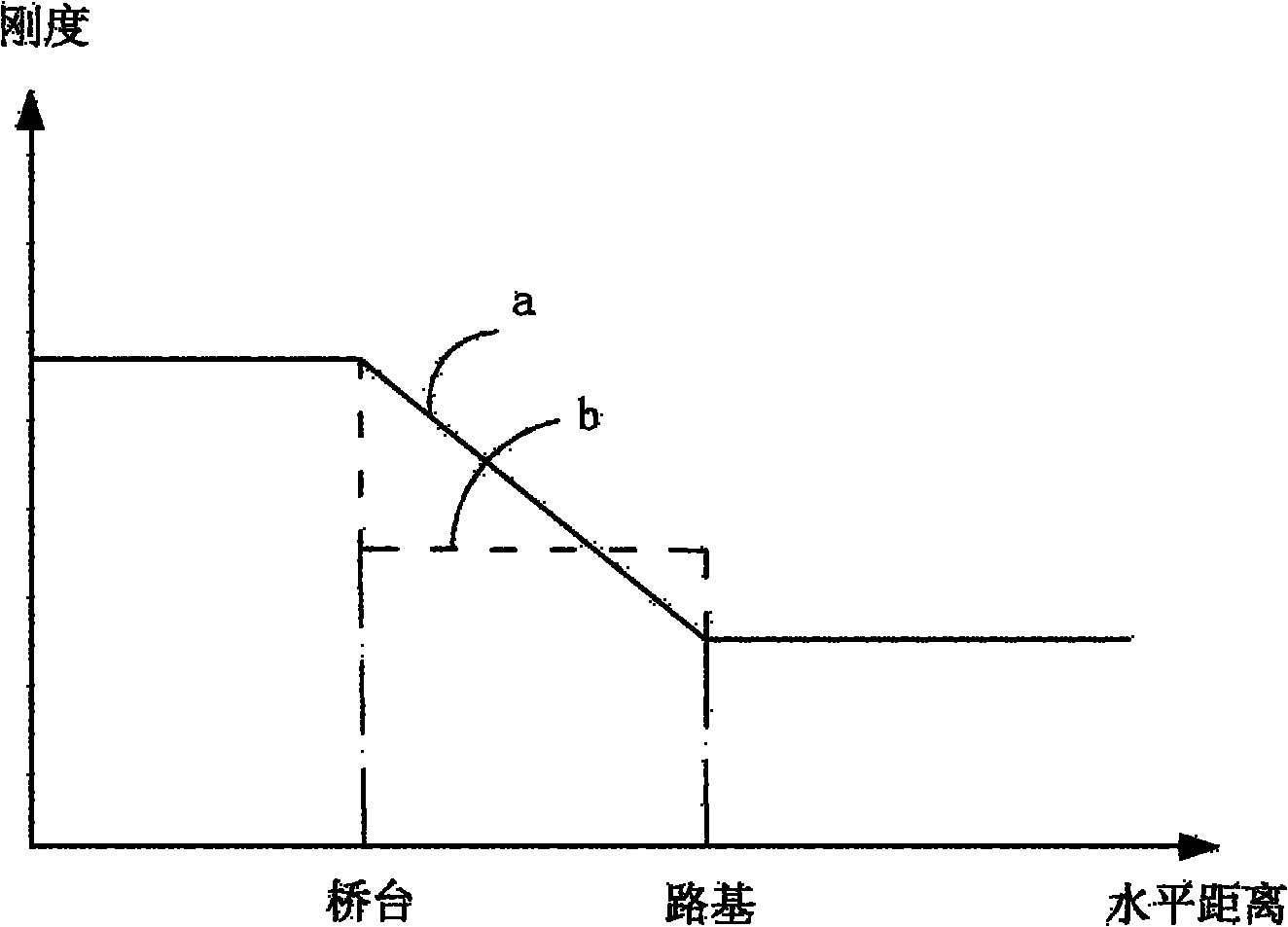

Transition roadway for managing bumping at bridge-head

The invention discloses a transition roadway for managing bumping at bridge-head, which is characterized in that one end of each reinforced concrete hollow slab of which the width is same as that of the roadway is embedded into an abutment with fixed reinforcing steel bars, and the reinforced concrete hollow slabs at the positions at which the fixed reinforcing steel bars locate are buried below a bed course; the other ends of the reinforced concrete hollow slabs are arranged on end strutting pieces closing to the original embankment, so that the reinforced concrete hollow slabs are obliquely arranged between the abutment and the end strutting pieces to form a transition roadway; and stiffness of the reinforced concrete hollow slabs is consistent with that of the abutment. The transition roadway provided by the invention is used, so that settlement and abrupt change of the road surface nearby the bridge head are not caused by continuous settlement, thus fundamentally solving the problem of bumping at bridge-head resulting from the settlement and abrupt change of the road surface.

Owner:合肥工大科教开发部

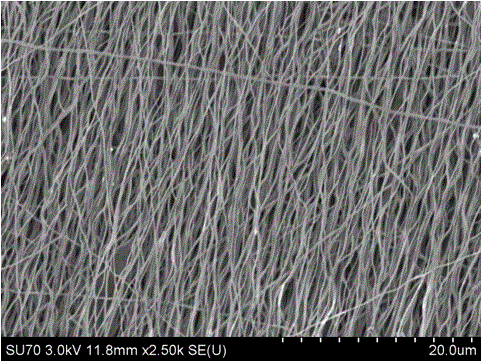

Lithium ion battery self-supporting silicon-based anode material with multilayered film and preparation method of anode material

ActiveCN106058209AGood flexibilityRelieve deformationCell electrodesSecondary cellsInjection volumeMass ratio

The invention discloses a lithium ion battery self-supporting silicon-based anode material with a multilayered film and a preparation method of the anode material. The anode material is made from silicon nano-particles and carbon nano-fibers through compounding, wherein the mass ratio of silicon to carbon is 1:0.5-1:6 and the thickness ratio of a carbon fiber layer to a silicon-carbon compound fiber layer is 1:1-1:5. The preparation method comprises the following steps: dispersing a mixture formed from silicon nano-particles / an organic high-molecular polymer and an organic high-molecular polymer in an organic agent, respectively, and performing fully stirring to obtain an uniform suspension and solution; through control of the injection volume and time of electrostatic spinning, obtaining a multilayered periodic structure of carbon-carbon silicon compound-carbon-carbon silicon compound...-carbon; and performing carbonization treatment in the protective atmosphere to obtain the lithium ion battery self-supporting silicon-based anode material with a multilayered film. The anode material has characteristics of self-supporting, high capacity, good cyclic stability and simple preparation.

Owner:ZHEJIANG UNIV

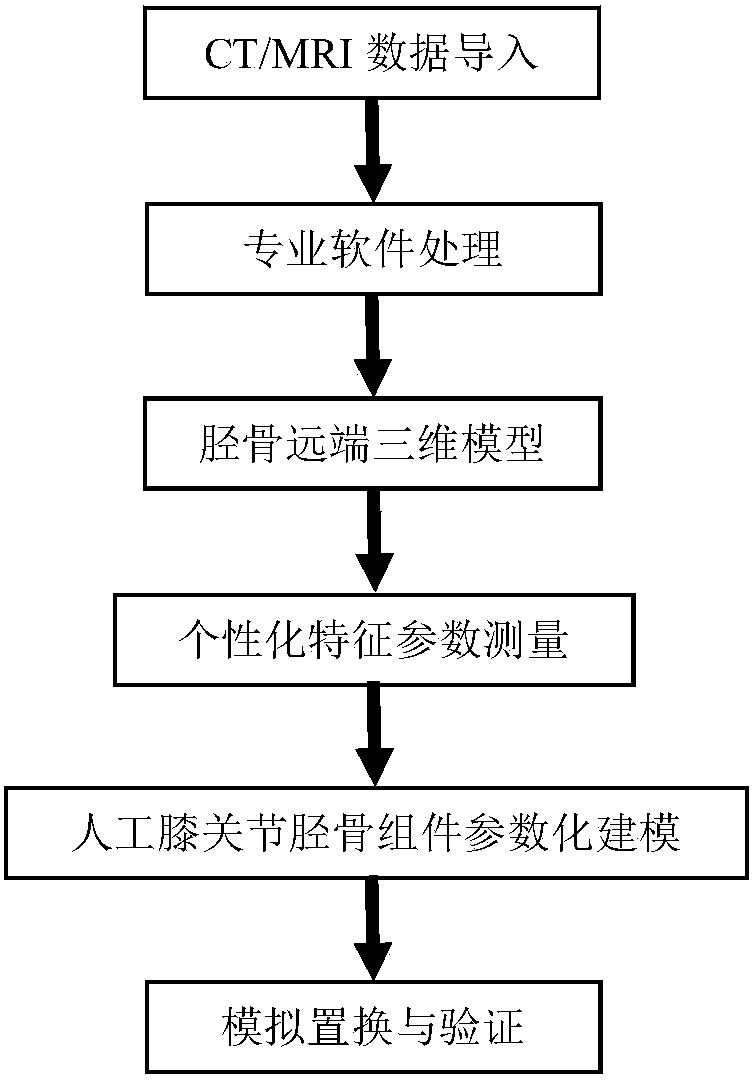

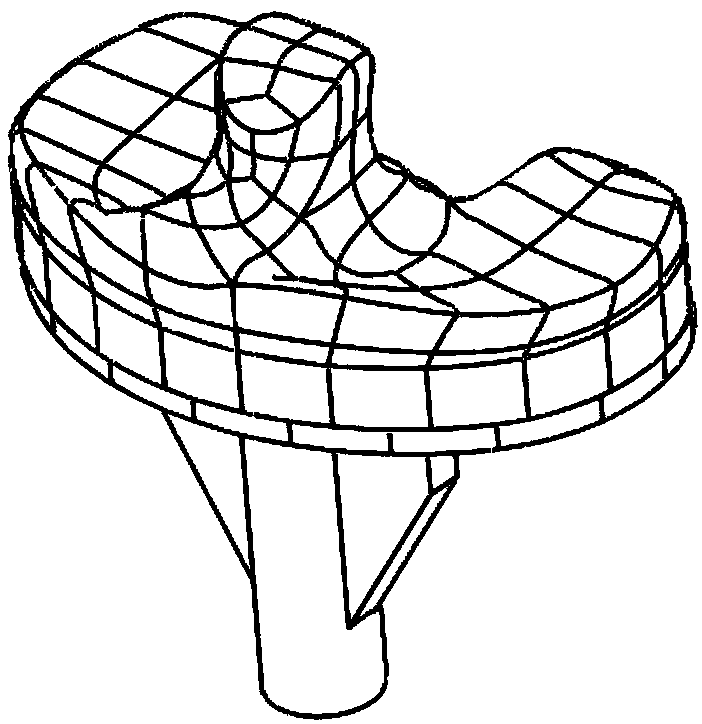

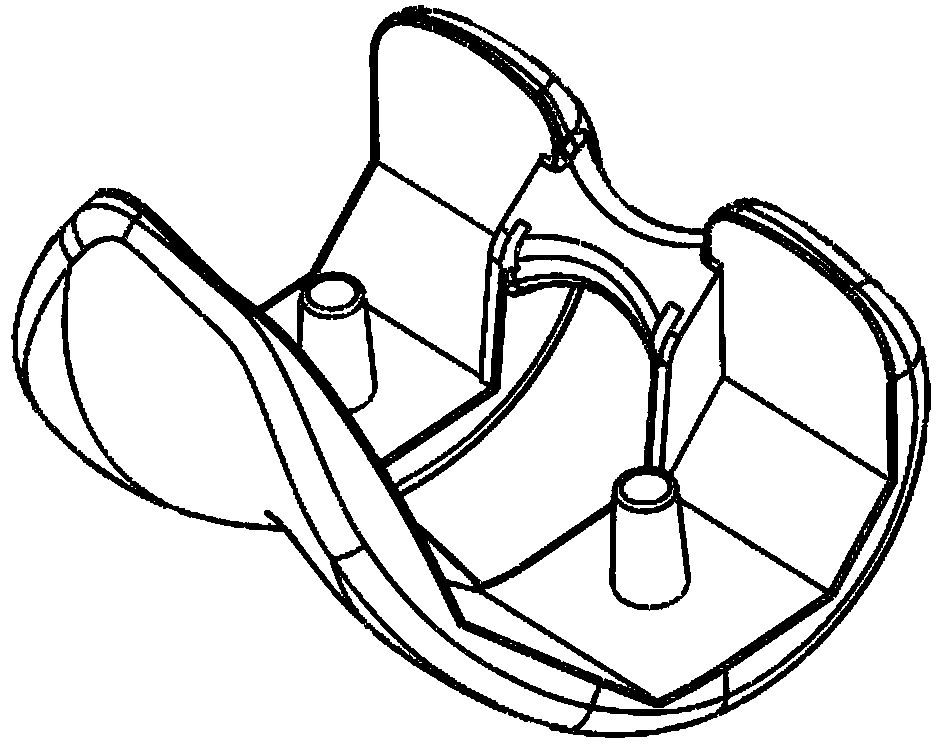

Method for precisely customizing knee joint prosthesis

InactiveCN107822745AReduce wearSmooth transitionJoint implantsKnee jointsHuman bodyPhysical medicine and rehabilitation

The invention relates to the field of medical instruments, in particular to a method for precisely customizing a knee joint prosthesis. The method for precisely customizing the knee joint prosthesis specifically comprises the steps of data entry, software processing, construction of a three-dimensional model of a knee joint prosthesis assembly, personalized feature parameter measurement, parametric modeling, simulation replacement and verification. The knee prosthesis comprises a femoral component and / or a tibial component. According to the method, a simple data image is used for acquiring personalized feature parameters of the knee joint prosthesis of the human body, and the method is simple, easy to use and capable of meeting production and clinical practical requirements at the same time.

Owner:李威

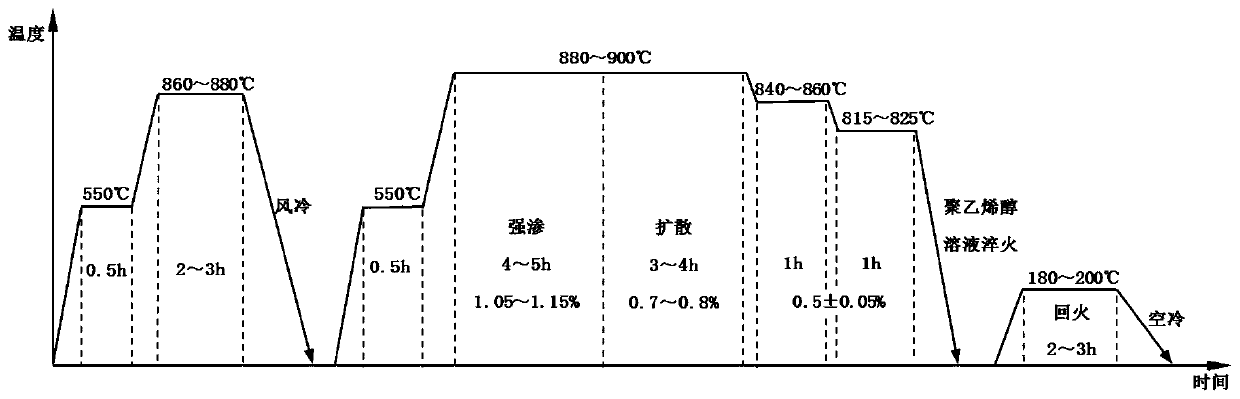

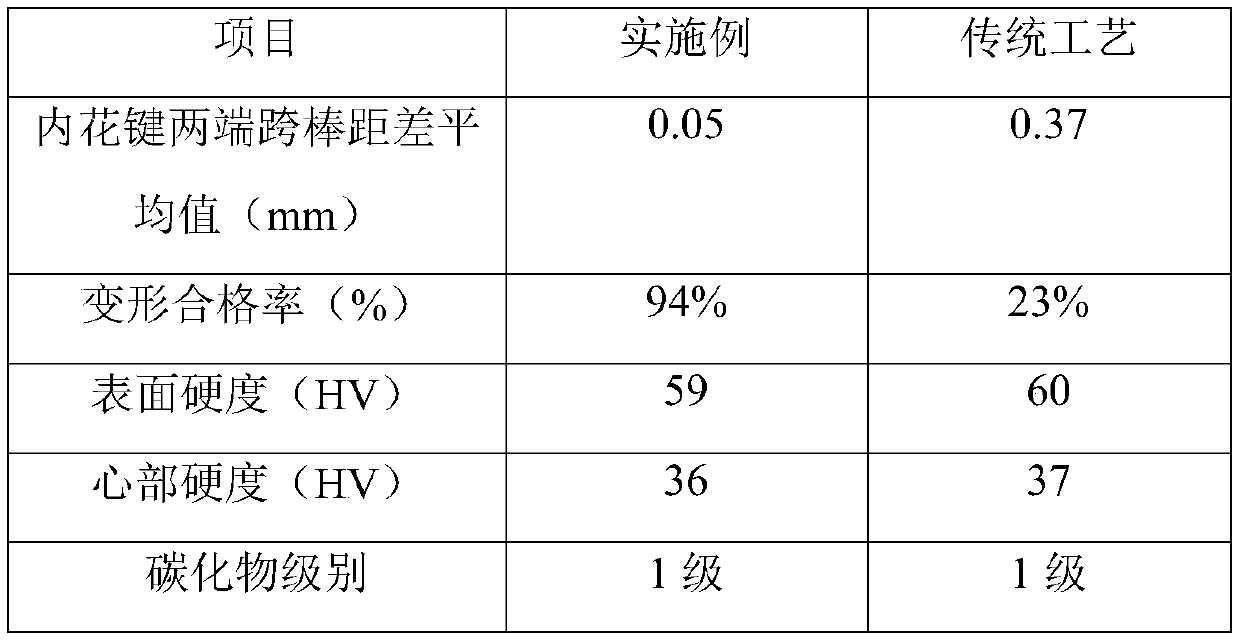

Sub-temperature carburizing heat treatment method for reducing heat treatment deformation of thin-wall gear

ActiveCN111020455AReduce the impact of uniformityIncreased speed of penetration into gear surfacesSolid state diffusion coatingFurnace typesCarbon potentialTempering

The invention relates to a sub-temperature carburizing heat treatment method for reducing heat treatment deformation of a thin-wall gear. The method comprises the following steps of S1, pre-sub-temperature normalizing; S2, slow speed shot blasting; S3, sub-temperature carburization, specifically, gradient heating is adopted to a sub-temperature carburizing temperature, a two-stage carburizing method is adopted in the sub-temperature carburizing process, the first stage is a strong carburizing stage, and the second stage is a diffusion stage; S4, gradient slow cooling quenching, specifically, firstly, gradient slow cooling is carried out on a carburized thin-wall gear forging to 840-860 DEG C, heat preservation is carried out for about 1h, then the slow cooling is continuously carried out to 815-825 DEG C, the heat preservation is carried out for about 1h, the carbon potential in the furnace is controlled to be 0.5-0.05%, and then quenching is carried out in a polyvinyl alcohol solution; and S5, low-temperature tempering. According to the method, the deformation degree of a gear workpiece can be greatly reduced, the production qualification rate can be obviously improved, meanwhile,crystal grains can be effectively refined, the hardness and strength of a gear can be improved, the service life of the gear can be obviously prolonged, and in addition, the refined crystal grains can obviously improve the carburizing speed, reduce the process time and reduce the energy consumption.

Owner:WUHAN UNIV OF TECH

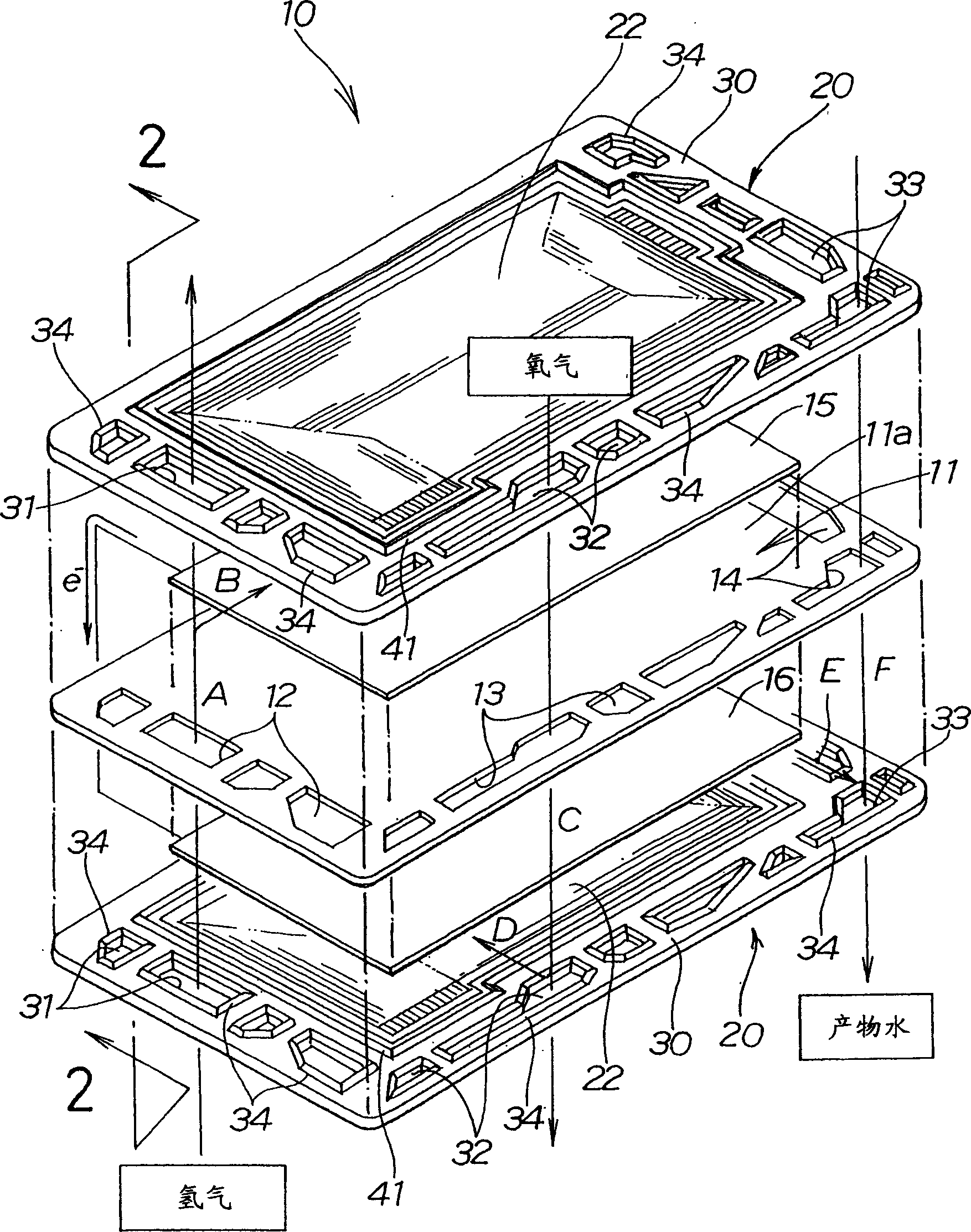

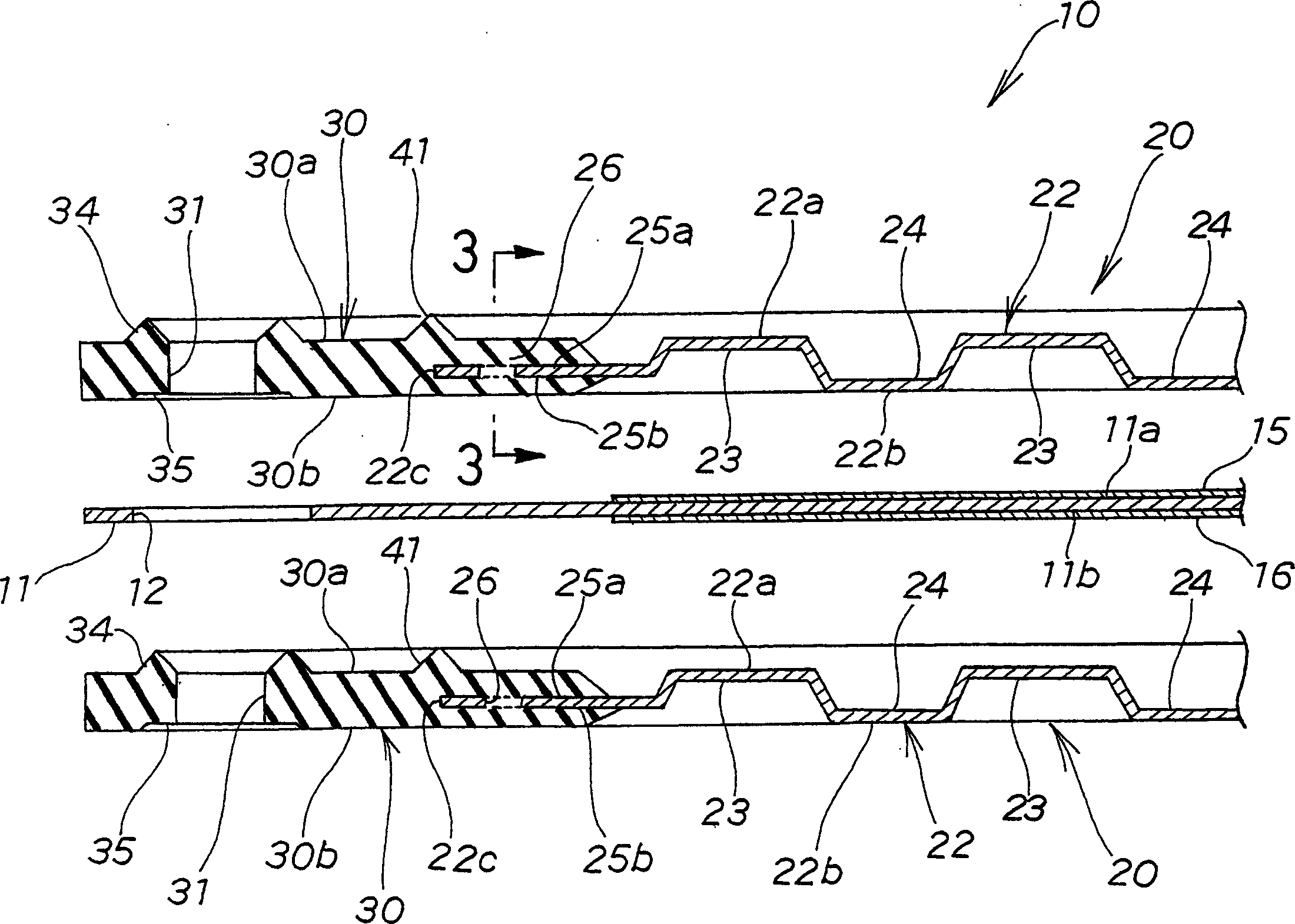

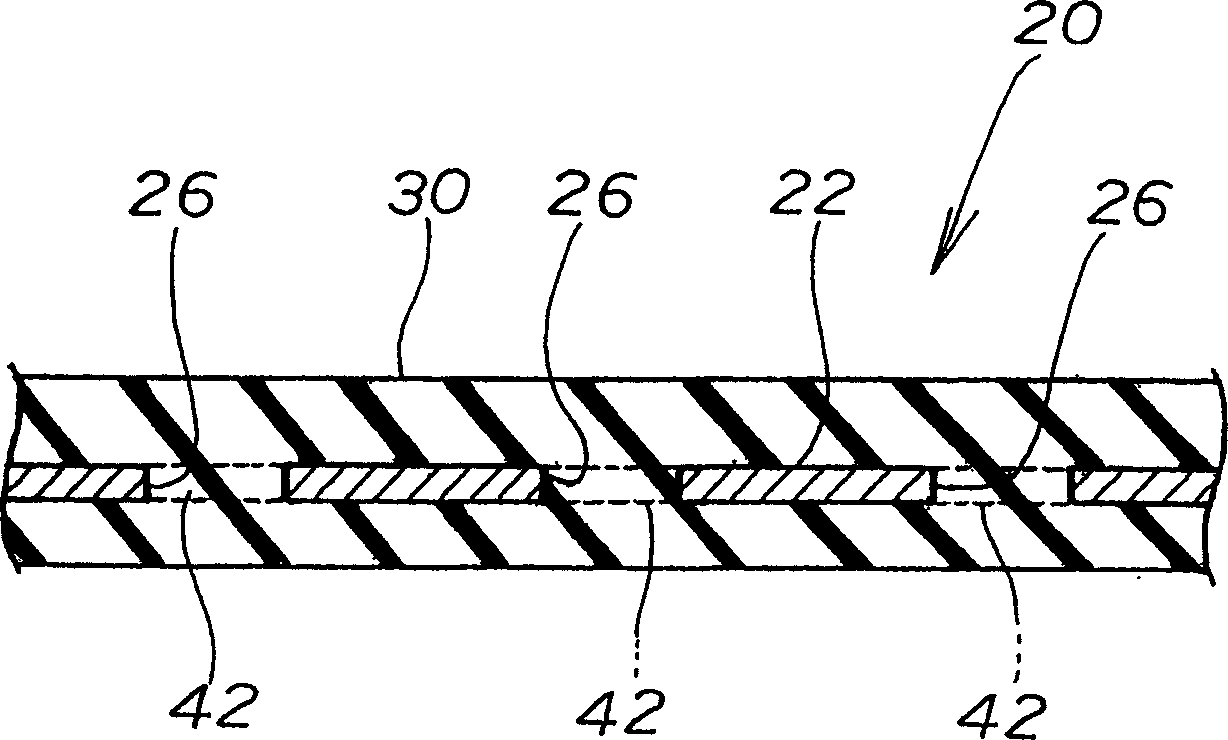

Fuel cell separator and method of manufacturing the separator

InactiveCN1666370ALow costIncrease productionFinal product manufactureCell component detailsFuel cellsEngineering

A fuel cell separator ( 20 ) having a central part ( 22 ) and an outer peripheral part ( 30 ). The central part is a metal member made of stainless steel or the like. Multiple gas passages ( 31, 32 ) and multiple product water passages ( 33 ) are formed in the peripheral part. To ensure corrosion resistance of the gas passages and the product water passages, the peripheral part is a rubber member made of silicone rubber. A projecting central seal part ( 41 ) for surrounding the central part is formed integrally with the peripheral part.

Owner:HONDA MOTOR CO LTD

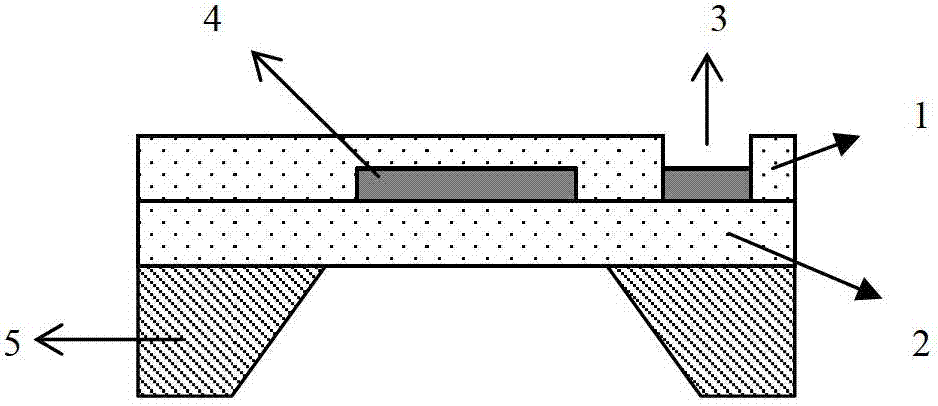

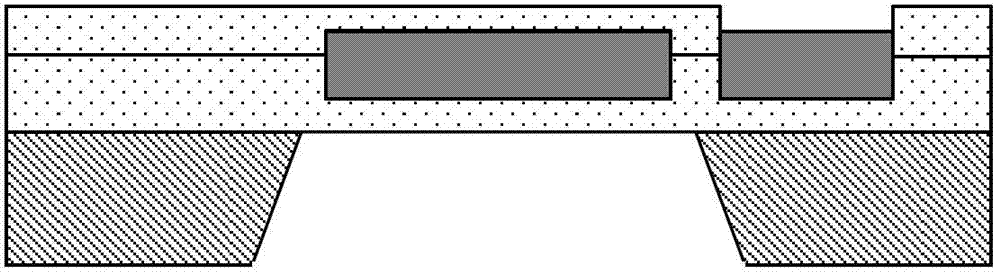

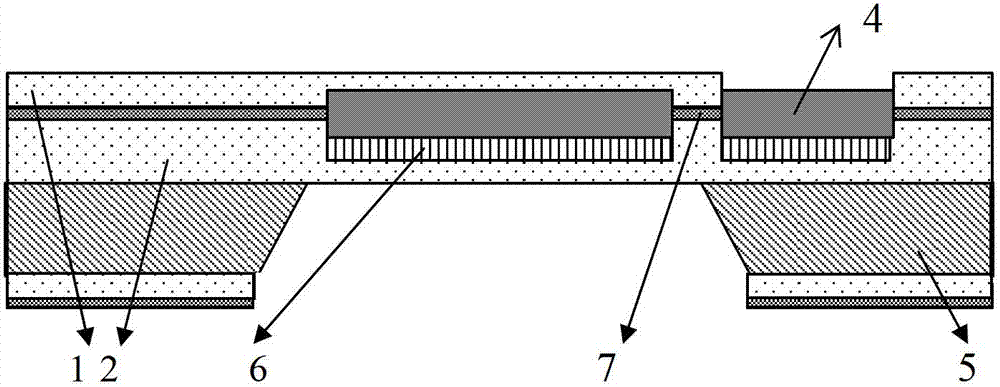

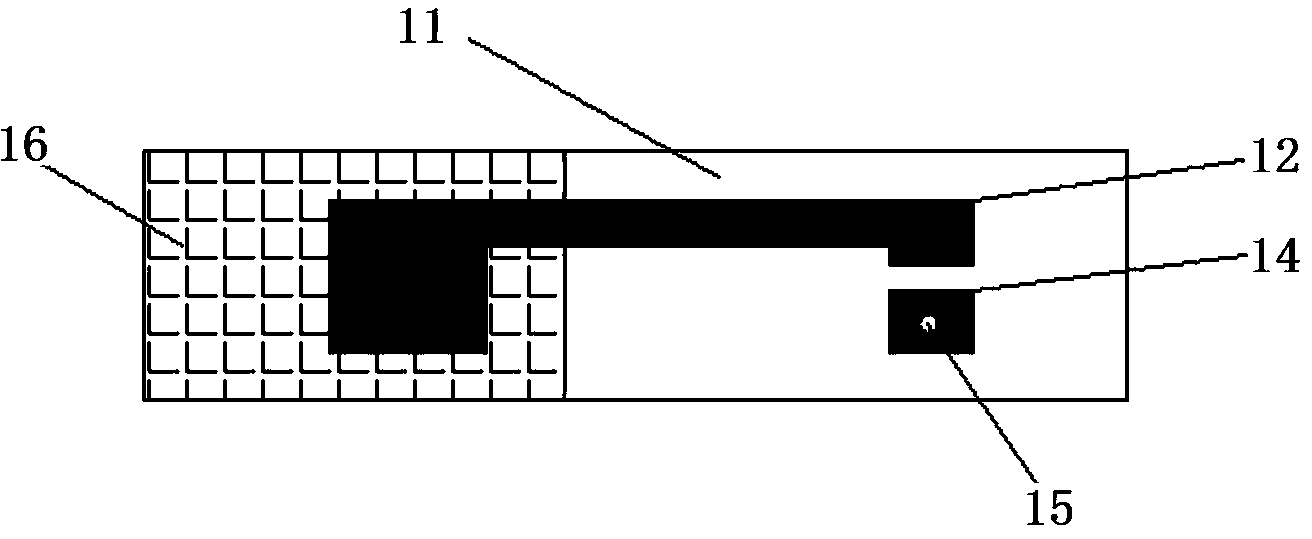

Silicon-based micro-heating plate provided with embedded heating wire, and processing method thereof

ActiveCN102730621AEasy to processReduce the stress of warping deformationDecorative surface effectsSolid-state devicesEngineeringThermal expansion

The invention discloses a silicon-based micro-heating plate provided with an embedded heating wire, and a processing method of the silicon-based micro-heating plate; and the micro-heating plate is prepared by silicon-based material and can be easily realized by a processing technology of a micro-electromechanical system (MEMS). The silicon-based micro-heating plate and the processing method are characterized in that based on the traditional 'sandwich' structure, the heating wire is embedded into a substrate insulating film layer, so that the influence to the stability of a device caused by thermal stress generated by the mismatch between the heating wire and the coefficient of thermal expansion of the insulating film layer can be reduced by the restraining function of the surrounding dense insulating film layer for the heating wire, and the influence of electromigration to the deformation of the heating wire can be effectively relieved; and therefore, the stability of the micro-heating plate can be improved during high-temperature work.

Owner:有光(常州)电子科技有限公司

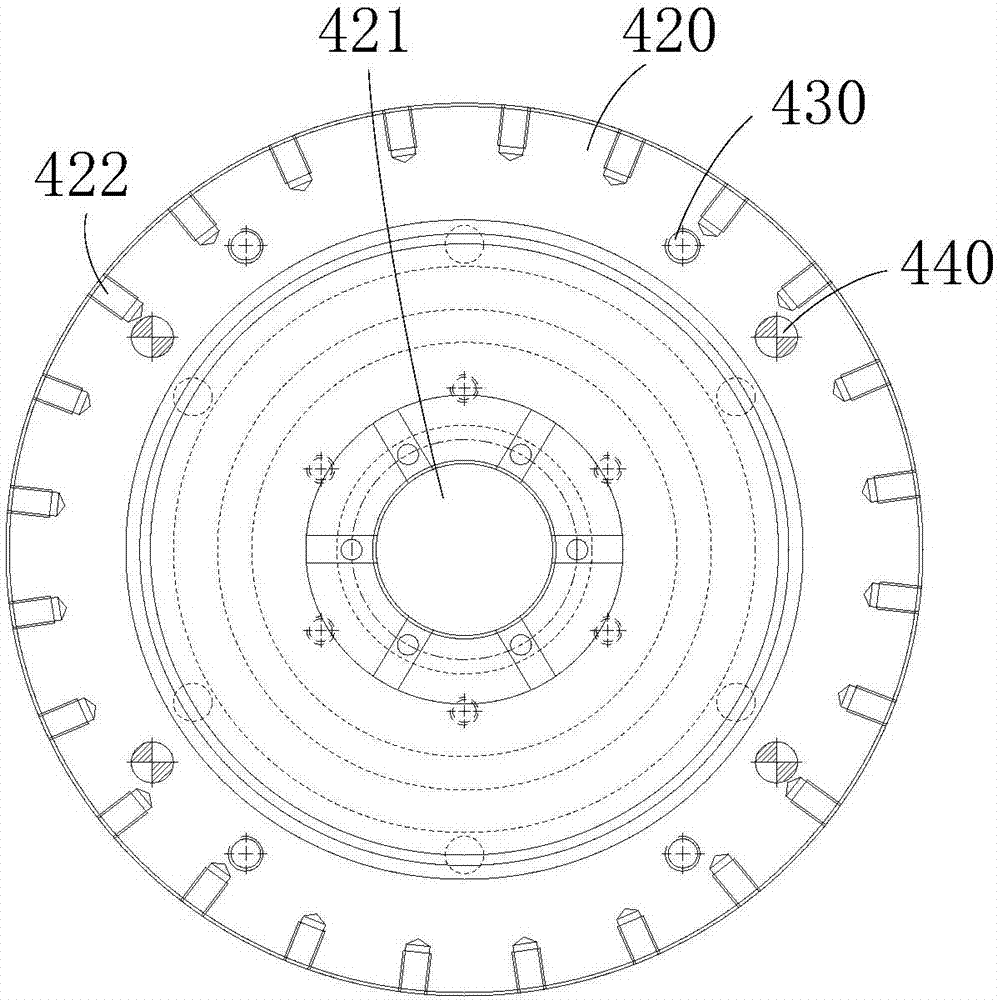

Step-by-step type arc-shaped nail bin

PendingCN113749713AImprove stitching effectIncrease the scope of application of sutureSurgical staplesEngineeringMechanical engineering

The invention relates to a step-by-step type arc-shaped nail bin which comprises a nail bin body, the nail bin body comprises a first closing part, the first closing part is used for being matched with a baffle extending into a cavity and conducting pressure suturing on the cavity, and the cross section of the part, matched with the first closing part, of the cavity is made to be in an arc shape during suturing. According to the scheme, when a cavity is sutured, a cavity part needing to form a channel is placed on the first closing part, and the baffle matched with the first closing part extends into the cavity of a patient, so that the first closing part and the baffle interact to apply pressure to suture cavity tissue, the cross section of the part, matched with the first closing part, of the cavity is in an arc shape, the defect that linear cutting and sewing are adopted for the cavity is overcome, the degree of stretching the cavity needing to form a channel to a flat shape in the sewing process is greatly reduced, the sewing effect is improved, and an annular channel capable of taking the separated tissues out of the cavity is formed in the cavity.

Owner:THE WEST CHINA SECOND UNIV HOSPITAL OF SICHUAN

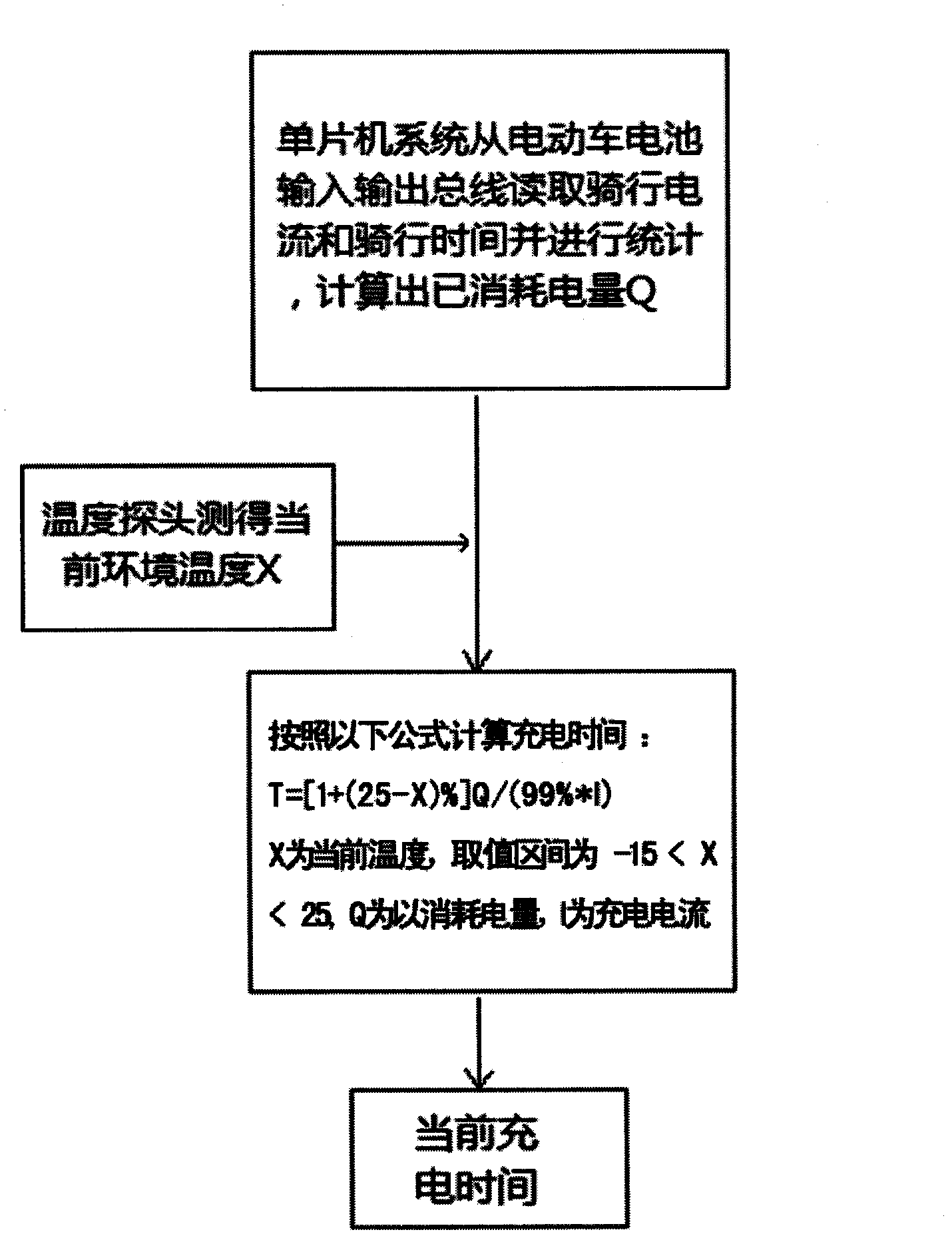

Automatic time-control charging method and intelligent charging device of electric bicycle

InactiveCN102361102ARelieve vulcanizationRelieve deformationBatteries circuit arrangementsSecondary cells charging/dischargingMicrocontrollerEngineering

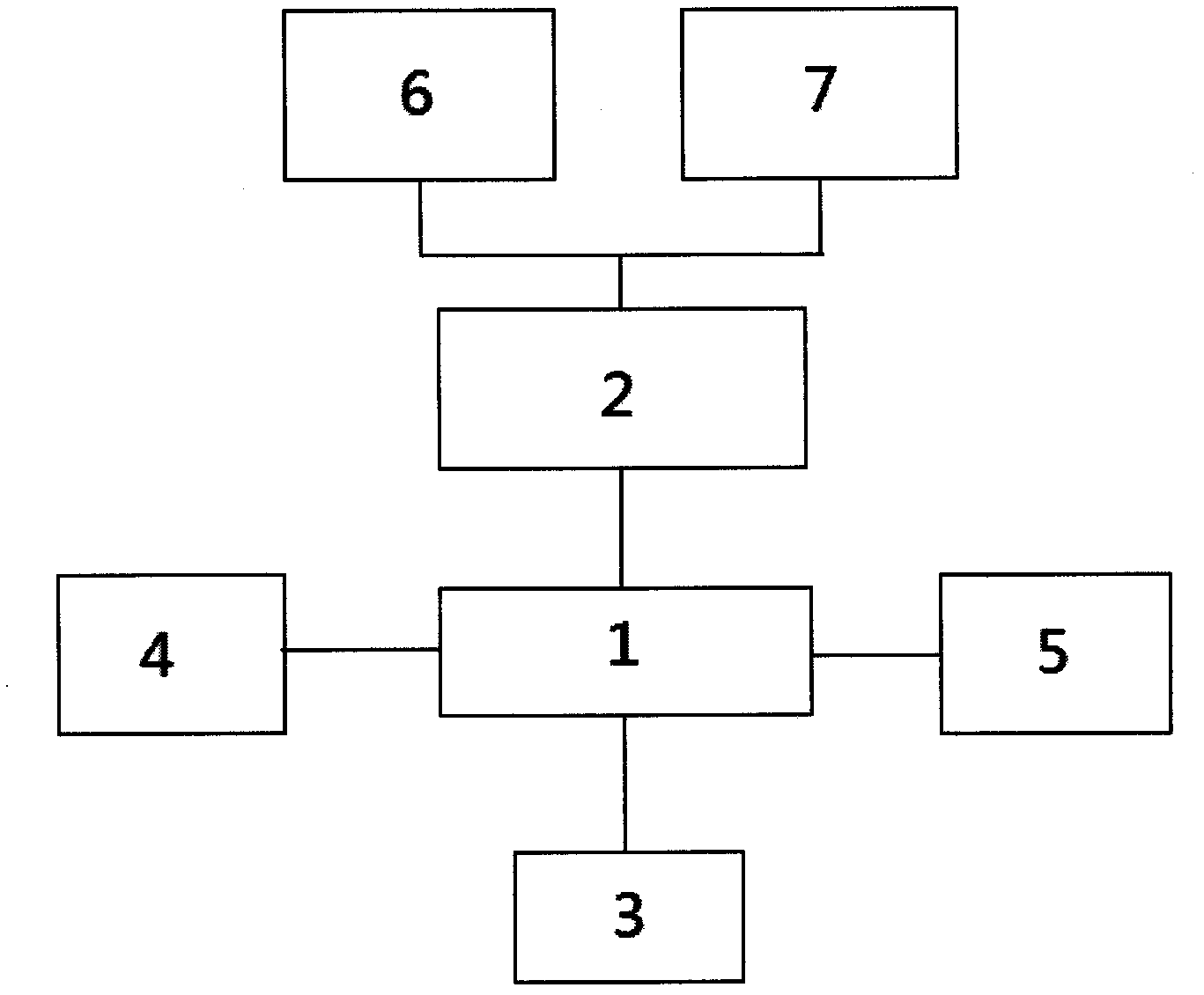

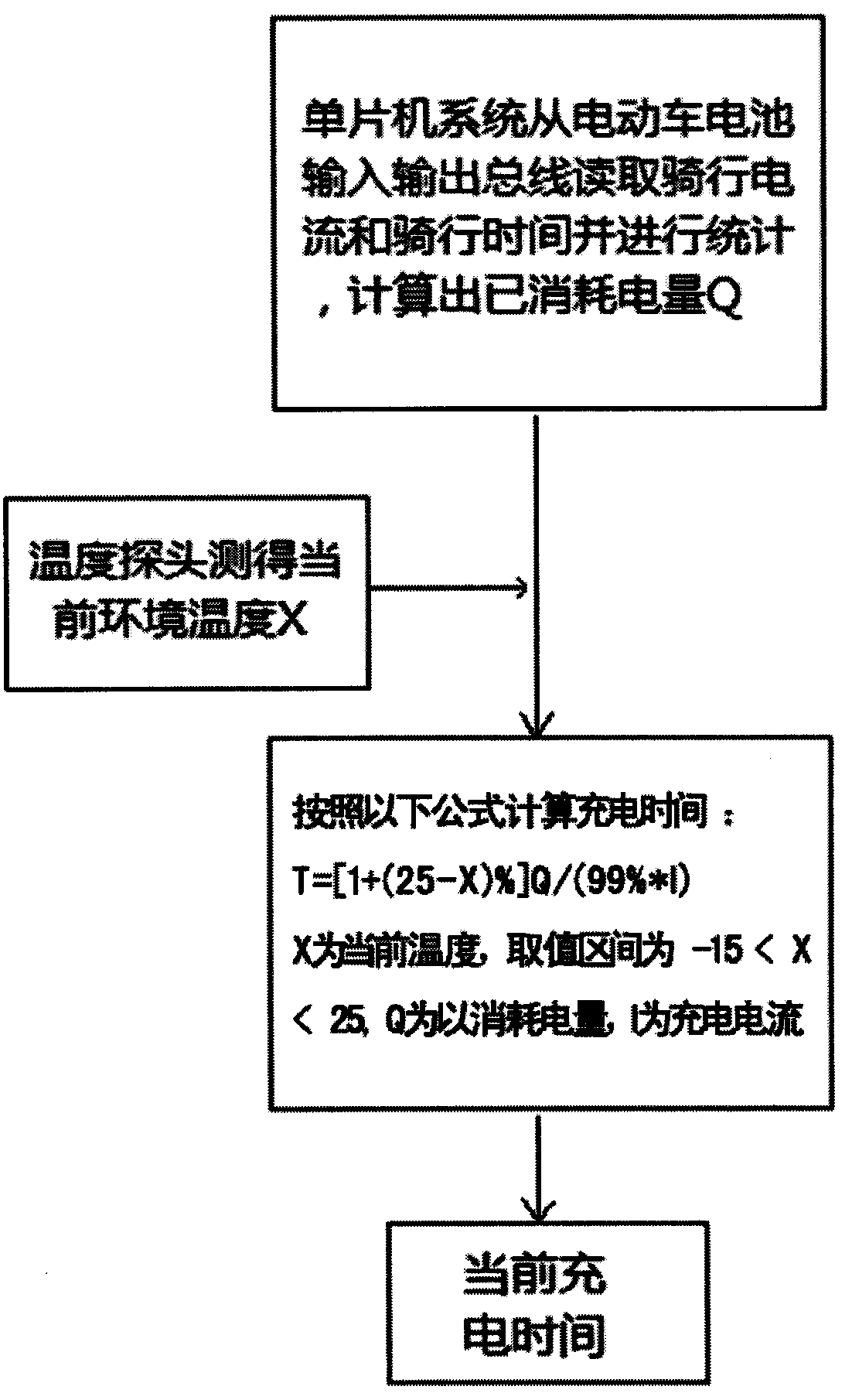

The invention relates to a charging method and equipment of an electric bicycle, in particular to an automatic time-control charging method and an intelligent charging device of the electric bicycle. The automatic time-control charging method comprises the following steps of: reading riding current and riding time from an input / output bus of an electric bicycle battery through utilizing a single chip system and performing the statistic, meanwhile, obtaining a temperature of the current environment and calculating the change of a battery capacity, and finally, calculating electric quantity needing to be supplemented; and through comprehensively considering factors including air temperature, energy conversion efficiency and the like, calculating the charging time by using the following formula: T=[1+(25-X)%]Q / (99%I), namely obtaining the current charging time. The intelligent charging device comprises a charger with a time-control relay; the electric bicycle is internally provided with the single chip system which is used for calculating the charging time of the electric bicycle; a signal input end of the single chip system is respectively connected with the input / output bus of the electric bicycle battery and a temperature probe through data lines; a signal output end of the single chip system is connected with the input / output bus of the electric bicycle battery and the temperature probe through the data lines of the charger; and the switching-on or switching-off of a working circuit of the charger is controlled through using the time-control relay.

Owner:刘先金

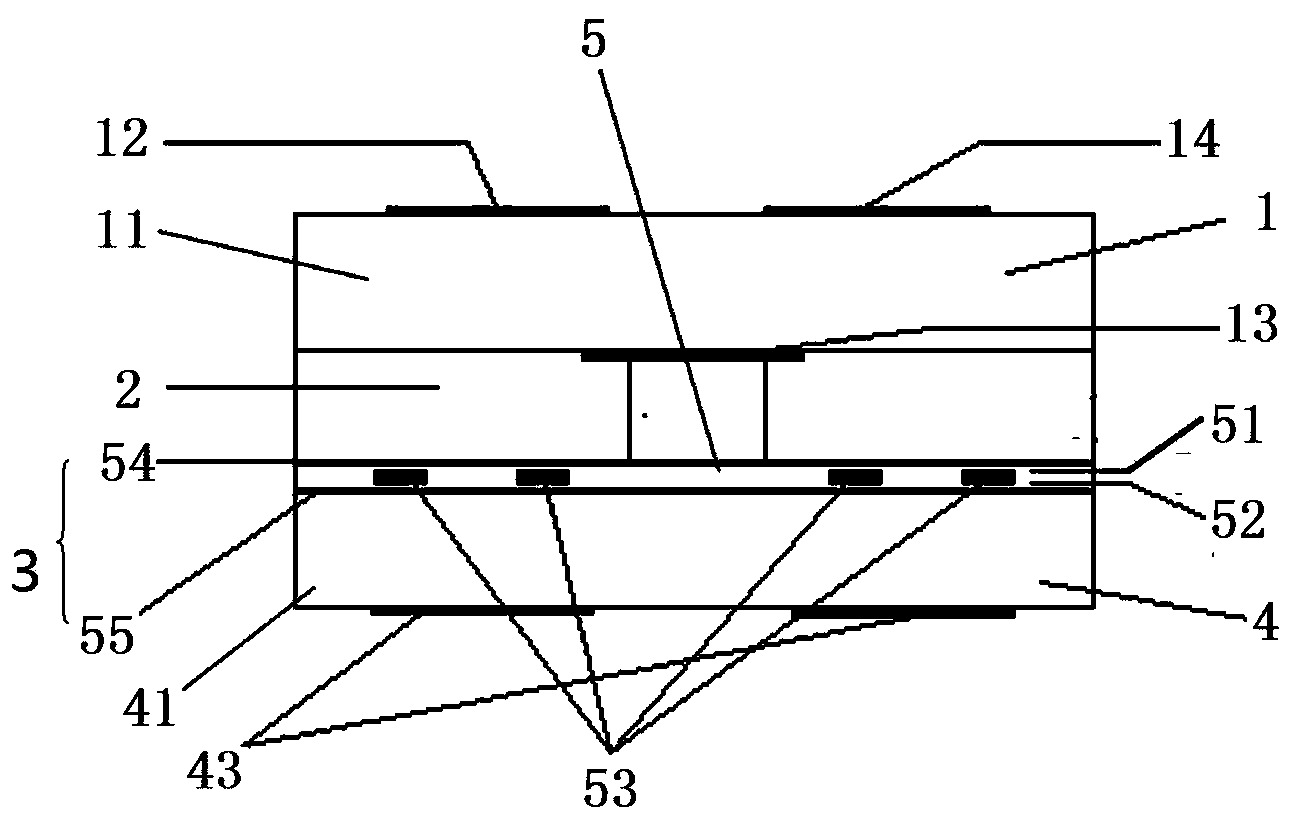

Dustproof structure for MEMS device and MEMS microphone packaging structure

The invention discloses a dustproof structure for an MEMS device and an MEMS microphone packaging structure. The dustproof structure for the MEMS device comprises a grid film and a carrier, wherein the grid membrane is provided with a fixed connection area, a buffer area and an acoustic transmission area, the buffer area surrounds the acoustic transmission area, the fixed connection area surroundsthe buffer area, the fixed connection area is located on the edge of the grid membrane, and a through hole penetrating through the grid membrane is formed in the buffer area; the carrier is providedwith a through opening, the carrier is connected to one side of the fixed connection area, and the position of the opening corresponds to the positions of the buffer area and the sound transmission area.

Owner:WEIFANG GOERTEK MICROELECTRONICS CO LTD

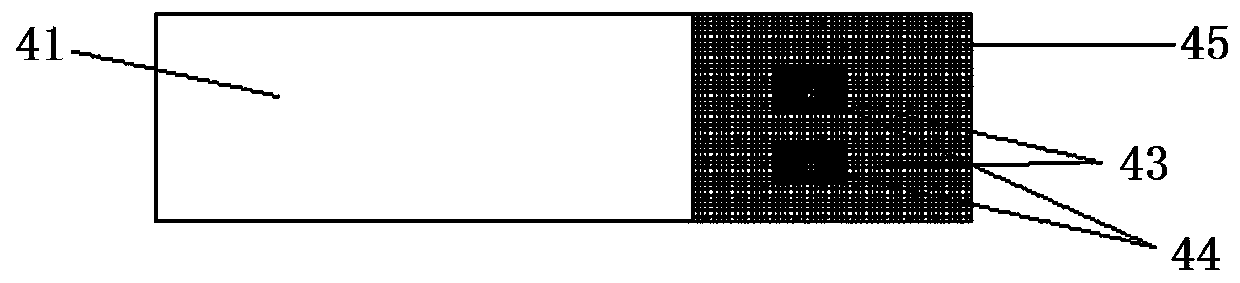

Novel sheet-type oxygen sensor

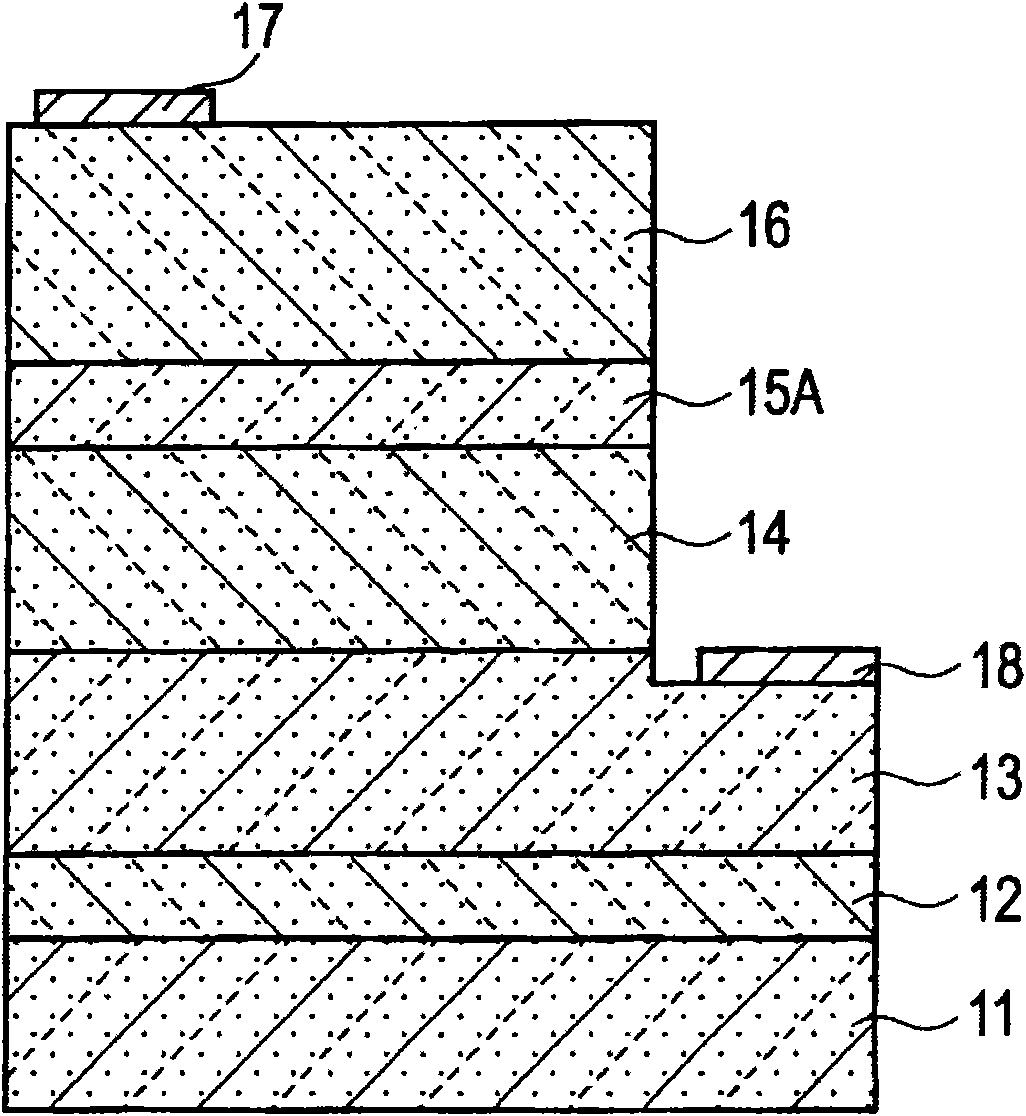

InactiveCN104297319AImprove adhesionRelieve deformationMaterial analysis by electric/magnetic meansInsulation layerOxygen sensor

Disclosed is a novel sheet-type oxygen sensor including, in a top-to-bottom successively arranging manner, a sensitive element layer, an air path layer and a heating layer, wherein the heating layer is composed of a heating substrate layer and a heating electrode insulating layer arranged above the heating substrate layer. The heating electrode insulating layer comprises an upper insulating sheet and a lower insulating sheet and a heating electrode clamped therebetween. An upper transition layer is arranged above the upper insulating sheet and a lower transition layer is arranged below the lower insulating sheet. In the sheet-type oxygen sensor, the insulation layers and the transition layers are added so that drying times during printing are reduced and processing time is saved. Meanwhile, a problem of drying crack caused by overmuch printing layers is solved. By means of the addition of the transition layers, a binding property between the insulating layers and zirconium oxide layers are enhanced so that deformation and cracking due to different thermal-expansion coefficients of the two different materials during sintering, thereby greatly improving product yield.

Owner:苏州衡业新材料科技有限公司

Method for connecting graphite and stainless steel through high-temperature brazing of composite gradient intermediate layer

ActiveCN112620851AAvoid formingGood mechanical propertiesSoldering auxillary devicesSS - Stainless steelGraphite

The invention relates to a high-temperature brazing connection method for graphite and stainless steel. The high-temperature brazing connection method for the graphite and the stainless steel comprises the steps of selecting amorphous TiZrNiCu foil brazing filler metal, a Ti foil, an amorphous BNi-2 brazing filler metal foil and an Ni foil as brazing materials; after cleaning the graphite, the stainless steel, the amorphous TiZrNiCu foil, the Ti foil, the amorphous BNi-2 foil and the Ni foil, forming a graphite / amorphous TiZrNiCu foil / Ti foil / amorphous BNi-2 foil / Ni foil / amorphous BNi-2 foil / stainless steel sandwich structure; and placing the structure in a vacuum furnace, increasing the temperature to 980 to 1080 DEG C at the speed of 5 to 8 DEG C / min, conducting heat preservation for 60 to 120 min, conducting brazing connection, and then conducting sectional heat preservation and slow cooling to the room temperature. The problems of serious mismatching and wettability of the thermal expansion coefficients of the graphite and the stainless steel are effectively solved, the thermal stress of a joint is greatly reduced, cracks are prevented from being generated in the joint area, and good connection of the graphite and the stainless steel is achieved.

Owner:XIANGTAN UNIV +1

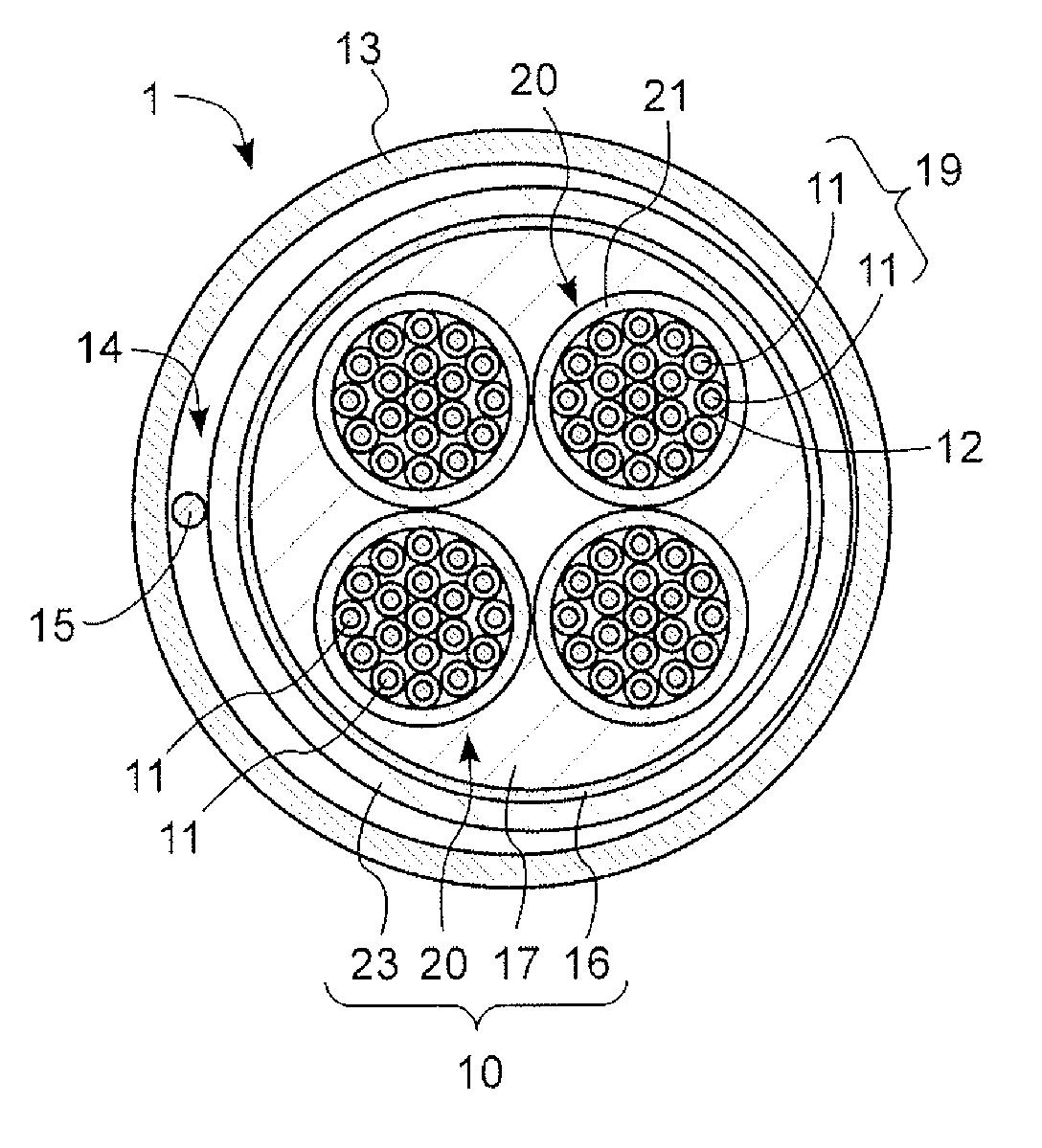

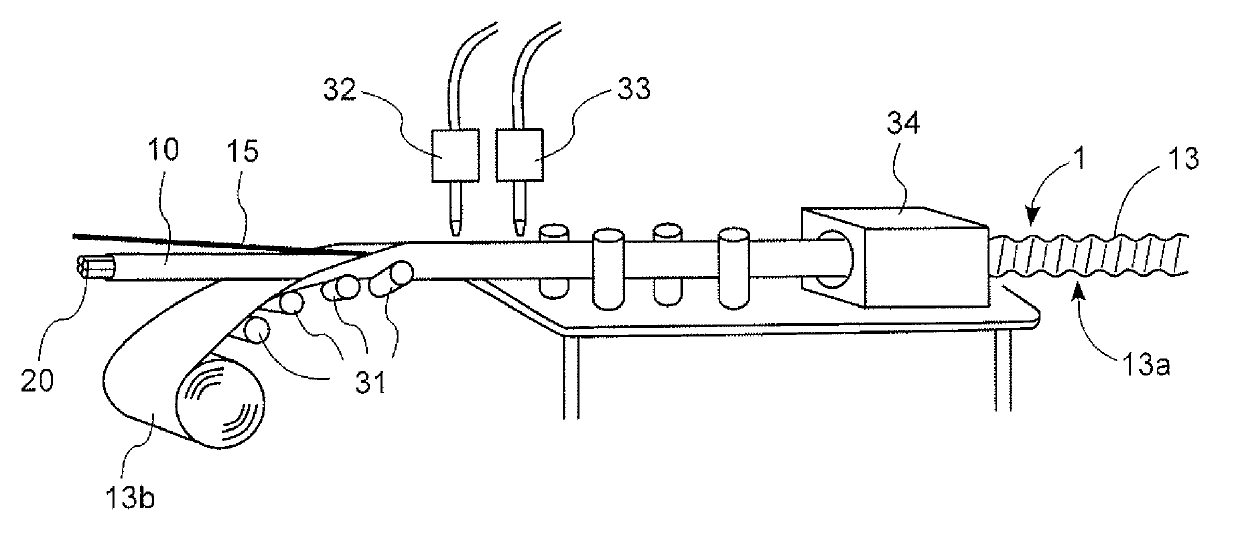

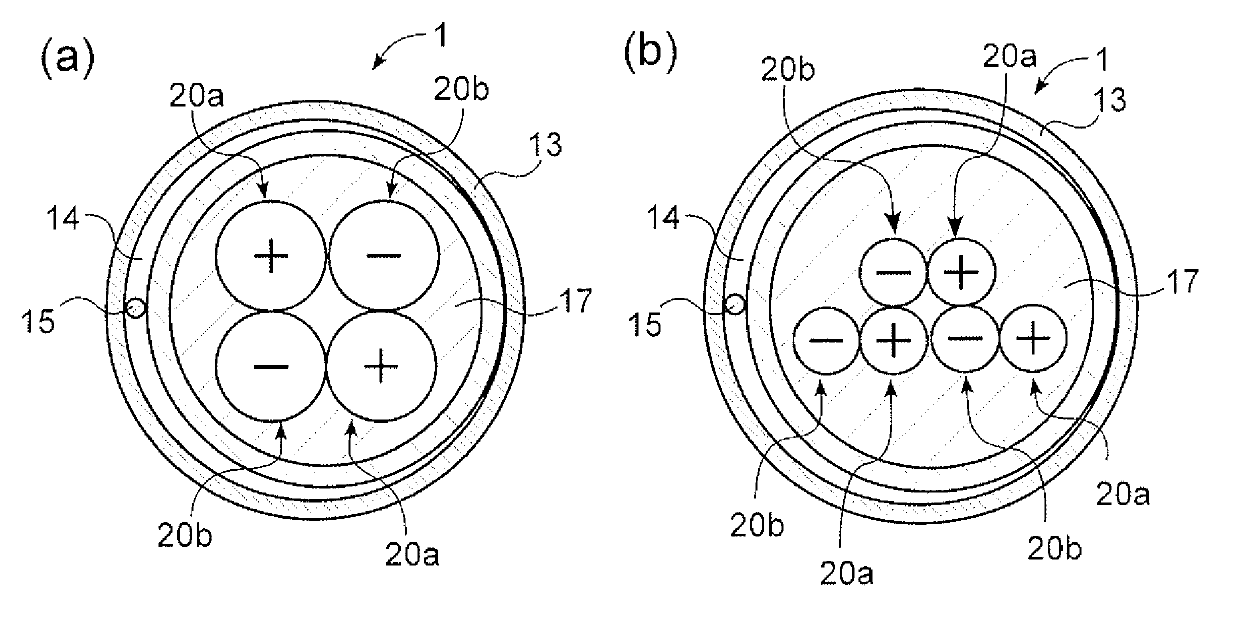

Power supply wire for high-frequency current

ActiveCN103106970AIncrease surface areaReduce skin effectRigid-tube cablesPower cables with screens/conductive layersElectrical conductorPower flow

The invention provides a power supply wire for high-frequency current which reduces a supply loss of current affected by the skin effect and has a high degree of freedom in laying. The power supply wire for high-frequency current (1) comprises: a corrugated tube made of metal (13); a combined electric wire (10) disposed inside the corrugated tube (13) and including a plurality of unit electric wires (20) and a sheath material (23), each of the unit electric wires (20) being formed by bundling together a plurality of conductive wires (11) individually coated with insulating films (12), and the sheath material (23) covering the plurality of unit electric wires (20); and a gap (14) formed between the corrugated tube (13) and the combined electric wire (10).

Owner:KANZACC

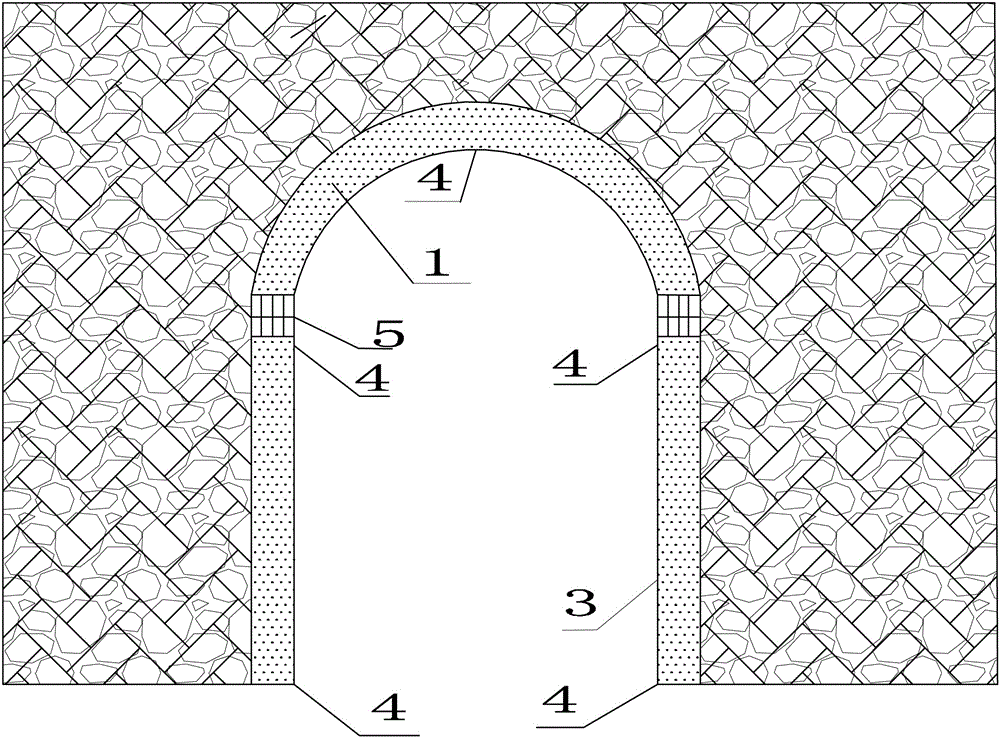

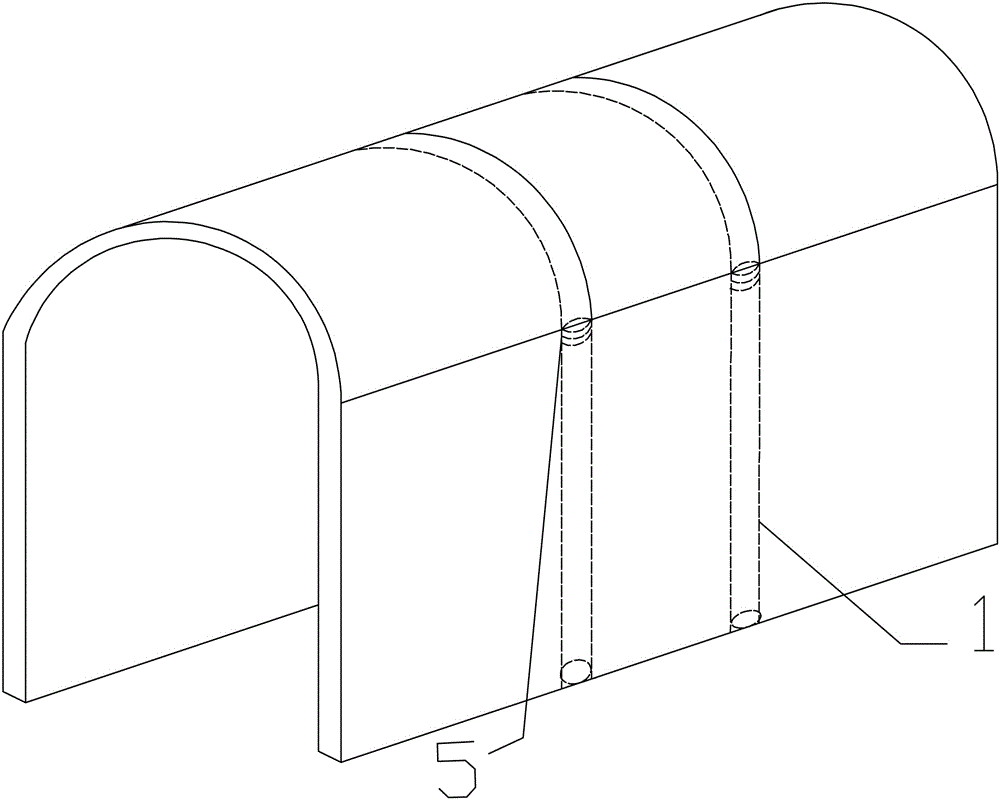

Mold type lining and foam concrete combined supporting structure and construction method

InactiveCN106368720AImprovement of side effectsAvoid punctureUnderground chambersTunnel liningFoam concreteStructural engineering

The invention discloses a mold type lining and foam concrete combined supporting structure and a construction method. The mold type lining and foam concrete combined supporting structure comprises a mold body. Foam concrete is poured on the two sides of the mold body. The two side faces of the foam concrete are sealed through inverted buckles. One end of each inverted buckle is anchored inside a rock body, and I-steel is fixedly mounted at the other end of each inverted buckle. The foam concrete is sealed between the two inverted buckles through the I-steel. The mold body is divided into three sections. Two sections are mounted on the left side and the right side of a tunnel correspondingly, and the other section is mounted on the tunnel vault. The portion, on the tunnel vault, of the mold body and the portions, on the left side and the right side of the tunnel, of the mold body are fixedly connected through stirrups. Gaps between the stirrups and the mold body are filled with the foam concrete. Four automatic pressure relief valves are mounted at the tops and the bottoms of the portions, on the left side and the right side of the tunnel, of the mold body correspondingly, and an automatic pressure relief valve is mounted in the middle of the portion, on the tunnel vault, of the mold body. The mold type lining and foam concrete combined supporting structure is low in manufacturing cost, easy to construct and high in practicability and can better meet the safety requirements.

Owner:CHINA THREE GORGES UNIV

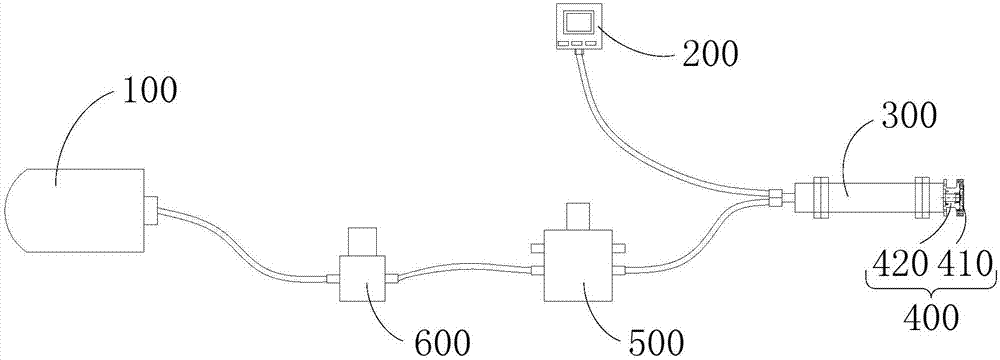

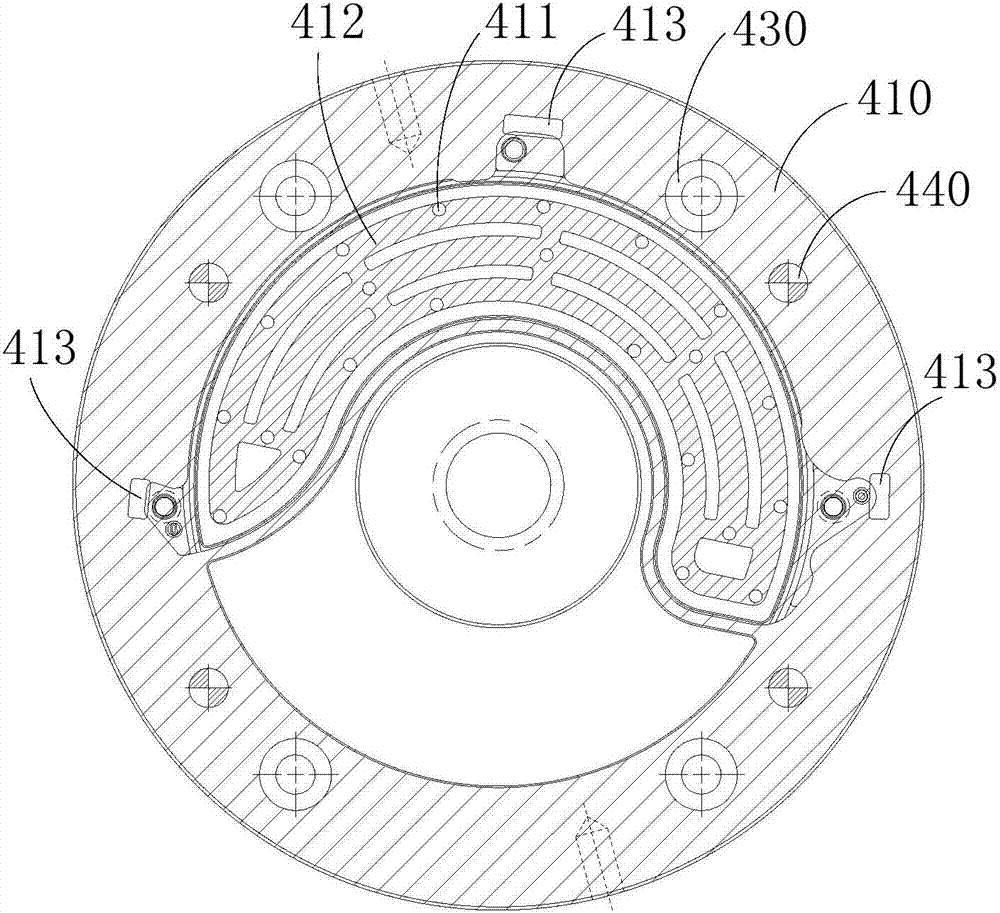

Clamping mechanism and turning machine tool

PendingCN107138995AAvoid deformationRapid positioningMeasurement/indication equipmentsPositioning apparatusPhysicsThin walled

The invention provides a clamping mechanism and a turning machine tool, and relates to the technical field of machining equipment. The clamping mechanism provided by the invention comprises a vacuum pump, a first vacuum gauge, a main shaft and a clamping assembly, wherein the vacuum pump and the first vacuum gauge are both connected with the main shaft, and the main shaft is connected with the clamping assembly; and the clamping assembly comprises a clamping fixture, a location surface is formed on the clamping fixture, a plurality of vacuum holes are formed in the location surface, and the plurality of vacuum holes all communicate with the interior of the main shaft. The clamping mechanism provided by the invention is applied to a process of clamping a workpiece to alleviate the technical problems of deformation of the thin-walled workpiece and low location efficiency, which are possibly caused by a clamping mechanism in the prior art.

Owner:SEKSUN TECH SUZHOU

Cable clamp and harness

ActiveUS20150090489A1Strong clamping forceImprove reliabilityCoupling device detailsInsulated cablesElectric cablesElectric wire

A cable clamp is configured to fix an electric cable including an electric wire section and an outer layer section covering the electric wire section to a fixed member. The cable clamp includes a first cylindrical portion for the electric wire section to be inserted therein, and a second cylindrical portion formed around outside the first cylindrical portion to surround the first cylindrical portion. The second cylindrical portion includes a receiving portion formed between it and the first cylindrical portion to receive the outer layer section. The second cylindrical portion is swaged with the electric wire section inserted in the first cylindrical portion and with the outer layer section received in the receiving portion, so that the outer layer section is gripped by the first cylindrical portion and the second cylindrical portion.

Owner:HITACHI METALS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com