Power supply wire for high-frequency current

A high-frequency current and wire technology, used in circuits, power cables with shielding/conducting layers, insulated cables, etc., can solve problems such as fire, and achieve suppression of AC resistance increase, prevention of disconnection, and partial resistance. The effect of a rise in value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

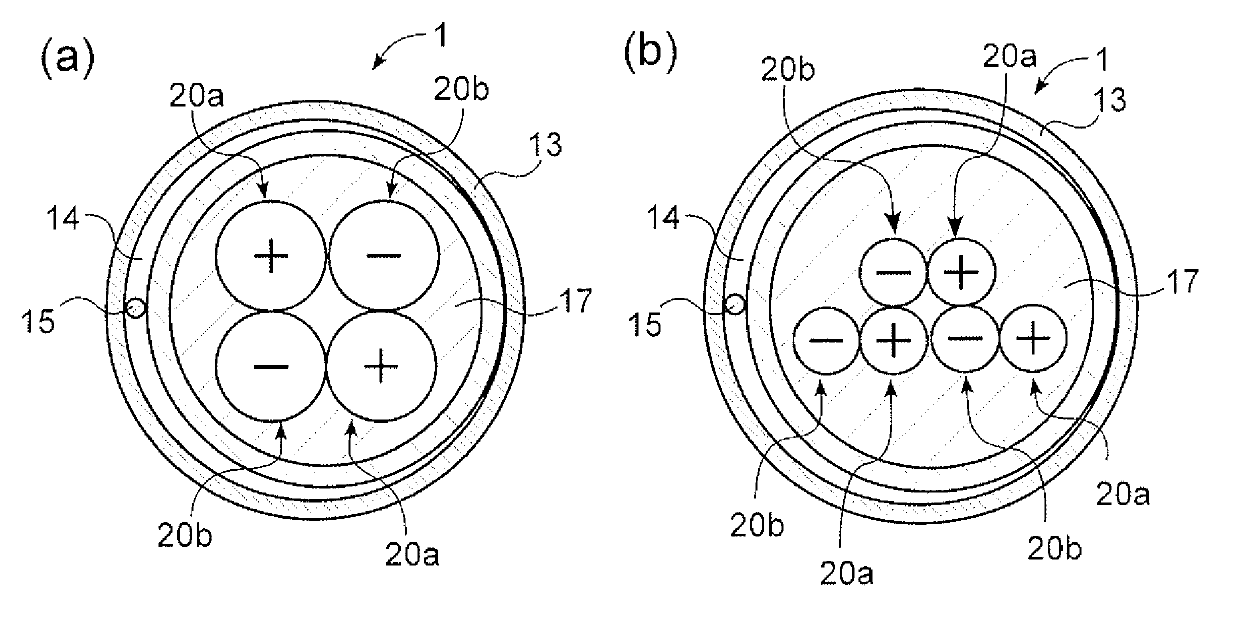

[0026] Hereinafter, the high-frequency current supply electric wire of this invention is demonstrated based on drawing.

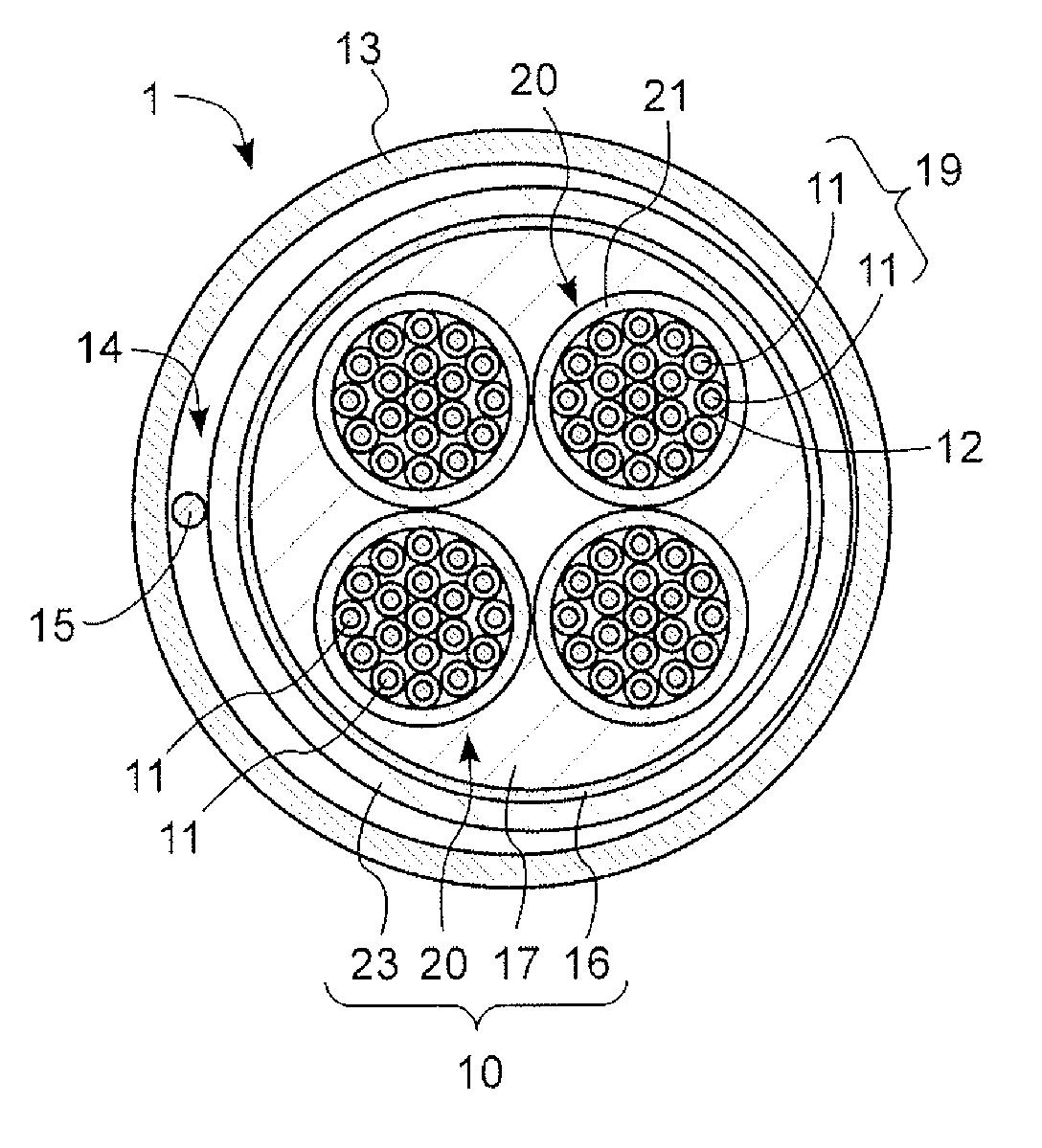

[0027] Such as figure 1 As shown, the high-frequency current supply electric wire 1 of the present invention is composed of a corrugated tube 13 and a composite electric wire 10 disposed inside the corrugated tube 13 .

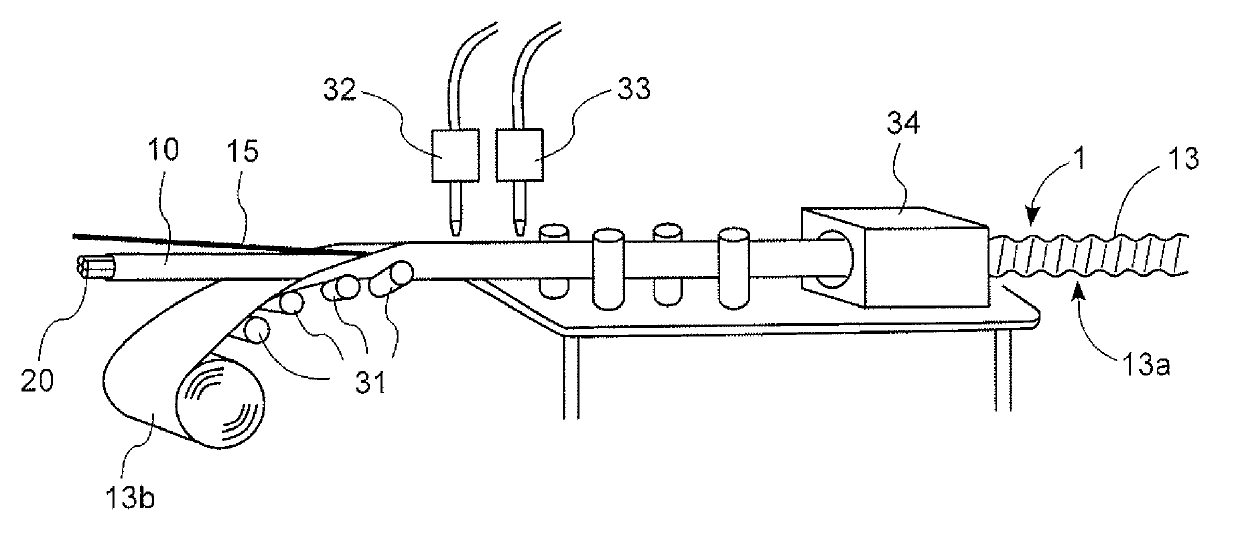

[0028] The corrugated tube 13 is a member that surrounds and protects the composite electric wire 10, and the corrugated tube 13 is a tube made of metal such as aluminum, aluminum alloy, copper, copper alloy, stainless steel, or steel. A corrugated bent portion 13a ( figure 2 ), and the bent portion 13a is helically formed around the tube. In order to prevent corrosion of the bellows 13 , an anticorrosion layer made of resin, coal tar, or the like may be formed on the outer peripheral surface of the bellows 13 . Here, the dimensions of the bellows 13 of the present invention are, for example, a plate thickness of 0.3 mm and an outer dia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com