Fuel cell separator and method of manufacturing the separator

A technology for fuel cells and separators, applied in the direction of fuel cells, fuel cell components, solid electrolyte fuel cells, etc., which can solve the problems of hindering the improvement of productivity, difficulty in covering the sealing member 115, and the decline in the yield of manufacturing separators, etc. problem, to achieve the effect of increasing production, restraining cost increase and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

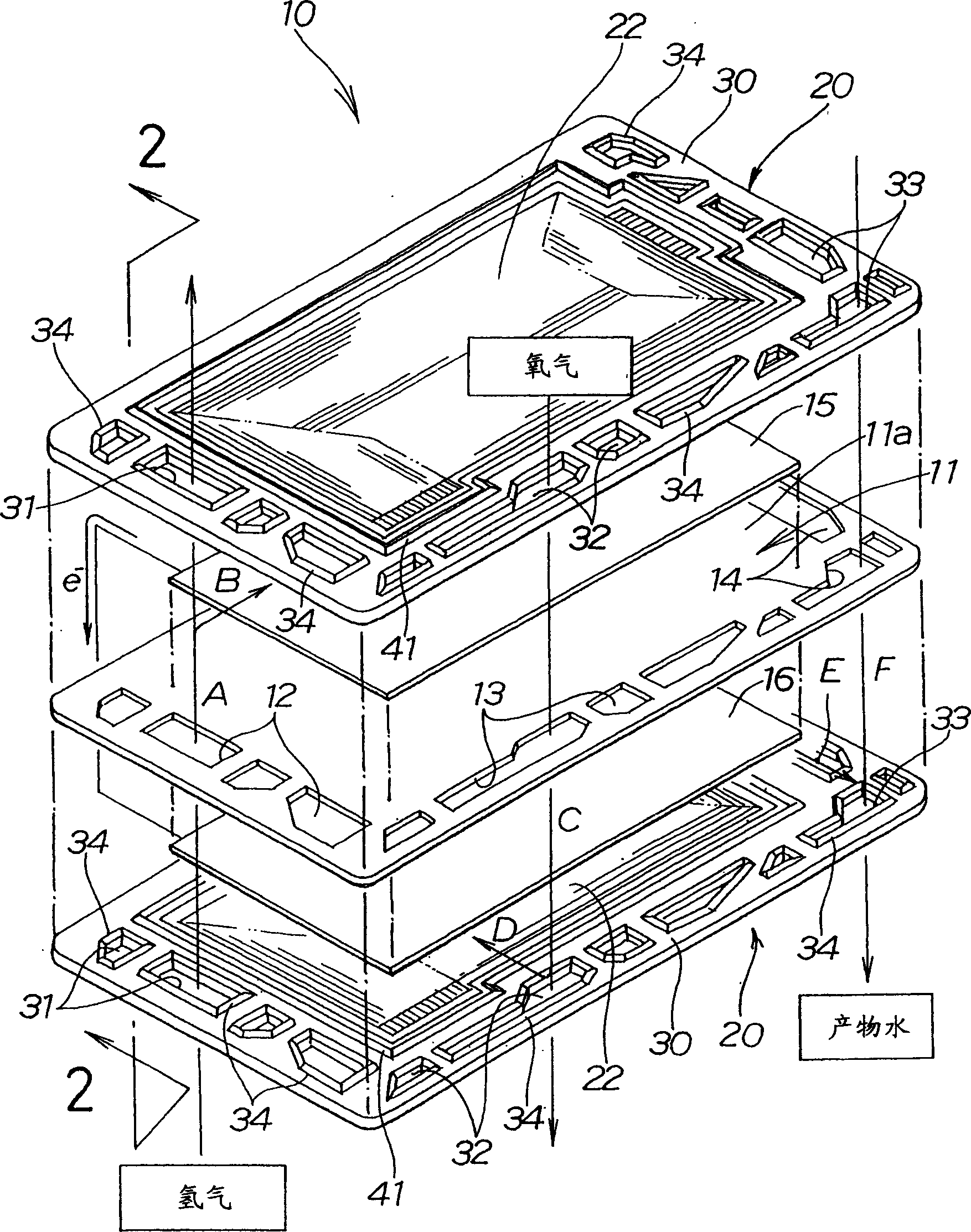

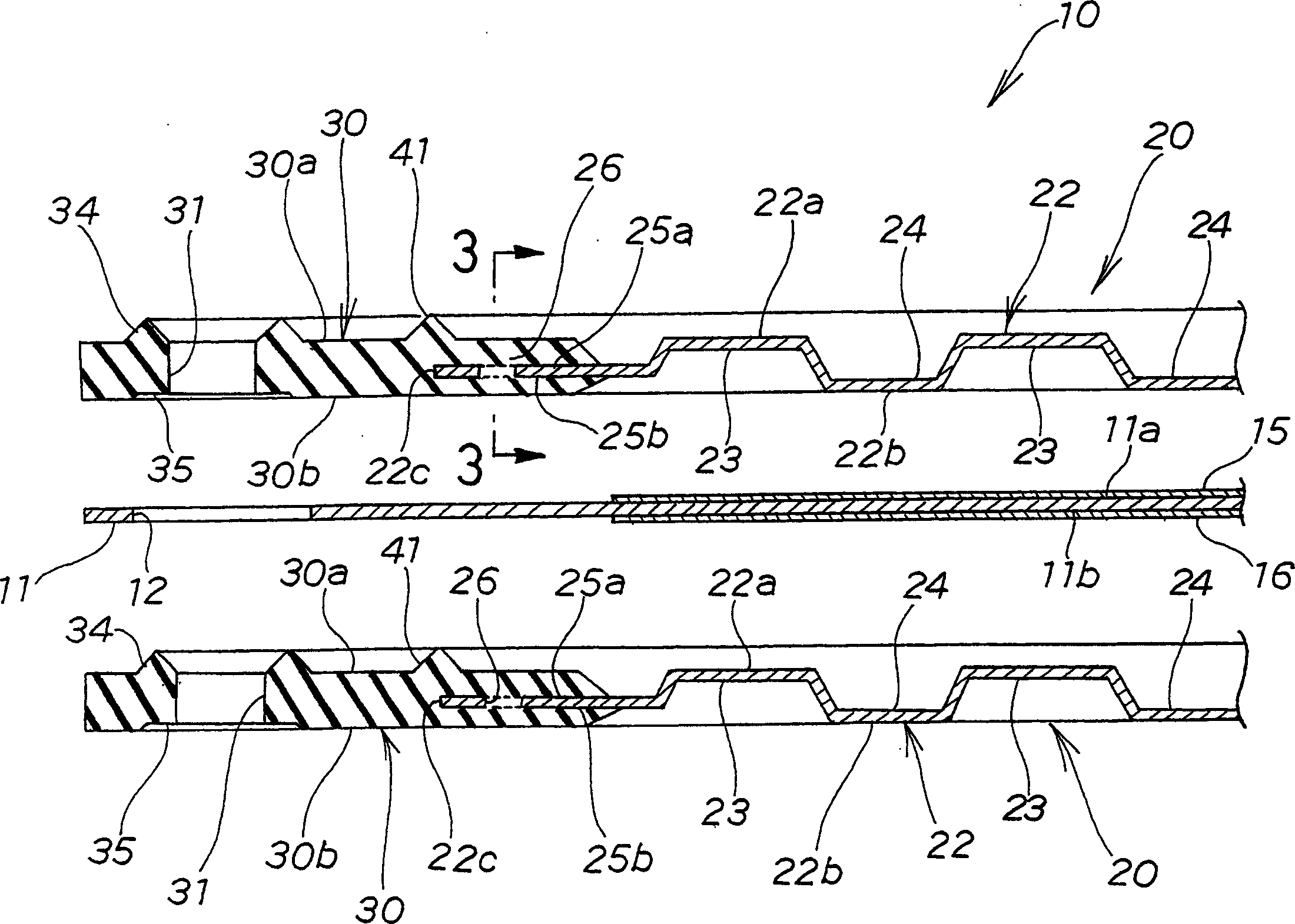

[0033] figure 1 The fuel cell 10 shown has the following structure: On the side of the upper surface 11a of the electrolyte membrane 11 and the lower surface 11b (see figure 2 ) sides are respectively arranged with a negative electrode 15 and a positive electrode 16, and an upper side separator 20 (fuel cell separator) is stacked on the negative electrode 15, and a lower side separator 20 is stacked on the positive electrode 16.

[0034] Here, the fuel cell 10 stacked by the electrolyte membrane 11, the negative electrode 15, the positive electrode 16, the upper separator 20, and the lower separator 20 is generally called a battery cell, and a plurality of stacked battery cells is called a fuel cell. In this specification, for ease of understanding, the battery unit is referred to as a fuel cell.

[0035] At the outer peripheral portion of the electrolyte membrane 11, there are a plurality of hydrogen gas passages (gas passages) 12 for introducing hydrogen gas (reaction gas)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com