Clamping mechanism and turning machine tool

A clamping mechanism and clamping tooling technology, applied in the direction of clamping, metal processing machinery parts, supports, etc., can solve the problems of deformation and positioning efficiency of thin-walled workpieces, achieve rapid positioning, improve positioning efficiency, and prevent deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

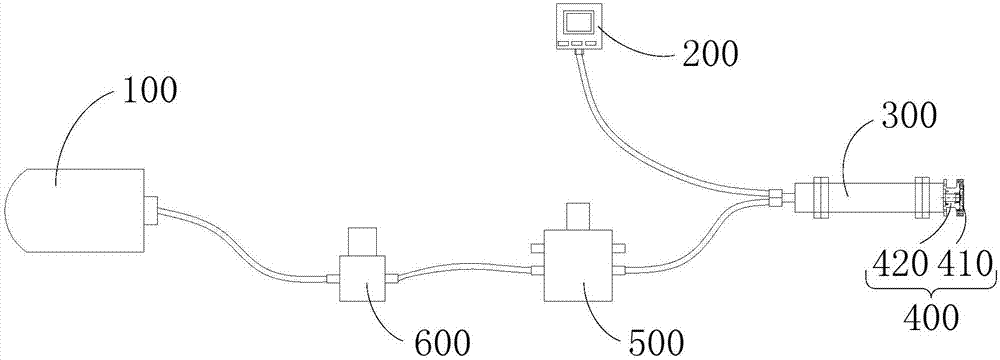

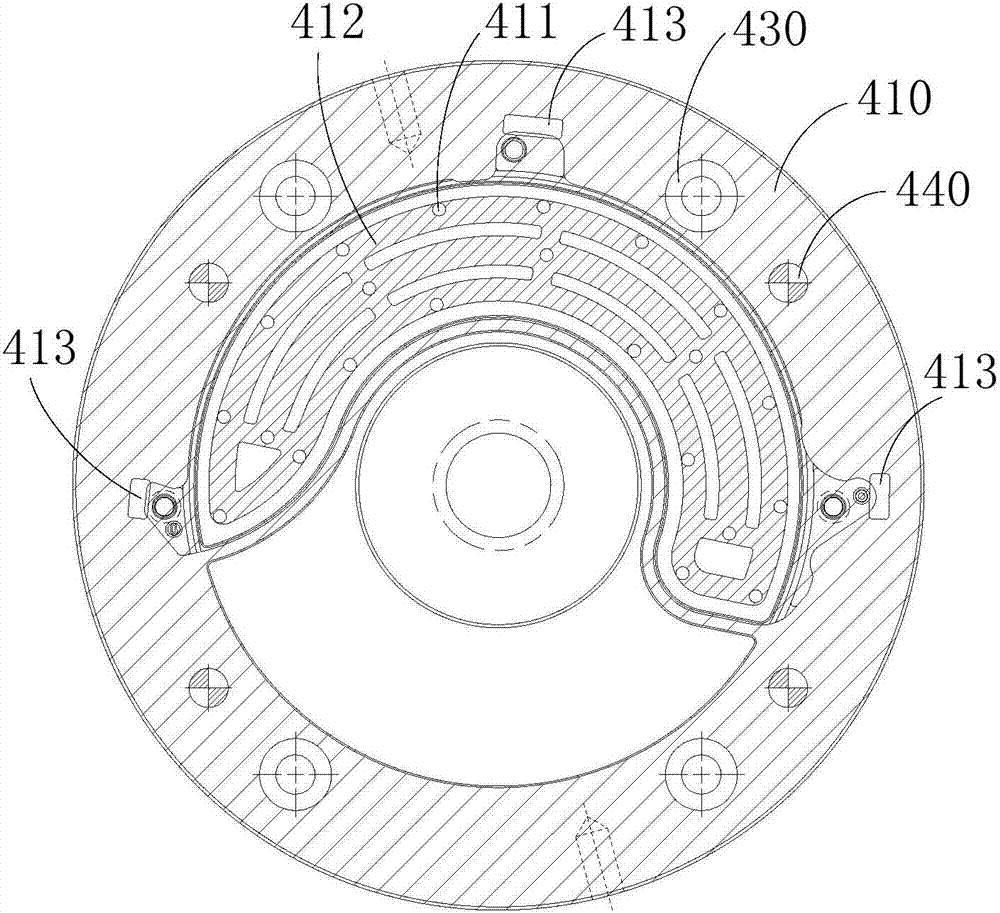

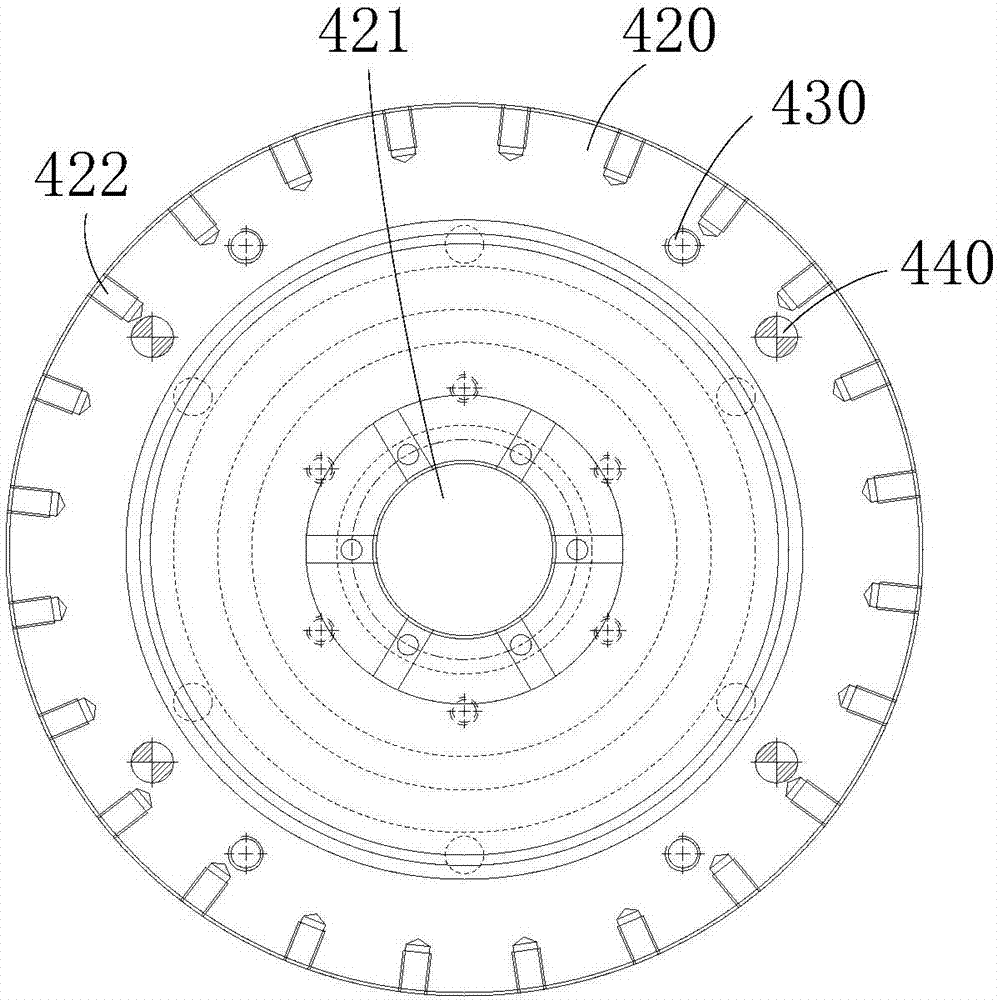

[0032] figure 1 A schematic structural diagram of a clamping mechanism is provided for an embodiment of the present invention, such as figure 1 As shown, the clamping mechanism provided by the embodiment of the present invention includes: a vacuum pump 100, a first vacuum gauge 200, a main shaft 300 and a clamping assembly 400, the vacuum pump 100 and the first vacuum gauge 200 are connected to the main shaft 300, the main shaft 300 is connected to the clamping The components 400 are connected; the clamping component 400 includes a clamping tool 410 , the clamping tool 410 is provided with a positioning surface, and a plurality of vacuum holes 411 are arranged on the positioning surface, and the plurality of vacuum holes 411 communicate with the inside of the main shaft 300 .

[0033] like figure 1 As shown, the main shaft 300 is a hollow tube, one end of the main shaft 300 is connected to the vacuum pump 100 through a vent pipe, and the other end is connected to the clamping...

Embodiment 2

[0056] The purpose of the second embodiment is to provide a turning machine tool to alleviate the technical problems in the prior art that the clamping mechanism may deform the thin-walled workpiece and the positioning efficiency is low.

[0057] The turning machine tool provided in the second embodiment includes the clamping mechanism provided in the first embodiment.

[0058] The turning machine tool provided in Embodiment 2 has the same advantages as the clamping mechanism provided in Embodiment 1 over the prior art, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com