Lithium-rich pole piece of lithium ion battery and preparation method thereof

一种锂离子电池、极片的技术,应用在富锂极片及其制备领域,能够解决金属锂与阳极材料共混难度大、降低活性物质颗粒连接、无法生产金属锂片等问题,达到增加间距、提高能量密度、缓解变形的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The method for preparing a lithium-rich pole piece of a lithium-ion battery according to the present invention is used to prepare the lithium-rich pole piece of a lithium-ion battery according to the first aspect of the present invention, comprising the steps of: forming an active material and a conductive agent, bonding agent and solvent to prepare a slurry and then coat it on the current collector and dry it to obtain the initial pole piece, wherein the slurry coated on the current collector becomes a diaphragm after drying; the metal lithium sheet is perforated to obtain a porous lithium electrode sheet. sheet, so that the capacity of the porous lithium sheet matches the capacity of the anode for lithium supplementation; the porous lithium sheet is covered on the membrane surface of the initial pole piece to obtain a lithium-rich pole piece of a lithium ion battery.

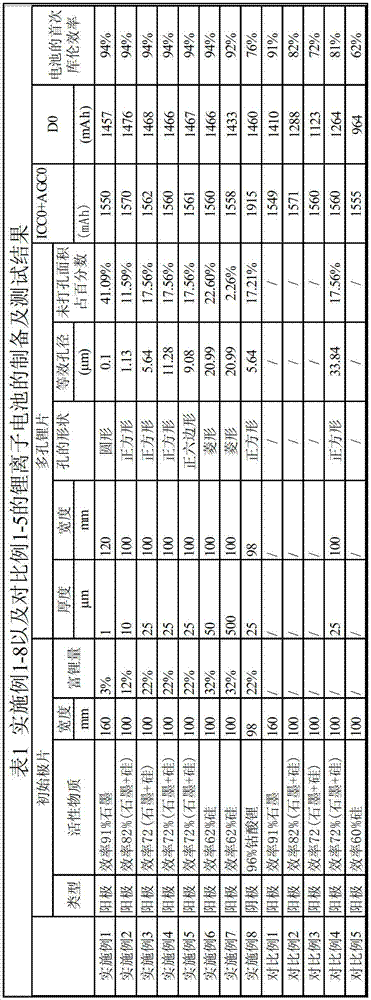

[0026] Next, examples and comparative examples of the lithium-rich pole piece of the lithium ion batt...

Embodiment 1

[0028] A Preparation of the initial pole piece

[0029] The active material graphite (where the graphite gram capacity is 340mAh / g, and the first Coulombic efficiency is 91%), the adhesive, and the conductive agent are uniformly mixed with the solvent according to the ratio of mass ratio = 92:3:5 to make a slurry, (where , the adhesive is PVDF, the conductive agent is conductive carbon black, and the solvent is N-methylpyrrolidone (NMP)), the slurry is coated on both sides of the copper foil current collector and the coating amount on each side is 100mg / 1540mm 2 ; Then dry to form a diaphragm and make the water content of the diaphragm not exceed 300ppm; then cold-press, slitting, and welding the corresponding tabs to obtain an initial pole piece with a width of 160mm. At this time, the initial pole piece is the initial anode pole piece.

[0030] B preparation of porous lithium sheets (membranes on each side of the current collector for the anode)

[0031] 1) Lithium-rich a...

Embodiment 2

[0047] With embodiment 1, except following difference with embodiment 1:

[0048] A Preparation of the initial pole piece

[0049] A mixture of graphite and silicon (wherein the gram capacity of the mixture is 400mAh / g, and the first Coulombic efficiency is 82%) is the active material;

[0050] The coating amount of slurry is 80mg / 1540mm 2 ;

[0051] The width of the prepared initial pole piece is 100 mm.

[0052] B preparation of porous lithium sheets (membranes on each side of the current collector for the anode)

[0053] 1) Lithium-rich amount of lithium-rich pole piece

[0054] The lithium-rich amount of the lithium-rich pole piece is 12% of the capacity of the initial pole piece;

[0055] The unit area of the initial pole piece requires lithium-rich capacity as:

[0056] 80mg / 1540mm 2 ×92%×400mAh / g×12%=2.29×10 -3 mAh / mm 2

[0057] 2) Provide lithium metal sheet

[0058] The provided lithium metal sheet has a thickness of 10μm and a width of 100mm;

[0059] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aperture size | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com