Novel sheet-type oxygen sensor

An oxygen sensor, chip technology, applied in the field of sensors, can solve the problems of inconvenience, dry crack printing of the insulating layer, etc., and achieve the effects of reducing dry cracks, increasing adhesion, and alleviating different coefficients of thermal expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

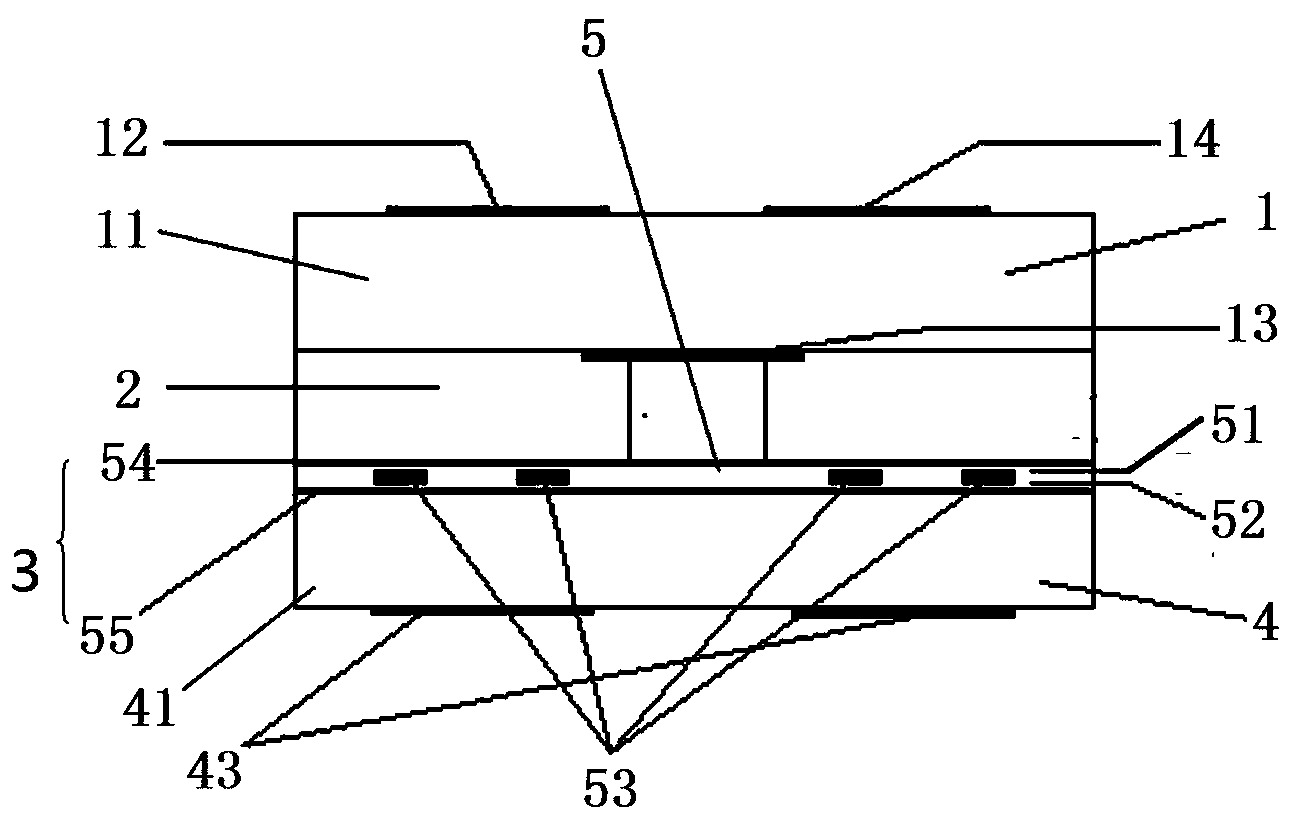

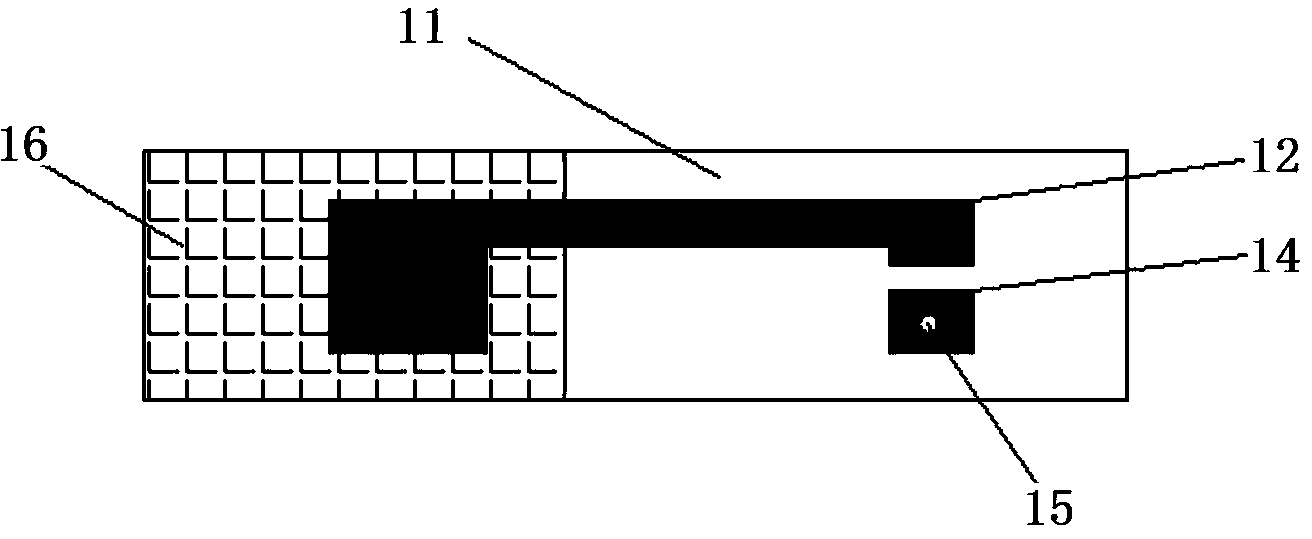

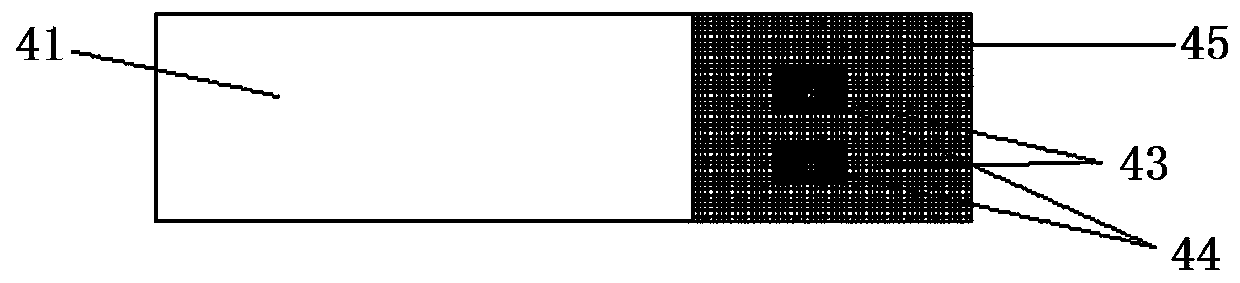

[0024] Figure 1-Figure 3 An embodiment of a novel chip oxygen sensor of the present invention is shown: it includes a sensing element layer 1, an air channel layer 2 and a heating layer 3 arranged in sequence from top to bottom, and the heating layer 3 consists of a heating substrate layer. 4, and the heating electrode insulating layer 5 arranged above the heating substrate layer 4 is composed, the heating electrode insulating layer 5 includes upper and lower insulating sheets 51, 52 and a heater sandwiched between the upper and lower insulating sheets 51, 52 Heating electrode 53, an upper transition layer 54 is also provided on the top of the upper insulating sheet 51, and a lower transition layer 55 is also provided below the lower insulating sheet 52; the sensitive element layer 1 is composed of the sensitive element layer body 11, outer The electrode 12 and the inner electrode 13 are formed, the outer electrode 12 is arranged on the upper surface of the sensitive element ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com