MEMS micro-lens driven by three piezoelectric cantilever beams and manufacturing method thereof

A cantilever beam and piezoelectric technology, applied in the direction of microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve the problems of difficult to meet the multi-axis deflection direction of the micromirror, weak piezoelectric performance, small driving force, etc., to achieve The effect of multiple deflection directions, low working voltage and large driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

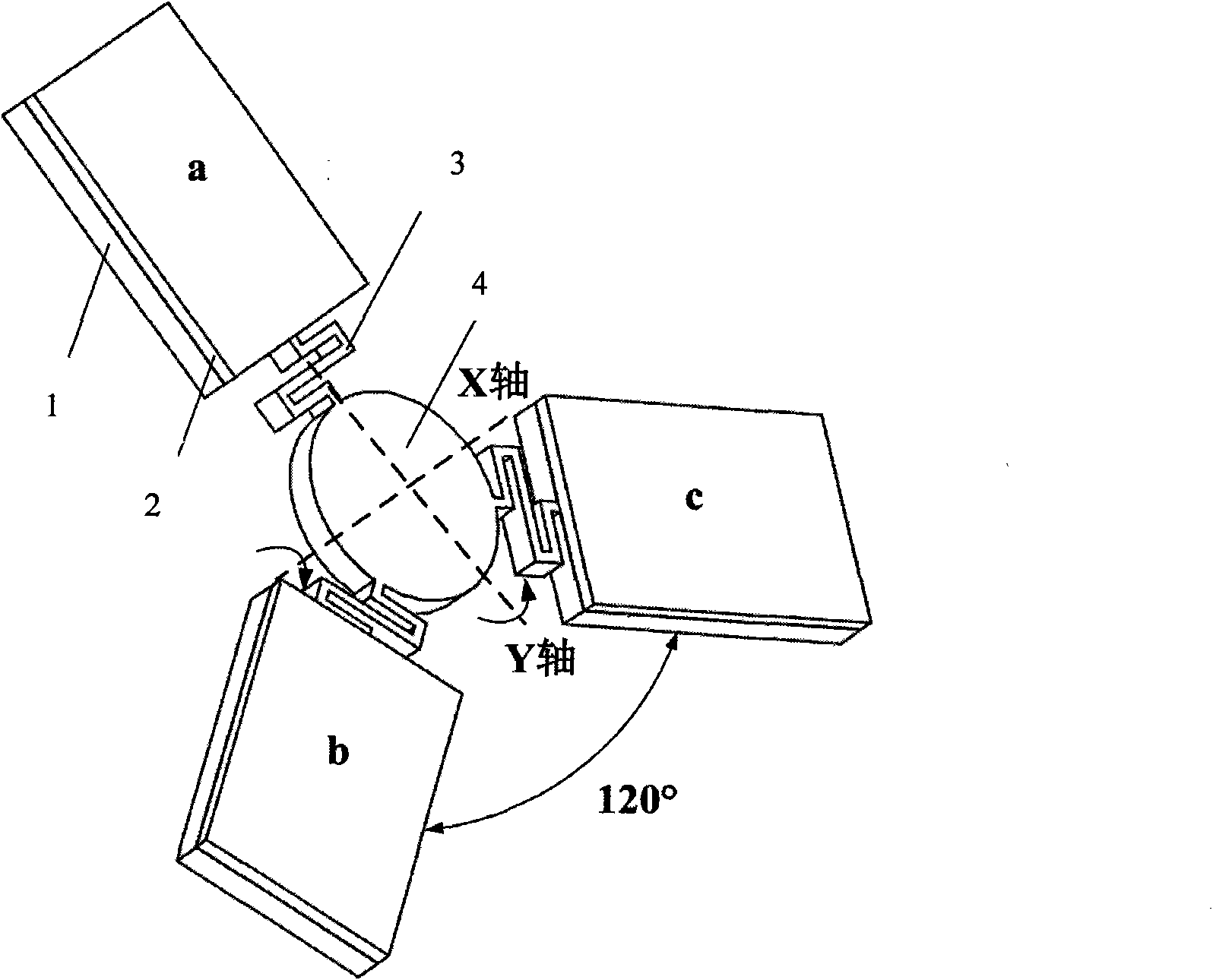

[0029] Such as figure 1 Shown, a kind of MEMS micromirror driven by three piezoelectric cantilever beams of the present invention comprises a microreflector 4, three piezoelectric cantilever beams and three arcuate curved elastic narrow beams 3, and the piezoelectric cantilever beams are made of silicon cantilever beams 1 Composed of a PZT drive film 2 with a fixed surface thickness of 3 μm; three piezoelectric cantilever beams are respectively connected to the micro-mirror surface 4 through three bow-shaped curved elastic narrow beams 3, and the three piezoelectric cantilever beams and the micro-mirror surface 4 are all on the same plane Inside, and the piezoelectric cantilever beams are distributed at an angle of 120° between each other.

[0030] The specific production steps are as follows:

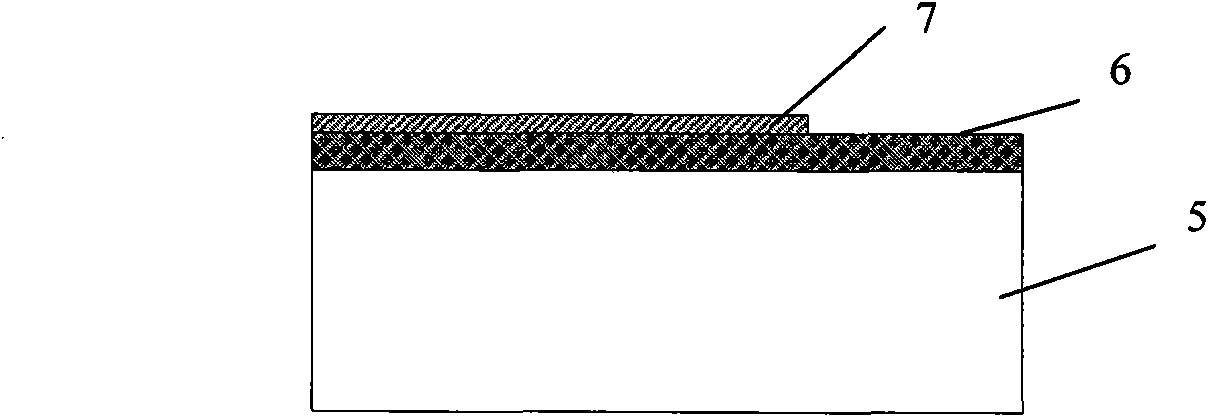

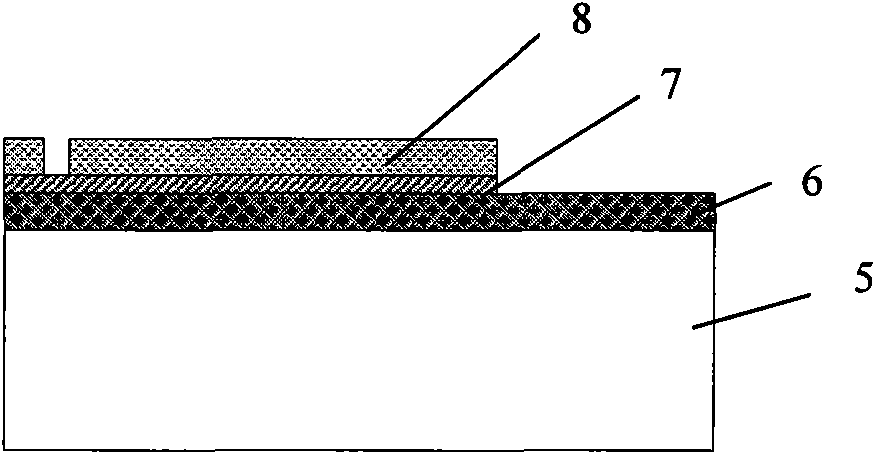

[0031] (1) if figure 2As shown, first, 2 μm SiO was deposited on a single side of a double-polished Si wafer substrate 5 by a physical enhanced chemical vapor deposition (PECVD) pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com