Sub-temperature carburizing heat treatment method for reducing heat treatment deformation of thin-wall gear

A technology of heat treatment deformation and heat treatment method, applied in the field of heat treatment, can solve the problems of large heat treatment deformation of thin-walled gears, and achieve the effects of shortening carburizing time, reducing deformation, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

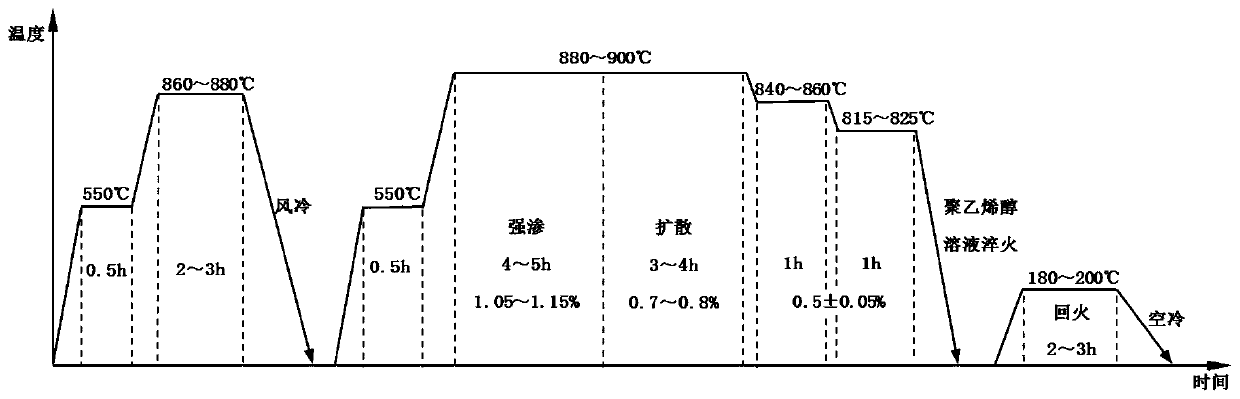

[0024] Such as figure 1 As shown, this embodiment takes a certain type of gear made of 20CrMnTiH as an example. The forging adopts a hot forging forming process, and its carburizing heat treatment method is realized according to the following steps:

[0025] (1) Sub-temperature normalizing in advance: Gradiently heat the thin-walled gear forgings to 550°C for 0.5h, then heat to 860-880°C, keep warm for 2-3h, then take out the furnace and air-cool to room temperature, according to the size of the thin-walled gear forgings , reasonably control the cooling rate at 5°C / s~10°C / s.

[0026] (2) Slow-speed shot peening: The thin-walled gear forgings that have been pre-treated by sub-temperature normalizing are subjected to slo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com