Low temperature polysilicon display unit and method for fabricating the same

A technology of low-temperature polysilicon and display devices, applied in static indicators, semiconductor/solid-state device manufacturing, instruments, etc., can solve the problems of high cost and low yield, reduce the impact, reduce costs, and improve the overall production yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

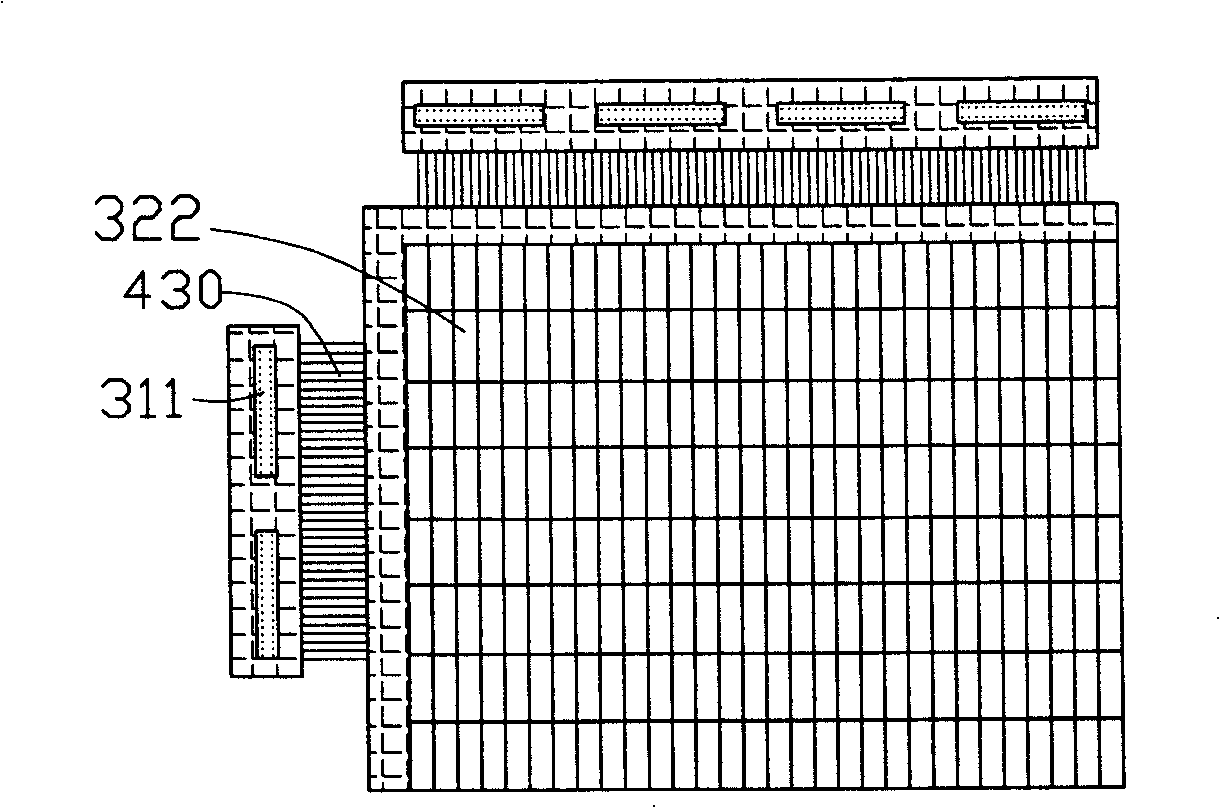

[0017] see Figure 3 to Figure 5 , is a schematic diagram of the low-temperature polysilicon display device of the present invention. The low temperature polysilicon display device includes a driving circuit 311 , a pixel unit 322 and a flexible circuit board 430 , wherein the pins of the driving circuit 311 and the TFT matrix pins of the pixel unit 322 are combined with the flexible circuit board 430 or conductive material. In the present invention, the driving circuit 311 and the pixel unit 322 are fabricated on different small and medium-sized insulating substrates 310 and the display panel 330 respectively, the insulating substrate 310 includes a plurality of driving circuits 311, and the display panel 330 includes a plurality of pixel units 322, Subsequently, the driving circuit 311 on the insulating substrate 310 and the pixel unit 322 on the display panel 330 are cut according to actual production requirements, and then connected. The insulating substrate 310 may be a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com