Patents

Literature

42results about How to "Shorten carburizing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

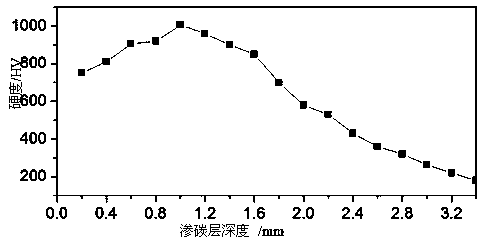

Hard alloy carburizing process resulting in gradient distribution of mechanical performance

InactiveCN1526847AHigh thickness valueReduce manufacturing costSolid state diffusion coatingProduction rateAlloy

The hard alloy carburizing process resulting in gradient distributioin of mechanical performance includes the steps of preparing carburizing agent, loading into boat and carburizing treatment. The carburizing agent consists of Al2O3, graphite grain, and carbonate and / or bicarbonate in certain proportion and mixed together. During the carburizing treatment, carbonate and / or bicarbonate are decomposed into CO2, CO2 is then reacted with graphite to produce relatively active CO, and CO enters to liquid phase and reacts with eta phase to produce WC while immigrating inwards and to speed the formation of gradient structure inside the alloy. The present invention has the features of relatively low carburizing temperature, high comprehensive mechanical strength formed, short carburizing time, etc.

Owner:ZIGONG CEMENTED CARBIDE CORP +1

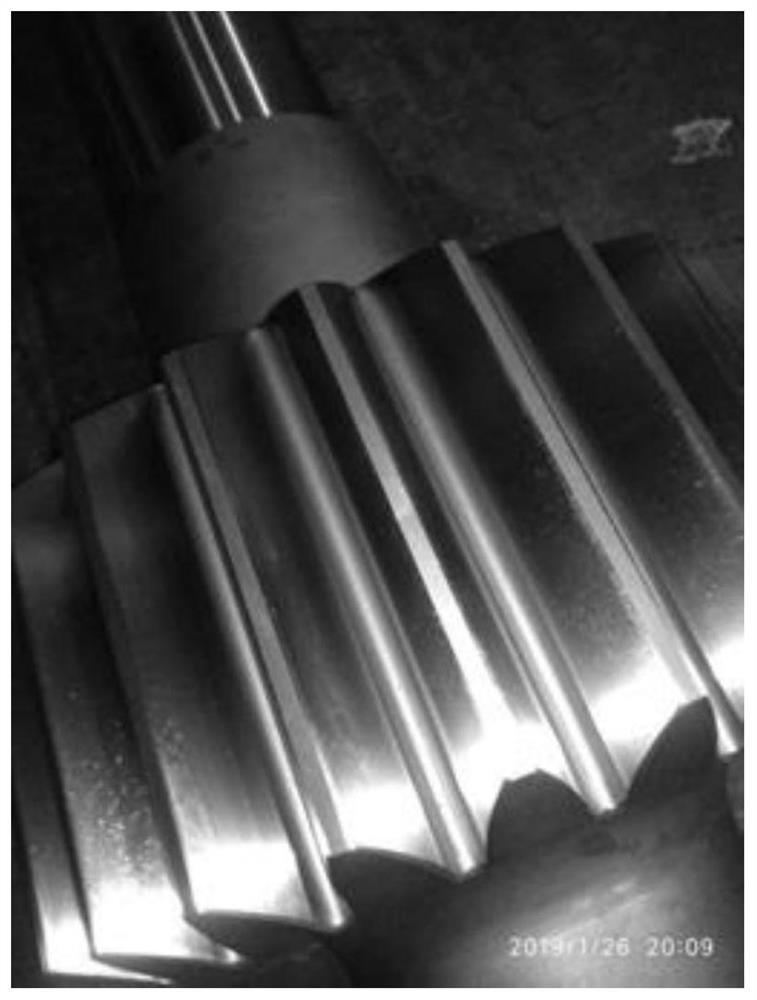

Automobile gearbox gear carburizing and quenching heat treatment method

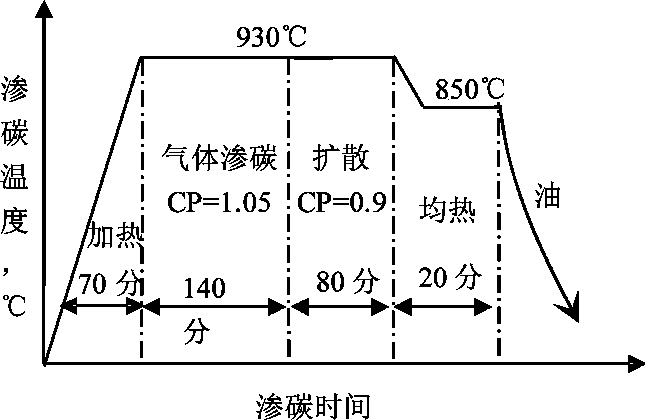

ActiveCN103710714AHigh surface hardnessImprove wear resistanceSolid state diffusion coatingFurnace typesCarbon potentialRoom temperature

The invention discloses an automobile gearbox gear carburizing and quenching heat treatment method. The method comprises the following steps: 1, carburizing: placing a gear in a heating furnace, and rising temperature of the heating furnace from room temperature to 900+ / -5DEG C for carburizing for 3-4h, wherein the carbon potential CP in a strong carburizing stage is 1.06+ / -0.3C%, and the carbon potential CP in a diffusion stage is 0.85+ / -0.03C%; 2, quenching: cooling the obtained carburized gear to 830+ / -5DEG C, samming for 25-35min, and quenching in 90+ / -10DEG C quenching oil; and 3, tempering: tempering the obtained quenched gear at 165+ / -5DEG C for 2-3h. The proper reduction of the carburizing temperature and the quenching temperature, the rising of the temperature of the quenching oil and the proper rising of the carburizing carbon potential are carried out on the premise of guaranteeing the quality of a carburized layer, so the carburizing time is not prolonged, and the energy consumption is reduced; and the appearance of black microstructures is prevented, so the surface hardness, the wear resistance and the fatigue strength of the gear are obviously improved, deformation is reduced, the driving balance of the gear is improved, noises are reduced, and the service life of the gear is prolonged.

Owner:厦门真冈热处理有限公司

Processing technology for gearbox gear

InactiveCN104762629AProlong carburizing timeReduce energy consumptionSolid state diffusion coatingGear transmissionCarburizing

The invention relates to a processing method for a gear, especially to a processing technology for a gearbox gear. The processing technology comprises the following steps: step 1, blanking and forging so as to obtain a cylindrical blank; step 2, homogenization treatment of components of the forged blank and drilling of a center hole through lathing; step 3, gear hobbing out of the cylindrical blank via a hobbing machine; step 4, carbonization of a workpiece; step 5, cooling and quenching after carbonization; and step 6, machining of the workpiece so as to form the gear. The processing technology provided by the invention has the following beneficial effects: a, carburizing temperature and quenching temperature are reduced, carburizing time is not prolonged, and energy consumption is reduced; b, generation of a black structure is prevented, a uniform carburizing layer is obtained, the microstructure of the carburizing layer having undergone carbonization and quenching is improved, an optimal metallographic structure is obtained, and thus, surface hardness, wear resistance and fatigue resistance of the gear are obviously improved; and c, deformation is reduced, gear processing and assembling dimension precision of the gear is improved, gear transmission balance is enhanced, noise is reduced, and the service life of the gear is prolonged.

Owner:SUZHOU LU LU SHUN ELECTRICAL EQUIP

Carburizing and quenching process

InactiveCN107245690AExtended service lifeShorten carburizing timeSolid state diffusion coatingQuenching agentsWear resistantHardness

The invention relates to a carburizing and quenching process, which belongs to the technical field of heat treatment of metal. The carburizing and quenching process comprises the steps of carburizing for the first time, carburizing for the second time, quenching for the first time, quenching for the second time, tempering at high temperature and tempering at low temperature. According to the carburizing and quenching process designed by the invention, two-time carburization is adopted during carburization, and the carburizing time of each time is shortened, so that the defects that metal hardness is low due to long-time heating and the anti-fatigue performance and the wear resistant performance are reduced can be effectively prevented, and the service life of a workpiece is greatly prolonged; in addition, two-time quenching is adopted, so that residual stress of the workpiece can be preferably released, and the service life is prolonged.

Owner:JIANGSU FENGDONG HEAT TREATMENT & SURFACE MODIFICATION ENG & TECH RES CO LTD

Thermal treatment method for carburizing and quenching of gearbox gears

InactiveCN105586599AHigh surface hardnessEasy to processSolid state diffusion coatingFurnace typesCarbon potentialRoom temperature

The invention discloses a thermal treatment method for carburizing and quenching of gearbox gears. The thermal treatment method includes the steps of A, carburizing, B, quenching and C tempering. In the step of A, carburizing, the gears are placed in a heating furnace, the temperature of the heating furnace is increased from the room temperature to the temperature of 850-900 DEG C for carburizing, and carburizing time is 2-5 h; the carburizing process includes a beginning stage, a strong carburizing stage and a diffusion stage; the carbon potential (CP) of the beginning stage is 0.9-1 C%, the CP of the strong carburizing stage is 1-1.1 C%, and the CP of the diffusion stage is 0.8-0.9 C%; the time of the beginning stage is 12-15 min, the time of the strong carburizing stage is 200-220 min, and the time of the diffusion stage is 20-40 min. In the step of B, quenching, the carburized gears are cooled to 810-850 DEG C, then temperature equilibrium is carried out for 20-40 min, and then the gears are quenched in quenching oil with the temperature being 85-95 DEG C. In the step C, tempering, the quenched gears are subjected to tempering at the temperature of 155-170 DEG C for 1-2 h.

Owner:CHONGQING CHUNGU MACHINERY MFG CO LTD

Heat processing method for carburizing and quenching

InactiveCN105986220AHigh surface hardnessEasy to processSolid state diffusion coatingFurnace typesCarbon potentialRoom temperature

The invention discloses a heat processing method for carburizing and quenching. The method comprises the following steps: A) a carburizing step, placing a gear in a heating furnace, and rising temperature of the heating furnace from room temperature to 850-900 DEG C for carburizing for 2-5 h, wherein the carbon potential CP in a strong carburizing stage is 1.02-1.1C%, and the carbon potential CP in a diffusion stage is 0.8-0.9C%; B) a quenching step: cooling the obtained carburized gear to 810-850 DEG C, equalizing the temperature for 20-40min, and quenching in 85-95 DEG C quenching oil; and C) a tempering step: tempering the obtained quenched gear at 155-170 DEG C for 1-2 h. The proper reduction of the carburizing temperature and the quenching temperature, the rising of the temperature of the quenching oil and the proper rising of the carburizing carbon potential are carried out on the premise of guaranteeing the quality of a carburized layer, so the carburizing time is not prolonged, and the energy consumption is reduced; and the appearance of black microstructures is prevented, so the surface hardness, the wear resistance and the fatigue strength of the gear are obviously improved, deformation is reduced, the driving balance of the gear is improved, noises are reduced, and the service life of the gear is prolonged.

Owner:重庆文力机械有限公司

Rare earth controllable carburizing method for furnace for periodical operation

InactiveCN1644750AShort carburizing process timeFast carburizingSolid state diffusion coatingCarbon potentialMetallurgy

The method of discontinuous running carburizing furnace rare-earth controllable changing carbon potential carburizing was introduced in the invention. It was involved in one kind of rare-earth controllable changing carbon potential carburizing. It is carried out by adding rare-earth cementation agent to the carburizing furnace when the furnace temperature rise to 820 deg.C in the period of air-out, the earbon, potential reduced from 0.6% to 1.45% till close the pore, the carburizing time is 80-120 min, the strong carburizing period I was 2-4h, the carbon potential reduced form 1.45% to 1.25%, the strong carburizing period II was 4-6, the carbon potential reduced from 1.25% to 1.1%. The diffusion period was 6-8h, the carbon potential reduced from 1.1% to 0.8%. Its advantages include advanced the potential of carburizing furnace; increased the carburizing speed; shorten the time of carburizing; the function of rare-earth cementation agent more effective when combined the high carbon potential; shorten the carburizing time more than 30%, power saved 25-35%.

Owner:HARBIN INST OF TECH

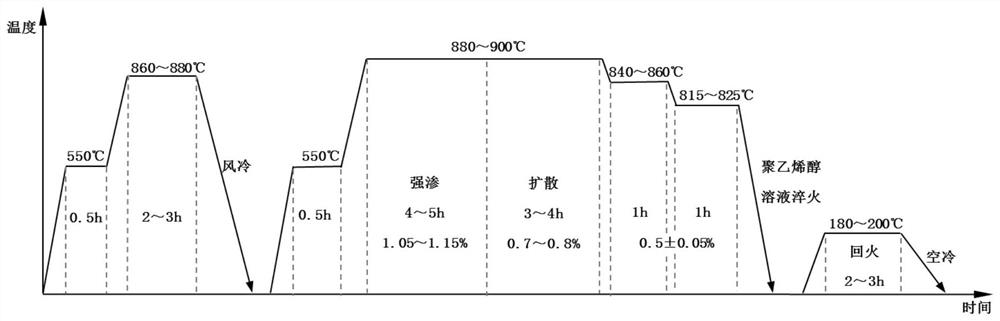

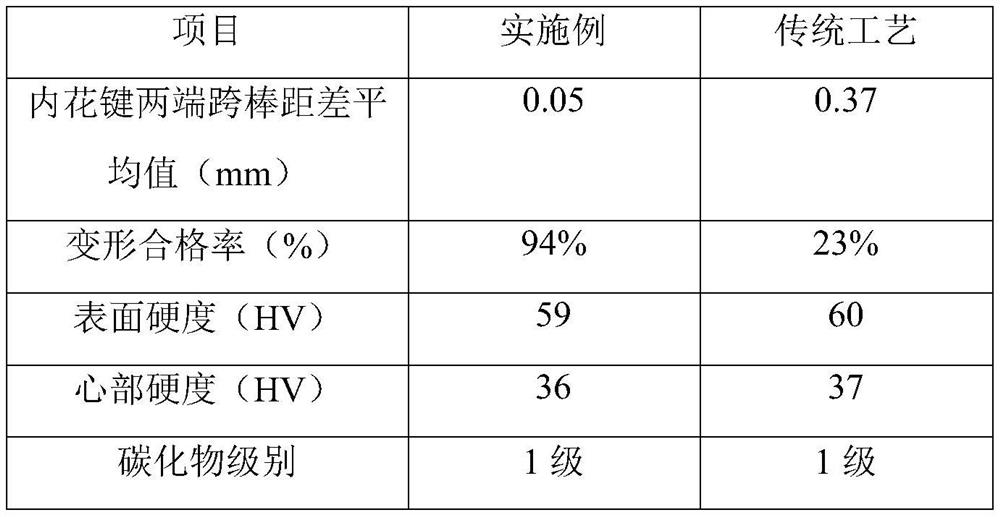

Sub-temperature carburizing heat treatment method for reducing heat treatment deformation of thin-wall gear

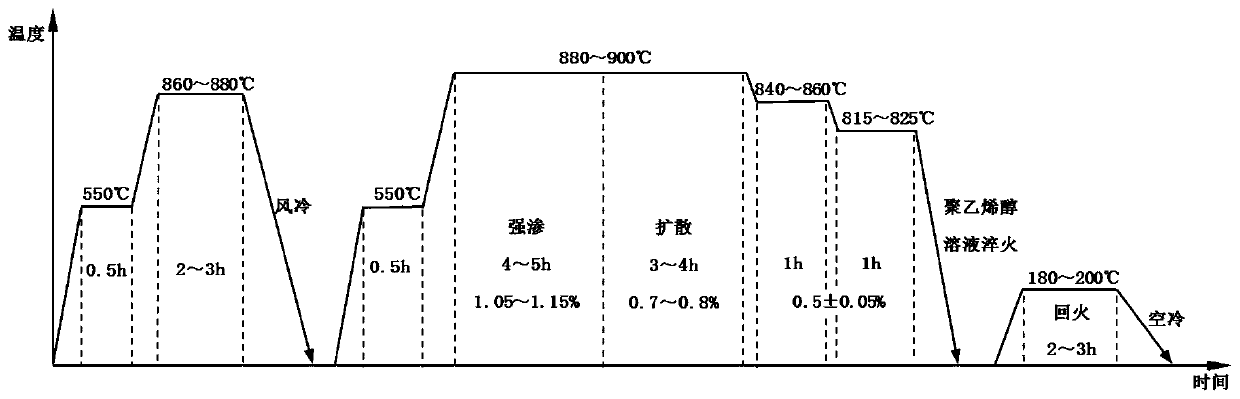

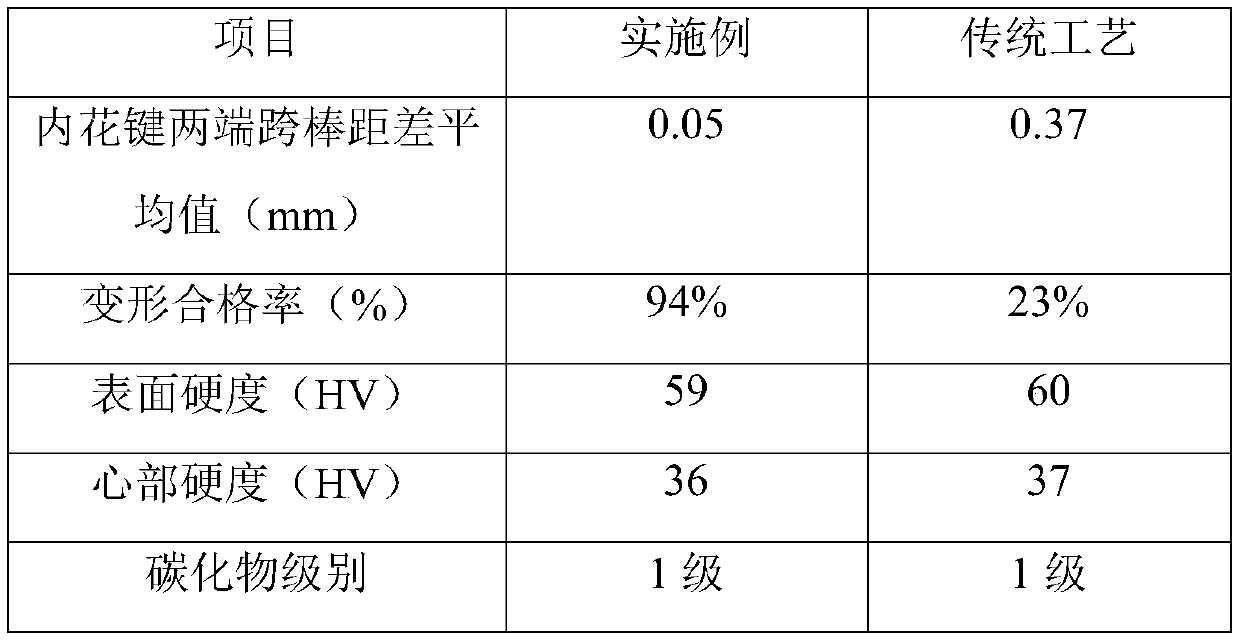

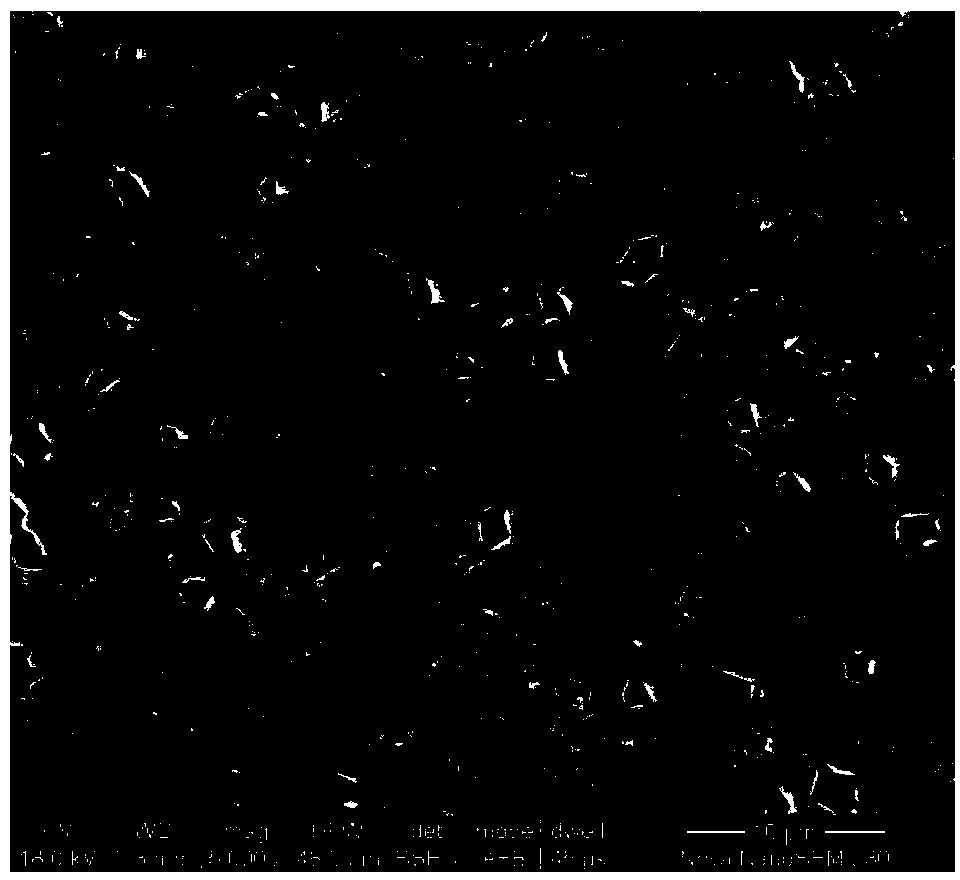

ActiveCN111020455AReduce the impact of uniformityIncreased speed of penetration into gear surfacesSolid state diffusion coatingFurnace typesCarbon potentialTempering

The invention relates to a sub-temperature carburizing heat treatment method for reducing heat treatment deformation of a thin-wall gear. The method comprises the following steps of S1, pre-sub-temperature normalizing; S2, slow speed shot blasting; S3, sub-temperature carburization, specifically, gradient heating is adopted to a sub-temperature carburizing temperature, a two-stage carburizing method is adopted in the sub-temperature carburizing process, the first stage is a strong carburizing stage, and the second stage is a diffusion stage; S4, gradient slow cooling quenching, specifically, firstly, gradient slow cooling is carried out on a carburized thin-wall gear forging to 840-860 DEG C, heat preservation is carried out for about 1h, then the slow cooling is continuously carried out to 815-825 DEG C, the heat preservation is carried out for about 1h, the carbon potential in the furnace is controlled to be 0.5-0.05%, and then quenching is carried out in a polyvinyl alcohol solution; and S5, low-temperature tempering. According to the method, the deformation degree of a gear workpiece can be greatly reduced, the production qualification rate can be obviously improved, meanwhile,crystal grains can be effectively refined, the hardness and strength of a gear can be improved, the service life of the gear can be obviously prolonged, and in addition, the refined crystal grains can obviously improve the carburizing speed, reduce the process time and reduce the energy consumption.

Owner:WUHAN UNIV OF TECH

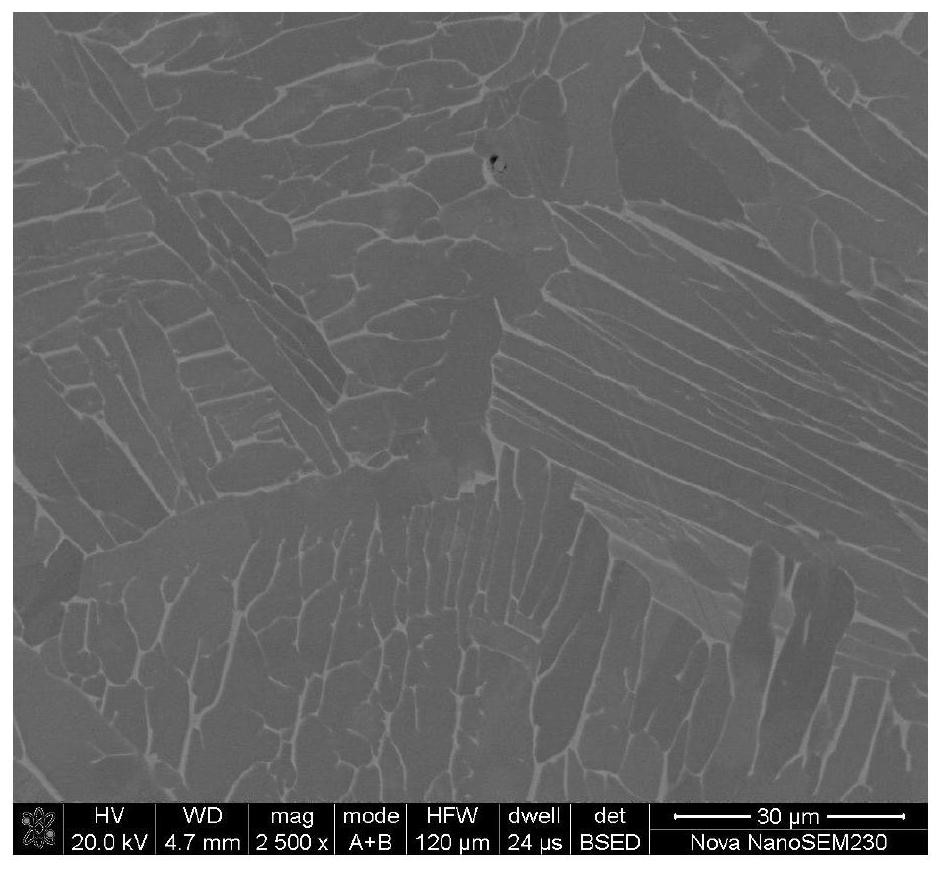

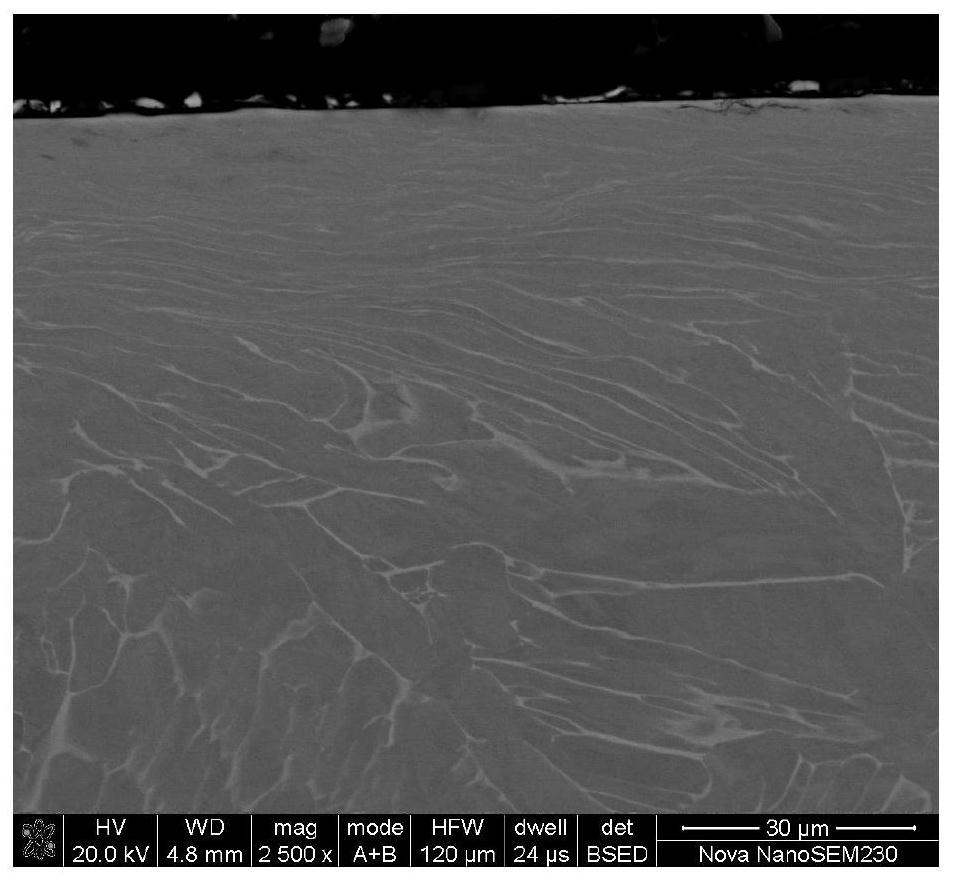

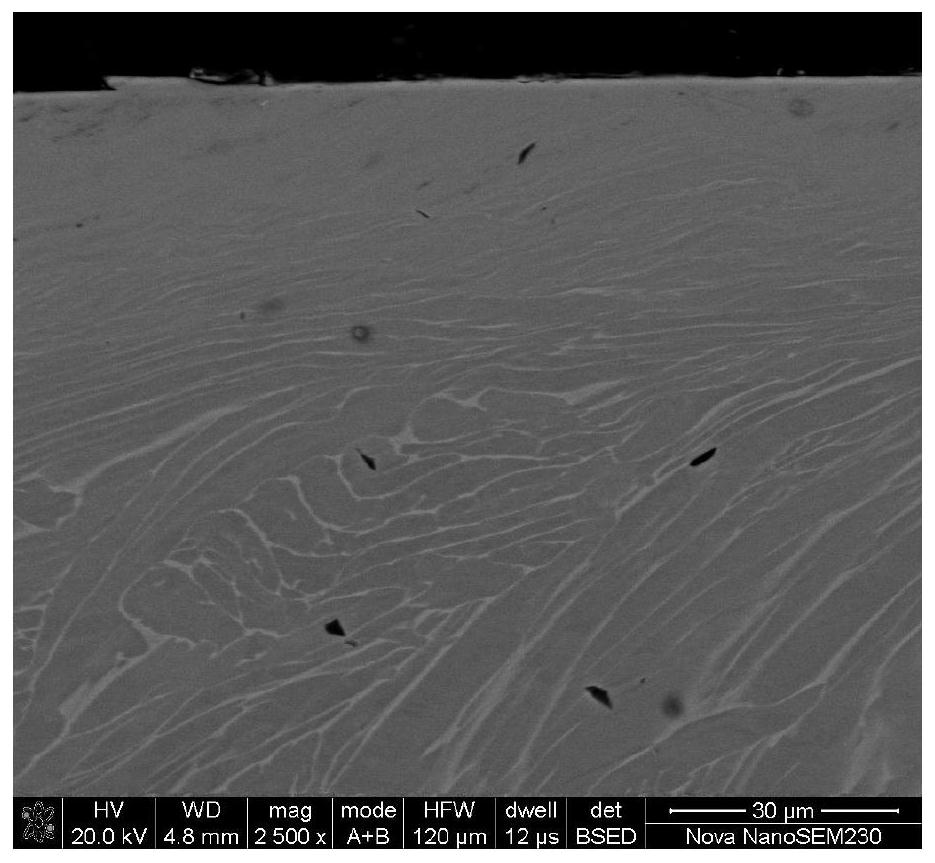

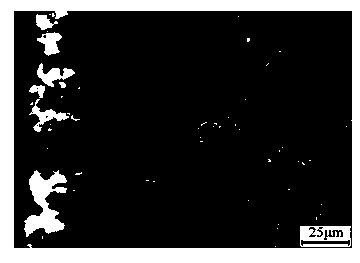

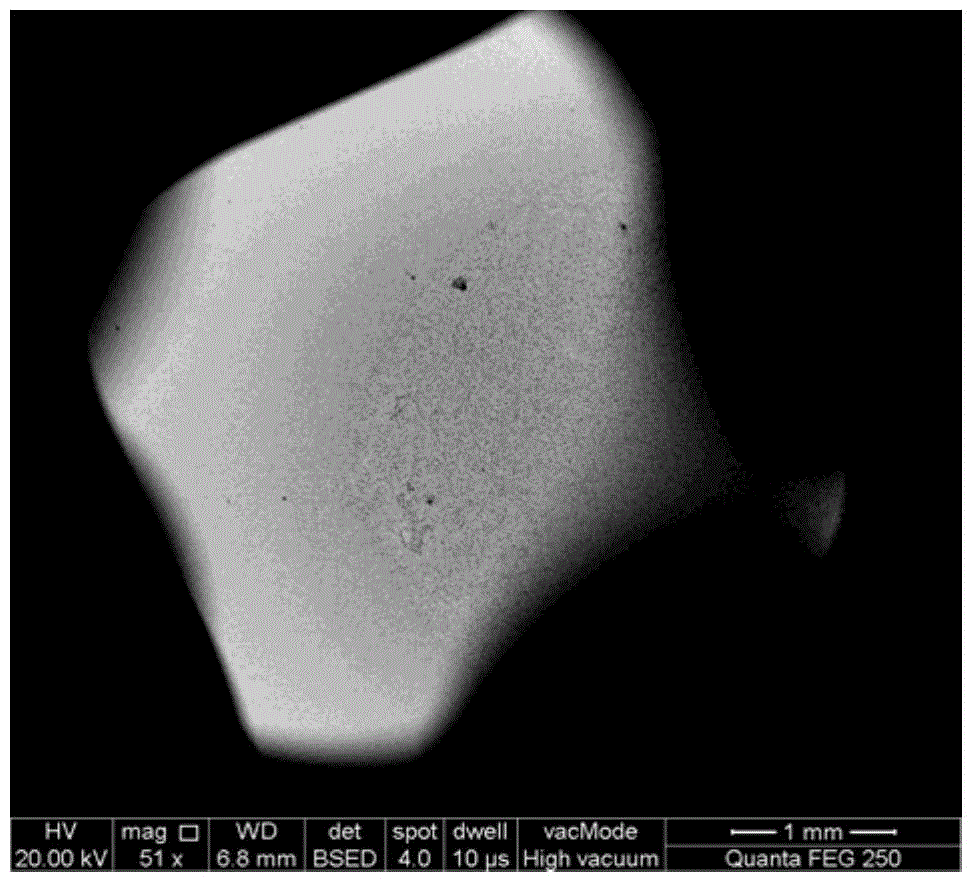

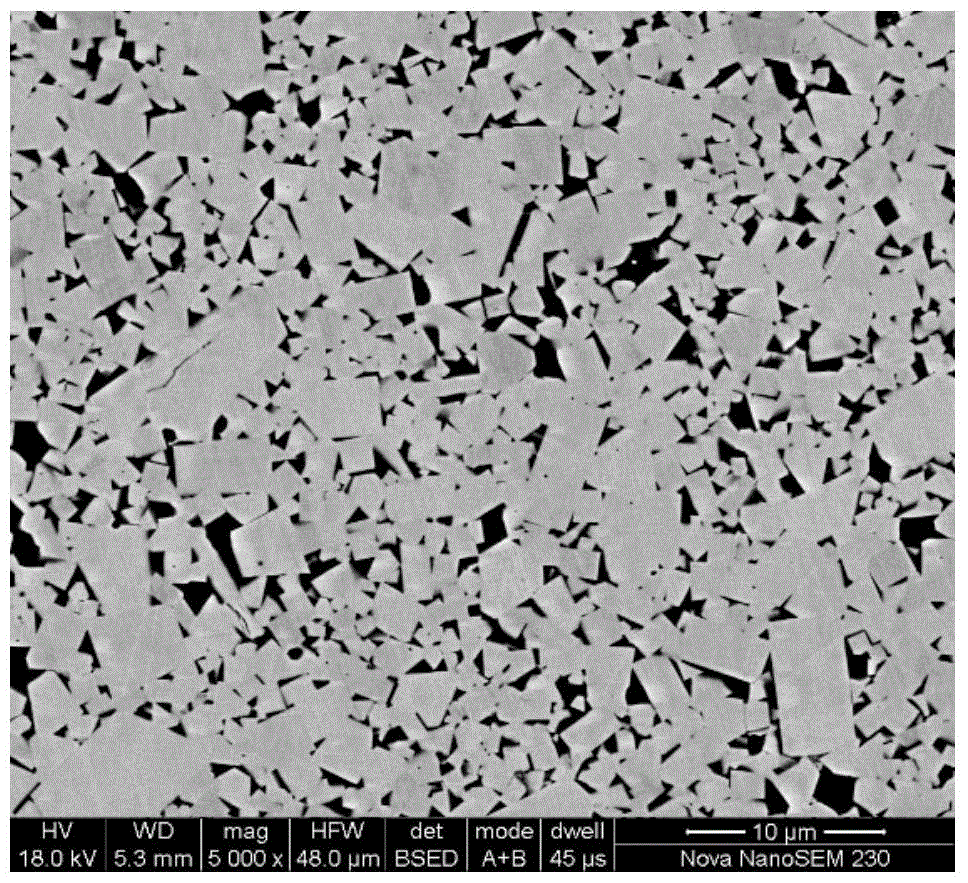

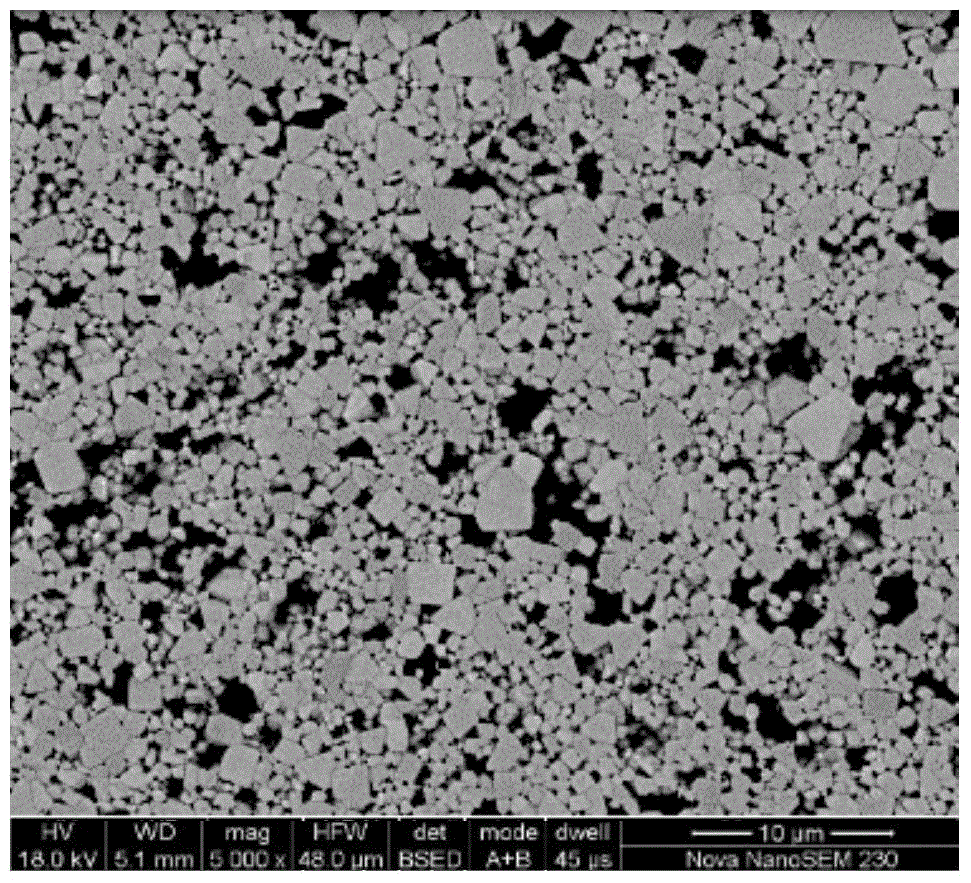

Method for quickly preparing gradient cemented carbide by adding rare-earth elements

The invention discloses a method for quickly preparing gradient cemented carbide by adding rare-earth elements, and belongs to the field of manufacturing cemented carbide materials. The method disclosed by the invention comprises the following steps: pressing and forming carbon-poor cemented carbide powder containing rare earth, and performing vacuum sintering to obtain a carbon-poor presintering base body; performing carburizing treatment for 40-120 minutes at the temperature of 1,400-1,460 DEG C under the hydrogen atmosphere to obtain the gradient cemented carbide, wherein the thickness of a gradient layer of the gradient cemented carbide is 200-3000 [mu]m. The rare-earth elements are added in the process of preparing the gradient cemented carbide, so that alloying components are solidified and dissolved in a Co phase in the presintering process, and the effect of inhibiting crystal grains from growing can be achieved. But in the carburizing process, the influence of adding the rare earth on the dissolution and the separation of WC (wolfram carbide) in the Co phase is weakened, and more passages are provided for the diffusion of activated carbon, so that the thickness of the gradient layer of the alloy can be quickly increased.

Owner:株洲金韦硬质合金有限公司

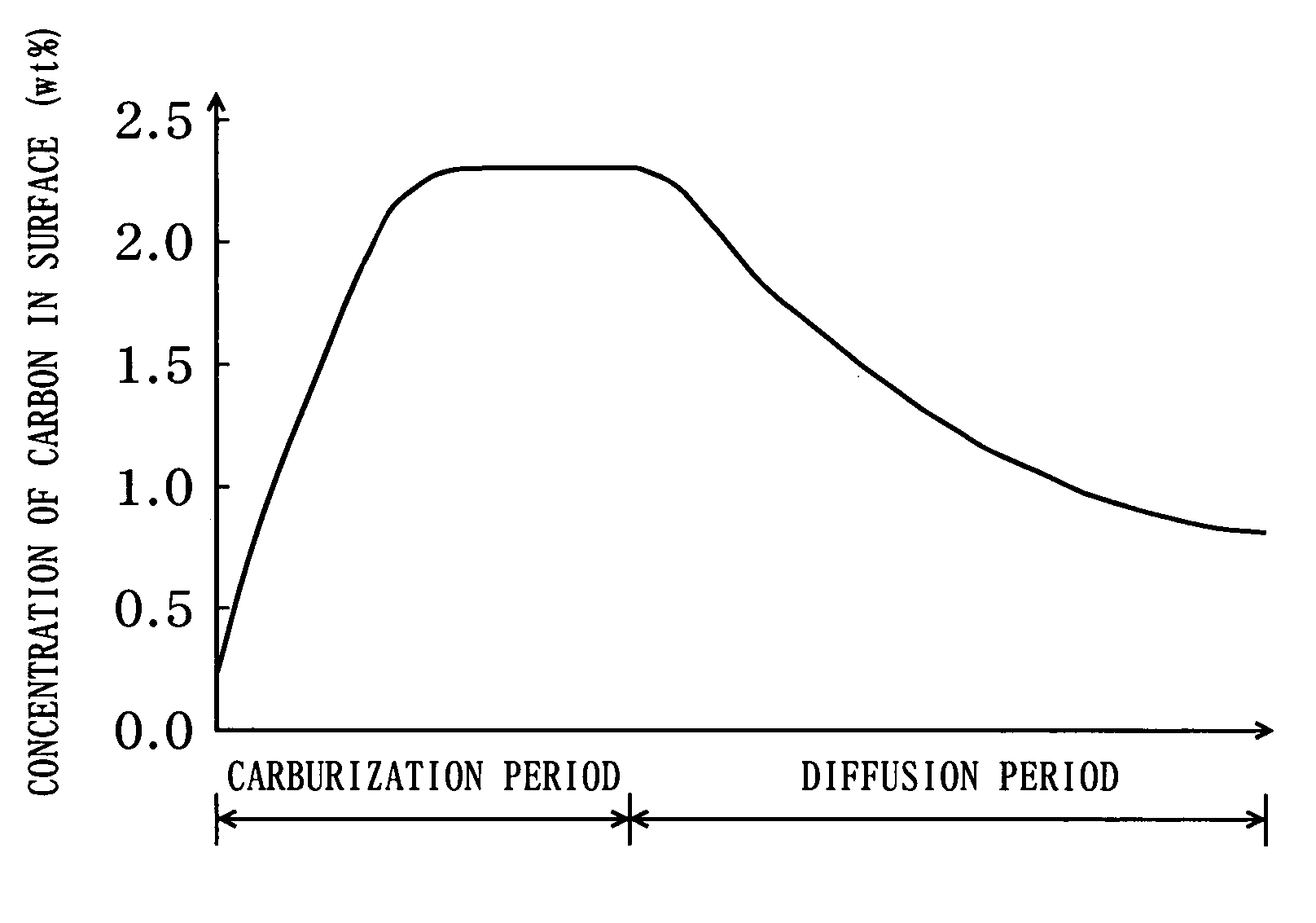

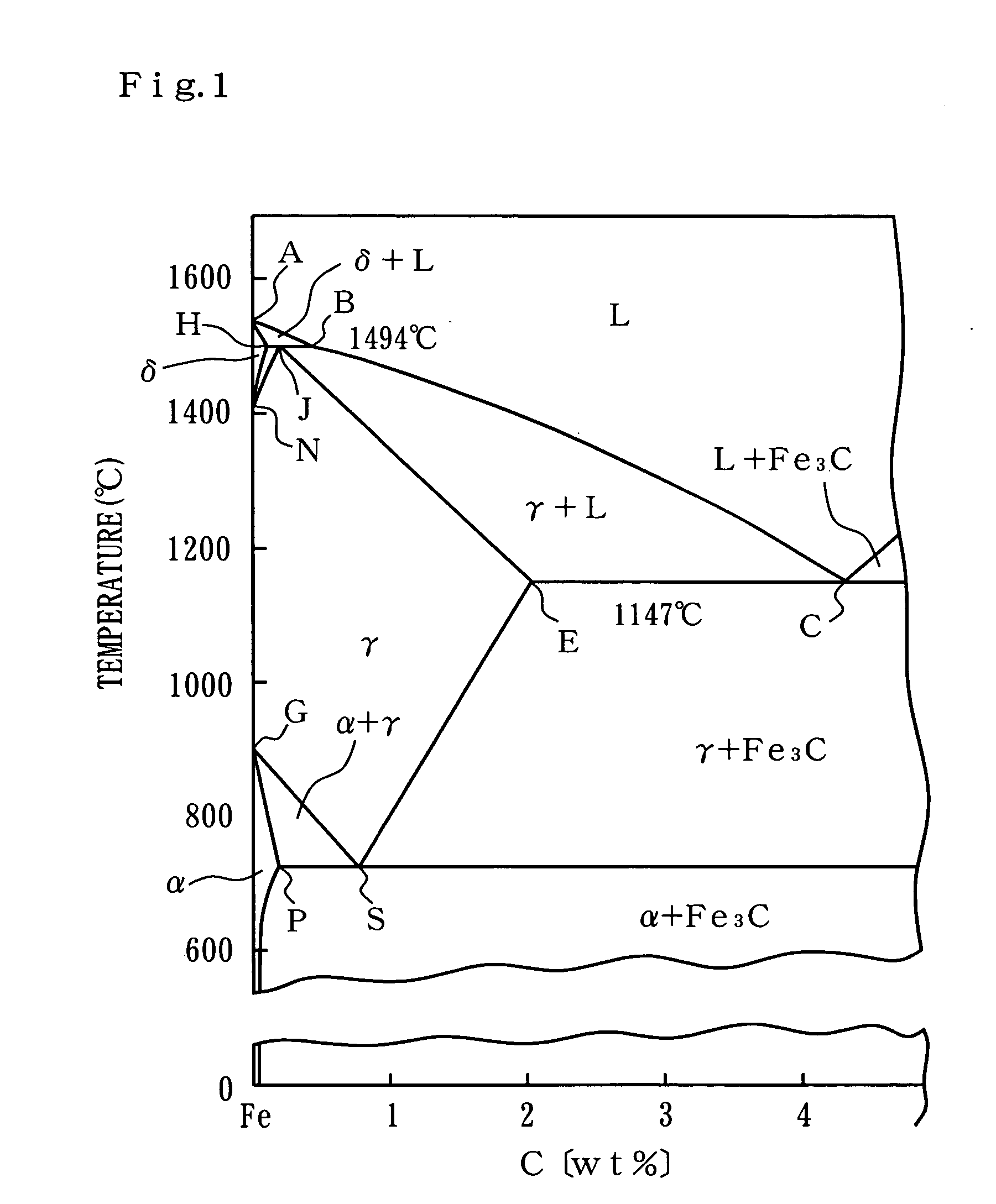

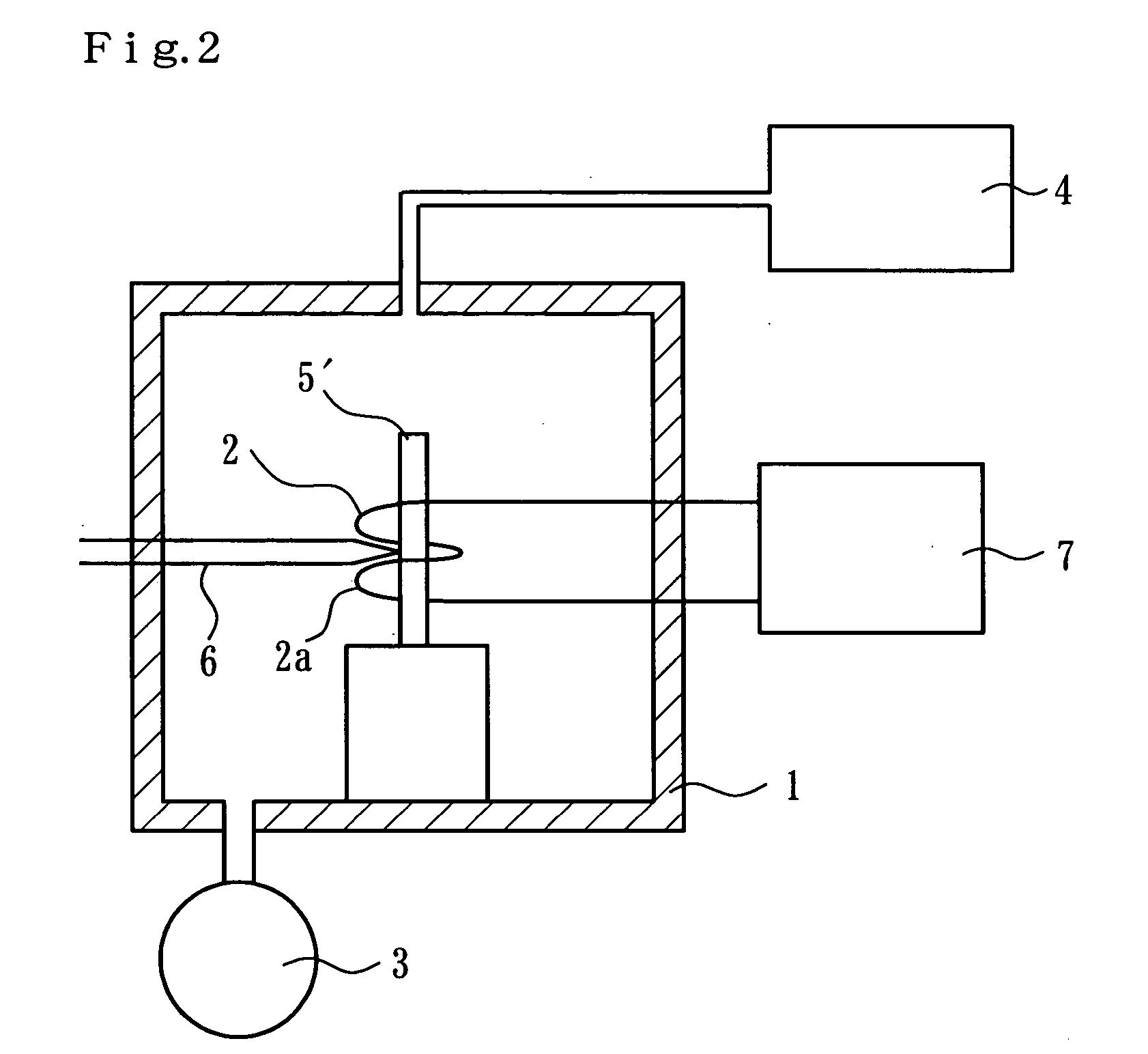

Method of gas carburizing

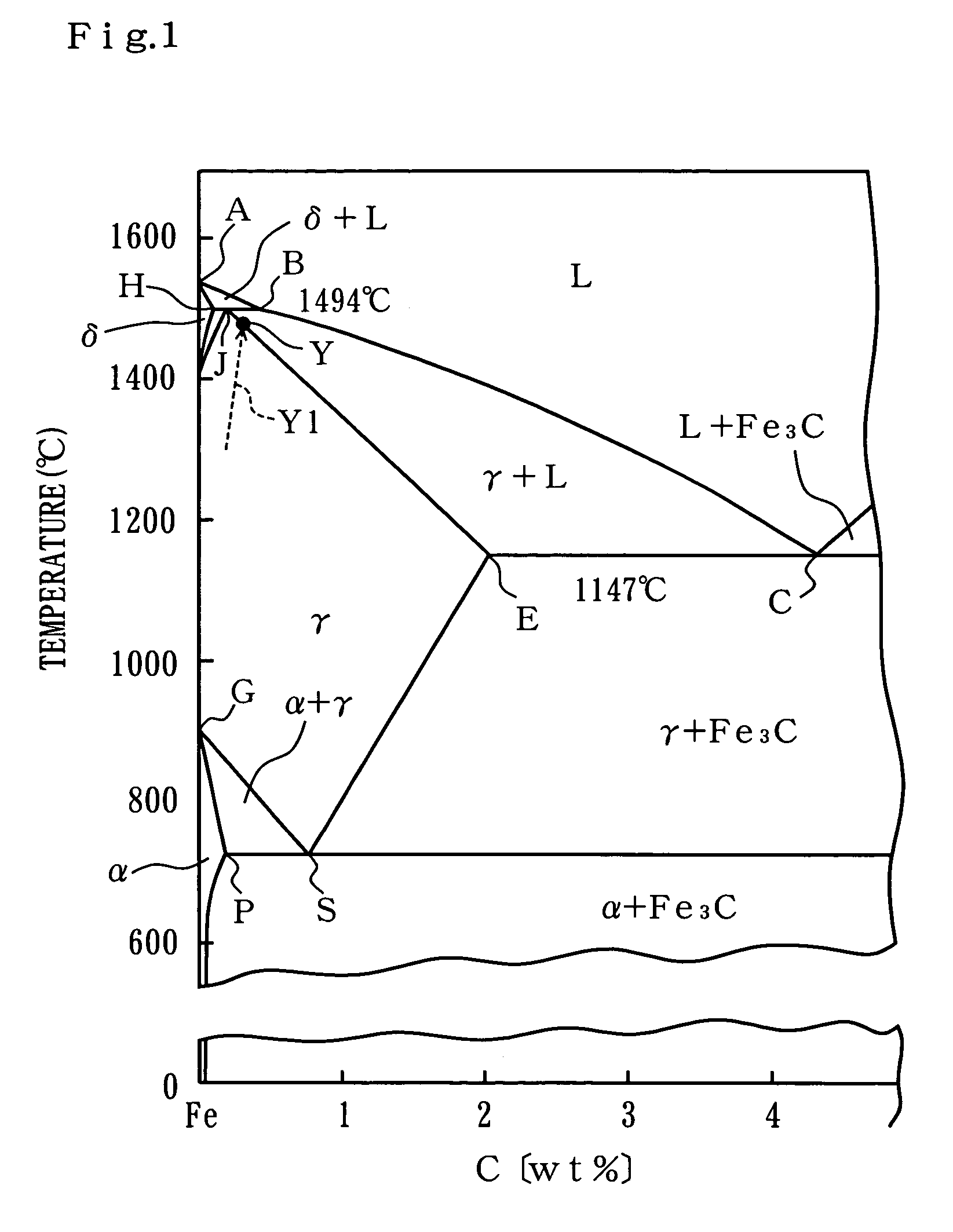

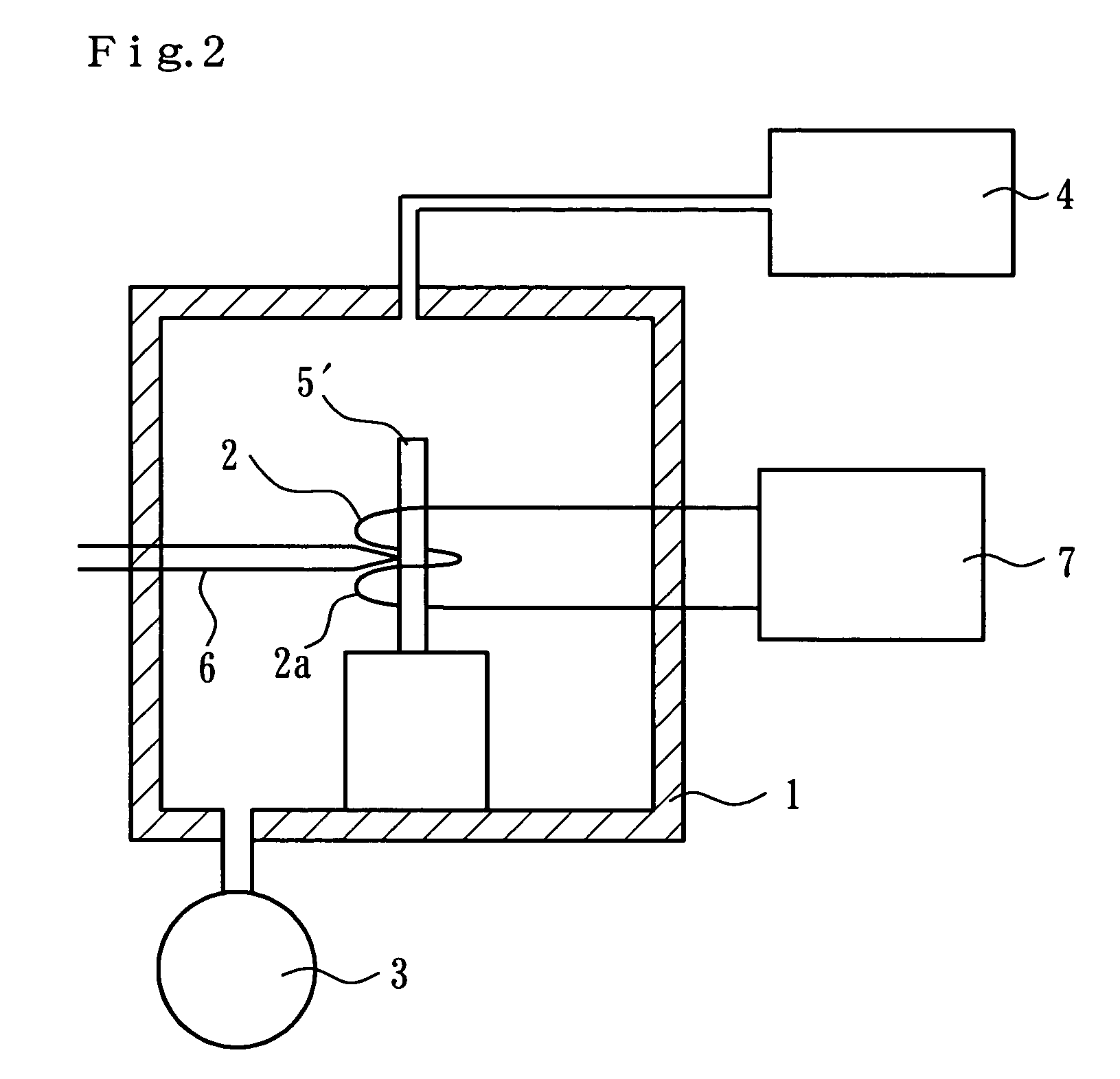

InactiveUS20050205164A1Improve heating efficiencySimple treatmentSolid state diffusion coatingSurface layerMetallurgy

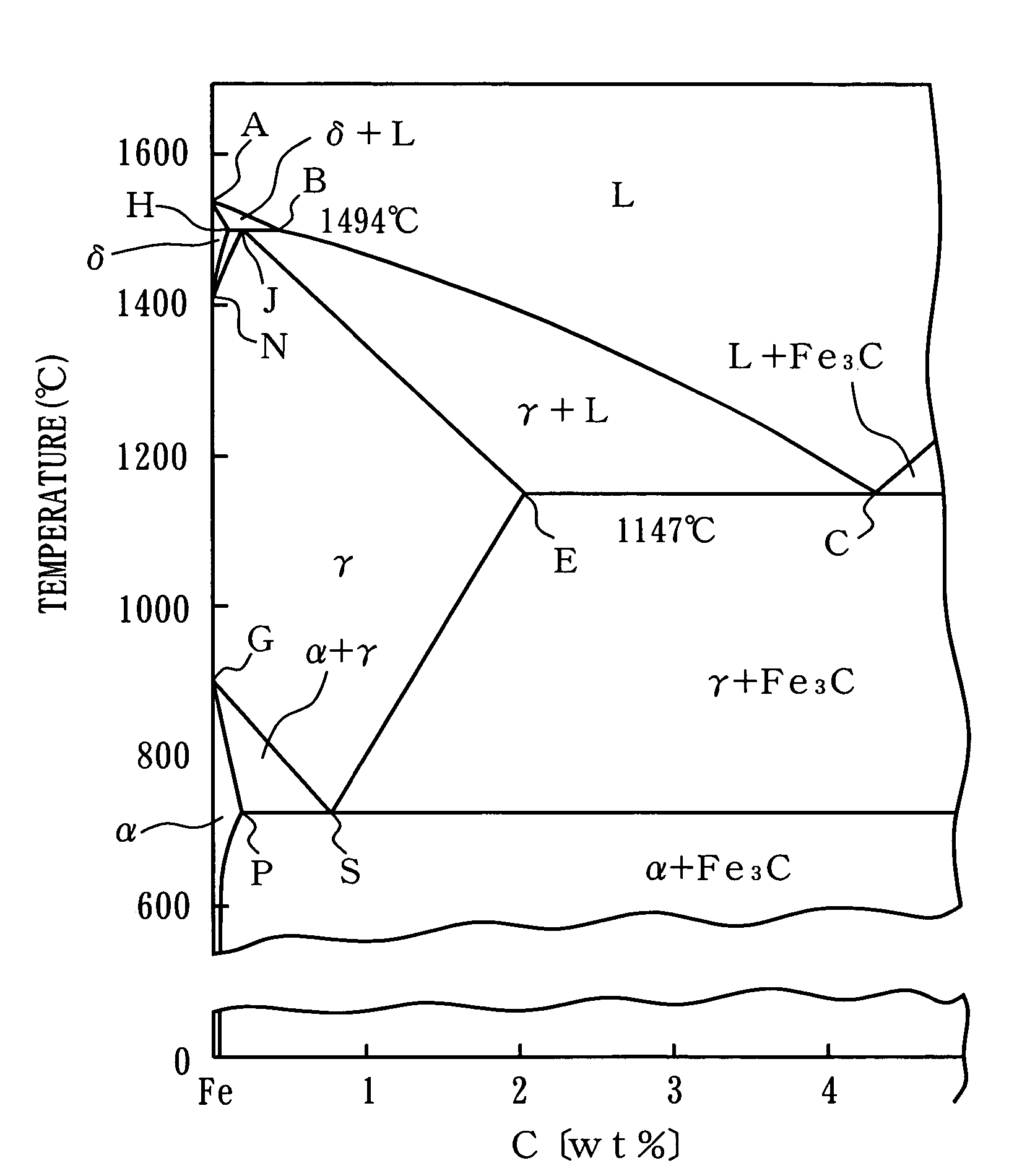

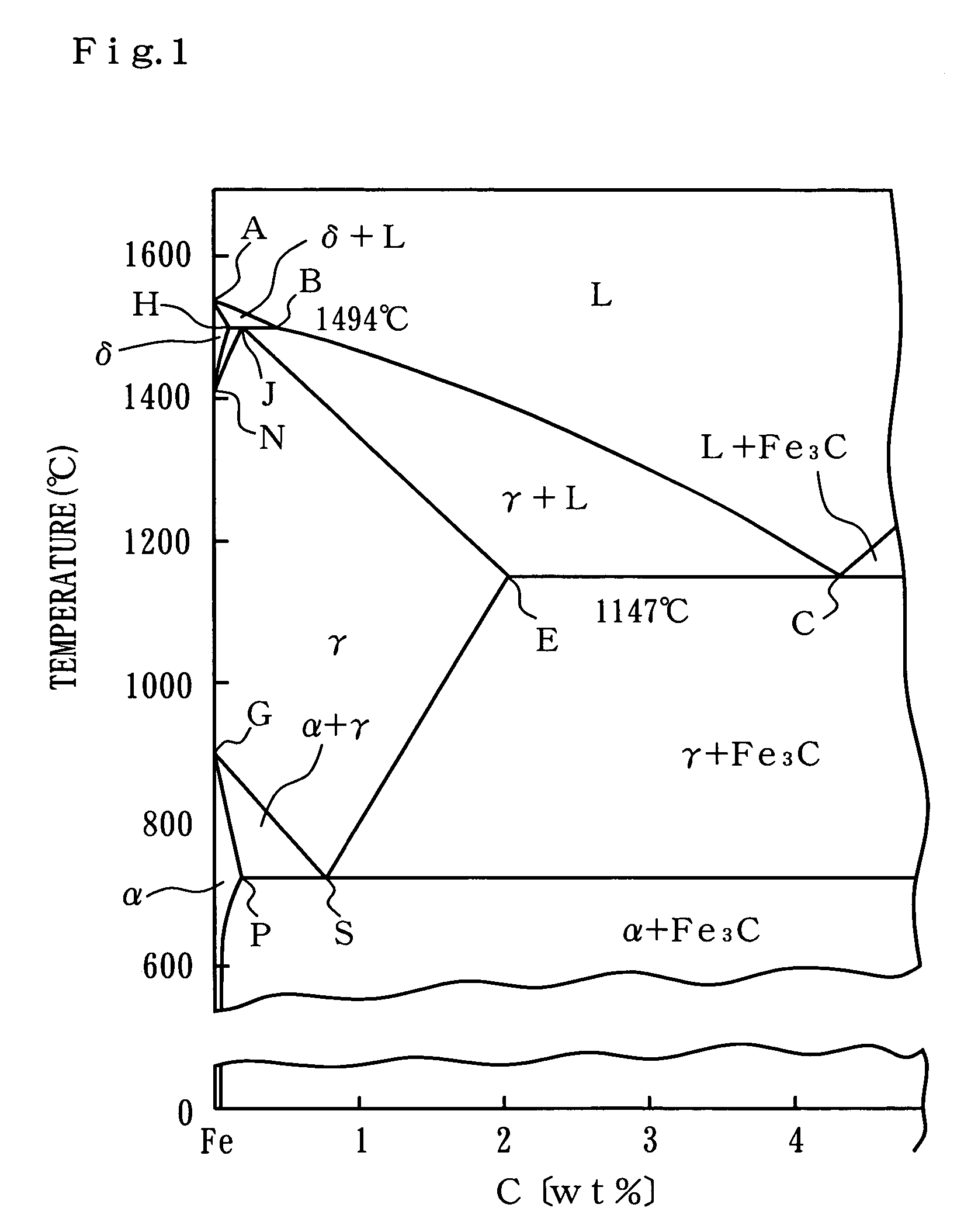

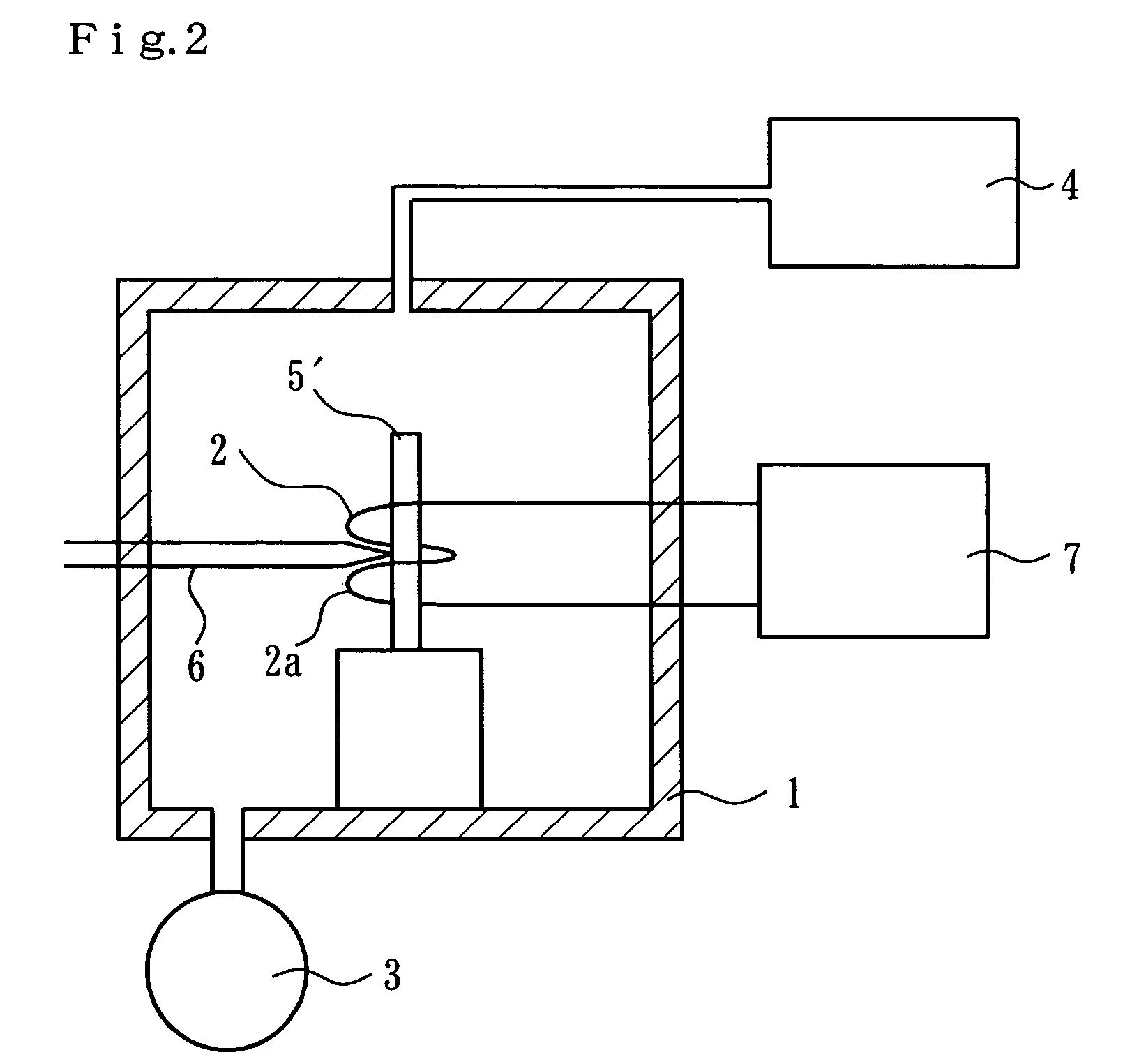

A method of gas carburizing is carried out at a carburizing temperature which is not higher than a peritectic point temperature at which δ iron and liquid phase are transformed into γ iron and not less than a eutectic point temperature at which liquid phase is transformed into γ iron and cementite. The method comprises the step of predetermining the limiting carburizing conditions at which the surface layer of a sample of a steel treatment object present in a carburizing atmosphere is austenitized without melting and the step of gas carburizing the treatment object under carburizing conditions which are set so as not to contradict the limiting carburizing conditions, at a carburizing temperature which is not higher than the peritectic point temperature and not less than the eutectic point temperature. The limiting carburizing conditions comprise an upper limit value of a partial pressure of carburizing gas at which the surface layer of the sample is austenitized without melting.

Owner:KOYO THERMO SYST CO LTD

Composite carburizing agent, carburizing method for detecting austenite grain size and detection method of austenite grain size

ActiveCN110643933AShort holding timeLow costInvestigating crystalsSolid state diffusion coatingAustenite grainTest sample

The invention relates to the field of steel heat treatment, in particular to a composite carburizing agent, a carburizing method for detecting the austenite grain size and a detection method of the austenite grain size. The composite carburizing agent is prepared from a first carburizing agent with the grain size of 1.0 mm-3.0 mm and a second carburizing agent with the grain size of 5.0 mm-8.0 mm.The mass percent of the first carburizing agent is 27%-33%. In the carburizing process of the composite carburizing agent, through mutual penetrating and inserting of the second carburizing agent andthe first carburizing agent with different grain sizes, gaps are filled mutually, a proper amount of oxygen seeps, reaction formation of active carbon atoms is guaranteed, a uniform and stable carburizing atmosphere is formed, a uniform carburizing layer with the thickness reaching the standard is formed on the surface of a test sample, and meanwhile the problem of serious oxidation caused by excessive oxygen is avoided.

Owner:SGIS SONGSHAN CO LTD

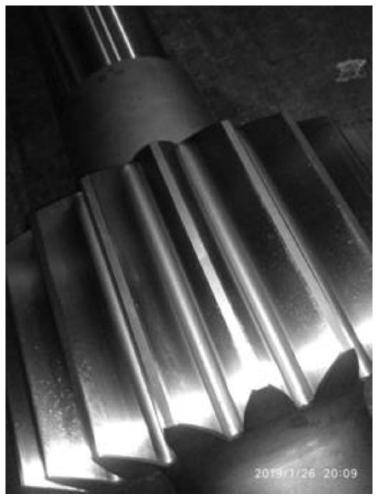

Heavy-duty gear carburizing and quenching method

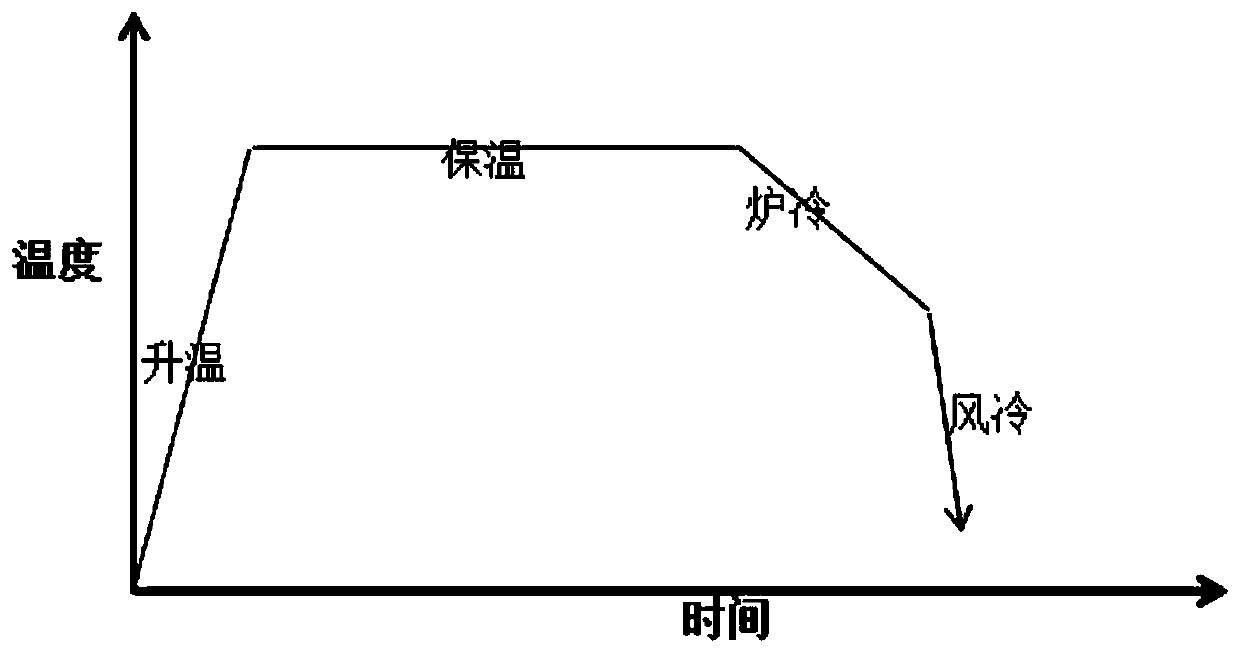

ActiveCN110331260AReduce quenching stressReduce stressSolid state diffusion coatingFurnace typesWater basedThermal insulation

The invention discloses a heavy-duty gear carburizing and quenching method, and relates to the technical field of special steel making. The method comprises the following steps that a gear workpiece is subjected to carburizing treatment in a gas carburizing furnace, and then is subjected to austenitizing heating thermal insulation after getting out of furnace; then the gear workpiece is subjectedto precooling quenching; the gear workpiece is subjected to water-base medium quenching, salt bath quenching and fog cooling in sequence; and the gear workpiece is washed after fog cooling is finished, and then is subjected to tempering treatment. With the heavy-duty gear carburizing and quenching method, the problem that for a large-control-section gear made of a low-hardenability material, a quenching method in the prior art cannot achieve the purposes of making the performance of a center part and a gear root excellent and having effectively control over stress type cracking at the same time is solved, it is achieved that a heavy-duty gear is controllable in carburizing and quenching deformation without cracks, and the hardness, the texture, a hardened layer and the dynamic performanceof the heavy-duty gear all meet the technological design requirements.

Owner:CHANGZHOU TIANSHAN HEAVY IND MACHINERY

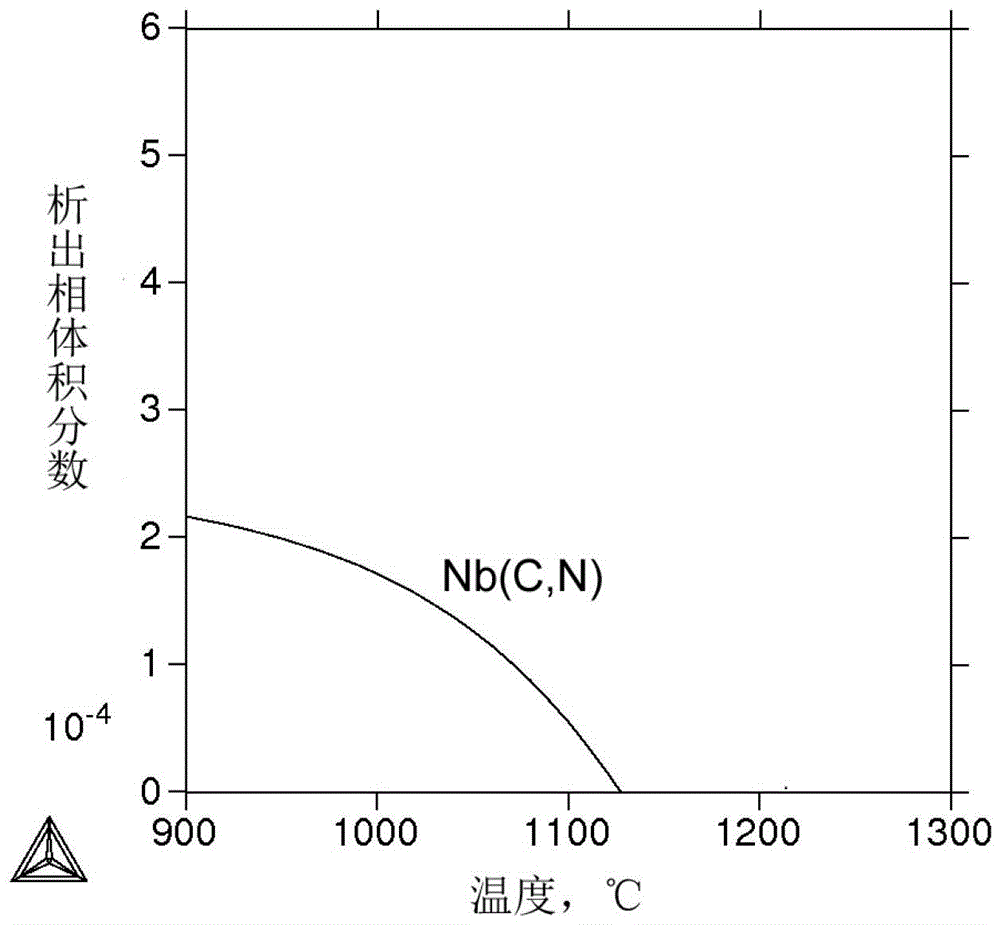

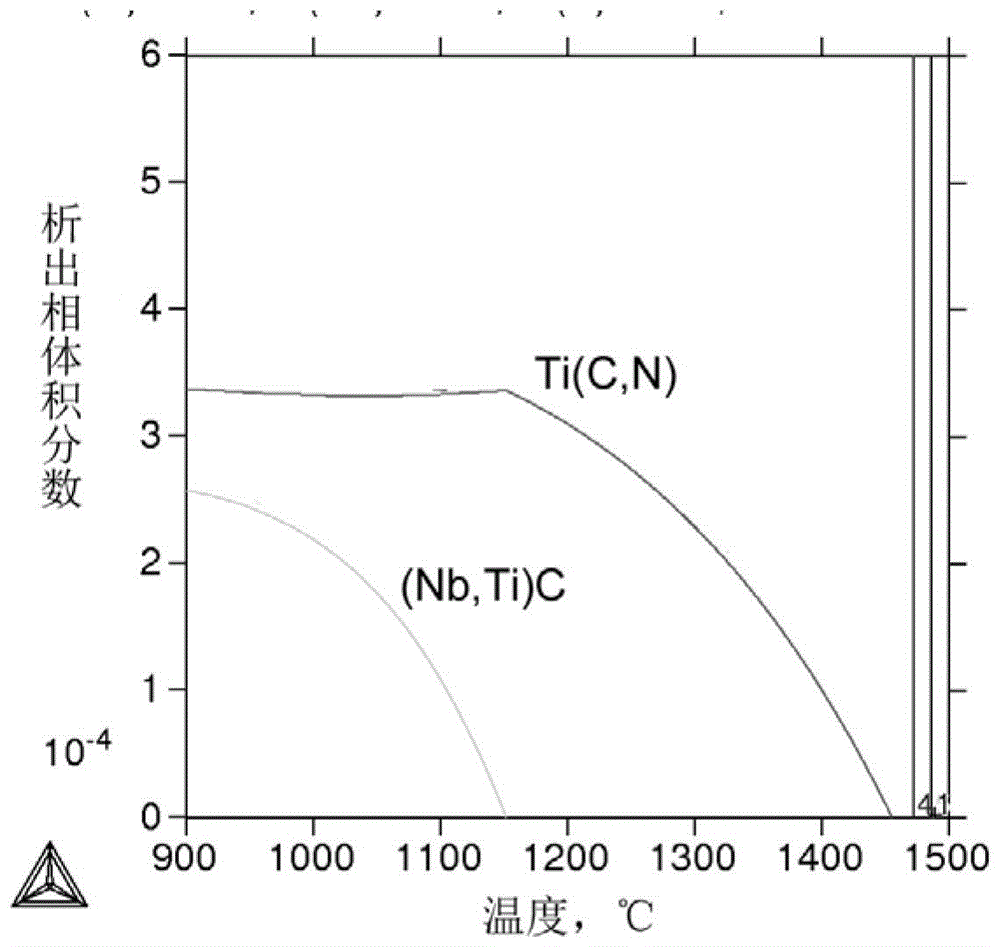

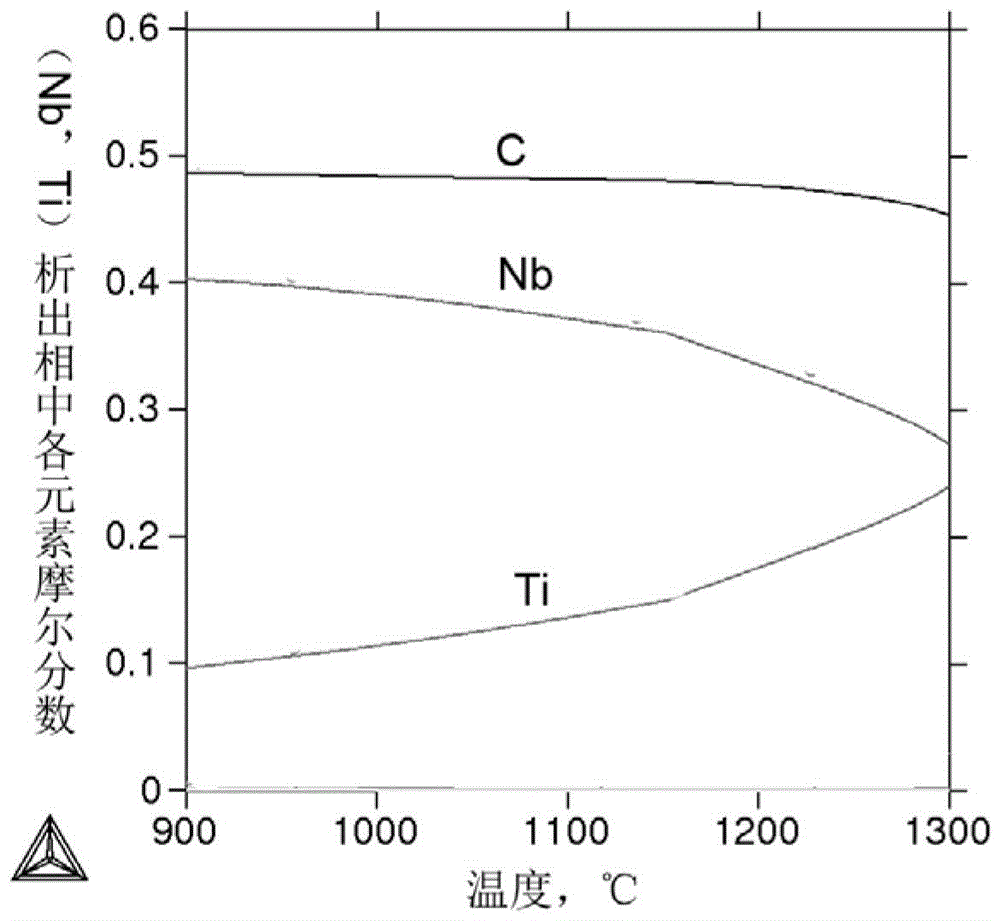

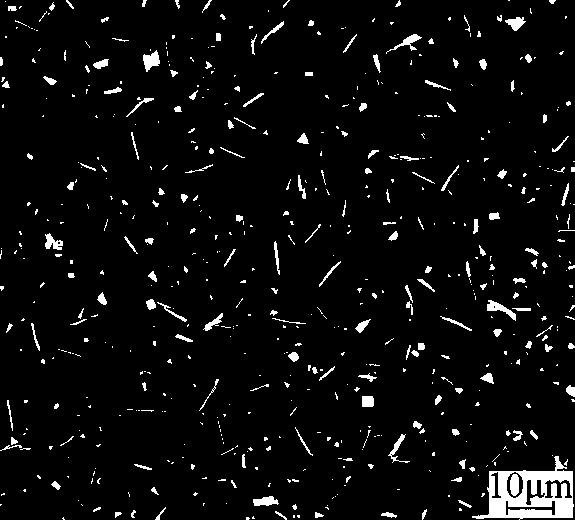

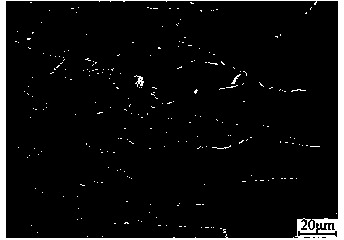

A kind of nb, ti composite microalloying high temperature carburizing gear steel

The invention relates to Nb and Ti composite micro-alloyed high-temperature carburized gear steel, and belongs to the technical field of alloy steel. The gear steel comprises the chemical components of, by mass: 0.17-0.22% of C, 0.20-0.35% of Si, 0.9-1.10% of Mn, 1.05-1.30% of Cr, 0.02-0.06% of Ti, 0.02-0.06% of Nb, 0.015-0.035% of Al, no more than 0.025% of P, 0.020-0.035% of S, and balance of Fe and inevitable impurities. The steel has the advantages that: through controlling the contents of Nb and Ti alloy elements, the carburization temperature of a current gear can be improved, gear carburization time can be reduced, and gear production cost can be reduced.

Owner:SHOUGANG CORPORATION

Surface carburizing process for mold

InactiveCN105648393AImprove mechanical propertiesImprove wear resistanceSolid state diffusion coatingProduction effectMechanical property

The invention discloses a surface carburizing process for a mold; 12Cr2Ni4A is adopted in material. The surface carburizing process for the mold is characterized by adopting the following steps: (1) a preparation stage; (2) a carburizing stage; and (3) a diffusing stage. The surface carburizing process for the mold, disclosed by the invention, is simple, and is capable of increasing surface mechanical property and abrasion resistance, shortening carburizing time and increasing service performance and a production effect of the mold.

Owner:CHONGQING YEGAO FURNITURE CO LTD

Rare earth controllable carburizing method for furnace for periodical operation

InactiveCN1325691CShort carburizing process timeFast carburizingSolid state diffusion coatingCarbon potentialMetallurgy

The method of discontinuous running carburizing furnace rare-earth controllable changing carbon potential carburizing was introduced in the invention. It was involved in one kind of rare-earth controllable changing carbon potential carburizing. It is carried out by adding rare-earth cementation agent to the carburizing furnace when the furnace temperature rise to 820 deg.C in the period of air-out, the earbon, potential reduced from 0.6% to 1.45% till close the pore, the carburizing time is 80-120 min, the strong carburizing period I was 2-4h, the carbon potential reduced form 1.45% to 1.25%, the strong carburizing period II was 4-6, the carbon potential reduced from 1.25% to 1.1%. The diffusion period was 6-8h, the carbon potential reduced from 1.1% to 0.8%. Its advantages include advanced the potential of carburizing furnace; increased the carburizing speed; shorten the time of carburizing; the function of rare-earth cementation agent more effective when combined the high carbon potential; shorten the carburizing time more than 30%, power saved 25-35%.

Owner:HARBIN INST OF TECH

Preparation method for surface-strengthened Fe-W alloy

The invention discloses a preparation method for a surface-strengthened Fe-W alloy. The Fe-W alloy is subjected to carburizing treatment by utilizing a rare earth infiltration catalysis process, and is subjected to water cooling and quenching after the carburization is completed. The Fe-W alloy prepared by the invention is low in cost; after the carburization is performed by utilizing a rare earth infiltration catalyst, the carburization time can be effectively shortened, the carburized layer depth can be increased, the carburized layer hardness gradient can be reduced, the tissue of the carburized layer is refined, the carbide dispersivity is increased, the high hardness is kept, and meanwhile, the alloy has high toughness.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Method of gas carburizing

InactiveUS7416614B2Avoid insufficient thicknessShorten carburizing timeSolid state diffusion coatingSurface layerMetallurgy

A method of gas carburizing is carried out at a carburizing temperature which is not higher than a peritectic point temperature at which δ iron and liquid phase are transformed into γ iron and not less than a eutectic point temperature at which liquid phase is transformed into γ iron and cementite. The method comprises the step of predetermining the limiting carburizing conditions at which the surface layer of a sample of a steel treatment object present in a carburizing atmosphere is austenitized without melting and the step of gas carburizing the treatment object under carburizing conditions which are set so as not to contradict the limiting carburizing conditions, at a carburizing temperature which is not higher than the peritectic point temperature and not less than the eutectic point temperature. The limiting carburizing conditions comprise an upper limit value of a partial pressure of carburizing gas at which the surface layer of the sample is austenitized without melting.

Owner:KOYO THERMO SYST CO LTD

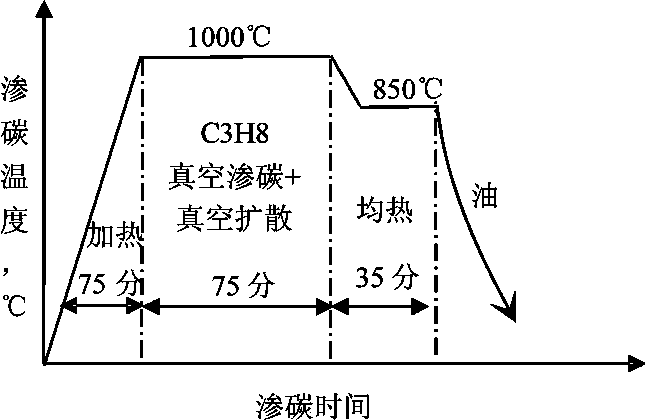

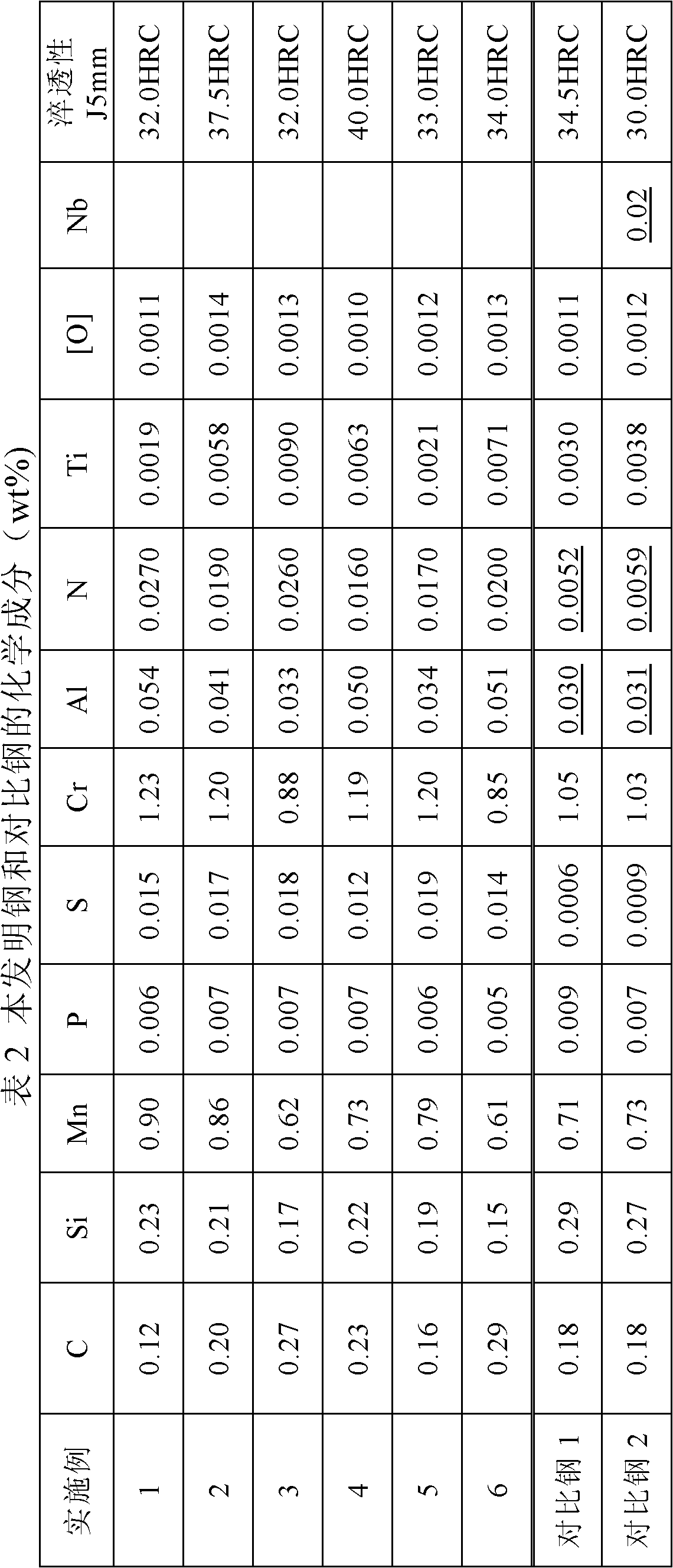

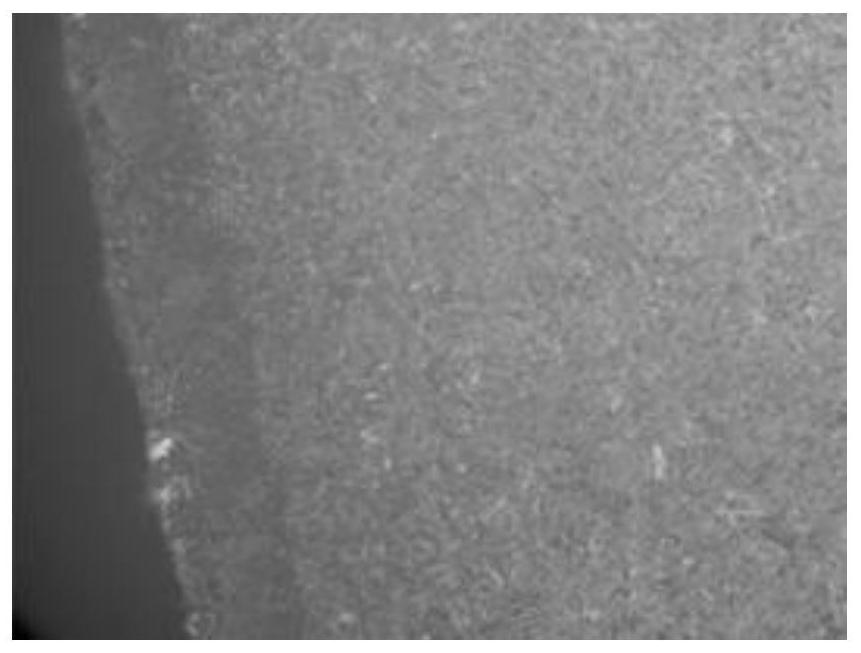

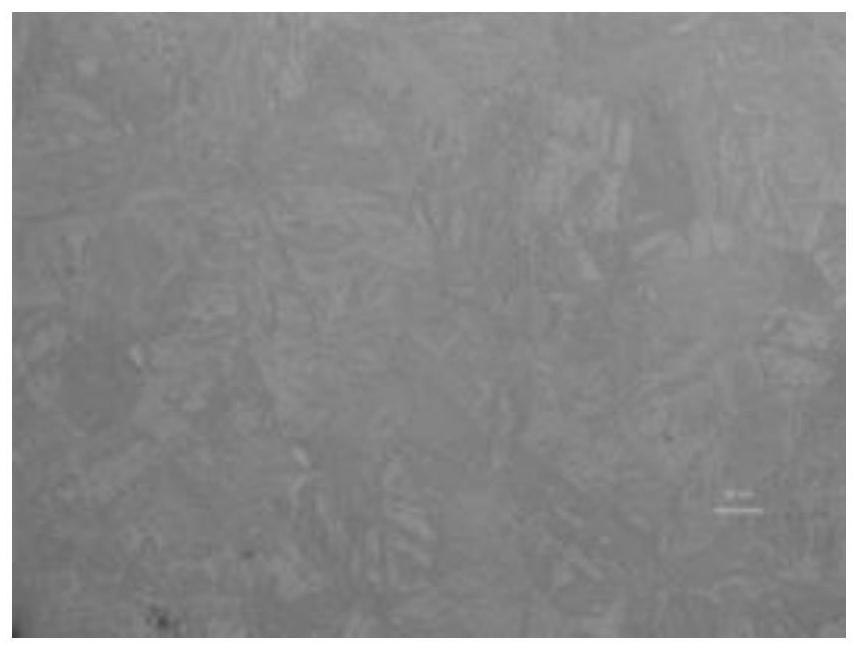

A high temperature vacuum carburized gear steel

InactiveCN102560255BRaise the roughening temperatureImprove product qualityAbnormal growthsAustenite grain

The invention discloses high-temperature vacuum carburized gear steel. The high-temperature vacuum carburized gear steel comprises: by weight, 0.10 to 0.30% of C, 0.15 to 0.25% of Si, 0.60 to 0.90% of Mn, less than or equal to 0.025% of P, 0.010 to 0.020% of S, 0.85 to 1.25% of Cr, 0.033 to 0.055% of Al, 0.0160 to 0.0300% of N, 0.001 to 0.009% of Ti, less than or equal to 0.0020% of O and the balance Fe and unavoidable impurities. Through a micro-alloying method, abnormal growth of austenite grains of gear steel in high-temperature vacuum carburizing is controlled and thus steel grain granularity is strictly controlled in a range of 7.0 to 8.0 grade and hardenability (J5mm) is stably controlled in a range of 32 to 42 HRC so that various performance requirements of common gear steel are satisfied. The high-temperature vacuum carburized gear steel contains simple alloy elements, has a low cost, allows stable and reliable process control, can be utilized for high-temperature vacuum carburizing, greatly reduces carburizing time, is environmentally friendly and saves energy.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

Manufacturing process of track pin bushing

The invention discloses a manufacturing process of a track pin bushing. The manufacturing process is characterized by comprising the process steps of blank making, machining, carburizing, quenching, inner hole quenching, finishing and the like; the depth of an effective hardening layer is obviously increased, control over the depth of the effective hardening layer is ensured during super-audio inner hole quenching, the carburizing time is greatly shortened, the energy consumption is greatly reduced, the time is saved, the production cycle is shortened, a high-hardness wear layer of an inner hole is obtained, the service life is greatly prolonged, meanwhile, an anti-impact toughness zone of a core part is obtained, and the impact resistance is enhanced.

Owner:孙永宁

Hard alloy carburizing process resulting in gradient distribution of mechanical performance

InactiveCN100441730CHigh thickness valueReduce manufacturing costSolid state diffusion coatingProduction rateGraphite

Owner:ZIGONG CEMENTED CARBIDE CORP +1

A carburizing and quenching method for heavy-duty gears

ActiveCN110331260BReduce quenching stressReduce stressSolid state diffusion coatingFurnace typesTemperingThermal insulation

The invention discloses a heavy-duty gear carburizing and quenching method, and relates to the technical field of special steel making. The method comprises the following steps that a gear workpiece is subjected to carburizing treatment in a gas carburizing furnace, and then is subjected to austenitizing heating thermal insulation after getting out of furnace; then the gear workpiece is subjectedto precooling quenching; the gear workpiece is subjected to water-base medium quenching, salt bath quenching and fog cooling in sequence; and the gear workpiece is washed after fog cooling is finished, and then is subjected to tempering treatment. With the heavy-duty gear carburizing and quenching method, the problem that for a large-control-section gear made of a low-hardenability material, a quenching method in the prior art cannot achieve the purposes of making the performance of a center part and a gear root excellent and having effectively control over stress type cracking at the same time is solved, it is achieved that a heavy-duty gear is controllable in carburizing and quenching deformation without cracks, and the hardness, the texture, a hardened layer and the dynamic performanceof the heavy-duty gear all meet the technological design requirements.

Owner:CHANGZHOU TIANSHAN HEAVY IND MACHINERY

Heat treatment method for carburizing and quenching of automobile gearbox gears

ActiveCN103710714BHigh surface hardnessImprove wear resistanceSolid state diffusion coatingFurnace typesCarbon potentialRoom temperature

The invention discloses an automobile gearbox gear carburizing and quenching heat treatment method. The method comprises the following steps: 1, carburizing: placing a gear in a heating furnace, and rising temperature of the heating furnace from room temperature to 900+ / -5DEG C for carburizing for 3-4h, wherein the carbon potential CP in a strong carburizing stage is 1.06+ / -0.3C%, and the carbon potential CP in a diffusion stage is 0.85+ / -0.03C%; 2, quenching: cooling the obtained carburized gear to 830+ / -5DEG C, samming for 25-35min, and quenching in 90+ / -10DEG C quenching oil; and 3, tempering: tempering the obtained quenched gear at 165+ / -5DEG C for 2-3h. The proper reduction of the carburizing temperature and the quenching temperature, the rising of the temperature of the quenching oil and the proper rising of the carburizing carbon potential are carried out on the premise of guaranteeing the quality of a carburized layer, so the carburizing time is not prolonged, and the energy consumption is reduced; and the appearance of black microstructures is prevented, so the surface hardness, the wear resistance and the fatigue strength of the gear are obviously improved, deformation is reduced, the driving balance of the gear is improved, noises are reduced, and the service life of the gear is prolonged.

Owner:厦门真冈热处理有限公司

Method of gas carburizing

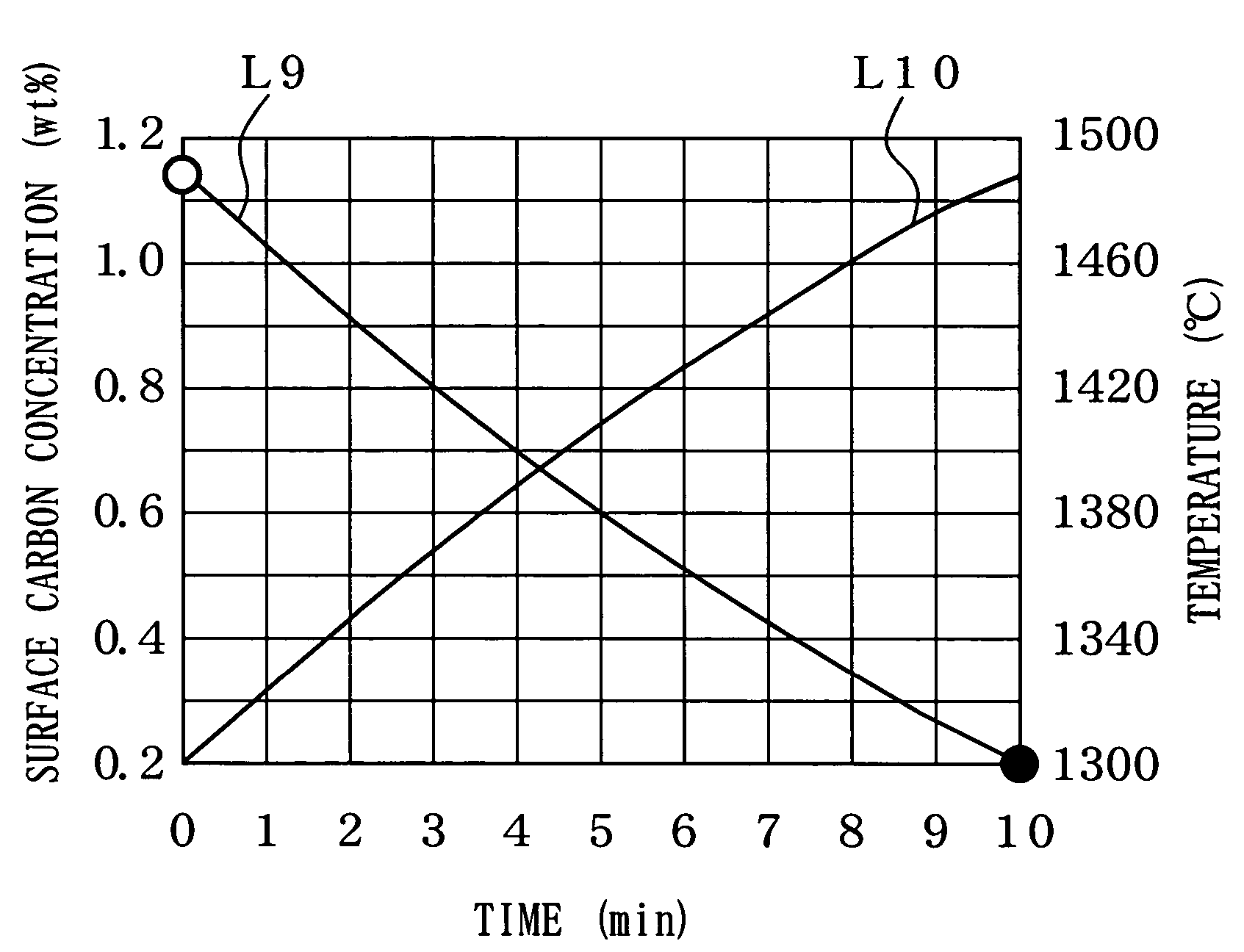

ActiveUS7029540B2Shorten carburizing timeShorten the timeSolid state diffusion coatingProduct gasCarburizing

In a first process of a method of gas carburizing, a steel treatment object in a carburizing atmosphere containing carburizing gas is heated to an initial set temperature which is not higher than a peritectic point at which δ iron and a liquid phase transform into γ iron and not less than a eutectic point at which the liquid phase transforms into γ iron and cementite, such that the surface carbon concentration thereof does not exceed a solid solubility limit. In a second process following the first process, the carburizing temperature is gradually decreased from the initial set temperature such that the surface carbon concentration of the treatment object increases without exceeding the solid solubility limit, and such that the carburized depth of the treatment object increases.

Owner:KOYO THERMO SYST CO LTD

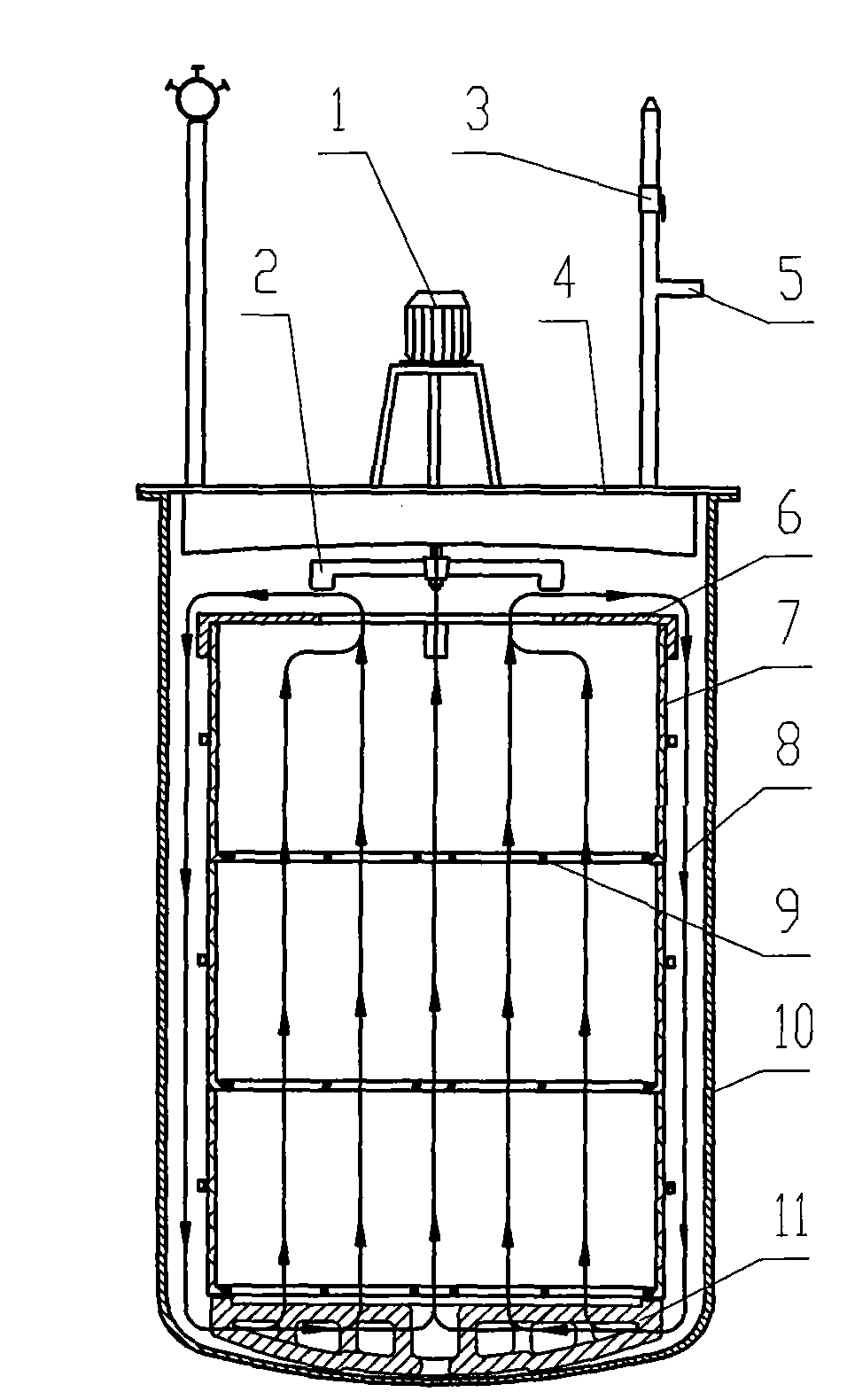

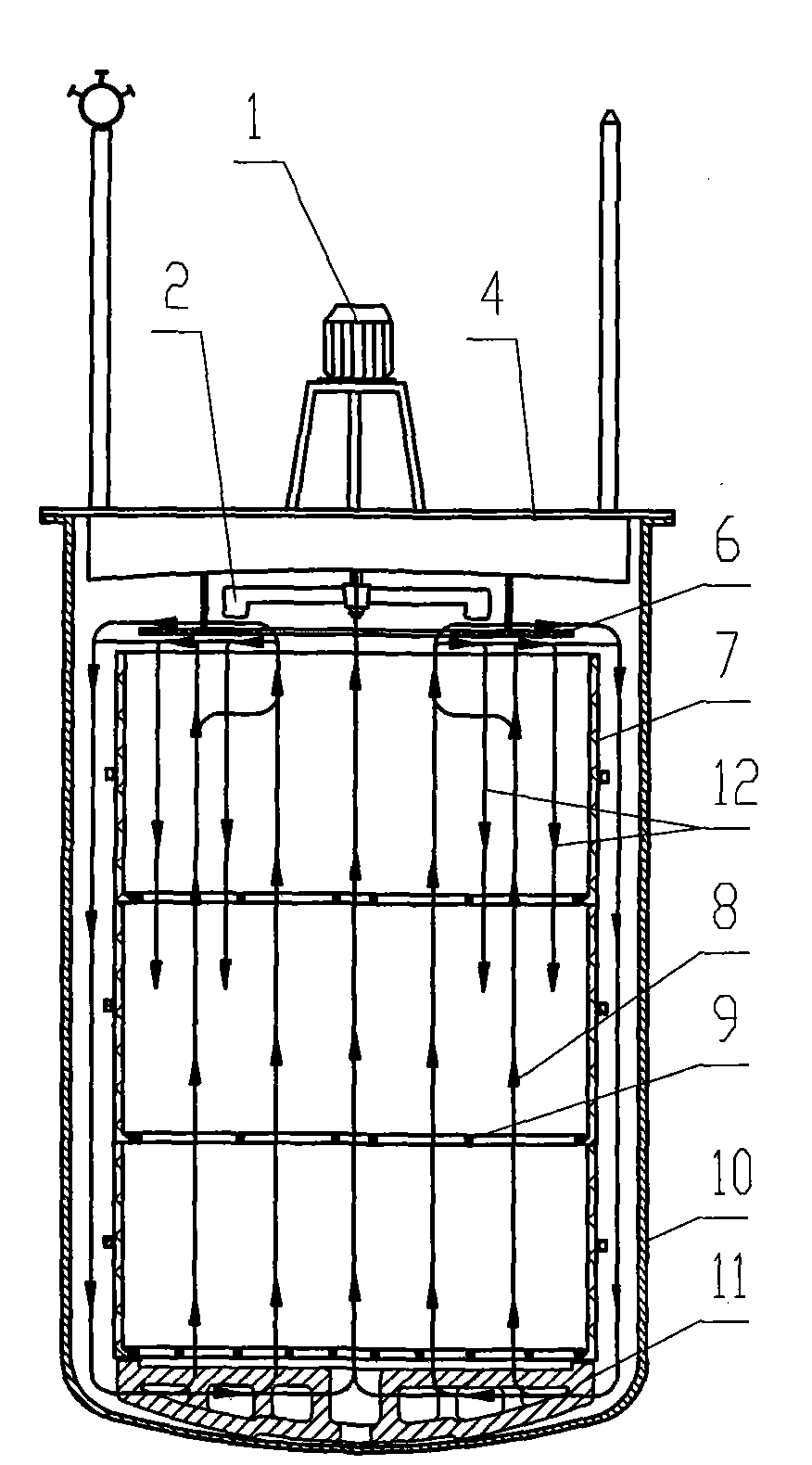

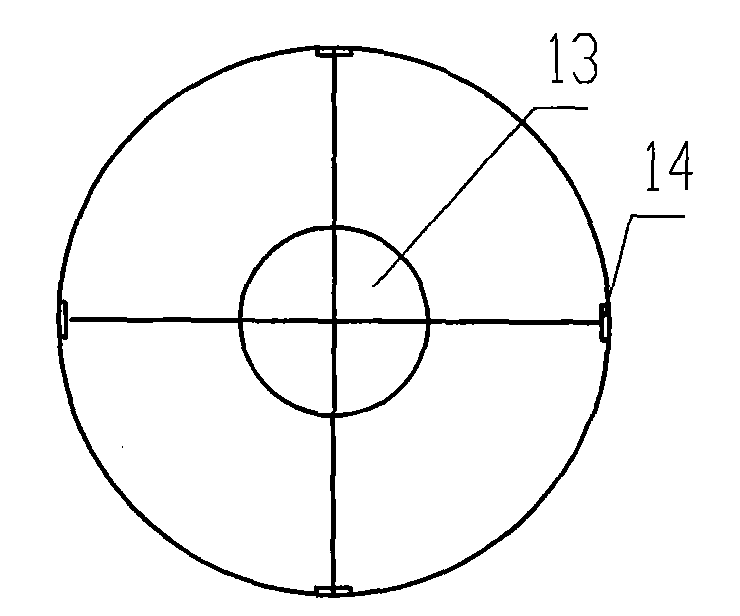

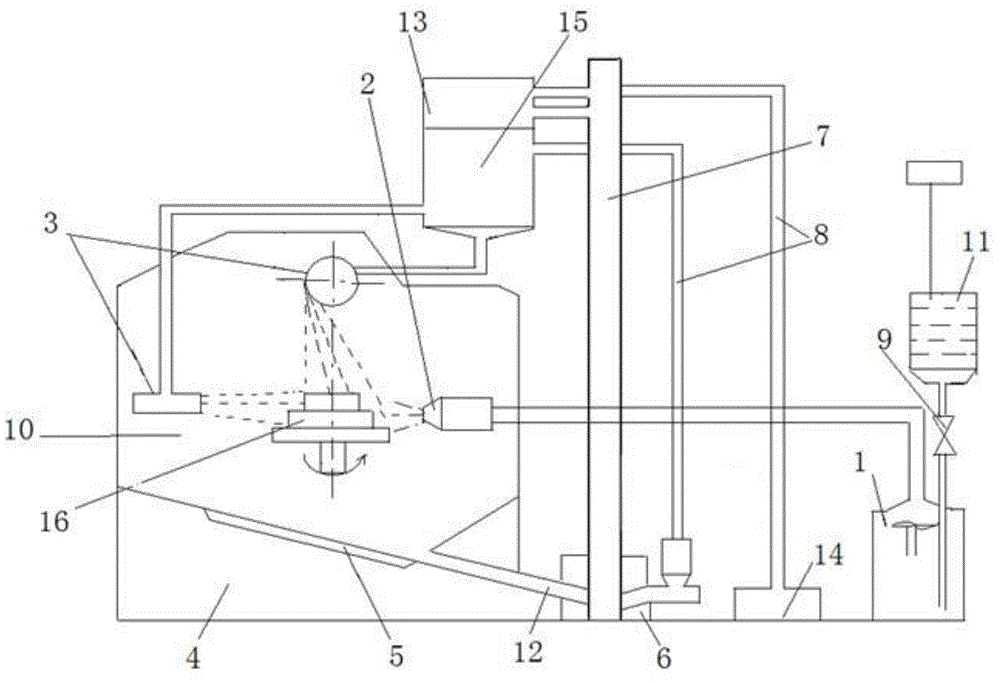

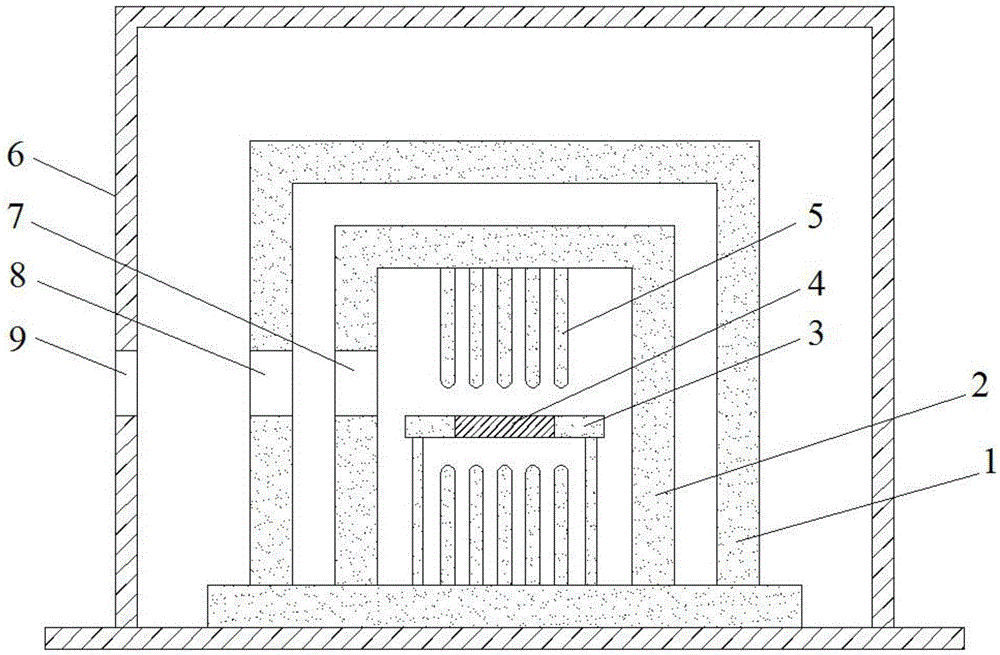

Well type air seep carbon stove and improvement of process thereof

InactiveCN101565809BIncrease carburizing speedIncrease productivitySolid state diffusion coatingCarbon potentialKerosene

The present invention discloses a well type air seep carbon stove and improvement of process thereof. The invention is characterized in that a traditional well type air seep carbon stove is improved; a wind shield is arranged on a charging basket; and the distance between the wind shield and a fan is increased. When a carburizing agent composed of kerosene and methanol is used for carburizing workpieces made from material of 20 Cr or 20 CrMnTi, the carburizing process includes carburizing period and diffusion stage, the temperatures of which respectively are 930 DEG C plus or minus 10 DEG C, 900 DEG C plus or minus 10 DEG C. During the carburizing period, the carburizing agent is added with kerosene of 10.3 ml / m<3> / min plus or minus 0.2 ml / m<3> / min, and methanol of 3.4 ml / m<3> / min plus or minus 0.2 ml / m<3> / min; and the carbon potential in the stove is 1.05 percent plus or minus 0.05 percent. During the diffusion stage, kerosene is of 8.0 ml / m<3> / min plus or minus 0.2 ml / m<3> / min, methanol is of 4.6 ml / m<3> / min plus or minus 0.2 ml / m<3> / min, and the carbon potential in the stove is 0.95 percent plus or minus 0.05 percent; and the pressure in the stove during the carburizing period ranges from 1.0 kPa to 1.5 kPa. By using the traditional well type air seep carbon stove, the invention has the advantages of enhancing carburization speed, saving carburization time, improving product quality, and adequately decomposing and absorbing the carburizing agent, and hardly producing carbon soot in the stove during the whole carburizing period, with the best effect when carburized depth ranges from 0.9 mm to 1.25 mm.

Owner:石家庄金刚内燃机零部件集团有限公司

Titanium alloy surface treatment method

ActiveCN113308663BControl thicknessImprove surface wear resistanceSolid state diffusion coatingCarburizingTitanium alloy

The invention discloses a titanium alloy surface treatment method, which uses a hemispherical cutter to carry out surface mechanical grinding treatment on a selected area of titanium alloy, and then infiltrates the titanium alloy which has undergone surface mechanical grinding treatment in the selected area at 800°C to 1000°C. Carbon 4 to 10 hours. The present invention adopts the SMGT+low-temperature carburizing process to first form a thicker and more uniform grain deformation layer on the surface of the titanium alloy, which provides a channel for the diffusion of carbon atoms in the carburizing step, and improves the thickness and uniformity of the carburizing layer, thereby Improve its surface wear resistance; secondly, the titanium alloy treated with SMGT can reduce the carburizing temperature and shorten the carburizing time, the carburizing depth is deeper, and the wear resistance is better, which improves the product preparation efficiency and reduces the cost.

Owner:HUNAN JINTIAN ALUMINUM HI TECH CO LTD

Method for realizing nitriding or carburizing by thermal airflow jetting heating and shot blasting

InactiveCN103046058BStrong targetingIncrease profitSolid state diffusion coatingSurface layerNitrogen

The invention discloses a method for realizing nitriding or carburizing by thermal airflow jetting heating and shot blasting. Crystal defects on the surface of manufactured metal can be controlled, and surfaces of components are precisely heated at high speed. The method comprises the following steps of: (1) installing the cleaned components in a chemical thermal treatment furnace, keeping the spacing distance of 15-100mm between the surfaces of the components needing nitriding or carburizing, and abutting the surfaces not needing nitriding or carburizing so as to save the space; (2) nitriding or carburizing: heating a nitriding agent to 300-500 DEG C or a carburizing agent to 650-800 DEG C by using a thermal airflow generator, jetting to the surfaces of the components through a thermal airflow nozzle so as to heat surface layers of the components at high speed; at the same time, jetting balls to the surfaces of the components by using a shot blasting machine so as to manufacture the crystal defects on the surface layers of the manufactured metal simultaneously with increasing the surface temperature of the components, wherein the nitriding time is 0.5-6 hours, and the carburizing time is 0.5-4 hours; and (3) cooling after nitriding or carburizing.

Owner:SHANDONG UNIV

Preparation method of rare earth carburized wear-resistant Fe-W alloy

The invention discloses a preparation method of rare earth carburized wear-resistant Fe-W alloy. The preparation method comprises the following steps: performing solid carburization, namely putting Fe-W binary alloy into a rare earth-containing carburization agent and carburizing at 890-930 DEG C for 4-9 hours; after carburizing, taking out a carburized part and quenching. The alloy prepared by the method not only can keep the integral plasticity toughness and processibility but also is better in wear resistance and hardness.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

A method for rapidly preparing gradient cemented carbide by adding rare earth elements

The invention discloses a method for quickly preparing gradient cemented carbide by adding rare-earth elements, and belongs to the field of manufacturing cemented carbide materials. The method disclosed by the invention comprises the following steps: pressing and forming carbon-poor cemented carbide powder containing rare earth, and performing vacuum sintering to obtain a carbon-poor presintering base body; performing carburizing treatment for 40-120 minutes at the temperature of 1,400-1,460 DEG C under the hydrogen atmosphere to obtain the gradient cemented carbide, wherein the thickness of a gradient layer of the gradient cemented carbide is 200-3000 [mu]m. The rare-earth elements are added in the process of preparing the gradient cemented carbide, so that alloying components are solidified and dissolved in a Co phase in the presintering process, and the effect of inhibiting crystal grains from growing can be achieved. But in the carburizing process, the influence of adding the rare earth on the dissolution and the separation of WC (wolfram carbide) in the Co phase is weakened, and more passages are provided for the diffusion of activated carbon, so that the thickness of the gradient layer of the alloy can be quickly increased.

Owner:株洲金韦硬质合金有限公司

A graphite source for glow-free hydrocarburization

ActiveCN103882369BIncrease sputtering rateImprove carburizing efficiencySolid state diffusion coatingHydrogenTitanium

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

A sub-temperature carburizing heat treatment method for reducing heat treatment deformation of thin-walled gears

ActiveCN111020455BReduce the impact of uniformityIncreased speed of penetration into gear surfacesSolid state diffusion coatingFurnace typesCarbon potentialPolyvinyl alcohol

The invention relates to a sub-temperature carburizing heat treatment method for reducing heat treatment deformation of thin-walled gears, comprising the following steps: S1, sub-temperature normalizing in advance; S2, slow shot peening; S3, sub-temperature carburizing: adopting gradient heating to sub-temperature Warm carburizing temperature, sub-temperature carburizing process adopts two-stage carburizing method, the first stage is the strong infiltration stage, and the second stage is the diffusion stage; S4, gradient slow cooling and quenching: first, the thin-walled gear forgings that have completed carburizing treatment Gradient slow cooling to 840-860°C, and keep warm for about 1h; then continue to cool slowly to 815-825°C, and keep warm for about 1h, during which the carbon potential in the furnace is controlled at 0.5±0.05%, and then quenched in polyvinyl alcohol solution; S5, low temperature tempering. The invention can greatly reduce the degree of deformation of the gear workpiece, significantly improve the production pass rate, and at the same time can effectively refine the grains, improve the hardness and strength of the gears, and significantly increase the service life of the gears. In addition, the refined grains can significantly improve The speed of carburizing reduces process time and reduces energy consumption.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com