A carburizing and quenching method for heavy-duty gears

A carburizing quenching and gear technology, applied in the direction of quenching agent, furnace, heat treatment equipment, etc., can solve the problems of excellent performance of the core and tooth root, save the carburizing time, reduce the limit carbon concentration, and improve the hardenability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

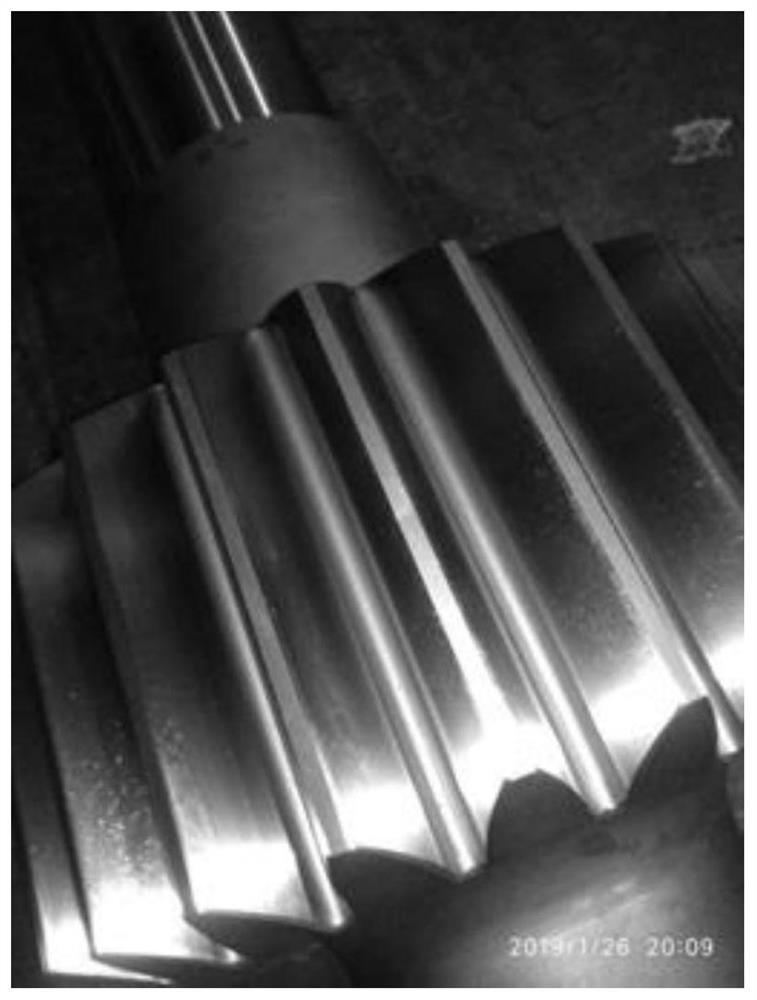

[0043] In this embodiment, taking a large heavy-duty gear with a control section of 350 mm, a modulus of 20, and a material of SAE8620H as an example, it is quenched by the above-mentioned carburizing and quenching method and conventional quenching method, and the results are shown in Table 1 and Table 2. The process effect shown.

[0044] Table 1. SAE8620H heavy-duty gear The effect comparison between the application process and the conventional process

[0045]

[0046]

[0047] Table 2. Comparison of the effect of SAE8620H heavy-duty gears between the application process and the conventional process

[0048]

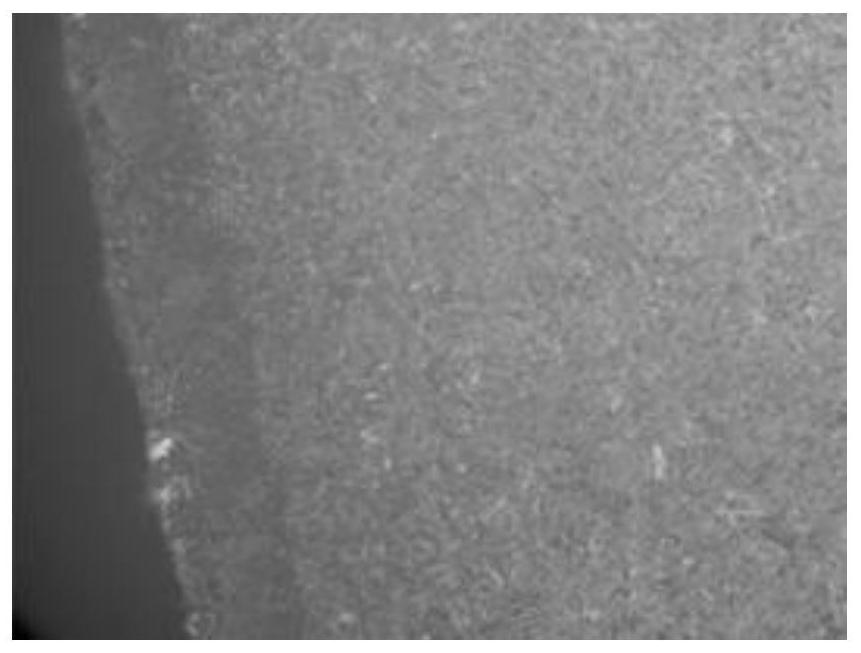

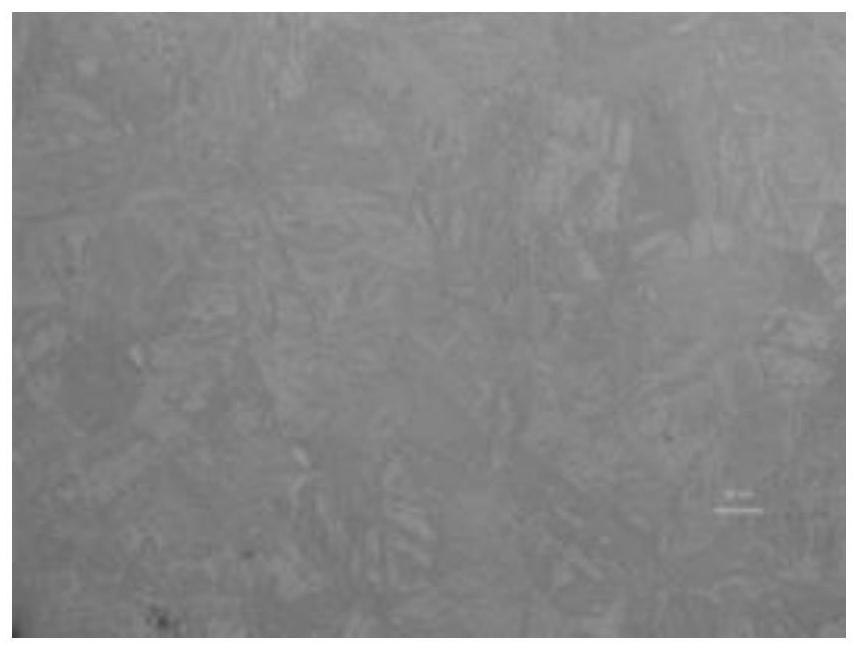

[0049] From the process effect comparison of table 1 and table 2 and figure 1 , figure 2 and image 3It can be seen from the figure that the water-based salt-bath composite quenching process of the present application not only has excellent performance at the core and root, but also has a small transition stress on the surface structure, which is extremel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com