Isothermal transformation thermal treatment method for superhigh-intensity steel

A heat treatment method and ultra-high-strength steel technology, applied in the field of metallurgy, can solve problems such as increased energy consumption, increased costs, and complex processes, and achieve the effects of reducing production energy consumption and production costs, saving energy, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Exemplary embodiments of the present invention will be described below with reference to the accompanying drawings, however, those of ordinary skill in the art should understand that these embodiments are provided so that this disclosure will be thorough and complete, and will fully convey the scope of the present invention to Those skilled in the art, the examples should not be construed as limiting the scope of the present invention.

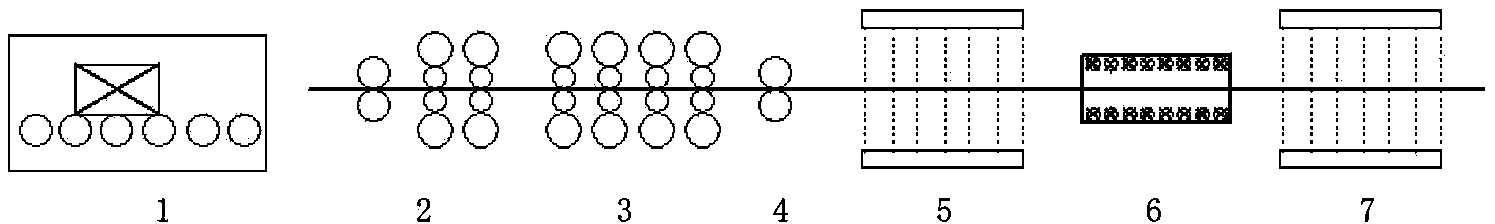

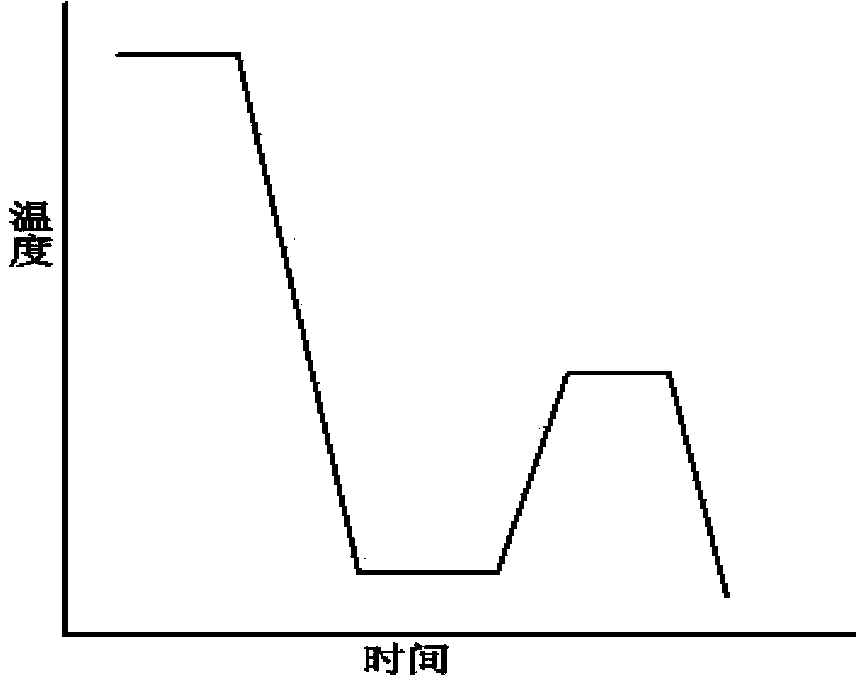

[0023] figure 1 is a schematic diagram of an isothermal transformation heat treatment device for ultra-high strength steel according to an exemplary embodiment of the present invention. figure 2 is a schematic diagram of an isothermal transformation heat treatment method for ultra-high strength steel according to an exemplary embodiment of the present invention.

[0024] refer to figure 1 and figure 2 , before using the method of the present invention to process the steel, the billet is first heated through the heating furnace 1, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com