Composite carburizing agent, carburizing method for detecting austenite grain size and detection method of austenite grain size

A technology of austenite grains and detection methods, which is applied in the direction of testing crystals, measuring devices, coatings, etc., can solve the problems of surface oxidation and long detection time, and achieve the effect of saving cost and saving time for carburizing and holding time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

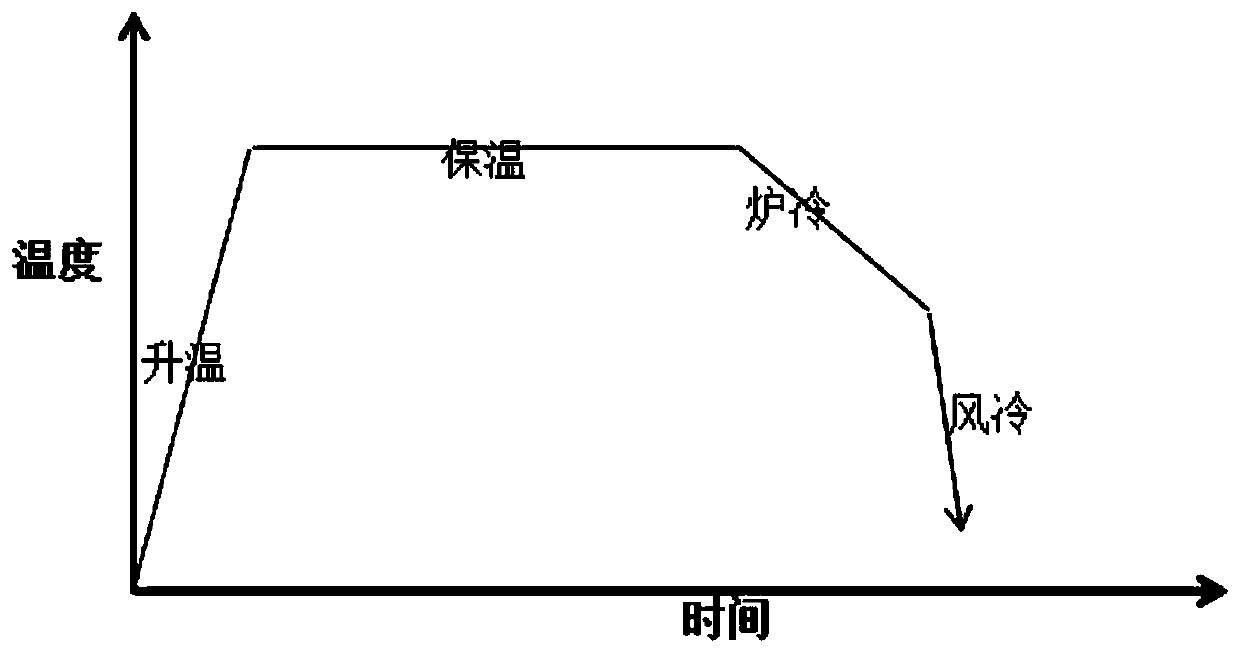

Method used

Image

Examples

Embodiment 1

[0089] This embodiment provides a composite carburizing agent. The composite carburizing agent includes a first carburizing agent with a particle size of 1.0-3.0 mm and a second carburizing agent with a particle size of 5.0-8.0 mm. Wherein, the mass percentage of the first carburizing agent is 30%, and the mass percentage of the second carburizing agent is 70%.

Embodiment 2

[0091] This embodiment provides a composite carburizing agent, which includes a first carburizing agent with a particle size of 1.0 to 3.0 mm and a second carburizing agent with a particle size of 5.0 to 8.0 mm; wherein, the first carburizing agent The mass percent of the carburizing agent is 27%, and the mass percent of the second carburizing agent is 73%.

Embodiment 3

[0093] This embodiment provides a composite carburizing agent, which includes a first carburizing agent with a particle size of 1.0 to 3.0 mm and a second carburizing agent with a particle size of 5.0 to 8.0 mm; wherein, the first carburizing agent The mass percent of the carburizing agent is 28%, and the mass percent of the second carburizing agent is 72%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com